Multi-Seasonal Risk Assessment of Hydrogen Leakage, Diffusion, and Explosion in Hydrogen Refueling Station

Abstract

1. Introduction

2. Mathematical Model

2.1. Numerical Methods

2.2. Control Equation

2.3. Mass Flow

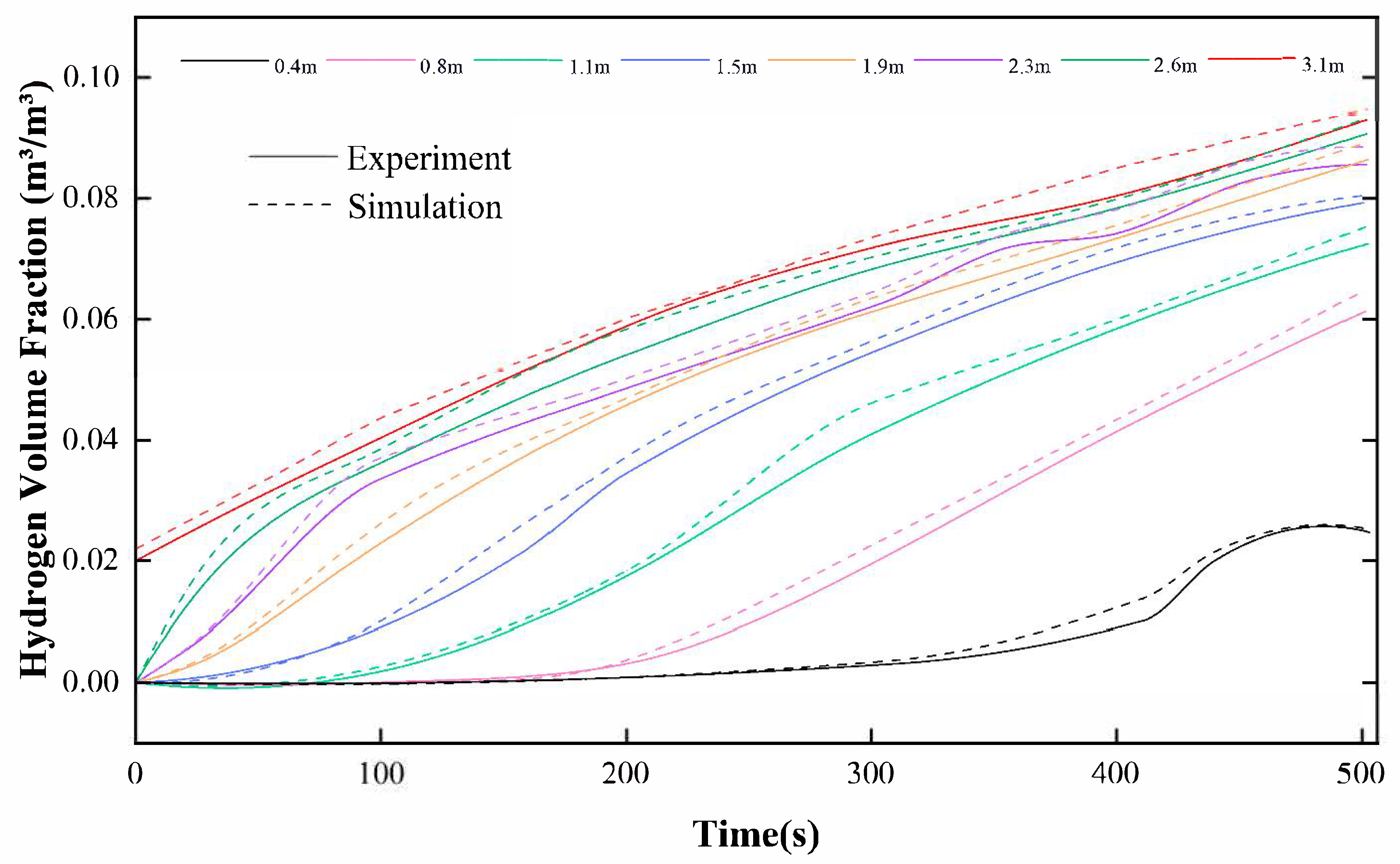

2.4. Software Applicability Verification

3. Research Methodology

3.1. Geometric Model

3.2. Initial Condition Settings

3.3. Grid Independence Verification and Division

3.4. Leakage Diffusion Analysis

3.4.1. Influence of Leakage Direction

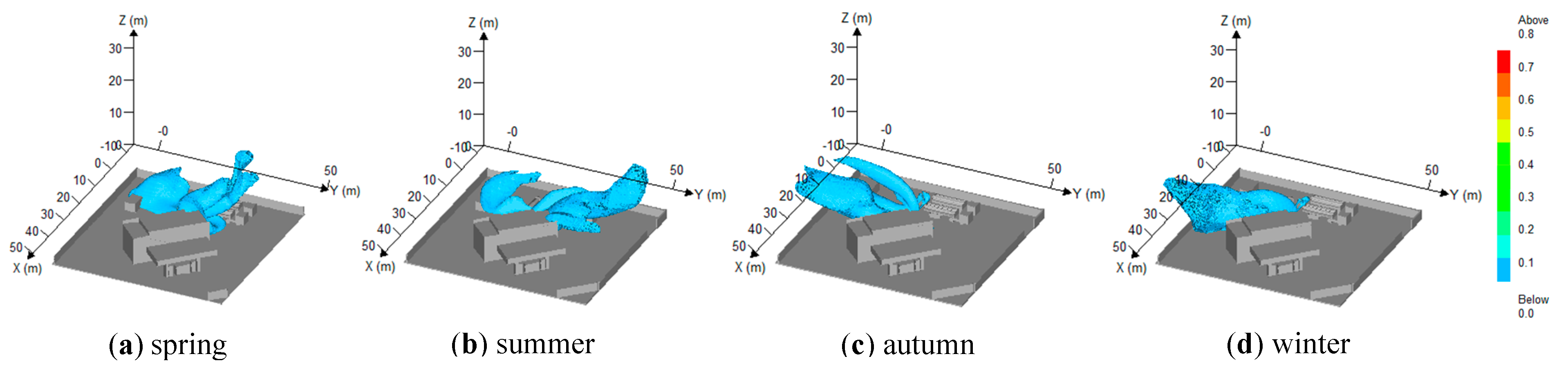

3.4.2. Influence of Seasonal Climate

3.5. Empirical Formula

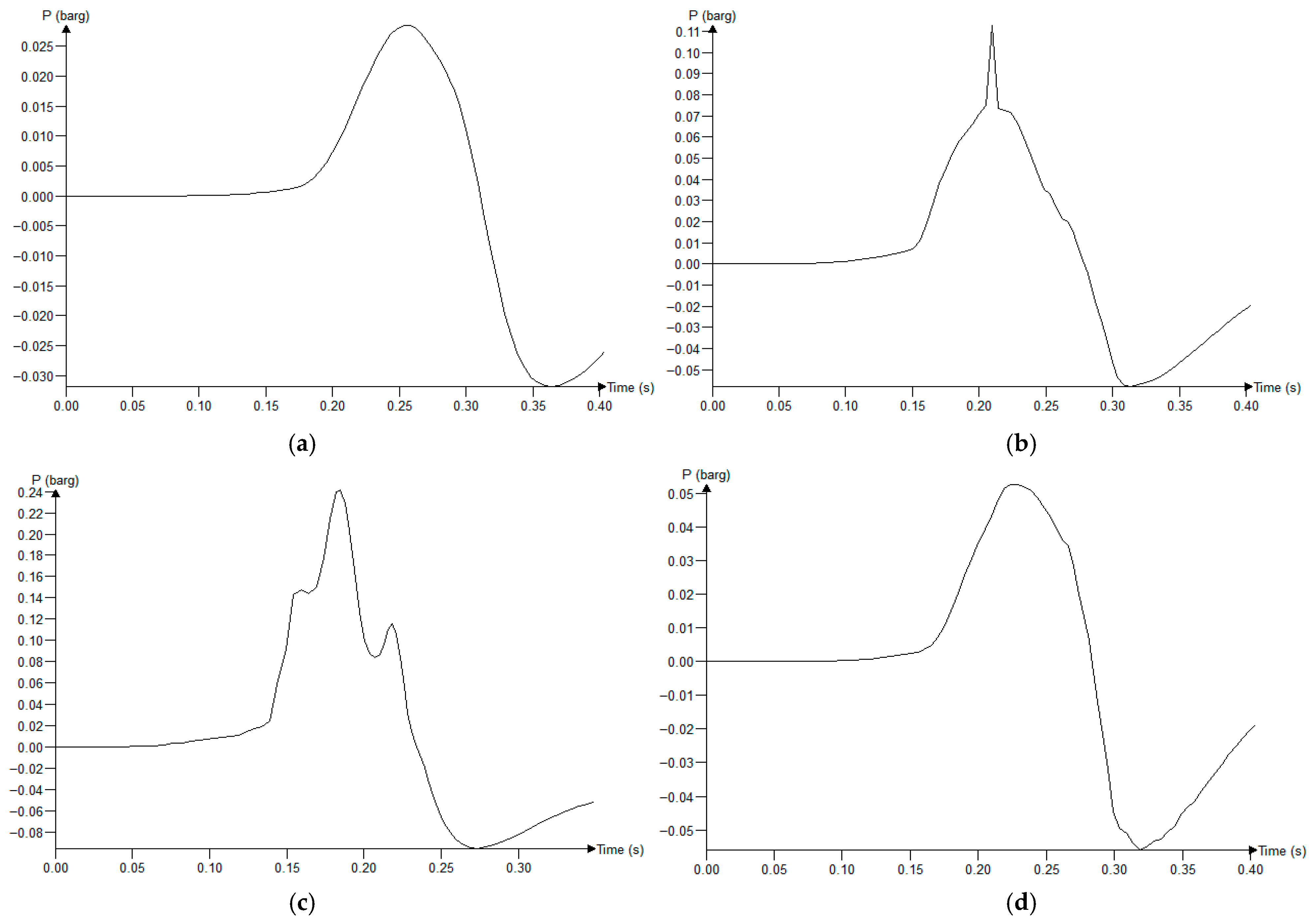

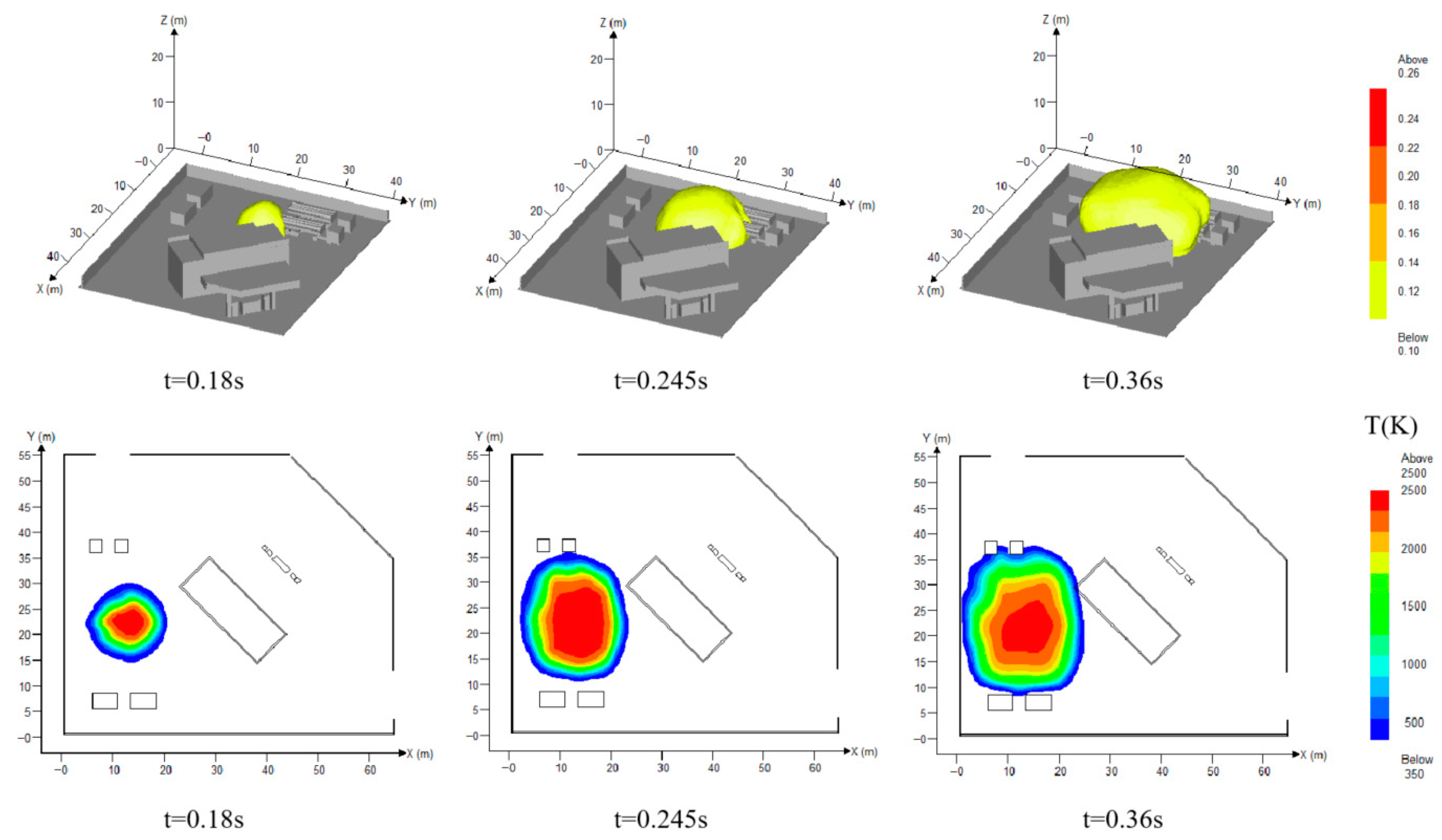

4. Simulation Results and Analysis of Hydrogen Explosion

5. Analysis and Discussion

- Under the leakage scenarios analyzed in this work (considering specific leakage rates, directions, and environmental conditions), it can be seen that, in comparison with leakage from compressors and hydrogen storage tanks, leakage from dispensers poses lower risks to station equipment. However, the coupling between leakage direction and wind fields may still cause risks in station building areas. It is recommended to deploy multiple concentration sensors around compressors and storage tanks.

- Southeast/south winds during spring and summer promote outward migration of hydrogen clouds, reducing on-site risks, but may cause localized accumulation near storage tanks. Conversely, north/northwest winds in autumn and winter significantly increase hydrogen concentrations near compressors and station buildings. Special attention should be paid to strengthening ventilation measures.

- Downward (−Z direction) leaks from storage tanks generate ground-hugging clouds with the largest diffusion range. If an ignition source is encountered, such scenarios exhibit explosion overpressure peaks of 0.25 barg and flame temperatures exceeding 2500 K, requiring priority prevention and control. We recommend installing ground ventilation slots near the storage tanks to accelerate the diffusion of ground-hugging hydrogen gas, and adding rapid-response explosion suppression systems.

- An empirical formula integrating climatic parameters and leakage directions was proposed to address the insufficient generalizability of traditional models. This formula can be used to predict the hydrogen concentration distribution under different seasons and leakage directions in similar HRSs (with the same equipment layout and environmental conditions), providing a reference for the risk assessment of HRSs. In addition, this method can also be applied to other HRSs. In the actual construction of HRSs, it is suggested to optimize ground ventilation facilities, dynamically adjust the sensor layout based on the empirical formula and seasonal wind field characteristics, and optimize equipment spacing to enhance risk prevention and control capabilities.

- Although small-scale experiments (such as wind tunnel tests) can provide valuable supplementary verification, conducting full-scale, multi-season, and multi-parameter coupled experiments has significant limitations in terms of cost and safety. This study ensured the reliability of the research results through three means: strict verification of grid independence, systematic multi-scenario coupling analysis covering 72 working conditions, and construction of empirical formulas (prediction error < 20%).

- However, this work focused on single-leakage scenarios; future studies should extend dynamic analysis to multi-leakage scenarios and complex meteorological conditions. In addition, the impact of long-term hydrogen exposure on leakage rate and explosion severity has not been studied either. Future studies can further introduce a leakage rate correction coefficient after long-term hydrogen exposure of materials (such as obtaining the variation law of the leakage aperture under different exposure durations through fatigue experiments), and analyze the impact of leakage rate changes on explosion overpressure and flame temperature in combination with explosion dynamics models, so as to more comprehensively evaluate the long-term operation risks of hydrogen refueling stations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eroi, T. Wind Power and Solar Photovoltaics Found to Have Higher Energy Returns than Fossil Fuels. Nat. Energy 2024, 9, 775–776. [Google Scholar] [CrossRef]

- Gielen, D.; Boshell, F.; Saygin, D.; Bazilian, M.D.; Wagner, N.; Gorini, R. The Role of Renewable Energy in the Global Energy Transformation. Energy Strategy Rev. 2019, 24, 38–50. [Google Scholar] [CrossRef]

- Behboodi, S.; Chassin, D.P.; Crawford, C.; Djilali, N. Renewable Resources Portfolio Optimization in the Presence of Demand Response. Appl. Energy 2016, 162, 139–148. [Google Scholar] [CrossRef]

- Li, X.; Ye, T.; Meng, X.; He, D.; Li, L.; Song, K.; Jiang, J.; Sun, C. Advances in the Application of Sulfonated Poly(Ether Ether Ketone) (SPEEK) and Its Organic Composite Membranes for Proton Exchange Membrane Fuel Cells (PEMFCs). Polymers 2024, 16, 2840. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Ji, K.; Duan, H.; Shao, M. Hydrogen Production Coupled with Water and Organic Oxidation Based on Layered Double Hydroxides. Exploration 2021, 1, 20210050. [Google Scholar] [CrossRef] [PubMed]

- International Energy Agency. Global Hydrogen Review 2023; OECD: Paris, France, 2023. [Google Scholar] [CrossRef]

- Shu, K.; Guan, B.; Zhuang, Z.; Chen, J.; Zhu, L.; Ma, Z.; Hu, X.; Zhu, C.; Zhao, S.; Dang, H.; et al. Reshaping the Energy Landscape: Explorations and Strategic Perspectives on Hydrogen Energy Preparation, Efficient Storage, Safe Transportation and Wide Applications. Int. J. Hydrogen Energy 2025, 97, 160–213. [Google Scholar] [CrossRef]

- Boettcher, S.W. Introduction to Green Hydrogen. Chem. Rev. 2024, 124, 13095–13098. [Google Scholar] [CrossRef]

- Hu, Q.; Zhang, X.; Hao, H. A Review of Hydrogen-Air Cloud Explosions: The Fundamentals, Overpressure Prediction Methods, and Influencing Factors. Int. J. Hydrogen Energy 2022, 48, 13705–13730. [Google Scholar] [CrossRef]

- Genovese, M.; Blekhman, D.; Dray, M.; Fragiacomo, P. Hydrogen Losses in Fueling Station Operation. J. Clean. Prod. 2020, 248, 119266. [Google Scholar] [CrossRef]

- Genovese, M.; Fragiacomo, P. Hydrogen Refueling Station: Overview of the Technological Status and Research Enhancement. J. Energy Storage 2023, 61, 106758. [Google Scholar] [CrossRef]

- Tanaka, T.; Azuma, T.; Evans, J.A.; Cronin, P.M.; Johnson, D.M.; Cleaver, R.P. Experimental Study on Hydrogen Explosions in a Full-Scale Hydrogen Filling Station Model. Int. J. Hydrogen Energy 2007, 32, 2162–2170. [Google Scholar] [CrossRef]

- Shirvill, L.C.; Roberts, T.A.; Royle, M.; Willoughby, D.B.; Gautier, T. Safety Studies on High-Pressure Hydrogen Vehicle Refuelling Stations: Releases into a Simulated High-Pressure Dispensing Area. Int. J. Hydrogen Energy 2012, 37, 6949–6964. [Google Scholar] [CrossRef]

- De Stefano, M.; Rocourt, X.; Sochet, I.; Daudey, N. Hydrogen Dispersion in a Closed Environment. Int. J. Hydrogen Energy 2019, 44, 9031–9040. [Google Scholar] [CrossRef]

- Niu, Y.; Ma, Z.; Jiang, B.; Li, P.; Zuo, J.; Kou, Y.; Liang, G. Experimental Study on High-Pressure Hydrogen Leakage and Diffusion in Full-Scale Hydrogen Refueling Stations. Int. J. Hydrogen Energy 2025, 135, 351–360. [Google Scholar] [CrossRef]

- Kim, E.; Park, J.; Cho, J.H.; Moon, I. Simulation of Hydrogen Leak and Explosion for the Safety Design of Hydrogen Fueling Station in Korea. Int. J. Hydrogen Energy 2013, 38, 1737–1743. [Google Scholar] [CrossRef]

- Tsunemi, K.; Yoshida, K.; Yoshida, M.; Kato, E.; Kawamoto, A.; Kihara, T.; Saburi, T. Estimation of Consequence and Damage Caused by an Organic Hydride Hydrogen Refueling Station. Int. J. Hydrogen Energy 2017, 42, 26175–26182. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, L.; Lv, X.; He, T. Numerical Simulation and Risk Mitigation Strategies for Hydrogen Leakage at Vehicle Hydrogenation Stations. Int. J. Hydrogen Energy 2025, 111, 735–750. [Google Scholar] [CrossRef]

- Liang, Y.; Pan, X.; Zhang, C.; Xie, B.; Liu, S. The Simulation and Analysis of Leakage and Explosion at a Renewable Hydrogen Refuelling Station. Int. J. Hydrogen Energy 2019, 44, 22608–22619. [Google Scholar] [CrossRef]

- Yang, Z.; Chen, Z.; Han, X.; Chen, G.; Wang, X. Numerical and Experimental Studies on the Evolution Characteristics of High-Pressure Hydrogen Leakage and Explosion Accidents in Hydrogen Refueling Stations. Int. J. Hydrogen Energy 2025, 142, 580–595. [Google Scholar] [CrossRef]

- Liu, K.; He, C.; Yu, Y.; Guo, C.; Lin, S.; Jiang, J. A Study of Hydrogen Leak and Explosion in Different Regions of a Hydrogen Refueling Station. Int. J. Hydrogen Energy 2023, 48, 14112–14126. [Google Scholar] [CrossRef]

- Lucas, M.; Atanga, G.; Hisken, H.; Mauri, L.; Skjold, T. Simulating Vented Hydrogen Deflagrations: Improved Modelling in the CFD Tool FLACS-Hydrogen. Int. J. Hydrogen Energy 2021, 46, 12464–12473. [Google Scholar] [CrossRef]

- Moen, A.; Mauri, L.; Narasimhamurthy, V.D. Comparison of K-ε Models in Gaseous Release and Dispersion Simulations Using the CFD Code FLACS. Process Saf. Environ. Prot. 2019, 130, 306–316. [Google Scholar] [CrossRef]

- Hall, J.E.; Hooker, P.; O’Sullivan, L.; Angers, B.; Hourri, A.; Bernard, P. Flammability Profiles Associated with High-Pressure Hydrogen Jets Released in Close Proximity to Surfaces. Int. J. Hydrogen Energy 2017, 42, 7413–7421. [Google Scholar] [CrossRef]

- Edelia, E.M.; Winkler, R.; Sengupta, D.; El-Halwagi, M.M.; Mannan, M.S. A Computational Fluid Dynamics Evaluation of Unconfined Hydrogen Explosions in High Pressure Applications. Int. J. Hydrogen Energy 2018, 43, 16411–16420. [Google Scholar] [CrossRef]

- Bénard, P.; Hourri, A.; Angers, B.; Tchouvelev, A. Adjacent Surface Effect on the Flammable Cloud of Hydrogen and Methane Jets: Numerical Investigation and Engineering Correlations. Int. J. Hydrogen Energy 2016, 41, 18654–18662. [Google Scholar] [CrossRef]

- Hu, J.; Christopher, D.M.; Li, X. Simplified Partitioning Model to Simulate High Pressure Under-Expanded Jet Flows Impinging Vertical Obstacles. Int. J. Hydrogen Energy 2018, 43, 13649–13658. [Google Scholar] [CrossRef]

- Middha, P.; Hansen, O.R.; Grune, J.; Kotchourko, A. CFD Calculations of Gas Leak Dispersion and Subsequent Gas Explosions: Validation against Ignited Impinging Hydrogen Jet Experiments. J. Hazard. Mater. 2010, 179, 84–94. [Google Scholar] [CrossRef]

- Holborn, P.G.; Benson, C.M.; Ingram, J.M. Modelling Hazardous Distances for Large-Scale Liquid Hydrogen Pool Releases. Int. J. Hydrogen Energy 2020, 45, 23851–23871. [Google Scholar] [CrossRef]

- Juwari, J.; Wicaksono, A.D.M.; Arbianzah, T.; Anugraha, R.P.; Handogo, R. Simulation of Dispersion and Explosion in Petrol Station Using 3D Computational Fluid Dynamics FLACS Software. J. Adv. Res. Fluid Mech. Therm. Sci. 2023, 2, 113–135. [Google Scholar] [CrossRef]

- Gexcon AS. FLACS-CFD V22.2 User’s Manual. 2023; pp. 82–88. [Google Scholar]

- Pitts, W.M.; Yang, J.C.; Blais, M.; Joyce, A. Dispersion and Burning Behavior of Hydrogen Released in a Full-Scale Residential Garage in the Presence and Absence of Conventional Automobiles. Int. J. Hydrogen Energy 2012, 37, 17457–17469. [Google Scholar] [CrossRef]

- Glasstone, S.; Dolan, P.J. The Effects of Nuclear Weapons. In Astoria; University of Pittsburgh Press: Pittsburgh, PA, USA, 2017; pp. 62–63. [Google Scholar] [CrossRef]

- Mironov, V.N.; Penyazkov, O.G.; Ignatenko, D.G. Self-Ignition and Explosion of a 13-MPa Pressurized Unsteady Hydrogen Jet under Atmospheric Conditions. Int. J. Hydrogen Energy 2015, 40, 5749–5762. [Google Scholar] [CrossRef]

| Model | Accuracy for High-Velocity Jets | Computational Cost | Key Limitations | Applicability to HRS Scenarios |

|---|---|---|---|---|

| k − ε | Moderate (empirical constants limit transient precision) | Low (efficient for large-scale geometries) | Under-predicts strong shear/curvature effects | Suitable for full-scale HRS models |

| LES | High (resolves large-scale turbulence) | Very high (10–50 × k − ε cost) | Requires fine grids; subgrid model dependence | Limited to small domains/single scenarios |

| DNS | Highest (resolves all turbulent scales) | Extremely high (prohibitive for industry cases) | Restricted to simple geometries/low Re | Not feasible for full-scale HRS models |

| Season | Average Wind Speed (m/s) | Wind Direction | Average Temperature (°C) | ||

|---|---|---|---|---|---|

| Spring (March to May) | −2.12 | 2.12 | 0 | Southeast | 20 |

| Summer (June to August) | 0 | 2 | 0 | South | 25 |

| Autumn (September to November) | 0 | −2.5 | 0 | North | 18 |

| Winter (December to February) | 1.63 | −1.63 | 0 | Northwest | 10 |

| Point | Coordinates (m) | Point | Coordinates (m) | Point | Coordinates (m) | Point | Coordinates (m) |

|---|---|---|---|---|---|---|---|

| M1 | (16.25, 13.75, 0.25) | M10 | (16.25, 13.75, 3.25) | M19 | (16.25, 13.75, 6.25) | M28 | (16.25, 13.75, 9.25) |

| M2 | (30.55, 13.75, 0.25) | M11 | (30.55, 13.75, 3.25) | M20 | (30.55, 13.75, 6.25) | M29 | (30.55, 13.75, 9.25) |

| M3 | (48.75, 13.75, 0.25) | M12 | (48.75, 13.75, 3.25) | M21 | (48.75, 13.75, 6.25) | M30 | (48.75, 13.75, 9.25) |

| M4 | (16.25, 27.55, 0.25) | M13 | (16.25, 27.55, 3.25) | M22 | (16.25, 27.55, 6.25) | M31 | (16.25, 27.55, 9.25) |

| M5 | (30.55, 27.55, 0.25) | M14 | (30.55, 27.55, 3.25) | M23 | (30.55, 27.55, 6.25) | M32 | (30.55, 27.55, 9.25) |

| M6 | (48.75, 27.55, 0.25) | M15 | (48.75, 27.55, 3.25) | M24 | (48.75, 27.55, 6.25) | M33 | (48.75, 27.55, 9.25) |

| M7 | (16.25, 41.25, 0.25) | M16 | (16.25, 41.25, 3.25) | M25 | (16.25, 41.25, 6.25) | M34 | (16.25, 41.25, 9.25) |

| M8 | (30.55, 41.25, 0.25) | M17 | (30.55, 41.25, 3.25) | M26 | (30.55, 41.25, 6.25) | M35 | (30.55, 41.25, 9.25) |

| M9 | (48.75, 41.25, 0.25) | M18 | (48.75, 41.25, 3.25) | M27 | (48.75, 41.25, 6.25) | M36 | (48.75, 41.25, 9.25) |

| Number | Wind Conditions | Compressor Leakage Location | Leak Direction | Core-Region Grid Size (m) | Grid Count |

|---|---|---|---|---|---|

| #1 | No wind | (13.25, 22.05, 0.95) | +X | 0.15 | 62,100 |

| #2 | No wind | (13.25, 22.05, 0.95) | +X | 0.2 | 51,772 |

| #3 | No wind | (13.25, 22.05, 0.95) | +X | 0.3 | 36,504 |

| #4 | No wind | (13.25, 22.05, 0.95) | +X | 0.4 | 25,725 |

| #5 | No wind | (13.25, 22.05, 0.95) | +X | 0.5 | 21,780 |

| A | a | b | c | d | e | f | g | h | α | B | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Hydrogen storage tank | −0.0651 | 0.264 | 0.1488 | 0.1 | 0.7602 | 0.7422 | 0.682 | 0.1 | 0.1 | 0.3459 | 0.0587 |

| Compressor | −0.8181 | 0.1001 | 0.1 | 0.1001 | 0.3986 | 0.2777 | 0.576 | 0.1 | 0.1 | 0.0307 | 0.6538 |

| Hydrogen dispenser | 3.0738 | 0.1 | 18.223 | 0.1 | 30 | 0.9209 | 2.4717 | 0.1 | 0.1 | 0.7485 | 0.0058 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Zeng, Y.; Zhao, G.; Hou, H.; Song, Y.; Ding, B. Multi-Seasonal Risk Assessment of Hydrogen Leakage, Diffusion, and Explosion in Hydrogen Refueling Station. Energies 2025, 18, 4172. https://doi.org/10.3390/en18154172

Liu Y, Zeng Y, Zhao G, Hou H, Song Y, Ding B. Multi-Seasonal Risk Assessment of Hydrogen Leakage, Diffusion, and Explosion in Hydrogen Refueling Station. Energies. 2025; 18(15):4172. https://doi.org/10.3390/en18154172

Chicago/Turabian StyleLiu, Yaling, Yao Zeng, Guanxi Zhao, Huarong Hou, Yangfan Song, and Bin Ding. 2025. "Multi-Seasonal Risk Assessment of Hydrogen Leakage, Diffusion, and Explosion in Hydrogen Refueling Station" Energies 18, no. 15: 4172. https://doi.org/10.3390/en18154172

APA StyleLiu, Y., Zeng, Y., Zhao, G., Hou, H., Song, Y., & Ding, B. (2025). Multi-Seasonal Risk Assessment of Hydrogen Leakage, Diffusion, and Explosion in Hydrogen Refueling Station. Energies, 18(15), 4172. https://doi.org/10.3390/en18154172