Abstract

Battery energy storage systems (BESS) are considered a good energy source to maintain supply and demand, mitigate intermittency, and ensure grid stability. The primary contribution of this paper is to provide a comprehensive overview of global energy markets and a critical analysis of BESS’ participation in frequency control ancillary service (FCAS) markets. This review synthesises the current state of knowledge on the evolution of the energy market and the role of battery energy storage systems in providing grid stability, particularly frequency control services, with a focus on their integration into evolving high-renewable-energy-source (RES) market structures. Specifically, solar PV and wind energy are emerging as the main drivers of RES expansion, accounting for approximately 61% of the global market share. A BESS offers greater flexibility in storage capacity, scalability and rapid response capabilities, making it an effective solution to address emerging security risks of the system. Moreover, a BESS is able to provide active power support through power smoothing when coupled with solar photovoltaic (PV) and wind generation. In this paper, we provide an overview of the current status of energy markets, the contribution of battery storage systems to grid stability and flexibility, as well as the challenges that BESS face in evolving electricity markets.

1. Introduction

Achieving the net-zero emission target by mid-century requires a paradigm shift in the energy sector and radical decarbonisation. The transition towards low-carbon-emission energy systems has accelerated the integration of large-scale renewable energy sources (RESs), such as solar PV and wind, into power systems. The accelerated integration of renewable energy sources (RESs) is displacing traditional power generation by synchronous generators. While RESs are critical to decarbonisation, their inherent intermittency significantly challenges power system reliability and flexibility []. In addition, the phasing out of synchronous generation is causing low system strength due to low inertia, further degrading power system stability. Due to the low system inertia, frequency stability is emerging as a more dominant issue in high-RES power grids [,]. One solution to mitigate this issue is to ensure that adequate frequency control ancillary services (FCASs) are provided. Battery energy storage systems (BESSs) are considered a good energy source to maintain supply and demand, mitigate intermittency, and ensure grid stability. A BESS can provide fast and precise responses, making it an ideal candidate for FCASs []. With the advancement of technologies, a BESS offers a wide range of energy storage solutions, enabling frequency regulation, voltage support, energy arbitrage, peak shaving, and smoothing ancillary services that support the grid with higher penetration of RESs [,,,].

Despite BESSs’ technical capabilities to provide frequency response in seconds, many electricity markets lack clarity on the role of BESSs in the ancillary markets []. The market rules are predominantly designed for thermal generation, with minimum durations, response rates, and ramp rates that are suitable for traditional generating units [,,,,]. Furthermore, while BESSs provide FCASs, frequent cycling and high-power discharges accelerate battery degradation [,]. Without proper degradation-aware control strategies and compensation, BESS operators may face challenges of accelerated degradation and reach the end of life (EOL) much sooner, resulting in a financial loss. The primary contribution of this paper is to provide a comprehensive overview of global energy markets and a critical analysis of battery energy storage systems (BESS) participation in frequency control ancillary service (FCAS) markets.

Contribution of This Paper

Understanding the rapid changes in the energy market and emerging technical challenges has become imperative. This review synthesises the current state of knowledge on the evolution of the energy market, the role of battery energy storage systems (BESSs) in providing grid stability, particularly frequency control services, with a focus on their integration into evolving high-renewable-energy-source (RES) market structures. While much of the existing literature has focused on the technical aspects of battery storage, this review goes a step further by connecting these technologies to real-world market dynamics and policy developments. It brings together insights from engineering, economics, and regulation to highlight the role of BESSs in grid stability and flexibility, as well as the challenges that BESSs face in evolving electricity markets. The key highlights of this study are as follows:

- Comprehensive Overview of Global Energy Markets: This review presents an in-depth analysis of the evolution and current landscape of global energy markets, with a particular emphasis on the increasing penetration of renewable energy sources (RESs), such as solar photovoltaics (PV) and wind power.

- Focus on Degradation Mechanisms: The study concentrates on degradation from high-cyclic and high-C-rate conditions typical in FCAS operations.

- Critical Analysis of BESSs in frequency control ancillary service (FCAS) Markets: This review critically examines the evolving role of battery energy storage systems (BESSs) in frequency control ancillary service (FCAS) markets. The review further discusses emerging cost-recovery mechanisms, such as pay-for-availability combined with energy throughput limits.

- Identification of Revenue Stacking Opportunities and Long-Term Value Pathways for BESSs: To complement its in-depth discussion of technical and market challenges, this paper also offers a critical and constructive analysis of value-creation opportunities for battery energy storage systems (BESSs) in ancillary service markets.

2. Global Energy Market Overview: Renewables Growth and Energy Market Evolution

Globally, the energy market is undergoing a drastic transformation. The projections show a significant increase in global electricity demand, estimated at 16,885 GW by 2030, up 39% from 2020, and increasing further to 30,227 GW by 2050, equating to a 166% increase from 2020. The higher penetration of RESs, primarily the generation of wind and solar photovoltaics (PV), has also accelerated the modernisation of power systems. In the next few decades, the integration of RESs is expected to grow significantly. A recent study suggests that RESs achieved a major milestone in 2023, when RESs exceeded 30% of global electricity generation for the first time []. This showed a steady increase in RESs of 2% from 27% in 2019 to 29% in 2020 [,]. The years 2020 to 2024 showed a notable increase in RESs, with installed capacity growing by about 117%, rising from 270.1 GW in 2020 to 585.2 GW in 2024 (Table 1). This growth accounted for 46% of the global power capacity by the end of 2024. Notably, supportive policies and the decline in the costs of renewable technologies are the main driver of this growth. By 2030, RES capacity is projected to be 10,300 GW, representing 61% of the installed capacity worldwide, and projected to reach 26,600 GW by 2050 (Table 2), accounting for 88% of total installed capacity [].

Table 1.

Global annual renewable capacity additions by technology (2020–2024) in GW [].

Table 2.

Projected global renewable capacity outlook for 2030 and 2050 [].

2.1. Solar PV and Wind

Solar PV technology demonstrated the most rapid expansion among all technologies, achieving a 245% increase in installed capacity between 2020 and 2024, while wind energy remained stable throughout that time frame (Table 1). Studies suggest that the rapid development of RESs is driven by lowering technological costs, commitments to net-zero emissions, increased investment in major global energy markets, including China, the European Union, and the United States, and geopolitical uncertainty in fuel and energy supply [,,]. A recent report from IRENA [] claimed that current growth was geographically concentrated in China, the European Union, and the United States, which accounted for 489 GW (83.6%) of renewable capacity installed in 2024.

Recently, at the 28th United Nations Climate Change Conference, COP28, 130 countries pledged to accelerate the energy transition and committed to triple RESs with an installed capacity of at least 11,000 GW by 2030 []. The tripling-RES goal aligns with the Paris Agreement target of limiting global warming to 1.5 °C []. Despite the challenges, recent forecasts (Table 2) predict that by 2050, approximately 90% of electricity generation could come from RESs, with around 61% supplied by solar PV and wind [,].

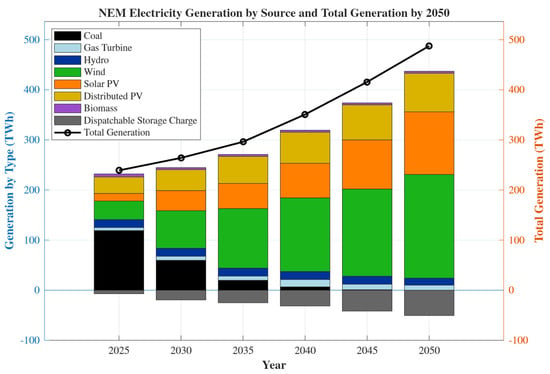

In Australia, a CSIRO forecast (Figure 1) indicates that the transformation of the National Electricity Market (NEM) follows global trends, and it is expected that total generation will increase from 225 TWh in 2025 to 439 TWh in 2050, an increase of 95%. Study have shown rapid growth in RESs, particularly solar PV with an increase of 200% and wind with an increase of 113% by 2050, projecting to reach 64% of variable energy sources by 2030 and 95% by 2050, predominantly from solar PV and wind. The CSIRO forecast projects an exponential growth in dispatchable storage from 10 TWh in 2025 to 75 TWh by 2050, with an increase in capacity of 650%. The BESS growth also follows the RES trends, and the expected dispatchable electricity storage capacity is expected to grow by 6.3 GW in 2023 and 44–96 GW/550–950 GWh by 2050 [,,].

Figure 1.

Forecast electricity and storage generation in the National Electricity Market (NEM) to 2050; Step Change scenario [].

The synthesis of the studies and recent data presented above supports the conclusion that RESs are growing rapidly. Specifically, solar PV and wind energy are emerging as the main drivers of RES expansion, accounting for approximately 61% of the global market share. This substantial integration of variable RES technologies is progressively displacing conventional synchronous generation, leading to a reduction in overall system inertia. As a result, the decline in system inertia poses a significant challenge to the stability and security of power systems.

2.2. Battery Energy Storage System (BESS)

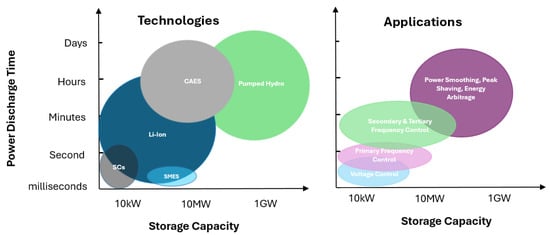

In recent years, technological advancements have positioned the battery energy storage system (BESS) as a viable solution to address emerging security risks of the system. Research on electricity storage technologies has underscored the critical role of BESSs in grid applications []. Compared to alternative technologies, a BESS offers greater flexibility in storage capacity, scalability, and rapid response capabilities, making it an effective solution to enhance grid stability. A BESS provides voltage and frequency control, load following, black start capability, deferral of power line upgrades, and other vital services (Figure 2).

Figure 2.

Examples of power system applications and suitable storage technologies [,,,].

In recent years, the deployment of BESSs has experienced exponential growth (Table 3 and Table 4). Global BESS additions surged in 2023 and 2024, reaching a cumulative capacity of approximately 150 GW/363 GWh by the end of 2024 []. Recent research suggests that China, the United States, Europe, and Australia are emerging as key growth drivers in the global battery energy storage system (BESS) market []. In 2023, the global BESS capacity saw significant growth, with China adding 23 GW, the United States 8 GW, Europe 6 GW, and Australia 1.3 GW [].

Table 3.

Global and key regional BESS installed capacity additions (GW/GWh), 2023–2024.

The IEA Net-Zero Emissions by 2050 (NZEs) scenario reported strong growth in BESSs and suggested that 1200–1500 GW of storage may be required by 2030 (Table 4). This growth is expected to be 8-fold by 2050 from the estimated installed capacity of 150 GW of BESSs in 2024. The BESS capacity projected under various scenarios is shown in Table 4. Technological advancement and a steep decline in manufacturing costs, i.e., from 2511 USD/kW in 2010 to 274 USD/kW in 2023, have contributed to the rapid expansion of battery energy storage systems (BESSs) [,].

Table 4.

Global BESS capacity projections (GW/GWh) for 2030 and 2050 under key scenarios [,,,,,,,,,].

Table 4.

Global BESS capacity projections (GW/GWh) for 2030 and 2050 under key scenarios [,,,,,,,,,].

| Region | Scenario | Year | Projected BESS Capacity (GW) | Projected BESS Capacity (GWh) | Key Assumptions |

|---|---|---|---|---|---|

| Global | IEA NZE | 2030 | 1200–1500 | N/A | 1.5 °C aligned pathway. |

| Global | IEA STEPS | 2030 | 790 | N/A | Policies, BESS addition rate. |

| Global | BNEF (April 2024) | 2030 | 137 (Annual Adds) | 442 (Annual Adds) | Updated forecast, 21% CAGR. |

| Global | IEA NZE | 2050 | 3100 | N/A | 1.5 °C aligned pathway. |

| Europe | EASE | 2050 | 200–600 | >600 | Based on the system needs assessment for net-zero emissions. |

| USA | NREL | 2050 | 22.4 | 35/58.3 | Range across scenarios based on costs, PV penetration. |

The outlook for the growth of battery energy storage systems (BESSs) is increasingly promising, driven by a combination of strong policy support, growing market interest, commitments to net-zero emissions, and rapid technological advancements. Ambitious scenarios, such as the IEA Net-Zero Emissions (NZEs) pathway, highlight the crucial role storage could play in building a cleaner and more resilient energy system. Even conservative projections like the IEA’s STEPS forecast indicate consistent growth aligned with the current trend.

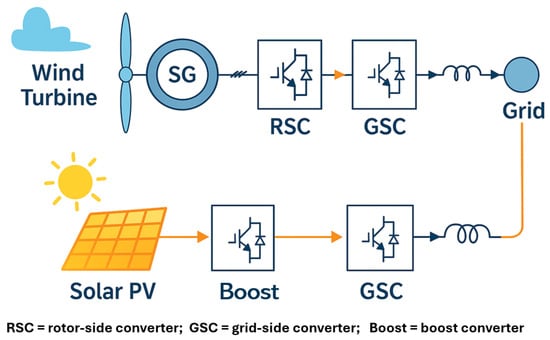

3. High-RES Impact on Power System Frequency

The primary concern is the reduction in system inertia, which is critical to maintaining grid stability during disturbance events []. RESs are inverter-based resources (IBRs), which are not directly connected to the power grid but are behind converters and decouple the RESs from the power systems (Figure 3). This decoupling reduces the natural support provided by the kinetic energy stored in the form of inertia and weakens the power system [,,]. In addition, solar photovoltaic systems do not have a rotating mass and do not provide inertia support. The weak grid with low system inertia introduces a higher rate of change of frequency (RoCoF), lower frequency nadir (the minimum level the frequency reached after a disturbance event), and weakens the damping performance, making grids more susceptible to frequency fluctuations []. The RoCoF (Hz/s) reflects the speed with which the system frequency changes following a disturbance event and indicates the strength of the system. An aggressive RoCoF may not provide sufficient time for under-frequency load shed (UFLS) schemes to operate and poses a risk of system blackouts [].

Figure 3.

Typical wind and solar PV system configurations.

In low-inertia systems, following a disconnection of loads/generators, the RoCoF increases rapidly [,,,,]. The RoCoF is the time derivative of the power system frequency (df/dt). The average RoCoF for N synchronous generators and loads is computed using the equation below:

where is a frequency deviation from the initial frequency at time just a moment after the disconnection of loads/generation . and are the inertia constant and the apparent power of the synchronous generator unit i, with i ranging from 1 to N []. Haque et al. [] investigated the frequency stability at 10%, 20%, 30%, and 40% of RES integration into the power system and concluded that the frequency nadir (Hz) decreased and RoCoF increased with an increase in RESs. A similar investigation was conducted by Saleem and Saha [] at 0%, 10%, 30%, 50% and 70% of RESs and concluded that with an increase in RESs, the decreased and RoCoF increased significantly. A key limitation of that study was the lack of empirical validation of the RoCoF and frequency nadir equations under high-renewable penetration conditions (i.e., 100% of RESs), due to limited availability of high-resolution post-contingency data from such grids; as a result, the broader applicability of these models remains to be fully established and is a key area for future research. Wind and solar energy inherently depend on environmental conditions and exhibit significant intermittency, variability, and uncertainty. This intermittent and variable nature of RESs introduces operational risk to the power system security and causes frequency, voltage, and ramp rate stability issues []. As an example, wind gusts cause rapid fluctuations in power generation and ramp rate. Similarly, cloud cover and irradiation intensity are the primary causes of power generation and ramp rate fluctuations in solar PV generation []. Power generation variability and ramp rate fluctuations cause frequency deviations in power systems. The system frequency deviation is determined by taking into account the dynamic effects of loads and generations, including inertia, primary, and secondary control []. The system frequency deviation is as follows:

where

In the above equations, means the Area Control Error, means the initial wind power change, means generated power from wind-generating systems, is the initial solar power change, means generated power from solar PV systems, means power generated by turbines, is the virtual inertia constant, is the virtual damping constant, is the time constant of the inverter-based ESS, and means virtual inertia power. and are industrial and residential loads, respectively.

Equations (2), (6), and (7) support the notion that active power variation ( and/or ) due to environmental factors such as irradiation and wind influences grid frequency. A recent investigation by Buch [] demonstrated that solar photovoltaic (PV) systems exhibited significant variations in power generation due to changes in irradiation under cloudy conditions. Similarly, a study by Yan et al. [] concluded that fluctuations in irradiation led to rapid changes in ramp rate, which consequently affected power output and system frequency. Liu et al. [] investigated the effects of wind fluctuation and its impact on power system security, concluding that wind fluctuations greatly influenced power output.

The increasing integration of renewable energy sources (RESs) represents a critical advancement toward achieving net-zero-emission targets. However, with increasing RESs, the system inertia is expected to reduce significantly. This will increase the rate of change of frequency (RoCoF) in power systems, thereby elevating the risk to power system stability and reliability. In this context, battery energy storage systems (BESSs) are becoming a viable and effective solution for addressing RES intermittency, thereby promoting grid stability, enhancing system reliability, and enabling the increased deployment of low-carbon-energy technologies.

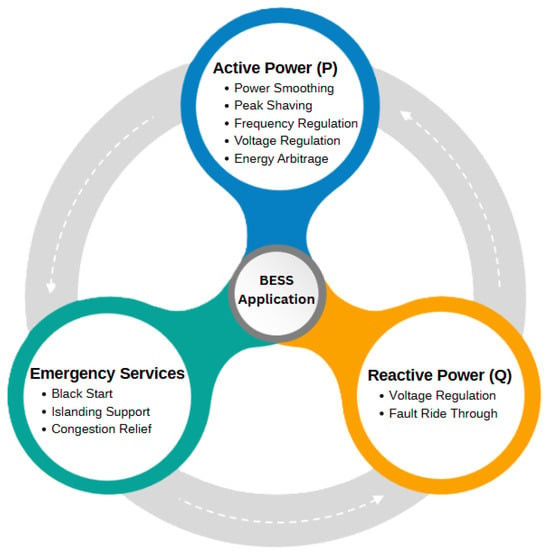

4. BESS Role in Modern Power Systems

BESSs are playing a critical role in modern power systems with a high integration of RESs. A BESS provides active power support through power smoothing when coupled with solar PV and wind generation. It also offers power levelling during low- and high-demand periods and peak shaving during high-demand periods. In addition, a BESS contributes to voltage and frequency regulation. A BESS also provides reactive power support and helps regulate power system voltage, as well as fault ride-through capabilities [,]. Grid-forming inverter technology positions BESS as an ideal solution for delivering emergency services such as black start capability, islanding grid support, and congestion relief (Figure 4). Due to the intermittent nature of RESs, voltage and frequency control have become a challenge for utilities. This problem is worsening with increasing RESs and decreasing system inertia []. This is a well-recognised issue that necessitates a better approach to managing safe and reliable grid operation.

Figure 4.

Examples of power system applications and suitable storage technologies.

Globally, grid frequency is managed through various mechanisms, including frequency control services and mandatory frequency support. The frequency regulation market design varies with markets and network conditions. The section below summarises the frequency control services in different global markets and their characteristics.

4.1. Frequency Control Ancillary Services (FCASs)

Historically, grid stability, particularly frequency stability, has been supported by the inherent physical property of inertia provided by large, rotating synchronous generators (e.g., thermal, hydro). The kinetic energy stored in these rotating masses naturally resists changes in system frequency, slowing down the rate at which frequency deviates (rate of change of frequency, RoCoF) following a disturbance, such as the sudden loss of a large generator or load (Figure 5). As RESs provide asynchronous generation and are typically behind the inverters, the inertial support from RESs is limited [,]. Transmission System Operators (TSOs) or Independent System Operators (ISOs) procure grid support services commonly known as ancillary services to regulate grid frequency within the acceptable range. Among the most critical services are the frequency control ancillary services (FCASs) in the National Electricity Market (NEM), the Frequency Co-Optimised Essential System Services (FCESSs) in the Wholesale Electricity Market (WEM), and frequency response services, Balancing Services and Frequency Containment Reserve (ENTSOE), particularly within European electricity markets [,,,,].

Figure 5.

Fundamental frequency control principle [].

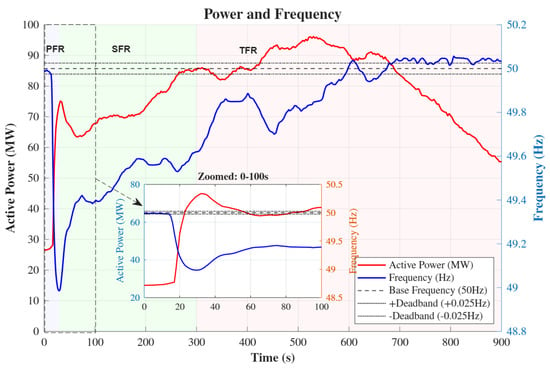

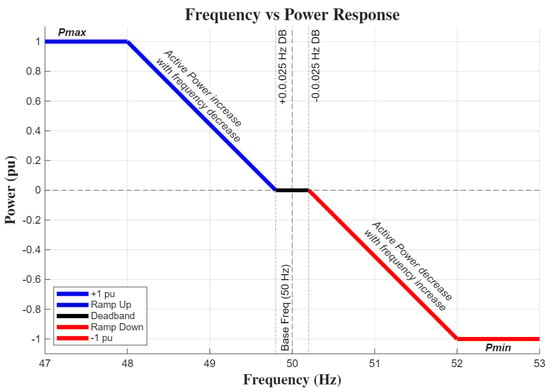

Several studies have explored the various frequency control services across major electricity markets and suggest that frequency control is typically achieved through a layered approach, involving different types of responses acting over various timescales following a frequency disturbance []. These layers work collaboratively to arrest the initial frequency deviation, stabilise the frequency of the system, restore it to its nominal value, and restore the reserves utilised []. Typically, a response is required when grid frequency operates outside the defined deadbands (Figure 6).

Figure 6.

Primary frequency regulation in 50 Hz markets.

The commonly known frequency responses are the following.

4.1.1. Inertial Response

This is the near-instantaneous (sub-second) response inherent in the physics of synchronous machines (Figure 5). When frequency changes, the kinetic energy stored in their rotating mass is naturally released (during low-frequency events) or absorbed (during high-frequency events), counteracting the change []. However, a BESS does not have any rotating mass and cannot provide inertia support. With technological advancements, BESSs with grid-forming inverters (GFM) can provide synthetic inertia by mimicking the active power response proportional to the RoCoF [].

4.1.2. Fast Frequency Response (FFR)

Fast-frequency-response services require an injection or rejection of active power (MW) in a couple of seconds to maintain grid stability [,,]. FFR responds to frequency excursions much faster than conventional generators and is the first responder after the inertia response. AEMC presents a comprehensive study on this subject, highlighting the close interaction between FFR services and the response to inertia []. The study identifies the challenge of differentiating FFR from the inertia response during the initial stage of the frequency response and the difficulty in explicitly distinguishing their contributions. Batteries, because of their fast response rate, are considered a good candidate for FFR service. In the Australian electricity market, the fast-frequency-response (FFR) provision must be activated within one second of a frequency disturbance event [,]. The United Kingdom market also has a similar response requirement, with the addition of sustained response for an additional 15 min []. In contrast, in the US and Canadian markets, the service is called Inertial Control and requires a full response in 0–12 s, offering flexibility. Due to its rapid response capabilities, BESSs can deliver a FFR in 1–2 s. However, this rapid power alteration at a very high C-rate might induce a high current in the BESS, leading to a quick temperature increase and accelerated battery degradation. Typically, the rapid response required within a few seconds leads to steep current transients during fast charging or discharging events, resulting in elevated I2R losses. Furthermore, during FFR events, batteries are subjected to aggressive ramp rates, for example, up to 1 C/s in response to a 1 Hz frequency deviation with a 2% droop setting, compared to typical ramp rates of approximately 0.0033 C/s (equivalent to a 20%/minute rated active power ramp rate) under normal operating conditions in the Australian market, representing an increase of nearly 300 times the standard rate. Although the total energy delivered/consumed during such events is relatively low, the high current over a short duration can result in significant degradation of battery components. In addition, high-C-rate operations can, in certain cases, induce irreversible changes in the cathode lattice structure, thereby accelerating battery degradation. Chemistries such as nickel cobalt manganese (NCM), lithium manganese oxide (LMO), and lithium cobalt oxide (LCO) exhibit relatively poor thermal stability; participation in FFR markets under such conditions may lead to premature battery failure and an increased risk of thermal runaway. Furthermore, these batteries are susceptible to structural changes in the cathode material at elevated temperatures, which further accelerate the likelihood of failure. In contrast, lithium iron phosphate (LiFePO4) batteries, when supported by effective thermal management strategies, are better suited for providing FFR services. However, they still experience an accelerated cycle-life degradation under high-C-rate operation, necessitating careful commercial evaluation and operational decision-making.

4.1.3. Primary Frequency Response (PFR)

This is the first active control response, typically activated within seconds of a frequency deviation, typically within 30 s, as shown in Figure 5 []. PFR or Frequency Containment Reserve (FCR) resources independently adjust their power output in proportion to the magnitude of the frequency deviation based on the droop settings. The primary goal of the PFR is to arrest the frequency fall or rise outside of the predefined frequency deadbands. This response is generally sustained for several minutes until slower acting reserves, typically the secondary frequency response (SFR), can take over [].

The PFR requirements in the Australian and UK markets are similar but differ slightly in their support for the response. There are no sustained response requirements in the National Electricity Market (NEM), but the Wholesale Market (WEM) on the West Coast of Australia requires sustained response for 15 min. In contrast, the UK market requires a sustained response of 20 s. Similar to FFR, the PFR is required within a short timeframe, resulting in higher-C-rate charge or discharge cycles for BESSs. In BESSs, during PFR, a high C-rate with a deep depth of discharge (DoD) leads to rapid temperature rises, resulting in capacity and power degradation. The rate of response (typically 4% frequency droop) and degradation when providing a PFR is lower than that of an FFR. At a 4% frequency droop, the battery will ramp up or down at 0.167 C/s over 6 s, which is 50 times higher than the standard, safe ramp rate of 0.0033 C/s. Furthermore, following the initial primary frequency response (PFR), both the Australian and UK markets require a sustained response lasting from several seconds (10 s) to a few minutes (30 m). Battery energy storage systems (BESSs) may face limitations in meeting these sustained response requirements, as their capability is constrained by the availability of remaining stored energy and state-of-charge dynamics. This constraint can be mitigated through the implementation of a comprehensive energy management strategy, which may include backup support from slower-responding generation units, the use of battery technologies that are not optimal for PFR but are capable of sustaining longer-duration responses, and the integration of energy-balancing mechanisms to maintain system stability and ensure sustained frequency support. A LiFePO4 battery with appropriate heat management system is suitable for providing a PFR. LiFePO4 batteries exhibit lower degradation rates compared to other lithium-ion chemistries and offer superior thermal stability. However, similar to the FFR, participation in PFR services imposes significant cycling stress, which can impact battery life and requires careful commercial evaluation and informed operational decision making.

4.1.4. Secondary Frequency Response (SFR)

Following the initial containment by PFR/FCR, the SFR/aFRR is activated to restore the system frequency to its nominal value. The SFR is typically slow compared to the FFR and PFR, typically 30 s to a few minutes. The SFR/aFRR is typically remotely controlled by the TSO/ISO, which sends automated signals (usually through automatic generation control (AGC) systems) to participating generating units, instructing them to adjust their power output []. The activation time for the SFR/aFRR is slower than that of the PFR/FCR, ranging from tens of seconds to several minutes. In Europe, this is known as aFRR. Markets like PJM differentiate within this category, offering signals such as RegD (dynamic regulation) tailored for faster and more precise adjustments, alongside traditional regulation signals (RegA). Similarly, CAISO procures the Regulation Up and Regulation Down services. BESS performance within the SFR offers better safety compared to the FFR and PFR, primarily due to its regulated charge–discharge rates and moderate temperature rise, which result in less battery wear and an extended BESS lifespan.

4.1.5. Tertiary Frequency Response (TFR)

The TFR services are executed to manage ongoing current and future contingencies. This is the slowest response frequency regulation service, typically activated manually by grid operators over minutes to hours. The TFR/mFRR involves adjusting the dispatch of generation units (or large loads) using SCADA to fully restore the balance between generation and load in the longer term, replenish the faster-acting reserves (PFR/FCR and SFR/aFRR), and manage anticipated changes or persistent imbalances. In the TFR market, a BESS undergoes frequent minor charge and discharge cycles. The long-term impact of repeated charging and discharging in micro- and mini-cycles has not been sufficiently studied and warrants further research.

4.1.6. Battery Operation in Other Markets

Grid-scale battery energy storage systems (BESSs) offer a wide range of services beyond frequency control ancillary services (FCASs), including energy arbitrage, peak shaving, renewable energy forming and shaping, and grid support. In profit-driven markets, energy arbitrage, when charging during low-price periods and discharging during peak demand, remains a key revenue stream. For example, the Hornsdale Power Reserve (HPR) in South Australia participates in both FCASs and energy arbitrage, with 30 MW of energy arbitrage and 70 MW of power reliability purposes []. The Hornsdale Power Reserve (HPR) is incorporated into the System Integrity Protection Scheme (SIPS), designed to reduce the risk of South Australia’s separation from the NEM due to sudden increases in flow on the Heywood Interconnector. The SIPS detects high interconnector flows and rapidly dispatches the HPR at 100 MW, with optional controlled load shedding to further mitigate the risk of separation. These customised schemes facilitate greater battery integration and contribute significantly to grid stability. Further, peak shaving helps reduce peak demand and mitigate price spikes, while BESSs also smooth the variability of solar and wind generation to better align supply with demand. Moreover, strategically sited storage can defer costly transmission and distribution upgrades. Studies suggest that optimising BESS operations through strategic charging and discharging minimises trading costs, maximises profits, and enables participation in markets such as FCAS, energy arbitrage, and peak shaving [,]. Ling et al. [] introduced a MILP model aimed at maximising operational revenue by incorporating battery dynamics. They used a simplified equivalent circuit model to linearise non-linear constraints. The model focused on minimising operational costs by optimising charge and discharge power in response to electricity prices and conversion efficiencies at each time step. Revenue was achieved by charging during low-price periods (off-peak period) and discharging during high-price periods (peak period). The study also highlighted that higher C-rates, typically observed during FCASs and other ancillary services, enhance battery power capabilities, allowing more frequent cycling and greater exploitation of price differentials, thereby increasing profit.

4.2. Frequency Control Markets Comparison

The frequency control services across major electricity markets globally vary in terms of response time and sustained response. The Australian markets require a fast frequency response, typically within a few seconds, <2 s for FFR services, and within 6 s for PFR services Table 5. The Wholesale Electricity Market (WEM) on the West Coast of Australia has established Frequency Co-optimised Essential System Services (FCESSs) equivalent to FCASs in the National Electricity Market (NEM). The WEM has a cost-recovery mechanism and incentivises market participants for frequency control services such as FFR, PFR, SFR, and TFR. One of the cost-recovery mechanisms in the Wholesale Electricity Market (WEM) is the inclusion of variable operating and maintenance (VOM) costs. Battery energy storage system (BESS) operators, as market participants, are permitted to incorporate VOM costs into their market offers, reflecting wear and tear associated with charging and discharging cycles. Additionally, market participants are allowed to recover costs related to round-trip efficiency losses, which are typically amortised and expressed on a AUD/MWh basis. Moreover, the market framework permits the inclusion of opportunity costs in the offers submitted by battery energy storage system (BESS) operators. These opportunity costs may reflect the foregone revenue associated with discharging energy during future Dispatch Intervals with higher prices or from providing alternative Market Services. The Wholesale Electricity Market (WEM) also provides cost-recovery mechanisms to market participants for the provision of Frequency Co-Optimised Essential System Services (FCESSs). FCESS Uplift Payments are issued to market participants when a generator is dispatched to provide FCESSs instead of energy and the market-price-based compensation is insufficient to cover the associated costs [].

Table 5.

Comparison of key FCAS markets.

In the National Electricity Market (NEM), the current cost-recovery mechanism is based on net energy import/export. Regulation Services’ payments are recovered through the Frequency Performance Payments (FPPs) framework, which operates as a double-sided incentive mechanism. Under this system, market participants are rewarded or penalised based on their contribution to system frequency control. Participants with positive contribution factors receive incentive payments, while those identified as primary contributors to frequency deviations, referred to as “causes”, are subject to penalties. Payments for Contingency Raise Services are recovered from Cost Recovery Market Participants (CRMPs) based on their Adjusted Sent-Out Energy (ASOE), while payments for Contingency Lower Services are recovered from CRMPs according to their Adjusted Consumed Energy (ACE) values [].

where MWE is the amount of MW enabled by NEMDE for the service being settled, and CP is the regional clearing price for the service in that trading interval. (note that as the bids and clearing price are defined as dollars per MW per hour, dividing the result by 12 brings the payment back in line with the five-minute trading interval) [].

The UK electricity market appears to operate primarily through a balancing mechanism, with no dedicated cost-recovery framework currently in place for battery energy storage system (BESS) operators. Similar findings have been observed in other European and North American markets, where the cost recovery of BESSs is typically achieved through participation in balancing markets and exposure to market-based pricing mechanisms. Cost-recovery mechanisms that rely on balancing markets may place battery energy storage system (BESS) operators at a disadvantage. For instance, when a battery provides frequency control ancillary services (FCASs) and sustains a response over an extended period, it may deplete its capacity at the prevailing balancing market price. This can result in missed opportunities to capitalise on potentially higher prices in subsequent market intervals. In addition, variable operating and maintenance (VOM) cost recovery for battery energy storage systems (BESSs) in PJM and other U.S. electricity markets is typically assumed to be zero. However, in practice, when batteries provide frequency control ancillary services (FCASs), particularly fast frequency response (FFR) and primary frequency response (PFR), intensive cooling is required, the demand for which increases with both the rate of response and the duration of service. Moreover, such operations accelerate battery capacity degradation beyond the rated levels. These additional costs and performance impacts are not currently compensated in most major electricity markets, which serves as a disincentive for BESS developers and operators to participate in FCAS markets.

4.3. Regulatory Requirements: Grid Code, Generator Performance Standards

Grid codes, also known as Generator Performance Standards (GPSs) in some energy markets, are comprehensive technical documents that outline the rules, regulations, operational mandates, and performance benchmarks for power-generating units. In Western Australia, for instance, GPSs are formally defined within Chapter 3A and Appendix 12 of the Wholesale Electricity Market (WEM) Rules []. These standards are designed to ensure that each connected generation asset adheres to its operational obligations and specified parameters, thus mitigating risks such as cascading failures and maintaining voltage and frequency within acceptable limits []. The current market rules are generic in nature and do not distinguish between traditional generators and battery energy storage systems (BESSs).

To regulate frequency, generating units such as BESSs must supply and sustain active power output according to the specified droop setting. The droop sets the rate of the active power response with respect to a frequency change, that is, in WEM, a 5% active power change is required with every 0.1 Hz frequency change, making it a 4% droop response. In some markets, a BESS is expected to provide a rapid response, i.e., FFR, PFR, LVRT, HVRT, FDRT, FRT, which causes a rapid charge or discharge of energy into the grid within a short timeframe (Table 6). This rapid charge and discharge cycle at elevated C-rates increases battery temperature, lithium depletion, and accelerates capacity degradation. Furthermore, a BESS has limited stored energy to support the grid during such an event and may not sustain a response beyond a certain level. This causes a lack of visibility and uncertainty in grid stability.

Table 6.

Grid code (GC)/Generator Performance Standards’ (GPSs) requirements.

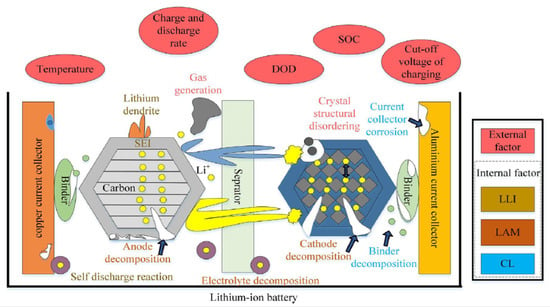

5. FCAS Impact on BESS’s Operational Life

When providing FCASs, many factors significantly influence the performance of BESSs, including the nature of charge/discharge and the depth of discharge, the temperature, and the chemistry of the battery cell. Several mature battery chemistries are currently in use, including lithium iron phosphate (LiFePO4), nickel cobalt manganese (NCM), sodium ion (Na-ion), lithium cobalt oxide (LCO), lithium manganese oxide (LMO), and nickel cobalt aluminium (NCA). Each of these chemistries possesses distinct electrochemical characteristics that critically influence their performance under high-cycle conditions, particularly at higher C-Rates, when used in FCASs (Table 7).

Lithium iron phosphate (LiFePO4) is considered the safest among other battery technologies. This is largely attributed to its stable olivine crystal structure, which minimises risks associated with thermal runaway []. The thermal runaway threshold for lithium iron phosphate (LiFePO4) is typically reported in the range of 250–300 °C, significantly higher than that of many other lithium-ion chemistries []. Additionally, the minimal ion displacement within the LiFePO4 structure contributes to its enhanced thermal stability. In addition, LiFePO4 batteries exhibit a flat discharge voltage profile and an exceptionally long cycle life, typically ranging from 2400 to over 8000 cycles, which makes them suitable for applications such as frequency control services. LiFePO4 batteries exhibit a low capacity degradation rate under high-C-rate operation, with reported degradation rates of approximately 0.005–0.02% per cycle at 1 C and 0.02–0.05% per cycle at 10 C, highlighting their robustness in high-power, long-duration applications [,,].

Lou et al. [] reported significantly enhanced cycling performance of LiFePO4/C cathodes with carbon coating, achieving a specific energy of 255 Wh/kg at a 30 C-rate, corresponding to a specific power of 7650 W/kg. While still in the development phase, these batteries demonstrate considerable promise for delivering high-performance energy storage in applications that require both high power and stability in FCASs. Although LiFePO4 batteries are safe and thermally stable, their lower energy density compared to NMC, LCO, and NCA batteries limits their applicability in compact energy storage systems. Additionally, when providing frequency control services, i.e., FFR and PFR, with a response time of 1–6 s, the C-rate-based battery degradation accelerates by 2.5 to 4 times.

Lithium nickel cobalt manganese oxide (NCM) batteries provide better power and energy density compared to LiFePO4 batteries. Their layered crystal structure facilitates rapid ion transport, enabling fast-charging and discharging capabilities. However, NCM-based lithium-ion batteries exhibit thermal sensitivity, with capacity degradation accelerating significantly under elevated temperatures and high-C-rate conditions, such as those encountered in frequency control services. For instance, the degradation rate at a 1 C-rate increases from 0.02% per cycle at 25 °C to 0.03% at 40 °C. In contrast, at a 5 C-rate, it rises from 0.05% per cycle at 25 °C to 0.06% at 40 °C, highlighting the detrimental impact of combined thermal and C-rate-induced stress on long-term performance. These conditions exacerbate cathode degradation, reduce coulombic efficiency, and increase the risk of thermal runaway, which limits their large-scale deployment in energy storage systems and FCASs.

Lithium cobalt oxide (LCO) batteries are rich in energy and power density, but they are sensitive to overvoltage. Under high-voltage operating conditions, lithium cobalt oxide (LCO) cathode materials undergo irreversible phase transformations, which compromise their structural integrity and thermal stability []. This degradation behaviour, coupled with the material’s sensitivity to rapid capacity loss at elevated temperatures, exhibiting a degradation rate of approximately 0.16% to 0.20% per cycle at a 1.5 C-rate, 10 times that of LiFePO4 batteries, raises significant concerns regarding the thermal and structural stability of the battery under high-C-rate operational conditions. Also, the thermal runaway threshold for LCO-based batteries is substantially lower (180 °C) compared to that of lithium iron phosphate (LiFePO4) batteries, which ranges from approximately 180 °C to 350 °C. Similar to LCO, lithium manganese oxide (LMO) and lithium nickel cobalt aluminium oxide (NCA) batteries offer a high energy density but limited thermal stability, lower thermal runaway thresholds, faster degradation at higher C-rate operation, and reduced cycle life. These limitations render them less suitable for demanding applications such as FCASs, where thermal resilience and long-term durability are critical.

Sodium-based cathode materials, such as NaFePO4, exhibit excellent cycling stability, retaining approximately 95% of their initial capacity after 1000 cycles at a 1 C-rate. Additionally, Na3V2(PO4)3/C composite cathodes demonstrate outstanding high-rate performance, maintaining around 90% capacity retention over 2000 cycles at a 5 C-rate, highlighting their strong potential for frequency control services [].

Table 7.

Comparative performance and degradation characteristics of battery chemistries for grid services.

Table 7.

Comparative performance and degradation characteristics of battery chemistries for grid services.

| Parameter | LFP (LiFePO4) | NCM | LCO | LMO | NCA | Na-Ion | References |

|---|---|---|---|---|---|---|---|

| Cycle Life (@80% DoD) | 2400–8000+ cycles | 1200–5600+ cycles | 1500–2600 cycles | 500–2200+ cycles | 250–1500 cycles | 2000–5000+ cycles (emerging) | [,,,,,,,,] |

| Thermal Stability | High | Moderate | Poor | Moderate | Poor | High | [,] |

| Thermal Runaway Threshold (@ > 50% SoC) | High (180–350 °C) | Medium (150–200 °C) | Medium (180 °C) | Medium (150–220 °C) | Medium (150–200 °C) | High (190–200 °C) | [,,,,,] |

| Degradation Rate (High C-rate) Per Cycle | Low (at 1 C-rate: 0.005–0.02%; at 10 C-rate: 0.02–0.05%) | High (at 1 C-rate: 0.02% @25 °C; 0.03% @40 °C; at 5 C-rate: 0.05% @25 °C; 0.06% @40 °C) | Very high (at 1.5 C-rate: 0.16–0.2%) | High (at 2 C-rate: 0.01–0.04% @25 °C; 0.04–0.08% @55 °C) | High (at 1 C-rate: 0.05–0.07%) | Very low (0.0012%) (emerging) | [,,,,,,,] |

| C-rate Capability | 1–3 C | 1–2 C | 1–3 C | 1–3 C | 1–3 C | 1–7 C (emerging) | [,,] |

| Power Density (W/kg) | 1500–3000 | 1044–2760 | 1500–3900 | 3500–6880 | 2200–3000 | 670–4000 | [,,,,,,,,] |

| Energy Density (Wh/kg) | 90–150 | 150–200 | 150–392 | 100–350 | 200–260 | 120–150 | [,,,,,,] |

| Cost (USD/kWh) | USD 101–400 | USD 94–230 | USD 357 | USD 133–251 | USD 98–418 | USD 262 | [,,,,,,] |

| Safety | Very high | Moderate (risk of thermal runaway) | Low (risk of thermal runaway) | Moderate (risk of thermal runaway) | Low (risk of thermal runaway) | High | [] |

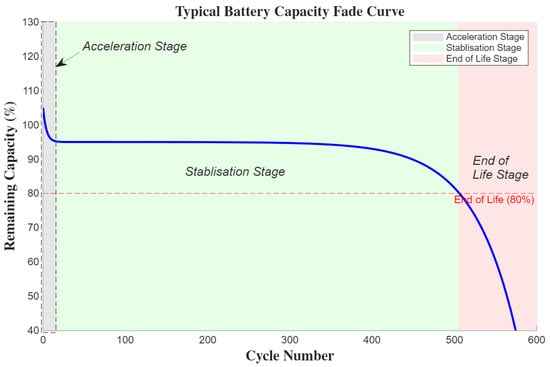

A BESS, when providing FCASs, undergoes many micro, mini, partial, and full charge and discharge cycles at different C-rates throughout its lifecycle [,,]. Under these dynamic conditions, varying C-rates make degradation non-linear, predicting the remaining useful life (RUL), typically between 70 and 80% of the full capacity of the BESS [,], is a significant challenge that substantially impacts its reliability and process safety.

There are three stages in battery capacity degradation, as shown in Figure 7. The first stage, the acceleration stage, is believed to be caused by the formation of the initial solid electrolyte interphase layer (SEI), which causes a rapid increase in the internal resistance of the battery and, consequently, a rapid decrease in capacity []. The second stage is the stabilisation stage, also known as Useful Life or Linear Aging, where the battery operates under normal conditions, providing energy and FCAS support. This stage is more useful, stable, and predictable in terms of the BESS response [,]. The third and final stage is the saturation stage, also known as non-linear aging. This stage occurs predominantly due to the loss of lithium, acid dissolution, or the higher internal resistance of the batteries. Batteries are considered unsafe to operate once they reach that stage. The point where the saturation stage starts, also known as the knee point, is considered the End of Life (EOL) of a battery [,,].

Figure 7.

The degradation is divided into three stages: acceleration, stabilisation, and End of Life (saturation).

Battery performance deteriorates sharply beyond the knee point, and the failure rate increases significantly. Therefore, manufacturers recommend stopping the operation when the knee point is reached or when the saturation stage is reached. To manage BESS effectively in FCAS and energy markets, several control strategies are deployed in grid-connected BESS. The next section discusses the commonly used control strategies.

5.1. Calendar Aging Impact

The aging degradation in BESSs is mainly due to variations in ambient temperature. Several studies have investigated the impact of temperature on battery aging. A recent review study by Zhang et al. [] investigated factors affecting the life expectancy of a lithium-ion battery and highlighted the importance of temperature on battery life. Zhang et al. [] pointed out that battery performance was ideal at a room temperature of 25 °C, and performance varied if used at higher or lower temperatures. In lithium-ion batteries, low temperature is one of the major contributors to irreversible depletion of lithium ions and dendrite formation []. Similarly, recent studies on the high-temperature impact on batteries discovered that battery aging degradation accelerated at high temperatures, and the major contributing factor to degradation was the growth of the solid electrolyte interphase (SEI) (Deshpande et al., 2017) []. Guan et al.’s [] experimental data suggest that at elevated temperatures (45 °C), a thick and unstable layer of SEI forms on the cathode, which contributes to the battery’s higher internal resistance and leads to a battery performance decrease. Their study also emphasises that 75% of capacity degradation on the anode is caused by SEI formation. Recently, Yang et al. [] revealed that the continuous growth of the SEI layer led to a reduction in anode porosity and the presence of lithium ions accelerated the reduction in anode porosity and promoted lithium plating. A study by Baghdadi et al. [] highlighted that during prolonged battery operation at elevated temperatures, calendar aging became the dominant contributor to total aging. With advancements in thermal management systems, this issue is being mitigated through effective cooling techniques, including forced-air and liquid-cooled battery operations []. That study investigates degradation mechanisms occurring under high-cycle and high-C-rate conditions, which more accurately reflect the operational profile of battery energy storage systems (BESS) during the provision of frequency control ancillary services (FCAS). Under such conditions, calendar aging is considered less significant and is therefore assumed to remain constant.

5.2. Cyclic Aging

Unlike aging degradation, cyclic degradation is more nonlinear and primarily caused by various internal and external factors such as SEI layer growth, lithium plating, mechanical stress on electrodes, electrolyte–electrodes reaction, loss of lithium, thermal effects, electrolyte decomposition particles cracking, dendrites formation, excessive temperature due to rapid charging and discharging, and cycling loading (Figure 8) [,].

Figure 8.

Schematic diagram of the causes of battery aging [].

5.2.1. Solid Electrolyte Interphase (SEI) Formation

The solid electrolyte interphase (SEI) Formation is one of the major causes of battery performance degradation. The SEI formation process results in lithium-ion loss and, consequently, performance degradation []. This relationship is further supported in a recent study [], which suggests that SEI formation interacts with other degradation mechanisms such as lithium plating. The SEI formation continues in both resting and operating modes, accelerating with high temperatures and high current throughputs, which leads to irreversible capacity loss and an increase in internal battery impedance []. When the battery is used to provide FCASs such as FFRs (response in 1–2 s) and PFRs (response in 6 s), it undergoes frequent and rapid charge–discharge cycles at higher C-rates (higher I2R losses), which elevate the cell temperature. Under such conditions, the SEI layer becomes mechanically unstable as a result of repeated cracking and reformation, further exacerbating degradation and affecting long-term battery performance (Figure 8).

During FCAS support, a battery undergoes various magnitudes of depth of discharge (DoD) and energy throughput. This results in elevated temperatures in battery cells, which are directly related to the formation of the SEI and cracking. The primary concern with LiFePO4 is I2R losses and active material loss due to SEI layer formation. In contrast, lithium cobalt oxide (LCO) cathodes are prone to rapid capacity degradation primarily due to lattice disorder, irreversible phase change, and gas evolution resulting from oxygen release during high-voltage operation.

5.2.2. Lithium Plating and Loss of Active Material

Lithium plating occurs on the surface of the Negative Electrode (NE) during charging []. The low-temperature operation leads to poor solid diffusivity, which restricts the movement of lithium ions and results in their accumulation on the electrode surface. The factors affecting lithium plating include fast charging. These findings are closely related to FCASs, where the response from a BESS is expected within a short period. This lithium plating increases the risk of short-circuiting within the cell and is a contributing factor in the loss of cycle life. Numerous studies have confirmed that lithium plating is an irreversible process and one of the primary reasons for dendrite formation in battery cells [,,].

5.3. Temperature Impact

A BESS’s temperature is another critical parameter that determines the state of health (SoH) and readiness of the BESS for FCASs. If the temperature exceeds the permissible level, it can lead to accelerated battery performance degradation and thermal runaway [,]. The performance degradation of BESSs is categorised into two categories, capacity and power degradation []. During both charging and discharging processes, battery energy storage systems (BESSs) generate heat primarily due to internal resistance (I2R losses), lattice structure disorder, and electrochemical activity. Furthermore, the temperature and reactions within the cell cause the depletion of active materials like lithium ions, leading to a reduction in BESS capacity. The capacity loss in LiFePO4 is primarily attributed to I2R losses and the loss of active material. In contrast, cathode materials such as NMC, LMO, and NCA exhibit more pronounced degradation at elevated temperatures, where irreversible changes in the lattice structure and significant loss of active material occur, which exacerbates degradation and leads to permanent capacity loss. Ali et al. [] examined the behaviour of lithium-ion batteries at temperatures exceeding 40 °C and determined that elevated temperatures accelerated chemical degradation processes, such as the dissolution of LiFePO4 particles and thickening of the SEI layer, resulting in increased internal resistance and higher I2R losses, which further increased temperature and subsequently reduced capacity. The study also highlighted that at higher temperatures, the battery caused the evaporation of electrolyte solvents, which increased the internal pressure and posed safety risks. At higher C-rates during BESS charging and discharging, the internal and surface temperatures of the battery increase, which accelerates battery degradation. Bandhauer et al. [] reviewed thermal challenges in lithium-ion batteries, noting a reduction in power output with rising internal impedance.

Main Causes of Heat Generation in BESSs

There are four fundamental sources of heat generation in BESSs: (1) ohmic losses (Joule heat losses) resulting from the movement of electrons and the internal impedance of the battery, (2) electrochemical reactions, (3) phase changes, and (4) mixing effects. Bernardi et al. [] proposed a comprehensive and general formulation of the energy balance for an electrochemical system, under the assumptions of uniform temperature and negligible pressure effects. Bernardi et al.’s [] equation can be simplified to:

where is the rate of heat generated or consumed, M is the mass per unit area of one cell, means specific heat capacity at constant pressure in J/g-K, and T is absolute temperature in K.

Equation (11) can be reformulated as follows:

For simplification, Equation (12) can be rearranged:

Here, V is the cell potential and U is the thermodynamic (open-circuit) potential of a reaction, evaluated at a reference electrode of a given kind. The term (V–U) is a potential drop equivalent to the term IR. Therefore, Equation (13) can be simplified as follows:

In Equation (14), the first term represents ohmic loss, which is irreversible heat loss and is directly related to C-rates, that is, at a higher C-rate, when a battery discharges or charges at a higher current, the losses result in increased battery temperature. Heat generation varies under different operating conditions, such as state of charge (SoC). In Equation (14), the second term, , denotes the entropic heat coefficient. This term reflects the variation in open-circuit voltage, U, as a function of temperature T, related to reversible entropic heat. Liu et al. [] examined thermal generation in lithium-ion batteries during charging and discharging, considering several influencing variables. The investigation concluded that heat generation was largely determined by operational factors such as ambient temperature, state of charge, and C-rates, which impacted both irreversible and reversible heat losses. The term characterises the rate of change in the internal temperature of the battery over time and is due to the electrochemical reactions and phase changes.

6. Conclusions

The rapid integration of renewable energy sources (RESs) into the evolving electricity market presents a significant risk to power system stability. Previous studies indicated that battery energy storage systems (BESSs), with their fast response capability, were suitable for enhancing grid stability. This review analysed the evolving energy market and the role of battery energy storage systems (BESSs) in frequency regulation. It also examined the technical, regulatory, and economic factors that shaped the operation of BESSs in these markets, as well as the associated challenges and opportunities.

The analysis revealed that the RES market share is projected to reach 61% by 2030, with solar photovoltaic (PV) and wind power collectively contributing 40%. By 2050, it is projected to increase to 88% of RES, with solar photovoltaic (PV) and wind energy collectively accounting for 68%. BESS integration is also forecasted to grow significantly, reaching 1200 GW by 2030, reflecting an increase of 1050 GW since 2024. This upward trajectory is expected to persist, reaching 3100 GW by 2050.

Rapidly changing market conditions, the high integration of RESs and BESSs into frequency control ancillary service (FCAS) operations without fully understanding the BESS limitations in the FCAS market present several challenges. The main challenges include degradation from cycling, thermal management challenges at high C-rates, and system-level risks arising from poor visibility of a BESS’s state of health (SoH) and uncertainties in its state of charge (SoC) and the effects of partial cycling. These factors can significantly impact the economic viability and reliability of BESS deployments, particularly in long-duration or high-frequency-response applications. The effects of mini-, micro- and partial cycles have not yet been thoroughly investigated, potentially disadvantaging BESS operators in capacity payment markets such as the Wholesale Electricity Market (WEM), where BESS operators receive compensation for variable cost elements.

Despite recent advancements, significant hurdles remain in optimising BESS performance and extending lifespan. Future research should focus on the development of advanced degradation models, adaptive control algorithms, and novel hybrid system configurations, such as battery energy storage systems (BESSs) integrated with tailored algorithms and a deeper understanding of cyclic aging mechanisms to address these gaps and unlock further performance improvements.

In conclusion, while BESSs have certain drawbacks, their role in frequency control markets is projected to increase. Ongoing research and regulatory advancements are crucial to overcome current barriers and fully exploit BESSs and low-emission energy systems.

Author Contributions

Conceptualisation, G.G.; Investigation, G.G.; Methodology, G.G.; Supervision, S.A., K.E., and S.G.J.; Writing—Original Draft, G.G.; Writing—Review and Editing, G.G., S.A., K.E., and S.G.J. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the Australian Government, Department of Education, under National Industry PhD Program Grant—40403.

Data Availability Statement

The relevant data are presented in the form of tables and graphs within this review paper.

Conflicts of Interest

There is no direct or indirect conflict of interest in this review paper.

Abbreviations

The following abbreviations are used in this manuscript:

| BESS | Battery Energy Storage System |

| BOL | Beginning of Life |

| DoD | Depth of Discharge |

| EMS | Energy Management System |

| EOL | End of Life |

| FCAS | Frequency Control Ancillary Service |

| FFR | Fast Frequency Response |

| GFL | Grid Following |

| GFM | Grid Forming |

| PFR | Primary Frequency Response |

| PLL | Phase Locked Loop |

| RES | Renewable Energy Source |

| SFR | Secondary Frequency Response |

| SoC | State of Charge |

| SoH | State of Health |

| TFR | Tertiary Frequency Response |

| VSC | Voltage Source Converter |

References

- Liu, Y.; Chen, M.; Xie, B.; Ban, M. Integrated control strategy of BESS in primary frequency modulation considering SOC recovery. IET. Renew. Power Gener. 2024, 18, 875–886. [Google Scholar] [CrossRef]

- Ratnam, K.S.; Palanisamy, K.; Yang, G. Future low-inertia power systems: Requirements, issues, and solutions—A review. Renew. Sustain. Energy 2020, 124, 109773. [Google Scholar] [CrossRef]

- Zhang, Z.; Ding, T.; Zhou, Q.; Sun, Y.; Qu, M.; Zeng, Z.; Ju, Y.; Li, L.; Wang, K.; Chi, F. A review of technologies and applications on versatile energy storage systems. Renew. Sustain. Energy 2021, 148, 111263. [Google Scholar] [CrossRef]

- Prakash, K.; Ali, M.; Siddique, M.N.I.; Chand, A.A.; Kumar, N.M.; Dong, D.; Pota, H.R. A review of battery energy storage systems for ancillary services in distribution grids: Current status, challenges and future directions. Front. Energy Res. 2022, 10, 971704. [Google Scholar] [CrossRef]

- Argiolas, L.; Stecca, M.; Ramirez-Elizondo, L.M.; Soeiro, T.B.; Bauer, P. Optimal Battery Energy Storage Dispatch in Energy and Frequency Regulation Markets While Peak Shaving an EV Fast Charging Station. IEEE Open Access J. Power Energy 2022, 9, 374–385. [Google Scholar] [CrossRef]

- Brivio, C.; Mandelli, S.; Merlo, M. Battery energy storage system for primary control reserve and energy arbitrage. Sustain. Energy Grids Netw. 2016, 6, 152–165. [Google Scholar] [CrossRef]

- International Energy Agency. Batteries and Secure Energy Transitions; International Energy Agency: Paris, France, 2024; p. 159. [Google Scholar]

- Fernández-Muñoz, D.; Pérez-Díaz, J.I.; Guisández, I.; Chazarra, M.; Fernández-Espina, Á. Fast frequency control ancillary services: An international review. Renew. Sustain. Energy 2020, 120, 109662. [Google Scholar] [CrossRef]

- Energy Policy WA. Wholesale Electricity Market Rules (WEM Rules); Energy Policy WA—Government of Western Australia: Perth, WA, Australia, 2024; p. 918. [Google Scholar]

- Australian Energy Market Operator. Market Ancillary Service Specification (MASSA); Australian Energy Market Operator (AEMO): Sydney, NSW, Australia, 2023; p. 39. [Google Scholar]

- Australian Energy Market Operator. Summary of Frequency Co-optimised Essential System Services (FCESS); Australian Energy Market Operator (AEMO): Sydney, NSW, Australia, 2024. [Google Scholar]

- Australian Energy Market Commission. National Electricity Rules; Australian Energy Market Commission (AEMC): Sydney, NSW, Australia, 2025; Volume 224, p. 39. [Google Scholar]

- Wu, C.H.; Jhan, J.Z.; Ko, C.H.; Kuo, C.C. Evaluating and Analyzing the Degradation of a Battery Energy Storage System Based on Frequency Regulation Strategies. Appl. Sci. 2022, 12, 6111. [Google Scholar] [CrossRef]

- Shamarova, N.; Suslov, K.; Ilyushin, P.; Shushpanov, I. Review of Battery Energy Storage Systems Modeling in Microgrids with Renewables Considering Battery Degradation. Energies 2022, 15, 6967. [Google Scholar] [CrossRef]

- Ember. World Passes 30% Renewable Electricity Milestone. 2024. Available online: https://ember-energy.org/latest-updates/world-passes-30-renewable-electricity-milestone/ (accessed on 21 April 2025).

- International Energy Agency. Global Energy Review 2021; International Energy Agency: Paris, France, 2021; p. 32. [Google Scholar]

- International Energy Agency. Renewables 2024—Analysis and Forecast to 2030; International Energy Agency: Paris, France, 2024; p. 177. [Google Scholar]

- International Energy Agency. Net Zero by 2050—A Roadmap for the Global Energy Sector; International Energy Agency: Paris, France, 2021; p. 224. [Google Scholar]

- International Renewable Energy Agency. Renewable Capacity Statistics 2025; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2025; p. 75. [Google Scholar]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Mahmood Ali, B.; Algburi, S.; Alzoubi, H.M.; Khudhair Al-Jiboory, A.; Zuhair Sameen, A.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy Transformations. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. World Energy Transitions Outlook 2024: 1.5 °C Pathway; International Renewable Energy Agency: Abu Dhabi, United Arab Emirates, 2024; p. 142. [Google Scholar]

- UNFCCC. Summary of Global Climate Action at COP 28. In Proceedings of the United Nations Climate Change Conference, Dubai, United Arab Emirates, 30 November–12 December 2023. [Google Scholar]

- Rose, S.K.; Richels, R.; Blanford, G.; Rutherford, T. The Paris Agreement and next steps in limiting global warming. Clim. Change 2017, 142, 255–270. [Google Scholar] [CrossRef]

- International Energy Agency. World Energy Outlook 2024; International Energy Agency: Paris, France, 2024; p. 396. [Google Scholar]

- CSIRO. Renewable Energy Storage Roadmap; CSIRO: Black Mountain, ACT, Australia, 2023; p. 200. [Google Scholar]

- He, C.; Geng, H.; Rajashekara, K.; Chandra, A. Analysis and Control of Frequency Stability in Low-Inertia Power Systems: A Review. IEEE/CAA J. Autom. Sin. 2024, 11, 2363–2383. [Google Scholar] [CrossRef]

- International Energy Agency. The Power of Transformation: Wind, Sun and the Economics of Flexible Power Systems; International Energy Agency: Paris, France, 2014. [Google Scholar]

- Mexis, I.; Todeschini, G. Battery energy storage systems in the United Kingdom: A review of current state-of-the-art and future applications. Energies 2020, 13, 3616. [Google Scholar] [CrossRef]

- Chen, H.; Cong, T.N.; Yang, W.; Tan, C.; Li, Y.; Ding, Y. Progress in electrical energy storage system: A critical review. Prog. Nat. Sci. 2009, 19, 291–312. [Google Scholar] [CrossRef]

- Sahoo, S.; Timmann, P. Energy storage technologies for modern power systems: A detailed analysis of functionalities, potentials, and impacts. IEEE Access 2023, 11, 49689–49729. [Google Scholar] [CrossRef]

- Pindar, R. Battery Report 2024: BESS Surging in the ‘Decade of Energy Storage’. Available online: www.mewburn.com/news-insights/battery-report-2024-bess-surging-in-the-decade-of-energy-storage (accessed on 22 April 2025).

- Gagné, J.F. Battery Storage Unlocked: Lessons Learned from Emerging Economies; National Renewable Energy Laboratory (NREL): Lakewood, CO, USA, 2024; p. 48. [Google Scholar]

- Nsitem, N. Global Energy Storage Market Records Biggest Jump Yet. Available online: https://about.bnef.com/blog/global-energy-storage-market-records-biggest-jump-yet/ (accessed on 23 April 2025).

- Rayner, T. Volta’s 2024 Battery Report: Falling costs drive battery storage gains. PV Magazine—Energy Storage. 29 January 2025. Available online: www.ess-news.com/2025/01/29/voltas-2024-battery-report-falling-costs-drive-battery-storage-gains/ (accessed on 22 April 2025).

- U.S. Energy Information Administration. Preliminary Monthly Electric Generator Inventory (Based on Form EIA-860M as a Supplement to Form EIA-860). U.S. Energy Information Administration: Washington, DC, USA, 2025. Available online: www.eia.gov/electricity/data/eia860m/ (accessed on 22 May 2025).

- Energy Information Administration. U.S. Battery Capacity Increased 66% in 2024. Available online: www.eia.gov/todayinenergy/detail.php?id=64705# (accessed on 31 May 2025).

- Rendón, M.A.; Novgorodcev, A.R.; de Almeida Fernandes, D. Mathematical Model of a 106 MW Single Shaft Heavy-Duty Gas Turbine. In Proceedings of the Anais do Simpósio Brasileiro de Sistemas Elétricos, Virtual, 25–28 August 2020. [Google Scholar]

- Arruebo, A.; Lits, C.; Rossi, R.; Schmela, M.; Acke, D.; Augusto, C.; Osenberg, J.; Chevillard, N.; Dupond, S.; SolarPower Europe. European Market Outlook for Battery Storage 2024–2028; SolarPower Europe: Brussels, Belgium, 2024. [Google Scholar]

- Clean Energy Council. Clean Energy Australia 2024; Clean Energy Council: Melbourne, VIC, Australia, 2024; p. 96. [Google Scholar]

- Zhang, X.; Han, Y.; Zhang, W. A review of factors affecting the lifespan of lithium-ion battery and its health estimation methods. Trans. Electr. Electron. Mater. 2021, 22, 567–574. [Google Scholar] [CrossRef]

- Jarbratt, G.; Jautelat, S.; Linder, M.; Sparre, E.; Rijt, A.v.d.; Wong, Q.H. Enabling Renewable Energy with Battery Energy Storage Systems. Available online: www.mckinsey.com/industries/automotive-and-assembly/our-insights/enabling-renewable-energy-with-battery-energy-storage-systems#/ (accessed on 23 April 2025).

- Blair, N.; Augustine, C.; Cole, W.; Denholm, P.; Frazier, W.; Geocaris, M.; Jorgenson, J.; McCabe, K.; Podkaminer, K.; Prasanna, A.; et al. Storage Futures Study: Key Learnings for the Coming Decades; National Renewable Energy Laboratory [NREL]: Golden, CO, USA, 2022; p. 28. [Google Scholar]

- European Association for Storage of Energy. Energy Storage Targets 2030 and 2050: Ensuring Europe’s Energy Security in a Renewable Energy System; European Association for Storage of Energy (EASE): Brussels, Belgium, 2022. [Google Scholar]

- Council of the European Union. Energy Storage—Underpinning a Decarbonised and Secure EU Energy System; Council of the European Union: Brussel, Belgium, 2023. [Google Scholar]

- Lomax, J. Battery Storage Connection Queue Double the Grid’s Requirement for 2030. Available online: www.cornwall-insight.com/press-and-media/press-release/battery-storage-connection-queue-double-the-grids-requirement-for-2030/ (accessed on 23 April 2025).

- Shair, J.; Li, H.; Hu, J.; Xie, X. Power system stability issues, classifications and research prospects in the context of high-penetration of renewables and power electronics. Renew. Sustain. Energy Rev. 2021, 145, 111111. [Google Scholar] [CrossRef]

- Alam, M.S.; Al-Ismail, F.S.; Salem, A.; Abido, M.A. High-Level Penetration of Renewable Energy Sources Into Grid Utility: Challenges and Solutions. IEEE Access 2020, 8, 190277–190299. [Google Scholar] [CrossRef]

- Saleem, M.I.; Saha, S. Assessment of frequency stability and required inertial support for power grids with high penetration of renewable energy sources. Electr. Power Syst. Res. 2024, 229, 110184. [Google Scholar] [CrossRef]

- Xiong, L.; Liu, X.; Liu, H.; Liu, Y. Performance Comparison of Typical Frequency Response Strategies for Power Systems With High Penetration of Renewable Energy Sources. IEEE J. Emerg. Sel. Top. Circuits Syst. 2022, 12, 41–47. [Google Scholar] [CrossRef]

- Haque, M.A.; Hasib, M.A.; Jawad, A.; Islam, M.Z. Investigation of Frequency and Voltage Stability of High Renewable Penetrated Grid. In Proceedings of the 2023 IEEE 11th Region 10 Humanitarian Technology Conference (R10-HTC), Rajkot, India, 16–18 October 2023; pp. 132–137. [Google Scholar]

- Broderick, C. Rate of Change of Frequency (RoCoF) Withstand Capability; ENTSO-E: Brussels, Belgium, 2018. [Google Scholar]

- Meng, L.; Zafar, J.; Khadem, S.K.; Collinson, A.; Murchie, K.C.; Coffele, F.; Burt, G.M. Fast Frequency Response From Energy Storage Systems—A Review of Grid Standards, Projects and Technical Issues. IEEE Trans. Smart Grid 2020, 11, 1566–1581. [Google Scholar] [CrossRef]

- Senarathna, N.T.; Somathilaka, S.P.; Hemapala, K.; Banda, H.W. Frequency Stability in Renewable-Rich Power Systems with High Solar Ramps. In Proceedings of the 2024 6th International Conference on Electrical, Control and Instrumentation Engineering (ICECIE), Pattaya, Thailand, 3 November 2024; pp. 1–5. [Google Scholar]

- Kerdphol, T.; Rahman, F.S.; Watanabe, M.; Mitani, Y.; Turschner, D.; Beck, H.-P. Enhanced virtual inertia control based on derivative technique to emulate simultaneous inertia and damping properties for microgrid frequency regulation. IEEE Access 2019, 7, 14422–14433. [Google Scholar] [CrossRef]

- Buch, K. Ramp-Rate Limiting Inverter Control Using Predicted Irradiance. In Proceedings of the 2024 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 12–13 February 2024; pp. 1–5. [Google Scholar]

- Yan, H.W.; Beniwal, N.; Farivar, G.G.; Pou, J. A power ramp rate control strategy with reduced energy storage utilization for grid-connected photovoltaic systems. In Proceedings of the 2023 IEEE Energy Conversion Congress and Exposition (ECCE), Nashville, TN, USA, 29 October–2 November 2023; pp. 657–662. [Google Scholar]

- Liu, J.; Song, Y.W.; Liu, Y.; Jiang, H.L.; Zheng, S.Q. Effect of Fluctuation of Wind Power Output on Power System Risk. Appl. Mech. Mater. 2014, 513–517, 2971–2974. [Google Scholar] [CrossRef]

- Datta, U.; Kalam, A.; Shi, J. A review of key functionalities of battery energy storage system in renewable energy integrated power systems. Energy Storage 2021, 3, e224. [Google Scholar] [CrossRef]

- Australian Energy Market Operator. Inertia in the NEM Explained. 2023. Available online: https://aemo.com.au/-/media/files/initiatives/engineering-framework/2023/inertia-in-the-nem-explained.pdf (accessed on 31 May 2025).

- Obaid, Z.A.; Cipcigan, L.M.; Abrahim, L.; Muhssin, M.T. Frequency control of future power systems: Reviewing and evaluating challenges and new control methods. J. Mod. Power Syst. Clean Energy 2019, 7, 9–25. [Google Scholar] [CrossRef]

- Australian Energy Market Operator. WEM Procedure Frequency Co-Optimised Essential System Services (FCESS) Accreditation; Australian Energy Market Operator (AEMO): Sydney, NSW, Australia, 2024; p. 45. [Google Scholar]

- Modig, N.; Eriksson, R.; Ruokolainen, P.; Ødegård, J.N.; Weizenegger, S.; Fechtenburg, T.D. Overview of Frequency Control in the Nordic Power System; Nordic Analysis Group: Brussels, Belgium, 2022; p. 20. [Google Scholar]

- National Energy System Operator. Frequency Response Services. 2024. Available online: https://www.nationalgrideso.com/industry-information/balancing-services/frequency-response-services (accessed on 29 August 2024).

- EirGrid. EirGrid Grid Code, Version 14.2; EirGrid: Dublin, Ireland, 2024; p. 461. [Google Scholar]

- Fernández-Guillamón, A.; Gómez-Lázaro, E.; Muljadi, E.; Molina-Garcia, Á. A review of virtual inertia techniques for renewable energy-based generators. Renew. Energy-Technol. Appl. 2020, 20, 92651. [Google Scholar]

- Shoeb, M.A.; Shahnia, F.; Shafiullah, G.M. A multilayer optimization scheme to retain the voltage and frequency in standalone microgrids. In Proceedings of the IEEE Innovative Smart Grid Technologies-Asia (ISGT-Asia), Auckland, New Zealand, 4–7 December 2017; pp. 1–6. [Google Scholar]

- Silva, M.F.; Guimarães, G.C.; Moura, F.A.M.; Rodrigues, D.B.; Souza, A.C.; Silva, L.R.C. System frequency support by synthetic inertia control via BESS. In Proceedings of the 2019 IEEE PES Innovative Smart Grid Technologies Conference—Latin America (ISGT Latin America), Gramado, Brazil, 15–18 September 2019; pp. 1–6. [Google Scholar]

- Australian Energy Market Commission. Fast Frequency Response Market Ancillary Services; Australian Energy Market Commission (AEMC): Sydney, NSW, Australia, 2021; p. 2. [Google Scholar]

- Greenwood, D.M.; Lim, K.Y.; Patsios, C.; Lyons, P.F.; Lim, Y.S.; Taylor, P.C. Frequency response services designed for energy storage. Appl. Energy 2017, 203, 115–127. [Google Scholar] [CrossRef]

- Bryant, M.J.; Ghanbari, R.; Jalili, M.; Sokolowski, P.; Meegahapola, L. Frequency Control Challenges in Power Systems with High Renewable Power Generation: An Australian Perspective; RMIT University: Melbourne, VIC, Australia, 2019. [Google Scholar]

- North American Electric Reliability Corporation. Fast Frequency Response Concepts and Bulk Power System Reliability Needs; The North American Electric Reliability Corporation: Atlanta, GA, USA, 2020; p. 29. [Google Scholar]

- Australian Energy Market Operator (AEMO). Initial Operation of the Hornsdale Power Reserve Battery Energy Storage System; Technical Report; Australian Energy Market Operator: Sydney, NSW, Australia, 2018. [Google Scholar]

- Zhuo, W.; Savkin, A.V. Profit Maximizing Control of a Microgrid with Renewable Generation and BESS Based on a Battery Cycle Life Model and Energy Price Forecasting. Energies 2019, 12, 2904. [Google Scholar] [CrossRef]

- Preciado, D.; Pham, P.; Subburaj, A.S.; Subburaj, V.H. Economic Analysis of Li-Ion Battery Energy Storage System. In Proceedings of the 2020 IEEE Green Technologies Conference (GreenTech), Oklahoma City, OK, USA, 1–3 April 2020; pp. 153–158. [Google Scholar]