Abstract

The inherent residual swirl at the furnace outlet of tangentially fired boilers induces severe thermal deviations on high-temperature heating surfaces. To reveal the evolutionary patterns of thermal deviation during peak regulation operation, this study employed a numerical method to analyze the thermal deviation characteristics of high-temperature heating surfaces in a 350 MW tangentially fired boiler under 12 operating conditions (covering 100%, 72%, 50%, and 28% loads). As the load decreases, the average absolute vorticity at the platen bottom plane also decreases. However, its decreasing rate is pretty slow compared with that of the load, indicating that the velocity deviation increases relatively. In addition, the flow field becomes more sensitive to the mill group operation mode. Correspondingly, the thermal deviations of the division platen superheater, rear platen superheater, finishing reheater, and finishing superheater all show an upward trend. When the load decreases from 100% to 28%, the average heat absorption deviations of the four heating surfaces increase to 3.48, 2.06, 1.27, and 1.99 times their original values, respectively. A comparison of the internal operating conditions under four loads shows that activating the lower-layer burners helps to reduce thermal deviation. This study proposes indicators for characterizing and analyzing the thermal deviation of high-temperature heating surfaces and provides general suggestions for the operation of tangentially fired boilers.

1. Introduction

Clean energy technologies, represented by renewable energy, can effectively mitigate the depletion of fossil fuels and environmental degradation []. However, their inherent intermittency and instability directly challenge the safe and stable operation of the power grid, power quality, and economic dispatch []. This issue is particularly prominent in China. To address global energy and environmental challenges, China set the carbon peaking and carbon neutrality goals in 2020, which have significantly accelerated the transformation and upgrading of its energy structure [,]. As the grid integration capacity of renewable energy continues to rise, ensuring its efficient and stable integration has placed the task of peak shaving on thermal power units, especially coal-fired power units [,].

In large-scale coal-fired power plants, tangentially fired combustion is a mainstream technology [,]. This technology involves arranging burners at the four corners of the furnace, enabling the injected pulverized coal airflow to be rapidly ignited by the flame from the adjacent upstream corner, thereby forming a strong swirling flow inside the furnace. This design offers several advantages, including thorough coal mixing, stable combustion, and structural simplicity [,]. However, its inherent drawback is that the flue gas still carries residual rotation upon the furnace outlet, leading to uneven distributions of flue gas velocity and temperature there. This non-uniformity induces thermal deviation issues on the high-temperature heating surfaces in Π-type boilers [,,]. Since high-temperature heating surfaces, such as the rear platen superheater, final superheater, and final reheater, are characterized by poor cooling conditions, high working fluid temperatures, and high sensitivity to operating conditions, the thermal deviation may cause localized tube wall temperatures to exceed safe limits, severely endangering equipment safety [].

During boiler operation, the overheating and tube rupture of heating surfaces are critical factors affecting the safe operation of thermal power plants []. Among the various causes of tube rupture, the overheating of superheaters and reheaters is the most prominent. Structural characteristics within the furnace, such as residual swirl, result in uneven distributions of temperature and flow velocity in both horizontal and vertical directions, directly leading to severe thermal deviations in the platen superheater []. However, previous studies on mill group operation modes have mainly focused on the furnace area [,,], while research on high-temperature heating surfaces has been relatively scarce. Considering this, this study employed the numerical simulation method to analyze the thermal deviation of the high-temperature heating surfaces of a 350 MW boiler under a total of 12 operating conditions. These conditions include four typical steady-state loads (100% load, 72% load equivalent to 250 MW, 50% load equivalent to 175 MW, and 28% load equivalent to 98 MW), as well as different mill group operation modes corresponding to each of these loads.

2. Methods

2.1. Numerical Model

Owing to the significant advancements in computer hardware in recent years, Computational Fluid Dynamics (CFD) technology has been widely applied in practical engineering [,,,]. Among these, CFD-based numerical simulation of boiler combustion has become quite mature []. Compared to on-site experiments, which can only obtain local data, numerical simulation breaks through the limitations of time and space, enabling a complete simulation of the entire combustion process and clearly presenting the distribution of pressure, temperature, velocity, and species concentrations at any location within the computational domain.

Leveraging this advantage, Ansys Fluent 2024 R1 software is employed to simulate the pulverized coal combustion process inside the furnace. The combustion process is an extremely complex process, involving gas-phase turbulence, particle motion, gas–solid two-phase coupling, convection, radiation, and multiple chemical reactions. Therefore, the proper selection of computational models during the simulation process directly determines the accuracy of the results. In addition to the three fundamental governing equations of momentum, energy, and mass conservation [], the specific computational models adopted in this study are described below.

2.1.1. Turbulence Model

The gas flow inside the furnace is a typical three-dimensional turbulence. Its multi-scale, irregular, yet structured nature makes it difficult to describe accurately through analytical methods. Considering that engineering applications are more concerned with the macroscopic average flow field changes caused by turbulence rather than transient details, the Reynolds-Averaged Navier–Stokes (RANS) simulation method has become the mainstream choice. The core of this method is Reynolds averaging, which time-averages the instantaneous Navier–Stokes equations to obtain the governing equations that describe the mean flow field. Based on this, a series of turbulence models have been developed, among which the most famous is the standard k-ε model proposed by Launder and Spalding. This model is widely employed in the flow field calculation inside boiler furnaces, demonstrating outstanding performance in terms of both computational cost and comprehensive accuracy [].

2.1.2. Species Model

The species model in this study is the non-premixed combustion model, which is based on the concept of mixture fraction, assuming that fuel and oxidizer are not premixed before entering the reaction zone, and that the combustion process is controlled by the mixing rate of the two. By solving the transport equation for the mixture fraction and utilizing the probability density function (PDF) to describe the interaction between turbulence and chemical reactions, this model can predict the temperature, species concentration, and heat release distribution within the furnace [,]. Its main advantage lies in avoiding the direct computation of complex chemical reaction mechanisms, thereby significantly improving computational efficiency, especially for industrial-scale combustion simulations. In pulverized coal boiler simulations, the non-premixed combustion model can effectively capture the mixing process between fuel and air and analyze the causes of thermal and velocity deviations. Pulverized coal combustion is a typical diffusion combustion process where pulverized coal particles and air (oxidant) mix and react simultaneously in the furnace, rather than being uniformly mixed in advance. The model does not require presetting the mixing ratio of fuel and oxidant and can naturally capture the local fuel-rich and fuel-lean regions in the furnace, which is consistent with the actual combustion conditions. Therefore, the non-premixed combustion model has become the mainstream choice for combustion simulation of pulverized coal boilers [].

2.1.3. Radiation Model

To accurately simulate thermal deviations in pulverized coal boilers, it is necessary to incorporate a radiation model to analyze the heat transfer process within the furnace. The P1 model is one of the most commonly employed radiation models, particularly suited for media with high optical thickness, such as pulverized coal combustion flames []. Its principle is based on the spherical harmonic expansion of the radiative transfer equation, simplifying the complex radiative heat transfer process into a diffusion equation for solution. The model assumes that the radiation intensity is isotropic in space and describes radiative heat exchange between gases and particles by calculating the radiative heat flux. This makes it especially suitable for high-temperature combustion scenarios containing particles. Compared to other radiation models such as the Discrete Ordinates (DO) model, the P1 model offers higher computational efficiency, though its accuracy is limited in scenarios with low optical thickness or anisotropic radiations [].

2.1.4. Gas–Solid Two-Phase Flow Model

The flow of flue gas and solid pulverized coal particles within the furnace is a typical gas–solid two-phase flow problem, whose numerical simulation primarily relies on the Eulerian–Lagrangian method and the Eulerian–Eulerian method []. The Eulerian–Eulerian method, also known as the continuum model, treats both the particle phase and the fluid phase as interpenetrating continua, described within a unified Eulerian framework. The distribution of each phase is characterized by introducing the concept of phase volume fraction. In contrast, the Eulerian–Lagrangian method, or the particle trajectory model, solves the time-averaged Navier–Stokes equations for the flue gas as a continuous phase in the Eulerian coordinate system, while tracking discrete pulverized coal particles in the Lagrangian coordinate system. This approach enables a precise depiction of the momentum, mass, and energy exchange processes along the particle trajectories. Given that the motion, dispersion, and accompanying complex physicochemical reactions (such as moisture evaporation, devolatilization, and heterogeneous char reactions) of pulverized coal during heating and intense combustion have a decisive influence on overall combustion characteristics, this study adopts the particle trajectory model described by the Eulerian–Lagrangian method for simulation, aiming to obtain more detailed insights into particle behavior and the combustion process.

2.1.5. Pulverized Coal Particle Combustion Model

Due to the presence of multiple complex components such as moisture, ash, sulfur, and volatile matter, the physical and chemical reaction processes of pulverized coal within the furnace are extremely complicated. To accurately simulate this process, the combustion of pulverized coal particles is typically decomposed into four consecutive stages: particle heating and drying, devolatilization, char and volatiles combustion, and burnout []. For each stage, distinct mathematical models are established and employed to describe the respective phenomena. The heating and drying processes of pulverized coal are described by the energy coupling in the gas–solid two-phase flow model and the wet combustion model built into Fluent []. The devolatilization process is implemented with the two-competing-rates model. The combustion processes of the gas and solid phases are described separately. The combustion of volatiles adopts the finite-rate/eddy-dissipation model, while the char combustion and burnout processes utilize the kinetic/diffusion-limited model. Details of the devolatilization and combustion models are as follows:

- 1

- Devolatilization model

Under continuous heating, pulverized coal undergoes pyrolysis, i.e., the release of volatile matter. The amount and rate of devolatilization increase significantly with rising temperature and faster heating rates, following an exponential trend. To accurately capture this characteristic, this study adopts the two-competing-rates model []. This model assumes that the release of volatile matter is governed by two independent reactions that dominate at different temperatures and employs distinct kinetic equations to calculate their respective reaction rates.

- 2

- Gas-phase combustion model

The volatiles released from coal devolatilization and char combustion undergo combustion under the high-temperature conditions within the furnace. This gas-phase combustion accounts for approximately 50% of the total heat released from pulverized coal, playing a critical role in coal ignition and flame stability. Therefore, this study adopts the finite-rate/eddy-dissipation model to describe this key gas-phase combustion process [].

- 3

- Char combustion model

After devolatilization, the pulverized coal particle transforms into a porous char. Char combustion is the dominant stage of the entire combustion process, with reactions occurring on both the external and internal surfaces of the particle. This process is governed by two key steps, namely the diffusion of the oxidant to the particle surface (mass transfer), and the chemical reaction taking place on the surface (kinetics). Additionally, due to the involvement of various complex factors such as temperature, pressure, intraparticle diffusion, changes in surface area, and particle fragmentation, char combustion represents a coupled process of heat transfer, mass transfer, and chemical reactions. Therefore, this study employs the kinetic/diffusion-limited model to comprehensively account for the influence of these factors [].

2.1.6. Solution Method

The numerical simulation employs the SIMPLE algorithm for pressure-velocity coupling. For spatial discretization, the gradient is computed employing the least squares cell-based method, while pressure is handled by the PRESTO! scheme. A second-order upwind discretization is applied to momentum, energy, mean mixture fraction, and mixture fraction variance. For enhanced stability, a first-order upwind scheme is utilized for turbulent kinetic energy and turbulent dissipation rate [].

2.2. Evaluation Criteria

In previous studies on the thermal deviation of high-temperature heating surfaces, qualitative descriptions often accounted for the majority [,], lacking intuitive quantitative indicators necessary to evaluate the advantages and disadvantages of thermal deviation under two different operating conditions. To this end, this study proposes to employ the coefficient of variation in the heat absorption capacity of the panels to measure thermal deviation, and supplement it with the average absolute vorticity to measure the velocity deviation at the inlet of the horizontal flue for quantitative analysis of thermal deviation.

2.2.1. Velocity Deviation

To accurately characterize the velocity deviation of the gas flow within the furnace, especially the rotational flow structure and its influence on the combustion process, the vorticity is introduced as a key evaluation parameter. Vorticity is a measure of the rotational intensity of a fluid element. In a two-dimensional flow field, its mathematical expression is given by []:

where ζ is the vorticity (s−1); ux and uy are the velocity components in the x and y directions, respectively (m s−1).

The distribution characteristics of the vorticity field can intuitively reflect the mixing intensity, swirl structure, and turbulent properties of the gas flow within the furnace. It serves as a critical basis for analyzing combustion organization methods, flame stability, and pollutant formation mechanisms. In the subsequent simulations, quantitative evaluation and structural analysis of the velocity deviation in the furnace flow field will be conducted based on the aforementioned vorticity definition.

2.2.2. Heat Absorption Deviation

The heat absorption deviation is primarily used to describe the differences in heat absorption among various high-temperature heating surfaces. Its mathematical expression is given as []:

where CV is the heat absorption deviation of each high-temperature heating surface; σ is the standard deviation of heat absorption among all panels in the heating surface (W); μ is the average heat absorption of all panels in the heating surface (W).

The heat absorption deviation can intuitively reflect the heat transfer process in the high-temperature heating surfaces of the boiler. The higher this indicator, the greater the possibility that individual tubes in one or several panels have abnormally high heat absorption, which in turn causes excessive tube wall temperatures and, in severe cases, even tube burst accidents. Subsequently, this will be employed to specifically analyze the magnitude of thermal deviations across different heating surfaces.

3. Case Study

3.1. Boiler Description

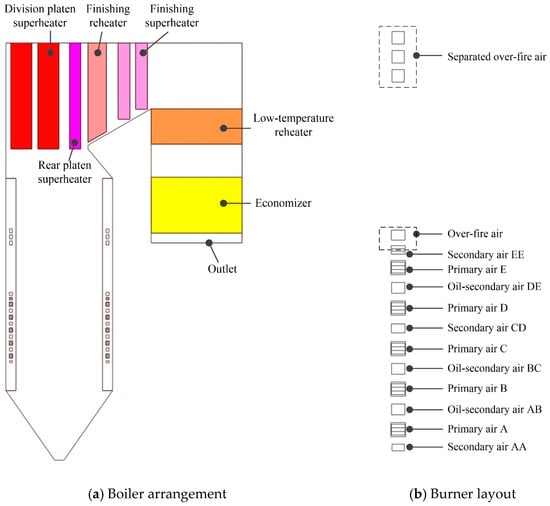

The boiler studied is a 350 MW supercritical boiler. The boiler operates in a variable pressure mode and is designed as a Π-type once-through boiler with a spiral tube configuration, as shown in Figure 1. It features a fully steel-frame suspended structure, single-stage intermediate reheating, tangential firing at the four corners, and a dry bottom ash removal system.

Figure 1.

The structure of the boiler.

The furnace has a width of 14,904 mm and a depth of 14,094 mm. The elevation of the lower water-cooled wall header is 6500 mm. The centerline elevation of the roof tubes is 61,900 mm. The bottom elevation of the main girder is 69,100 mm. The angle of the furnace bottom ash hopper is 55°. The furnace is of a single-chamber structure composed of membrane walls. The tube circuits around the furnace are arranged as spiral tubes from the ash hopper inlet up to an elevation of 42,972.5 mm, with a tube specification of Φ32 mm, a pitch of 48 mm, and an inclination angle of 17.2°. Above this elevation, the tube circuits transition to a vertical tube arrangement, also with a tube specification of Φ32 mm and a pitch of 54 mm. The transition between the spiral and vertical tube sections is achieved through an intermediate mixing header. The horizontal flue contains the division platen superheater, the rear platen superheater, the finishing reheater, and the finishing superheater. The tail flue houses the low-temperature reheater and economizer. The boiler arrangement and burner layout are shown in Figure 1.

There are 5 primary air nozzles at each corner, namely primary air A to E. The four primary air nozzles on each layer are supplied by one coal mill. The five layers of primary air nozzles correspond to coal mills A to E. Under 100% load, generally 5 or 4 coal mills are in operation. Under low load, only 3 coal mills may be activated. Since the coal mills put into operation are not fixed, different mill group operation modes are generated. Different mill group operation modes correspond to the commissioning of different primary air nozzles, thus resulting in different flow fields and temperature fields.

3.2. Physical Model and Mesh Generation

A 1:1 scale three-dimensional model of the supercritical boiler is established. Previous studies have mainly focused on the furnace area [,], with relatively few studies on the impact of changes in in-furnace operating parameters on high-temperature heating surfaces. To break through this limitation, this study also conducts detailed modeling of the high-temperature heating surfaces, retaining important features such as their shape, number of panels, and pitch, so as to facilitate the detailed extraction of thermal deviation data of the high-temperature heating surfaces in subsequent work. During the modeling process, the structure of the heating surfaces is appropriately simplified. The water-cooled wall surface is considered flat. Each plane of the high-temperature heating surfaces is simplified to a rectangular or trapezoidal plane with zero thickness. In addition, for the burner, only its nozzle outlet plane is retained as the inlet for air and pulverized coal.

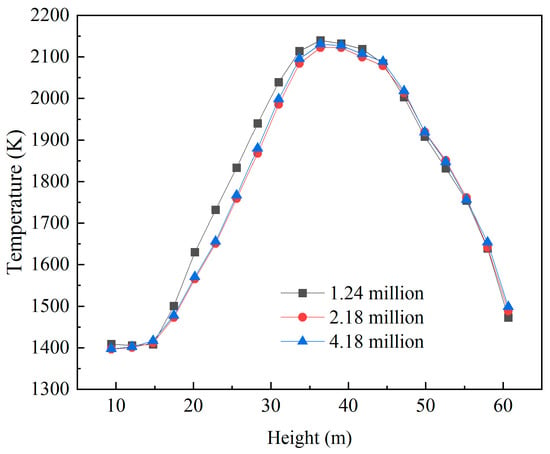

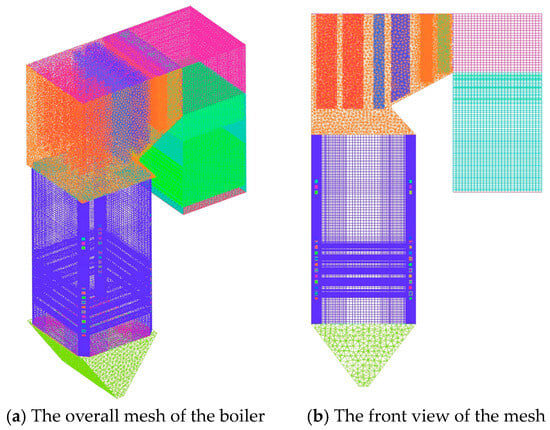

Since the boiler structure does not involve complex curved surfaces, unstructured meshes, which are computationally expensive and require a large number of elements, are not adopted. Instead, high-quality hexahedral structured meshes are employed for their high computational accuracy and speed. Additionally, due to the large gradients of physical quantities in the main combustion zone, a zonal meshing strategy is applied, with local refinement in the burner region to accurately capture the flow characteristics in that area. The cross-section of the burner region is octagonal, while the upper and lower sections are quadrilateral. Therefore, an interface is set at the junction to ensure proper data transfer between the mesh regions. A grid independence test is performed by comparing three sets of meshes with grid numbers of 1.24 million, 2.18 million, and 4.18 million, as shown in Figure 2. Based on the grid independence test, the final number of grids is 2.18 million. The mesh of the boiler is shown in Figure 3.

Figure 2.

Distribution of flue gas temperature along the height direction of the furnace centerline under three different grid numbers.

Figure 3.

The mesh of the boiler.

3.3. Boundary Conditions

The inlet parameters are primarily derived from on-site measured data and boiler operating conditions provided by the power plant. Specifically, the inlet boundary is set as the mass-flow-inlet type. The outlet boundary adopts the outflow type to simulate the free flow at the furnace outlet. For the solid walls of the furnace, in addition to being defined as the wall type, no-slip and no-penetration conditions are imposed. The particle size distribution of pulverized coal follows the Rosin–Rammler distribution []. The fuel property analysis is shown in Table 1. During computation, the particles are introduced into the furnace in discrete phase form through the burner inlets. The SIMPLE algorithm is employed for pressure-velocity coupling, and the solution is carried out utilizing the line-by-line iteration method with under-relaxation factors. The pressure term is discretized utilizing the Standard scheme, while other terms are discretized with the first-order upwind difference scheme. A converged solution is considered achieved when the residuals of all equations fall below 10−3.

Table 1.

Fuel property analysis.

3.4. Simulated Operating Conditions

Four operating load conditions are simulated, namely 100%, 72%, 50%, and 28% of BMCR. Unlike previous studies that typically focused on a single set of fixed combustion parameters under a specific load [], this study takes into account various possible mill group operation modes during the actual boiler operation under the same load. Such a comprehensive analysis facilitates a deeper understanding of how changes in operation parameters affect thermal deviation. A total of 12 sets of operating parameters are selected from the boiler operation data for simulation, as shown in Table 2. Among them, there are 2 sets each for 100%, 72%, and 28% loads, and 6 sets for 50% load. This is because the boiler may have the most kinds of operating mill groups under the 50% load condition.

Table 2.

Parameters of the simulated operating conditions.

4. Results and Discussion

4.1. Model Validation

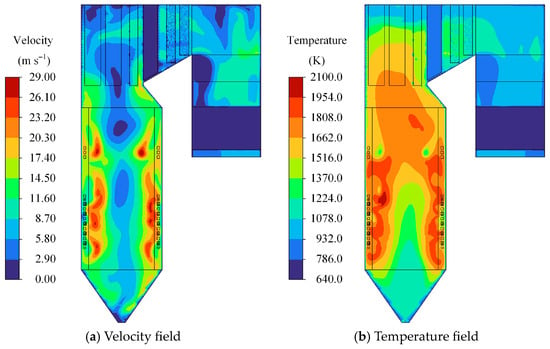

The contours of the velocity field and temperature field under 100% load are shown in Figure 4. The numerical simulation results of flue gas temperature are compared with the boiler design values. Under 100% load, the numerical results of the flue gas temperature at the bottom of the division platen superheater and the flue gas temperature at the furnace outlet are 1609.0 K and 1216.4 K, respectively, while the design values are 1603.2 K and 1239.15 K, respectively. The differences between the two are only 5.8 K and 22.75 K, respectively, which is sufficient to illustrate the accuracy of this model [].

Figure 4.

Contours of the velocity field and temperature field under 100% load.

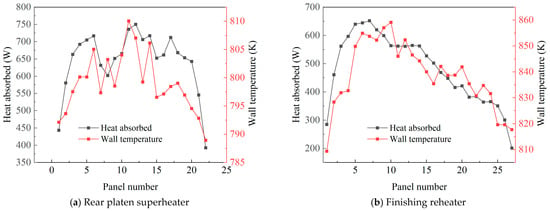

In addition, the calculated heat absorption results of the rear platen superheater and the finishing reheater under operating condition 1 are compared with the measured outlet wall temperature data, as shown in Figure 5. The outlet wall temperature data are obtained by K-type thermocouples arranged at the connection positions between each platen of the rear platen superheater and the finishing reheater and the outlet header. As mentioned before, the boundary conditions of the simulated operating conditions are derived from the historical operating data of the power plant. These wall temperature data are also obtained at the same time and exported from the Safety Instrumented System (SIS). For these superheaters and reheaters, since the inlet working fluid temperature is the same, the wall temperature at the outlet of the platen with higher heat absorption will also be higher. It can be seen that the calculated distribution trend of heat absorption fits well with the measured wall temperature data, which fully indicates the accuracy of the model established in this study.

Figure 5.

Comparison between calculated heat absorption values and measured outlet wall temperature data of the rear platen superheater and finishing reheater under operating condition 1.

4.2. Velocity Deviation

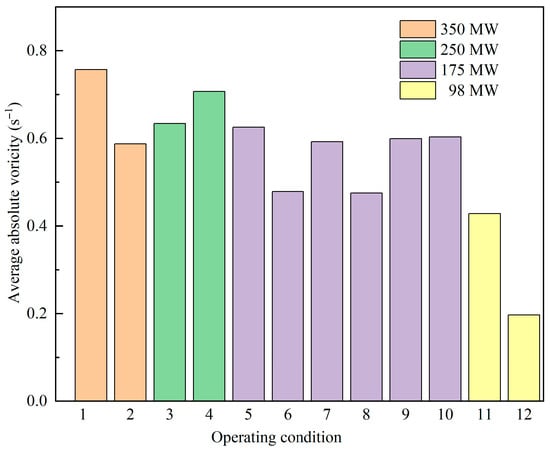

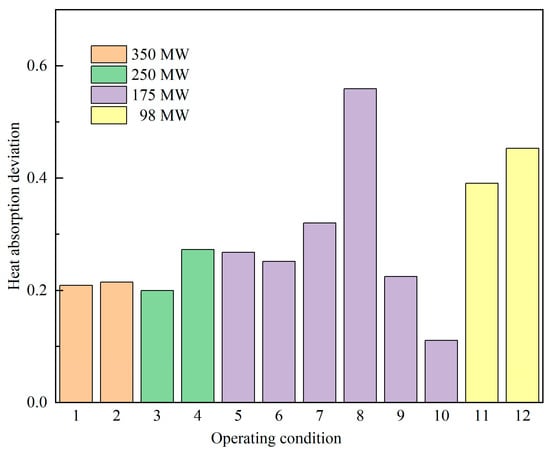

According to Equation (1), the absolute values of the average vorticity under twelve operating conditions are calculated. The plane selected for vorticity calculation is the rectangular area located below the division platen superheater. The resulting data are plotted as shown in Figure 6.

Figure 6.

Average absolute vorticity under different operating conditions.

As shown in the figure, the twelve operating conditions are categorized into four types of operating loads, with specific allocations detailed in Section 3.4. Under 100% and 72% loads, the values of the average vorticity are approximately equal, with the average values at the two loads being 0.672 s−1 and 0.670 s−1 respectively. Under 50% load, the absolute values of the average vorticity for different operating conditions fluctuate around the average value of 0.563 s−1. Under 28% loads, the absolute values of the average vorticity exhibit a significant decrease, falling to around 0.313 s−1.

It can be concluded that the absolute value of the average flue gas vorticity generally decreases with the reduction in operating load. This is mainly because as the load decreases, the total flue gas volume in the furnace also decreases approximately proportionally []. However, the rate of decrease in average absolute vorticity is much slower than that of the load, indicating that the flue gas velocity deviation increases relatively with the decrease in load. In addition, as the load decreases, the fluctuation of average absolute vorticity under different operating conditions shows an overall upward trend. Especially at 28% load, the average absolute vorticity of operating condition 11 is 2.18 times that of operating condition 12, which suggests that with the decrease in load, the flue gas filling degree in the furnace decreases [], and the flow field in the furnace becomes more sensitive to changes in operating parameters.

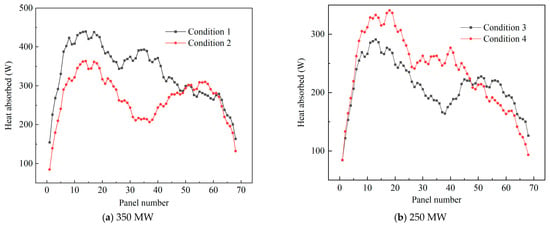

4.3. Heat Absorption Deviation

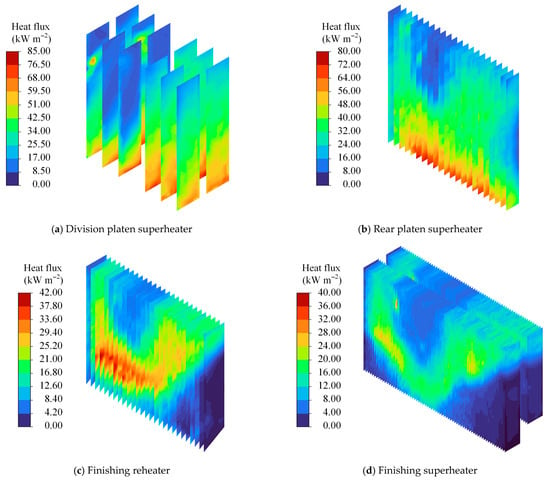

Based on the numerical calculation results, the heat absorption of each panel in the high-temperature heating surfaces is calculated. Then, according to Equation (2), the heat absorption deviation of various high-temperature heat-absorbing surfaces in the boiler can be calculated. This study primarily focuses on analyzing the heat absorption deviation of the division panels, rear panels, final reheater, and final superheater. Taking operating condition 1 as an example, the heat absorption of the heating surfaces is shown in Figure 7. Each of these heating surfaces consists of a varying number of panels, and the data obtained correspond to the heat flux on each panel under each operating condition. The heat absorption deviation for each heat-absorbing surface is then calculated based on this heat flux data.

Figure 7.

Heat absorption of the heating surfaces under operating condition 1.

4.3.1. Division Platen Superheater

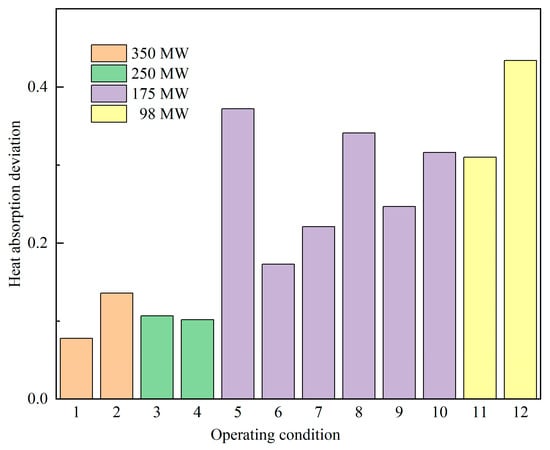

The division platen superheater is the first high-temperature heating surface encountered by the flue gas in this boiler. There are a total of six panels in the division platen superheater. Heat absorption calculations are taken for each panel sequentially from the left wall to the right wall. The specific heat absorption values under different operating conditions are illustrated in Figure 8. Based on the heat absorption data, the heat absorption deviation for each operating condition is calculated. The resulting deviations are presented in Figure 9.

Figure 8.

Heat absorption of different panels in the division platen superheater under different operating conditions.

Figure 9.

Heat absorption deviation in the division platen superheater under different operating conditions.

According to Figure 8, the heat absorption of each panel in the division platen superheater is always unequal. Under 28% load, there is a distinct maximum heat absorption at the central position of the division panel in both operating conditions, reaching 1212 W and 956 W, respectively. Under other load conditions, the heat flux fluctuates within a certain range. As shown in Figure 9, under 100% load and 72% load operating conditions, the heat absorption deviation is relatively low, fluctuating around 0.10. In the operating condition 5 under 50% load, the heat absorption deviation rises sharply to 0.37, then begins to decrease with fluctuations in subsequent parallel conditions. Under 28% load, the heat absorption deviation continues to increase, with the maximum heat absorption reaching 1212 W and 956 W, respectively. It can thus be concluded that the heat absorption deviation tends to increase as the load decreases, indicating that the higher the boiler operating load is, the lower the heat absorption deviation of the division platen superheater is.

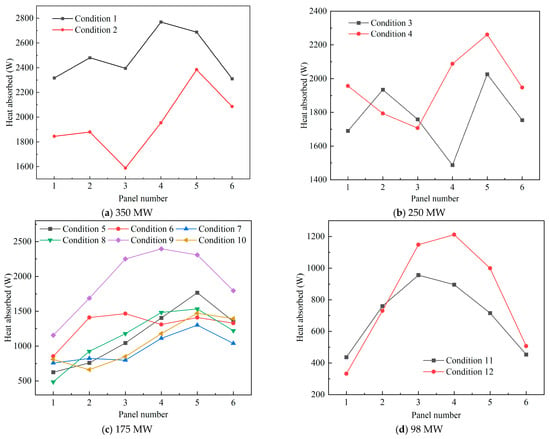

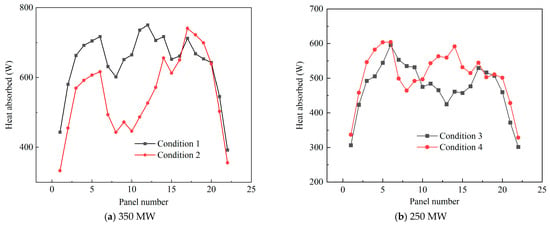

4.3.2. Rear Platen Superheater

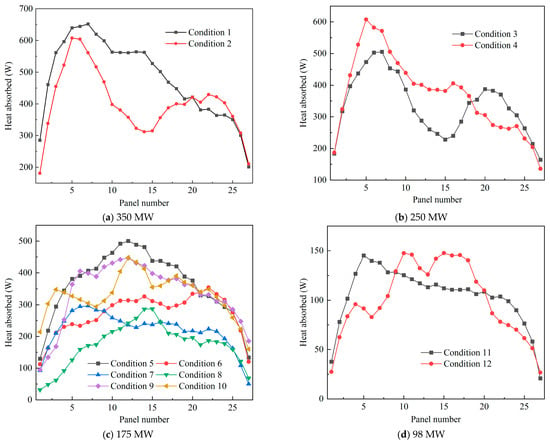

The rear panel in this boiler consists of 22 panels. Calculations of heat absorption are taken for each panel sequentially from the left wall to the right wall, with the heat absorption values under different operating conditions presented in Figure 10. The heat absorption deviation for each operating condition is illustrated in Figure 11.

Figure 10.

Heat absorption of different panels in the rear platen superheater under different operating conditions.

Figure 11.

Heat absorption deviation in the rear platen superheater under different operating conditions.

According to Figure 10, under each operating load, the heat absorption variation trends across different heating surfaces in the rear platen superheater are consistent across various operating conditions. In all cases, the maximum heat absorption occurs at the panel near the center of the rear platen superheater. Taking the operating condition 11 under 28% load for instance, the maximum heat absorption of 400 W is observed at the 12th panel. As shown in Figure 11, different operating loads correspond to different deviation values, with a clear demarcation between them. The heat absorption deviations under 100% load and 72% load are approximately equal, at around 0.17. In contrast, under 50% and 28% loads, the heat absorption deviations generally fluctuate around 0.33. Overall, the heat absorption deviation of the rear platen under the latter two operating loads is significantly higher than under the former two. Therefore, to reduce the heat absorption deviation of the rear platen superheater, it is necessary to consider the operating conditions under low load.

4.3.3. Finishing Reheater

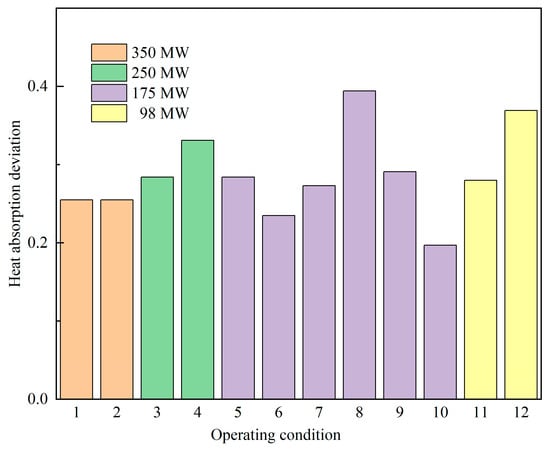

In this boiler, the final reheater consists of 27 heating panels. Heat flux calculations are taken for each panel sequentially from the left wall to the right wall, with the specific heat absorption distributions under various operating conditions shown in Figure 12. The heat absorption deviation for each operating condition is presented in Figure 13.

Figure 12.

Heat absorption of different panels in the finishing reheater under different operating conditions.

Figure 13.

Heat absorption deviation in the finishing reheater under different operating conditions.

In all cases, the heat absorption is always lowest at the most left and right panels, while it is relatively higher at the central panels. Particularly under 50% operation, the peak heat absorption in each condition generally occurs around the 12th panel, with peak values ranging from 300 to 500 W. As shown in Figure 13, with changes in boiler load, the heat absorption deviation of the finishing reheater exhibits an overall fluctuating upward trend. The maximum deviation occurs under 50% load, reaching approximately 0.39. Additionally, the heat absorption deviation under full load is consistently lower than that under the other three loads.

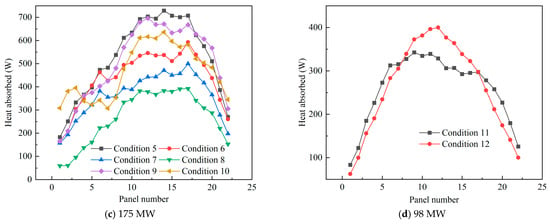

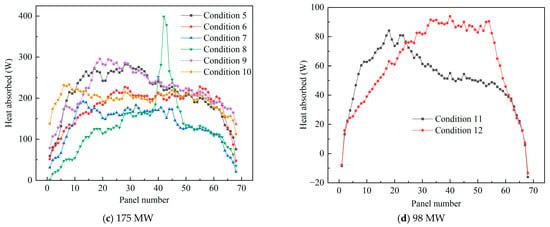

4.3.4. Finishing Superheater

In this boiler, the final superheater consists of 68 heat-absorbing panels. The specific heat absorption distributions under various conditions are shown in Figure 14. The heat absorption deviation for each operating condition is illustrated in Figure 15.

Figure 14.

Heat absorption of different panels in the finishing superheater under different operating conditions.

Figure 15.

Heat absorption deviation in the finishing superheater under different operating conditions.

According to Figure 14, under the same operating load, the heat flux variation trends across different panels in the finishing superheater are approximately consistent across different operating conditions. For instance, under 50% and 28% loads, the heat flux is lowest at the most left and right panels and highest at the central panels. Under 100% and 50% loads, in addition to the same trend mentioned above, a declining trend in heat flux is observed across panels 5 to 15 of the finishing superheater, though the minimum values remain higher than those at the most left and right ends. As shown in Figure 15, under 100%, 72%, and 28% loads, the heat absorption deviation of the finishing superheater changes gently with varying operating conditions, at approximately 0.20, 0.25, and 0.40, respectively. Under 50% load, the heat absorption deviation fluctuates more significantly across different operating conditions but generally remains around 0.28.

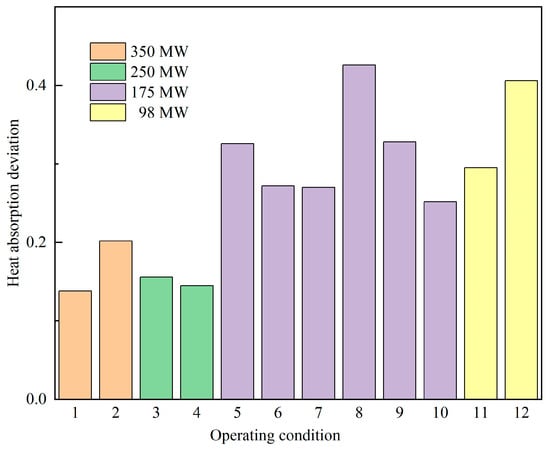

4.4. Thermal Deviation Mitigation Measures

Based on the above analysis, appropriate mill group operation modes can be selected for each steady-state load from the perspective of reducing thermal deviation. At 100% load, the optimal operation mode is condition 1, i.e., all mills are in operation. Compared with condition 2, the thermal deviation of the division platen superheater decreases by 42.6% and that of the rear platen superheater decreases by 31.7% under this condition. At 72% load, the two operation modes exhibit similar performance in thermal deviation control, among which condition 3 (i.e., mills A, B, C, and D are in operation) is slightly better. Compared with condition 4, the thermal deviation of the finishing reheater decreases by 14.2% and that of the finishing superheater decreases by 26.7% under condition 3. At 50% load, condition 6 (i.e., mills B, C, and D are in operation) is selected as the optimal option after comprehensive consideration. Under this condition, the thermal deviations of the four heating surfaces decrease by 53.5%, 36.2%, 40.4%, and 54.9%, respectively, compared with the condition with the maximum thermal deviation. At 28% load, condition 11 (i.e., mills A, B, and C are in operation) is more advantageous, under which the thermal deviations of the four heating surfaces decrease by 28.6%, 27.3%, 24.1%, and 13.7%, respectively, compared with condition 12.

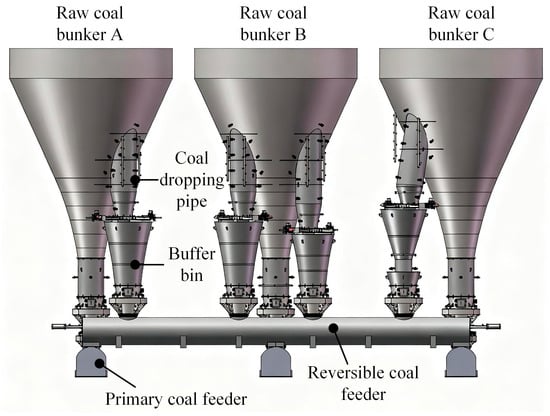

By adopting the aforementioned mill group operation mode optimization measures and integrating other optimization and transformation strategies on the coal feeding side, the thermal deviation of high-temperature heating surfaces can be significantly improved. As shown in Figure 16, the intelligent coal blending system can effectively stabilize the calorific value of coal fed into the furnace by adjusting the blending ratio of coal types with different calorific values in real time, thereby reducing the negative impact of coal quality fluctuation on the combustion and heat transfer processes. For instance, the design of bidirectional conveying belt coal feeders and buffer bins enables rapid switching between high-calorific-value and low-calorific-value coal during peak shaving. This not only meets the requirement of the unit for rapid load up and down regulation but also avoids combustion instability and local overheating of heating surfaces caused by poor coal quality adaptability. In addition, the intelligent coal blending system is equipped with anti-blocking structural design, flexible coal bunker combination function, and the capability of seamless integration with the existing coal feeding system, providing key technical support for the safe, stable, and economical operation of the boiler within a wide load range.

Figure 16.

Intelligent coal blending system.

4.5. Practical Significance

This study proposes and demonstrates a comprehensive numerical framework for quantitatively analyzing thermal deviations in high-temperature heating surfaces of tangentially fired boilers across a wide range of operating loads. The application of this framework to a 350 MW boiler under 12 distinct operating conditions provides a detailed and systematic understanding of how load reduction exacerbates thermal non-uniformity, quantified through both velocity deviation (vorticity) and heat absorption deviation metrics.

The primary practical significance of this research lies in its direct guidance for the safe and optimized operation of industrial boilers. Based on the quantitative analysis, the study conclusively shows that activating lower-layer burners under low-load conditions is an effective strategy to mitigate thermal deviation. While this operational recommendation has been suggested in previous studies and practice [,], the justification has predominantly been from the perspective of stabilizing combustion within the furnace. This study, however, provides a novel and critical linkage by quantitatively demonstrating how this specific operational adjustment directly improves the heat transfer safety of the heating surfaces in the horizontal pass. Therefore, the findings offer generalizable operational principles that can be applied to other tangentially fired units facing similar peak-shaving demands. By integrating the proposed optimization strategies with other supporting measures like intelligent coal blending systems, plant operators can significantly enhance boiler reliability and prevent tube overheating incidents during flexible operation.

5. Conclusions

This study employed a numerical method to analyze the thermal deviation characteristics of high-temperature heating surfaces (division platen superheater, rear platen superheater, finishing reheater, finishing superheater) in a 350 MW tangentially fired boiler under 12 operating conditions (covering 100%, 72%, 50%, and 28% loads), clarifying the influence of load on velocity and heat absorption deviations.

- The average absolute vorticity of flue gas decreases with load reduction. Its average values at 100%, 72%, 50% and 28% loads are 0.672 s−1, 0.670 s−1, 0.563 s−1 and 0.313 s−1 respectively. However, the decrease rate is much slower than that of the load, indicating that the relative velocity deviation of the flue gas increases as the load decreases.

- With the decrease in load, the thermal deviations of the division platen superheater, rear platen superheater, finishing reheater, and finishing superheater all show an upward trend. When the load decreases from 100% to 28%, the average heat absorption deviations of these four heating surfaces increase from 0.11, 0.17, 0.26, and 0.21 to 0.37, 0.35, 0.32, and 0.42, respectively.

- Under 100%, 72%, 50%, and 28% loads, from the perspective of reducing thermal deviation, the recommended mill group operation modes are ABCDE, ABCD, BCD, and ABC, respectively. This indicates that activating the lower-layer burners tends to reduce thermal deviation.

Author Contributions

Conceptualization, D.Y., J.K. and B.Q.; methodology, J.K. and F.P.; validation: F.P. and W.D.; formal analysis, W.D., J.Y. and L.D.; investigation, D.Y. and F.P.; resources, B.Q. and L.D.; data curation, D.Y., W.D. and J.Y.; writing—original draft preparation, D.Y. and F.P.; writing—review and editing, J.K., B.Q. and L.D.; supervision, L.D.; project administration, D.Y. and L.D.; funding acquisition, D.Y., J.K. and B.Q. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the China Energy Jiangsu Power Co., Ltd. Science and Technology Innovation Project, grant number JS-KJ-2024-25.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available due to privacy.

Conflicts of Interest

Authors Dianhong Yuan, Junfeng Kong and Bin Qin were employed by the company China Energy Jiangsu Power Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The authors declare that this study received funding from China Energy Jiangsu Power Co., Ltd. The funder was not involved in the study design, collection, analysis, interpretation of data, the writing of this article or the decision to submit it for publication.

References

- Anwar, S.; Aslam, Z.; Aslam, U.; Mehmood, U.; Rana, A.G.; Mahmood, N.; Rafique, A. Advances and challenges in photocatalytic water splitting: Recent developments and trends. Fuel 2026, 404, 136280. [Google Scholar] [CrossRef]

- Magdy, G.; Shabib, G.; Elbaset, A.A.; Mitani, Y. Renewable power systems dynamic security using a new coordination of frequency control strategy based on virtual synchronous generator and digital frequency protection. Int. J. Electr. Power Energy Syst. 2019, 109, 351–368. [Google Scholar] [CrossRef]

- Qi, Y.; Liu, T.L.; Jing, L.Y. China’s energy transition towards carbon neutrality with minimum cost. J. Clean. Prod. 2023, 388, 135904. [Google Scholar] [CrossRef]

- Zhou, X.; Strunz, K.; Brown, T.; Sun, H.; Neumann, F. Multi-energy system horizon planning: Early decarbonisation in China avoids stranded assets. Energy Internet 2024, 1, 81–98. [Google Scholar] [CrossRef]

- Babosalam, S.; Kargar, S.M.; Moazzami, M.; Zanjani, S.M. Occupancy-aware energy optimization in building-to-grid systems using deep neural networks and model predictive control. J. Build. Eng. 2025, 112, 113714. [Google Scholar] [CrossRef]

- Wang, H.S.; Ding, H.L.; Ouyang, Z.Q.; Li, S.Y.; Su, K.; Chen, Q.S.; Wu, L.M. Experimental study on peak shaving operations for efficient pulverized coal combustion and working fluid coordination. Fuel 2026, 404, 136237. [Google Scholar] [CrossRef]

- Ihsan, S.; Prabowo; Widodo, W.A.; Saputra, I.; Hariana. Utilization of palm frond waste as fuel for co-firing coal and biomass in a tangentially pulverized coal boiler using computational fluid dynamic analysis. Biomass 2024, 4, 1142–1163. [Google Scholar] [CrossRef]

- Samantaray, U.; Nemalipuri, P.; Mailapalli, V.K.; Vitankar, V.; Das, H.C.; Pradhan, M.K. Computational study on the blended fuel combustion in an industrial tangentially fired boiler. Int. J. Coal Prep. Util. 2025, 1–27. [Google Scholar] [CrossRef]

- Azizah, A.N.; Amalia, R.; Satrio, D. Analysis of combustion characteristic in tangentially fired pulverized-coal boiler with tilting burner angle variation using CFD. IOP Conf. Ser. Earth Environ. Sci. 2022, 972, 012067. [Google Scholar] [CrossRef]

- Yudha, A.T.; Prayogo, B. Optimizing combustion in supercritical tangentially-fired boilers through numerical analysis and incorporating rear pass temperature optimization with the PSO algorithm. In Proceedings of the 2024 International Conference on Technology and Policy in Energy and Electric Power (ICTPEP), Bali, Indonesia, 3–5 September 2024; pp. 7–11. [Google Scholar]

- Yin, H.Y.; Jin, D.H.; Liu, X.; Li, C.; Li, X.Y.; Wang, H.Y. Prediction of the tube temperature and oxide scale formation of boiler superheater by a coupled combustion and hydrodynamic model. Int. Commun. Heat Mass Transf. 2025, 163, 108664. [Google Scholar] [CrossRef]

- Zhou, Y.G.; Xu, T.M.; Hui, S.; Zhang, M.C. Experimental and numerical study on the flow fields in upper furnace for large scale tangentially fired boilers. Appl. Therm. Eng. 2009, 29, 732–739. [Google Scholar] [CrossRef]

- Akkinepally, B.; Shim, J.; Yoo, K. Numerical and experimental study on biased tube temperature problem in tangential firing boiler. Appl. Therm. Eng. 2017, 126, 92–99. [Google Scholar] [CrossRef]

- Li, P.; Bao, T.; Guan, J.; Shi, Z.F.; Xie, Z.X.; Zhou, Y.G.; Zhong, W. Computational analysis of tube wall temperature of superheater in 1000 MW ultra-supercritical boiler based on the inlet thermal deviation. Energies 2023, 16, 1539. [Google Scholar] [CrossRef]

- Jin, D.H.; Yan, J.W.; Liu, X.; Zhang, C.Q.; Wang, H.Y. Prediction of tube temperature distribution of boiler platen superheater by a coupled combustion and hydrodynamic model. Energy 2023, 279, 128116. [Google Scholar] [CrossRef]

- Saputra, N.A.A.; Prabowo; Setiyawan, A.; Kusuma, G.B.W.; Ishan, S.; Darmawan, A.; Hariana. Numerical analysis of burner position and EFB-coal co-firing effects on combustion performance and emissions in pulverized coal boilers. Int. J. Heat Technol. 2025, 43, 479–492. [Google Scholar] [CrossRef]

- Rawlins, B.T.; Laubscher, R.; Rousseau, P. Application of computational fluid dynamics and process modeling to investigate low-load operation of a subcritical utility-scale boiler. J. Therm. Sci. Eng. Appl. 2022, 14, 101008. [Google Scholar] [CrossRef]

- Ma, D.; Zhang, S.; He, X.; Ding, X.; Li, W.; Liu, P. Combustion stability and NOx emission characteristics of three combustion modes of pulverized coal boilers under low or ultra-low loads. Appl. Energy 2024, 353, 121998. [Google Scholar] [CrossRef]

- Faizal, W.M.; Mazlan, N.M.; Shaukat, S.I.; Khor, C.Y.; Haidiezul, A.M.; Syafiq, A.K.M. The Convergence of computational fluid dynamics and machine learning in oncology: A review. Comput. Model. Eng. Sci. 2025, 144, 1335–1369. [Google Scholar] [CrossRef]

- Fazlizan, A.; Muzammil, W.K.; Al-Khawlani, N.A. A review of computational fluid dynamics techniques and methodologies in vertical axis wind turbine development. Comput. Model. Eng. Sci. 2025, 144, 1371–1437. [Google Scholar] [CrossRef]

- Hassan, M.H.A.; ElSherif, I.A.; El-latif, M.A.; Shaheen, M.M.; Elmesalamy, A.S.; Mahmoud, H. A comprehensive review of numerical simulation techniques for wind turbines: From computational fluid dynamics and finite element analysis to advanced turbulence modeling. Beni-Suef Univ. J. Basic Appl. Sci. 2025, 14, 92. [Google Scholar] [CrossRef]

- Maccioni, L.; Concli, F. Exploring the potential of CFD in gear jet lubrication design: A systematic literature review. Forsch. Im Ingenieurwesen-Eng. Res. 2025, 89, 121. [Google Scholar] [CrossRef]

- Sankar, G.; Kumar, D.S.; Balasubramanian, R. Computational modeling of pulverized coal fired boilers—A review on the current position. Fuel 2019, 236, 643–665. [Google Scholar] [CrossRef]

- Feng, Y.; Zhao, N.; Wang, B.; Li, Q. A method for monitoring internal temperature field distribution of transformers based on heat transfer coefficient under different operating conditions. Case Stud. Therm. Eng. 2025, 75, 107094. [Google Scholar] [CrossRef]

- Kardas, D.; Polesek-Karczewska, S.; Wardach-Swicicka, I. Integrating flow field dynamics and chemical atmosphere predictions for enhanced sulfur corrosion risk assessment in power boilers. Materials 2024, 17, 4919. [Google Scholar] [CrossRef]

- Vilakazi, L.N.; Madyira, D. Coal combustion modeling: A comparative study. Energy Sci. Eng. 2024, 12, 3465–3475. [Google Scholar] [CrossRef]

- Sun, W.J.; Zhong, W.Q.; Zhang, J.Z.; Echekki, T. Large Eddy simulation on the effects of coal particles size on turbulent combustion characteristics and NOx formation inside a corner-fired furnace. J. Energy Resour. Technol. 2021, 143, 082302. [Google Scholar] [CrossRef]

- Chetverushkin, B.N.; Olkhovskaya, O.G.; Gasilov, V.A. Stabilized scheme for calculating radiation transfer in the P1 approximation. Dokl. Math. 2024, 110, 393–398. [Google Scholar] [CrossRef]

- Rajak, U.; Panchal, M.; Verma, T.N.; Dwivedi, G. The effect of thermal radiation using different models on methane-air flames combustion modelling using CFD. Environ. Dev. Sustain. 2024, 1–23. [Google Scholar] [CrossRef]

- Sikka, A.; Singh, D.; Chander, S. An experimental and numerical study of cooling by air/water mist jet impingement at low mist loading fraction. Int. J. Therm. Sci. 2025, 212, 109788. [Google Scholar] [CrossRef]

- Dong, L.; Hu, S.W.; Wang, Y.F.; Liu, X.H.; Chen, W.; Ren, Y. Discrete simulations of combustion dynamics in coal particles: Insights into heat and mass transfer mechanisms. Particuology 2025, 105, 217–228. [Google Scholar] [CrossRef]

- Zhang, J.; Prationo, W.; Zhang, L.; Zhang, Z. Computational fluid dynamics modeling on the air-firing and oxy-fuel combustion of dried Victorian brown coal. Energy Fuels 2013, 27, 4258–4269. [Google Scholar] [CrossRef]

- Ghose, P.; Sahoo, T.K.; Sahu, A.K. Pulverized coal combustion computational modeling approach: A review. Proc. Inst. Mech. Eng. Part A J. Power Energy 2023, 237, 797–818. [Google Scholar] [CrossRef]

- Ezzahra, L.F.; Abdallah, B.; Senda, A.; Sadiki, A.; Chrigui, M. Full-scale cfd study of swirl number effect on particle and flow behavior in interaction with combustion dynamics inside coal pulverized burner. Heat Transf. Res. 2023, 54, 79–95. [Google Scholar] [CrossRef]

- Wartha, E.M.; Haugen, N.E.; Karchniwy, E.; Bösenhofer, M.; Harasek, M.; Lovås, T. The effect of turbulence on the conversion of coal under blast furnace raceway conditions. Fuel 2023, 331, 125840. [Google Scholar] [CrossRef]

- Aydın, A.; Engin, T.; Kılıç, S. Design and optimization of a combi boiler heat exchanger: A CFD-based approach. Appl. Therm. Eng. 2024, 257, 124178. [Google Scholar] [CrossRef]

- Yan, L.; Yan, J.; Pu, J.; Song, Y.; Wu, X.; Lu, X. Study on superheater wall temperature in a 1000 MW ultra-supercritical power plant under flexible load operations. Case Stud. Therm. Eng. 2025, 74, 106994. [Google Scholar] [CrossRef]

- Du, J.; Li, Y.; Zhao, Y.; Da, Y.; Che, D. Numerical study of supercritical opposed wall-fired boiler furnace temperature and high-temperature heating surface stress under variable load operation. Energies 2024, 17, 663. [Google Scholar] [CrossRef]

- Skalak, Z. A remark on the regularity criterion for the Navier–Stokes equations in terms of one directional derivative of the velocity. Nonlinear Anal. Real World Appl. 2026, 87, 104437. [Google Scholar] [CrossRef]

- Jalilibal, Z.; Amiri, A.; Castagliola, P.; Khoo, M.B.C. Monitoring the coefficient of variation: A literature review. Comput. Ind. Eng. 2021, 161, 107600. [Google Scholar] [CrossRef]

- Chong, P.A.; Zhu, X.L.; Li, J.N.; Li, X.; Deng, L. Investigation on hydrodynamic performance and wall temperature of water-cooled wall in 1000 MW boiler under low-load conditions. Energies 2024, 17, 5751. [Google Scholar] [CrossRef]

- Liu, H.; Wang, Y.; Zhang, W.; Wang, H.; Deng, L.; Che, D. Coupled modeling of combustion and hydrodynamics for a 1000 MW double-reheat tower-type boiler. Fuel 2019, 255, 115722. [Google Scholar] [CrossRef]

- Zhang, G.H.; Fan, Y.B.; Yang, R.S.; Li, S.H. Application of the Rosin-Rammler function to describe quartz sandstone particle size distribution produced by high-pressure gas rapid unloading at different infiltration pressure. Powder Technol. 2022, 412, 117982. [Google Scholar] [CrossRef]

- Zhu, M.; Lu, H.; Zhao, W.; Huang, S.; Chang, X.; Dong, L.; Kong, D.; Jing, X. A numerical study of ash deposition characteristics in a 660MW supercritical tangential boiler. Adv. Theory Simul. 2023, 6, 2300133. [Google Scholar] [CrossRef]

- Zima, W.; Taler, J.; Gradziel, S.; Trojan, M.; Cebula, A.; Oclon, P.; Dzierwa, P.; Taler, D.; Rerak, M.; Majdak, M.; et al. Thermal calculations of a natural circulation power boiler operating under a wide range of loads. Energy 2022, 261, 125357. [Google Scholar] [CrossRef]

- Chen, G.; Li, Z.; Zhang, H.; Huang, L.; Liu, Z.; Fan, W. Influences of ultra-low load operation strategies on performance of a 300 MW subcritical bituminous coal boiler. Appl. Therm. Eng. 2024, 256, 124037. [Google Scholar] [CrossRef]

- Qin, M.; Liu, D.Y.; Wu, S.H.; Cao, Q.X. Numerical simulations on flow characteristics of flue gas in furnace with four-wall tangential firing. Combust. Sci. Technol. 2017, 189, 2135–2153. [Google Scholar] [CrossRef]

- Chong, P.; Li, J.; Zhu, X.; Jing, D.; Deng, L. Numerical Study on Combustion Characteristics of a 600 MW boiler under low-load conditions. Processes 2024, 12, 2496. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Y.G.; Zou, L.; Bai, Y.Y.; Shen, T.; Wei, Y.W.; Li, F.X.; Zhao, Q.X. Numerical investigation of stable combustion at ultra-low load for a 350 MW wall tangentially fired pulverized-coal boiler: Effect of burner adjustments and methane co-firing. Appl. Therm. Eng. 2024, 246, 122980. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).