Abstract

This paper aims to fill a gap in relation to herbaceous biomass, which is the second most important source of biomass used for the production of solid biofuels in the form of pellets. Our research focuses on the final stage of compacted fuel production, specifically on the pressure densification of biomass into pellets. This review was conducted using bibliometric techniques. This analysis included searching indexed publications in the Web of Science—Core Collection and Scopus databases. The time range of the searched data was 1991–2024. First, bibliometric data were collected and quantitative analyses were performed. The next stage consisted of analyzing keywords from the authors’ publications using the VOSviewer program. The generated term maps allowed for the analysis of the frequency of keywords in different years and the most frequently cited ones, which enabled the identification of current research topics and the evolution of trends. Based on the collected data, applications, process parameters and raw materials used in the biomass densification process were determined. Following the bibliometric analysis, detailed analyses were carried out on the factors influencing the pressure compaction process.

1. Introduction

The European climate and energy package “Fit for 55”, aimed at reducing greenhouse gas emissions and counteracting climate change, may constitute a significant impulse for the further development of renewable energy, including biomass production.

Energy from plant (lignocellulosic) biomass is one of the commonly used sources of renewable energy and is increasingly considered a real alternative to fossil fuels [1,2,3].

Numerous studies have shown that biomass has the greatest energy potential of all renewable energy sources and can be directly burned to obtain energy. It can also be converted to various liquid biofuels, gaseous biofuels and solid biofuels [1,4].

Biofuel-processing methods enable the improvement in physical, mechanical and chemical parameters. These methods include physical, thermochemical, chemical and biological processing. These types of conversion can be used separately or in combination [4].

One of the main methods for processing solid biofuels is thermal processing. Depending on the temperature used, the thermal processes can be divided into drying, torrefaction, pyrolysis and gasification [4]. Thermal biomass treatment can improve energy, physico-mechanical and chemical properties. Pyrolysis is a thermal process with absence of air. Torrefaction is characteristic of the 150–300 °C (low temperature range). Above that, pyrolysis occurs.

The process of monopyrolysis of lignocellulosic biomass is used to produce bio-oil, biochar and biogas. Some environmental problems are the high reactivity and corrosiveness, as well as low thermal stability and low energy density of biofuels obtained in the production process (coal and monopyrolysis oil). An interesting alternative to the typical monopyrolysis process is co-pyrolysis, which has attracted special attention from scientists in recent years. An example is the co-pyrolysis of lignocellulosic biomass and used tires. This process is cost-effective, efficient and environmentally friendly. The selection of co-raw materials plays a key role in the co-pyrolysis process. It is necessary to ensure the availability of the raw material and the ability to improve the quality of the product without the need for secondary processing [3]. One very interesting possibility is the co-pyrolysis of lignocellulosic biomass and used tires, due to its cost effectiveness, efficiency and environmental friendliness.

As the importance of renewable energy sources grows, it becomes crucial to know the properties of biomass and optimally adapt processing systems to the specificity of the raw material, which will allow for the effective use of its various sources.

The diversity of plants used as raw materials is associated with variable properties, which affect the processing into pellets and briquettes [5,6,7,8,9,10,11], the economic profitability of production, and the assessment of the suitability of energy crops for densification processes for fuel purposes [12,13,14]. It is indicated that materials used in pressure agglomeration should be assessed individually, taking into account their specific properties, such as physical characteristics and the content of organic and inorganic substances that may support this process [15,16,17,18].

The literature does not provide clear information on the impact of technology on the quality of the raw material, the densification process or the properties of the final product, especially in the context of the geometry of the pellet-forming channel. In the case of non-woody biomass, there are no precise guidelines regarding the shape of the channel that would allow for the attainment of fuel with the required quality parameters, such as density or strength. This paper aims to fill this gap in relation to herbaceous biomass, which is the second most important source of biomass used for the production of solid biofuels in the form of pellets.

This paper focuses on the final stage of compacted fuel production, specifically on the pressure densification of biomass into pellets, which is not yet well studied compared to the densification used in the feed, food, or pharmaceutical industries [2,5,19,20,21,22,23,24,25].

1.1. The Potential of Solid Biofuels

Based on the review of the existing scientific literature and reports, it is concluded that the generation of solid waste in developing countries is huge (i.e., mainly agricultural residues). Different waste management technologies have been studied, but the main problem remains the implementation of these technologies at the local level. The quality of solid biofuels produced in developing countries is not inferior to that produced in developed countries (possibly using more advanced technologies), which proves the adaptability and effectiveness of these promising technologies [12]. Considering the information available in the literature, it is obvious that the challenges to be addressed in the near future are more related to socio-economic, political/government aspects and stakeholder engagement.

1.2. Classification of Solid Biofuels

The EN ISO 16559:2022-06 standard [26] defines biomass as material of biological origin (plant and animal) excluding materials contained in geological formations and/or fossils. The EN ISO 17225-1:2021-11 standard [27] introduces a classification of biomass by source.

The EN ISO 17225-1:2021 standard also regulates the issues of solid biofuels, taking into account the most popular commercial forms. It also contains information on dimensional characteristics and fuel preparation methods. The fuels with the highest degree of processing and unification of technical parameters include pellets and briquettes. Their use is convenient and can be largely automated, which makes them increasingly popular, even though their production process is associated with higher costs and the final product itself is more expensive compared to other types of solid biofuels.

2. Materials and Methods

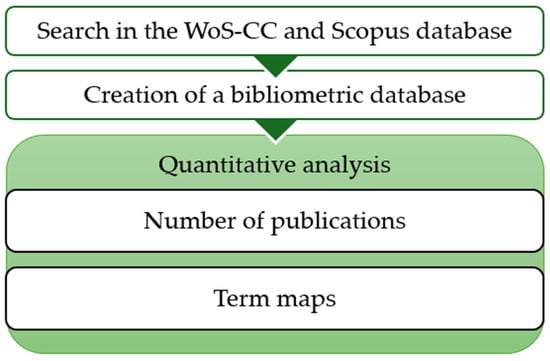

This review was conducted according to the methodology described in [2,4,5,28,29,30,31], using bibliometric techniques (see Figure 1). This analysis included searching indexed publications in the Web of Science—Core Collection (WoS-CC) and Scopus databases. The time range of the searched data was 2010–2024, and the language of the publications was limited to English. Documents of the type “article” were searched with the phrase “biomass*”, “densi*” and “pellets*” in the TITLE field.

Figure 1.

Searching indexed publications in the Web of Science—Core Collection (WoS-CC) and Scopus databases.

First, bibliometric data were collected and quantitative analyses were performed. These analyses included the number of publications addressing the issue of biomass densification and the quality of pellets produced from biomass.

The next stage consisted of analyzing keywords from the authors’ publications using the VOSviewer version 1.6.20 program. This is a free tool for visualizing bibliometric networks, enabling the analysis of authors, keywords, journals and other elements. Thematic maps generated by the program allow for the examination of the frequency of keywords in different years, citations and the network of connections. All analyzed documents concerned the WoS-CC Energy Fuels category and the Scopus Energy area available in Open Access. The generated term maps allowed for the analysis of the frequency of keywords in different years and the most frequently cited ones, which enabled the identification of current research topics and the evolution of trends. Open access documents are easily accessible, which is particularly important in industry, enabling the implementation of research results and technologies in production. Titles, keywords, abstracts and full texts of publications were analyzed to indicate the process parameters, materials used for pressure densification and applications of this process. Based on the collected data, applications, process parameters and raw materials used in the biomass densification process were determined.

In order to maintain transparency and keep the data up to date, the presented bibliometric analysis refers to the period of 2010–2024.

Following the bibliometric analysis, detailed analyses were carried out on the factors influencing the pressure compaction process.

Graphical bibliometric analyses are an extremely valuable tool in modern science, facilitating the understanding of complex knowledge structures, research trends, and relationships between authors, institutions, and fields of science. By using visualization of bibliometric data—such as co-authorship maps, citation networks, and thematic cluster analyses—it is possible to quickly and intuitively capture key information that would be difficult to capture in traditional text form.

One of the greatest advantages of this type of analysis is its ability to reveal hidden patterns and relationships in data sets that include thousands of publications. It helps identify the most influential works, authors, and research centers, and allows one to track the evolution of individual topics over the years. In an era of scientific information explosion, graphical analyses are becoming invaluable in planning research strategies, selecting partners for cooperation, or assessing the impact of scientific institutions.

The analysis of the literature in the field of densification has shown that the process is carried out in multiple stages and is influenced by many factors, including intermolecular connections, densification pressure, water content in the material, the temperature at which the densification process is carried out, natural binders present in the material (lignins and resins), the speed of the process, particle size, coefficient of friction of the material and the geometry of the matrix used during the densification process.

3. Results

3.1. Results of Bibliometric Analysis

The search yielded 796 scientific articles published in journals indexed in the WoS-CC database and 1834 documents in the Scopus database. Of these, 303 in the WoS-CC database and 728 in the Scopus database are open access.

Figure 2 illustrates the distribution of the number of publications with an open access license that are indexed in the WoS-CC and Scopus databases. Based on the data, it can be seen that the interest in the topic related to solid biofuels, production and product quality is still high and the topic itself is attractive for researchers.

Figure 2.

Number of articles in years indexed on WoS-CC and Scopus with an open access license—2017–2024.

The next step was to analyze keywords for three time ranges: 2010–2014, 2015–2019, 2020–2024. This allows for a visual presentation of the relationships between individual keywords.

Additionally, the analysis of keyword citations allows for the identification of research areas that are of the greatest interest to scientists.

In the first part of the analysis, the co-occurrence of keywords in three specific time periods was checked. This allowed us to determine how research trends changed over time, how analyses for individual issues were deepened, and how interest in specific issues of the scientific community changed. It should be noted that the more recent the time period, the more connections between keywords appear. It was also noted that the newer the research, the more new keywords appear in a given topic, which indicates that the topic is still attractive, and the issues and analyses are still deepened.

The following graphics present the results of the bibliometric analysis for three time periods conducted on the WoS-CC and Scopus databases. The analysis omitted older editions in order to base it on the latest/current literature sources.

The first part of the analysis concerned the frequency of keywords in individual years in the WoS-CC and Scopus databases (Figure 3, Figure 4, Figure 5, Figure 6, Figure 7 and Figure 8). The colors correspond to specific amount of co-occurrence—the more combinations of co-occurring words appear, the brighter the color is.

Figure 3.

Keyword map created based on publications in the WoS-CC database from the period of 2010–2014.

Figure 4.

Keyword map created based on publications in the WoS-CC database from the period of 2015–2019.

Figure 5.

Keyword map created based on publications in the WoS-CC database from the period of 2020–2024.

Figure 6.

Keyword map created based on publications in the Scopus database from the period of 2010–2014.

Figure 7.

Keyword map created based on publications in the Scopus database from the period of 2015–2019.

Figure 8.

Keyword map created based on publications in the Scopus database from the period of 2020–2024.

- Dark blue/blue/light blue—low co-occurrence.

- Green—medium co-occurrence.

- Yellow—high co-occurrence.

The resulting maps show changes in the research topics undertaken and the evolution of those previously selected—from general topics defining solid biofuels and factors influencing the quality of pellets to increasingly specific data, as well as their detailed analysis.

Based on Figure 3, it can be seen that the most popular keywords in the years 2010–2014 were “pellets”, “torrefecation”, “pelletization”—they had about 70 connections with other search terms. In turn, the fewest connections were noticed with the words “rewenable energy”, “biofuel” and “cellulosic biomass”.

Figure 4 presents keywords and their co-occurrence in the period of 2015–2019. In comparison to the previous time period considered, a larger number of keywords can be noticed, and therefore a broader consideration of the topic. The results suggest that the authors of the publication are still looking for new technical solutions, but also for further connections and factors that affect the quality of pellets and the course of the densification process.

The greatest changes in the trends of keyword co-occurrence in the WoS-CC database can be seen in Figure 5. At first glance, it can be seen that the number of entries has increased significantly, which indicates the development of issues related to biomass, pellets and densification. This means that answers are sought to more and more questions related to the production and quality of solid biofuels, and the state of knowledge is still being supplemented by subsequent scientific publications. The influence of an increasing number of factors on the final product is being studied, which also indicates that the pellet itself is being improved to meet the needs of customers, but answers are also being sought to the following question: how to improve pellets so that they meet increasingly stringent quality criteria?

In turn, looking at the results of the analysis obtained from the Scopus database, it can be noticed that in the years 2010–2014, the most frequently associated keyword was “torrefaction”. Moderately used words were “biomass”, “pellet”, “durability”, “bioenergy”, “renewable Energy”. The least popular co-occurring keywords were found to be “pelleting”, “biofuel”, “density”, “cellulosic biomass”.

In the next time period covering the years 2015–2019, an increase in the number of co-occurring keywords can be observed (Figure 7). This shows how interest in the topic of biomass densification for energy purposes has developed over the past few years.

The last timeframe of works published in Scopus is presented in Figure 8. Comparing the results with the results obtained from the previous time frames, the conclusion is that pellets, biomass, and densification for energy purposes is a rapidly developing field of science that is constantly being developed. The increasing number of keywords associated with the basic entries indicates that answers are still being sought to many questions regarding the quality and the influence of factors on biofuels, but also the process of biomass densification for energy purposes.

To summarize, there has been a clear increase in recent years in the scientific publications on the process of pelleting, as well as on the quality of obtained pellets. This phenomenon is reflected not only in the growing number of articles, but also in the increasing diversity of keywords related to this topic. Bibliometric analyses, especially in graphic form, allow for a clear and synthetic presentation of these changes, at the same time indicating the main directions of research and their intensification over the last years.

The growing co-occurrence of terms such as “pellet*” and “densi*” is becoming particularly important, indicating a significant interest in issues related to the density, structure and physicochemical properties of pellets. The use of bibliometric data visualization tools (e.g., keyword maps, cluster analyses or citation networks) enables the identification of dominant research topics and links between different aspects of the pelleting process—from raw material selection, through technological conditions, to the assessment of the quality and application of the final product.

The graphical form of these analyses allows for aa quick grasp of the directions of development of the field and identification of areas with the greatest research potential. Owing to this, it is possible not only to summarize the current state of knowledge, but also to effectively plan future research and indicate niches that remain insufficiently explored. In the context of the growing importance of biomass as a renewable energy source, the significance of such analyses becomes particularly important.

3.2. Pressure Compaction

Compaction (briquetting, pelleting) involves compressing the prepared biomass under high pressure. Usually, this process is carried out without the use of additional binding substances (adhesives). The starting material can be practically any plant raw material, provided that it is properly prepared. As mentioned earlier, wood, non-wood and fruit biomass is agglomerated in Poland, usually in the form of sawdust and chopped straw. Miscanthus, Sida hermaphrodita, sylvestris, sunflower and buckwheat husks [18], wheat bran, fruit pomace [32], etc. are compacted to a lesser extent. The final form of the obtained fuel depends primarily on its intended use. Generally speaking, recipients of processed solid biofuels can be divided into three main groups: large thermal power systems, medium-sized power plants and individual recipients. Quality requirements vary depending on the group.

The densification process occurs in many industrial sectors. It is used, among others, in the food, pharmaceutical, feed, chemical, metallurgical and fuel industries, including the production of solid biofuels [33,34,35,36]. The main goal of this process is to obtain a final product characterized by high durability, specific dimensions and uniform shape. A properly conducted process leads to obtaining a granule that meets the quality requirements applicable in a given industrial sector.

Achieving the required properties of granules largely depends on appropriately selected process factors, which are usually adapted to the characteristics of the material subjected to densification [37].

The process of biomass densification is widely used due to its numerous advantages. This process allows for the attainment of:

- Volume reduction;

- Density maximization;

- Uniform dose composition;

- Storage cost reduction;

- Simplified storage;

- Reduction in the amount of dust;

- Transport cost reduction.

Densification as a process consists of three characteristic stages. In the first stage, the material particles move relative to each other, which causes a reduction in free space and maximization of the contact surface between particles. In the second stage, elastic–plastic deformations of particles occur (the pressure increases to the maximum value). During this stage, the particles are already tightly packed relative to each other, establishing intermolecular connections between them. The last, third stage of the densification process is stabilization. In this stage, the pressure decreases and the material being densified expands, which means that its volume increases slightly. The course of such a process is shown in Figure 9.

Figure 9.

Particle densification scheme. Source: own study based on the work of Pietsch, 2001 [38].

3.3. Intermolecular Connections and Factors Influencing Them

During the densification process, in the presence of pressure and temperature, the material molecules press against each other, creating interactions [39]. This is important because as a result of these interactions, intermolecular connections are created, which have a direct effect on the mechanical strength of the granulated material. Connections can be created as a result of the temperature (softening of the material and activation of natural bonding substances) [40], and an appropriate moisture content of the material. This was confirmed by Kaliyan and Morey in their studies [41], as well as many others. Pietsch [38], in his extensive work thoroughly discussing the densification process and all its components, described the types of intermolecular connections that can be created as a result of the densification process. The types of these connections are presented in Figure 10.

Figure 10.

Types of intermolecular connections: (a)—partial melting, (b)—chemical reactions, (c)—liquid bridges, (d)—molecular forces, (e)—molecular blocking, (f)—capillary forces. Source: Pietsch 2001 [38].

The occurrence of such connections was confirmed by Kaliyan and Morey [42], and their presence and the influence of other factors can have a positive effect on the strength and durability of the obtained granulates. The results of these studies and knowledge of the occurring intermolecular connections allow for planning the production process and its subsequent optimization [42]

3.4. Factors Influencing the Pressure Compaction Process

The factors that directly affect the densification process can be divided into three groups of parameters: material parameters (type of biomass, fraction size, chemical composition, etc.), technological parameters (moisture, temperature, pressure, densification rate, time, etc.), and structural parameters of the system (geometry of the densification chamber, compression ratio) [43]. As is commonly known, materials are characterized by different properties that must be taken into account during the densification process, which suggests that these materials will densify in different ways. In order to determine the appropriate conditions and parameters of densification for a given raw material, basic research should be performed, which will be the basis for further, more detailed research.

The mechanical strength and the degree of compaction of the produced granulate depend on many important factors accompanying the compaction process, such as compaction pressure, the rate of increase in compaction pressure, lateral pressures, friction coefficient, compression coefficient, die and piston geometry, the temperature at which the process takes place, the presence of binders, and biomass preheating [42,44,45].

3.4.1. Pressure

The basic and effective factor of the process is the pressure exerted on the material being compacted in the chamber. Without this factor, the process cannot be carried out. The influence of pressure on the quality of solid biofuels is studied by many scientists [19,43,46,47,48,49,50,51,52,53,54,55,56,57]. It has been shown that this is one of the most important factors that mainly affects the quality of compacted fuels. Pressure, combined with the appropriate process temperature and material moisture, can significantly reduce the cost of biofuel production. It is due to pressure that it is possible to reduce the volume in favor of increasing the density of the final product.

However, it should be remembered that pressure will have a different effect on individual materials; so, it is worth approaching each of them individually, defining compaction curves from which it will be possible to read the appropriate pressure values needed to properly compact the material.

Too low pressure values during the densification process may result in a low degree of densification, which, in turn, results in low mechanical strength of the granulate and density. The reason will be the low reduction in intermolecular spaces and a small contact surface of the particles. The large packing of the particles also favors the formation of bonds and intermolecular connections.

High-pressure values greatly facilitate the pressure compaction process, while values that are too high may cause damage to the pellet press dies, e.g., cracks.

Rahaman [58], in his research, showed that for the densification of rice grass with the addition of sawdust as a binder, a pressure of 34.5 MPa is sufficient to obtain briquettes of satisfactory quality. In turn, in Križan’s research [59], the pressure necessary to obtain good-quality briquettes from woody biomass using a low temperature of the entire production was determined. It was shown that at lower temperatures of biomass compaction, a higher pressure is needed, and it was 286 MPa. Kulig and his team [60] found that increasing the agglomeration pressure of the material in the range of 45–96 MPa results in an increase in the density of the produced granules by an average of 26%, while the expansion of the biofuel increases by about 51%. It was also noted that with the increase in pressure, the mechanical strength of the obtained agglomerates increased (an average of 83%). A further increase in pressing pressure does not bring statistically significant changes in product quality in the cases of Jerusalem artichoke and reed canary grass densification. In case of Korszyński’s caragana, it was determined that the densification process should be carried out at a pressure of 50–110 MPa so that the final product is of good quality [61]. Demirbas and his team [62] investigated the pressure compaction process using spruce wood sawdust as the test material. The results demonstrate that compressive strength and shatter index increase with rising pressure. However, it was observed that as briquette density increased, their combustion capacity decreased. The optimal results were achieved for briquettes compacted from material with 15% moisture content under 350 MPa pressure. In studies conducted by Li and Liu [51], wood residues were used as the test material. They found that oak bark compacted more easily than wood, while hardwood proved more compressible than softwood. The results indicate that pressures exceeding 100 MPa are required to obtain pellets with adequate density and strength. Li et al. [63] examined corn straw in their research. Their findings show that as the compaction process temperature increases, the required pressure decreases. Orisaleye’s [64] research demonstrated that an increase in compaction pressure and temperature, along with particle size reduction, led to higher density of corn cob briquettes. Zvicevičius et al. [65] revealed in their study that increasing the applied pressure from 156.1 MPa to 780 MPa reduced the optimal moisture content of milled A. dubia biomass by 1.6 percentage points (from 11.0% to 9.4%). Notably, this reduction was observed up to 624 MPa, beyond which the optimal moisture level stabilized at 9.4% within the 624–780 MPa pressure range. Granado [66] observed in his research that compaction pressure directly affects briquette density. It was also noted that cassava can be compacted without temperature changes or binder additives. Studies by Wongsiriamnuay and Tippayawong [67] show that pellets produced from maize residues achieved mechanical strength of 80% (below the minimum threshold for A1 quality class) when processed at 80 °C and 150 MPa pressure. Ismail et al. [68] studied Khaya senegalensis as their test material. Their results indicate that at a processing temperature of 125 °C, the fuel pellets exhibited peak axial (66.06 MPa) and diametral (7.59 MPa) compressive strengths while maintaining virtually unaffected durability at 99.47%.

A comparison of parameters, materials and authors is listed in the following Table 1.

Table 1.

Pressure values used by different authors in the process of densification of various types of biomass.

3.4.2. Moisture Content

The water content in the tested material can have both a positive and negative effect on the mechanical strength of the pellets. Its presence allows for the interaction of natural binders/adhesives with the particles, which can ultimately give a positive or negative effect, causing greater or lower durability of the pressure compaction product.

In the case of oak, pine and poplar, it has been shown that too low humidity can result in the crumbling of the granulate and its low strength. This is due to the fact that granulate with low moisture becomes brittle and less stable due to the absorption of water from the air [51]. In the case of Scots pine Pinus sylvestris L., the most favorable range was 11–13% water content [69].

However, it was also found that the presence of moisture in biomass has a positive effect on the increase in van der Waals forces [70]. It was noticed that briquettes with a moisture content in the range of 5–10% are characterized by higher mechanical strength, density and stability.

Skonecki and Kulig [71] demonstrated in their research that increasing the moisture content of materials such as wheat straw and basket willow from 10% to 18% leads to several effects: a rise in the maximum raw material density within the densification chamber, a reduction in the density of the resulting agglomerate, enhanced material compressibility, and greater agglomerate expansion. However, this also results in a decrease in the mechanical strength of the agglomerate.

The optimal conditions for the production of biofuels from cellulosic biomass in terms of raw material moisture content are considered to be in the range of 8–12% depending on the species [72,73]. It was also found that lower moisture content results in higher density of the final product of the densification process [73,74]. Laloon et al. [75] conducted studies on eucalyptus powder. Their research demonstrated successful pelletization at a rotational speed of 275 rpm. Effective pellet formation was achieved using dies with 3 mm and 4 mm apertures at 17.69% moisture content (wet basis), while a 5 mm die aperture required a higher moisture content of 20.21%. Tumuluru [76] employed notably higher feedstock moisture content than other referenced authors. His findings indicate that even such elevated moisture levels, when combined with properly selected process parameters (die geometry), can produce high-quality pellets (durability > 97.5%). In subsequent research, Tumuluru and Fillerup [77] characterized the briquetting of mixed woody and herbaceous biomass. Their studies revealed that optimal briquetting parameters depend on feedstock moisture content and mill screen size. Process parameters ensuring high density included 12–15% moisture content and 4.8 mm mill screen size. Parameters yielding high durability were 15–18% moisture content and screen sizes ranging from 12.7 to 19.05 mm. The authors of [65] observed that pellets produced from low-moisture material (4.3–12.9%) showed minimal density variation and required comparable compaction pressures. In contrast, material with a 15.5–21.5% moisture content exhibited enhanced plastic deformation.

A comparison of moisture, materials and authors is listed in the following Table 2.

Table 2.

Moisture content values used by different authors in the process of densification of various types of biomass.

3.4.3. Temperature of the Compaction Process

The raw material subjected to pressure agglomeration must undergo a series of processes that will enable its further processing. Such pre-treatment of biomass can have a significant impact on the chemical composition and mechanical properties of the input material, which can improve the quality of the final product [45,78].

During pressure densification of biomass, the temperature increases due to friction. It can also be increased using an additional system integrated with the material densification installation. Temperature is one of the most important factors that have a significant impact on quality parameters, i.e., durability and density of densified biomass (pellets). Commonly available research indicates a significant, often positive effect of temperature on the biomass densification process [16]. It is usually combined with other factors as a factor whose presence is an activator of natural binders contained in plants (resins, lignins) [79].

From available sources we learn that at the appropriate temperature of the densification process, a material with a higher water content and lower pressure can be used, which allows for saving energy during the process [80]. Todaro et al. [81], in their studies, showed that wood subjected to thermal treatment is characterized by a higher calorific value. In turn, Rhen [52] and his team showed that the best conditions for the densification process of a sample from Norwegian spruce are low water content in the sample and high temperature of the pressure agglomeration process. Hall and Hall [82], in their studies. proved that for a specific moisture content of the densified material, the densification pressure of alfalfa and Bermuda grass can be reduced by using an appropriately high temperature. Moreover, owing to the temperature, it is possible to agglomerate a raw material with a higher moisture content while still obtaining the appropriate density of the granulate. Smith et al. [83] noted in their studies on wheat straw briquetting that the increase in temperature from 60 to 140 °C increased the degree of material densification and the subsequent stability of the briquettes. A reduction in the occurrence of the expansion phenomenon was also observed. Tabil [84] observed an increase in the durability of pellets made from alfalfa after adding a temperature factor above 90 °C to the densification process. In turn, Kaliyan and Morey [85] used the glass transition temperature of lignin in their studies to better understand the behavior of particles under its influence. They observed that at temperatures of 75 and 100 °C, i.e., within the glass transition temperature, the results were higher than at 150 °C, i.e., significantly beyond the previously described range. Wongsiriamnuay and Tippayawong [67] observed that pellet density increased with rising temperature (>1000 kg·m−3 at 80 °C). Ismail’s research [68] demonstrated that high-quality pellets with mechanical strength reaching 99.47% could be produced at 125 °C. Meanwhile, Li et al. found that increasing the pellet mill die temperature reduced compaction pressure—a crucial factor for production cost reduction. Their studies recommended 100 °C as the optimal temperature for corn straw pelletization, as it achieved the required density (>1.0 g·cm−3) while nearly halving the pressure compared to 200 °C processing. Orisaleye et al. [64] conducted statistical analysis revealing significant effects (p < 0.05) of pressure, temperature, and particle size on briquette density. A statistically significant interaction (p < 0.05) was also observed between temperature and particle size of milled corn cobs. These findings establish clear relationships between compaction parameters and the resulting density of corn cob briquettes.

A comparison of temperature, materials and authors is listed in the following Table 3.

Table 3.

Temperature values used by different authors in the process of densification of various types of biomass.

3.4.4. Natural Binders Used for Biomass Densification

Plants contain many different substances in their cells, which, in different proportions, give plants properties characteristic of a given species. These substances can have a significant impact on the physico-mechanical parameters of the processed biomass from these plants. This can be observed, among others, during the densification process, where the presence of natural binders, such as lignin or resins, significantly affects the final product, such as pellets or briquettes. These binders are usually activated by temperature, but their action is also influenced by other factors, such as humidity or densification pressure [86]. As already mentioned, the most important natural binders are:

Lignin—next to cellulose and hemicellulose, one of the main components of wood, in which its share is about 20% [87]. It is a substance with viscous properties, causing the compactness of the wood cell structure. Its content causes stiffness and mechanical resistance to compression.

Resins—a substance produced in plants, particularly in trees, especially conifers [88]. Resins are water-insoluble, amorphous or partially crystalline mixtures of non-volatile organic compounds, mainly terpenoids (resin acids and their derivatives) and phenolic compounds (phenolic acids, phenols) [89].

3.4.5. Compaction Process Speed

Scientists are also examining the speed of the pressure agglomeration process [17,34,35,90]. This is due to the fact that a longer residence time of the material in the compaction chamber allows for the formation of more durable bonds between the particles of the compacted material, which will be characterized by greater mechanical strength. In turn, too short a thickening process may result in the formation of granules with low durability, which is related to too short a time in which the particles can bond with each other.

For eucalyptus, studies demonstrated successful densification at 275 rpm using a material with a 17.69% moisture content and screen sizes of 3–4 mm, or alternatively with a 20.21% moisture content when using a 5 mm screen [75]. Dołżyńska’s research [35] showed that the highest pellet density (849.46 kg·m−3) was achieved at a die rotation speed of 170 rpm, though these pellets did not exhibit the highest mechanical strength. Gageanu’s investigations [90] into compaction speed revealed an inverse relationship between process velocity and resulting pellet density. Obidziński’s [34] research team conducted compaction at 120, 170, and 220 rpm, determining optimal processing conditions at 120 rpm with a 25% material moisture content. Szyszlak-Bargłowicz [17] evaluated energy consumption during miscanthus compaction at 260 rpm. The results indicated that with a copra meal content not exceeding 30%, the pellets met the quality standards with durability >95%, density >1200 kg·m−3, and bulk density >417 kg·m−3. Notably, the process achieved 44% energy demand reduction while maintaining an energy yield of 4815 Wh·kg−1. These findings position copra meal as a promising additive for miscanthus pellet production, offering advantageous physicochemical and economic properties. The speed at which the pellet mill die rotates also affects energy consumption. The higher the revolutions, the greater the electricity consumption.

A comparison of rotation, speed, materials and authors is listed in the following Table 4.

Table 4.

Rotation values used by different authors in the process of densification of various types of biomass.

3.4.6. Fraction Size

The particle size of the compacted material is a key factor that directly affects the quality characteristics of the granulate. This is due to the fact that during the process of pressure agglomeration of the material, smaller particles have a larger contact surface. This is due to the fact that by reducing the particle size, we also reduce the free spaces between the particles, which facilitates the packing of the particles and, consequently, increases the contact surface [37,42,45,91,92,93].

Moreover, particle size reduction can significantly influence higher efficiency of the material densification process and lower energy consumption during the agglomeration process [94]. It was also noticed that reducing the size of material particles increases the density of pellets and their mechanical strength. It was also observed that the granules were characterized by low hygroscopicity and high resistance to crumbling, which is an advantage during transport or storage cycles [95,96].

The experiment described by Hill and Pulkinen [7] showed that increasing the particle size during alfalfa pelleting from 2.8 mm to 6.4 mm results in a deterioration of mechanical strength of 15%. The authors claim that standardization of particle size and mechanical strength of pellets should correspond to the energy necessary for biomass processing. In turn, Kronbergs’ research [97], which concerned straw briquetting, showed that reducing the material particles from 20 mm to 1.5 mm resulted in an increase in the density of the briquettes by as much as 25%.

The influence of particle size on the mechanical strength of straw pellets from wheat, corn or barley was also noticed by Mani et al. [98]. The bonding properties of the material have also been linked to particle size. Peleg, together with Mannheim [99], note that smaller particles with a larger contact surface are characterized by higher bond energy in relation to a unit of mass. Therefore, compacting properly processed biomass with high bulk density makes it possible to obtain granules with a higher density. This is related to the reduction in the free space between particles and precisely the amount of reduced air. Obidziński [100] states that the binding of particles with high bulk density occurs in the presence of lower pressure of the compaction process. The higher the bulk density of the compacted material, the lower the energy demand.

A comparison of particle size, materials and authors is listed in the following Table 5.

Table 5.

Fraction sizes used for densification of different types of biomass.

3.4.7. Friction Coefficient

The influence of the friction coefficient on the compaction process and the quality of the resulting granules has been studied in many research centers for various materials [102,103,104,105,106,107,108,109]. The authors unanimously demonstrate the significant impact of this factor on the energy consumption of the compaction process. The results obtained from analyses of the physical properties of the thickened raw material are of key importance for the design of production, processing and thickening lines.

Koval’chenko conducted a series of studies on Newtonian and non-Newtonian porous solids compacted in the presence of temperature. He showed that external friction (between the material and the die wall) causes an uneven flow of the compacted material [105]. In the same work, he also found that reducing the external friction coefficient has a beneficial effect on the speed of the agglomeration process, making it possible to obtain increased and more uniform density along with improved physico-mechanical properties of compacted semi-finished products and components. Sologubik et al. [107] determined the physical properties of two varieties of barley grains with a moisture content ranging from 10.12 to 42.17%. The following changed with water content: dimensions, volume, unit mass, sphericity, angle of repose, and friction coefficient. Markowska reached similar conclusions in her research [110]. The work showed the effect of water content in grains on their physical properties—including friction. An increase in the friction coefficient was observed with increasing humidity. Similar observations were shared by Wójcik et al. [109] in their research on granulated plant materials. Kabas and Ozmerzi [103] took the prickly pear Opuntia ficus india L. as the tested material and determined the static and dynamic friction coefficients for its two varieties. Four different surfaces were taken as a reference point: galvanized steel, rubber, plywood and paper. The research showed that neither speed nor friction surface affected either variety of prickly pear in a similar way.

A comparison of coefficient, materials, surfaces and authors is listed in the following Table 6.

Table 6.

Friction tests during compaction of different types of biomass.

3.4.8. Die Geometry

When talking about die geometry, the size and type of die (flat or annular) are usually taken into account. However, additional dimensions must be added, such as the inlet diameter of the densification channel, the height of the densification cone, the angle of the densification cone in the densification channel, the diameter of the densification channel or the length of the densification channel, which does not mean the thickness of the die, because it can be smaller. In such a case, we usually have an additional expansion channel that makes it easier for the granulate to leave the densification channel.

The above-mentioned dimensions have a significant impact on the amount of material that can be granulated at a given moment, but also on the force that will accompany this process. They also affect the quality of the final pellet.

The compaction cone is the first section that the material to be compacted must pass through in the compaction system. As the name suggests, it has the shape of a cone, which is shortened at an appropriate length and passes into a cylindrical compaction channel. Cones can also have different geometry, starting from height, inlet and outlet diameter to the angle of opening. Currently, few authors conduct research on the effect of a specific angle on the compaction process. There is little and largely general information available. Nielsen, in his research on the compaction of woody biomass [111], checked the energy consumption during the agglomeration process using a matrix with an opening angle of the compaction cones of 60°. It was found that 74% of the total energy consumption of the compaction process was consumed by the “flow elements” during the agglomeration of beech and 66% in the case of pine compaction. Križan [112] also conducted research on the influence of the geometry of the densification chamber for wood biomass. The object of his research was the influence of densification channels with angles of 2°, 4°, 6°, 10°, and 14°. His research focused mainly on the optimization of geometry, and the result of his analyses was to determine the ratio of the material contact surface to the volume of the densification chamber. With the change in the densification cone, this ratio changes. Winter [113] chose RDF as the research material in his research. He studied the influence of angles of 0°, 4°, 14°, and 28° on the production of single granules. The obtained results indicate that the angle of 28° was accompanied by the lowest densification pressure, and the pellet produced was of the best quality among all variants. The qualitative criterion was crack resistance. Mišljenović et al. [6] pelleted wheat straw using a single station, but also in a pilot scale using a flat die with a densifying cone with an angle of 37.6° Their experience showed that pellets extruded using a station for the production of single granules were characterized by higher mechanical strength. Hu et al. [114] studied the energy consumption during the densification of rice grass using five angles in the range of α = 29.5–60.5°. The lowest energy consumption was achieved using an angle of α = 60.5°. Wu et al. [115] simulated the densification process for angles α in the range of α = 15–120°. They found that decreasing values of angle α reduced the granulation force and thus the friction.

The ratio of the length of the densification channel opening to its diameter (L/D), also known as the compression coefficient, can take values from 4 to 7.5. Its value must be selected for the pelleted material because the materials are distinguished by their individual characteristics [116].

Increasing the length of the densification channel generally leads to higher pelleting pressure. However, if the channel diameter is also increased, the force required to push the material through the channel tends to decrease. This observation highlights that the geometry of the pelleting die plays a significant role in influencing the operating conditions of the technical system [117]. Heffiner and Pfost [118] checked the effect of die geometry on the mechanical strength of pellets in three geometric variants. The studies show that the highest resistance to crumbling was characterized by granules produced on the die with the shortest length.

The experiments of Butler and McColly [119] proved that at a constant material dose and a specific production pressure, the density and length of the pellets were greater for smaller densification chambers. Tumuluru et al. [92] compared the results obtained from densification of biomass on a die with an inlet diameter of 7.2 mm and 6.4 mm. It was confirmed that pellets produced on dies with a larger inlet diameter were characterized by lower mechanical strength. Hill and Pulkinen [7], in their studies, determined that the highest durability was attributed to alfalfa agglomerate extruded through a die with a compression coefficient of 8–10.

Krizan et al. and Styks et al. found that the relationship between material, channel geometry and pellet quality may be sufficiently universal to allow for optimal selection of forming channel parameters and conducted verification research [120,121]. It takes into account various factors, such as raw material moisture, grain composition, binder addition, process temperature, or material dose, while minimizing the required compaction pressure. The results of the conducted research can support activities aimed at obtaining a product that meets quality standards and consumer expectations while improving the efficiency of the production process.

A comparison of geometry, materials and authors is listed in the following Table 7.

Table 7.

Geometry of the matrix for compacting different types of biomass.

3.5. Compaction Models

This literature review showed that research is ongoing on the development of compaction models for various plant materials. A compaction model for biomass obtained from coconut core was developed by Viswanathan and Gothandapani [123], which describes the change in packing density due to the applied pressure. Ferrero et al. [124], Faborode and O’Callaghan [125], and Butler and McColly [119] described a compaction model for straw, also establishing the density change in relation to pressure as the parameters determining the model. O’Dogherty and Wheeler [126] selected fibrous grasses as the research material and their model also refers to the pressure-induced change in the density of the compacted material. Walker [127], Kawakita and Lüdde [128], Shapiro [129], and Jones [130] developed a mathematical model of powder densification and used pressure and density as components. Bilanski et al. [131] and Afzalinia and Roberge [132] modeled the densification process of alfalfa, which was also described as a change in density due to pressure.

All models mathematically describe the process of material compaction, where the main elements of the equation are the pressure and density of the given material. Unfortunately, none of the models address the issue of changing the geometry of the compaction channel in which the material is compacted. None of them discuss the strength of the agglomerate either, which is, apart from density, the most important quality parameter dependent on the agglomeration process.

As already mentioned, pellets must have the right energy parameters, but this is ensured by the right raw material, not the densification process. The process, on the other hand, is required to bring the raw material to the right density (and this is mainly described by mathematical models of the densification process). First, the process is to create an agglomerate resistant to its degradation processes occurring during storage and transport. In other words, the pellet must have high resistance to crumbling, i.e., be mechanically strong. This ensures that the shape given at the place of production will be maintained at the distribution stages, until it is fed to the combustion chamber. The mechanical strength of durability prevents crumbling, dusting and the inconveniences associated with it. From the customer’s point of view, durability is a more important parameter than density. A decrease in density only increases the volume of the fuel, while a decrease in durability causes a whole host of problems related to the appearance of a dusty fraction in the pellet bed.

The quality requirements that fuel pellets made from biomass must meet are included in the standards PN-EN ISO 17225-2:2021 [133] (wood pellets) and PN-EN ISO 17225-6:2021 [134] (non-wood pellets).

For wood pellets, the standard provides for three quality classes: A1, A2 and B. Regardless of the class, the bulk density of the pellet should be at least 600 kg·m−3 and not exceed 750 kg·m−3. In the case of durability, class A1 requires a value of this parameter of at least 98% for 6 mm pellets and 97.5% for 8 mm pellets, A2 requires a durability of at least 97.5% regardless of diameter, and class B requires a durability of at least 96.5%, also regardless of diameter. In the case of non-wood pellets, we have two quality classes A and B. Class A requires pellets with a bulk density of at least 600 kg·m−3 and mechanical strength of at least 97.5%. In the case of class B, the pellet should have a bulk density of 550 kg·m−3 and mechanical strength of 96%.

During the process, it is not enough to pack the material particles appropriately to obtain the required density, but the mechanisms that bind these particles must be activated strongly enough to obtain the required strength. This must take place in the compaction chamber of the pelletizing die, and the geometry of this chamber is responsible for this. However, it is still an open question what this geometry should be depending on the compacted material because there is no universal solution.

4. Conclusions

To summarize, graphical bibliometric analyses not only support the decision-making process in science, but also democratize access to knowledge, making it more transparent and understandable for researchers from various fields.

The analysis of the literature in the field of densification has shown that the process is carried out in multiple stages and is influenced by many factors, including intermolecular connections, densification pressure, the water content in the material, the temperature at which the densification process is carried out, natural binders present in the material (lignins and resins), the speed of the process, particle size, the coefficient of friction of the material and the geometry of the matrix used during the densification process. This work focuses on the analysis of selected research items covering the above-mentioned factors, the proper selection of which undoubtedly affects the quality of the product obtained during the densification process (solid biofuel).

Based on the analyzed publications, it can be stated that future research directions should concern the comprehensive influence of various factors on the biomass densification process.

These studies should aim to generalize the obtained relationships. So far, studies have been conducted on a specific type of biomass and generalizations to other types of biomass are impossible. It would be very interesting to describe biomass using universal parameters and develop generalized relationships describing the process of densification of lignocellulosic biomass.

Another direction of research should be mathematical modeling of the densification process (e.g., using artificial neural networks or other artificial intelligence tools). Such models would allow for the optimization of the process in terms of product quality, efficiency and production costs.

Author Contributions

Conceptualization, J.S. and S.F.; methodology, J.S. and S.F.; validation, J.S., M.W. and S.F.; investigation, J.S.; data curation, J.S. and M.W.; writing—original draft preparation, J.S. and S.F.; writing—review and editing, J.S., M.W. and S.F.; visualization, J.S.; supervision, J.S., M.W. and S.F. All authors have read and agreed to the published version of the manuscript.

Funding

The article-processing charges were financed from the subsidy of the Ministry of Education and Science for the Agricultural University of Hugo Kołłątaj in Krakow for the year 2025.

Data Availability Statement

Data are contained within this article. Further inquiries can be directed to the corresponding authors.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Francik, S.; Knapczyk, A.; Francik, R.; Ślipek, Z. Analysis of Possible Application of Olive Pomace as Biomass Source; Springer: Cham, Switzerland, 2018; pp. 583–592. [Google Scholar]

- Francik, S.; Knapik, P.; Łapczyńska-Kordon, B.; Francik, R.; Ślipek, Z. Values of Selected Strength Parameters of Miscanthus × Giganteus Stalk Depending on Water Content and Internode Number. Materials 2022, 15, 1480. [Google Scholar] [CrossRef] [PubMed]

- Lin, S.; Li, L.; Wei, Z.; Liang, J.; Lin, Z.; Evrendilek, F.; He, Y.; Ninomiya, Y.; Xie, W.; Sun, S.; et al. CO2-Induced Co-Pyrolysis of Pennisetum Hydridum and Waste Tires: Multi-Objective Optimization of Its Synergies and Pyrolytic Oil, Char and Gas Outputs. Energy 2025, 317, 134670. [Google Scholar] [CrossRef]

- Knapczyk, A.; Francik, S.; Jewiarz, M.; Zawiślak, A.; Francik, R. Thermal Treatment of Biomass: A Bibliometric Analysis—The Torrefaction Case. Energies 2020, 14, 162. [Google Scholar] [CrossRef]

- Francik, S.; Knapczyk, A.; Knapczyk, A.; Francik, R. Decision Support System for the Production of Miscanthus and Willow Briquettes. Energies 2020, 13, 1364. [Google Scholar] [CrossRef]

- Mišljenović, N.; Čolović, R.; Vukmirović, Đ.; Brlek, T.; Bringas, C.S. The Effects of Sugar Beet Molasses on Wheat Straw Pelleting and Pellet Quality. A Comparative Study of Pelleting by Using a Single Pellet Press and a Pilot-Scale Pellet Press. Fuel Process. Technol. 2016, 144, 220–229. [Google Scholar] [CrossRef]

- Hill, B.; Pulkinen, D.A. A Study of Factors Affecting Pellet Durability and Pelleting Efficiency in the Production of Dehydrated Alfalfa Pellets; A Special Report; Agriculture Development Fund: Riyadh, Saudi Arabia, 1988. [Google Scholar]

- Kuboń, M.; Skibko, Z.; Borusiewicz, A.; Romaniuk, W.; Gajda, J.S.; Kłosowska, O.; Wasąg, Z. Influence of the Parameters of an Agricultural Biogas Plant on the Amount of Power Generated. Appl. Sci. 2024, 14, 4200. [Google Scholar] [CrossRef]

- Jewiarz, M.; Wróbel, M.; Mudryk, K.; Szufa, S. Impact of the Drying Temperature and Grinding Technique on Biomass Grindability. Energies 2020, 13, 3392. [Google Scholar] [CrossRef]

- Puig-Arnavat, M.; Shang, L.; Sárossy, Z.; Ahrenfeldt, J.; Henriksen, U.B. From a Single Pellet Press to a Bench Scale Pellet Mill—Pelletizing Six Different Biomass Feedstocks. Fuel Process. Technol. 2016, 142, 27–33. [Google Scholar] [CrossRef]

- Szufa, S.; Piersa, P.; Adrian, Ł.; Czerwińska, J.; Lewandowski, A.; Lewandowska, W.; Sielski, J.; Dzikuć, M.; Wróbel, M.; Jewiarz, M.; et al. Sustainable Drying and Torrefaction Processes of Miscanthus for Use as a Pelletized Solid Biofuel and Biocarbon-Carrier for Fertilizers. Molecules 2021, 26, 1014. [Google Scholar] [CrossRef]

- Angulo-Mosquera, L.S.; Alvarado-Alvarado, A.A.; Rivas-Arrieta, M.J.; Cattaneo, C.R.; Rene, E.R.; García-Depraect, O. Production of Solid Biofuels from Organic Waste in Developing Countries: A Review from Sustainability and Economic Feasibility Perspectives. Sci. Total Environ. 2021, 795, 148816. [Google Scholar] [CrossRef]

- Kożuch, A.; Cywicka, D.; Adamowicz, K.; Wieruszewski, M.; Wysocka-Fijorek, E.; Kiełbasa, P. The Use of Forest Biomass for Energy Purposes in Selected European Countries. Energies 2023, 16, 5776. [Google Scholar] [CrossRef]

- Musiał, W.; Zioło, M.; Luty, L.; Musiał, K. Energy Policy of European Union Member States in the Context of Renewable Energy Sources Development. Energies 2021, 14, 2864. [Google Scholar] [CrossRef]

- Obidziński, S. Analysis of Usability of Potato Pulp as Solid Fuel. Fuel Process. Technol. 2012, 94, 67–74. [Google Scholar] [CrossRef]

- Obidziński, S.; Hejft, R. Badanie Nacisków Wywieranych Przez Materiał Na Ściankę Otwartej Komory Zagęszczania. Inżynieria Rol. 2012, 3, 175–184. [Google Scholar]

- Szyszlak-Bargłowicz, J.; Słowik, T.; Zając, G.; Blicharz-Kania, A.; Zdybel, B.; Andrejko, D.; Obidziński, S. Energy Parameters of Miscanthus Biomass Pellets Supplemented with Copra Meal in Terms of Energy Consumption during the Pressure Agglomeration Process. Energies 2021, 14, 4167. [Google Scholar] [CrossRef]

- Obidziński, S.; Piekut, J.; Dec, D. The Influence of Potato Pulp Content on the Properties of Pellets from Buckwheat Hulls. Renew. Energy 2016, 87, 289–297. [Google Scholar] [CrossRef]

- Hejft, R.; Obidziński, S. Ciśnieniowa Aglomeracja Materiałów Roślinnych—Innowacje Technologiczno-Techniczne. Część 1. J. Res. Appl. Agric. Eng. 2012, 57, 63–65. [Google Scholar]

- Iryani, D.A.; Halimatuzzahra, H.; Taharuddin, T.; Haryanto, A.; Hidayat, W.; Hasanudin, U. Physicochemical Characterization of Wood Mixed with Coffee Waste Pellet. IOP Conf. Ser. Earth Environ. Sci. 2023, 1187, 012007. [Google Scholar] [CrossRef]

- Kong, X.; Cao, Q.; Niu, Z. Experimental Research on Breakage Characteristics of Feed Pellets under Different Loading Methods. Agriculture 2024, 14, 1401. [Google Scholar] [CrossRef]

- Mitrus, M.; Tydman, K.; Milanowski, M.; Soja, J.; Lewko, P.; Kupryaniuk, K.; Wójtowicz, A. Influence of the Forming Die Design on Processing and Physical Properties of Gluten-Free Crisps. Agric. Eng. 2024, 28, 87–96. [Google Scholar] [CrossRef]

- Mitrus, M.; Combrzyński, M.; Biernacka, B.; Wójtowicz, A.; Milanowski, M.; Kupryaniuk, K.; Gancarz, M.; Soja, J.; Różyło, R. Fresh Broccoli in Fortified Snack Pellets: Extrusion-Cooking Aspects and Physical Characteristics. Appl. Sci. 2023, 13, 8138. [Google Scholar] [CrossRef]

- Priese, F.; Wiegel, D.; Funaro, C.; Mondelli, G.; Wolf, B. Comparison of Mini-Tablets and Pellets as Multiparticulate Drug Delivery Systems for Controlled Drug Release. Coatings 2023, 13, 1891. [Google Scholar] [CrossRef]

- Wójtowicz, A.; Combrzyński, M.; Biernacka, B.; Oniszczuk, T.; Mitrus, M.; Różyło, R.; Gancarz, M.; Oniszczuk, A. Application of Edible Insect Flour as a Novel Ingredient in Fortified Snack Pellets: Processing Aspects and Physical Characteristics. Processes 2023, 11, 2561. [Google Scholar] [CrossRef]

- PN-EN ISO 16559:2022-06; Biopaliwa Stałe—Terminologia. Polish Committee for Standardization: Warsaw, Poland, 2022.

- PN-EN ISO 17225-1:2021; Biopaliwa Stałe—Specyfikacje Paliw i Klasy—Część 1: Wymagania Ogólne. Polish Committee for Standardization: Warsaw, Poland, 2021.

- Francik, S.; Łapczyńska-Kordon, B.; Francik, R.; Wójcik, A. Modeling and Simulation of Biomass Drying Using Artificial Neural Networks. In Renewable Energy Sources: Engineering, Technology, Innovation: ICORES 2017; Springer International Publishing: Berlin/Heidelberg, Germany, 2018; pp. 571–581. [Google Scholar]

- Francik, S.; Łapczyńska-Kordon, B.; Hajos, M.; Basista, G.; Zawiślak, A.; Francik, R. Modeling the Drying Process of Onion Slices Using Artificial Neural Networks. Energies 2024, 17, 3199. [Google Scholar] [CrossRef]

- Knapczyk, A.; Francik, S.; Fraczek, J.; Slipek, Z. Analysis of Research Trends in Production of Solid Biofuels. In Proceedings of the 18th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 22–24 May 2019; Latvia University of Life Sciences and Technologies: Jelgava, Latvia, 2019; Volume 18, pp. 1503–1509. [Google Scholar]

- Knapczyk, A.; Francik, S.; Pedryc, N.; Hebda, T. Bibliometric Analysis of Research Trends in Engineering for Rural Development. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; pp. 700–707. [Google Scholar]

- Dołżyńska, M.; Obidziński, S.; Kowczyk-Sadowy, M.; Krasowska, M. Densification and Combustion of Cherry Stones. Energies 2019, 12, 3042. [Google Scholar] [CrossRef]

- Obidziński, S.; Dołżyńska, M.; Stasiełuk, W. Production of Fuel Pellets from a Mixture of Sawdust and Rye Bran. IOP Conf. Ser. Earth Environ. Sci. 2019, 214, 012073. [Google Scholar] [CrossRef]

- Obidziński, S.; Puchlik, M.; Dołżyńska, M. Pelletization of Post-Harvest Tobacco Waste and Investigation of Flue Gas Emissions from Pellet Combustion. Energies 2020, 13, 6002. [Google Scholar] [CrossRef]

- Dołżyńska, M.; Obidziński, S.; Piekut, J.; Yildiz, G. The Utilization of Plum Stones for Pellet Production and Investigation of Post-Combustion Flue Gas Emissions. Energies 2020, 13, 5107. [Google Scholar] [CrossRef]

- Zawiślak, K.; Sobczak, P.; Kraszkiewicz, A.; Niedziółka, I.; Parafiniuk, S.; Kuna-Broniowska, I.; Tanaś, W.; Żukiewicz-Sobczak, W.; Obidziński, S. The Use of Lignocellulosic Waste in the Production of Pellets for Energy Purposes. Renew. Energy 2020, 145, 997–1003. [Google Scholar] [CrossRef]

- Wróbel, M. Zagęszczalność i Kompaktowalność Biomasy Celulozowej; Polskie Towarzystwo Inzynierii Rolniczej: Kraków, Poland, 2019; ISBN 978-83-64377-35-8. [Google Scholar]

- Pietsch, W. Agglomeration Processes: Phenomena, Technologies, Equipment; Wiley: Hoboken, NJ, USA, 2001; ISBN 9783527619801. [Google Scholar]

- Anglès, M.N.; Ferrando, F.; Farriol, X.; Salvadó, J. Suitability of Steam Exploded Residual Softwood for the Production of Binderless Panels. Effect of the Pre-Treatment Severity and Lignin Addition. Biomass Bioenergy 2001, 21, 211–224. [Google Scholar] [CrossRef]

- Bika, D.; Tardos, G.I.; Panmai, S.; Farber, L.; Michaels, J. Strength and Morphology of Solid Bridges in Dry Granules of Pharmaceutical Powders. Powder Technol. 2005, 150, 104–116. [Google Scholar] [CrossRef]

- Kaliyan, N.; Morey, R.V. Natural Binders and Solid Bridge Type Binding Mechanisms in Briquettes and Pellets Made from Corn Stover and Switchgrass. Bioresour. Technol. 2010, 101, 1082–1090. [Google Scholar] [CrossRef] [PubMed]

- Kaliyan, N.; Vance Morey, R. Factors Affecting Strength and Durability of Densified Biomass Products. Biomass Bioenergy 2009, 33, 337–359. [Google Scholar] [CrossRef]

- Križan, P.; Šooš, L.; Matúš, M.; Beniak, J.; Svátek, M. Research of Significant Densification Parameters Influence on Final Briquettes Quality. Wood Res. 2015, 60, 301–316. [Google Scholar]

- Skonecki, S. Modelowanie Ciśnieniowego Zagęszczania Materiałów Roślinnych; Wydaw. AR: Lublin, Poland, 2004; pp. 9–89. [Google Scholar]

- Tumuluru, J.S.; Wright, C.T.; Kenney, K.L.; Hess, J.R. A Technical Review on Biomass Processing: Densification, Preprocessing, Modeling, and Optimization. In Proceedings of the The 2010 ASABE Annual International Meeting, Pittsburgh, PA, USA, 20–23 June 2010. [Google Scholar]

- Hejft, R. Ciśnieniowa Aglomeracja Materiałów Roślinnych; Wydawnictwo i Zakład Poligrafii Instytutu Technologii Eksploatacji: Białystok, Poland, 2002. [Google Scholar]

- Križan, P. The Densification Process of Wood Waste; Capello, E., Boyd, M., Eds.; Walter de Gruyter GmbH & Co. KG: Berlin, Germany, 2015; ISBN 978-3-11-044001-0. [Google Scholar]

- Križan, P.; Matúš, M.; Šooš, J.; Beniak, J. Behavior of Beech Sawdust during Densification into a Solid Biofuel. Energies 2015, 8, 6382–6398. [Google Scholar] [CrossRef]

- Križan, P.; Svátek, M.; Matúš, M.; Beniak, J.; Lisý, M. Determination of Compacting Pressure and Pressing Temperature Impact on Biomass Briquettes Density and Their Mutual Interactions. In Proceedings of the 14th SGEM GeoConference on Energy and Clean Technologies, Albena, Bulgaria, 17–26 June 2014; pp. 133–140. [Google Scholar]

- Kulig, R.; Laskowski, J. The Effect of Preliminary Processing on Compaction Parameters of Oilseed Rape Straw. Teka Komisji Motoryzacji I Energetyki Rolnictwa 2011, 11, 209–217. [Google Scholar]

- Li, Y.; Liu, H. High-Pressure Densification of Wood Residues to Form an Upgraded Fuel. Biomass Bioenergy 2000, 19, 177–186. [Google Scholar] [CrossRef]

- Rhén, C.; Gref, R.; Sjöström, M.; Wästerlund, I. Effects of Raw Material Moisture Content, Densification Pressure and Temperature on Some Properties of Norway Spruce Pellets. Fuel Process. Technol. 2005, 87, 11–16. [Google Scholar] [CrossRef]

- Stelte, W.; Holm, J.; Sanadi, A.; Barsberg, S.; Ahrenfeldt, J.; Henriksen, U. Fuel Pellets from Biomass: The Importance of the Pelletizing Pressure and Its Dependency on the Processing Conditions. Fuel 2011, 90, 3285–3290. [Google Scholar] [CrossRef]

- Wrobel, M.; Mudryk, K.; Jewiarz, M.; Knapczyk, A. Impact of Raw Material Properties and Agglomeration Pressure on Selected Parmeters of Granulates Obtained from Willow and Black Locust Biomass. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018; pp. 1933–1938. [Google Scholar]

- Wróbel, M.; Jewiarz, M.; Mudryk, K.; Knapczyk, A. Influence of Raw Material Drying Temperature on the Scots Pine (Pinus Sylvestris L.) Biomass Agglomeration Process—A Preliminary Study. Energies 2020, 13, 1809. [Google Scholar] [CrossRef]

- Mudryk, K.; Fraczek, J.; Wrobel, M.; Jewiarz, M. Pressure Agglomeration Herbaceous Raw Materials Intended for Consumer Purposes. In Proceedings of the 17th International Scientific Conference Engineering for Rural Development, Jelgava, Latvia, 23–25 May 2018. [Google Scholar]

- Jewiarz, M.; Mudryk, K.; Wróbel, M.; Frączek, J.; Dziedzic, K. Parameters Affecting RDF-Based Pellet Quality. Energies 2020, 13, 910. [Google Scholar] [CrossRef]

- Rahaman, S.A.; Salam, P.A. Characterization of Cold Densified Rice Straw Briquettes and the Potential Use of Sawdust as Binder. Fuel Process. Technol. 2017, 158, 9–19. [Google Scholar] [CrossRef]

- Križan, P. Research of Factors Influencing the Quality of Wood Briquets. Acta Montan. Slovaca 2007, 12, 223–230. [Google Scholar]

- Kulig, R.; Łysiak, G.; Skonecki, S.; Kobus, Z.; Rydzak, L.; Guz, T. Określenie Zależności Między Ciśnieniem a Parametrami Zagęszczania Wybranych Roślin Energetycznych. Motrol 2014, 16, 55–58. [Google Scholar]

- Zhang, J.; Guo, Y. Physical Properties of Solid Fuel Briquettes Made from Caragana Korshinskii Kom. Powder Technol. 2014, 256, 293–299. [Google Scholar] [CrossRef]

- Demirbas, A.; Sahin-Demirbas, A. Briquetting Properties of Biomass Waste Materials. Energy Sources 2004, 26, 83–91. [Google Scholar] [CrossRef]

- Li, C.; Chen, Z.; Wang, Q. Effect of Temperature on Densification Pressure and the Unit Density in Production of Corn Straw Pellet with a Post-Heating Method. Energies 2022, 15, 842. [Google Scholar] [CrossRef]

- Orisaleye, J.I.; Jekayinfa, S.O.; Adebayo, A.O.; Ahmed, N.A.; Pecenka, R. Effect of Densification Variables on Density of Corn Cob Briquettes Produced Using a Uniaxial Compaction Biomass Briquetting Press. Energy Sources Part A Recovery Util. Environ. Eff. 2018, 40, 3019–3028. [Google Scholar] [CrossRef]

- Zvicevičius, E.; Raila, A.; Čiplienė, A.; Černiauskienė, Ž.; Kadžiulienė, Ž.; Tilvikienė, V. Effects of Moisture and Pressure on Densification Process of Raw Material from Artemisia Dubia Wall. Renew. Energy 2018, 119, 185–192. [Google Scholar] [CrossRef]

- Granado, M.P.P.; Suhogusoff, Y.V.M.; Santos, L.R.O.; Yamaji, F.M.; De Conti, A.C. Effects of Pressure Densification on Strength and Properties of Cassava Waste Briquettes. Renew. Energy 2021, 167, 306–312. [Google Scholar] [CrossRef]

- Wongsiriamnuay, T.; Tippayawong, N. Effect of Densification Parameters on the Properties of Maize Residue Pellets. Biosyst. Eng. 2015, 139, 111–120. [Google Scholar] [CrossRef]

- Ismail, R.I.; Khor, C.Y.; Mohamed, A.R. Pelletization Temperature and Pressure Effects on the Mechanical Properties of Khaya Senegalensis Biomass Energy Pellets. Sustainability 2023, 15, 7501. [Google Scholar] [CrossRef]

- Samuelsson, R.; Larsson, S.H.; Tyhrel, M.; Lestander, T.A. Moisture Content and Storage Time Influence the Binding Mechanisms in Biofuel Wood Pellets. Appl. Energy 2012, 99, 109–115. [Google Scholar] [CrossRef]

- Mani, S.; Tabil, L.G.; Sokhansanj, S. An Overview of Compaction of Biomass Grinds. Powder Handl. Process. 2003, 15, 160–168. [Google Scholar]

- Skonecki, S.; Kulig, R. Wpływ Wilgotności Biomasy Roślinnej i Nacisku Tłoka Na Parametry Brykietowania i Wytrzymałość Aglomeratu. Autobusy Tech. Eksploat. Syst. Transp. 2011, 10, 375–386. [Google Scholar]

- Sokhansanj, S.; Mani, S.; Bi, X.; Zaini, P.; Tabil, L. Binderless Pelletization of Biomass. In Proceedings of the 2005 ASAE Annual Meeting, Tampa, FL, USA, 17–20 July 2005; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2005. [Google Scholar]

- Styks, J.; Wróbel, M.; Frączek, J.; Knapczyk, A. Effect of Compaction Pressure and Moisture Content on Quality Parameters of Perennial Biomass Pellets. Energies 2020, 13, 1859. [Google Scholar] [CrossRef]

- Shaw, M.D.; Tabil, L.G. Compression and Relaxation Characteristics of Selected Biomassgrinds. In Proceedings of the 2007 ASAE Annual Meeting, Minneapolis, MN, USA, 17–20 June 2007; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2007. [Google Scholar]

- Laloon, K.; Junsiri, C.; Sanchumpu, P.; Ansuree, P. Factors Affecting the Biomass Pellet Using Industrial Eucalyptus Bark Residue. Biomass Convers. Biorefin. 2024, 14, 10101–10113. [Google Scholar] [CrossRef]

- Tumuluru, J.S. High-moisture Pelleting of Corn Stover Using Pilot- and Commercial-scale Systems: Impact of Moisture Content, L/D Ratio and Hammer Mill Screen Size on Pellet Quality and Energy Consumption. Biofuels Bioprod. Biorefining 2023, 17, 1156–1173. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Fillerup, E. Briquetting Characteristics of Woody and Herbaceous Biomass Blends: Impact on Physical Properties, Chemical Composition, and Calorific Value. Biofuels Bioprod. Biorefining 2020, 14, 1105–1124. [Google Scholar] [CrossRef]

- Bhattacharya, S.C.; Sivasakthy, S.; Shrestha, R.M. State of the Art for Biomass Densification. Energy Sources 1989, 11, 161–182. [Google Scholar] [CrossRef]

- Zabava, B.-S.; Voicu, G.; Dinca, M.-N.; Ungureanu, N.; Ferdes, M. Durability of Pellets Obtained from Energy Plants: Review. Eng. Rural Dev. 2018, 23, 1838–1843. [Google Scholar]

- Carone, M.T.; Pantaleo, A.; Pellerano, A. Influence of Process Parameters and Biomass Characteristics on the Durability of Pellets from the Pruning Residues of Olea europaea L. Biomass Bioenergy 2011, 35, 402–410. [Google Scholar] [CrossRef]

- Todaro, L.; Rita, A.; Cetera, P.; D’Auria, M. Thermal Treatment Modifies the Calorific Value and Ash Content in Some Wood Species. Fuel 2015, 140, 1–3. [Google Scholar] [CrossRef]

- Hall, G.E.; Hall, C.W. Heated-Die Wafer Formation of Alfalfa and Bermudagrass. Trans. ASAE 1968, 11, 0578–0581. [Google Scholar] [CrossRef]

- Smith, I.E.; Probert, S.D.; Stokes, R.E.; Hansford, R.J. The Briquetting of Wheat Straw. J. Agric. Eng. Res. 1977, 22, 105–111. [Google Scholar] [CrossRef]

- Tabil, L. Binding and Pelleting Characteristics of Alfalfa. Doctoral Dissertation, University of Saskatchewan, Saskatoon, SK, Canada, 2022. [Google Scholar]

- Kaliyan, N.; Morey, R.V. Densification Characteristics of Corn Stover and Switchgrass. Trans. ASABE 2009, 52, 907–920. [Google Scholar] [CrossRef]

- Kulig, R.; Skonecki, S.; Łysiak, G.; Laskowski, J.; Rudy, S.; Krzykowski, A.; Nadulski, R. The Effect of Pressure on the Compaction Parameters of Oakwood Sawdust Enhanced with a Binder. Teka Komisji Motoryzacji i Energetyki Rolnictwa 2013, 13, 83–88. [Google Scholar]

- Lautenschläger, K.H.; Schröter, W.; Wanninger, A. Nowoczesne Kompendium Chemii; Wydawnictwo Naukowe PWN: Warszawa, Poland, 2007. [Google Scholar]

- Malinowski, E. Anatomia Roślin; PWN: Warszawa, Poland, 1966. [Google Scholar]

- Szweykowska, A.; Szweykowski, J. Słownik Botaniczny, 2nd ed.; Wiedza Powszechna: Warszawa, Poland, 2003. [Google Scholar]

- Gageanu, I.; Cujbescu, D.; Persu, C.; Tudor, P.; Cardei, P.; Matache, M.; Vladut, V.; Biris, S.; Voicea, I.; Ungureanu, N. Influence of Input and Control Parameters on the Process of Pelleting Powdered Biomass. Energies 2021, 14, 4104. [Google Scholar] [CrossRef]

- Taulbee, D.; Patil, D.P.; Honaker, R.Q.; Parekh, B.K. Briquetting of Coal Fines and Sawdust Part I: Binder and Briquetting-Parameters Evaluations. Int. J. Coal Prep. Util. 2009, 29, 1–22. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Sokhansanj, S.; Lim, C.J.; Bi, T.; Lau, A.; Melin, S.; Sowlati, T.; Oveisi, E. Quality of Wood Pellets Produced in British Columbia for Export. Appl. Eng. Agric. 2010, 26, 1013–1020. [Google Scholar] [CrossRef]

- Tumuluru, J.S.; Wright, C.T.; Hess, J.R.; Kenney, K.L. A Review of Biomass Densification Systems to Develop Uniform Feedstock Commodities for Bioenergy Application. Biofuels Bioprod. Biorefining 2011, 5, 683–707. [Google Scholar] [CrossRef]

- Kirsten, C.; Lenz, V.; Schröder, H.-W.; Repke, J.-U. Hay Pellets—The Influence of Particle Size Reduction on Their Physical–Mechanical Quality and Energy Demand during Production. Fuel Process. Technol. 2016, 148, 163–174. [Google Scholar] [CrossRef]