Multi-Objective Sensitivity Analysis of Hydraulic–Mechanical–Electrical Parameters for Hydropower System Transient Response

Abstract

1. Introduction

- Hydropower system Modeling: Some researchers have failed to adequately consider the influence of mechanical and electrical systems in their models, relying solely on existing commercial software for stability analysis of the hydraulic system. Moreover, while some scholars have established relatively complete hydraulic–mechanical–electrical coupled models, these models tend to overemphasize the coupling relationships between the mechanical and electrical subsystems, neglecting the complexity of the hydraulic system itself and its impact on the overall system stability.

- Parameter Sensitivity Analysis: Current research often focuses on a single category of parameters (e.g., structural, operating, or control parameters), leading to insufficient depth and breadth in the analysis of parameter impacts. There is a lack of comprehensive cross-comparison of multiple parameters, which hinders the identification of the relative importance of different parameter types in the operation of hydropower units and the quantification of the impact of core parameters on unit stability indicators.

2. Hydropower Generator System Modeling

2.1. Diversion System

- Upstream and downstream reservoirs

- 2.

- Surge tank

- 3.

- Elbow pipe

- 4.

- Bifurcated pipe

- 5.

- Unit

2.2. Hydro-Turbine

2.3. Generator and Load

2.4. PID Governor

3. Results and Analysis

3.1. Influence of Pipe Structural Parameters on Unit Operation Stability

3.1.1. Main Branch Pipe Diameter Ratio

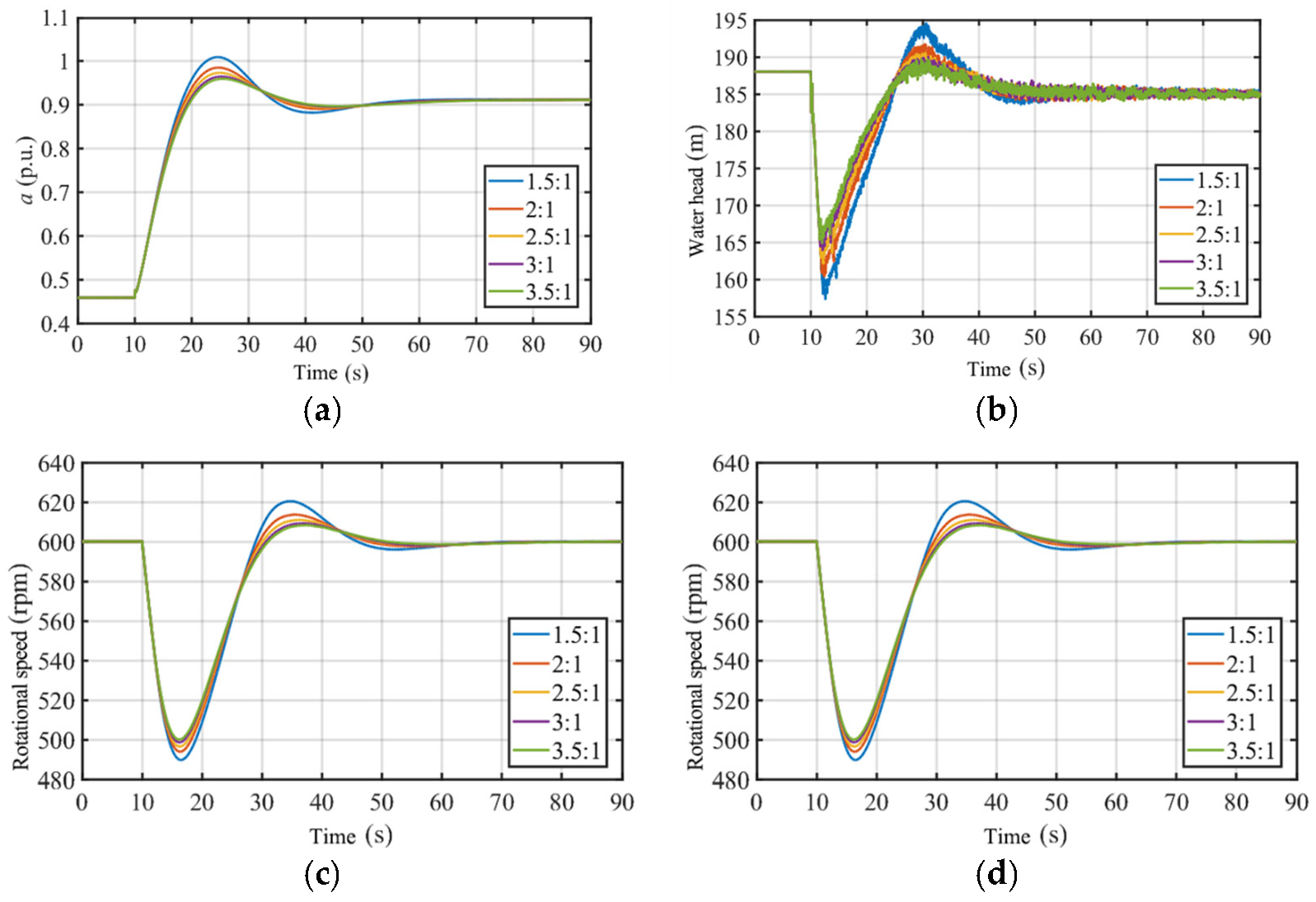

3.1.2. Surge Tank Location

3.2. The Impact of Operating Conditions on the Stability of the Unit Operation

3.2.1. Initial Load

3.2.2. Characteristic Water Head

3.3. Influence of Control Parameters on the Stability of Unit Operation

3.3.1. Proportional Gain

3.3.2. Integral Gain

3.4. Sensitivity Analysis of Unit Dynamic Response

4. Discussion

5. Conclusions

- Increasing the main branch pipe diameter ratio and the distance between the surge tank and the upstream reservoir improves stability during the transition. Among these factors, the main branch pipe diameter ratio is most sensitive to the inversion power peak time, while the surge tank’s position shows strong sensitivity to the rotational speed regulation time.

- A larger initial load and characteristic water head enhance the stability of the hydropower plant during the load increase transition process. Among these, the initial load shows strong sensitivity to rotational speed overshoot and inversion power peak, while the characteristic water head is highly sensitive to the rotational speed rise time, rotational speed peak time, and inversion power peak time.

- Lowering the proportional gain and increasing the integral gain reduces the stability of the hydropower plant system during the transition process. The sensitivity analysis shows that the proportional gain (Kp) is highly sensitive to the rotational speed regulation time, while the integral gain (Ki) strongly affects the rotational speed rise time.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bao, H.Y.; Long, L.T.; Fu, L.; Wei, J.F. Study on stability of load regulation transition process of hydro turbine governor in power mode. Trans. Chin. Soc. Agric. Eng. 2019, 35, 50–57, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Binama, M.; Su, W.-T.; Li, X.-B.; Li, F.-C.; Wei, X.-Z.; An, S. Investigation on pump as turbine (PAT) technical aspects for micro hydropower schemes: A state-of-the-art review. Renew. Sustain. Energy Rev. 2017, 79, 148–179. [Google Scholar] [CrossRef]

- Zhang, B.T. Energy Revolution Inevitable, Pumped Storage Thriving. Hydropower Pumped Storage 2017, 3, 5. Available online: http://old.hydropower.org.cn/showNewsDetail.asp?nsId=22105 (accessed on 13 October 2024). (In Chinese with English abstract).

- Yang, W.; Norrlund, P.; Chung, C.Y.; Yang, J.D.; Lundin, U. Eigen-analysis of hydraulic-mechanical-electrical coupling mechanism for small signal stability of hydropower plant. Renew. Energy 2018, 115, 1014–1025. [Google Scholar] [CrossRef]

- Khalid, M.; AlMuhaini, M.; Aguilera, R.P.; Savkin, A.V. Method for planning a wind–solar–battery hybrid power plant with optimal generation-demand matching. IET Renew. Power Gen. 2018, 12, 1800–1806. [Google Scholar] [CrossRef]

- Zhang, H.; Hu, P. Study on regulating oscillation in multi hydro turbine generators sharing flow channel structure of tailrace surge tank. J. Hydraul. Eng. 2015, 46, 10. Available online: http://jhe.ches.org.cn/jhe/ch/reader/view_abstract.aspx?file_no=201502013 (accessed on 1 December 2024). (In Chinese with English abstract).

- Goyal, R.; Gandhi, B.K. Review of Hydrodynamics Instabilities in Francis Turbine During Off-design and Transient Operations. Renew. Energy 2018, 116, 697–709. [Google Scholar] [CrossRef]

- Li, H.H.; Xu, B.B.; Arzaghi, E.; Abbassi, R.; Chen, D.Y.; Aggidis, G.A.; Zhang, J.J.; Patelli, E. Transient Safety Assessment and Risk Mitigation of a Hydroelectric Generation System. Energy 2020, 196, 117135. [Google Scholar] [CrossRef]

- Liu, Y.N.; Yang, J.D.; Zeng, W. Setting conditions of surge chambers at hydropower station in elastic model based on operation stability. J. Hydroelectr. Eng. 2016, 35, 6, (In Chinese with English abstract). [Google Scholar] [CrossRef]

- Kamal, M.M.; Abbas, A.; Prasad, V.; Kumar, R. A numerical study on the performance characteristics of low head Francis turbine with different turbulence models. Mater. Today Proc. 2022, 49, 349–353. [Google Scholar] [CrossRef]

- El-Sapa, S.; Lotfy, K.; El-Bary, A. Impact of laser short-pulse heating and variable thermal conductivity on photo-elasto-thermodiffusion waves of fractional heat excited semiconductor. J. Electromagn. Waves Appl. 2022, 36, 2628–2646. [Google Scholar] [CrossRef]

- El-Sapa, S.; Lotfy, K.; El-Bary, A.A. Non-local semiconductor photothermal excitation medium in moisture diffusivity subjected to heating by pulsed laser. Eur. Phys. J. Plus 2023, 138, 368. [Google Scholar] [CrossRef]

- El-Sapa, S.; Lotfy, K.; El-Bary, A. Laser short-pulse impact on magneto-photo-thermo-diffusion waves in excited semiconductor medium with fractional heat equation. Acta Mech. 2022, 233, 3893–3907. [Google Scholar] [CrossRef]

- Celebioglu, K.; Altintas, B.; Aradag, S.; Tascioglu, Y. Numerical research of cavitation on Francis turbine runners. Int. J. Hydrogen Energy 2017, 42, 17771–17781. [Google Scholar] [CrossRef]

- Yang, W.; Norrlund, P.; Saarinen, L.; Yang, J.; Guo, W.; Zeng, W. Wear and tear on hydro power turbines—Influence from primary frequency control. Renew. Energy 2016, 87, 88–95. [Google Scholar] [CrossRef]

- Valentín, D.; Presas, A.; Egusquiza, E.; Valero, C.; Egusquiza, M.; Bossio, M. Power Swing Generated in Francis Turbines by Part Load and Overload Instabilities. Energies 2017, 10, 2124. [Google Scholar] [CrossRef]

- Zhang, L.; Wu, Q.Q.; Ma, Z.Y.; Wang, X.N. Transient vibration analysis of unit-plant structure for hydropower station in sudden load increasing process. Mech. Syst. Signal Process. 2019, 120, 486–504. [Google Scholar] [CrossRef]

- Ma, W.C.; Zhao, Z.G.; Yang, J.B.; Lai, X.; Liu, C.P.; Yang, J.D. A transient analysis framework for hydropower generating systems under parameter uncertainty by integrating physics-based and data-driven models. Energy 2024, 297, 131141. [Google Scholar] [CrossRef]

- Zhu, Z.; Tan, X.; Lu, X.; Liu, D.; Li, C. Hopf bifurcation and parameter sensitivity analysis of a doubly-fed variable-speed pumped storage unit. Energies 2022, 15, 204. [Google Scholar] [CrossRef]

- Lei, L.W.; Li, F.; Kheav, K.L.; Jiang, W.; Luo, X.Q.; Patelli, E.; Xu, B.B.; Chen, D.Y. A start-up optimization strategy of a hydroelectric generating system: From a symmetrical structure to asymmetric structure on diversion pipes. Renew. Energy 2021, 180, 1148–1165. [Google Scholar] [CrossRef]

- Li, W.X. Study on the Hydraulic Transition Process Calculation of Three Different Arrangements of Tailwater Pressure Chamber. Master’s Thesis, Xi’an University of Technology, Xi’an, China, 2021. (In Chinese with English abstract). [Google Scholar]

- Liao, Y.W.; Yang, W.J.; Zhao, Z.G.; Li, X.D.; Ci, X.H.; Bidgoli, M.A.; Yang, J.D. Influence mechanism of backlash nonlinearity on dynamic regulation stability of hydropower units. Sustain. Energy Technol. Assess. 2022, 51, 101917. [Google Scholar] [CrossRef]

- Liu, H.; Fan, B.Y.; Tang, C.; Ge, S.Y.; Wang, Y.; Guo, L. Game theory based alternate optimization between expansion planning of active distribution system and siting and sizing of photovoltaic and energy storage. Autom. Electr. Power Syst. 2017, 41, 38–45, 116. Available online: https://epjournal.csee.org.cn/dlxtzdh/article/id/564fb3c1-4b09-489c-a3ae-210fd7d344a5 (accessed on 4 December 2024). (In Chinese with English abstract).

- Singh, M.K.; Naresh, R.; Gupta, D.K. Optimal tuning of temporary droop governor of hydro power plant using genetic algorithm. In Proceedings of the 2013 International Conference on Energy Efficient Technologies for Sustainability, Nagercoil, India, 10–12 April 2013; pp. 1132–1137. [Google Scholar] [CrossRef]

- Feng, X.Y. Analysis of the Transient Performance of the Water Turbine Regulation System. Master’s Thesis, North China University of Water Resources and Electric Power, Baoding, China, 2016. (In Chinese with English abstract). [Google Scholar]

- Riasi, A.; Tazraei, P. Numerical analysis of the hydraulic transient response in the presence of surge tanks and relief valves. Renew. Energy 2017, 107, 138–146. [Google Scholar] [CrossRef]

- Guo, W.C.; Peng, Z.Y. Hydropower system operation stability considering the coupling effect of water potential energy in surge tank and power grid. Renew. Energy 2019, 134, 846–861. [Google Scholar] [CrossRef]

- Hou, J.J.; Li, C.S.; Guo, W.C.; Fu, W.L. Optimal successive start-up strategy of two hydraulic coupling pumped storage units based on multi-objective control. Int. J. Electr. Power Energy Syst. 2019, 111, 398–410. [Google Scholar] [CrossRef]

| Pipe Diameter Ratio | Rotational Speed Regultion Time | Rotational Speed Overshoot | Rotational Speed Rise Time | Rotational Speed Peak Time | Inversion Power Peak | Inversion Power Peak Time |

|---|---|---|---|---|---|---|

| 1.3:1 | 34.78 | 0.180 | 14.03 | 26.67 | 6.00 | 19.51 |

| 1.5:1 | 33.56 | 0.170 | 15.02 | 27.60 | 5.67 | 18.47 |

| 1.7:1 | 31.77 | 0.163 | 16.09 | 28.57 | 5.53 | 18.37 |

| 1.9:1 | 20.92 | 0.159 | 17.02 | 29.93 | 5.46 | 17.44 |

| 2.1:1 | 21.35 | 0.156 | 17.33 | 30.16 | 5.41 | 18.26 |

| Location of the Surge Tank | Rotational Speed Regulation Time | Rotational Speed Overshoot | Rotational Speed Rise Time | Rotational Speed Peak Time | Inversion Power Peak | Inversion Power Peak Time |

|---|---|---|---|---|---|---|

| 1.5:1 | 32.54 | 0.184 | 12.64 | 24.92 | 6.25 | 18.31 |

| 2.0:1 | 32.61 | 0.177 | 13.35 | 25.48 | 5.94 | 17.58 |

| 2.5:1 | 32.40 | 0.173 | 14.03 | 36.18 | 5.80 | 16.59 |

| 3.0:1 | 32.20 | 0.169 | 14.57 | 36.80 | 5.71 | 16.79 |

| 3.5:1 | 31.70 | 0.167 | 15.00 | 37.42 | 5.65 | 17.34 |

| Initial Load | Rotational Speed Regulation Time | Rotational Speed Overshoot | Rotational Speed Rise Time | Rotational Speed Peak Time | Inversion Power Peak | Inversion Power Peak Time |

|---|---|---|---|---|---|---|

| 50% | 21.35 | 0.152 | 18.17 | 30.04 | 5.38 | 17.84 |

| 60% | 20.88 | 0.115 | 17.97 | 30.94 | 4.06 | 17.45 |

| 70% | 20.53 | 0.081 | 19.05 | 31.84 | 2.77 | 17.38 |

| 80% | 19.07 | 0.050 | 19.20 | 31.56 | 1.71 | 17.79 |

| 90% | 14.06 | 0.018 | 19.79 | 30.71 | 0.63 | 14.64 |

| Characteristic Water Head | Rotational Speed Regulation Time | Rotational Speed Overshoot | Rotational Speed Rise Time | Rotational Speed Peak Time | Inversion Power Peak | Inversion Power Peak Time |

|---|---|---|---|---|---|---|

| 223.36 | 16.45 | 0.125 | 13.54 | 23.22 | 5.55 | 12.79 |

| 214.52 | 17.30 | 0.131 | 14.25 | 24.64 | 5.53 | 13.41 |

| 205.68 | 18.39 | 0.138 | 15.37 | 26.63 | 5.47 | 15.02 |

| 196.84 | 19.63 | 0.144 | 16.49 | 28.67 | 5.42 | 16.52 |

| 188.00 | 21.35 | 0.152 | 18.17 | 30.04 | 5.38 | 17.84 |

| Proportional Gain | Rotational Speed Regulation Time | Rotational Speed Overshoot | Rotational Speed Rise Time | Rotational Speed Peak Time | Inversion Power Peak | Inversion Power Peak Time |

|---|---|---|---|---|---|---|

| 0.6 | 38.19 | 0.170 | 14.81 | 28.37 | 5.72 | 20.25 |

| 0.8 | 34.51 | 0.160 | 16.24 | 28.85 | 5.53 | 18.21 |

| 1.0 | 21.35 | 0.152 | 18.17 | 30.04 | 5.38 | 17.84 |

| 1.2 | 22.51 | 0.145 | 22.46 | 33.78 | 5.23 | 16.69 |

| 1.4 | 24.50 | 0.138 | 36.09 | 36.09 | 5.12 | 15.08 |

| Integral Gain | Rotational Speed Regulation Time | Rotational Speed Overshoot | Rotational Speed Rise Time | Rotational Speed Peak Time | Inversion Power Peak | Inversion Power Peak Time |

|---|---|---|---|---|---|---|

| 0.21 | 25.45 | 0.155 | 26.27 | 37.79 | 5.19 | 19.26 |

| 0.23 | 23.17 | 0.153 | 21.31 | 33.00 | 5.25 | 17.41 |

| 0.25 | 21.35 | 0.152 | 18.17 | 30.04 | 5.38 | 17.84 |

| 0.27 | 20.01 | 0.151 | 16.28 | 27.67 | 5.46 | 17.14 |

| 0.29 | 18.87 | 0.149 | 14.77 | 26.65 | 5.57 | 16.36 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Y.; Guo, Y.; Li, M.; Lei, L.; Hu, H.; Chen, D.; Zhao, Z.; Xu, B. Multi-Objective Sensitivity Analysis of Hydraulic–Mechanical–Electrical Parameters for Hydropower System Transient Response. Energies 2025, 18, 2609. https://doi.org/10.3390/en18102609

Li Y, Guo Y, Li M, Lei L, Hu H, Chen D, Zhao Z, Xu B. Multi-Objective Sensitivity Analysis of Hydraulic–Mechanical–Electrical Parameters for Hydropower System Transient Response. Energies. 2025; 18(10):2609. https://doi.org/10.3390/en18102609

Chicago/Turabian StyleLi, Yongjia, Yixuan Guo, Ming Li, Liuwei Lei, Huaming Hu, Diyi Chen, Ziwen Zhao, and Beibei Xu. 2025. "Multi-Objective Sensitivity Analysis of Hydraulic–Mechanical–Electrical Parameters for Hydropower System Transient Response" Energies 18, no. 10: 2609. https://doi.org/10.3390/en18102609

APA StyleLi, Y., Guo, Y., Li, M., Lei, L., Hu, H., Chen, D., Zhao, Z., & Xu, B. (2025). Multi-Objective Sensitivity Analysis of Hydraulic–Mechanical–Electrical Parameters for Hydropower System Transient Response. Energies, 18(10), 2609. https://doi.org/10.3390/en18102609