Abstract

The twin-screw compressor exhibits significant application value in the fields of energy, refrigeration, construction, transportation, and related domains. Owing to the benefits of short cycles and low costs, numerical simulation technology has attracted increasing attention. Over recent years, the numerical simulation technology for twin-screw compressors has advanced rapidly, and many important results have been achieved. This paper comprehensively discusses the modeling method of twin-screw compressors, the meshing technique, advances in numerical simulation of internal flow, the research status of numerical simulation research regarding structural operating conditions, and performance optimization. The synergistic potential between these technologies for improving the performance and efficiency of twin-screw compressors is investigated. The numerical simulation research progress of the internal flow and performance optimization of twin-screw compressors is systematically reviewed. Against the background of global energy saving and carbon reduction, this paper offers readers an in-depth understanding of the technical challenges, research hotspots, and development directions in the related field. It fills the relevant gaps within the current literature. The results highlight the role and potential of deep exploration of the intrinsic relationship between local complex flow characteristics and structural optimization for the performance optimization of twin-screw compressors. For conforming to actual conditions and pertinency, mathematical models such as multiphase flow and turbulence models should be further improved. The current research results remain constrained by the lack of comprehensive consideration of multi-field coupling. In the future development of energy-saving and environment-friendly high-performance twin-screw compressors, numerical simulation research should be developed for high precision, multi-physical field coupling, influencing mechanism research, energy-saving, and environmental friendliness, and intelligence. It establishes a theoretical foundation for further enhancing the performance and mechanism theory of twin-screw compressors.

1. Introduction

Through periodic volumetric variations, twin-screw compressors accomplish suction, compression, and exhaust processes [1]. They exhibit many advantages such as stable performance, high reliability, excellent power balance, strong adaptability, simple operation, and low maintenance costs. Twin-screw compressors serve as key basic components of high-end equipment in the fields of energy, refrigeration, construction, food, pharmacy, mining, transportation, and other fields. They demonstrate broad development prospects and huge demand. Given its energy-extensive consumption and wide application, optimizing twin-screw compressors to improve performance will contribute to overall energy use efficiency and facilitate the decarbonization process.

The multiform working medium can be used as the motive fluid of the twin-screw compressor, such as gas, dry steam, or multi-phase mixtures involving phase transition phenomena. Twin-screw compressors are categorized as dry-type and wet-type. There is no physical contact between screw rotors in the dry-type screw compressor. Therefore, it is necessary to leave enough space between the rotors to prevent the rotor’s interference. Dry-type twin-screw compressors have limited maximum pressure rise capabilities. Moreover, their operating life is significantly compromised, owing to the thermal stress and potential friction of the components. However, such compressors are widely adopted in industries that should not involve oil, such as food processing. Wet-type twin-screw compressors typically involve injected oil [2] or other fluids [3] during compression or expansion for lubrication, noise reduction, sealing, and cooling. For the most commonly used oil-injected screw compressors, oil primarily functions not only as a coolant but also a sealant to reduce the compressed gas leakage from the high-pressure cavity to the adjacent low-pressure cavity. Therefore, oil injection enhances the volume efficiency. Moreover, oil functions as a lubricant to mitigate frictional interaction between the rotors and the shell. Typically, oil is extracted from the compressed gas and then reinserted into the compressors [4]. The numerical simulation of twin-screw compressors constitutes a crucial aspect of the research on internal flow characteristics and performance optimization. The simulation results enable analyzing the distribution of the internal flow field for different structures and operating conditions in detail and predicting the compressor performance parameters accurately. Therefore, the relationship between the internal flow characteristics and the twin-screw compressor performance must be established to realize the structural parameter optimization and the compressor performance improvement. In addition, the flow loss, heat transfer loss, and leakage loss can be analyzed using simulation results to find the theoretical basis for and new methods to improve the energy efficiency of compressors. Moreover, abundant calculation and analysis may be conducted by numerical simulation methods within a short time without building complex and expensive experimental devices, which shortens the R&D cycle and minimizes the research cost. The main research areas on these compressors are summarized in Table 1.

Table 1.

Main research areas of twin-screw compressors.

Current review articles on the numerical simulation of screw compressors mainly concentrate on single-screw compressors [8,9,10]. However, the review articles on twin-screw compressors only focus on their experimental research progress [11] and the similarities and differences with single-screw compressors [4]. There is a lack of review articles addressing the latest developments for both the internal flow fields and performance optimization research of twin-screw compressors. Accordingly, in this paper, advances in the modeling methods, meshing technologies, and numerical simulations of internal flow, structural operating condition optimization, and twin-screw compressor performance improvement are emphatically introduced. The synergistic potentiality, shortcomings, and future research directions of these technologies in improving the performance and efficiency of twin-screw compressors are discussed. These unique perspectives clearly offer researchers insights into prevailing research priorities, progress, and shortcomings in the numerical simulation of twin-screw compressors and fill a significant gap in the current relevant literature against the background of global energy-saving and carbon reduction.

2. Advances in Modeling Twin-Screw Compressors

2.1. Physical Models of Twin-Screw Compressors

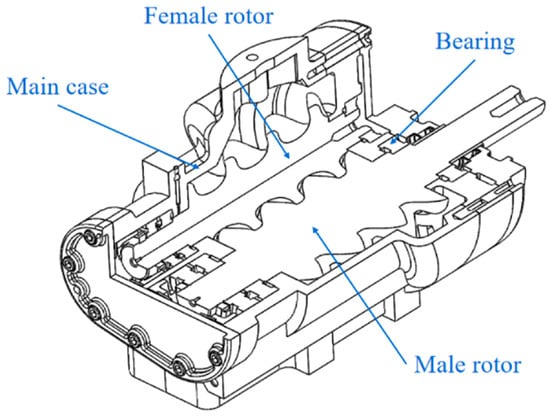

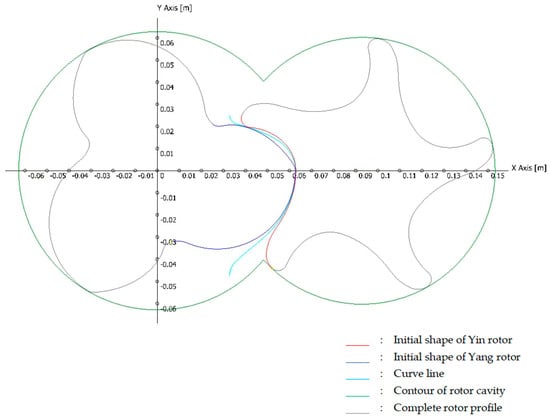

Twin-screw compressors belong to volumetric rotary machines comprising two helical rotors that intermesh and rotate inside a stationary and fully enclosed shell, as shown in Figure 1. The main shape profile of screw compressors is composed of symmetrical circular arc lines and asymmetric shape lines, as shown in Figure 2 [11]. Three textbooks cover the profile topic well. Sakun [12] gave full details of the generation of circular and elliptic profiles, as well as a Russian asymmetric profile named SKBK. Amosov et al. [13] was the first to demonstrate how to generate the SRM’s unsymmetric profile. Rinder [14] presented a method based on gear theory to reconstruct the SRM’s unsymmetric profile. These early textbooks were pioneers in the research and design of twin-screw compressors, laying the foundation and providing references for the industrial standards for the generation of profiles of screw compressors [15]. Tiny gaps exist between the rotors and shell to prevent mutual friction. The rotors are powered by a motor and engage in a manner similar to gears. The rotation of the rotors results in a gradual narrowing of the gap between the two rotors and the shell, causing a decrease in volume and a rise in the pressure of the gas trapped between them. Gas flows into the compressor through an inlet port located where the volume is great. Moreover, the exit port is situated where the trapped volume is minimized, thus achieving the desired pressure increase [16].

Figure 1.

Structure diagram of a twin-screw compressor [4].

Figure 2.

Schematic diagram of the rotor profiles of a twin-screw compressor.

The impact of oil, gas leakage, and gaps between the screw and the shell on compressor performance, as well as the research value of the thermodynamic process in compressor operation, should be considered. It is necessary to reserve the appropriate positions and connection modes for the relevant components in establishing physical models according to the need for leakage heat transfer, the flow of the exhaust orifice, and the mathematical model of oil and gas heat transfer.

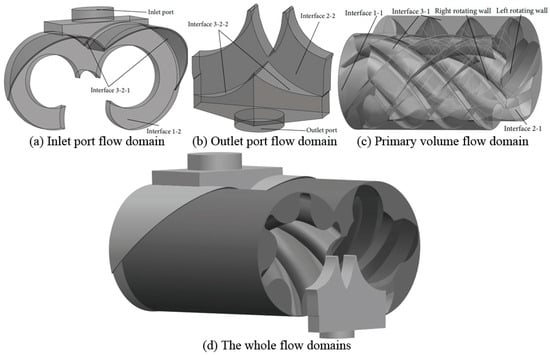

Twin-screw compressors were invented by A. Lsholm in 1934 and have been applied and developed in the industry. During the 1980s, simulating and modeling for screw compressors commenced with the initial development of computer technology. The establishment of physical models of screw compressors in this period was two-dimensional, which simplified the internal structure into two-dimensional planes [17]. The research on the rotor profiles of twin-screw compressors has also achieved certain results in this stage. The characteristics of these profiles are embedded into the modeling process to improve the accuracy of the models. Twin-screw compressor modeling technology has entered a stage of rapid development alongside the continuous improvement in computer technology and computing power after the 1970s. The 3D models of screw compressors are constructed with more and more sophisticated methods. Screw compressor modeling technology gradually matured until the 1990s, and 3D modeling technology has been widely utilized to realize the multi-physics field numerical model that has gradually become a new research hotspot. The physical models of twin-screw compressor flow fields are shown in Figure 3d, composed of the inlet port flow domain (Figure 3a), outlet port flow domain (Figure 3b), and primary volume flow domain (Figure 3c) [18]. The relevant information on common industrial software applied to the physical model establishment of twin-screw compressors is summarized in Table 2. Among them, it is worth noting that the specialization software SCORG and TwinMesh focus on mesh generation with CFD simulation optimization for complex rotor geometry. SCORG can automatically generate high-quality structured meshes through parametric methods, support a variety of rotor profiles, and accurately control the mesh density in the meshing area. It is suitable for dynamic clearance simulation and multi-condition analysis. Its advantage lies in the efficient handling of asymmetric profiles and transient flows. TwinMesh is deeply integrated with ANSYS and uses slip mesh technology to generate conformal meshes to support high-fidelity transient simulation of rotor motion. It is characterized by automatic preprocessing and boundary layer optimization, which is suitable for flow field analysis of industrial-grade injection and oil-free compressors. Both SCORG and TwinMesh can improve the simulation accuracy of key parameters such as leakage flow and pressure pulsation and provide reliable technical support for the performance optimization of screw compressors.

Figure 3.

Physical model of twin-screw compressor flow field [18].

Table 2.

Common industrial software applied to physical model building of twin-screw compressors.

2.2. Mathematical Models of Twin-Screw Compressors

The innovation and development of mathematical models reduce the R&D cycle and cost of screw compressors and improve the accuracy of simulation results fundamentally. It plays a pivotal role in developing numerical simulation studies on twin-screw compressors and has garnered sustained scholarly attention.

Regarding the selection of existing models, Rane et al. [19] found that CFD solvers have a certain impact on the simulation results. Basha et al. [2] investigated the volume of fluid (VOF) and the pseudo-single-fluid multiphase (SFM) model of mixtures. The performance of oil-injected twin-screw compressors was predicted, and the results were compared to the experimental values. They observed that compared with the VOF, the results of the SFM model demonstrated closer alignment with the experimental findings. Rane [20] considered the influence of the real gas state equation on the numerical simulations and studied the performance of the twin-screw expander with four different working fluids. He found that the simulation results of the ideal gas state equation led to significant deviations in flow rate and power compared with those of the real gas state equation. Tsao et al. [21] used CFD and TwinMesh dynamic mesh technology and studied the influence of the angle and pressure ratio on performance under the modes of twin-screw mechanical compression and expansion by using the real gas model and k-ω SST turbulence model. Furthermore, all of the existing related studies have employed the Reynolds-averaged Navier–Stokes (RANS) method to deal with turbulence. Although there are multiple RANS turbulence models to choose from, some limitations are still present in accurately simulating the complex turbulent flow inside a screw compressor. For example, the standard k-ε turbulence model is not accurate enough to simulate complex flow phenomena such as strong swirls and separated flows, resulting in certain errors in the prediction of pressure distribution, velocity distribution, and energy loss of the compressor.

Scholars are dedicated to the innovation and development of mathematical models of twin-screw compressors to improve the simulation precision. Huagen et al. [22] proposed a novel mathematical model specifically designed for twin-screw refrigeration compressors that are suitable for analyzing geometric parameters related to the rotation angle of the male rotors, such as the groove volume, slide valve bypass port area, and discharge port area. Moreover, the model considered the influence of oil injection, gas-oil heat transfer, and the refrigerant property simultaneously. Tian et al. [23] proposed a thermodynamic model for water-injected twin-screw steam compressors to investigate the influence of various operating parameters, including the injected water flow rate, rotating speed, suction pressure, and discharge pressure, on compressor performance and the optimal injected water flow rate. This research provides certain value for the modeling and operation parameters of water-injected twin-screw steam compressors. Ding et al. [24] proposed an innovative method of mixed timescale coupling to collect the conjugate heat transfer data of compressors and conduct numerical modeling. The results accurately solved the time scale differences and optimized the 3D modeling approach for twin-screw compressors. Shamanskiy and Simeon [25] proposed a numerical simulation method for the thermal expansion of twin-screw compressors based on isogeometric analysis (IGA). They modeled the rotor and the casing geometry through NURBS, generated a 3D parametric model by using cubic B-spline approximation of point cloud data, and solved the thermal expansion equations in the Galerkin method. The results showed that the radial expansion of the rotor led to the complete closure of the high-pressure end gap under the temperature gradient of 70–180 °C. Compared with traditional finite element analysis, IGA achieved consistent results with commercial software with fewer meshes. This result verified the advantages of high global smoothness NURBS in thermodynamic analysis of rotating machinery. As for multiphase flow model development, Rane et al. [26], combined with the Lee evaporation-condensation model, established an air-liquid two-phase flow model, introduced phase-specific mass and energy sources, and studied the impact of water injection on the internal temperature field and leakage in the twin-screw compressors. This evaporation model can effectively predict leakage paths and thermal deformations. Kovacevic et al. [27] proposed an inhomogeneous model of the multiphase flow model that can accurately simulate oil distribution and heat transfer. The applicability of multi-field extended models such as cavitation and solid particles needs to be extended in the future. Basha et al. [28] compared the inhomogeneous and homogeneous Eulerian multiphase models. They found that the flow error predicted by the inhomogeneous model was only 0.5%, and the temperature distribution was closer to the experiment. The homogeneous model has an error rate of 30% due to neglecting the relative slip between the phases. It has been proven that the inhomogeneous model can accurately capture the oil film sealing and cooling effects with a high calculation cost. Casari et al. [29] realized a full 3D transient CFD simulation of twin-screw compressors by coupling the open-source software SCORG+OpenFOAM. They used SCORG to generate structured dynamic meshes, developed a custom motion solver to control node interpolation, and solved the high Reynolds number k-ε model through OpenFOAM. The simulation showed that the dynamic deformation of meshes successfully captured the chamber pressure evolution at 8000 rpm and a 1.3 pressure ratio. However, the high CFL number (>1) led to non-physical pressure and temperature spikes in the gap. After limiting the CFL number (<1), the flow field distribution was consistent with the theory, and the discharge chamber pressure was significantly higher than that of the inlet. The feasibility of open-source tools in PD mechanical simulation was verified, which lays the foundation for subsequent experimental comparison and multiphase flow expansion. In their follow-up research, Casari et al. [30] developed dynamic mesh technology and real gas models to study the flow and heat transfer characteristics of single- and twin-screw machines based on the OpenFOAM open-source platform. For single-screw expanders, they proposed the “key frame remeshing” method to handle large deformations, simulate the R134a expansion process, and capture the temperature drop caused by gap flow. For twin-screw compressors, they used SCORG to generate structured meshes and combined the CoolProp library to perform non-real gas calculations. The results showed that the forecast error of the flow was less than 10%. The study validated the feasibility of OpenFOAM in complex PDM simulations, and the single-screw geometry model was open-sourced for verification. Ulrich et al. [31] developed a quasi-one-dimensional model by utilizing Modelica’s language to apply liquid-injected screw compressors for oil-gas separation in high-temperature heat pumps. The working process of an oil-free liquid-injected twin-screw compressor was simulated by this model. This model considers factors such as liquid injection flows, injection positions, leakages, and heat losses. Kaufmann et al. [32] utilized an innovative low-order polynomial model for predicting the performance of twin-screw compressors. The isentropic efficiency and compressor speed can be predicted by this model based on the external pressure ratio and the compressor inlet flow rate. The calculation speed can be increased by 375 times. The high accuracy and low computational cost of this model have expanded the existing technology. Wang et al. [33] developed a one-dimensional computational model for the non-uniform pressure distribution inside twin-screw compressors to replace the traditional chamber model that assumes a uniform pressure distribution. The results showed that this model can capture the pressure fluctuations inside twin-screw compressors. Moreover, the pressure distribution plays a pivotal role in compressor design optimization and energy efficiency enhancement.

In summary, mathematical models of twin-screw compressors have been improved continuously in recent years, and assumptions about the models have evolved to be more and more realistic [34]. The applications of real-gas state equations [35], choices in turbulence models, and development of multiphase models [2,36] should be paid more attention. Target models for different application conditions have garnered increasing preference by scholars emphatically [37,38].

2.3. Application and Research Progress of Mesh Generation Technology for Twin-Screw Compressors

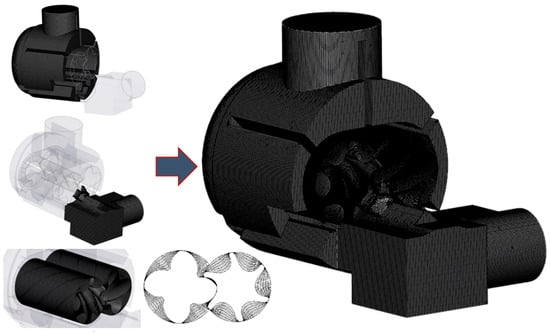

Meshing is discretizing a geometric model into a finite number of elements. An appropriate mesh type and size should be selected according to the geometry and flow characteristics of the screw compressors when establishing a mesh, which can improve the efficiency and accuracy of simulations and capture the details of fluid flow in twin-screw compressors accurately. The 3D fluid domain in the internal space of twin-screw compressors presents a complex and diverse irregular structure. The internal fluid region undergoes continuous dynamic changes during rotor rotational motion, and the rotor has complex shapes and tiny gaps. The above are all extremely demanding on the generation of high-quality mesh technology. Efficient high-quality mesh generation technology becomes imperative for the accurate prediction of mainstream flow, boundary layer flow, and gap flow, as shown in Figure 4. In addition, mesh structure can be updated in real time by dynamic mesh technology to adapt to changes in fluid domains, thus accurately simulating the dynamic working process of screw compressors.

Figure 4.

Mesh of the fluid domain of a twin-screw compressor.

SCORG [39], TwinMesh [40], Ansys (Gambit, ICEM) [41], and STAR-CCM+ [42] represent the prevailing mesh generation software for twin-screw compressors. John and Vierendeels [43] conducted a 3D numerical simulation of the flow field in the internal basin of a oil-free screw compressor and proposed a new method to address the block-structured meshing challenges. The results can be used to optimize the control of slip mesh techniques. Kovacevic A. [44] generated a new fully structured hexahedral adaptive numerical mesh for oil-free and oil-injected twin-screw compressors, which automatically and accurately adjusted the mesh density with the continuous change of the flow field. The accuracy of the simulation results of the 3D flow in screw compressors can be improved by the method when combined with CFD programs. He et al. [18] obtained the dynamic characteristics of the flow domains in a screw compressor and simulated the suction, compression, and discharge process based on the grid interface method and dynamic mesh technique with Fluent. The findings indicated that the simulated data of the pressure-volume variation in the compressor were in good agreement with the experimental data. Zhang et al. [45] designed a high-quality hexahedral grid with TwinMesh. They collected the pressure gradients on the rotor surfaces and velocity vector fields in the screw compressor model under the condition of oil-free and oil injection. The results can be used to optimize the slider design as well as understand the gap distribution of the oil. Yang et al. [39] generated the structured dynamic grids for the twin-screw computational domain using the specialized meshing software SCORG. They captured and analyzed the operational pressures across multiple critical positions, including the inner surface of the screw rotor housing, the male screw groove, and the internal suction and discharge flowing paths. Based on the structured dynamic mesh generated by SCORG software, Borriello et al. [46] used Simerics MP+ for simulations and obtained the transient flow field under different speeds and outlet pressures. The experimental data verify that this method can predict the volumetric efficiency and leakage characteristics of the pump with high precision. Kovacevic et al. [27] reviewed the application of differential grid generation in multiphase twin-screw machinery such as compressors, expanders, and pumps. The elliptic PDE smoothing of algebraic grids was used to optimize orthogonality and computational efficiency. Rane et al. [47] compared the generation methods of algebraic and differential grids and proposed a combined approach to generate high-quality single-domain rotor grids. It was applied to CFD analysis of oil injection compressors, and the predicted flow and indicated power error were less than 4%. The results showed that the user-defined node displacement method had better stability in the highly deforming domains, while the diffusion smoothing method was prone to grid distortion.

In summary, the precision of computational modeling and the simulation efficiency are largely determined by the quality of the meshes. Although the mesh generation technology of twin-screw compressors has made great progress, its quality, efficiency, and convenience should be further improved.

3. Advances in Numerical Simulation of Internal Flow of Twin-Screw Compressors

The study on the internal flow characteristics of twin-screw compressors not only provides theoretical references and inspirations for the development of fluid dynamics, mechanical engineering, and other relevant disciplines but also has important practical significance in engineering for performance improvement and meeting industrial production needs. In fluid dynamics, the complex flow phenomena in twin-screw compressors provide typical cases for researching turbulence and multiphase flow. In mechanical engineering, the traditional design methods and empirical formulas can meet the basic design requirements of twin-screw compressors to some extent. However, limitations exist in the increasingly complex working conditions and higher performance indicators. Therefore, clarifying the relationship between the internal flow field and the structure of twin-screw compressors benefits the improvement of the precision and reliability of mechanical designs.

The continuous innovation of model buildings and the rapid development of various examples of numerical simulation software have provided increasingly perfect conditions for studying the internal flow of twin-screw compressors in recent years. The internal flow field in compressors can be visually obtained through numerical simulation. It reveals the change regulation of the physical quantities in the flow process to establish theoretical foundations for optimizing the structural design and operational parameters of compressors. Screw compressor laser Doppler and PIV anemometry started with works of Gerrato and Nouri [48]. Compared with the experimental method, the numerical simulation technology enables real-time observation of complex flow phenomena such as vortex and separation, which are difficult to observe accurately in twin-screw compressors, locally describe the distribution of their speed, pressure, temperature, and other conditions and make quantitative analysis of the micro-process under the action of complex factors in detail, thus providing a theoretical basis for studying their physical nature and optimizing the design.

Kovacevic et al. [1] presented the results of the methods of three-dimensional modeling of the fluid dynamics and the solid–fluid interaction within screw compressors in 2007. This book is the first ever publication on screw compressors which represents a basis of all screw compressor CFD models ever published. It includes four examples, which outline the scope of the applied mathematical model for three-dimensional calculation of fluid flow and stresses in the solid parts of a screw machine.

Twin-screw compressors experience vibration and noise disturbances due to both fluid and mechanical origins under operational conditions. Among them, the main fluid source that causes vibration and noise is the gas pulsation caused by the unstable flow through the suction and discharge ports [7]. A study on the internal flow characteristics of twin-screw compressors can solve the problem of the fluid source to find a new method of structural optimization. With the in-depth numerical simulation study of the internal flow of twin-screw compressors, the internal relationship between the flow field characteristics and the structural optimization should be further explored. This helps find new ways to optimize the structural parameters and improve the performance of compressors. Shen et al. [49] simulated the flow field and sound field of a semi-hermetic variable frequency twin-screw refrigeration compressor. They proposed two methods to evaluate the effect of noise reduction: one for the end face attenuation passage and the other for discharge pipe damping. The findings indicated that the average noise attenuation level exhibited a positive correlation with the rotational speed. Wang et al. [50] obtained the discharge noise spectrum of the twin-screw compressor through numerical simulation, verified the model accuracy through experiments, and optimized the compressor exhaust end structure. The results indicated significant pressure pulsation in the discharge orifice, which reduced the intensity in the discharge cavity. The displacement of the discharge flow passageway and the opening of the radial discharge orifice are advantageous to the entire compressor and can minimize the loss of pressure considerably. Wu et al. [51] simulated the intermittent gas flow generating pressure oscillations in the twin-screw refrigeration compressor, which causes structural vibration and noise. The results showed that the vibration acceleration was reduced by 36.2~41.1% after a pressure pulsation dampener (PPD) was applied in the discharge chamber.

In a study on the pressure field of a twin-screw compressor, Braga et al. [52] compared the effects of three discharge systems, such as a constant-diameter tube and venturi tube, on pressure pulsation and performance in twin-screw compressors by combining ANSYS CFX with TwinMesh dynamic mesh technology. They used non-reflective boundary conditions to suppress outlet fluctuations and analyzed the pressure-angle (P-α) curves and frequency domain characteristics under different configurations. The study found that the venturi tube experienced an increase in exhaust pressure peaks due to the leakage rate, but the average pressure remained consistent with the set value. An increase in the reflection factor aggravated the pressure oscillation, which verifies the necessity of non-reflection conditions. The results showed that the internal pressure of the emission system design has a limited effect, but geometric optimization can reduce the fluctuation amplitude. Borriello et al. [46] simulated and obtained the transient flow field under different speeds. The results indicate that the pressure increased uniformly along the screw shaft, the speed had little influence on the pressure field, and the gap leakage was mainly driven by the pressure difference. Sun et al. [53] employed a numerical simulation methodology to investigate pressure characteristics, pressure wave propagation, and its influence on the compression efficiency of twin-screw refrigeration compressors under different working conditions. Moreover, they simultaneously compared the p-θ maps for different rotational speeds and working fluids. They found that the SESPL originates from the restricted flow passage between the working volume and suction chamber, while the CPSPR primarily arises from the inflow and outflow movement in the closed cavity of the vapor injection port. These efficiency losses can be avoided by suitably postponing the angle at which the suction ends and obstructing the vapor injection port. Wang et al. [41] simulated and analyzed the internal flow field and pressure distribution of a large twin-screw refrigeration compressor. Analysis revealed that as the rotational speed escalated, the pressure wave intensified, and the non-uniformity was more obvious. The pressure distribution was also different when different refrigerants were adopted. Postponing the suction end angle and adjusting the discharge port to optimize the compressor design and improve efficiency were suggested.

In a study on the tempreture field of a twin-screw compressor, Rane et al. [26] adopted the numerical simulation method to study the effect of water injection on the internal temperature field of a twin-screw compressor. They analyzed the effect of water evaporation on the compressor’s sealing performance and temperature distribution under different speed and humidity conditions. The results showed that the local high temperature of about 200 °C could be significantly reduced with appropriate water spraying. However excessive water spraying requires the addition of a separation system, which provides a reliable basis for optimizing the thermal management of compressor water spraying. Husak et al. [54] discussed how the temperature of the rotor and casing surfaces calculated from the one-dimensional chamber model in the SCORG could be used as a boundary condition for a steady-state thermal and structural analysis of a screw compressor’s solid parts. Deformations in the rotors and casing under temperature load were calculated using a commercial finite element analysis code (ANSYS).

For in-depth numerical simulation studies on the internal flow of twin-screw compressors, the internal relationship between the flow field characteristics and the structural optimization should be further explored. This would help find new ways to optimize the structural parameters and improve the performance of compressors.

4. Numerical Simulation Research on Performance Optimization of Twin-Screw Compressors

4.1. Structure and Performance Optimization

Due to the high requirement of structural design accuracy in twin-screw compressors, improper design not only severely limits the compressor performance but also increases the body vibration and noise level. Furthermore, problems such as wear and collision between rotors and between rotors and the body can also be caused, leading to damage to key components such as the rotors, bearings, and shaft seals. Therefore, optimization of the structure and performance of twin-screw compressors has been continuously studied by scholars. In 1993, O’Neil [55] systematically expounded the theory and technical application of industrial compressors, covering compressor design, thermodynamic and hydrodynamic bases, operating characteristics, and equipment selection. In this book, the structural characteristics and working principles of screw, centrifugal, reciprocating, and other mainstream compressors were analyzed in detail. Application optimization in industrial refrigeration, central air conditioning, and transport refrigeration was discussed, with engineering examples. In addition, the authors deeply analyzed compressor leakage path modeling and efficiency loss mechanisms and emphasized the key role of sealing technology in performance improvement, providing theoretical guidance for the design of small compressors.

The traditional research and development process for twin-screw compressors necessitates various physical prototype tests, which are costly, have long cycles, and are limited by test conditions and measurement methods. Different structural solutions in the design phase can be quickly evaluated and optimized using numerical simulation methods, minimizing the number and cost of physical prototype tests, expediting R&D cycles, anticipating potential problems, and facilitating technological innovation and development.

The important index for evaluating twin-screw compressor performance is volume efficiency. Leakage is the most important factor affecting the volume efficiency of rotary compressors [56]. These leakage paths are preserved in the design due to the need for working gaps, or they are determined by the geometric characteristics of the machine itself [57]. It is necessary to leave a certain gap between the rotors, the rotors and the body, and the rotor’s end face and the seat at the suction and exhaust ends. Excessive gaps can cause the leakage of high-temperature and high-pressure gas to increase, increasing the overall compressor temperature and decreasing volume efficiency and adiabatic efficiency. Conversely, there exists the wear and occlusion risk of rotors and bodies with excessively tiny gaps, resulting in damage to key parts such as the rotors, bearings, and shaft seals. In addition, the load pressure causes the rotor and bearing to skew, and the load temperature causes the rotor and cavity to deform. All these factors interact with each other to influence the gap size and flow pattern of every leakage channel in the operation, which has a significant impact on compressor performance [58]. Compressor performance can be optimized by analyzing the rotor thermal deformation to correct the profile in reverse or adding a coating to optimize gaps. The specific quantities of rotor thermal deformation can be obtained by thermodynamic models or CFD models, where the CFD models can utilize thermo-solid coupling or thermo-fluid-solid coupling to obtain the thermal deformation of rotors accurately. Husak et al. [54] studied the effect of thermal and structural deformation of the rotors and casing of a twin-screw compressor on the operating clearance by coupling the SCORG thermodynamic model with ANSYS finite element analysis. Based on the steady-state temperature field boundary conditions, they simulated the thermal expansion behavior of the compressor under high-temperature conditions and verified the temperature distribution through thermal imaging experiments. The results showed that the radial clearance on the exhaust side of the rotor was reduced by 40–80 μm, the deformation of the casing was up to 200 μm, and the asymmetric deformation led to uneven distribution of the clearance. Therefore, the assembly clearance should consider thermal deformation to avoid contact, which provides a basis for thermal deformation prediction for high-precision manufacturing. Wu et al. [59] combined multibody dynamics simulation and experimental verification to study the dynamic response of oil-lubricated twin-screw compressor rotors under gas-induced cyclic loads. By establishing a dynamic model including a rotor and bearing and introducing gas-induced loads, they found that the frequency domain spectrum of the rotor contact force coincided with the experimental noise in the fundamental frequency and the first five harmonics. But the fourth harmonic only appeared when the rotor shaft was not aligned. This explained the effect of thermal deformation on the actual compressor and provided a basis for optimal design. Fleming and Tang [60] systematically analyzed the influence of six types of leakage paths on the performance of the twin-screw compressor by establishing a thermodynamic model and experimental verification. It was found that contact line leakage had the greatest impact on the volumetric efficiency, while the tip-sealing line and the spike leakage hole had significant impacts on the isentropic efficiency. By optimizing the rotor profile and reducing the area of the peak leakage hole, the isentropic efficiency could be improved by 1.95%. The error between the model’s prediction and the measured data was within 5%, which provides design guidance for reducing leakage loss and improving compressor efficiency. Kovacevic et al. [61] conducted a three-dimensional numerical simulation of the influence of fluid–solid interaction on rotor deformation and performance in a screw compressor. The results show that the pressure and temperature loads led to rotor bending and thermal expansion, which could significantly change the working clearance. The oil-immersed compressor had little deformation, while the dry compressor had an expansion deformation of 50 μm due to the high temperatures. Sufficient clearance should be reserved in a design to avoid getting stuck. The model agreed well with the experimental data and revealed the influence of deformation on leakage and efficiency in CO2 compressors with high pressure ratios. Xing et al. [62] simulated the leakage characteristics of twin-screw compressors, defined five leakage paths, and established mathematical models. They obtained the leakage region length and leakage amount under different working conditions, as well as their influence on the volumetric efficiency. The results show that the leakage of the rotor meshing area and the high-pressure side face accounted for more than 60% of the total leakage, which was the main factor of the efficiency loss. The efficiency of the small compressor could be improved by 5–8% by optimizing the sealing structure. The research makes clear the priority of the leakage path and provides a theoretical basis for high-precision seal design and operation parameter optimization. Spille-Kohoff and Hesse [63] studied the heat transfer between the gas and the rotors and the leakage flows in the gap. The simulation results indicated that the leakage mass flow rate of the gap of four positive rotors (the sum of the axial and radial parts) was up to 3% of the total mass flow rate, and that of six negative rotors was up to 2% of the total mass flow rate. Rane et al. [64] used bi-directional coupling CFD and a structural solver combined with SCORG mesh generation technology to study the thermal deformation and leakage gap variation of oil-free twin-screw compressors. The results show that optimization of the gap could improve the flow and volume efficiency by 8.2% and the adiabatic efficiency by 5.5%. However, rotor deformation was not considered in this study, and the model needed to be further expanded. Wang et al. [65] simulated the leakage of water-lubricated twin-screw compressors. They found that both the leakage of the rotor tip gap and the discharge end face gap significantly influenced compressor efficiency. However, the effects of compression start hole blowing, the suction end face gap, and the contact line were negligible. These results can be leveraged to refine compressor design and alleviate the detrimental effects of each leakage path. Rane et al. [66] used CFD numerical simulation to analyze the thermal performance of a 3–5 twin screw vacuum pump. By simulating different air injection cooling port designs, they found that the original design was inefficient due to cooling flow back mixing, with exhaust temperatures reaching 55 °C. The improvement schemes, such as increasing the AI opening angle to 240° and increasing the width of the air inlet, as well as reducing the exhaust temperature to 42 °C, reducing the leakage, and increasing the vacuum flow to 0.906 kg/min, were proposed. The research show that optimizing the AI ports could reduce power consumption by 30% and alleviate the local overheating problem of the rotor inlet. To sum up, determination of the gap value and resolution of the leakage problem are complex and difficult issues because they are related to many factors, such as the screw end face profile, the method of gap acquisition, the machining accuracy, and the deformation of parts. These problems have not been fully solved thus far.

The structural optimization of twin-screw compressors should be comprehensive to realize the research and development of high-power, first-level, energy-efficient screw compressors. Arbon [67] published a textbook in English on the design and application of rotary twin-shaft compressors in the oil and gas processing industry. Smith et al. [68] developed a suitable procedure for optimization of a screw compressor‘s shape, size, dimensions, and operating parameters, which resulted in the most appropriate design for a given compressor application and fluid. It was shown that the compressor performance after optimization was better than that under the traditional method. For example, the flow rate of a 3/5 rotor dry compressor was more than 10% higher than that of similar products in the market. Stosic et al. [69] developed a twin-screw compressor-expander integrated structure, in which spiral rotors meshing with each other are arranged in the housing and both ends are supported by end wall bearings. The shell’s interior is divided into a longer compressor portion and a shorter expander portion by a transverse partition. They innovatively arranged the high-pressure ports of the compressor and the expander symmetrically on the axis plane of the rotor on both sides of the separator, and the low-pressure ports were distributed on both sides of the axis plane near the end wall. The asymmetric layout reduced the rotor bearing load by 30–40% by balancing the axial force generated by the pressure gradient while optimizing the flow field distribution in the high-pressure area. Its core advantages are an enhanced, compact structure and extended bearing life, which are suitable for highly integrated energy recovery systems. Patel et al. [11] summarized the analysis of multiple parameters, including but not limited to noise, capacity control, optimization of the rotor, and indicator diagrams. They stated that in addition to various leaks, thermal management also seriously affects the structural optimization and performance of twin-screw compressors. Wang et al. [70] optimized the suction configuration of a twin-screw refrigeration compressor with high speed. They established several CFD models to analyze the influence of the suction delay, rotor wrap angle, and suction bearing distance on the suction port of a twin-screw refrigeration compressor with high speed. How to improve the efficiency of compressors by modifying the angle of the suction end, the wrap angle, and the bearing position was summarized. The results show that the optimization of the above parameters could significantly improve the twin-screw compressor performance at high speed and provide a reference for the suction design of the compressor. Li et al. [71] established a semi-empirical model of the twin-screw refrigeration compressor with MATLAB software to analyze the operation status under different capacity control methods and the thermodynamic performance under partial load conditions. They found that the compressor was more efficient under the variable frequency condition, while the efficiency was significantly reduced under the partial load condition. Therefore, it is necessary to optimize the inlet flow path and increase the area of the suction port when a twin-screw refrigeration compressor with high speed is designed. Tankhiwale et al. [72] studied the scope for improvement in performance as impacted by compressor ports. A hexahedral numerical mesh was used to represent the flow field, which was generated by SCORG. The flow solver ANSYS CFX was employed with these single domain-deforming rotor grids. The results indicate that the radial suction flange could be adopted for better compatibility with the oil-free package, and the CFD model applied in the analysis could be used for optimization of the air end under different operating conditions.

Traditional single-stage screw compressors adopt a single compression. With the development of modern technology, screw compressors with two-stage and even multi-stage compression have gradually entered the market. Shen et al. [73] addressed and theoretically evaluated the two-stage water vapor compression method, combining a centrifugal compressor with a twin-screw compressor. The results indicate that the combined system had greater energy efficiency under different operating conditions. Therefore, the compression process of the compressor can be long enough to ensure that the oil and gas are fully mixed after adopting two-stage compression. Moreover, the internal and external leakage of each stage should be reduced to improve compressor efficiency, thereby improving the compressor’s performance.

4.2. Operating Conditions and Performance Optimization

In addition to structural optimization studies of twin-screw compressors, working condition optimization studies are also quite important for optimizing performance, reducing the specific power and power consumption of screw compressor operation, and improving energy efficiency. The performance and efficiency of screw compressors are affected by operating parameters such as the exhaust pressure, temperature, speed, fuel injection rate, and suction rate.

In the early studies, in 1988, Konka [74] detailed the design criteria of processing for gas- and oil-free as well as oil-injected cooling compressors, analyzed the influence of refrigerant characteristics on performance, and illustrated the layout of multi-stage compression systems and the optimization of operating parameters through examples. In 2013, Chamoun et al. [75] established a high-temperature level compression cycle model for twin-screw compressors to investigate the compressor performance as a function of compression ratios fixed by components of the heat pump, the rotation speed fixed by the inverter, and for different injected mass flow rates. They revealed the changes in the key parameters (pressure, temperature, leakage, and heat transfer) in the compression cycle to be a function of the angular position of the male rotor and highlighted the impact of the compression ratio on under- and over-compression. Moreover, the understanding of compressor performance and the variation in the characteristic curves was deepened. In 2018, Yan et al. [76] generated dynamic meshes based on SCORG. They combined them with the VOF method and the homogeneous cavitation model to analyze the cavitation intensity and distribution of twin-screw pumps. The results showed that the increase in speed significantly increased the cavitation intensity, while the emission pressure had little influence. Cavitation mainly occurred in the radial region near the suction inlet, leading to a reduction in the leakage rate, and the excess bubbles generated reduced the volumetric efficiency.

In recent studies, Wu et al. [77] established a homogeneous multiphase flow model and simulated the working process of twin-screw compressors under variable vapor injection pressures and positions. They analyzed the influence of vapor injection on compressor performance and stated that the optimal vapor injection pressure and position can maximize the efficiency of compressors. The twin-screw compressor performance can be significantly improved by correct vapor injection settings. Wang et al. [78] studied the power consumption distribution characteristics of water-lubricated twin-screw air compressors in fuel cell applications and analyzed power consumption at different speeds in the different parts of compressors. They stated that the thrust bearings had the largest power loss, accounting for more than 52% of the total power loss. Reducing the indicated power loss of thrust bearings and liquid water emerged as the primary focus for enhancing compressor performance, which provides a theoretical basis for further optimization of water-lubricating twin-screw air compressors. Shamet and Antar [79] integrated a parallel cross-feed multi-effect desalination system with water-injected twin-screw compressors. They studied the effects of different operating conditions on specific power consumption, exergy efficiency, exergy destruction, and the final cost of produced water with the numerical simulation method. The results show that water injection during compression improved system efficiency and reduced energy consumption and production costs. Zhou et al. [40] simulated a marine steam twin-screw compressor with chilled liquid fuel and analyzed the compressor performance under different working conditions. They determined that the efficiency of the compressor was greatly affected by the suction temperature and discharge pressure, and the efficiency was reduced under low-temperature conditions. This provides the theoretical basis and practical guidance for optimizing twin-screw compressor performance under low-temperature conditions. Tian et al. [23] established a thermal dynamic model for water-injected twin-screw steam compressors. They explored the influence of different operational parameters such as the injection water flow rate, rotational speed, suction pressure, and discharge pressure on compressor performance and the optimum injected water flow rate. The results show that water injection is an effective way to enhance twin-screw compressor performance. There exists an optimum injected water flow rate that is almost proportional to the rotational speed and suction pressure. Furthermore, the compressor performance decreases rapidly when the pressure difference increases. Tsao et al. [21] used R-134a as the working medium and studied the influence of the angle and pressure ratio on the performance under the mode of twin-screw machinery compression and expansion with the numerical simulation method. They analyzed the relationship between the sealing line, leakage flow, and efficiency. The results of the experiment had some findings. Under the compression mode, an increase in the wrap angle reduced volumetric efficiency from 75% to 72%, and an increase in the compression ratio led to increased leakage. Under the expansion process, there was an under-expansion issue when the built-in expansion ratio was 7:1, resulting in a volumetric efficiency of only 69.2%. This research provided data support for the flow and thermodynamic characteristics of multi-mode optimization in screw machinery. Rane et al. [80] used the Eulerian-Eulerian multiphase model and Lee evaporation-condensation model to study the evaporative cooling effect of water injection twin-screw compressors. The results indicate that the exhaust temperature could be reduced to 187 °C when the water injection was 10 times the saturation mass. However, the water injection needed to be optimized to avoid droplet residue. The results revealed the water film distribution and the thermal hot spots, which provide a basis for thermal deformation prediction and efficient design.

There are still various low-end twin-screw compressors on the market at present, and the share of first-level energy efficiency products is less than 8%, which runs contrary to the original intention of energy saving. The high-energy consumption of twin-screw compressors primarily stems from the jamming of rotors, being prone to hot temperatures, high processing and manufacturing costs, and high-energy consumption of gas compression. Optimization of the compressor structural parameters (refer to Section 4.1 for details), working condition parameters, and driving form are three important ways to solve this problem. Energy-saving operations for screw compressors can be achieved by utilizing new forms and technologies (for instance, using different regulation methods, such as frequency conversion regulation and throttle regulation, or waste heat recovery schemes, such as hot water recovery and hot air recovery). Furthermore, scholars generally believe that on the one hand, the temperature in the working cavity is reduced by the injected lubricating oil, which renders the compression process closer to the isothermal process to reduce power consumption. On the other hand, the injected oil increases the viscous shear force and stirring work. Therefore, there exists an optimal amount of fuel injection and injection position to achieve the minimum power consumption and the highest performance [6,81]. Increasing injection pressure to strengthen the oil atomization effect for achieving a compression process close to the isothermal process is unadvisable because fuel injection consumption is too large. Feng et al. [82] adopted an optimization algorithm in MATLAB to minimize energy consumption. They realized energy-saving control by directly adjusting the slide valve position in the high-temperature stage screw compressor, and the energy-saving rate could be up to 17.55%. This method shows good stability and energy saving in practice.

In summary, the performance optimization of twin-screw compressors not only has the academic value of theoretical research but also has important industrial value. Firstly, energy efficiency can be improved. By optimizing the rotor profile, clearance, and so on, the compressor can reduce energy consumption in operation, greatly save power costs for industrial production, and meet the development requirements of energy conservation and emission reduction. At the same time, the compression efficiency can also be improved such that the amount of gas compression per unit of time can be increased, and the production efficiency can be improved. The optimized compressors operate more and more stably, which reduces the amount of downtime due to equipment failures, the costs of maintenance, and the risk of production disruptions. In addition, performance optimization can reduce the noise level, improve the working environment, ensure the physical and mental health of employees as well as work comfort, and indirectly improve work efficiency.

5. Present Challenges and Future Research Directions

A twin-screw compressor serves as a critical component within the realm of energy-efficient systems and equipment. In this paper, the numerical simulation studies of internal flow and performance optimization of twin-screw compressors were comprehensively reviewed. The existing relevant technical achievements were summarized, the shortcomings of current relevant studies were put forward, and future research directions are pointed out:

- (1)

- The precision and accuracy of models should be further improved.

A complex geometric structure, tiny gaps, and constant changes in the internal fluid area with rotors rotating are the three difficulties of mesh generation for twin-screw compressors. These challenges make it difficult to create a high-quality mesh that can accurately represent the flow field. For instance, the complex shape of the rotors and the small gaps between them and the casing require a fine-grained mesh to capture the flow details. The mesh generation technology of twin-screw compressors should be further improved in three aspects: integration of grid generation quality, efficiency, and convenience.

Existing turbulence models of the Reynolds-averaged Navier–Stokes (RANS) method still have limitations in simulating the complex turbulent flow accurately in screw compressors. Advanced and matched turbulence models should be explored and developed constantly. Turbulence in twin-screw compressors is highly complex, with swirling and recirculating flows. The RANS models, although widely used, average out the turbulent fluctuations, which may lead to inaccurate predictions of flow characteristics such as the velocity and pressure distributions (e.g., based on the large eddy simulation (LES) or direct eddy simulation (DES), combining the specific flow characteristics of screw compressors to improve and optimize the existing models to improve the simulation accuracy of complex flow phenomena, such as strong swirl flow and separated flow).

The existing gas-liquid two-phase flow model of two-screw compressors should be further improved. The mathematical descriptions of atomization, evaporation, interaction with gas, and the application of real gas state equations should be focused upon.

The development of mathematical models of twin-screw compressors should be further improved in the direction of conforming to actual conditions and pertinency. For example, the thermal stress and thermal deformation of solid structures have an important influence on the performance and reliability of compressors in fluid–structure interaction simulations. However, the existing numerical simulation methods often adopt simplified models and assumptions, resulting in the accuracy of the simulation results not being high enough to simulate the thermal stress and thermal deformation.

In addition, how to verify the simulation results’ accuracy for twin-screw compressors effectively and comprehensively is a technical problem at present. The experimental techniques should be more and more diversified to obtain comprehensive experimental results. For example, traditional pressure and temperature measurements may not be able to capture the detailed flow field information. By using a combination of techniques such as particle image velocimetry (PIV) for flow velocity measurement, infrared thermography for temperature distribution measurement, and high-speed photography for observing the internal flow behavior, more comprehensive data to verify the simulation results can be obtained.

- (2)

- Lack of comprehensive consideration of multi-field coupling.

The working process of twin-screw compressors involves the interaction of several physical fields, including hydrodynamics, thermodynamics, mechanical mechanics, and electromagnetism. However, current numerical simulations often consider only one or two of these physical fields. There are few comprehensive considerations for multi-physical field coupling. For example, for the frequency conversion of a screw compressor, the electromagnetic characteristics of motors have a significant influence on the compressor’s performance. However, the influence of electromagnetic properties is often neglected in numerical simulations. The influence of physical fields such as electromagnetism and acoustics on the performance of screw compressors should be fully considered. Theoretical research on multi-physical field coupling simulation should be further carried out, and the coupling mechanism and influence law between different physical fields should be deeply analyzed. This provides theoretical support for the establishment of more and more perfect and accurate multi-physical field coupling models, and the multi-field coupling numerical simulation of twin-screw compressors is conducted comprehensively.

- (3)

- Internal relationships between flow characteristics and structural optimizations should be further explored.

The key difficulty of the comprehensive and in-depth structural optimization of twin-screw compressors is to clarify the internal connection between complex flow characteristics and compressor performance. The design of high-performance twin-screw compressors is closely related to complex flow phenomena on the “local scale”. The “local scale” determines the choice of the “component scale” (i.e., the boundary conditions and structural parameters of compressors) and then determines the system performance of the “system scale” associated with twin-screw compressors. For example, the flow patterns near the rotor tips and in the gaps between the rotors can cause energy losses. By understanding these local flow characteristics, we can optimize the shape and size of the rotors, as well as the clearances between components, to improve the overall performance of the compressor. Continuous in-depth studies of the internal flow characteristics of twin-screw compressors and comprehensive exploitation of the internal relationship between flow characteristics and structural optimization are helpful for finding new methods to optimize the structure and improve the performance.

- (4)

- Strengthen research on energy saving and noise reduction in screw compressors, and develop more and more environmentally friendly high-performance twin-screw compressor products.

The high-energy consumption of twin-screw compressors primarily stems from jamming of rotors, proneness to becoming hot, high processing and manufacturing costs, and high energy consumption of gas compression. Rotor jamming can increase friction and energy loss, and the high temperature generated during operation also reduces the efficiency. High processing and manufacturing costs limit the widespread application of energy-efficient technologies. Green environmental protection design is bound to become an important direction in screw compressor design with the continuous improvement in environmental awareness. To realize the research and development of high-power, first-level, energy-efficient twin-screw compressors, in addition to the innovation-driven form, optimization of the structure and operating conditions should be more and more comprehensive. On this basis, the development of two-stage and even multi-stage compression for twin-screw compressors can further meet the needs of energy saving and environmental protection.

- (5)

- Intelligent design.

Intelligent industrial machinery design will gradually become an important trend in screw compressor design with the rapid development of artificial intelligence technology in the future.

Accordingly, numerical simulation studies should be developed in the direction of high precision, multi-physical field coupling, influencing mechanism research, energy saving, environmental friendliness, and intelligence. It lays a theoretical foundation for further improving the performance and mechanism theory of twin-screw compressors. High-precision simulations can provide more accurate predictions of compressor performance. Multi-physical field coupling research can better understand the complex working process. Studying the influence mechanism can help us identify the key factors affecting performance. Energy-saving and environmentally friendly design meets the requirements of sustainable development, and intelligent design can improve the design efficiency and product quality, making twin-screw compressors more competitive in the market.

Author Contributions

Conceptualization, Y.L. and S.S.; Methodology, Y.L., S.L, C.W., S.S. and X.Z.; Software, S.S. and Y.G.; Validation, C.W. and S.L.; Formal analysis, Y.L., X.Z., S.L., C.W. and Y.G.; Investigation, S.L., C.W. and X.Z.; Resources, Y.L. and S.S.; Data curation, X.Z.; Writing – original draft, Y.L.; Writing – review & editing, S.L., C.W. and X.Z.; Visualization, S.S. and Y.G.; Supervision, Y.L.; Project administration, Y.L. and S.S.; Funding acquisition, Y.L. All authors have read and agreed to the published version of the manuscript.

Funding

This project was supported by “the Fundamental Research Funds for the Provincial Universities of Liaoning” (No. LJ212410150010).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ahmed, K.; Nikola, S.; Ian, S. Screw Compressors: Three Dimensional Computational Fluid Dynamics and Solid Fluid Interaction; Springer: New York, NY, USA, 2007. [Google Scholar]

- Basha, N.; Kovacevic, A.; Rane, S. Analysis of Oil-Injected Twin-Screw Compressor with Multiphase Flow Models. Designs 2019, 3, 54. [Google Scholar] [CrossRef]

- Wang, C.; Xing, Z.; Chen, W.; Yang, Q.; He, Z. Development of an oil free water-lubricated twin-screw air compressor. Appl. Therm. Eng. 2018, 143, 396–402. [Google Scholar] [CrossRef]

- Wang, C.; Wang, B.; Liu, M.; Xing, Z. A Review of Recent Research and Application Progress in Screw Machines. Machines 2022, 10, 62. [Google Scholar] [CrossRef]

- Wei, J.; Hua, Q.; Wang, J.; Jiang, Z.; Wang, J.; Yuan, L. Overview of the Development and Application of the Twin Screw Expander. Energies 2020, 13, 6586. [Google Scholar] [CrossRef]

- Yang, S.; Ouyang, H.; Wu, Y.; Wang, L. Experimental study of lubricating oil impact on pressure pulsation for twin-screw refrigera-tion compressor. Int. J. Refrig. 2020, 112, 324–332. [Google Scholar] [CrossRef]

- Mujic, E.; Kovacevic, A.; Stosic, N.; Smith, I.K. Noise generation and suppression in twin-screw compressors. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2011, 225, 127–148. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, Z. Development of single screw compressor technologies and their tendency. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2022, 236, 738–751. [Google Scholar] [CrossRef]

- Davide, Z.; Eckhard, A.G.; James, E.B.; De Paepe, M. Review and Update on the Geometry Modeling of Single-Screw Machines with Emphasis on Expanders. Int. J. Refrig. 2018, 92, 10–26. [Google Scholar]

- Wu, W.; Hao, X.; He, Z.; Li, J. Design of the Curved Flank for the Star-Wheel Tooth in Single Screw Compressors. J. Mech. Des. 2014, 136, 051006. [Google Scholar] [CrossRef]

- Patel, H.H.; Lakhera, V.J. A critical review of the experimental studies related to twin screw compressors. Proc. Inst. Mech. Eng. Part E J. Process. Mech. Eng. 2020, 234, 157–170. [Google Scholar] [CrossRef]

- Sakun, I.A. Vintovie kompresorii (Screw Compressors); Mashinostroenie: Leningrad, Russia, 1960. [Google Scholar]

- Amosov Amosov, P.E.; Bobrikov, N.I.; Schwartz, A.I.; Vernii, A.L. Vintovie kompresomie mashinii -Spravochnik (Screw Compressor Machines -Handbook); Mashinstroienie: Leningrad, Russia, 1977. [Google Scholar]

- Rinder, L. Schraubenverdichter (Screw Compressors); Springer Verlag: New York, NY, USA, 1979. [Google Scholar]

- Stosic, N.; Smith, I.K.; Kovacevic, A.; Venumadhav, K. Retrofit ‘N’ Rotors for Efficient Oil-Flooded Screw Compressors. In Proceedings of the International Compressor Engineering Conference, West Lafayette, IN, USA, 25–28 July 2000. [Google Scholar]

- El Samad, T.; Zabnieńska-Góra, A.; Jouhara, H.; Sayma, A.I. A review of compressors for high temperature heat pumps. Therm. Sci. Eng. Prog. 2024, 51, 102603. [Google Scholar] [CrossRef]

- Lieblein, S. Loss and Stall Analysis of Compressor Cascades. J. Basic Eng. 1959, 81, 387–397. [Google Scholar] [CrossRef]

- He, X.; Dai, J.; Wu, M.; Liu, H.; Li, C. The Three-Dimensional Numerical Simulation and Experimental Research on Screw Compressor. Adv. Mech. Eng. 2015, 7, 189579. [Google Scholar] [CrossRef]

- Rane, S.; Kovacevic, A.; Stosic, N.; Jiang, Y.; Lowry, S. Influence of approaches in CFD Solvers on Performance Prediction in Screw Compressors. In Proceedings of the 22nd International Compressor Engineering Conference, West Lafayette, IN, USA, 14–17 July 2014. [Google Scholar]

- Rane, N.S.I. Analysis of real gas equation of state for CFD modelling of twin screw expanders with R245fa, R290, R1336mzz(Z) and R1233zd(E). Int. J. Refrig. 2021, 121, 313–326. [Google Scholar] [CrossRef]

- Tsao, C.-C.; Lin, W.-K.; Lai, K.-Y.; Yavuzkurt, S.; Liu, Y.-H. Numerical Investigation of Compression and Expansion Process of Twin-Screw Machine Using R-134a. Energies 2023, 16, 3599. [Google Scholar] [CrossRef]

- Huagen, W.; Ziwen, X.; Pengcheng, S. Theoretical and experimental study on indicator diagram of twin screw refrigeration compressor. Int. J. Refrig. 2004, 27, 331–338. [Google Scholar] [CrossRef]

- Tian, Y.; Geng, Y.; Yuan, H.; Zhao, Z. Investigation on water injection characteristics and its influence on the performance of twin-screw steam compressor. Energy 2022, 259, 124886. [Google Scholar] [CrossRef]

- Ding, H.; Jiang, Y.; Dhar, S. CFD Modelling of Coupled Heat Transfer between Solid and Fluid in a Twin Screw Compressor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 604, 12005. [Google Scholar] [CrossRef]

- Shamanskiy, A.; Simeon, B. Isogeometric simulation of thermal expansion for twin screw compressors. IOP Conf. Ser. Mater. Sci. Eng. 2018, 425, 012031. [Google Scholar] [CrossRef]

- Kovačević, S. Rane, N. Stošić, and G. Stupple, Analysis of Water Evaporation in Twin Screw Compressors Using CFD. Mašinstvo 2018, 15, 65–76. [Google Scholar] [CrossRef]

- Kovacevic, A.; Rane, S.; Stosic, N. Modelling of Multiphase Twin Screw Machines; Springer: Cham, Switzerland, 2018. [Google Scholar]

- Basha, N.; Rane, S.; Kovacevic, A. Multiphase Flow Analysis in an Oil-injected Twin Screw Compressor. In Proceedings of the 3rd World Congress on Momentum, Heat and Mass Transfer (MHMT’18), Budapest, Hungary, 12–14 April 2018. [Google Scholar]

- Casari, N.; Pinelli, M.; Suman, A.; Kovacevic, A.; Rane, S.; Ziviani, D. Full 3D numerical analysis of a twin screw compressor by employing open-source software. IOP Conf. Ser. Mater. Sci. Eng. 2018, 425, 012017. [Google Scholar] [CrossRef]

- Casari, N.; Fadiga, E.; Pinelli, M.; Suman, A.; Ziviani, D. CFD Simulations of Single- and Twin-Screw Machines with OpenFOAM. Designs 2020, 4, 2. [Google Scholar] [CrossRef]

- Ulrich, A.M.; Ignat, T.; Kristian, T.E.; Hafner, A.; Wang, R.; Eikevik, T.M. Numerical investigation of an oil-free liquid-injected screw compressor with ammonia-water as refrigerant for high temperature heat pump applications. Appl. Therm. Eng. 2023, 219, 119425. [Google Scholar]

- Kaufmann, F.; Irrgang, L.; Schifflechner, C.; Spliethoff, H. Fast and accurate modelling of twin-screw compressors: A generalised low-order approach. Appl. Therm. Eng. 2024, 257, 124238. [Google Scholar] [CrossRef]

- Wang, B.; Wang, C.; Wu, X.; Zhang, Z.; Xing, Z. Development of a chamber model considering non-uniform pressure distribution for twin-screw compressors. Int. J. Refrig. 2024, 165, 209–222. [Google Scholar] [CrossRef]

- Seshaiah, N.; Ghosh, S.K.; Sahoo, R.K.; Sarangi, S.K. Mathematical modeling of the working cycle of oil injected rotary twin screw com-pressor. Appl. Therm. Eng. 2007, 27, 145–155. [Google Scholar] [CrossRef]

- Papes, I.; Degroote, J.; Vierendeels, J. New insights in twin screw expander performance for small scale ORC systems from 3D CFD analysis. Appl. Therm. Eng. 2015, 91, 535–546. [Google Scholar] [CrossRef]

- Wang, C.; Xing, Z.; Hou, F.; Wu, H.; Yu, Z. Research on axis orbit of the journal bearing lubricated with oil and refrigerant mixtures in a twin-screw refrigeration compressor. Int. J. Refrig. 2018, 90, 1–11. [Google Scholar] [CrossRef]

- Krichel, S.V.; Sawodny, O. Dynamic modeling of compressors illustrated by an oil-flooded twin helical screw compressor. Mechatronics 2011, 21, 77–84. [Google Scholar] [CrossRef]

- Tian, Y.; Shen, J.; Wang, C.; Xing, Z.; Wang, X. Modeling and performance study of a water-injected twin-screw water vapor compressor. Int. J. Refrig. 2017, 83, 75–87. [Google Scholar] [CrossRef]

- Yang, S.; Ouyang, H.; Wu, Y.; Wang, L.; Mei, L.; Wang, H. CFD simulation for the internal pressure characteristics of an oil-injected twin-screw refrigeration compressor. Int. J. Refrig. 2021, 126, 143–154. [Google Scholar] [CrossRef]

- Zhou, Y.; Guo, Y.; Wang, Y.; Diao, A.; Peng, X. Study on the performance of the boil-off gas twin-screw compressor based on the thermal-fluid-structure coupling method. Int. J. Refrig. 2024, 163, 17–31. [Google Scholar] [CrossRef]

- Wang, B.; Wu, X.; Wang, C.; Zhang, Z.; Sun, S.; Xing, Z. Study on non-uniform internal pressure distribution of twin-screw refrigeration compressor. Int. J. Refrig. 2023, 152, 214–222. [Google Scholar] [CrossRef]

- Byeon, S.-S.; Lee, J.-Y.; Kim, Y.-J. Performance Characteristics of a 4 × 6 Oil-Free Twin-Screw Compressor. Energies 2017, 10, 945. [Google Scholar] [CrossRef]

- Voorde, J.B.V.; Vierendeels, J. ALE Calculations of Flow Through Rotary Positive Displacement Machines. In Proceedings of the ASME 2005 Fluids Engineering Division Summer Meeting, Houston, TX, USA, 19-223 June 2005; pp. 1405–1415. [Google Scholar] [CrossRef]

- Kovacevic, A. Boundary adaptation in grid generation for CFD analysis of screw compressors. Int. J. Numer. Methods Eng. 2010, 64, 401–426. [Google Scholar] [CrossRef]

- Zhang, J.W.; Wu, Y.R.; Hsieh, S.H.; Huang, C.S. Use of CFD to Investigate Flow Characteristics and Oil Distribution Inside an Oil-injected Screw Compressor. IOP Conf. Ser. Mater. Sci. Eng. 2019, 604, 012016. [Google Scholar] [CrossRef]

- Borriello, P.; Frosina, E.; Senatore, A.; Monterosso, F. Numerical Modelling and Experimental Validation of Twin-Screw Pumps Based on Computational Fluid Dynamics using SCORG ® and SIMERICS MP+ ®. E3S Web Conf. 2021, 312, 5007. [Google Scholar]

- Rane, S.; Kovaevi, A.; Stoi, N.; Smith, I. Highly Deforming Computational Meshes for CFD Analysis of Twin-Screw Positive Displacement Machines. In Computational Fluid Dynamics—Basic Instruments and Applications in Science; IntechOpen: London, UK, 2018. [Google Scholar]

- Guerrato, D.; Nouri, J.; Stosic, N.; Arcoumanis, C; Smith, I. Flow measurements around the discharge port of a twin screw compressor. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2008. [Google Scholar] [CrossRef]

- Shen, J.; Chen, W.; Yan, S.; Zhou, M.; Liu, H. Study on the noise reduction methods for a semi-hermetic variable frequency twin-screw refrigeration compressor. Int. J. Refrig. 2021, 125, 1–12. [Google Scholar] [CrossRef]

- Wang, R.; Zhou, M.; Chen, W.; Shen, J. Numerical and Experimental Research on the Discharge Noise of Twin-screw Refrigeration Compressors. J. Mech. Eng. 2017, 53, 169. [Google Scholar]

- Wu, X.; Xing, Z.; Chen, W.; Wang, X. Performance investigation of a pressure pulsation dampener applied in the discharge chamber of a twin screw refrigeration compressor. Int. J. Refrig. 2018, 85, 70–84. [Google Scholar] [CrossRef]

- Braga, V.; Silva, E.; Dutra, T.; Caetano, A.; Silva, O.; Andreazza, A. Numerical Investigation of Pressure Pulsation in Oil-Free Twin Screw Compressor Discharge Systems Adopted to Oil and Gas Industry. In Proceedings of the 27th International Compressor Engineering Conference at Purdue, West Lafayette, IN, USA, July 2024. [Google Scholar]

- Sun, S.; Wu, X.; Li, D.; Wang, C.; Xing, Z. Study on suction pressure loss near suction end and stagnant pressure rise in p-θ diagram of Twin-screw refrigeration compressor for chiller. Therm. Sci. Eng. Prog. 2022, 34, 101410. [Google Scholar] [CrossRef]

- Husak, E.; Kovacevic, A.; Karabegovic, I. Calculation of clearances in twin screw compressors. IOP Conf. Ser. Mate-Rials Sci. Eng. 2019, 604, 12001–12010. [Google Scholar] [CrossRef]

- O’Neill, P. Industrial Compressors: Theory and Equipment; Elsevier Science & Technology Books: Amsterdam, The Netherlands, 1993; pp. 31–3253. Available online: https://www.ebay.com/p/935293 (accessed on 20 February 2025).

- Yin, X.; Cao, F.; Pan, S.; Song, Y.; Fei, J.; Wang, X. Numerical investigation on screw rotor deformation and influence on volumetric efficiency of the twin-screw multiphase pump. Appl. Therm. Eng. 2017, 111, 1111–1118. [Google Scholar] [CrossRef]

- Tian, Y.; Lu, J.; Shen, J.; Wu, H.; Xing, Z. Optimization on shaft seals for a twin-screw steam compressor based on a novel uniform property region (UPR) model on discharge end-face. Int. J. Refrig. 2018, 91, 167–176. [Google Scholar] [CrossRef]

- Sauls, J. Development of a Comprehensive Thermodynamic Modeling System for Refrigerant Screw Compressors. In Proceedings of the 1996 International Compressor Engineering Conference, West Lafayette, IN, USA, 23–26 July 1996. [Google Scholar]

- Wu, Y.R.; Tran, V.T.; Hsu, P.H. Dynamic Analysis for Rotors of a Twin-Screw Compressor with Gas-Induced Cyclic Loads. Appl. Mech. Mater. 2015, 789–790, 220–225. [Google Scholar] [CrossRef]

- Fleming, J.S.; Tang, Y. The analysis of leakage in a twin screw compressor and its application to performance improvement. Arch. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 1989–1996. 1995, 209, 125–136. [Google Scholar] [CrossRef]