Predictive Maintenance of Proton-Exchange-Membrane Fuel Cells for Transportation Applications

Abstract

1. Introduction

2. PEMFC HI Estimation for Transportation Applications

2.1. Data Processing

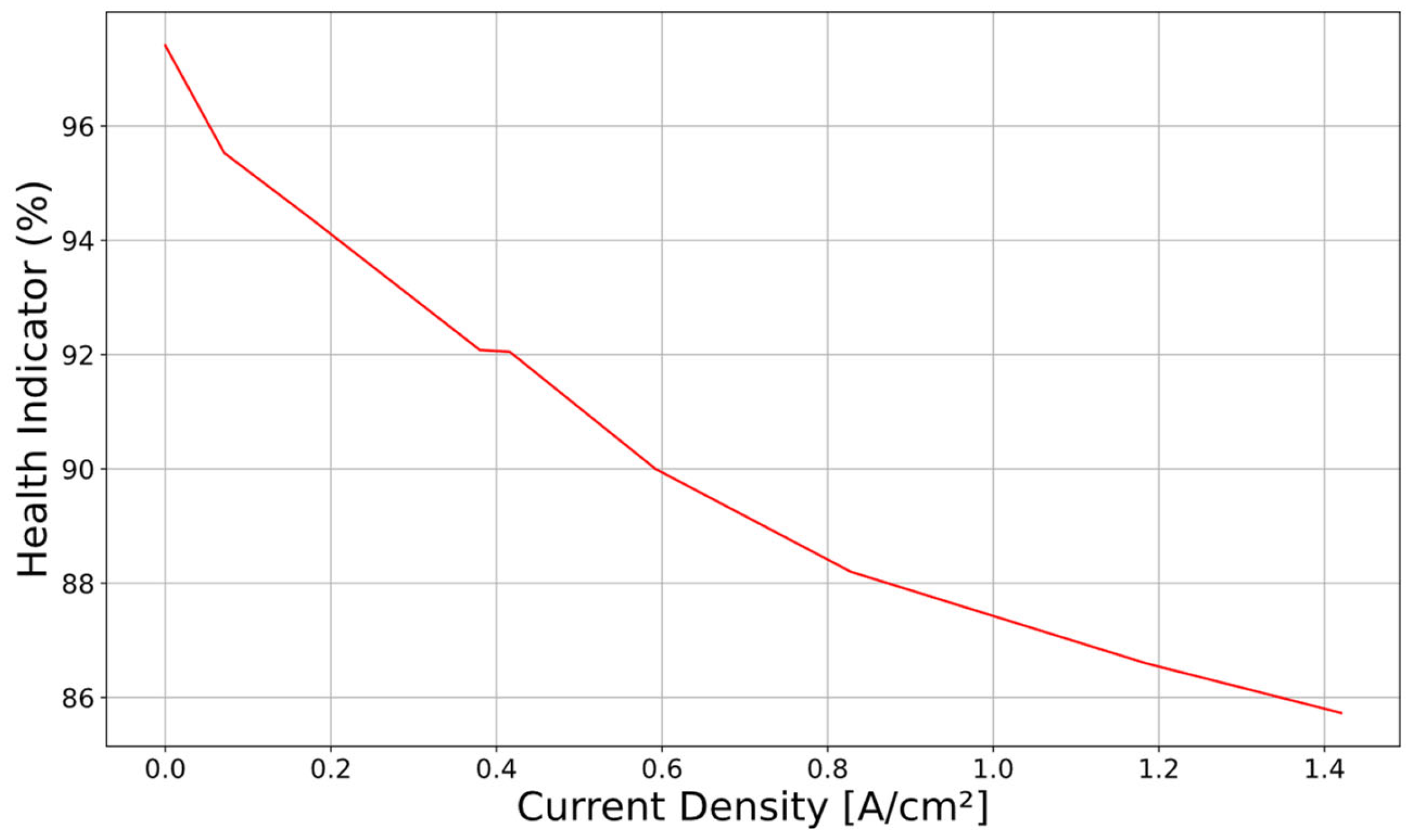

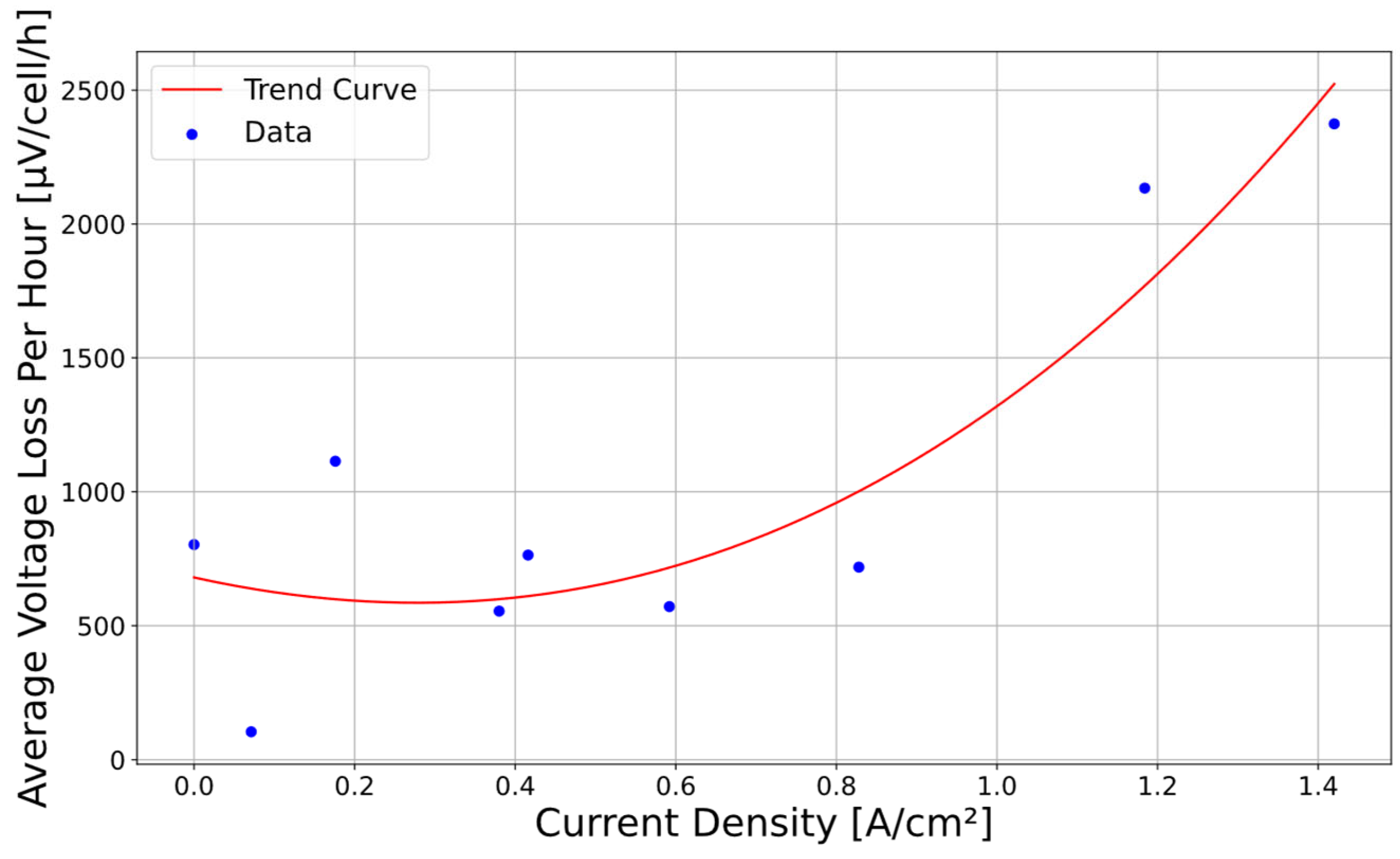

2.2. Diagnostic Results

- Over time, the voltage decreases more rapidly at high current densities due to the accelerated degradation of PEMFC components such as the electrode, gas diffusion layer, bipolar plates and membrane.

- At a high current density, water production at the cathode is greater, resulting in poor water management and thus affecting the durability of the PEMFC.

- A high current density can cause mechanical stresses on the membrane as a result of the increased flow rate required to deliver the desired current density, thus accelerating PEMFC degradation.

- A high current density can accelerate corrosion of the carbon in the electrodes, thus speeding up degradation of the PEMFC.

- A high current density can promote the formation of free radicals, which attack the membrane, accelerating PEMFC degradation.

- Assumption 1: The highest current density will be used to calculate the system’s overall SOH, because we obtain the lowest SOH for this current point.

- Assumption 2: The operating time per current density point does not alter the fact that the highest current density point induces the lowest HI.

3. PEMFC RUL Prediction for Transportation Applications

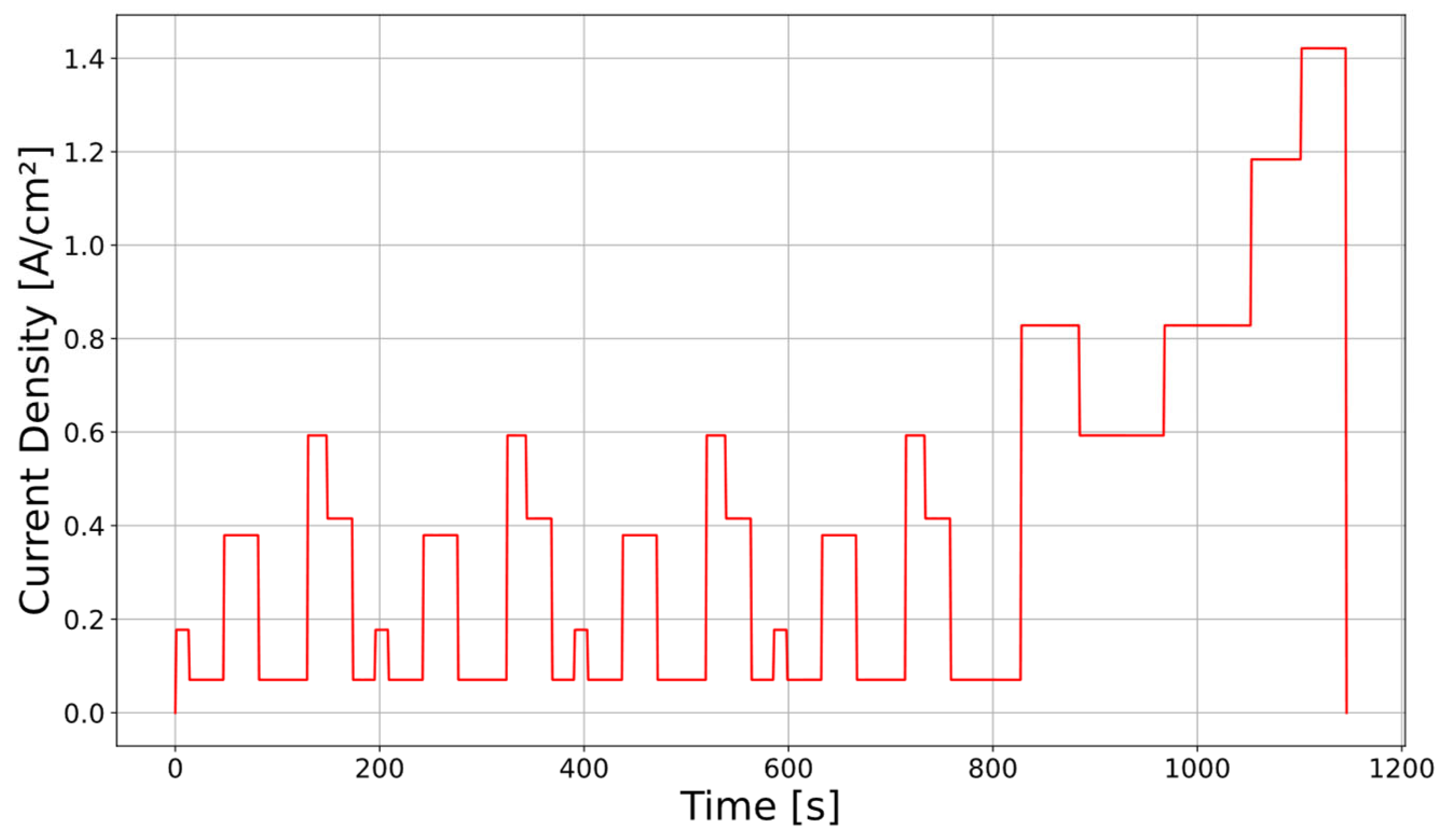

3.1. Data Processing and Algorithm Choice

- We extracted the fuel cell voltage for the highest current density point, in this case, 1.42 A/cm2 As demonstrated, it was necessary to recover only the voltage for the highest current density to obtain the overall SOH of the PEMFC. This voltage was used to predict the overall RUL.

- We extracted the overall fuel cell operating time. It was necessary to extract the overall operating time because the system operates dynamically over several current density points. If only the operating time for the maximum current density had been extracted, then it would have been impossible to find the system’s true RUL.

- We eliminated outliers using a logic filter. These outliers are generally due to measurement errors or system shutdown/breakdown, either because of a technical problem or to carry out characterization such as a polarization curve or an electrochemical impedance spectrum.

- We reduced the number of redundant data to significantly improve the computation time of the prediction algorithm. To achieve this, the raw voltage data were divided into n clusters. Then, for each cluster, the average was calculated. The n averages were then linked to create a new vector, which was considered the original data vector, named “Original Data” in Figure 4.

- We smoothed the data using the Savitzky–Golay filter to eliminate measurement noise and smooth the performance recovery phenomena. This filtering allowed us to recover the overall trend rather than local variations, which are of no interest when predicting the RUL.

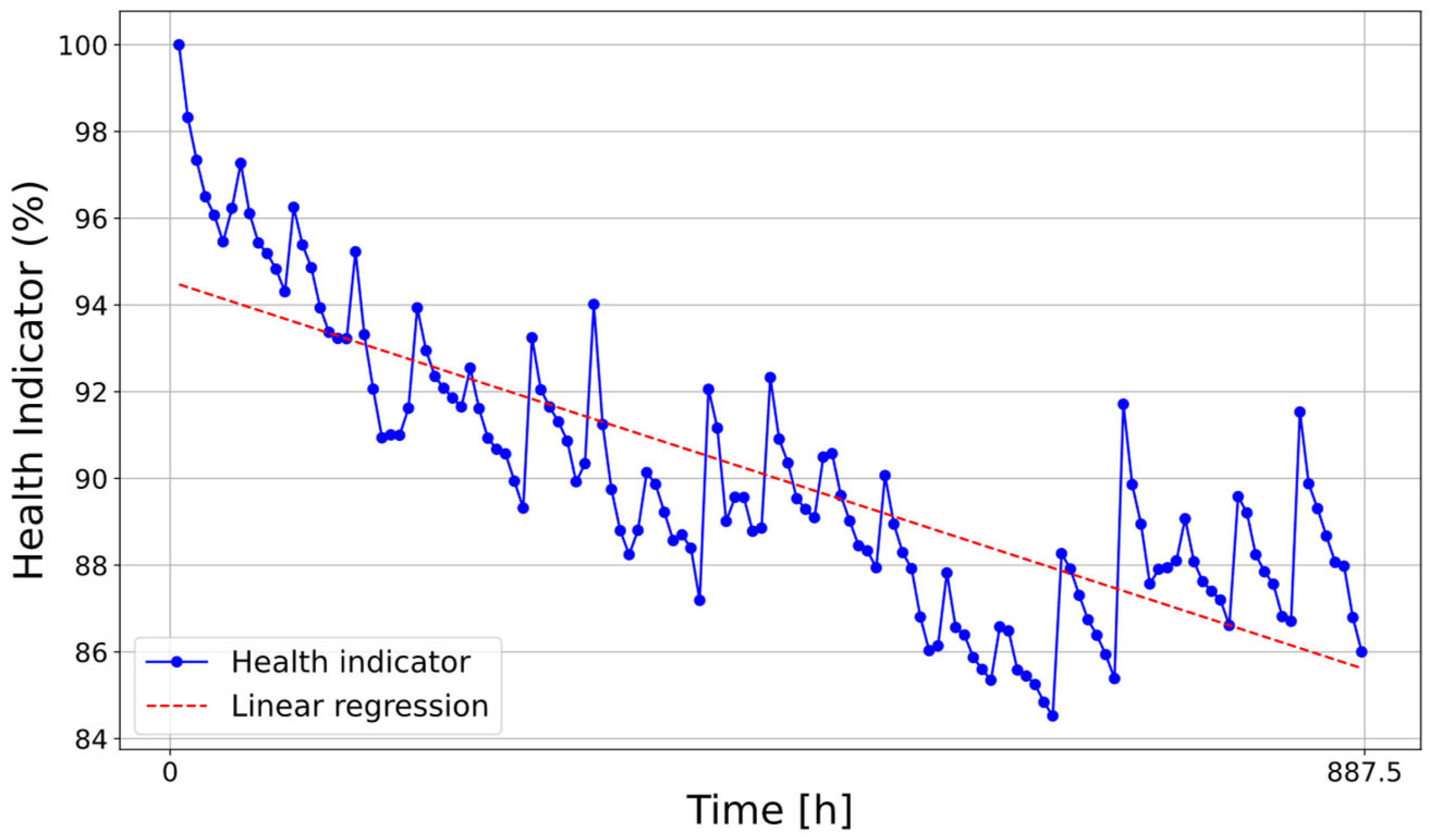

3.2. Prognostic Results

- It uses always-available measurements (voltage, current and time).

- It has a fast computation time, so predictions can be rerun to ensure quality, and online re-training can also be carried out.

- It allows the automatic optimization of setting parameters.

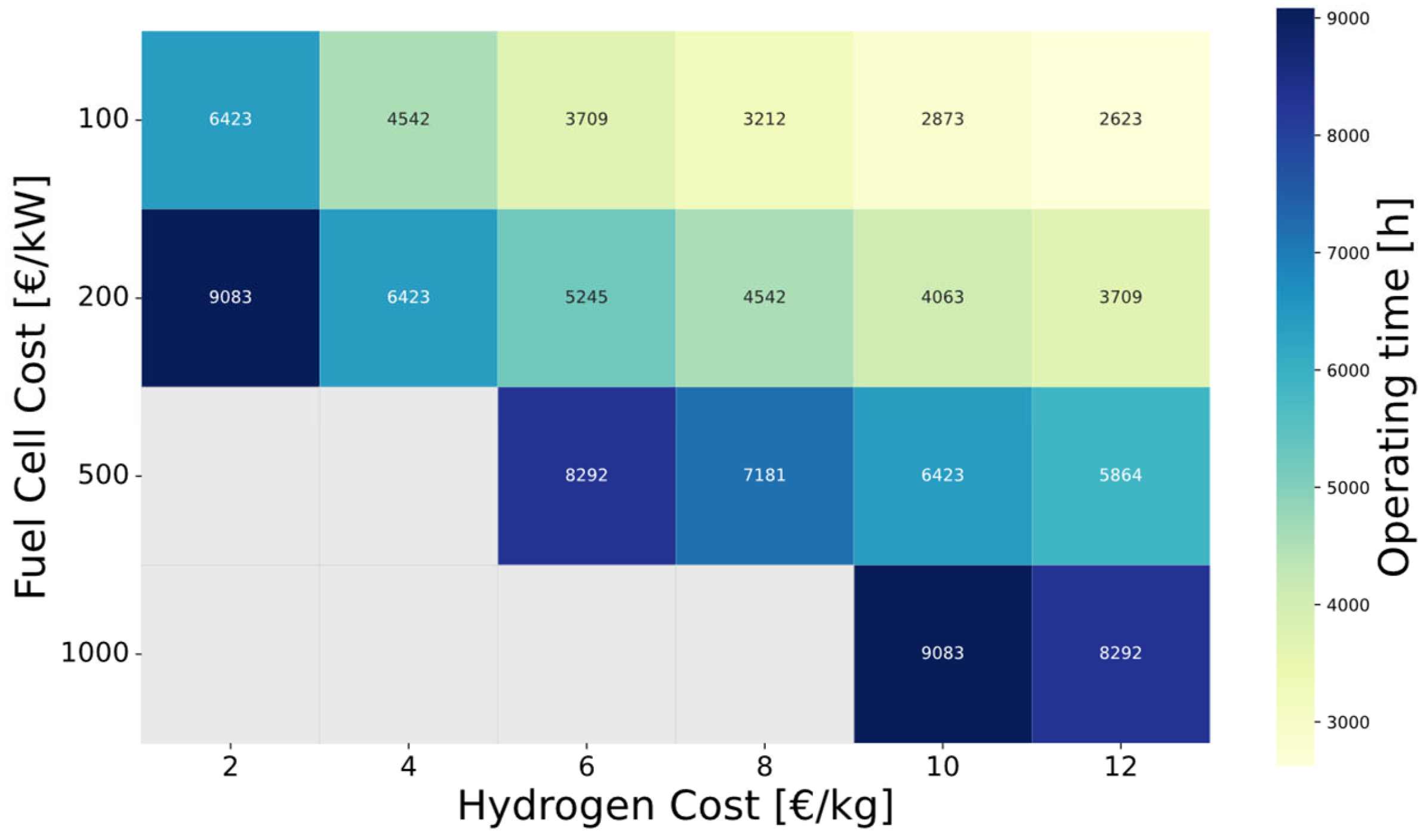

4. PEMFC Maintenance Scheduling Optimization

4.1. Methodology and Assumptions

- PEMFC power [W].

- PEMFC HI [%].

- PEMFC operating time [h].

- Hydrogen consumed by the PEMFC [kg/h].

- PEMFC cost [EUR/kW].

- Hydrogen cost [EUR/kg].

- HI is assumed to decrease linearly over time. This assumption is consistent with Figure 5.

- The EoL is declared when the PEMFC has lost 20% of its performance versus the beginning of life (heavy-duty vehicle application) after 10,000 h of operation.

- Calculation of reference hydrogen flow (without aging) using Equation (6).

- Calculation of actual hydrogen flow rate as a function of SOH (with aging):

- Calculation of additional hydrogen costs:

- Calculation of cumulative additional hydrogen costs:

- If the cumulative extra cost exceeds the price of a new PEMFC, the time from which this occurred will be displayed in Figure 6. This date tells us that it is economically worthwhile, or even necessary, to replace the degraded PEMFC with a new one. On the other hand, if this has not occurred, no value will be displayed.

4.2. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, J.; Zhou, D.; Lyu, C.; Lu, C. A Novel Health Indicator for PEMFC State of Health Estimation and Remaining Useful Life Prediction. Int. J. Hydrogen Energy 2017, 42, 20230–20238. [Google Scholar] [CrossRef]

- Gibey, G.; Pahon, E.; Zerhouni, N.; Hissel, D. Diagnostic and Prognostic for Prescriptive Maintenance and Control of PEMFC Systems in an Industrial Framework. J. Power Sources 2024, 613, 234864. [Google Scholar] [CrossRef]

- Chanal, D.; Steiner, N.Y.; Chamagne, D.; Pera, M.-C. Voltage Prognosis of PEMFC Estimated Using Multi-Reservoir Bidirectional Echo State Network. In Proceedings of the 2022 10th International Conference on Systems and Control (ICSC), Marseille, France, 23–25 November 2022; pp. 352–359. [Google Scholar]

- Chen, K.; Liu, K.; Zhou, Y.; Li, Y.; Wu, G.; Gao, G.; Wang, H.; Laghrouche, S.; Djerdir, A. State of Health Prognosis for Polymer Electrolyte Membrane Fuel Cell Based on Principal Component Analysis and Gaussian Process Regression. Int. J. Hydrogen Energy 2025, 98, 933–943. [Google Scholar] [CrossRef]

- Zhang, M.; Amiri, A.; Xu, Y.; Bastin, L.; Clark, T. Self-Adaptive Digital Twin of Fuel Cell for Remaining Useful Lifetime Prediction. Int. J. Hydrogen Energy 2024, 89, 634–647. [Google Scholar] [CrossRef]

- Chen, L.; Yang, J.; Wu, X.; Deng, P.; Xu, X.; Peng, Y. Remaining Useful Life Prediction of PEMFCs Based on Mode Decomposition and Hybrid Method under Real-World Traffic Conditions. Energy 2025, 314, 134279. [Google Scholar] [CrossRef]

- Zuo, J.; Lv, H.; Zhou, D.; Xue, Q.; Jin, L.; Zhou, W.; Yang, D.; Zhang, C. Deep Learning Based Prognostic Framework towards Proton Exchange Membrane Fuel Cell for Automotive Application. Appl. Energy 2021, 281, 115937. [Google Scholar] [CrossRef]

- Morizet, N.; Desforges, P.; Geissler, C.; Pahon, E.; Jemei, S.; Hissel, D. An Adaptative Approach for Estimating the Remaining Useful Life of a Heavy-Duty Fuel Cell Vehicle. J. Power Sources 2024, 597, 234152. [Google Scholar] [CrossRef]

- Tamilarasan, S.; Wang, C.-K.; Shih, Y.-C.; Kuan, Y.-D. Generative Adversarial Networks for Stack Voltage Degradation and RUL Estimation in PEMFCs under Static and Dynamic Loads. Int. J. Hydrogen Energy 2024, 89, 66–83. [Google Scholar] [CrossRef]

- Zhu, W.; Li, Y.; Xu, Y.; Zhang, L.; Guo, B.; Xiong, R.; Xie, C. Interval Prediction of Fuel Cell Degradation Based on Voltage Signal Frequency Characteristics with TimesNet-GPR under Dynamic Conditions. J. Clean. Prod. 2025, 486, 144503. [Google Scholar] [CrossRef]

- Dirkes, S.; Leidig, J.; Fisch, P.; Pischinger, S. Prescriptive Lifetime Management for PEM Fuel Cell Systems in Transportation Applications, Part I: State of the Art and Conceptual Design. Energy Convers. Manag. 2023, 277, 116598. [Google Scholar] [CrossRef]

- Dirkes, S.; Leidig, J.; Fisch, P.; Pischinger, S. Prescriptive Lifetime Management for PEM Fuel Cell Systems in Transportation Applications, Part II: On-Board Operando Feature Extraction, Condition Assessment and Lifetime Prediction. Energy Convers. Manag. 2023, 283, 116943. [Google Scholar] [CrossRef]

- Vignesh, S.; Che, H.S.; Selvaraj, J.; Tey, K.S.; Lee, J.W.; Shareef, H.; Errouissi, R. State of Health (SoH) Estimation Methods for Second Life Lithium-Ion Battery—Review and Challenges. Appl. Energy 2024, 369, 123542. [Google Scholar] [CrossRef]

- Zuo, J.; Lv, H.; Zhou, D.; Xue, Q.; Jin, L.; Zhou, W.; Yang, D.; Zhang, C. Long-Term Dynamic Durability Test Datasets for Single Proton Exchange Membrane Fuel Cell. Data Brief 2021, 35, 106775. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Li, T.; Tang, Q.; Wang, Y.; Su, Y.; Gou, J.; Zhang, Q.; Du, X.; Yuan, C.; Li, B. The Life Prediction of PEMFC Based on Group Method of Data Handling with Savitzky–Golay Smoothing. Energy Rep. 2022, 8, 565–573. [Google Scholar] [CrossRef]

- Chen, K.; Laghrouche, S.; Djerdir, A. Fuel Cell Health Prognosis Using Unscented Kalman Filter: Postal Fuel Cell Electric Vehicles Case Study. Int. J. Hydrogen Energy 2019, 44, 1930–1939. [Google Scholar] [CrossRef]

- Hua, Z.; Zheng, Z.; Pahon, E.; Péra, M.-C.; Gao, F. Remaining Useful Life Prediction of PEMFC Systems under Dynamic Operating Conditions. Energy Convers. Manag. 2021, 231, 113825. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, H.; Zhang, T. Review on System Mitigation Strategies for Start-Stop Degradation of Automotive Proton Exchange Membrane Fuel Cell. Appl. Energy 2022, 327, 120058. [Google Scholar] [CrossRef]

- Pahon, E.; Jemei, S.; Chabriat, J.-P.; Hissel, D. Impact of the Temperature on Calendar Aging of an Open Cathode Fuel Cell Stack. J. Power Sources 2021, 488, 229436. [Google Scholar] [CrossRef]

- Alink, R.; Gerteisen, D.; Oszcipok, M. Degradation Effects in Polymer Electrolyte Membrane Fuel Cell Stacks by Sub-Zero Operation—An in Situ and Ex Situ Analysis. J. Power Sources 2008, 182, 175–187. [Google Scholar] [CrossRef]

- Li, C.; Lin, W.; Wu, H.; Li, Y.; Zhu, W.; Xie, C.; Gooi, H.B.; Zhao, B.; Zhang, L. Performance Degradation Decomposition-Ensemble Prediction of PEMFC Using CEEMDAN and Dual Data-Driven Model. Renew. Energy 2023, 215, 118913. [Google Scholar] [CrossRef]

- Rou, P.; Wang, X.; Wang, L.; Jia, L. Model-Based Remaining Useful Life Prediction of PEMFC Using EMD and ARIMA. In Proceedings of the 2024 China Automation Congress (CAC), Qingdao, China, 1–3 November 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 4932–4937. [Google Scholar]

- Gaddam, S.; Reddy, P.S.; Joshi, S.V. Modeling and Performance Analysis of PEM Fuel Cells Using Machine Learning Techniques. In Proceedings of the 2025 International Conference on Intelligent and Innovative Technologies in Computing, Electrical and Electronics (IITCEE), Bangalore, India, 16 January 2025; IEEE: Piscataway, NJ, USA, 2025; pp. 1–6. [Google Scholar]

- María Villarreal Vives, A.; Wang, R.; Roy, S.; Smallbone, A. Techno-Economic Analysis of Large-Scale Green Hydrogen Production and Storage. Appl. Energy 2023, 346, 121333. [Google Scholar] [CrossRef]

- Curcio, E. Techno-Economic Analysis of Hydrogen Production: Costs, Policies, and Scalability in the Transition to Net-Zero. Int. J. Hydrogen Energy 2025, 128, 473–487. [Google Scholar] [CrossRef]

- Gül, M.; Akyüz, E. Techno-Economic Viability and Future Price Projections of Photovoltaic-Powered Green Hydrogen Production in Strategic Regions of Turkey. J. Clean. Prod. 2023, 430, 139627. [Google Scholar] [CrossRef]

- Cigolotti, V.; Genovese, M.; Fragiacomo, P. Comprehensive Review on Fuel Cell Technology for Stationary Applications as Sustainable and Efficient Poly-Generation Energy Systems. Energies 2021, 14, 4963. [Google Scholar] [CrossRef]

- Whiston, M.M.; Azevedo, I.L.; Litster, S.; Whitefoot, K.S.; Samaras, C.; Whitacre, J.F. Expert Assessments of the Cost and Expected Future Performance of Proton Exchange Membrane Fuel Cells for Vehicles. Proc. Natl. Acad. Sci. USA 2019, 116, 4899–4904. [Google Scholar] [CrossRef]

| Reference | Approach Type | Approach Purpose | Dynamic Load Profile? |

|---|---|---|---|

| Gibey et al. [2] | Data-driven | RUL prediction | No |

| Chanal et al. [3] | Data-driven | RUL prediction | No |

| K. Chen et al. [4] | Data-driven | RUL prediction | No |

| Zhang et al. [5] | Data-driven | RUL prediction | No |

| L. Chen et al. [6] | Hybrid | RUL prediction | No |

| Zuo et al. [7] | Data-driven | RUL prediction | Yes |

| Morizet et al. [8] | Data-driven | RUL prediction | Yes |

| Tamilarasan et al. [9] | Data-driven | RUL prediction | Yes |

| Zhu et al. [10] | Data-driven | Degradation prediction | Yes |

| Current [A] | Current Density [A/cm²] | Operating Time [h] | Initial Voltage [V] | Final Voltage [V] | HI [%] | Voltage Drop [%] | Average Voltage Loss [µV/cell/h] |

|---|---|---|---|---|---|---|---|

| 0 | 0 | 29.9 | 0.943 | 0.919 | 97.45 | 2.55 | 802.68 |

| 1.78 | 0.0712 | 373.7 | 0.877 | 0.838 | 95.56 | 4.44 | 104.36 |

| 4.4 | 0.176 | 42.2 | 0.830 | 0.783 | 94.34 | 5.66 | 1113.74 |

| 9.5 | 0.38 | 111.8 | 0.783 | 0.721 | 92.08 | 7.92 | 554.56 |

| 10.4 | 0.416 | 81.2 | 0.780 | 0.718 | 92.05 | 7.95 | 763.55 |

| 14.8 | 0.592 | 129.5 | 0.746 | 0.672 | 90.08 | 9.92 | 571.43 |

| 20.7 | 0.828 | 115.5 | 0.706 | 0.623 | 88.24 | 11.76 | 718.61 |

| 29.6 | 1.184 | 40.3 | 0.640 | 0.554 | 86.56 | 13.44 | 2134 |

| 35.5 | 1.42 | 35.8 | 0.596 | 0.511 | 85.74 | 14.26 | 2374.3 |

| ARIMA (10%) | ARIMA (20%) | |

|---|---|---|

| Setting parameters | Automatic optimization of polynomial orders Order found by automatic optimization: (0, 2, 3) | Automatic optimization of polynomial orders Order found by automatic optimization: (2, 2, 3) |

| Prediction horizon | 372 h | 223 h |

| Computation time | 3.8 s | 9.2 s |

| Estimated RUL | 293 h | 120 h |

| Real RUL | 305 h | Unknown |

| Error between estimated and real RUL | 12 h (0.98%) | Unknown |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gibey, G.; Pahon, E.; Zerhouni, N.; Hissel, D. Predictive Maintenance of Proton-Exchange-Membrane Fuel Cells for Transportation Applications. Energies 2025, 18, 2957. https://doi.org/10.3390/en18112957

Gibey G, Pahon E, Zerhouni N, Hissel D. Predictive Maintenance of Proton-Exchange-Membrane Fuel Cells for Transportation Applications. Energies. 2025; 18(11):2957. https://doi.org/10.3390/en18112957

Chicago/Turabian StyleGibey, Gaultier, Elodie Pahon, Noureddine Zerhouni, and Daniel Hissel. 2025. "Predictive Maintenance of Proton-Exchange-Membrane Fuel Cells for Transportation Applications" Energies 18, no. 11: 2957. https://doi.org/10.3390/en18112957

APA StyleGibey, G., Pahon, E., Zerhouni, N., & Hissel, D. (2025). Predictive Maintenance of Proton-Exchange-Membrane Fuel Cells for Transportation Applications. Energies, 18(11), 2957. https://doi.org/10.3390/en18112957