Abstract

This paper presents the optimal design and cost–benefit analysis of an off-grid solar photovoltaic system integrated with a hybrid energy storage system for a Category 3 rural healthcare facility in Elands Bay, South Africa. The optimal configuration, designed in Homer Pro, consists of a 16.1 kW solar PV array, 10 kW lithium-ion battery, 23 supercapacitor strings (2 modules per string), 50 kW fuel cell, 50 kW electrolyzer, 20 kg hydrogen tank, and 10.8 kW power converter. The daily energy consumption for the selected healthcare facility is 44.82 kWh, and peak demand is 9.352 kW. The off-grid system achieves 100% reliability (zero unmet load) and zero CO2 emissions, compared to the 24,128 kg/year of CO2 emissions produced by the diesel generator. Economically, it demonstrates strong competitiveness with a levelized cost of energy (LCOE) of ZAR24.35/kWh and a net present cost (NPC) of ZAR6.05 million. Sensitivity analysis reveals the potential for a further 20–40% reduction in LCOE by 2030 through anticipated declines in component costs. Hence, it is established that the proposed model is a reliable and viable option for off-grid rural healthcare facilities.

1. Introduction

Reliable energy access is critical for socioeconomic development and improvement of quality of life [1]. Although global electricity access increased from 87% (2015) to 91.4% (2023) [2], sub-Saharan Africa remains deprived, with 598.8 million (>50% of the population) lacking electricity by 2023 [2,3]. The situation is worse in rural areas, where approximately 80% of the population lack electricity or are underserved [2]. Reliable and cost-effective energy supply is crucial for rural healthcare facilities for powering their medical equipment such as ultrasound machines, sterilizers, and refrigeration units for storing vaccines and medications [4]. Without it, many facilities have to depend on lamps or candles, which in turn affects quality of their service [3], contributing to high mortality rates amounting to approximately; 72 infant, 71 child (per 1000 live births), 536 maternal (per 100,000 births), and 275 adult deaths (per 1000) [5]. Reliable electricity supply could reduce rural mortality rates by 70% [4,6,7].

Diesel generator (DG) is mostly used in rural areas to ensure reliable electricity to healthcare facilities; but they are cost-intensive, environmentally harmful, and prone to fuel supply disruptions [6]. Renewable energy sources (RESs), particularly solar PV, offer a viable option due to their availability, ease of installation, and low operating costs [7]. Off-grid solar PV systems can reduce expenses, mitigate environmental pollution, and improve healthcare delivery in rural facilities. However, solar PV systems face inherent power output fluctuations, resulting in supply and demand mismatch [8]. This challenge is mostly addressed by integrating suitable energy storage system(s). Therefore, this study focused on the optimal design and cost–benefit analysis of an off-grid solar PV system with hybrid energy storage system (HESS) that combines lithium-ion batteries, hydrogen fuel cells, and supercapacitors for rural healthcare facilities.

Previous studies have explored hybrid renewable energy systems (HRESs) with a single energy storage system (SESS) [1,7,9] or single renewable energy source (SRES) integrated with a SESS [10,11,12,13,14]. However, none have examined the optimal design and cost–benefit analysis of a solar PV-based HESS particularly for off-grid Category 3 healthcare facilities in South Africa. Therefore, this study presents an optimal off-grid system design for a Category 3 rural healthcare facility in Elands Bay, South Africa, comprising a 16.1-kW solar PV array, a 10-kW li-ion battery, a 20-kW hydrogen fuel cell, and two strings of 23 supercapacitors. The study provides detailed understanding of the optimal system design, the demand profile of healthcare facilities, and the cost of operating the proposed system. Special emphasis was given to refrigeration and heating loads, lighting, and other critical medical equipment loads in off-grid mode. The study was conducted using HOMER pro ×64 software (version 3.18.0, build 3.18.8823.1207) with Elands Bay weather data. The system configuration, including the design of each component, is presented in Section 3. The major contributions of this research are:

- Optimal design of a solar PV system that integrates a HESS comprising lithium-ion battery, hydrogen fuel cell, and supercapacitor for reliable, efficient, and sustainable energy supply.

- Cost–benefit analysis, showcasing the economic advantages of the proposed system over conventional diesel generator.

- Technical and economic comparison of the use of diesel generator alone to a solar PV-HESS system.

The remainder of this paper is structured as follows: Section 2 presents the review relevant literature, Section 3 details the methodology along with component design, Section 4 presents the case studies, Section 5 discusses the results, and Section 6 presents the conclusion with recommendations for future research.

2. Literature Review

Power outages in sub-Saharan Africa significantly impact service quality in Category 3 rural healthcare facilities, especially those requiring substantial refrigeration capacity for medications, vaccines, and other temperature-sensitive medical supplies [15]. Regular scheduled power outages, or “load-shedding,” implemented by the national power utility, have disrupted healthcare services in these areas, affecting effective service delivery and increasing operational costs [16]. According to [15], rural healthcare facilities in sub-Saharan Africa experience 8–12 h of power outages weekly, resulting in the loss of temperature-sensitive laboratory samples. These outages cost an average of USD 10,000 (ZAR 180,000) per facility annually, including additional costs for hiring of emergency DGs [15]. The conversion from USD to South African Rands (ZAR) is based on an exchange rate of USD 1/ZAR18, accessed on 1 February 2025, and applied consistently throughout this paper.

According to [17], 60% of rural healthcare facilities in South Africa face delays in laboratory services due to power outages, extending patient wait times and affecting service quality. These interruptions unduly affect critical services including maternal and child healthcare, surgical procedures, emergency care, and neonatal incubators operations. Power outages are linked to a 15–20% increase in maternal and infant mortality rates in rural South Africa [17]. Additionally, the high operational costs of emergency power supply stretch already limited budgets, diverting limited resources from other essential services. According to [18], rural healthcare facilities in South Africa spend around 30% of their annual budgets on diesel for backup DGs, diverting funds for critical medical supplies and staff. These financial burdens suggest the need for sustainable, reliable energy solutions like solar PV-HESS systems to enhance healthcare delivery in these facilities.

Approximately 85% of South Africa’s uninsured population depends on just 30% of the doctors in the country, while rural facilities employ only 12% of doctors and 19% of nurses, with the rest concentrated in urban areas [19]. Improving rural electrification could help mitigate this disparity. While post-apartheid reforms expanded electricity access from 35% to 85% [20], about 2 million mostly rural households still lack access to reliable electricity [21]. Connecting these communities to the grid is not cost-effective, making off-grid renewable microgrids a viable option [22]. This energy poverty significantly impacts healthcare quality, highlighting the need for renewable energy solutions. South Africa has abundant solar irradiance (5–6.5 kW/m2/day) [23,24] and dependable wind speeds (5–7 m/s at 10 m above ground) [25], making hybrid renewable microgrids mostly appropriate for powering rural healthcare facilities.

While global adoption of renewable energy for rural healthcare facilities has increased substantially, major challenges continue, particularly in optimizing system designs and demonstrating economic viability for integrated solutions. Reference [26] designed a stand-alone renewable microgrid for six remote healthcare facilities across the six geopolitical zones in Nigeria, comprising solar PV, a DG, wind turbines, and a lithium-ion battery as the only ESS. Using HOMER Pro software, the study evaluated the environmental and economic benefits at each location, based on the availability of RESs. The results indicated that the solar PV/DG/lithium-ion battery configuration was the most cost-effective option across all locations, with a levelized cost of energy (LCOE) ranging from USD 0.507 (ZAR9.126) to USD 0.542 (ZAR9.756) per kWh and a net present cost (NPC) of USD 12,779 (ZAR230,022) to USD 13,646 (ZAR245,628). This system achieved a renewable energy fraction of 70–80%. Additionally, [27] investigated the technical, environmental, and economic benefits of renewable energy solutions for off-grid healthcare facilities in rural Ghana. The study examined three solar PV systems using the HOMER Pro software. Results showed that for a healthcare facility with an energy demand of 4.30–7.58 kWh/day, a 3 kWp solar PV system with lithium-ion battery storage had the lowest LCOE and CO2 emissions. The system also generated 148–304 kWh of excess electricity monthly, which could power local economic initiatives. The study also demonstrated that reliable, sustainable electricity in rural communities increased household income by approximately 30%, reduced infant and maternal mortality rates by 50%, and improved healthcare service delivery by 25%. These improvements saved 15–43 economic hours per month, this is time redirected toward income-generating activities, especially benefiting women and children. The study concluded that electrification disproportionately empowers women due to their greater participation in productive economic activities.

Ref. [28] conducted a comparative analysis of grid-connected and stand-alone hybrid renewable energy systems (HRES) to determine the optimal technical and economic configuration for an agricultural settlement in Napier, Western Cape, South Africa. The system included a solar PV, wind turbines, and hydrogen fuel cells connected in both modes (grid-connected and off-grid). The load demands, including lighting, hot water geysers, a small refrigerator, and the charging of mobile phones and laptops, were modelled as critical and non-essential loads that were switched on at intervals. The most viable option was determined using the NPC. The results showed that the grid-connected configuration was the more cost-effective option at USD 21.02 (ZAR378.36)/kWh, compared to the off-grid configuration at USD 35.99 (ZAR647.82)/kWh. The NPC was USD 107 million (ZAR1.926 billion) and USD 183 million (ZAR3.294 billion), respectively. Likewise, ref. [29] optimally designed and simulated a renewable energy system comprising solar PV, wind turbines, and hydrogen fuel cells for an off-grid police station in Sagar, Central India. The study evaluated the economic and technical feasibility of the system in both grid-connected and off-grid modes. The results validated against the BIG BANG CRUNCH (BBC) algorithm and GAME theory showed off-grid mode’s advantage. Specifically, the off-grid system had an NPC of USD 37,487 (ZAR674,766) and an annual operating cost (OC) of USD 977 (ZAR17,586), outperforming the grid-connected option (NPC: USD 39,557 [ZAR712,026]; OC: USD 997 [ZAR17,946]). The LCOE for useful electricity was USD 0.305 (ZAR5.49)/kWh (off-grid) against USD 0.470 (ZAR8.46)/kWh (grid-connected). Hence, the authors suggested an off-grid system combining solar PV, wind turbines, and hydrogen fuel cells, due to its improved NPC.

To mitigate power outages (load shedding) in rural Ngazidja Island, Comoros, ref. [30] designed a renewable energy microgrid with hydrogen fuel cell storage and evaluated its economic feasibility. The power system comprises three wind turbines with different power ratings, a solar PV plant, power converters, AC loads, and a hydrogen fuel cell that also has a variable power rating. The optimal configuration, based on the cost of electricity, included 250 kW wind turbines, a 2250 kW solar PV plant, a 1000 kW fuel cell, a 1000 kW electrolyzer, and a 10,000 kg hydrogen storage unit. The LCOE was established at USD 1.724 (ZAR31.032)/kWh. Again, the results showed an excess electricity production of 538.138 kWh/year and zero unmet load. The operation and maintenance costs were USD 133 (ZAR2394) per year. The system effectively mitigated power outages and reduced reliance on fossil fuel-based energy sources. The authors of [31] compared the economic benefits for various stakeholders under different operational modes in photovoltaic poverty alleviation power stations (PPAPSs), using primary data from China. The study evaluated PPAPSs over the project’s cost lifespan and conducted a sensitivity analysis to identify risk-influencing variables. The results demonstrated that PPAPSs yield significant economic benefits when operations and maintenance (O&M) are outsourced, while initial capital investment and power generation capacity critically impact the project’s return on investment (ROI). The study concluded by proposing policy measures to mitigate these risks.

Again, ref. [32] proposed an innovative framework for optimizing off-grid microgrid systems in semi-urban Beijing, addressing both economic and environmental challenges. The study introduced two evaluation metrics: dynamic avoided GHG emissions (AGE) and a cost–benefit index (CBI). Using enhanced MORIME optimization with MCMC methods, the analysis managed renewable generation and load demand uncertainties while comparing system configurations. Results showed PV/wind/fuel cell systems achieved optimal emissions at higher costs, while PV/wind/battery systems offered balanced environmental and economic benefits. The framework provides policymakers with robust tools for sustainable microgrid planning in Beijing and similar regions. These findings further support the proposed microgrid system as a viable option, capable of providing an uninterrupted power supply to the community and other rural off-grid locations.

Authors of [33] conducted a study to optimize the hybrid renewable energy system for the Turkish Training and Research Hospital in Mogadishu, Somalia, which currently depends entirely on diesel generators. The HOMER-based analysis integrated three critical local parameters: costs of diesel per liter, site-specific solar irradiance data, and measured wind speed profiles. Results showed that the optimal system configuration consists of a 350 kW diesel generator, a 1000 kW wind turbine, 300 battery units, and a 250 kW power converter. This hybrid design achieved an NPC of USD 5,056,700 and LCOE of USD 0.191/kWh, representing a 62% reduction compared to Somalia’s current average of USD 0.5/kWh. Environmentally, the system had less CO2 emissions compared to diesel generator-based operation while ensuring high renewable energy penetration. The study conclusively demonstrates that this configuration is a cost-effective and environmentally sustainable solution for off-grid hospitals in areas with similar weather conditions.

Some studies have demonstrated the effective implementation of HRES with suitable SESS (lithium-ion battery) for off-grid rural healthcare facilities [26,27]. Others have evaluated the economic viability of HRES in both grid-connected and off-grid modes for agricultural settlements and local police stations using SESS (hydrogen fuel cell) [28,29,30]. Previous studies did not clearly present the optimal design and cost–benefit analysis of a HESS (lithium-ion battery, hydrogen fuel cell, supercapacitor), nor did it compare the results with DG-only configuration. The hybridization of ESSs, attained through the integration of lithium-ion batteries, supercapacitors, and hydrogen fuel cells, presents tangible advantages over SESSs [13]. The HESS combines the strengths of three technologies: the hydrogen fuel cell (extended discharge, high efficiency), the lithium-ion battery (high energy density, long cycle life for continuous use), and the supercapacitor (fast charge-discharge for stability during peak demand) [13,34,35]. By combining the strength of each ESS, HESSs reduce initial capital, operational, and maintenance costs while enhancing energy security via improved reliability and resilience. HESSs collectively overcome inherent limitations of SESSs, including capacity degradation and ineffectiveness in managing variable load demands. These configurations provide substantial cost savings through the optimized use of resources and the reduction of operational costs. Simultaneously, they improve energy security by enhancing system reliability, grid stability, and operational flexibility. The introduction of hydrogen fuel cells aligns with South Africa’s policy on hydrogen adoption and sustainability [36]. Refs. [37,38] provide a detailed and respective evaluation of the design, feasibility, and analysis of hydrogen-based energy storage systems within islanded microgrids and off-grid installations for South African healthcare facilities. These investigations highlight the growing strategic importance of hydrogen storage within the South African and broader African energy security and sustainability landscape.

HESS have distinct advantages over SESS in both economic and operational dimensions. The capital costs of HESS are minimized through optimized component sizing, while SESS requires oversizing to manage load variability, resulting in higher initial capital. The operational effectiveness of HESS is shown in reduced maintenance costs, achieved through efficient charge-discharge cycling and mitigated degradation. In contrast, SESS requires frequent maintenance due to accelerated wear and frequent components replacements. These factors produce a lower LCOS for HESS, supported by improved efficiency and extended lifespan, whereas SESS incurs higher LCOS from operational inefficiencies. In grid applications, HESS provides essential ancillary services, including renewable energy intermittency mitigation and reduced fossil fuel dependence, while SESS often requires backup systems to manage variable loads. Reliability assessments demonstrate HESS’s resilience against single-point failures, a critical vulnerability in SESS configurations. Additionally, HESS supports multifunctional applications like load shifting and emergency backup across multiple scales, unlike SESS’s limited single-purpose functionality [13,35,39,40]. Therefore, this study presents the optimal design and cost-benefit analysis of a solar PV-HESS that includes a lithium-ion battery, supercapacitor, hydrogen fuel cell for rural healthcare facility.

3. Materials and Methods

This section describes the methodology used to determine the optimal off-grid solar PV-HESS configuration for the Elands Bay healthcare facility in South Africa. Solar PV was chosen due to the location’s high solar irradiance, which provides approximately 2500 h of sunshine annually [41]. The HESS integrates lithium-ion batteries, hydrogen fuel cells, and supercapacitors to leverage their complementary strengths. Lithium-ion batteries offer high energy density, large storage capacity, extended lifecycle, rapid charging capability, and low cost [42], and hydrogen fuel cells provide sustainable, emission-free long-term storage ideal for large-scale applications [43]. The supercapacitor complements these by supporting fast charge–discharge cycles to stabilize power during peak demand [44]. Collectively, these technologies enhance system reliability, efficiency, and environmental sustainability. The section further details the design process, including site selection, resource and load assessment, and component sizing.

3.1. Site Description and Solar Energy Resources

The Category 3 rural healthcare facility selected for this study is in Elands Bay, a coastal city in the Cederberg sub-district of Western Cape province in South Africa (see Figure 1 as obtained from Google Maps [45]). The facility provides essential services, including emergency care, medical consultations, and maternal and child health support to local populations, alongside preventive, curative, and minor surgical care for underserved communities.

Figure 1.

Elands Bay in Western Cape province, South Africa [45].

Elands Bay, renowned for its fishing activities and scenic views, is situated approximately 220 km north of Cape Town along the Atlantic coast. The healthcare facility is located at approximately 32.3121° S latitude and 18.3304° E longitude. Given the identical meteorological conditions between locations, the study used Cape Town’s solar irradiance and temperature data as representative of Elands Bay due to their geographical proximity [46]. Table 1 presents the monthly clearness index (a measure of atmospheric clarity) and daily solar radiation levels (kWh/m2/day). These values help determine monthly energy generation estimates for the solar PV system. As shown in Table 1, the lowest clearness index occurs in June at 0.582, while the highest is in January at 0.681, corresponding with the peak winter and summer months in South Africa, respectively. Furthermore, the lowest and highest daily radiation values are recorded in June and December at 2.810 kWh/m2/day and 8.180 kWh/m2/day, respectively [46].

Table 1.

Solar irradiation characteristics of the site of the health care facility [45].

3.2. Load Profile of Rural Healthcare Facility

Globally, rural healthcare facilities are classified into three categories based on electrical load demand [5]. Group 1 (1–10 kWh/day), often referred to as health posts, operates with few staff and provides basic primary healthcare, including child delivery, maternal care, and emergency services [47]. These facilities lack medical laboratories, compelling patients to travel long distances for diagnostic services such as X-rays, ultrasounds, and laboratory tests [48]. Group 2 (10–20 kWh/day) includes facilities with functional medical laboratories capable of basic blood tests, minor surgical operations, and dental procedures [48]. Staffed with laboratory technician(s), nurse(s), and doctor(s), they provide better healthcare services for residents [47]. Group 3 (>20 kWh/day) is the most advanced, characterized by expanded medical teams (doctors, nurses, medical lab technicians, and specialists) and advanced medical equipment capable of handling complex cases and surgical procedures. These facilities significantly improve rural healthcare services, accessibility, and outcomes [48]. This study focuses on Group 3 because it supports South Africa’s National Development Plan objective to provide quality healthcare for all citizens and residents [49].

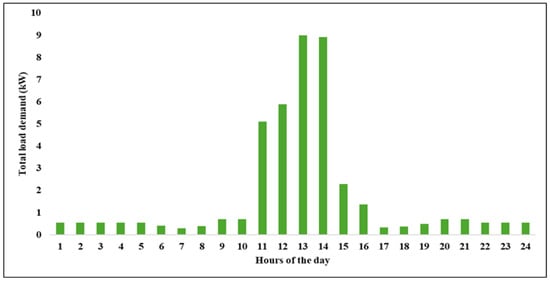

According to [48], the load profile of a regular rural healthcare facility shows load demand progressively increasing from early morning, peaking at midday, and declining toward the evening. This pattern is ideal for solar PV systems integration, as peak load aligns with maximum solar energy generation, enhancing system efficiency and reliability. For this study, the load profile from a February 2024 summer weekday was selected due to inherently higher summer temperatures and the resulting weekday peak load demands from cooling systems such as vaccine refrigerators and HVAC systems. It uses a 12-bed Group 3 facility as recorded in [7,26,47] as the standard for a South African rural healthcare. This includes a medical laboratory providing basic diagnostic services, vaccine freezers, male/female wards, laboratory, maternity room, emergency room, operating theatre, and consulting room [7]. Derived from IEA standards [48] and Elands Bay solar data [45], Figure 2 shows the load profile with peak load between 11:00 and 14:00, while Table 2 and Table 3 presents the load types and operating hours. To ensure clarity on the nature of the load demand, this paper adopts the format for Table 3 from [38].

Figure 2.

Load demand profile of a rural healthcare facility.

Table 2.

IEA standard load profile for Group 3 healthcare facility [48].

Table 3.

Load demand for the health care facility with operating hours.

The hourly load demand and the total daily energy consumption can be calculated using Equations (1) and (2), respectively:

where is power consumed by each electrical load type (kW), M is the total number of different types of components in a specific hour, k is a number representing a specific component, is the number of units of a component of type is the daily total energy demand (kWh), is the hour. Using Table 2 and Table 3 and Equations (1) and (2), the peak hourly total load demand is calculated as 9.352 kW, and the daily total energy consumption is 44.82 kWh. The total power () represents the sum of all components’ power ratings (kW), while the total energy consumption () is the cumulative daily energy consumption of all loads (kWh). The aforesaid values serve as inputs in HOMER Pro for all system modelling and optimization.

As shown in Figure 2, the load demand peaks between 11h00 and 14h00, mainly caused by refrigeration loads due to high ambient temperatures, coupled with increased medical equipment usage and patient influx. Base loads comprise of lighting and communication devices. To manage surge in load demands and fluctuations, a HESS combining lithium-ion batteries, supercapacitors, and hydrogen fuel cells is proposed. Lithium-ion batteries provide constant energy storage for base loads, while supercapacitors handle spikes and transient demands, mitigating over-reliance on the batteries. Hydrogen fuel cells serve as long-lasting backup during extended demand surges or power outages. Despite their high initial cost, this integration enhances reliability, increases component lifespans, and ensures stable power for healthcare services [5].

3.3. Optimal PV-HESS (Case 1) System Design and Configuration

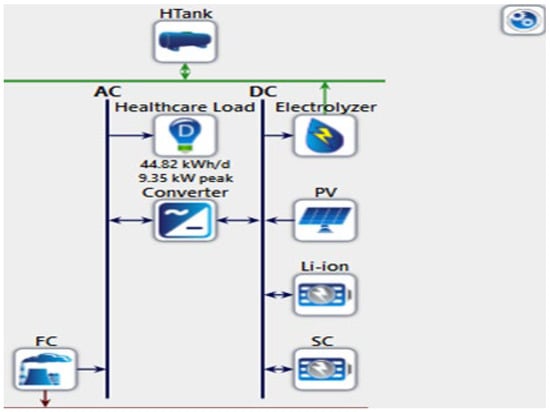

The proposed solar PV-HESS off-grid system (Case 1) was modelled in HOMER Pro using the calculated daily energy consumption (44.82 kWh/day) and peak load (9.352 kW). The software evaluates technical and economic feasibility by comparing different configurations to identify the cost-effective solution under defined constraints [29], balancing energy production and consumption at each time step to estimate lifecycle costs (design, installation, operation, and maintenance). The optimization of component parameters for South African weather conditions is conducted using site-specific data. Local solar irradiance is used for PV sizing, while temperature impact on degradation rates informs the battery model. The load profile is used to define fuel cell efficiency, and diesel costs include carbon taxes for accurate generator costing. The components are presented in Figure 3.

Figure 3.

Solar PV-HESS system configuration (Case 1).

3.3.1. Solar PV Design and Power Output

The performance of the solar PV system, including its power output and efficiency, depends on solar irradiance, atmospheric conditions, temperature, and site-specific factors. PV output changes diurnally (day/night) and seasonally (summer/winter) due to variations in solar conditions [50]. The hourly power output can be calculated as a function of solar irradiance and temperature as shown in Equation (3) [51]:

where is the rated capacity of the module at standard test conditions (kW), is the PV derating factor (%), is the global solar irradiance hitting the PV surface , is the solar irradiance under standard test conditions , is the temperature coefficient power of the PV (/), represents the operational temperature of the PV module , is the module temperature at standard test conditions. This study used a standardized flat-plate PV system by National Renewable Energy Laboratory (NREL). The = 20 kW, = 90%, = 1 kW/m2, , . Assuming 5 h daily sunshine, . The initial cost of solar PV is ZAR18,000 per kW, with an annual operation and maintenance (O&M) cost of ZAR300 and a system lifetime of 25 years [52]. To ensure reliability, the solar PV capacity was calculated using (3), considering the daily energy consumption (44.82 kWh/day), peak load (9.352 kW), and local solar irradiance as:

However, to mitigate operational losses (such as temperature derating, inefficiencies) and ensure reliable off-grid operation, a 20 kW array was selected from HOMER Pro software library.

3.3.2. Hybrid Energy Storage System (HESS)

The HESS integrates lithium-ion batteries to handle base loads, supercapacitors to manage sudden spikes in power demand, and hydrogen fuel cells to provide backup and extended-duration power, ensuring a reliable, efficient, and sustainable energy supply. The battery charges when the solar PV’s power output exceeds the load demand and the battery’s SOC is below 80%. To ensure optimal performance, systematic charge and discharge management is necessary to avoid deep discharge. Equations (4) and (5) are used to evaluate the amount of battery charge at a specific time [53,54]:

The battery SOC at a specific time can be expressed as:

where is the initial battery SOC (%), (V) and (A) are the battery voltage and current, respectively.

The li-ion battery is sized to handle 25% of the daily energy demand, calculated as: . A 10 kW li-ion battery with a nominal voltage of 48 V, maximum capacity of 300 Ah, and theoretical energy capacity of 14.4 kWh was selected. With a round-trip efficiency of 90%, the usable capacity drops to = 12.96 kWh, ensuring sufficient energy within set efficiency constraints. The battery sizing was optimized based on the load profile and assumed to have a lifetime of 10 years.

Hydrogen Fuel Cell

The modeling approach and data for the hydrogen fuel cell simulation are adopted from [37,38,54,55]. The hydrogen fuel cell system comprises an electrolyzer, fuel cell, and hydrogen storage tank. The electrolyzer uses available electricity to separate water into hydrogen and oxygen through electrolysis. The rate of hydrogen production () from the electrolyzer can be calculated using Equation (6) [37]:

where is the hydrogen production rate (kg/h), is Faraday’s efficiency (%), is the number of cells connected in series, is the electrolyzer current (A), is the number of electrons/mol, and F is the Faraday’s constant valued at 96,485,309 (C/mol). The hydrogen produced through electrolysis is stored in a pressurized tank, with the power required for compression expressed as Equation (7) [38]:

where is the power required for hydrogen compression (kW), is the polytrophic coefficient, T is the temperature of the compressor (K), is efficiency of the compressor (%), R is the gas constant (j/(kgK)), and are the inlet and outlet pressures of the electrolyzer, respectively (Pa), and is the mass flow rate of hydrogen (kg/s). The hydrogen pressure in the tank can be expressed as Equation (8) [38]:

where is the number of moles in the hydrogen tank and is the tank volume (m3).

Furthermore, to enhance the renewable energy mix in the system, the fuel cell converts the stored hydrogen into useable electrical energy [55]. The output power of the fuel cell can be expressed using Equation (9) [52] as:

where is the lower heating value of hydrogen gas taken as 33.3 (kWh/kg), is the fuel cell efficiency normally approximated to be 0.6, is the compressed hydrogen gas density expressed in kg/m3 [56]. The technical parameters of the electrolyzer are presented in Table 4 and adopted from [38]. These parameters determine the hydrogen production rate and define HOMER inputs for efficiency, energy consumption, and cost modeling.

Table 4.

Technical parameters of electrolyzer [38].

Supercapacitor

Supercapacitors (SCs) are high-power-density units with rapid response, high efficiency (~95%), and long cycle life, making them ideal for handling power spikes and transient loads. In this system, the SC handles fast solar PV fluctuations while the lithium-ion battery provides medium-term storage and hydrogen fuel cells ensure long-term energy supply, collectively enhancing system reliability [44,57]. The electrical charge (capacitance) and energy are expressed using Equations (10) and (11) as:

where C is the capacitance (F), Q is the charge (C), and V is the voltage across the supercapacitor (V). In this study, a generic supercapacitor with 95% efficiency is used. Its sizing is based on the daily energy consumption (44.82 kWh) and peak load (9.352 kW). A SC with a nominal voltage of 4 V, capacitance of 3000 F, and a lifetime of 25 years is selected. The stored charge and energy are calculated using (10) and (11) as: and energy per SC is

3.3.3. Power Converters

The power converter is essential for managing the energy flow between the DC bus and AC bus. It is a 3-phase bidirectional converter designed for off-grid microgrid applications. The selected converter has a lifespan of 15 years and an operational efficiency of 90–95%. The technical parameters of the converter are presented in Table 5 and adopted from [38].

Table 5.

Technical parameters of converter [38].

3.3.4. System Modelling and Simulation

The search space data inputs used for component sizing are presented in Table 6 and adopted from [37,38,50,57]. The solar PV, fuel cell, supercapacitor, li-ion battery, and power converter are sized using HOMER Pro’s integrated optimization tool, which uses a set of rules to reduce design errors and identify the most cost-effective configuration. The electrolyzer and hydrogen tank are optimized through the search space method, using predefined decision variables to systematically determine the optimal solution.

Table 6.

Components sizing and system configuration [38,51,58].

Both load-following and cycle-charging dispatch strategies were simulated to ascertain the best strategy. Load-following strategy showed better operational efficiency compared to cycle-charging. Executed in HOMER Pro, load-following strategy matches power supply and load demand, reducing environmental impact while improving cost-effectiveness [59]. Load-following strategy used smaller components, optimizes hydrogen usage, and improved peak load management by supercapacitors. Furthermore, the integration of a 16.1 kW solar PV enhanced reliability without requiring larger PV-HESS configurations typical of cycle-charging. These advantages collectively show that the load-following strategy optimally balances technical performance, economic feasibility, and environmental sustainability.

3.3.5. Solar PV-HESS System Optimization

The optimal system configuration is selected based on NPC and LCOE as key performance metrics, with the goal of ensuring system reliability and an adequate power supply aligned with the load profile. The system optimization approach and calculation processes are based on approaches reported in [37,38,50,51,59,60]. These indices are derived using the annualized capital cost (CACC) of each component in the system, which can be calculated as Equation (12) [38]:

where is the initial cost (ZAR/year) and is the capital recovery factor of each component, respectively. The which is also referred to as the “return on investment (ROI),” can be calculated as Equation (13) [38]:

where is the interest rate (%) and N is the lifespan of the component expressed in years.

The total annualized capital cost (CTACC) of the project, measured in ZAR/year, is obtained by aggregating the annualized capital costs (CACC) of all components in the system. This can be calculated as Equation (14) [52]:

where, n is the number of renewable energy components in the microgrid configuration.

Additionally, the NPC is the sum of all the annualized costs of each component within the system. This includes the initial capital cost, replacement costs, operational costs, maintenance costs, and fuel costs, minus the estimated salvage value at the end of the project lifespan. The NPC, a major parameter in optimizing system configurations expressed in South African Rands (ZAR), is calculated as Equation (15) [60]:

where is the capital recovery factor of the project (initial cost, replacement cost, operational and maintenance costs) and is the project lifespan in years.

The LCOE in ZAR, which represents the average cost per kWh of useful energy generated by the system, can be expressed as Equation (16) [38]:

where; is the total load demand of the healthcare facility (kWh/year). The system imposed an interest rate of 8% and inflation of 2% [50].

The costs of all components used in the simulation are presented in Table 7. Solar PV panels, the inverter, supercapacitor, fuel cell, electrolyzer, and hydrogen tank costs were obtained from [38], while lithium-ion battery costs were from [61]. Replacement and operational/maintenance costs were estimated based on [52].

Table 7.

Cost of components in ZAR [38,52,61].

Using the above optimization criteria, the optimal configuration comprises of a 16.1 kW generic solar PV, a 10.8 kW converter, a 50 kW fuel cell, a 50 kW electrolyzer, a 20 kg hydrogen tank, a 10 kW lithium-ion battery, and 2 strings of 23 supercapacitors, as shown in Table 8. The lifespans for each component were obtained from [38,52].

Table 8.

Optimization results using load following dispatch strategy.

Electricity Production by Components

This section presents the results from the HOMER simulation of the solar PV-HESS, demonstrating how component synchronization mitigates renewable intermittency through systematic analysis of hourly solar irradiance data and load demand profiles. The solar PV system generates 18,047 kWh/year, representing 99.8% of total energy output with an 8.03% capacity factor that reflects local solar conditions and system efficiency, while the hydrogen fuel cell contributes 20.2 kWh/year (0.112% of generation) with a 0.0546% capacity factor, operating exclusively during PV output shortages as presented in Table 9. The simulation results show that the fuel cell functions primarily as an energy storage solution, supplementing power shortages caused by the intermittent nature of solar PV rather than serving as a continuous power source. The HESS design significantly enhances system reliability, with the fuel cell supplying 0.112% of annual generation during solar deficits and the SC managing 85% of peak loads to prevent high-load stress on the li-ion battery. This configuration delivers multiple benefits: emission reductions of 24.128 kgCO2 e/h compared to DGs, extended li-ion battery lifespan through 50% fewer deep charge/discharge cycles and contained degradation costs at 6.08–14.9% of initial capital. By effectively managing peak demands and reducing grid dependence, the SC integration increases renewable energy utilization while improving overall cost-effectiveness. These results collectively validate the PV-HESS as a reliable, emission-mitigating solution for off-grid applications, where optimized component synchronization successfully balances renewable intermittency while maximizing operational efficiency and lifetime cost savings.

Table 9.

Electricity generation by components for Case 1.

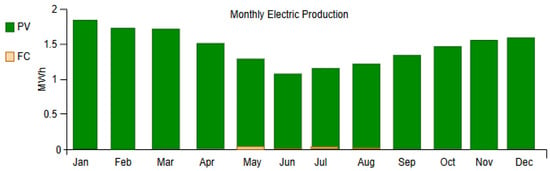

The primary renewable energy source for this system is solar PV, as demonstrated in the monthly energy generation breakdown in Figure 4. The figure reveals that the highest power output occurs during the summer months (December to February), corresponding with peak solar irradiance levels in South Africa during this period. These elevated solar irradiance levels significantly enhance the performance of the solar PV, enabling it to meet over 99% of the total energy demand efficiently. However, during months with lower solar irradiance, the system is designed to depend on the hydrogen fuel cell as a backup energy supply solution, mitigating shortages and ensuring consistent power supply despite seasonal variability.

Figure 4.

Monthly average energy generation for Case 1.

4. Case Studies and Summary of Results

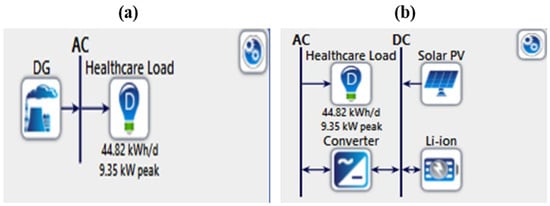

The study evaluated the viability of the proposed HESS configuration by comparing it with three case studies, PV-fuel cell-battery (Case 2), diesel generator only (Case 3) and PV- battery (Case 4). All the cases were distinctly configured with different components and energy storage technologies while maintaining the same load demand as shown in Figure 5. The comparison was based on metrics such as LCOE, NPC, capital, excess electricity, unmet load, operating and maintenance (O&M) costs, and CO2 emissions. These metrics were used to evaluate the economic and environmental implications of each case. This method allows for a better understanding and comparison of the case studies relative to the proposed HESS. All results have been presented in Table 10, Table 11 and Table 12.

Figure 5.

(a) Case 3 configuration; (b) Case 4 configuration.

4.1. Case 1: Solar PV-HESS

Case 1 evaluates the economic and environmental benefits of a PV system integrated with a HESS. The optimal configuration for this case combines a 16.1 kW PV array, 10.8 kW converter, 50 kW fuel cell, 50 kW electrolyzer, 20 kg hydrogen storage tank, 10 kW li-ion battery, and 23 supercapacitor strings (2 modules per string) to optimize energy management by leveraging the strengths of each energy storage technology. The results show an NPC of ZAR6,045,120 and an LCOE of ZAR24.35/kWh, with an O&M cost of ZAR6,835.45. The system’s performance shows a total annual electricity production of 18,067 kWh, with solar PV generating 18,047 kWh/year (99.8%) and the fuel cell contributing 20.2 kWh/year (0.11%). The system produces 401 kWh/year of excess electricity (2.2%), consumes 464 kWh/year in the electrolyzer, and maintains zero unmet load. The system used a load-following dispatch strategy that dynamically matches generation to demand while using excess energy to charge ESS. This integrated approach demonstrates how the HESS can simultaneously reduce diesel dependence, enhance system reliability, and improve economic viability through adequate energy management. This highlights the financial benefits achievable through optimized renewable-storage integration in appropriate market conditions.

4.2. Case 2: Solar PV-Fuell Cell-Battery

Case 2 evaluates the operational and economic impact of SC removal in the proposed HESS. The optimal configuration consists of a 20.8 kW PV array, a 50 kW FC, a 50 kW electrolyzer, a 20 kg hydrogen tank, an 11 kW converter, and a 16 kW li-ion battery. Daily energy consumption and peak load demand remain unchanged from Case 1. The system has an NPC of ZAR6,650,915, LCOE of ZAR27.24, and O&M costs of ZAR16,207.02. In terms of performance, annual electricity production is 41,539 kWh/year, with PV generation contributing 40,922 kWh/year (98.5%) and the FC supplying 617 kWh/year (1.49%). The system produces 17,527 kWh/year of excess electricity (42.2%), while unmet load is minimal at 10.7 kWh/year (0.066%). The electrolyzer consumes 6480 kWh/year of this energy. However, Case 2 demonstrates higher costs compared to Case 1, primarily due to accelerated battery degradation caused by frequent high-power discharges, increased FC degradation leading to higher replacement costs, and reduced system efficiency during load surges.

4.3. Case 3: Diesel Generator (DG)

In this case, the solar PV and HESSs are disconnected, and the total load demand is met exclusively using the DG. The DG operates at full capacity to ensure maximum power output, corresponding to the high load demand. However, this results in a high diesel consumption rate, which corresponds to the high load demand. While the efficiency of the DG increases with higher load demands, this also leads to more fuel consumption and related costs. Though the initial capital cost of a DG is less than that of renewable energy resources, its operational and maintenance costs are substantially higher due to high cost of diesel and the need for regular maintenance. The optimal configuration for this case comprises a DG with a rated capacity of 12 kW, serving a daily load demand of 44.82 kWh/day and a peak load demand of 9.352 kW. The DG is oversized by 22% (relative to the peak load) to ensure reliability, accommodate load transients, mitigate full-load stress, and support future expansion. The economic parameters include an initial capital cost of ZAR86,400, a replacement cost of ZAR86,400, a lifetime of 15,000 h, and an O&M cost of ZAR100/hour. The diesel price is ZAR21/L. Performance results indicate an annual electricity production of 21,054 kWh/year, with excess electricity amounting to 4695 kWh/year (22.1% of total demand). The LCOE is ZAR79.42/kWh, annual O&M costs total ZAR1,292,500, and CO2 emissions reach 24,128 kg/year.

4.4. Case 4: Solar PV-Battery

Case 4 simulates and evaluates the operational feasibility of a solar PV system and lithium-ion batteries. This configuration is designed to reduce over-reliance on fossil fuel-based sources, such as DGs, and promote renewable energy options. The solar PV serves as the primary source of power, while the lithium-ion battery is the ESS, ensuring a reliable, continuous, and stable power supply during power outages, low solar irradiance, or during cloud cover. The optimal system configuration comprises a 27.4 kW PV array (25-year lifespan, 90% derating factor), a 64 kW li-ion battery (15-year lifespan, 80% initial SOC), and an 11.1 kW power converter. The system supplies the load demand (44.82 kWh/day, 9.352 kW peak) at an LCOE of ZAR8.96/kWh and an NPC of ZAR2,498,771. Key performance metrics include annual excess electricity (35,002 kWh/year), minimal unmet load of 9.83 kWh/year (0.06% of total demand), annual O&M costs of ZAR57,568.63, and zero CO2 emissions.

As shown in Table 11, Case 4 initially seems more cost effective due to its lower LCOE of ZAR8.96/kWh and NPC of ZAR2.5 million. However, a systematic examination shows that Case 1 presents better performance metrics. Case 1 provides 100% power availability with no unmet load, while Case 4 has an unmet load of 9.83 kWh/year, posing a risk of operational downtime. Additionally, Case 1 manages energy far more efficiently, wasting only 401 kWh/year (just 2.2% of production) compared to Case 4 of 35,002 kWh/year (42% of generation). This efficiency leads to significant long-term savings. Case 1 annual O&M costs are only ZAR6,835, which is 8.4 times lower than Case 4 of ZAR57,569, quickly negating the initial cost advantage of Case 4. Both cases produce zero CO2 emissions, but the integration of SC in Case 1 ensures continuous supply, unlike Case 4, which may require DG backup during prolonged outages. When compared to other options, such as the unmet load of 10.7 kWh/year in Case 2 and extremely high costs (ZAR79.42/kWh LCOE) in Case 3, Case 1 stands out as the best overall solution, offering reliability, efficiency, and long-term sustainability.

5. Discussions of Results

Four cases are compared: Case 1 (solar PV-HESS), Case 2 (PV-fuel cell-battery), Case 3 (DG only), and Case 4 (solar PV-battery). The comparison evaluates the LCOE, NPC, capital costs, excess electricity production, unmet load, O&M costs, and CO2 emissions (see Table 10). These represent the economic and technical analysis of each case. Additionally, a sensitivity analysis examines the impact of supercapacitor price variations on system performance, considering its high costs. The PV-HESS system generates 18.067 MWh/year against a total demand of 16.8 MWh/year, which comprises an AC primary load of 16.4 MWh/year, electrolyzer consumption of 0.000464 MWh/year. The system has excess electricity of 401 kWh/year and losses of 843 kWh/year due to system inefficiencies, including converter and battery inefficiencies. The solar PV generates 18.047 MWh/year, while the fuel cell (FC) contributes 20.2 kWh/year. The power generation capacities and details are presented in Table 10.

Table 10.

Economic, technical, and environmental results for Cases.

Table 10.

Economic, technical, and environmental results for Cases.

| Parameter | Unit | Case 1 | Case 2 | Case 3 | Case 4 |

|---|---|---|---|---|---|

| Economic results | |||||

| NPC | ZAR | 6,045,120 | 6,650,915 | 16,796,500 | 2,498,771 |

| LCOE | ZAR/kWh | 24.35 | 27.24 | 79.42 | 8.96 |

| O&M | ZAR/year | 6835.45 | 16,207.02 | 1,292,500 | 57,568.63 |

| Salvage | ZAR | −731,408.37 | −500,000 | 150,000 | −300,000 |

| CAPEX | ZAR | 5,150,450 | 5,756,244 | 86,400 | 1,892,977 |

| Technical results | |||||

| Renewable energy penetration | % | 100 | 100 | 0.00 | 100 |

| Energy production | kWh/year | 18,067 | 41,539 | 21,054 | 51,371 |

| Unmet load | kWh/year | 0.0 | 10.7 | 0.00 | 9.83 |

| Load (AC load) | kWh/year | 16,359 | 16,359 | 16,359 | 16,359 |

| Excess electricity | kWh/year | 401 | 17,527 | 4695 | 35,002 |

| Losses | kWh/year | 843 | 1162 | 0.00 | 0.17 |

| Environmental results | |||||

| CO2 emission | kg/year | 0.00 | 0.00 | 24,128 | 0.00 |

| Nitrogen oxides | kg/year | 0.00 | 0.00 | 142 | 0.00 |

5.1. Comparative Economic Analysis of the Cases

To evaluate the economic feasibility of the proposed system, a comparative economic analysis is conducted and compared with Cases 2, 3, and 4. This analysis uses the NPC approach within HOMER Pro software, allowing for a detailed evaluation of long-term cost-effectiveness. The economic analysis highlights significant difference between the Cases. As shown in Table 10, Case 3 has the highest LCOE at ZAR79.42/kWh, rendering it economically unsustainable and uncompetitive. Cases 4 and 2 have LCOE of ZAR8.96/kWh and ZAR27.24/kWh, respectively. While Case 4 demonstrates the lowest LCOE at ZAR8.96/kWh, representing a 63.2% reduction compared to Case 1 (ZAR24.35/kWh), 67% improvement over Case 2 (ZAR27.24/kWh), and 88.7% advantage against Case 3 (ZAR79.42/kWh), a detailed economic analysis shows that Case 1 offers better long-term value. Although Case 4 exhibits a lower NPC (ZAR2.499 million), its configuration incurs significant costs from frequent li-ion battery replacements and high O&M expenses. In contrast, Case 1 achieves a marginally better NPC (ZAR6.045 million) compared to Case 2 (ZAR6.50 million), demonstrating the economic viability of the HESS configuration. This LCOE amount aligns with both the economic reality of the South African energy market and available literature [52]. Twenty-three (23) supercapacitor strings (2 modules per string) were used to optimize energy management by leveraging their strengths. The CAPEX is ZAR5,150,450, and the supercapacitor cost is ZAR136,000, representing 2.6% of the CAPEX, as shown in Table 11.

The operational cost differentials further emphasize the advantage of Case 1, with annual O&M of just ZAR6,835.45 representing only 42.2% compared to Case 2 (ZAR16,207.02) and 99.5% to Case 3 (ZAR1,292,500). These substantial savings enable capital reinvestment on an accelerated 14-month cycle relative to conventional DG. The result also shows that Case 1 achieves ROI in 3.7 years compared to Case 4 (5.4 years), while simultaneously avoiding the price fluctuation associated with diesel price and minimizing battery replacement costs that affect alternative configurations. In South Africa, Case 1 saves ZAR1,285,664.55 annually against DG, combining both economic and environmental benefits. The proposed system is more cost-effective with an LCOE of ZAR24.35/kWh. This represents a significant improvement over both Case 2 (ZAR27.24/kWh), where its economic viability is affected by frequent battery replacement costs, and Case 3 (ZAR79.42/kWh), whose O&M costs are dominated by high diesel consumption. The comparative LCOE reduction of 10.6% and 69.4% relative to Cases 2 and 3, respectively, highlights the technical and economic advantages of the optimized hybrid configuration. The economic parameters for Case 1 are presented in Table 11.

Table 11.

Capital and net present cost of the solar PV-HESS System (Case 1).

Table 11.

Capital and net present cost of the solar PV-HESS System (Case 1).

| Components | Capital Cost (ZAR) | Replacement Cost (ZAR) | O&M Cost (ZAR) | Salvage Cost (ZAR) | Total (ZAR) |

|---|---|---|---|---|---|

| Solar PV | 289,800 | 0.00 | 210,710 | 0.00 | 500,510 |

| Fuel Cell | 2,799,028.39 | 0.00 | 28,312 | −542,316 | 2,285,024.39 |

| Converter | 123,541.21 | 92,655 | 45,561 | −42,354.21 | 219,403 |

| Lithium-ion | 180,000 | 13,5000 | 53,256 | −10,587.23 | 236,168.77 |

| Supercapacitor | 136,000 | 0.00 | 0.00 | −85,568.54 | 50,431.46 |

| Electrolyzer | 1,262,080.40 | 946,560 | 235,524 | −50,582.39 | 2,393,582.01 |

| Hydrogen tank | 360,000 | 0.00 | 0.00 | 0.00 | 360,000 |

| NPC | 5,150,450 | 1,052,715 | 573,363 | −731,408.37 | 6,045,119.63 |

5.2. Comparative Technical Analysis of the Cases

The four cases demonstrate distinct technical capabilities. Case 2 has high reliability with 10.7 kWh/year unmet load, but its high O&M costs due to frequent replacement of the li-ion battery is a major challenge. Case 3 can theoretically meet the entire load demand with perfect reliability (0.00 kWh/year unmet load), but its practical implementation is compromised by fuel supply disruptions that affect temperature-sensitive medicine storage, along with poor surge current handling. Although Case 4 demonstrates relatively high reliability with an unmet load of only 9.83 kWh/year, its dependence on solar PV makes it vulnerable to extended cloud cover. This could lead to temperature fluctuations that may compromise vaccine storage quality. Case 4 performance is inherently constrained by the intermittency of solar PV output and the battery’s SOC, which depends on both the solar PV power output and load demand. Conversely, Case 1 presents optimal technical performance, achieving 100% reliability with zero unmet load and lowest O&M costs. Through its optimized configuration, the integrated HESS sustains refrigeration temperature stability despite prolonged low solar irradiance and extended cloud covers. The HESS shows better energy utilization (18,067 kWh/year against 41,539 kWh/year in Case 2 and 35,002 kWh/year in Case 4). By integrating the SCs for instantaneous surge current management in Case 1, FCs provides up to 72 h of backup power and extended li-ion battery lifetime. The hydrogen tank was empty (0 kg) at the beginning of the year but has a total storage capacity of 20 kg, providing 357 h of system autonomy and an operational energy capacity of 667 kWh. The system produces approximately 4152 kg of hydrogen annually, requiring 192,543 kWh of energy input from its 50 kW electrolyzer. This configuration achieves 52% efficiency (137,000 kWh H2 energy output ÷ 192,543 kWh input) and operates for 3851 h/year (192,543 kWh ÷ 50 kW) to achieve full production. The results show that the hydrogen content in the tank is underutilized. However, in practice, the system is typically designed with dedicated controllers to effectively manage power generation units. The low capacity factor is expected because the FC operates solely as a backup (ESS).

Furthermore, while Cases 2 and 4 requires regular battery replacements, Case 1 systematic load distribution reduces li-ion discharge cycles, significantly extending component lifespan. For critical healthcare applications, only Case 1 satisfies all technical requirements of a stable power supply, WHO-compliant cold-chain maintenance, simultaneous operation of vaccine, refrigerators and medical equipment, and total reliance on renewable energy resources. Case 1 shows optimal technical performance, providing the most reliable, environmentally friendly, and sustainable power solution.

5.3. Sensitivity Analysis

Sensitivity analysis in HOMER Pro involves iterative simulations with varying input parameters to determine the optimal system configuration. This study evaluates the costs of SC, PV, li-ion batteries, electrolyzers, and FCs, using present and projected costs from the U.S. Department of Energy, alongside discount rates of 6% and 7%. Three cost scenarios were analyzed: present, midterm, and 2030 projections, selected for their significant impact on system economics. The result demonstrates that reducing the present costs by 20% and 40% substantially lowers both NPC and LCOE. The LCOE dropped from ZAR24.35/kWh to ZAR19.48/kWh and ZAR14.61/kWh (at 20% and 40% reductions), while NPC from ZAR6,045,120 to ZAR5,150,451 and ZAR4,120,361, respectively. The 40% reduction (2030 projection) appears as the most cost-effective option, balancing affordability, reliability, and scalability required for rural healthcare facilities (see Table 12). A reduction in the prices of these components and the outcome of this study will support South Africa’s renewable energy goals by enabling clean power integration, create jobs, and enhance energy security while supporting decarbonization. It aligns with the Hydrogen Roadmap (2022), provides R&D data, advances Just Energy Transition targets, and indirectly improves healthcare through reduced emissions.

Table 12.

Results of the sensitivity analysis for Case 1.

Table 12.

Results of the sensitivity analysis for Case 1.

| Parameters | Case 1SA | Case 1SB | Case 1SC |

|---|---|---|---|

| Solar PV (ZAR/kW) | 18,000 | 14,400 | 10,800 |

| Li-ion (ZAR/kW) | 9000 | 7200 | 5400 |

| SC (ZAR/300 F) | 1080 | 864 | 648 |

| FC cost (ZAR/kW) | 72,000 | 57,600 | 43,200 |

| Electrolyzer (ZAR/kW) | 19,800 | 15,840 | 11,880 |

| Discount rate (%) | 8 | 7 | 6 |

| LCOE (ZAR/kWh) | 24.35 | 19.48 | 14.61 |

| O&M (ZAR/year) | 573,363 | 458,690.4 | 344,017.8 |

| NPC (ZAR) | 61,045,120 | 5,150,451 | 4,120,362 |

The sensitivity analysis shows that future cost reductions in critical components like solar panels, batteries, and hydrogen systems could make the proposed configuration far more affordable for rural clinics. If prices drop by 40% by 2030 (as projected), the energy cost for these systems could fall from ZAR24.35/kWh to ZAR14.61/kWh, while total system costs could decrease from ZAR6.05 million to ZAR4.12 million. These savings make renewable energy a practical alternative to expensive, polluting diesel generators.

6. Conclusions and Recommendation

In South Africa, off-grid healthcare facilities often depend on DG, a costly and environmentally harmful solution that leads to unreliable electricity supply, poor quality of healthcare delivery, and significant environmental damage. This study presents an off-grid power system combining solar PV with a hybrid energy storage system (HESS) comprising li-ion batteries, supercapacitors, and a hydrogen fuel cell. Designed to provide uninterrupted power for a Category 3 rural healthcare facility in Elands Bay, Western Cape, South Africa, the system was optimized to evaluate its technical, economic, and social viability. The analysis used site-specific solar irradiance data (averaging 5.589 kWh/m2/day, significantly above the global average) and a calculated daily load demand of 44.82 kWh/day with a 9.352 kW peak load.

The optimal configuration (Case 1) comprises a 16.1 kW solar PV, a 20 kW hydrogen FC, a 10-kW li-ion battery, a 50 kW electrolyzer, a 20 kg hydrogen storage tank, and 2 strings of 23 supercapacitors. The results show that this configuration is more economically viable than the other three cases, with an NPC of ZAR6,045,120 and LCOE of ZAR24.35/kWh. By comparison, Cases 2 (PV-fuel cell-battery), 3 (DG only), and 4 (PV-battery) had NPC and LCOE values of ZAR6,650,915 (ZAR27.24/kWh), ZAR16,796,500 (ZAR79.42/kWh), and ZAR2,498,771 (ZAR8.96/kWh), respectively. A sensitivity analysis on the cost of supercapacitors demonstrated their significant impact on the overall system cost, indicating that projected cost reductions would enable the integration of larger capacities for greater economic and technical benefits.

The proposed system offers critical multiple-dimensional benefits. Technically, it ensures reliable power for medical equipment, temperature-sensitive medicine storage (particularly vaccines), and emergency lighting. Economically, it reduces dependence on fluctuating fuel prices and reduces long-term operational costs. Environmentally, it significantly reduces greenhouse gas emissions, supporting South Africa’s clean energy transition. Socially, it enhances healthcare delivery in remote areas, supports immunization programs through reliable vaccine storage, and creates local employment opportunities in installation and maintenance. By integrating lithium-ion batteries with supercapacitors, the system reduces power interruptions while eliminating the noise pollution associated with diesel generators. This integrated approach provides a sustainable, cost-effective power solution that addresses both immediate energy needs and long-term development goals, aligning with national renewable energy policies. Although this study focused on Category 3 facilities, the system components can be adapted for Categories 1 and 2, which have different scales and operational requirements. Smaller clinics typically have lower energy needs, often limited to vaccine refrigeration and basic medical equipment; this reduced demand may allow for smaller system capacities and lower costs, adjusted to each clinic’s critical needs and local conditions.

The authors acknowledge that while this study focused on technical feasibility and system-level optimization using HOMER’s global cost datasets, a deeper analysis is required for real-world implementation. Future work must account for localized hydrogen infrastructure costs, the continuous power supply requirements of temperature-controlled medical loads, local socio-economic conditions, supply chain complexities, and technology readiness levels (TRLs). Consequently, future research by authors in hybrid energy storage is planned as below:

- (a)

- A lab-based prototype will be developed to validate the technical performance and simulation results of the aforesaid PV-HESS system, bridging the gap between theory and practical deployment.

- (b)

- This research looked at health care facility loads in general categories and not specifically to temperature-controlled equipment. The authors plan to prioritize and carefully assess the continuous power supply requirements for temperature-controlled loads.

- (c)

- Authors plan to collect and incorporate real-life data from similar facilities and regions to better understand underlying drivers and robustly validate system design and feasibility.

- (d)

- Authors will conduct detailed research on the optimal sizing of hydrogen storage by taking a more nuanced view of the practical technical and economic factors that impact it.

In general, future research should focus on optimizing hybrid energy storage systems, particularly the role of supercapacitors, to reduce capital and operational costs. Additionally, there is potential for exploring the integration of off-grid systems with local microgrids to improve energy reliability and resilience. Research could also investigate the social impacts of energy transitions in rural areas, focusing on healthcare outcomes and community well-being. Scalability assessments will be crucial for applying this system to larger or different settings, while evaluating other renewable sources, such as wind energy, could diversify energy supply and enhance system robustness.

Author Contributions

Conceptualization, O.S.S. and S.C.; methodology, O.S.S.; software development, O.S.S.; validation, O.S.S. and S.C.; analytical modeling, O.S.S.; investigation, O.S.S.; materials and tools, S.C.; data management, O.S.S.; manuscript drafting, O.S.S.; manuscript revision and editing, S.C.; graphics and figures, O.S.S.; supervision, S.C.; coordination, S.C.; funding procurement, S.C. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Research Foundation of South Africa, grant number 150523.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Acknowledgments

The authors gratefully acknowledge National Research Foundation, South Africa for funding this research and Electrical Engineering Department, University of Cape Town, South Africa for providing infrastructure support for this research.

Conflicts of Interest

The authors declare no conflicts of interest.

Nomenclature

| FCelect | Output power of the fuel cell |

| CC | Cycle charging |

| CO2 | Carbon dioxide |

| DG | Diesel generator |

| FC | Fuel cell |

| H2 | Hydrogen |

| HESS | Hybrid energy storage system |

| HRES | Hybrid renewable energy systems |

| LCOE | Levelized Cost of Energy |

| LF | Load following |

| NPC | Net Present Cost |

| O&M | Operation and maintenance |

| OC | Operating cost |

| PPV | Photovoltaic panel power output |

| PV | Photovoltaic |

| Qbatt | battery charge |

| RES | Renewable energy sources |

| ROI | Return on investment |

| SC | Supercapacitors |

| SESS | Single energy storage system |

| SOC | State of charge |

| SRES | Single renewable energy source |

| Mass flow rate of hydrogen |

References

- Chowdhury, T.; Chowdhury, H.; Hasan, S.; Rahman, M.S.; Bhuiya, M.M.K.; Chowdhury, P. Design of a stand-alone energy hybrid system for a makeshift health care center: A case study. J. Build. Eng. 2021, 40, 102346. [Google Scholar] [CrossRef] [PubMed]

- IEA. World Energy Outlook 2023. 2023. Available online: www.iea.org/terms (accessed on 10 February 2025).

- World Health Organization. World Health Statistics 2023: Monitoring Health for the SDGs Sustainable Development Goals. 2023. Available online: https://www.who.int/publications/book-orders (accessed on 30 January 2025).

- World Health Organization. Immunization Supply Chain and Logistics: A Neglected but Essential System for National Immunization Programmes; WHO Immunization Practices Advisory Committee: Geneva, Switzerland, 2015. [Google Scholar]

- World Bank and World Health Organization. Access to Modern Energy Services for Health Facilities in Resource-Constrained Settings: A Review of Status, Significance, Challenges and Measurement. 2015. Available online: www.who.int (accessed on 7 February 2025).

- Olatomiwa, L.; Sadiq, A.A.; Longe, O.M.; Ambafi, J.G.; Jack, K.E.; Abd’azeez, T.A.; Adeniyi, S. An Overview of Energy Access Solutions for Rural Healthcare Facilities. Energies 2022, 15, 9554. [Google Scholar] [CrossRef]

- Olatomiwa, L.; Blanchard, R.; Mekhilef, S.; Akinyele, D. Hybrid renewable energy supply for rural healthcare facilities: An approach to quality healthcare delivery. Sustain. Energy Technol. Assess. 2018, 30, 121–138. [Google Scholar] [CrossRef]

- Showers, O.S.; Chowdhury, S. Enhancing Energy Supply Reliability for University Lecture Halls Using Photovoltaic-Battery Microgrids: A South African Case Study. Energies 2024, 17, 3109. [Google Scholar] [CrossRef]

- Citalingam, K.; Go, Y.I. Hybrid energy storage design and dispatch strategy evaluation with sensitivity analysis: Techno-economic-environmental assessment. Energy Storage 2022, 4, e353. [Google Scholar] [CrossRef]

- Gajewski, P.; Pieńkowski, K. Control of the hybrid renewable energy system with wind turbine, photovoltaic panels and battery energy storage. Energies 2021, 14, 1595. [Google Scholar] [CrossRef]

- Li, B.; Liu, Z.; Wu, Y.; Wang, P.; Liu, R.; Zhang, L. Review on photovoltaic with battery energy storage system for power supply to buildings: Challenges and opportunities. J. Energy Storage 2023, 61, 106763. [Google Scholar] [CrossRef]

- Chauhan, S.; Singh, B. Control of solar PV-integrated battery energy storage system for rural area application. IET Renew. Power Gener. 2021, 15, 1030–1045. [Google Scholar] [CrossRef]

- Sharma, P.K.; Kurmar, D.A.; William, P.; Obulesu, D.; Pandian, P.M.; Khan, T.K.H.; Manikandan, G. Energy storage system based on hybrid wind and photovoltaic technologies. Meas. Sens. 2023, 30, 100915. [Google Scholar] [CrossRef]

- Gaitan, N.C.; Ungurean, I.; Corotinschi, G.; Roman, C. An Intelligent Energy Management System Solution for Multiple Renewable Energy Sources. Sustainability 2023, 15, 2531. [Google Scholar] [CrossRef]

- Ouedraogo, I.; Jiya, A.N.; Dianda, I. On the effects of access to electricity on health capital accumulation in Sub-Saharan Africa. J. Energy Dev. 2022, 48, 83–108. [Google Scholar]

- Maphumulo, W.T.; Bhengu, B.R. Challenges of quality improvement in the healthcare of South Africa post-apartheid: A critical review. Curationis 2019, 42, e1–e9. [Google Scholar] [CrossRef] [PubMed]

- Laher, A.E.; Van Aardt, B.J.; Craythorne, A.D.; Van Welie, M.; Malinga, D.M.; Madi, S. “Getting out of the dark”: Implications of load shedding on healthcare in South Africa and strategies to enhance preparedness. S. Afr. Med. J. 2019, 109, 899–901. [Google Scholar] [CrossRef] [PubMed]

- Centre for Development and Enterprise (CDE). South Africa’s Electricity Crises: How Did We Get Here? And How Do We Put Things Right? 2008. Available online: https://cde.org.za/south-africas-electricity-crisis-how-did-we-get-here-and-how-do-we-put-things-right/ (accessed on 2 February 2025).

- Jenkins, L.S.; Gunst, C.; Blitz, J.; Coetzee, J.F. What keeps health professionals working in rural district hospitals in South Africa? Afr. J. Prim. Health Care Fam. Med. 2015, 7, 805. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Allela, T. A 2020 desk review of Power Africa. J. Int. Dev. 2022, 34, 334–348. [Google Scholar] [CrossRef]

- Tazvinga, H.; Dzobo, O.; Mapako, M. Towards sustainable energy system options for improving energy access in Southern Africa. J. Energy S. Afr. 2020, 31, 59–72. [Google Scholar] [CrossRef]

- Masuku, B. Rethinking South Africa’s household energy poverty through the lens of off-grid energy transition. Dev. South. Afr. 2024, 41, 467–489. [Google Scholar] [CrossRef]

- Edkins, M.T.; Marquard, A.; Winkler, H. The Effectiveness of National Solar and Wind Energy Policies in South Africa. 2010. Available online: https://www.researchgate.net/publication/236347814 (accessed on 12 March 2025).

- Edkins, M.; Marquard, A.; Winkler, H. Assessing the Effectiveness of National Solar and Wind Energy Policies in South Africa; University of Cape Town: Cape Town, South Africa, 2010. [Google Scholar]

- Ayodele, T.R.; Jimoh, A.A.; Munda, J.L.; Agee, J.T. Wind distribution and capacity factor estimation for wind turbines in the coastal region of South Africa. Energy Convers. Manag. 2012, 64, 614–625. [Google Scholar] [CrossRef]

- Babatunde, O.M.; Adedoja, O.S.; Babatunde, D.E.; Denwigwe, I.H. Off-grid hybrid renewable energy system for rural healthcare centers: A case study in Nigeria. Energy Sci. Eng. 2019, 7, 676–693. [Google Scholar] [CrossRef]

- Opoku, R.; Adjei, E.A.; Obeng, G.Y.; Severi, L.; Bawa, A.-R. Electricity Access, Community Healthcare Service Delivery, and Rural Development Nexus: Analysis of 3 Solar Electrified CHPS in Off-Grid Communities in Ghana. J. Energy 2020, 2020, 1–10. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Decision-making between a grid extension and a rural renewable off-grid system with hydrogen generation. Int. J. Hydrogen Energy 2018, 43, 9535–9548. [Google Scholar] [CrossRef]

- Khare, V.; Nema, S.; Baredar, P. Optimization of hydrogen based hybrid renewable energy system using HOMER, BB-BC and GAMBIT. Int. J. Hydrogen Energy 2016, 41, 16743–16751. [Google Scholar] [CrossRef]

- Mariama, S.M.; Scipioni, A.; Davat, B.; El Ganaoui, M. The idea of feeding a rural area in Comoros with a micro-grid system with renewable energy source with hydrogen storages. In Proceedings of the 6th International Renewable and Sustainable Energy Conference, Rabat, Morocco, 5–8 December 2018; pp. 1–5. [Google Scholar]

- Ding, L.; Zhang, Z.; Dai, Q.; Zhu, Y.; Shi, Y. Alternative operational modes for Chinese PV poverty alleviation power stations: Economic impacts on stakeholders. Util. Policy 2023, 82, 101524. [Google Scholar] [CrossRef]

- Cai, C.; Zhang, L.; Lai, G.; Zhou, J.; Zhou, L.; Qin, Y.; Tang, Z. Optimal sizing and cost-benefit assessment of stand-alone microgrids with different energy storage considering dynamic avoided GHG emissions. J. Energy Storage 2025, 109, 115128. [Google Scholar] [CrossRef]

- Dursun, S.; Aykut, E.; Dursun, B. Assessment of Optimum Renewable Energy System for the Somalia-Turkish Training and Research Hospital in Mogadishu. J. Renew. Energy Environ. 2021, 8, 54–67. [Google Scholar] [CrossRef]

- Hamukoshi, S.S.; Mama, N.; Shimanda, P.P.; Shafudah, N.H. An overview of the socio-economic impacts of the green hydrogen value chain in Southern Africa. J. Energy S. Afr. 2022, 33, 12–21. [Google Scholar] [CrossRef]

- Nadaleti, W.C.; Santos, G.B.D.; Lourenço, V.A. The potential and economic viability of hydrogen production from the use of hydroelectric and wind farms surplus energy in Brazil: A national and pioneering analysis. Int. J. Hydrogen Energy 2020, 45, 1373–1384. [Google Scholar] [CrossRef]

- Bessarabov, D.; Human, G.; Kruger, A.J.; Chiuta, S.; Modisha, P.M.; Preez, S.P.D.; Oelofse, S.P.; Vincent, I.; Van Der Merwe, J.; Langmi, H.W.; et al. South African hydrogen infrastructure (HySA infrastructure) for fuel cells and energy storage: Overview of a projects portfolio. Int. J. Hydrogen Energy 2017, 42, 13568–13588. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Energy management system for a hybrid hydrogen fuel cell-supercapacitor in an islanded microgrid. In Proceedings of the 2019 Southern African Universities Power Engineering Conference/Robotics and Mechatronics/Pattern Recognition Association of South Africa (SAUPEC/RobMech/PRASA), Bloemfontein, South Africa, 28–30 January 2019; IEEE: Piscataway, NJ, USA, 2019; pp. 611–615. [Google Scholar]

- Ayodele, T.R.; Mosetlhe, T.C.; Yusuff, A.A.; Ogunjuyigbe, A.S.O. Off-grid hybrid renewable energy system with hydrogen storage for South African rural community health clinic. Int. J. Hydrogen Energy 2021, 46, 19871–19885. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, G.; Li, Q.; You, Z.; Chen, W.; Liu, H. Hierarchical energy management for PV/hydrogen/battery island DC microgrid. Int. J. Hydrogen Energy 2019, 44, 5507–5516. [Google Scholar] [CrossRef]

- da Silva Lima, L.; Quartier, M.; Buchmayr, A.; Sanjuan-Delmás, D.; Laget, H.; Corbisier, D.; Mertens, J.; Dewulf, J. Life cycle assessment of lithium-ion batteries and vanadium redox flow batteries-based renewable energy storage systems. Sustain. Energy Technol. Assess. 2021, 46, 101286. [Google Scholar] [CrossRef]

- Boateng, L.; Mhangara, P. A Comparative Assessment of Annual Solar Irradiance Trends between Mpumalanga and Northern Cape Province in South Africa Using PVGIS. Energies 2023, 16, 6665. [Google Scholar] [CrossRef]

- Khan, F.M.N.U.; Rasul, M.G.; Sayem, A.S.M.; Mandal, N.K. Design and optimization of lithium-ion battery as an efficient energy storage device for electric vehicles: A comprehensive review. J. Energy Storage 2023, 71, 108033. [Google Scholar] [CrossRef]

- Ali, D.M.M. Hydrogen Energy Storage. In Energy Storage Devices; IntechOpen Limited: London, UK, 2019. [Google Scholar] [CrossRef]

- Zhang, J.; Gu, M.; Chen, X. Supercapacitors for renewable energy applications: A review. Micro Nano Eng. 2023, 21, 100229. [Google Scholar] [CrossRef]

- Google Maps. Elands Bay Clinic—Google Maps. Available online: https://www.google.com/maps/place/Elands+Bay+Clinic/@-32.3127336,18.3443281,636m/data=!3m2!1e3!4b1!4m6!3m5!1s0x1c33996f3cbaec1d:0x6e56ef3d35d43d9!8m2!3d-32.3127382!4d18.346903!16s%2Fg%2F11g88f03m7?entry=ttu&g_ep=EgoyMDI1MDMxMS4wIKXMDSoASAFQAw%3D%3D (accessed on 14 March 2025).

- Mosher, S.G.; Power, M.J.; Quick, L.J.; Haberzettl, T.; Kasper, T.; Kirsten, K.L.; Braun, D.R.; Faith, B.T. Examining the effects of climate change and human impacts on a high-resolution, late Holocene paleofire record from South Africa’s winter rainfall zone. Quat. Sci. Adv. 2024, 14, 100194. [Google Scholar] [CrossRef]

- USAID. Powering Health: Electrification Options for Rural Health Centers. 2020. Available online: https://www.ctc-n.org/resources/powering-health-electrification-options-rural-health-centers (accessed on 4 March 2025).

- Al-Akori, A. PV Systems for Rural Health Facilities in Developing Areas: A Completion of Lessons Learned; DGS: Berlin, Germany, 2014. [Google Scholar]

- National Planning Commission, The Presidency, Republic of South Africa. National Development Plan 2030: Our Future-Make it Work. 2012. Available online: https://www.nationalplanningcommission.org.za/assets/Documents/ndp-2030-our-future-make-it-work.pdf (accessed on 11 February 2025).

- Guinot, B.; Champel, B.; Montignac, F.; Lemaire, E.; Vannucci, D.; Sailler, S.; Bultel, Y. Techno-economic study of a PV-hydrogen-battery hybrid system for off-grid power supply: Impact of performances’ ageing on optimal system sizing and competitiveness. Int. J. Hydrogen Energy 2015, 40, 623–632. [Google Scholar] [CrossRef]

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower System Modeling with Homer. In Integration of Alternative Sources of Energy; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006; pp. 379–418. [Google Scholar] [CrossRef]

- Luta, D.N.; Raji, A.K. Optimal sizing of hybrid fuel cell-supercapacitor storage system for off-grid renewable applications. Energy 2019, 166, 530–540. [Google Scholar] [CrossRef]

- Diaf, S.; Diaf, D.; Belhamel, M.; Haddadi, M.; Louche, A. A methodology for optimal sizing of autonomous hybrid PV/wind system. Energy Policy 2007, 35, 5708–5718. [Google Scholar] [CrossRef]

- Brka, A.; Al-Abdeli, Y.M.; Kothapalli, G. The interplay between renewables penetration, costing and emissions in the sizing of stand-alone hydrogen systems. Int. J. Hydrogen Energy 2015, 40, 125–135. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, P.; Niu, M.; Maddy, J. The survey of key technologies in hydrogen energy storage. Int. J. Hydrogen Energy 2016, 41, 14535–14552. [Google Scholar] [CrossRef]

- Alves, H.J.; Junior, C.B.; Niklevicz, R.R.; Frigo, E.P.; Frigo, M.S.; Coimbra-Araújo, C.H. Overview of hydrogen production technologies from biogas and the applications in fuel cells. Int. J. Hydrogen Energy 2013, 38, 5215–5225. [Google Scholar] [CrossRef]