Abstract

Solid Oxide Fuel Cells (SOFCs) are emerging as a leading solution in sustainable power generation, boasting high power-to-energy density and minimal emissions. With efficiencies potentially exceeding 60% for electricity generation alone and up to 85% when in cogeneration applications, SOFCs significantly outperform traditional combustion-based technologies, which typically achieve efficiencies of around 35–40%. Operating effectively at elevated temperatures (600 °C to 1000 °C), SOFCs not only offer superior efficiency but also generate high-grade waste heat, making them ideal for cogeneration applications. However, these high operational temperatures pose significant thermal management challenges, necessitating innovative solutions to maintain system stability and longevity. This review aims to address these challenges by offering an exhaustive analysis of the latest advancements in SOFC thermal management. We begin by contextualizing the significance of thermal management in SOFC performance, focusing on its role in enhancing operational stability and minimizing thermal stresses. The core of this review delves into various thermal management subsystems such as afterburners, heat exchangers, and advanced thermal regulation strategies. A comprehensive examination of the recent literature is presented, highlighting innovations in subsystem design, fuel management, flow channel configuration, heat pipe integration, and efficient waste heat recovery techniques. In conclusion, we provide a forward-looking perspective on the state of research in SOFC thermal management, identifying potential avenues for future advancements and their implications for the broader field of sustainable energy technologies.

1. Introduction

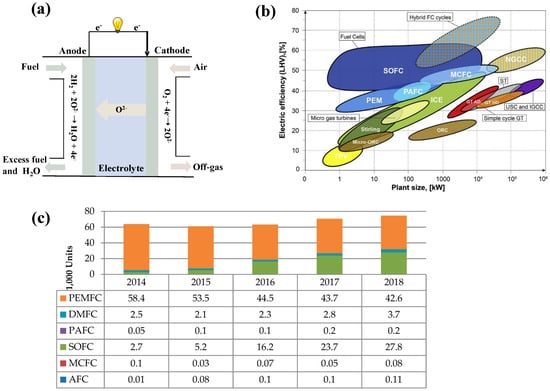

Among the myriad of electrochemical conversion and storage technologies being intensively researched, including all-solid-state batteries, fuel cells, lithium-ion batteries and capacitors, aimed at facilitating the decarbonization of our environment [1,2,3,4,5,6], fuel cells stand out as particularly promising. The variety within fuel cell technology primarily stems from the type of electrolyte used, leading to several variants such as Solid Oxide Fuel Cells (SOFCs), Molten Carbonate Fuel Cells (MCFCs), Polymer Electrolyte Membrane Fuel Cells (PEMFCs), Phosphoric Acid Fuel Cells (PAFCs), Direct Methanol Fuel Cells (DMFCs), and Alkaline Fuel Cells (AFCs) [7]. SOFCs, in particular, have garnered widespread attention as energy conversion devices capable of directly transforming the chemical energy of fuel gas and oxidant combinations into electricity (Figure 1a). This attention is due to their solid structure, high energy conversion efficiency, and broad adaptability to various fuel gases [8,9,10]. Under normal power density conditions, fuel cells demonstrate electrical efficiencies ranging from 30% to 60%, with the remainder of the energy primarily dissipated as heat. However, SOFCs exhibit superior performance across most relevant power ranges compared to other electricity generation technologies. This superiority is especially pronounced in ‘hybrid’ configurations, where SOFCs are combined with gas turbines or other thermodynamic cycles, enabling electrical efficiencies exceeding 70% (Figure 1b) [11]. From 2014 to 2018, the deployment of SOFC units saw a significant increase, from approximately 2700 units to 27,800 units (Figure 1c) [12].

Figure 1.

The basic principle and the major features of Solid Oxide Fuel Cells (SOFCs). (a) Schematic of the SOFCs. (b) Schematic illustration of the relationship between achievable electrical efficiency and power plant scale in state-of-the-art fuel-based power generation solutions [11]. Copyright 2016 Elsevier. (c) Shipments of different types of fuel cell [12]. Copyright 2019 MDPI.

While high operating temperatures afford SOFCs certain advantages, they also introduce challenges [13], such as potential degradation of the fuel cell stack due to thermal stress during heating [14], gas seal integrity [15,16], thermal integration of the electrochemical reformer [17], prolonged start-up/shutdown durations, and the selection of appropriate materials to ensure compatibility with the physical characteristics of fuel cell stack components [18,19].

Thermal management in SOFCs presents a complex challenge, influenced by various interrelated factors. These fuel cells generate heat through electrochemical reactions and ohmic losses, necessitating efficient heat dispersion to maintain thermal equilibrium. Achieving a uniform temperature distribution within the stack is crucial for preventing differential expansion, minimizing thermal stress, and avoiding cell failure. The SOFC system represents a sophisticated, multi-faceted entity where electrical, thermal, and gas dynamics are tightly interwoven. Heat sources, indicated by deeper red zones, are predominantly located in the heat exchanger, stack, and afterburner chamber. The heat exchanger and the afterburner chamber play critical roles in effective thermal management within SOFC systems. The heat exchanger is key for recovering waste heat, whereas the afterburner chamber enhances heat transfer efficiency by channeling high-temperature exhaust gases. Focusing research efforts on these components is essential to improve SOFC thermal management strategies.

To mitigate the thermal management challenges in high-temperature SOFC systems, researchers have explored various strategies and technologies. These include enhancing gas channel designs, optimizing fluid flow, identifying hotspots [20], reducing temperature gradients [21], integrating heat pipes, decreasing the operating temperature [22] and adjusting fuel compositions for efficient operation. Zeng et al. [23] conducted a comprehensive review of heat transfer and thermal management in SOFCs, focusing on temperature gradients and methods to reduce them within stacks. Tarancon et al. [24] examined approaches for lowering SOFC operating temperatures to intermediate levels, highlighting the benefits for material stability and thermal management. Skabelund et al. [25] discussed integrating partial oxidation with SOFCs, examining micro-reformer technology for converting hydrocarbons into syngas and the thermal management nuances of direct flame and flame-assisted fuel cells. Through such insights into heat transfer, temperature control, and thermal management, research contributes to advancing SOFC technology and energy solutions [26]. While the existing research predominantly reviews the thermal management of stacks and reformers, the thermal management of the Balance of Plant (BOP), a significant heat source in the system, is also critical. However, system-level analysis of SOFC thermal management subsystems, including burners, heat exchangers, and strategies, remains underexplored. This review aims to bridge this gap by focusing on the thermal management within SOFC systems, particularly examining burners, heat exchangers, and their strategies. These components are pivotal to thermal management, as they play a significant role in affecting SOFC performance and reliability.

This review strives to deliver an encompassing view on thermal management in SOFC systems. It highlights the pivotal functions of burners, heat exchangers, management strategies, and modeling and control of the thermal subsystem for improving performance and reliability. By examining recent research breakthroughs and engineering methodologies, we aim to furnish insights for forthcoming studies and practical engineering endeavors. Given the indispensable nature of adept thermal management for SOFC application success, this review is intended to serve as essential guidance and stimulus for ongoing research and development in the domain.

The structure of this review is organized as follows: We introduce the various types and functions of burners within the SOFC combustion chamber, synthesizing current research on design optimization, as well as modeling and empirical validation analyses. Subsequently, we offer a detailed examination of the recognized types of SOFC heat exchangers, emphasizing their design improvements. Following this, we delve into the most recent advancements in SOFC thermal management strategies, with a focus on innovations in fuel and flow channel designs, heat pipe configurations, and the effective utilization of waste heat. Finally, a comprehensive overview of the current state of research in the field will be provided, and potential future research topics will be identified.

2. Thermal Management in SOFC Combustion Chambers

SOFCs typically operate at temperatures ranging from 800 to 1000 °C [27]. SOFCs produce exhaust gases at the cathode and anode that not only carry considerable waste heat but also combustible constituents such as H2, CH4 and CO [28]. Optimizing the combustion and energy recovery from these SOFC exhaust gases is key to significantly enhancing the overall energy efficiency of these systems. The thermal management subsystem is primarily comprised of an afterburner chamber and heat exchangers. The afterburner is vital within the SOFC system, transforming the chemical energy present in the exhaust gases from the cathode and anode into thermal energy. This conversion is crucial for maintaining the thermal balance of the system [29]. Currently, researchers have shown more interest in SOFC reformers and stack efficiency [30], mainly concerning fuel utilization and preheating temperatures, while there has been less focus on the research of the afterburners for exhaust gas treatment [31,32,33].

2.1. Types and Functions

A burner, which mixes and ignites fuel (such as natural gas, liquefied petroleum gas, kerosene, etc.) with oxygen to generate high-temperature and high-pressure gases, is pivotal in applications ranging from heating to power generation. Burners are classified by size into macro, meso, and micro scales [34]. In SOFC systems, the need for fuel and air preheating and high-grade thermal energy has spurred various efficiency-improving techniques. SOFCs, unlike PEMFCs, necessitate preheated air for high-temperature functioning, typically via heat recovery and afterburners [35]. Essential processes like internal reforming are supported by recirculating anode and cathode gases, optimizing thermal management, minimizing equipment size [36], and enhancing overall system efficiency [37]. Afterburners in SOFC systems serve to combust unreacted fuels, and their selection is contingent on whether a catalyst is used, aligning with specific SOFC configurations.

Burners are classified according to their characteristics and applications into internal, external, premixed, partially premixed, discrete, ceramic, and metal types, each tailored to complement various SOFC systems, as illustrated in Table 1. In addition, ceramic burners cater to high-temperature systems, whereas metal burners are designed for medium-to-low-temperature operations. Internal recirculation burners, rerouting combustion products for added heat and efficiency, enhance temperature uniformity. The selection among these options hinges on specific system requirements and design objectives, providing a spectrum of solutions to optimize SOFC performance and efficiency.

Table 1.

The types and descriptions of SOFCs burners.

In summary, research has predominantly focused on enhancing the efficiency of SOFC reformers and stacks, while afterburners, vital for exhaust gas treatment, have received less attention. Afterburners are key to improving energy recovery efficiency and offer a variety of solutions for different applications, with Table 2 listing different types of burners and providing a brief introduction. When designing SOFC systems, the selection of an appropriate burner should align with SOFC specifications and application requirements. Future in-depth studies and optimization of afterburners are expected to improve the performance and efficiency of SOFCs.

Table 2.

The types and descriptions of SOFCs burners.

2.2. Design and Performance Optimization

Burner design plays a crucial role in SOFCs thermal management subsystem. A new burner design was developed and its performance was comprehensively assessed under diverse conditions using a computational fluid dynamics model for non-premixed combustion. The accurate simulations informed the development of automated control systems for burners in SOFC systems, improving operational adaptability [33].

On the other hand, addressing the limitations of conventional indirect heating, Noie et al. [45] introduced a direct heating method for SOFC modules to harmonize performance and stability. They determined a new burner design through thermal flow analysis, featuring clustered nozzles to avert flashback and a diffuser plate at the air inlet. Fundamental experiments were conducted to assess the combustion traits and viability of surface combustion burners for direct heating of SOFC modules, enhancing the refinement of the SOFC module heating approach.

Additionally, a compact porous media burner paired with a heat recovery unit was developed for processing biomass gases, managing to maintain stable combustion at ultra-lean ratios with operational temperatures ranging from 1300 to 1550 K, and significantly reducing emissions. The burner demonstrated a heat recovery efficiency of up to 93% and an overall system efficiency of 54%, illustrating its capability for highly efficient energy utilization and recovery in biomass fuel processing [47].

Porous Media Combustion (PMC) technology, aimed at burning low-caloric fuels often unsuitable for conventional burners, utilizes a novel approach by pre-mixing fuel and air within a solid porous matrix to enable combustion without free flames. This matrix recycles thermal energy to the reaction zone, increasing flame speed and flammability range [19]. Attracting considerable scholarly attention, research in PMC delves into different burner types and identifies performance factors such as porosity, material, and fuel type. These studies offer critical insights into PMC design and optimization, vital for boosting efficiency and sustainability across applications.

Yu et al. [48] assessed emission characteristics and thermal efficiency across porous media combustors made of metal fibers, ceramics, and stainless steel fins. The findings indicated that combustors with reduced porosity exhibited increased CO emissions and diminished thermal efficiency, informing the design of advanced condensing boilers. Banerjee et al. [49] reviewed advancements in porous media combustion, emphasizing the optimization of basic and operational parameters for compact, high-efficiency energy systems, while also highlighting existing challenges and potential research directions. Howell et al. [50] studied the emissions and radiative output of single and multi-stage porous media combustors, concentrating on non-catalytic combustion processes within the porous media, yielding key data for performance optimization. An exploration into two distinct porous media zones indicated that achieving stable combustion with low emissions across a wide range of equivalence ratios is possible, a critical discovery for improving the efficiency of porous media combustors [51]. Delalic et al. [52] developed a porous media combustor with an integrated heat exchanger to enhance heat capacity and improve flame stability. Zeng et al. [53] developed a catalytically enhanced porous media combustor integrated with a flat-chip SOFC, introducing an innovative flat-chip flame fuel cell system. In another study, Zeng et al. [54] designed a biogas-powered Flame Fuel Cell for micro-combined heat and power (CHP) systems, leveraging local resources. This setup combined a porous media combustor with a micro-tubular SOFC within the biogas FFC reactor, achieving stable combustion and steam reforming in high-temperature conditions without the need for a catalyst. An evaluation of a novel porous media combustor integrated with a heat exchanger was conducted, measuring thermal efficiency, combustion chamber temperature, and pressure drop, providing valuable data for the design of porous media combustors [55].

Design and performance optimization in current burner technology have introduced diverse approaches to boost SOFC system efficacy. Key strategies involve enhancing combustion efficiency, refining heating techniques, and perfecting porous media burners. Research predominantly centers on porous media burners, underlining the analysis of their performance across different operational scenarios. This focus is anticipated to provide pivotal insights for the ongoing evolution and deployment of SOFC technologies, aimed at escalating their efficiency and sustainable use.

2.3. Modeling and Experimental Validation of Combustors

In this section, the paper revisits the innovation and practical application of SOFC burner design concepts. The importance of model analysis and experimental validation in the advancement of burner technology is highlighted, aiming to ensure that novel burners are not only theoretically innovative but also demonstrate superior performance and reliability in practical applications. By synthesizing various experimental data and models, this section lays a solid scientific foundation and provides practical guidance for the future design and optimization of SOFC burners.

2.3.1. Modeling Analysis

In the field of burner performance for SOFC systems, modeling and experimental research have delved into critical aspects such as combustion flow, fuel efficiency, temperature profiles, and heat recovery. CFD models have been crucial in simulating burners’ internal combustion processes and analyzing performance under various conditions. Studies have examined the use of unreacted hydrogen to enhance combustion temperature and the influence of nitrogen on combustion. Table 3 provides a summary of the modeling analysis research pertaining to SOFC burners.

Table 3.

Modeling analysis of the SOFCs afterburners.

Wu et al. [59] conducted a study on the thermal performance of the afterburner in a natural gas SOFC system using computational fluid dynamics simulations. They found that the flow rate, temperature, gas composition ratio, and steam-to-carbon ratio are crucial factors influencing the temperature distribution in the afterburner. Kashmiri et al. [56] developed a three-dimensional model of an integrated combustion unit. Their simulations demonstrated that harnessing unreacted hydrogen from the SOFC anode as combustor fuel markedly increased temperature and heat transfer to the reformer, optimizing combustor function and conserving natural gas.

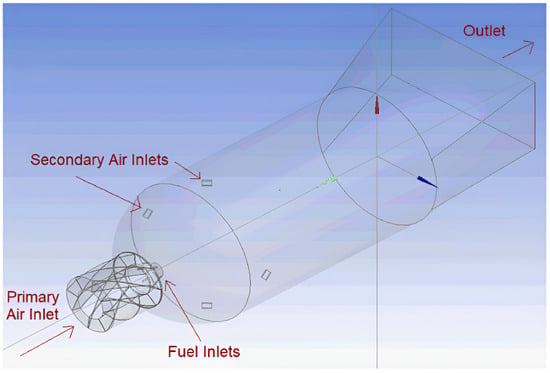

Jaimes et al. [60] developed a simple yet efficient burner to support a hybrid power system comprising SOFC and Gas Turbines (GT). A typical Gas Turbine annular combustor was designed, and its CFD model is presented (Figure 2). It is designed with primary air injection upstream of these fuel inlets, utilizing an axial swirl stage, and secondary air is strategically introduced into deeper areas of the combustion chamber through specialized “cooling holes”. Chang et al. [29] developed a CFD model for an afterburner to simulate its combustion flow field, mixing exhaust with hydrogen and nitrogen gases in various ratios. Their findings indicated that with hydrogen levels below 60%, exhaust temperatures fell below 950 °C, facilitating the use of materials unsuitable for higher temperatures and thus cutting costs. Additionally, their research highlighted nitrogen’s substantial influence on both temperature uniformity and outlet temperatures.

Figure 2.

The 3D CFD model for a Gas Turbine Combustor, part of a Chemical Reactor Network, includes six fuel inlets and two distinct air inlets [60]. Copyright 2021 Elsevier.

Ilbas et al. [44] applied CFD to model swirl combustors under various combustion scenarios, analyzing temperature distributions by modulating oxygen levels and examining their impact on SOFCs, alongside flame characteristic studies within the SOFC framework. Feng and Chen [57] employed CFD to evaluate the flow dynamics within SOFCs, aiming to ensure temperature consistency and efficient combustor operation. Their innovations include a plate combustor design that minimizes pressure drop and fuel residue, with adjustable airflow to control NOx emissions. Additionally, porous media combustion technology, recognized for enhancing combustion power, flame stability, and lean flammability limits, is prevalently used for burning ultra-low heating value gases. Dai et al. [58] created a numerical model for a two-dimensional porous media combustor, investigating the combustion dynamics of low-concentration coal mine gas and steam. Their study assessed how steam concentration affects temperature distribution, flame stability, and chemical processes. Findings revealed an inverse relationship between peak temperatures and steam mole fraction, noting a reduction in flame stability range with increased steam content.

2.3.2. Experimental Validation

Experimental work has supported these models, exploring optimal operational parameters and integrating burners into SOFC systems for effective heat management, providing valuable insights for system integration. Table 4 provides a summary of the experimental validation research pertaining to SOFC burners.

Table 4.

Experimental validation of the SOFCs afterburners.

Chen et al. [28] explored the combustion properties of SOFC exhaust by developing a pre-mixing system and a testbed for porous media combustion. The designed SOFC exhaust gas premixing and combustion system can be divided into four parts: the gas supply section, heating section, measurement section, and combustion section.

Their experimental analysis of exhaust gas combustion under varied fuel utilizations revealed a decline in combustible elements and a consequent drop in combustion zone temperature with higher fuel utilization. Furthermore, the airflow speed at the combustor’s inlet notably influenced the combustion’s power, temperature, and stability. The research delineated how stable combustion limits and adiabatic flame temperatures shifted with fuel utilization, offering insights critical for optimizing SOFC exhaust usage efficiency.

Yen et al. [32] integrated a combustor into an SOFC system to achieve heat recovery by combusting residual fuel from the anode side with high-temperature air from the cathode side. The combustor operates continuously from the system startup phase to the normal operating phase to adapt to the dynamic operation of the SOFC stack. Noie et al. [45] recognized the issues with indirect heating methods, including the need for heat exchangers and high-temperature piping to transfer heat from the combustor to the module, which complicates the structure and results in thermal losses. Hossain et al. [61] evaluated an electrolyte-supported SOFC with air/ethylene premixed flames, analyzing its performance through electrochemical reactions with ethylene. They examined power density changes in relation to cell-burner spacing and air/fuel mix ratios, especially at maximum power density points corresponding to current density shifts. Danylo et al. [62] established a mixed SOFC-gas turbine power generation test rig and focused on the impact of internal fuel utilization on system efficiency. The results indicated that the hybrid system could achieve high electric power generation efficiency (>70%) over a wide range of operational conditions (60% < fuel utilization rate < 90%). However, with the reduction in the size of the SOFC stack, fuel utilization efficiency decreased.

Yen et al. [32] conducted experiments with a custom combustor for recuperating exhaust from a 1 kW SOFC, finding optimal operation at a cathode exhaust temperature of 650 °C, anode exhaust temperature of 390 °C, and an excess air ratio of 2, with the capability for sustained continuous operation. Yu et al. [63] experimentally studied the combustion characteristics of high-temperature fuel cell exhaust using catalytic combustion. A numerical study was conducted on combustors designed for handling SOFC anode exhaust, with results compared to experimental data to validate the simulations’ accuracy. These findings assist in the advancement of self-regulating combustors for SOFC exhaust processing [33]. Kim et al. [46] studied a Hot BoP system for a 2 kW SOFC, aimed at harnessing high-temperature exhaust. This Hot BoP system, incorporating a combustor, an air preheater, and a steam generator, sought to reclaim waste heat from combustion. Performance evaluations under different loads showed that the system achieved approximately 60% thermal efficiency at 2 kW SOFC operation, with reduced CO emissions beyond an equivalence ratio of 0.25, providing insights into efficient SOFC waste heat utilization.

This section reviews advancements in burner research for SOFC systems, including diversity in afterburner types and their selection based on application needs and design. While current studies prioritize SOFC reformers and efficiency, afterburner research lags. Focus on enhancing porous media burners is notable for its potential to boost SOFC efficiency. CFD and experiments are pivotal for analyzing performance metrics like combustion flow and heat recovery, providing insights to optimize SOFC performance and informing future SOFC applications through improved burner design and operation.

3. Thermal Management of SOFC Heat Exchangers

The heat exchanger is fundamental in SOFC systems, impacting temperature regulation, heat recuperation, and system stability. It manages the operational temperature, ensuring the fuel cell remains within an optimal range, and harnesses the cell’s released heat for additional applications like space heating or water heating, thereby elevating the system’s efficiency and curtailing energy loss. Concurrently, by dissipating surplus heat, the heat exchanger safeguards against fuel cell overheating, maintaining a consistent temperature profile essential for SOFC performance.

Significant advancements have been achieved in SOFC heat exchanger research, including material studies [64,65], design and optimization [66,67], performance evaluation, durability research, as well as integration and system optimization. These studies aim to address issues related to temperature control, heat recovery, durability, and overall system performance, thereby driving the continuous development and commercial application of SOFC technology. Such research contributes to enhancing the efficiency, reliability, and sustainability of SOFC systems, thereby advancing the field of clean energy.

When designing the thermal management of fuel cell systems, three key aspects need to be considered: system size/weight, thermal resistance, and electrical resistance. Moreover, the design of heat exchangers should pay particular attention to two critical factors: pressure drop and heat transfer, as they have a significant impact on the performance of different types of fuel cell stacks, including PEMFCs and SOFCs [64]. Therefore, when designing heat exchangers, other important parameters of the fuel cell stack should be taken into account.

3.1. Types and Functions

Heat exchangers are pivotal in fuel cell systems, essential for regulating internal temperatures to maintain optimal operating conditions for cells and components, thereby underpinning system performance, efficiency, and stability. They are broadly categorized into two primary types: tubular and plate heat exchangers. Table 5 provides a summary of the types and descriptions to SOFCs heat exchangers.

Table 5.

The types and descriptions of SOFCs heat exchangers.

Tubular heat exchangers facilitate heat transfer through tube walls and include designs such as shell-and-tube, helical-coil, and double-pipe configurations. Plate heat exchangers, on the other hand, achieve heat transfer through plate surfaces and come in various forms, including flat-plate, spiral-plate, and plate-fin designs. Among plate heat exchangers, further distinctions can be made based on structural variations, such as fin patterns, including offset strip fins, louvered fins, and corrugated fins, as well as crossflow and counterflow designs.

These heat exchanger types find applications in various areas, including preheating cathode air, heat recovery, and thermal exchange networks, aiming for high heat transfer efficiency, low pressure drop, and excellent mechanical performance to minimize thermal stress. To optimize performance, multi-objective optimization algorithms are often used, and the selection of suitable materials, such as ceramics, is considered along with different structural variations, such as rectangular or coiled designs.

In summary, the diversity of heat exchanger types and designs is integral to enhancing energy efficiency and performance across various industries and energy systems. The selection of an appropriate heat exchanger design is thus tailored to the specific demands of the application and operational context.

3.2. Design and Performance Optimization

In the field of heat exchangers for fuel cell systems, researchers have conducted a series of significant works aimed at enhancing system performance, efficiency, and sustainability. These efforts have encompassed various heat exchanger types and application areas, providing a crucial theoretical foundation and experimental validation for different types of fuel cell systems.

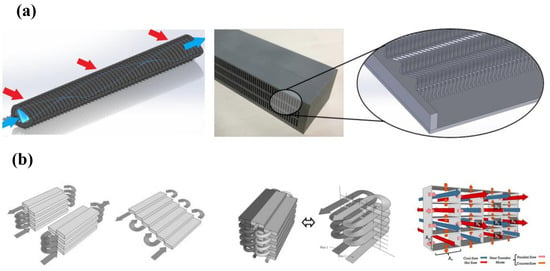

Odabaee et al. [64] conducted experimental research to optimize the design of heat exchangers, focusing on the heat transfer performance of metal foam placed between two bipolar plates. They verified its feasibility. Hollmann et al. (Figure 3a) [65] explored two different additive manufacturing methods for producing heat exchangers (3D-HEX) and designed efficient heat exchangers to achieve compact designs within limited space and prevent gas leakage. Córdova et al. [66] developed a low-pressure drop ceramic heat exchanger for SOFC cathode air preheaters, utilizing a quasi-spiral flow channel array design to improve heat transfer performance (Figure 3b). Nguyen et al. [68] designed and fabricated a coil-in-tube heat exchanger installed at the front end of the fuel inlet of SOFC devices to elevate the inlet gas temperature, significantly improving system performance (Figure 4a). Magistri et al. [69] studied the role of heat exchangers in low-temperature fuel cell systems and high-temperature hybrid gas turbine systems, emphasizing the significant impact of heat exchangers on performance. Wan et al. [70] proposed brazing manufacturing techniques and isothermal solidification brazing technology, enhancing the microstructure of plate-fin heat exchangers to improve their strength and ductility, promoting the long-term operation of SOFCs. Tanozzi et al. [71] developed a model to calculate key characteristics of heat exchangers, providing design guidelines for rectangular small channel heat exchangers (Figure 4b). Murphy et al. [67] introduced the design, manufacturing, and performance of a novel ceramic microchannel reactor for heat exchangers and fuel reforming applications (Figure 4c).

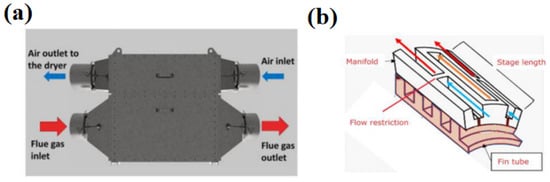

Figure 3.

Outlines the design and performance optimization of diverse heat exchangers for SOFCs. (a) Additive manufacturing was used to create 3D heat exchangers (3D-HEX) for space-efficient, leak-proof designs [65]. Copyright 2022 MDPI. (b) A low-pressure drop ceramic exchanger with a quasi-spiral channel array designed for cathode air preheating is elaborated, including design schematics [66]. Copyright ASME 2016 Power Conference.

Figure 4.

Outlines the design and performance optimization of diverse heat exchangers for Solid Oxide Fuel Cells (SOFCs). (a) The design and positioning of a tubular heat exchanger for an SOFC fuel inlet are explained, with a corresponding design schema [68]. Copyright 2018 Elsevier. (b) A model offering design parameters for rectangular microchannel heat exchangers is discussed [71]. Copyright 2019 Elsevier. (c) A ceramic microchannel reactor are depicted in an exploded view [67]. Copyright 2011 ECS Transactions.

The study employed the PINCH technique to design a heat exchanger network for ethanol-fueled SOFC systems. This approach effectively utilizes waste gases from the fuel cell and combustion processes within the heat exchanger network to achieve energy balance requirements [72]. Tsikonis et al. [73] developed a mathematical model for a working thermocouple and integrated it into a mathematical model for a heat exchanger, enhancing temperature control for heat exchangers to more accurately approximate actual gas temperatures. Chen et al. [74] studied the natural convection phenomena in a novel plate heat exchanger for solid oxide fuel cell system heat cycling through a combination of computational fluid dynamics simulations and experimental temperature measurements. Li et al. [75] established a partial load component model through multi-objective optimization methods for the design and optimization of heat exchanger networks and physical structures, emphasizing thermal integration to reduce external cooling utility demands while balancing heat transfer coefficients and pressure losses in heat exchanger designs. Jouhara et al. [76] employed a heat pipe heat exchanger to recover waste heat from ceramic kilns and successfully implemented it in factories, providing a replicable waste heat recovery tool (Figure 5a). Tiwari et al. [77] designed an innovative manifold microchannel heat exchanger with commercially available finned tubes as the geometric shape for microchannels and flow distribution through 3D-printed polymer manifolds, reducing manufacturing costs and enhancing performance, suitable for large-scale manufacturing (Figure 5b). Amakiri et al. [78] conducted a mathematical model to describe a dual-pipe heat exchanger with internal fins to recover heat from SOFC cathode waste gases, investigating the capture and utilization of SOFC waste gases to provide energy for refrigerated trucks.

Figure 5.

Outlines the design and performance optimization of diverse heat exchangers for SOFCs. (a) A Heat Pipe Heat Exchanger (HPHE) for the Balance of Plant (BOP) is detailed, highlighting its utility in waste heat recovery [76]. Copyright 2021 Elsevier. (b) An innovative finned tube tubular manifold microchannel heat exchanger with a 3D-printed manifold is presented, including cross-sectional views and a prototype [77]. Copyright 2019 Elsevier.

Meier et al. [79] presented a simple method to predict the thermal characteristics of a micro-SOFC system. They explored the basic design requirements for thermally self-sustaining operation at a stack temperature of about 550 °C. They found that at high electrical efficiencies and, hence, low heat-release rates, a recuperator is needed to achieve the desired operating temperature. Mottaghizadeh et al. [80] proposed an isolated microgrid system that integrated stacks of SOFCs and electrolyzers to realize a thermally self-sustaining energy storage system. The thermal management of solid oxide electrolyzer cells (SOEC) was achieved by utilizing the heat from SOFCs and a heat exchanger network in combination with control strategies. Ki et al. [81] simulated the start-up transients of a Compact Heat Exchange Reformer (CHER) for small SOFC systems, exploring integrated heat and reforming processes with varying temperatures, steam-to-carbon ratios, pressure gradients, and flow configurations.

These studies have involved using metal foam [64], additive manufacturing techniques [65], different materials [66], and structural designs to improve heat exchanger performance. Their objectives include reducing pressure drops, enhancing heat transfer efficiency, and increasing system reliability. Notably, unique designs for various applications, such as ceramic heat exchangers for SOFC cathode air preheaters and coil-in-tube heat exchangers, as well as the critical role of heat exchangers in low-temperature fuel cell systems and high-temperature hybrid gas turbine systems, have been highlighted.

These research efforts also encompass the application of multi-objective optimization methods to achieve performance balance, reduce energy waste in systems, while meeting various constraints. Furthermore, some studies emphasize the importance of energy efficiency and waste heat recovery, providing powerful tools for fuel cell systems and industrial applications.

In summary, these studies provide valuable insights into the design and optimization of heat exchangers, with the potential to drive the advancement of fuel cell technology, enhancing the efficiency, reliability, and sustainability of energy systems. Through ongoing research and innovation, we can better meet specific application requirements, reduce energy waste, and mitigate adverse environmental impacts. Research on heat exchangers within SOFC systems has advanced, spanning metal foam, additive manufacturing, ceramic, tubular, and heat pipe exchangers to meet diverse application needs. These studies aim to enhance system reliability by improving heat transfer efficiency and reducing pressure losses, employing multi-objective optimization to balance performance and energy savings. Despite progress, challenges persist. Some research focuses narrowly on specific SOFC systems, lacking broader applicability. Comprehensive studies on the sustainability and life-cycle analysis of heat exchangers are needed to fully understand their environmental impacts. Additionally, heat management, particularly thermal loss, remains a technical hurdle in fuel cell efficiency. Future research must concentrate on multi-objective optimization and innovation in heat exchanger materials and manufacturing processes. Advancing efficient and sustainable heat exchanger technologies towards commercialization necessitates in-depth and extensive research to overcome technical challenges and knowledge gaps.

4. SOFC Thermal Management Strategy

SOFCs technology has been a subject of significant interest due to its numerous advantages, including high efficiency, low emissions, and fuel flexibility. However, in practical applications of SOFCs, thermal management has been a persistent concern, especially at high operating temperatures, which can lead to increased temperature gradients and, consequently, reduced system efficiency and cell performance. To address this issue, researchers have proposed various thermal management strategies and technologies to ensure that SOFC systems operate in a suitable high-temperature environment.

4.1. Fuel Composition Management

The source of fuel greatly influences the environmental impact of fuel cells [82]. The diversity of fuels poses a challenge to the thermal management of the system, as varying fuel compositions can induce different thermal stresses and changes in system performance [83,84]. When researchers employ various types of fuels within the same integrated fuel cell reformer system, it can potentially lead to significant thermal management issues [85,86]. Sun et al. [87] assessed four configurations of integrated ammonia-based SOFC systems, pinpointing the most effective system integration and operational parameters. Their research revealed that, despite varying fuel flow rates, the internal gas partial pressure in the fuel cell stacks remains largely stable. However, with increased fuel flow, there is a corresponding rise in current density, which escalates polarization losses, thereby augmenting both irreversible and reversible heat outputs. Kim et al. [88] conducted a three-dimensional numerical simulation to analyze the geometry and operating conditions of a 1 kW stack, providing spatial analysis of the heat conditions within 30 individual cells of the stack. The study revealed that temperatures within the stack vary with air flow, especially as air and fuel enter the top of the stack, indicating the significant influence of gas heating, optimizing gas flow (especially at the bottom of the stack), and conduction heat transfer through interconnects are key strategies. These strategies can alter critical heat transfer paths and internal thermal conditions to ultimately optimize the performance of SOFC stacks.

Menon et al. [31] emphasized the significance of fuel adaptability and thermal management in proton-conducting SOFCs. Their computational model suggested that high fuel channel inlet velocities can increase current and power density but may reduce fuel utilization and efficiency. Therefore, effective thermal management and innovative materials are essential for improving system performance and sustainability.

On the other hand, Selvam et al. [89] used artificial neural networks and parameters like pressure drop, fuel utilization, etc., to improve the efficiency of ammonia and hydrogen-fueled SOFC systems, achieving approximately 12% higher efficiency compared to traditional systems. This demonstrates that improvements in system design and fuel management can significantly enhance SOFC system performance. Additionally, Dong et al. [90] designed a 1 kW comprehensive auxiliary power device system, studying the impact of factors such as fuel type and channel size on system performance. Their research emphasized the importance of channel size on SOFC performance and net efficiency.

Fuel component management is also a critical issue. Zhang et al. [84] focused on SOFC systems using hydrogen and methane as fuels, discovering differences in thermoelectric properties at different power levels. Their work provides a foundation for future system control strategies, particularly regarding the thermal management of SOFC stacks, to improve fuel adaptability and ensure stack temperature safety. Kim et al. [91] examined the performance of SOFC stacks by conducting thermal and fluid dynamic analyses on four-cell stack configurations they developed, exploring a range of fuel and flow variables. Fardadi et al. [92] proposed a novel approach relying on partial internal reforming to maintain the strong power tracking performance of fuel cells while minimizing thermal stress. This is crucial for stability and performance optimization of SOFC systems. Yang et al. [93] conducted dynamic analysis on a 10 kW SOFC-CHP system, finding the need to optimize adjustments to airflow and operating current related to fuel utilization for maximum power generation and efficiency. Hartwell et al. [94] investigated the effects of system design modifications, environmental variables, and fuel composition on SOFC performance. Their simulation work, which centered on methane combustion exhaust gas, uncovered intricate reaction pathways of carbon monoxide as a fuel, leading to a minor performance dip yet with minimal overall effect, thereby informing the advancement of SOFC-CHP systems. Nonetheless, stability assessments highlighted the necessity for the stringent management of operating parameters and carbon deposition control. These studies collectively underscore the critical factors in SOFC systems, including fuel component management, feedstock management, system fuel utilization, and air management, to enhance performance, efficiency, and sustainability. By leveraging these insights, future SOFC technology can advance towards higher efficiency and sustainability.

In conclusion, researchers have focused on fuel adaptability, recognizing that various fuel components can impact thermal stress and system performance. They have utilized methods such as 3D numerical simulations, adaptability analysis for proton-conductive SOFCs, and neural network applications, highlighting the importance of controlling gas heating, optimizing gas flow, and heat transfer to enhance SOFC performance. Studies have also revealed the impact of fuel type and channel size on system performance, providing valuable insights for design while acknowledging challenges like thermal management complexity and the need for more comprehensive adaptability research.

4.2. Flow Channel and Arrangement Design

Metal interconnects play a crucial role in SOFC stacks, serving not only to delineate individual cells but also to establish gas flow channels and ensure efficient thermal conductivity. Advancements in SOFC performance are increasingly reliant on the innovation of channel designs, including the refinement of height-to-width ratios, channel spacing, and the introduction of new geometries. However, the operation of SOFC stacks under conditions of high fuel utilization introduces significant chemical potential gradients that can adversely affect cell performance. In response, the targeted optimization of channel geometries, particularly in high-utilization scenarios, is crucial for reducing these gradients and thereby bolstering cell efficiency and longevity. This focus on channel design optimization is pivotal for enhancing the overall efficiency and sustainability of SOFC technology, signifying a critical pathway for the advancement of this robust energy system.

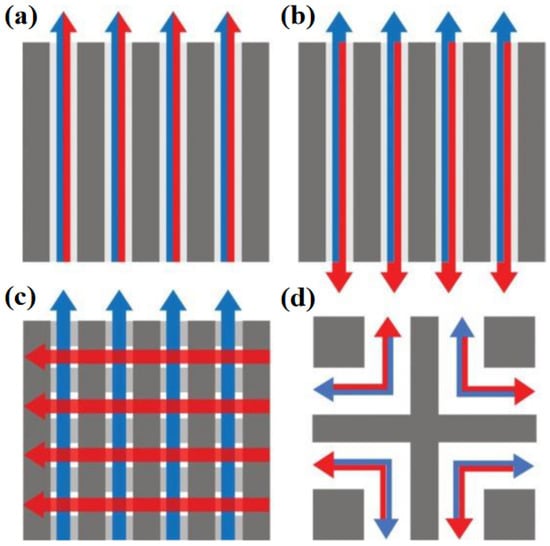

There are three primary flow configurations in SOFCs: counter-flow, co-flow, and cross-flow. It is generally believed that under similar conditions, counter-flow results in a larger temperature gradient compared to co-flow [95,96]. Recknagle et al. [97] compared the temperature fields under these three flow modes and found that the co-flow configuration exhibited the smallest temperature difference, while the cross-flow mode showed the largest. Gong et al. [98] proposed a novel rotary L-shaped flow field and conducted comparative studies on four different flow field configurations. The flow directions in the parallel flow fields are depicted in Figure 6a,b. Figure 6c,d illustrate the flow directions in the cross-flow and rotary L-shaped flow fields, respectively.

Figure 6.

Flow directions in the main flow fields, the red arrow indicates the direction of the fuel intake and the blue arrow represents the air intake: (a) co-flow in a parallel flow field; (b) counter-flow in a parallel flow field; (c) cross-flow field; (d) rotary L-shaped flow field [98]. Copyright 2023 Elsevier.

Manglik and Magar [99] conducted a study on the heat and mass transfer processes in planar single cells using three different flow channel structures: rectangular, triangular, and trapezoidal. Their findings indicated that shallower rectangular channels are more conducive to heat and mass transfer, thereby optimizing the temperature distribution. Wu et al. [83] developed three novel channel structures (semi-circular, rectangular, and trapezoidal baffles), which effectively reduce the temperature gradient and enhance the performance of SOFCs, with the rectangular baffle structure demonstrating particularly significant improvements. Xu et al. [100] developed a two-dimensional multiphysics model to investigate the influence of various operational and structural parameters on the heating process and cell temperature of porous SOFCs. Their findings indicated that reducing the porosity of the electrolyte can help lower the maximum temperature. Additionally, it was observed that at lower operating potentials, the maximum temperature in electrolyte-supported cell structures is higher than in anode-supported cell structures. Andersson et al. [101] designed rectangular flow channels of three different sizes to study the impact of channel dimensions on the mass and heat transfer processes. The results demonstrated that wider and thinner channel designs could reduce the mass transfer resistance of gases, increase current density, and thereby enhance the electrochemical heat generation and the maximum temperature. Danilov et al. [102] designed a channel equipped with semi-circular baffle tubes to optimize heat and mass transfer in SOFCs.

Zeng et al. [103] conducted experimental research on the performance of tubular flame fuel cell modules equipped with heat pipes. The experimental results showed that with the aid of thermal management by the heat pipes, the axial temperature gradient was reduced from 24 K/10 mm to 14 K/10 mm. Marra et al. [104] employed CFD to refine the design of current collectors and gas distributors, with their models providing significant insights based on key fluid dynamic parameters. Gong et al. [98] introduced a novel rotating L-shaped main flow field that improved temperature distribution and subsequently enhanced SOFC performance. Magar et al. [105] focused on convective heat and mass transfer to ensure uniform electrochemical reaction rates. Their simulation studies revealed that the cross-sectional aspect ratio of interconnect channels and relative thickness of the anode porous layer played a crucial role in performance. Manglik et al. [99] conducted computational simulations to investigate the impact of different bipolar plate interconnect channel shapes on heat and mass transfer. Rectangular channels, especially those with relatively shallow depths, demonstrated superior thermal management performance.

Hesami et al. [16] conducted a study on the impact of different flow channel types (rectangular, trapezoidal, and triangular) on SOFC performance, utilizing a three-dimensional numerical model for their analysis. Wu et al. [83] innovated with three unique channel structures that incorporated semi-circular, rectangular, and trapezoidal shapes to mitigate temperature disparities and enhance SOFC function, with the rectangular design yielding particularly notable improvements. Sun et al. [106] conducted a numerical study to evaluate the impact of four different flow channel designs (serpentine, double serpentine, rod bundle, and oblique rib) on cell performance in a co-flow configuration, finding limited differences in polarization curves. Lee et al. [107] reduced chemical potential gradients by using diffuser-shaped fuel channels and optimized their design to decrease electrochemical reaction rates at the reaction electrode. Kim et al. [108] introduced a novel interconnect design to enhance thermal management by achieving uniform temperature distribution through changes in the gas manifold’s positioning.

Computational fluid dynamics and 3D numerical models have been employed to refine the design of current collectors and gas distributors, enhancing temperature uniformity and ensuring consistent electrochemical reaction rates. Researchers have investigated various interconnect channel shapes and structures, as well as porous ceramic insulator designs, to reduce thermal conductivity and improve thermal management. The studies underscore the critical impact of flow channel design on SOFC performance, particularly under high fuel utilization conditions. Despite progress in metal interconnects and flow channel design, gaps remain in areas such as experimental validation, fuel adaptability studies, long-term stability analysis, and multi-parameter optimization.

4.3. Heat Pipe Design

A heat pipe is an efficient and streamlined heat transfer device, notable for its lack of moving parts. The device comprises a hollow tube, its inner wall lined with multiple layers of metal wire mesh, referred to as the “wick” or “core”. The tube is filled with a liquid medium, the physical properties of which are compatible with the evaporation and condensation temperatures prevalent in its application environment [109].

The design of heat pipes is aimed at effectively managing the heat generated within SOFCs to ensure uniform temperature distribution, improve performance, and extend their lifespan. Radiative heat transfer is a crucial factor in SOFC systems, influencing temperature fields and overall operating conditions [110]. Typically, heat pipes are integrated within the chimneys of SOFCs, which complicates the chimney design and makes it challenging to manufacture [111,112], Santhanam et al. suggest positioning the heat pipes between two stacks, rather than integrating them within the SOFC stacks themselves [109].

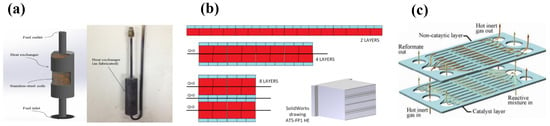

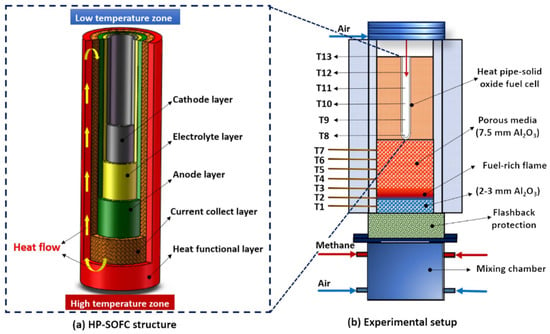

Magar et al. [113] studied various geometric shapes for interconnect channels to enhance the heat and mass transfer characteristics of SOFCs, particularly by employing geometries with offset interrupted walls, achieving improved cooling effects. Dilling et al. [114] established a three-dimensional model of a SOFC, which integrates a heat pump and an internal reforming reaction unit. Zeng et al. [115] conducted research on a highly thermally integrated heat pipe-solid oxide fuel cell (HP-SOFC). The HP-SOFC is composed of a thermal functional layer, a current collecting layer, an anode layer, an electrolyte layer, and a cathode layer (Figure 7). Marocco et al. [116] investigated methods to enhance the performance of SOFC systems, especially under extreme thermal conditions, using heat pipes. They found that heat pipes significantly improved system performance, resulting in higher current density and power density.

Figure 7.

HP-SOFC structure and experimental setup [115]. Copyright 2018 Elsevier.

Zeng et al. [115] designed a heat pipe–SOFC system to balance temperature distribution and enhance electrochemical performance. Their research highlighted the potential advantages of heat pipes in improving SOFC system performance. Promsen et al. [117] improved temperature distribution and air utilization by integrating metal phase-change materials (mPCMs) into the SOFC stack, reducing parasitic losses from the air blower. Lai et al. [118] established a full cell model for a single-tube direct ammonia cracking SOFC, analyzing the mechanisms of thermal shock formation, providing theoretical support for optimizing the thermal management of ammonia cracking SOFCs. Zheng et al. [119] introduced a novel cooler for SOFC stacks, which precisely controls the internal thermal ammonia decomposition reaction to reduce the maximum temperature difference within the SOFC stack, thereby improving system performance. Zeng et al. [120] reduced the axial temperature gradient by introducing circular disturbances in the airflow channels, thereby enhancing the convective heat transfer coefficient. The local convective heat transfer coefficient of the airflow with these localized disturbances was found to be approximately four times that of conventional channels.

Heat pipe design is crucial in SOFC systems for effective thermal management, performance enhancement, and lifespan extension. Studies have focused on radiative heat transfer and radiation transport within electrodes and electrolyte layers. While heat pipes have improved SOFC performance and thermal and mass transfer properties, and the integration of mPCMs and flat heat pipes has enhanced thermal management and operational flexibility, gaps remain in experimental validation, practical applications, and long-term stability research.

4.4. Exhaust Gas Recovery Strategy

Recycling exhaust gases can significantly enhance the efficiency of SOFC systems. Among various strategies for exhaust gas recovery in SOFC systems, the utilization of Anode Off-Gas (AOG) has garnered particular interest due to its content of unreacted fuel, steam, and heat. Strategies for utilizing AOG include mixing it with inlet fuel to harness its heat [121], steam [122], and unreacted fuel [123] for reforming, aimed at improving fuel efficiency, as well as combining it with Cathode Off-Gas (COG) for oxidation to serve as a heat source for heat exchangers [124]. Beyond anode exhaust recovery, cathode exhaust and afterburner exhaust recycling also present viable solutions, albeit with a need to consider potential drawbacks of cathode inlet dilution. Additionally, the high-temperature exhaust from SOFCs offers a high-quality heat source for the integrated thermal cycles of equipment such as gas turbines [125], steam turbines [126], and Rankine cycles [127], further optimizing energy utilization.

4.4.1. Recovery and Recycling of Anode and Cathode Exhaust Gases

In SOFC systems, the ability to efficiently integrate into district heating networks is facilitated by their inherent heat generation. The preference for external reforming, widely adopted due to SOFCs’ low carbon deposition risk and minimal temperature gradients [128], allows the transformation of hydrocarbon fuels into hydrogen and carbon monoxide [129]. Steam reforming stands out as the prevalent hydrogen production method for SOFCs [130,131], while explorations into dry (DR-SOFC) [129,132] and partial oxidation reforming (POR-SOFC) [133] systems seek to expand fuel processing methods. Though steam and dry reforming require significant heat, partial oxidation offers a lower thermal demand at the expense of potential fuel efficiency and safety concerns. Autothermal reforming has emerged as a solution to optimize fuel processing. Wang et al.’s tri-reforming approach [30], combining steam, dry, and partial oxidation reforming, proposes four system configurations to enhance cogeneration in marine SOFC systems by optimizing exhaust gas recirculation (COGR), thus improving exhaust heat quality and reducing air preheating needs.

Van Veldhuizen et al. [134] and further studies by Mehr et al. [135] and Chen et al. [136] support using COGR for preheating, enhancing thermal efficiency. Wang et al. [137] introduced a low-temperature cathode recirculation strategy to address high-temperature COGR challenges, albeit with increased thermal losses and system size. Ejectors offer an alternative for recirculation but present control challenges [138].

4.4.2. Waste Heat Recovery

Waste heat recovery plays a crucial role in improving the efficiency of SOFC systems and reducing environmental impacts. Researchers employ various strategies to recover and effectively utilize the waste gases produced by SOFCs. These strategies include using rich fuel combustion, integrating heat management and fuel processing systems, transforming residential and industrial heating equipment into CHP systems, multistage waste gas energy recovery, utilizing flame fuel cells and biogas as fuels to enhance system efficiency and reduce material requirements. Additionally, waste heat recovery strategies convert the waste heat from SOFCs into secondary fuels, such as hydrogen, thereby increasing system efficiency and reducing complexity and costs. Thermal control strategies also have a significant impact on the overall system performance. Hybrid SOFC systems are one of the key directions in future power technologies, offering advantages such as high efficiency, low emissions, and fuel diversification. The comprehensive application of these strategies holds the potential to drive the development of renewable and clean energy, reduce carbon emissions, and enhance environmental protection.

Configurations of SOFC power plants and hybrid generation systems are fully analyzed in [139]. An innovative tri-generation process with a high sustainability index was proposed, utilizing sequential thermal recovery in three stages [140]. Milcarek et al. [141] introduced an innovative stove system that incorporates flame-assisted fuel cells. This system combines heat management and fuel processing by using rich fuel combustion. It not only provides electricity and heat for homes and businesses but also offers resilient heating during power outages. This strategy improves traditional heating systems and enhances energy efficiency. Tan et al. [142] presented a novel CHP/CCP system integrating a SOFC-GT plant with a solar-assisted lithium bromide absorption cooling/heating unit. This system effectively matches waste heat with solar thermal water, achieving balanced electricity and thermal/cooling output. A novel geothermal ORC-SOFC-GT combined power generation system has been proposed. The high-grade heat in the SOFC exhaust gas can effectively enhance the performance of geothermal power generation [143].

Zhang et al. [144] proposed a multistage waste gas energy recovery strategy to improve the efficiency and performance of SOFC-CHP systems. The strategy, known as multistage exhaust gas combustion, significantly boosts system efficiency, reduces operating temperatures, and lowers material requirements, ultimately achieving an overall combined power generation efficiency of 92%. Zeng et al. [54] introduced a micro CHP system that utilizes local resources, using biogas as fuel. This system directly integrates a porous medium combustor and micro-tubular SOFC into a biogas reformer, achieving efficient rich fuel-steady combustion and providing a high-temperature environment and steam reforming capability to the SOFC. McLarty et al. [145] developed an innovative cogeneration system that converts waste heat from fuel cells into secondary fuels like hydrogen, enhancing system efficiency while reducing complexity and costs. They also developed a unique controller for fuel cooling in fuel cell systems.

The study conducted a thermoeconomic optimization and assessed the performance of a dual-loop organic Rankine cycle system, utilizing 20 different working fluids for waste-heat recovery from SOFCs. Key findings include an exergy efficiency of 52%, the generation of 969 kW of electricity, and a cooling capacity of 564 kW. However, the study noted limitations, such as the lack of environmental analysis and the absence of hydrogen generation assessment in the system [127]. Hai et al. [146] focused on designing and developing an Electricity/Cooling Cogeneration System (ECCS) that utilizes a methane-fueled SOFC, along with a booster/ejector-assisted organic flash cycle. This system is engineered to recover heat from the exhaust gases. Zhang et al. [147] proposed a Biomass Energy with Carbon Capture and Storage (BECCS) system that integrates biomass gasification (BG), SOFCs (SOFC), micro gas turbines (MGT), heat recovery (HR), and carbon capture and storage (CCS). The system achieved an electricity generation efficiency of 46.2% and a CHP efficiency of 73.6%. Soleymani et al. [148] developed a novel configuration integrating SOFCs and gas turbines, combined with a biogas reforming cycle, for the purpose of the cogeneration of heat and power, as well as hydrogen production. Park et al. [146] proposed a system layout for the solid oxide fuel cell/gas turbine system and conducted a comparative evaluation of its performance. It was found that in terms of SOFC thermal management, the exit gas recirculation scheme exhibited better performance than the cathode heat exchange scheme. Arpino et al. [149] introduced a zero-dimensional model for simulating micro CHP systems based on SOFCs, emphasizing the significant impact of thermal control strategies on system performance. Nikiforakis et al. [150] conducted research on SOFC/ICE hybrid systems, placing the engine downstream of the SOFC subsystem. They explored anode exhaust gas combustion under different combustion modes to optimize system performance. They found that the system’s performance varied significantly under different modes, with the homogeneous charge compression ignition (HCCI) mode yielding the best results. Chung and colleagues investigated the impact of energy recovery on SOFC efficiency [151]. They supplied the high-temperature unreformed fuel directly from the SOFC to the afterburner and improved overall system efficiency from 50% to 68% by partially combusting anode exhaust gas and recycling steam. Kim et al. [46] studied a 2-kilowatt SOFC system with a focus on the integrated Hot BoP system for recovering waste heat from high-temperature exhaust gases. Experimental results showed a thermal efficiency of approximately 60% under the rated operation.

Waste heat recovery is critical for enhancing the efficiency of SOFC systems and reducing their environmental impact. Researchers have devised numerous strategies, including maximizing the chemical energy utilization from exhaust gases and integrating thermal management with fuel processing systems. Despite significant advancements, there are still areas lacking in-depth research, such as the need for practical application validation, the analysis of system long-term operation and stability, and limited studies on the synergistic optimization of multiple system components and parameters at the system level, as well as cost–benefit evaluations. Future research must delve into these areas to advance SOFC technology development and its practical application.

4.5. Strategies for Mitigating SOFC Degradation and Enhancing System Efficiency

Degradation in SOFCs systems is impacted by the material composition and structural integrity of anodes, cathodes, electrolytes, and interconnects. It has been identified that developing materials with slower degradation rates stand as a pivotal approach to address degradation issues [152]. The aging process in SOFCs, characterized by a gradual decline in performance over time, is attributed to a myriad of chemical and physical factors that influence different SOFC components, resulting in decreased power output and efficiency [153,154]. The key factors contributing to SOFC aging include thermal cycling, sintering of electrode materials under high operational temperatures, and chemical interactions between cell materials and fuel impurities. These factors lead to mechanical and chemical degradation, affecting the system’s electrochemical performance [155]. Strategies to mitigate aging involve suppressing carbon formation on nickel-based anodes [156,157,158,159] and exploring fuel dilution and optimal biogas upgrading to prevent rapid degradation [160]. Advanced techniques, such as synchrotron-based X-ray nanocomputed tomography, have been employed to study electrode degradation mechanisms [155]. Additionally, research on fuel doping strategies and the comparison of hybrid SOFC systems with standalone units reveals potential for reducing electricity costs and CO2 emissions, underscoring the importance of innovative solutions to enhance SOFC durability and efficiency [161].

4.6. Options to Decrease the Operating Temperature of SOFC

Traditional High-Temperature (HT) SOFCs operate at temperatures ranging from 800 to 1000 °C. Such high operating temperatures exacerbate severe material issues in SOFC components, including elemental inter-diffusion between different components, electrode densification, impurity segregation, and the formation of detrimental secondary phases, subsequently diminishing the SOFC’s performance and durability [162,163,164,165,166]. Moreover, the elevated temperatures prolong the startup and cooldown periods of SOFC systems, restricting their practical applications in portable power sources and the transportation sector. Undoubtedly, the maintenance and material costs for HT-SOFCs are also considerably high. Consequently, the development of Intermediate-Temperature (IT) and Low-Temperature (LT) SOFCs has emerged as a focal point, aiming to enhance operational performance and durability, expand the range of material choices, and reduce system costs. IT-SOFCs and LT-SOFCs typically operate within the temperature ranges of 600–800 °C and 300–600 °C, respectively. However, lower operating temperatures also introduce disadvantages, such as reduced electrode reaction rates and electrolyte ionic conductivity [22,167]. Despite these challenges, IT-SOFCs and LT-SOFCs are generally viewed as more competitive from a commercial perspective. In recent years, two main solutions have been recognized as effective in reducing the operating temperature of SOFCs without significantly compromising performance [168]. One solution focuses on utilizing highly active component materials, starting with electrode materials of higher catalytic activity or electrolytes of higher ionic conductivity. However, the selection of SOFC component materials that reduce temperature while remaining cost-effective is quite limited [169,170]. Alternatively, temperature reduction can be achieved through improvements in manufacturing processes, such as nanostructured components and thin-film electrolytes [171,172].

5. SWOT Analysis of SOFCs

In their statement, Wachsman et al. [22] highlight a common misconception that categorizes fuel cells, particularly within the hydrogen economy narrative, as a futuristic energy source, largely due to the anticipated overhaul required for existing hydrocarbon fuel systems. However, they also note an exception in SOFCs, which, unlike PEMFCs, can integrate with current infrastructure to enhance efficiency and reduce CO2 emissions. The SWOT analysis of SOFC technology underscores its high electrical efficiency and fuel flexibility as key strengths, as seen in Table 6, with long operational life and low emissions further augmenting its appeal in a market with growing environmental consciousness. Yet, the technology faces significant challenges, including high operational temperatures (around 800 °C), which lead to material and cost constraints, as well as operational complexity, such as thermal cycling.

Table 6.

SWOT Analysis of SOFCs.

SOFCs present numerous opportunities, especially with the expansion of the renewable energy sector and the potential for integration with renewable sources. Technological advancements and government incentives create a favorable environment for growth and development. The increasing awareness of environmental issues and the rising energy demand in remote areas also provide significant opportunities for deploying SOFCs. Conversely, threats to SOFC technology mainly stem from the competitive landscape of alternative fuel cell technologies and conventional energy sources. Strategic focus on maintaining relevance and competitiveness is required in the face of market competition, policy fluctuations, and the potential for rapid obsolescence due to technological leapfrogging. A high dependency on critical raw materials adds another layer of risk.

In summary, while SOFCs demonstrate considerable potential in transforming energy conversion and contributing to a decarbonized future, navigating the complex interplay of market forces, technological innovation, and policy environments is essential. Continuous advancements in material science and engineering, coupled with strategic partnerships and supportive policies, are key to overcoming challenges and fully harnessing the potential of SOFCs.

6. Conclusions and Outlook

In the coming decades, as we face environmental degradation and seek to reduce dependence on fossil fuels, a broader adoption of clean energy sources, particularly hydrogen energy, is anticipated. Hydrogen is expected to play a pivotal role in the electrification process and contribute to the decarbonization of the global energy system. This energy transition trend brings with it numerous challenges and opportunities, one of which is enhancing the performance and sustainability. SOFCs are highly anticipated due to their high power/energy density and low emission output, capable of efficient operation at high temperatures and producing high-quality waste heat suitable for cogeneration applications. Although high-temperature operation offers significant advantages, it also poses challenges for thermal management within the systems. After reviewing the literature covering SOFC thermal management subsystems, afterburners, heat exchangers, and thermal management strategies, we have arrived at three main conclusions:

(1) Current research is predominantly focused on SOFC reformers and stack efficiency, with relatively less study on afterburners. There is a wide variety of burners, and the choice of afterburner type depends on application requirements and system design. In terms of burner design and performance optimization, researchers have provided multiple methods and solutions, including improving combustion efficiency, enhancing heating methods, and optimizing porous media burners. Porous media burners, in particular, have received extensive attention in current research, with the potential to improve the performance and efficiency of SOFC systems. Burner modeling and experimental validation are key research directions; researchers have explored critical parameters such as combustion flow fields, temperature distribution, and heat recovery within burners using CFD models and experimental studies. Future work could delve deeper at a systems level to better understand the conditions for stable operation of SOFC afterburners.

(2) Compared to the afterburners in SOFC system, there is more extensive research on heat exchangers, but it is often focused on specific types of fuel cell systems, and there is a need to enhance the universality of optimized heat exchangers. The studies on the sustainability and lifecycle analysis of heat exchangers are relatively limited and require a broader scope to understand their environmental impact better. Thermal loss and thermal management issues in efficient fuel cell systems still present a challenge that necessitates in-depth research for solutions. Multi-objective optimization and improvements in materials and manufacturing technologies are crucial areas for future research. To realize more efficient and sustainable heat exchanger technology for commercialization, further in-depth studies are needed to overcome these challenges.

(3) The review of SOFC thermal management strategies reveals that despite significant progress, there is still a need to address the complexity of thermal management, deepen our understanding of fuel adaptability and its impact, enhance system efficiency and stability at high temperatures and under extreme conditions, and develop new materials and components that meet high-performance requirements. Additionally, for commercialization, system-level integration optimization, cost-benefit assessments, and practical application validation cannot be overlooked. Finally, to ensure that theoretical research is aligned with practical applications, the further strengthening of experimental validation and optimization of multi-parameter models is necessary.

Author Contributions

Conceptualization, writing—original draft preparation and methodology, M.L. and J.W.; software, visualization, and validation, X.L.; formal analysis, Z.C. and X.Q.; data curation and investigation, C.C. and M.R.; resources, supervision, funding acquisition, and project administration, K.X. and C.S.; writing—review and editing, D.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key Research and Development Program of China (Grant No. 2022YFB4003605); the Guangdong Key Areas R& D Program Funding (Grant No. 2022B0111130004).

Data Availability Statement

Data sharing not applicable. No new data were created or analyzed in this study. Data sharing is not applicable to this article.

Acknowledgments

Many thanks to Guangdong Energy Group Science and Technology Research Institute for their support to the project.

Conflicts of Interest

Authors Mingfei Li, Zhengpeng Chen, Xiuyang Qian, Chuanqi Sun, Mumin Rao, Chuangting Chen were employed by the company Guangdong Energy Group Science and Technology Research Institute Co., Ltd. Author Di Gan was employed by the company Guangdong Huizhou Lng Power Co., Ltd. Author Kai Xiong was employed by the company Guangdong Energy Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Cementon, C.; Ramireddy, T.; Dewar, D.; Brennan, M.; Glushenkov, A.M. We may be underestimating the power capabilities of lithium-ion capacitors. J. Power Sources 2024, 591, 233857. [Google Scholar] [CrossRef]

- Hu, B.; He, S.; Zhu, D.; Xu, L.; Su, X.; Wang, X. Study of optimization and prediction methods for PEMEC performance considering the effects of multiple operating parameters. Int. J. Hydrogen Energy 2024, 55, 1273–1285. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, T.; Ege, D.; Kamali, A.R. Cobalt Oxide-Decorated on Carbon Derived from Onion Skin Biomass for Li-Ion Storage Application. Metals 2024, 14, 191. [Google Scholar] [CrossRef]

- Hoang, A.T.; Pandey, A.; De Osés, F.J.M.; Chen, W.H.; Said, Z.; Ng, K.H.; Ağbulut, Ü.; Tarełko, W.; Ölçer, A.I.; Nguyen, X.P. Technological solutions for boosting hydrogen role in decarbonization strategies and net-zero goals of world shipping: Challenges and perspectives. Renew. Sustain. Energy Rev. 2023, 188, 113790. [Google Scholar] [CrossRef]

- de Troya, J.J.; Álvarez, C.; Fernández-Garrido, C.; Carral, L. Analysing the possibilities of using fuel cells in ships. Int. J. Hydrogen Energy 2016, 41, 2853–2866. [Google Scholar] [CrossRef]

- Zheng, M.; Li, X.; Sun, J.; Wang, X.; Liu, G.; Yu, W.; Dong, X.; Wang, J. Research progress on chloride solid electrolytes for all-solid-state batteries. J. Power Sources 2024, 595, 234051. [Google Scholar] [CrossRef]

- Manage, M.; Hodgson, D.; Milligan, N.; Simons, S.; Brett, D. A techno-economic appraisal of hydrogen generation and the case for solid oxide electrolyser cells. Int. J. Hydrogen Energy 2011, 36, 5782–5796. [Google Scholar] [CrossRef]

- Chaisantikulwat, A.; Diaz-Goano, C.; Meadows, E.S. Dynamic modelling and control of planar anode-supported solid oxide fuel cell. Comput. Chem. Eng. 2008, 32, 2365–2381. [Google Scholar] [CrossRef]

- Singhal, S.C. Advances in solid oxide fuel cell technology. Solid State Ionics 2000, 135, 305–313. [Google Scholar] [CrossRef]

- Srinivasan, S.; Mosdale, R.; Stevens, P.; Yang, C. Fuel cells: Reaching the era of clean and efficient power generation in the twenty-first century. Annu. Rev. Energy Environ. 1999, 24, 281–328. [Google Scholar] [CrossRef]

- Campanari, S.; Mastropasqua, L.; Gazzani, M.; Chiesa, P.; Romano, M.C. Predicting the ultimate potential of natural gas SOFC power cycles with CO2 capture–Part A: Methodology and reference cases. J. Power Sources 2016, 324, 598–614. [Google Scholar] [CrossRef]

- Felseghi, R.A.; Carcadea, E.; Raboaca, M.S.; Trufin, C.N.; Filote, C. Hydrogen fuel cell technology for the sustainable future of stationary applications. Energies 2019, 12, 4593. [Google Scholar] [CrossRef]

- Ivers-Tiffée, E.; Weber, A.; Herbstritt, D. Materials and technologies for SOFC-components. J. Eur. Ceram. Soc. 2001, 21, 1805–1811. [Google Scholar] [CrossRef]

- Khanafer, K.; Al-Masri, A.; Vafai, K.; Preethichandra, P. Heat up impact on thermal stresses in SOFC for mobile APU applications: Thermo-structural analysis. Sustain. Energy Technol. Assess. 2022, 52, 102159. [Google Scholar] [CrossRef]

- Zhu, P.; Yao, J.; Wu, Z.; Huang, S.M.; Mansor, M.R.A.; Yang, F.; Zhang, Z. Construction of a transient multi-physics model of solid oxide fuel cell fed by biomass syngas considering the carbon deposition and temperature effect. Chem. Eng. J. 2022, 442, 136159. [Google Scholar] [CrossRef]

- Hesami, H.; Borji, M.; Rezapour, J. Three-dimensional numerical investigation on the effect of interconnect design on the performance of internal reforming planar solid oxide fuel cell. Korean J. Chem. Eng. 2021, 38, 2423–2435. [Google Scholar] [CrossRef]