Abstract

The recent announcement by the European Union of the Fit for 55 Package and a prospective ban on the sale of new internal combustion engine vehicles by 2035 has prompted a notable surge in the electric vehicle (EV) market. The shift toward EVs concurrently presents challenges, namely the resource management of used EV batteries, particularly their reuse, recycling, and remanufacturing. Accordingly, this study aims to analyze the effects of the reduced environmental impacts of a remanufactured portable power station (RPPS) compared with those of a new portable power station (NPPS) using life cycle assessment (LCA) and the economic benefits gained from reusing used EV batteries. The results of the LCA of the RPPS indicated a notable environmental advantage, with reductions of 42.01% in GWP and 41.91% in ADP compared with those achieved by the NPPS. Moreover, the economic benefits of the waste battery remanufacturing business amounted to USD 593,212 at an annual sales volume of 1000 units. The environmental benefits of remanufacturing practices represent valuable support for policies centered on remanufacturing and reusing used EV batteries. The findings of this study could stimulate a future market for products repurposed from used EV batteries, thereby further fostering sustainability in this sector.

1. Introduction

The European Union announced Fit for 55 at the European Green Deal on 14 July 2021, confirming a ban on the sale of new vehicles with internal combustion engines in 27 member countries from 2035 [1]. The policy shift is expected to stimulate growth in the market for electric vehicles (EVs). Furthermore, industries associated with the circular economy in EV batteries and resource management, encompassing processes such as the recycling, remanufacturing, and repurposing of used EV batteries, have gained prominence. Waste EV batteries could be repurposed strategically for energy storage systems (ESSs) provided the residual capacity remains above 80% of their original capacity. Moreover, beyond their use for ESSs, retired EV batteries could be applied in electric charging stations, products with low energy output, emergency generators, and portable power stations (PPSs), in addition to their role in energy storage [2,3]. However, substantial capacity decline and severe damage necessitate the extraction and recycling of valuable metals in these batteries [4,5]. Choosing a strategic approach, it makes sense to prioritize reusing batteries over immediate recycling unless significant damage is apparent. Commencing with reuse before recycling not only extends the battery lifespan but also has the potential to reduce the necessity for new battery production, consequently reducing environmental impact [6].

In this regard, Lee [7], Kim [8,9], Jung [10], and Jasper [11] focused on life cycle assessment (LCA) for fuel cell-based energy storage systems. Philippot et al. [6] analyzed two distinct scenarios, with the first involving repurposing discarded EV batteries for continued use within EVs, and the second exploring their reuse as stationary ESSs after repurposing. Similarly, Loakimidis et al. [12] compared the environmental implications of reutilizing used EV batteries as components of EVs with those of repurposing them for employment in ESSs. Ahmadi et al. [13] conducted an LCA employing a lithium-ion battery pack in an EV as a stationary ESS. Wang et al. [14] performed an LCA of lithium iron phosphate batteries from the manufacturing phase, use, potential for reuse, and eventual recycling. This study set up two end-of-use/life (EOL) scenarios, namely one in which the battery is recycled after being reused as an ESS, and the other in which the battery is recycled immediately after being reused in an EV. In addition, an energy supply scenario was added to compare and analyze the environmental effects of using the Spanish electricity mix and energy supply from solar photovoltaic (PV) panels. Cusenza et al. [15] and Bobba et al. [16] conducted LCAs with EV lithium-ion batteries reused as ESSs in a solar power plant power grid. Yu [17] conducted an LCA of four types of lithium-ion batteries for EVs and evaluated the environmental and economic effects of three recycling methods. Table 1 provides an overview of the literature review results.

Table 1.

Studies with life cycle assessment (LCA) on battery systems.

In their studies, Ahmadi et al. [13] and Wang et al. [14] adopted the ReCiPe (ReCiPe is a method for the life cycle impact assessment (LCIA). The method has been given the name ReCiPe as it provides a ‘recipe’ to calculate life cycle impact category indicators. The acronym also represents the initials of the institutes that were the main contributors to this project and the major collaborators in its design: RIVM and Radboud University, CML, and P RRé Consultants) methodology, including diverse parameters such as global warming potential (GWP), abiotic depletion potential (ADP), particulate matter formation potential (PMFP), freshwater eutrophication potential (FEP), photochemical oxidant formation potential (POFP), and fossil depletion potential (FDP). In their research, Cusenza et al. [15] used 14 impact categories. In other studies, Phillippot et al. analyzed the impact on GWP and acidification [5], whereas Bobba et al. [16] analyzed the impact on GWP and ADP, with the LCA results related mainly to those of the impact categories. As outlined previously, a considerable body of research has been dedicated to the LCA of lithium batteries in EVs. Ample research has been conducted to investigate the environmental ramifications of repurposing batteries as stationary ESSs after their use in EVs. To the best of our knowledge, to date, no empirical study has comparatively analyzed the environmental characteristics of products incorporating reusable batteries and products using new batteries. Moreover, given the difficulty in obtaining primary data in most studies, it appears that data were acquired through the literature, excluding the four studies in Table 1.

According to Kang [18], remanufacturing could significantly reduce costs. However, studies pertaining to the economic evaluation of repurposing and recycling used EV batteries have focused primarily on the recycling phase, with a notable omission of the entire product lifecycle. Table 2 provides an overview of the literature review results regarding the economic evaluation of EV battery reuse/recycling. Most literature studies primarily focus on the economic evaluation of EV battery reuse, recycling, and repurposing processes. However, there seems to be a lack of economic assessments that consider both the revenue and costs associated with the sale of specific systems and products using waste EV batteries.

Table 2.

Studies with economic evaluation of EV battery reuse/recycling.

The literature review on LCA studies of battery systems revealed a research gap, indicating a lack of primary data for products and systems, with limitations to certain battery systems. Also, the scientific relevance we considered when choosing the product is how remanufactured products contribute to improving the environment. Remanufacturing is the activity of using used products or parts to create items with the same performance as new ones through a series of specialized processes [18]. Hence, we compared the environmental impact of remanufactured items (RPPSs) and regular ones (NPPSs) with similar performances to assess their environmental impacts. Additionally, in the case of economic evaluation, existing research has primarily focused on the economic assessment of recycling methods for EV batteries, with a lack of economic analysis for products sold using waste EV batteries.

The primary objective of the current study is to address the significant research gaps observed in existing studies. We conducted an LCA, using two PPS products as examples. The first product, RPPS, utilizes used batteries from EVs for remanufacturing, while the second product, NPPS, uses new LFP batteries. The goals of the current study are as follows: (1) to quantify the environmental impact of the RPPS and NPPS among similar models; (2) to identify the hotspots and the stages with the most significant environmental impact throughout the life cycle; (3) to derive the economic benefits by calculating the costs and revenues associated with selling RPPSs. This study can provide environmental and economic advantages of the remanufacturing of used EV batteries, thereby promoting the growth of the battery remanufacturing market and contributing to the establishment of a circular economy system.

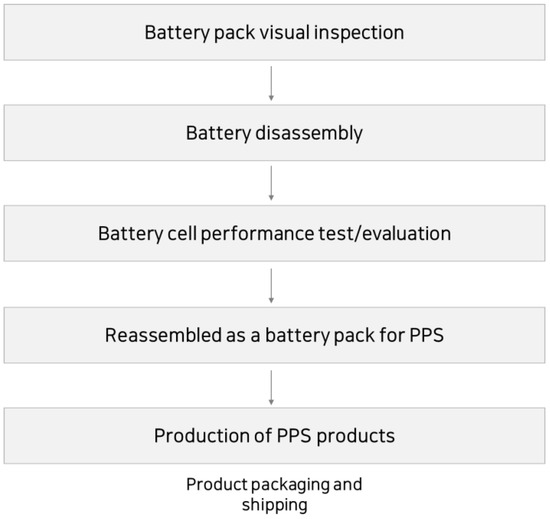

2. Remanufacturing Process of a Portable Power Station

The remanufacturing procedure of a PPS is shown in Figure 1. The process is initiated by a meticulous visual examination of the battery pack. This step entails a thorough assessment of any visible damage to the battery pack to determine whether a specific unit warrants further inspection. Subsequently, if the external condition of the battery is satisfactory, the battery pack is disassembled into pack, module, and cell units. Subsequently, a comprehensive performance test/evaluation is performed on the dismantled battery cells, covering tests on insulation resistance, capacity, and internal resistance. The cell units are assessed, and the test results are utilized to categorize cells with similar performance characteristics. Afterward, cells with similar test results are classified and reassembled using a battery pack for the PPS. These PPS products are produced by assembling parts, such as reassembled battery packs, external cases, control boards, and displays. After assembling the components, a quality inspection is performed, including an evaluation of their appearance, functionality, and safety. Finally, the complete product is packaged into individual units, placed in a designated storage bag, and enclosed in a box for shipping.

Figure 1.

PPS remanufacturing process.

3. Environmental Impact Analysis Methods

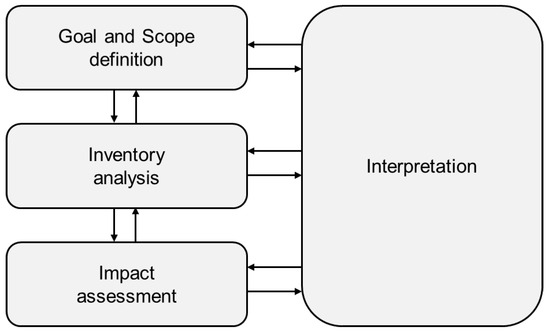

The environmental effects of the RPPS and NPPS were evaluated using LCA, which is an internationally standardized environmental assessment methodology specified in the 14040 series of the International Organization for Standardization [24]. The LCA is used to analyze the environmental load and potential environmental impact occurring ‘from cradle to grave’ of a product. The four key phases of an LCA study are described in Figure 2. Initially, the goals and scope are defined, outlining the study’s objectives and boundaries. The second phase, the Inventory Analysis (LCI), entails collecting comprehensive data on material and energy flows. Subsequently, the Impact Assessment (LCIA) phase provides additional insights into the environmental significance of identified impacts. Finally, the Interpretation phase summarizes results, facilitating conclusions and decisions aligned with the study’s goals and scope [24].

Figure 2.

Life cycle assessment framework [24].

The methodology is well suited for presenting the dual objectives of resource conservation and environmental impact reduction, which are central to the concept of repurposing [25]. We used the following procedure in our study. First, the products, functions, and functional units subjected to the LCA were defined. Second, the scope of the study was determined by setting target system boundaries. Third, the data at each stage were collected and processed based on functional units. Fourth, the environmental impact was evaluated based on the collected and analyzed data. Finally, the environmental benefits of remanufacturing were derived by comparing and analyzing the LCA results of the RPPS and NPPS.

3.1. Data Collection and Calculation

The data quality used for the environmental assessment of the product is as described in Table 3. For the data collection in the premanufacturing, manufacturing, and distribution stages of the RPPS, on-site data were acquired directly from Company G (Yangju-si, Republic of Korea), the manufacturer of the RPPS. In the case of other stages and the NPPS, assumptions, statistical data, and LCI DB were mainly used. In summary, for the premanufacturing, manufacturing, and distribution stages of the RPPS, primary data were utilized, while for all other stages of the RPPS and all stages of the NPPS, secondary data were used. The LCI DB used in this study involves the Korean national LCI DBs and Ecoinvent 3.8.

Table 3.

The data quality used for LCA of RPPS and NPPS.

3.1.1. Premanufacturing

The premanufacturing phase comprises the extraction of primary resources, processing of these resources into raw materials, and subsequent fabrication of components. As regards the input of component information into the RPPS, data pertaining to the material and weight of each component were compiled from Company G. As acquiring NPPS component information through direct manufacturing channels is not feasible, data could alternatively be gathered from product sales websites. The lithium iron phosphate batteries used in the NPPS were produced and assembled in China, along with other parts, which were transported to the Republic of Korea, packaged, and sold. It was assumed that the components used in the NPPS had the same composition as each component of the RPPS, and the weight was calculated by reflecting the total weight of the NPPS and the weight ratio of the parts of the RPPS.

3.1.2. Manufacturing

In the manufacturing stage, each component was assembled and its performance was evaluated. The electricity consumption data directly consumed by the manufacturing facilities were collected in this step. The electricity consumption required to produce one product was allocated based on the number of products produced during the period after collecting the annual consumption data. The data from Company G were collected for the electricity consumption of the RPPS; however, owing to data security issues, it was difficult to collect data and it was assumed that the electricity consumption of the NPPS was the same as for the RPPS based on functional units.

3.1.3. Distribution

A transportation scenario from the manufacturing plant distributed to each consumer was considered. The annual product sales ratio by region was collected from Company G data, and the transport distance by region was obtained from Annex 3 of the Korean Product Category Rules (PCR) [26]. For the NPPS, transportation from China to the Republic of Korea and from Korean product distributors to consumers was considered.

3.1.4. Use

During the use stage, when the PPS was charged, data on the power consumed by the charger that was not used for charging were collected. The environmental impact of electricity consumption was calculated by referring to the power consumption derived from the charging calculation method of portable wireless communication devices for the internet (EPD 024) in the Republic of Korea [27]. The total electricity consumption of charging a PPS was calculated using Equation (1). For the annual number of charges in Equation (1), statistical data on the average number of camping events and the number of car camping events per year were used [28].

: total electricity consumption (kWh);

: power consumption per charge (kWh/event);

: number of recharges per year (events/year);

: lifespan of portable wireless communication devices for the internet (years).

3.1.5. End-of-Use/Life

For the end-of-use/life scenario, the recycling, landfill, and incineration ratios were set by referring to the Product Environmental Footprint Category Rule (PEFCR) battery. Table 4 lists the scope of PEFCR [29]. Product systems include mobility using electricity, information and communication technologies such as phones and computers, and cordless power tools such as drills and electric screwdrivers. In addition, batteries with lithium-ion technology were included in the product system but a PPS was not mentioned. However, as the subject of this study is a PPS based on nickel manganese cobalt (NMC) and lithium iron phosphate (LFP) battery systems, it was included in the scope of the PEFCR. Additionally, it was assumed that the parts recycled in the end-of-use/life stage replaced the new materials constituting the PPS, and the avoidance effect was calculated and deducted from the premanufacturing stage.

Table 4.

Battery PEFCR scope [29].

3.2. Selection of Methodology for Impact Assessment and Impact Category

Global warming potential (GWP) and abiotic depletion potential (ADP) were selected as environmental impact categories for this study, as shown in Table 5. It was found that the most significant environmental impacts occur during the pre-manufacturing and use stages. Components such as aluminum and batteries, known for high ADP and GWP during the raw material extraction stage and in the premanufacturing stage, were identified [30,31]. Additionally, in the use stage, the high GWP was attributed to the electricity consumption throughout the product’s lifespan. Consequently, the analysis concentrated on these two environmental impact categories.

Table 5.

Environmental impact category and unit.

4. Economic Benefits Analysis Methods

In this study, we estimated the economic benefits of remanufacturing businesses. As shown in Equation (2), the economic benefit of the waste battery remanufacturing business sector was calculated by subtracting sales revenue (A) from the waste battery pack purchase cost (B1) and operating cost (B2) of the remanufacturing process. The revenue from the sale of the remanufactured products (A) was calculated by multiplying the annual sales volume of the PPS by the sales price. The cost of purchasing the waste battery pack (B1) was multiplied by the purchase cost and the annual number of battery pack purchases. The operating cost of the remanufacturing process (B2) was calculated by adding the annual labor, waste purchase, distribution, and management costs. The costs and benefits were calculated based on the values generated in the Republic of Korea, and the values were derived using the 2022 average exchange rate of KRW/USD 1291.95.

: economic benefits of spent battery remanufacturing (USD/year);

: revenue from sale of remanufactured goods (USD/year);

: purchasing cost of spent battery pack (USD/year);

: operation cost of the remanufacturing process (USD/year).

5. Results

5.1. Setting Targets and Scope

The targets of this study were RPPS and NPPS. The RPPS is a 2 kW capacity product of Company G, which was remanufactured from three cells of a waste EV lithium-ion battery. For comparison, the NPPS is a 2.5 kW capacity product of Company A (Shenzhen, China) imported from China that uses a lithium iron phosphate battery. The reason for selecting LFP battery packs as a comparison is due to their widespread use in the market, where they are favored for their cost-effectiveness. The purpose of the product is to supply temporary power for using electric devices in emergency situations, e.g., when the power supply is interrupted or electricity is limited, such as outdoors [32], and the functional unit is one product. Considering the capacity difference between the RPPS and NPPS, the NPPS was converted based on a weight of 2 kW. Figure 3 shows the components of the product.

Figure 3.

Contents of the RPPS model selected for this study.

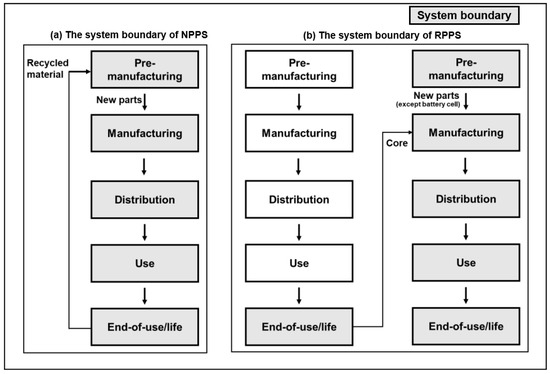

5.2. System Boundary

In both RPPS and NPPS, the premanufacturing, manufacturing, distribution, use, and end-of-use/life stages of the product are considered. At the end-of-use/life stage of the NPPS system boundary, the process involves sending reusable parts to the manufacturing stage of the RPPS system boundary for reuse/remanufacturing. The remaining components are divided into material recycling or landfill/incineration. The system boundaries of the product are illustrated in Figure 4.

Figure 4.

System boundaries of NPPS and RPPS.

5.3. Data Collection and Calculation

5.3.1. Premanufacturing

A summary of the weights and materials of each component constituting the RPPS and NPPS is presented in Table 6. The calculated total weight of the RPPS was 19.4 kg and that of the NPPS was 20.43 kg. Most items making up the product were the same; however, the carrier bags were not included in the NPPS, and the materials making up the battery cell differed.

Table 6.

Product bill of materials (BOM) based on functional unit.

5.3.2. Manufacturing

When a PPS is manufactured, electricity is predominantly used for operating a battery performance tester. When 1000 units of the RPPS were produced, the electricity consumption was 9000 kWh, and the result of converting this per-product standard was an electricity consumption of 9 kWh. As collecting data was difficult, the electricity consumption during the production of the NPPS was assumed the same as that for producing the RPPS.

5.3.3. Distribution

The transportation distances by region from the metropolitan area where the RPPS manufacturing plant is located to various delivery regions are listed in Table 7. The table also shows the corresponding sales figures for each region, considering an annual sales volume of 1000 units. The products are primarily transported by trucks between different regions, but Jeju Island transportation is a combination of trucks and maritime shipping. The average transport distance per RPPS product was calculated to be 146.38 km as described in Table 8. The consumer distribution for the NPPS was assumed the same as that of the RPPS.

Table 7.

Distribution scenario of RPPS.

Table 8.

Average transport distance of RPPS.

The transport scenarios for NPPS imports are shown in Table 9. The process of importing products is shown in three routes, considering the distance from the product manufacturer in China to the Chinese shipping port, from the Chinese shipping port to Incheon Port in the Republic of Korea, and from Incheon Port to the NPPS vendor. The total import distance of the NPPS was estimated to be 2307 km. For the truck transport route, the distance was calculated by searching Google Maps, and the distance provided by Netpas was used for the transport route to the port [33].

Table 9.

Import scenario of NPPS.

5.3.4. Use

Power is the utility used in the use stage to charge the PPS. The amount of power used during PPS charging was calculated using the product life, number of camping events, number of car camping events, power consumption, and charging time of the product for a single charge.

The power consumption of the RPPS was calculated using the dataset provided by Company G, setting the power consumption per charge to 1 kW, the time required for a single charge to 20 h, and the lifespan to 10 years. That of the NPPS was calculated using data provided on the sales website, setting the power consumption per charge to 1.26 kW, the time required for one charge to 33 h, and the lifespan to 10 years. In addition to information on product lifespans provided by the company, according to Philippot et al. [6], the repurposed duration should be limited to 10 years, owing to potential safety concerns.

For annual charging, the statistical data of the annual average number of camping and car camping events [28] were used. A PPS is intended to be used in emergency situations when the power supply is interrupted; however, as it is difficult to quantify such cases, its usage was limited to outdoor and leisure activities. Therefore, the use and charging of the PPS were based on the rounded number of camping/car camping events in 2020 derived from statistical data.

Table 10 shows the average annual number of camping events and car trips in the Republic of Korea. In this study, the assumed average annual number of camping and car camping events in 2020 were five and three, respectively, and charging of the PPS was set to eight times a year.

Table 10.

Average number of camping events and car trips per year in Republic of Korea.

For leisure events, the calculated power consumption results were 160 kWh for RPPS and 264 kWh for NPPS when the PPS was used and charged eight times a year and eighty times over a total life span of 10 years.

5.3.5. End-of-Use/Life

According to Annex 12 of the revised EU Battery Directive (Directive 2006/66/EC) [29], the objective for the recycling rate of batteries based on lithium is 70% by 2030. The recycling rates of the system included in the PEFCR battery are listed in Table 11. The recycling rate of PPSs was assumed to be 75% by adding 45%, which is the recycling rate of cordless power tools (CPTs) + information and communication technology (ICT), and 30%, which is an unidentified stream. In addition, 16% of the product would go to landfills, and 9% would be incinerated. As the battery cells of the RPPS were reused batteries, the environmental impact of disposing the battery cells was zero. Recycling, landfill, and incineration rates were applied for the packaging materials, using statistical data from the Ministry of the Environment of the Republic of Korea [34].

Table 11.

End-of-use/life scenario in EU to be applied in the product environmental footprint (PEF) declaration [29].

5.4. Applied Life Cycle Inventory Databases (LCI DBs)

The life cycle inventory databases (LCI DBs) used in this study are listed in Table 12. The Korean national LCI DBs and the Ecoinvent database are used in this study.

Table 12.

Applied life cycle inventory databases (LCI DBs).

5.5. Environmental Impact Assessment of RPPS and NPPS

The results of the LCA and the contribution analysis of the RPPS are listed in Table 13. The environmental impact was highest in the order of use, premanufacturing, manufacturing, end-of-use/life, and distribution stages. The use stage had the highest environmental impact owing to the amount of power consumed for charging during the 10-year lifespan of the product, with ADP accounting for 54.7% and GWP for 59.0%. In the premanufacturing stage, all components comprising the RPPS used new products, except for battery cells; therefore, the environmental impact was relatively high. However, the NPPS used a new battery, whereas the RPPS used a remanufactured battery; therefore, the environmental impact was relatively small. In the manufacturing stage, only the power consumption for the operation of the battery performance tester was considered. Therefore, a relatively low environmental impact was derived, and the same values were derived for both the RPPS and the NPPS. The environmental impact is expected to increase if the data are reflected through data collection and allocation to other utilities in the manufacturing stage in the future. In the use stage, a difference occurs in the charging time; however, the charging time of the RPPS is shorter than that of the NPPS, resulting in a lower environmental impact. The disposal stage has a relatively low environmental impact, owing to the high recycling rate of the product. In the distribution stage, the environmental impact was low because of the light weight and short transportation distance of the product.

Table 13.

Analysis of contribution and life cycle environmental impact of RPPS.

A summary of the LCA and contribution analysis findings for the NPPS is provided in Table 14. The environmental impact was highest in the order of premanufacturing, use, manufacturing, disposal, and distribution stages based on ADP and highest in the order of use, premanufacturing, manufacturing, disposal, and distribution stages based on GWP. In the premanufacturing stage, the NPPS had a higher environmental impact than the RPPS because all the parts were new. The use stage had a high environmental impact owing to the influence of the power consumption of charging for the 10-year lifespan of the product. In the manufacturing stage, only the power consumption for the operation of the battery performance tester was considered; therefore, a relatively low environmental impact was derived. If it were possible to collect data on other utilities that would be included in NPPS manufacturing in the future, the environmental impact of the manufacturing stage would differ. The disposal stage had a relatively low environmental impact because of the high recycling rate of the product. The distribution stage had the lowest environmental impact, attributable to the light weight of the product, despite the relatively long transport distance, as the product had been imported from China.

Table 14.

Contribution analysis and life cycle environmental impact of NPPS.

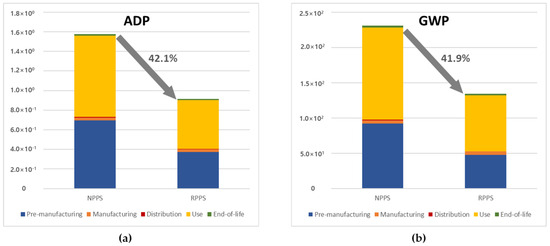

The total environmental impact of one product and the environmental impact comparison results of NPPS and RPPS are shown in Table 15 and Figure 5. The ADP showed a decrease of 42.01% in the RPPS compared with that in the NPPS, and a decrease of 41.91% in GWP compared with that of the NPPS. In this respect, Lee et al. [37] also indicated that among the environmental impact factors associated with the remanufacturing of turbochargers, the most significant effects were the reductions in GWP and ADP.

Table 15.

Comparison of the environmental evaluation results for RPPS and NPPS.

Figure 5.

(a) Comparison of the ADP of RPPS and NPPS. (b) Comparison of the GWP of RPPS and NPPS.

5.6. Economic Benefits Induced by Remanufactured Portable Power Stations

In this study, economic benefits were analyzed by calculating the annual costs and benefits of producing RPPSs by remanufacturing batteries from EVs. Labor, waste purchase, distribution, and management costs, i.e., the remanufacturing process costs, were investigated and calculated as annual costs. Those cost data were collected from Company G. Regarding benefits, the annual benefits generated by the remanufacturing business were calculated considering the sales volume and price of an RPPS. The economic benefits of the spent battery remanufacturing business sector were also calculated.

Table 16 shows a list of labor, distribution, and management costs, which constitute the operational expenses of the remanufacturing process for a single product. Additionally, the costs for labor and management are calculated for the sale of 1000 products per year. When producing 1000 products, labor costs were USD 38,392, distribution costs were USD 270,908, and administrative expenses were USD 15,480. Therefore, the total operating expense of the remanufacturing process is USD 464,105.

Table 16.

Operating expenses of remanufacturing process (unit: USD).

The sale price of a single product, along with the yearly sales revenue from 1000 units, is provided in Table 17. The sales revenue of RPPS products is USD 1153 per unit and USD 1,153,295 for 1000 units sold.

Table 17.

Annual sales revenue based on 1000 product units (unit: USD).

The calculated economic benefit of remanufacturing waste batteries was USD 593,312, assuming annual sales of 1000 units, as shown in Table 18.

Table 18.

Economic effects of annual remanufactured product sales (unit: USD).

6. Conclusions

In this study, an environmental and economic assessment of a remanufactured portable power station (RPPS), compared to those of a new portable power station (NPPS), using a life cycle approach is presented. The materials and associated inventory data for all the components were obtained from commercial PPS vendors. The methodology provided dependable outcomes with respect to the environmental enhancements stemming from utilizing remanufactured electric vehicle (EV) products and enhanced the accuracy of the inventory data.

We analyzed the environmental effects of an NPPS and RPPS. The environmental properties of the NPPS and RPPS were compared using the life cycle assessment (LCA) method, with the following results. The LCA results for the RPPS reusing EV batteries indicated the introduction of environmental impacts characterized by an abiotic depletion potential (ADP) of 9.15 × 10−1 kg Sb-eq. and a global warming potential (GWP) of 1.34 × 102 kg CO2-eq. These figures for NPPS were an ADP of 1.58 × 100 kg Sb-eq. and a GWP of 2.31 × 102 kg CO2-eq. The analyses showed that the environmental advantages of the RPPS were a 42.01% reduction in ADP and a 41.91% reduction in GWP compared with those of the NPPS. Notably, both products registered their most significant environmental impacts during the premanufacturing and use phases.

The computed economic benefits of the waste battery remanufacturing business were USD 593,212 considering an annual sales volume of 1000 units.

The anticipated outcomes of this study can be applied to the revitalization of associated industries, including battery recycling and reuse and the preparation of institutional devices. This significance is particularly pronounced as the volume of waste EV batteries is increasing in the burgeoning EV market. Furthermore, these results are projected to positively impact the prospective growth of the PPS and battery remanufacturing product markets by leveraging discarded EV batteries. As a follow-up study, precise values could be derived by securing data from companies for some of the assumptions made in this study to facilitate more precise assessment.

Author Contributions

Conceptualization, H.Y.K. and Y.W.H.; Methodology, S.J.Y.; Validation, Y.W.K. and M.S.P.; Formal Analysis, S.J.Y.; Investigation, S.J.Y.; Resources, J.H.N.; Data Curation, J.H.N.; Writing—Original Draft, S.J.Y.; Writing—Review and Editing, H.Y.K., Y.W.K. and M.S.P. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the Korea Institute of Energy Technology Evaluation and Planning (KETEP) grant funded by the Korean government (Ministry of Trade, Industry and Energy) (No. 20214000000520, Human Resource Development Project in Circular Remanufacturing Industry and No. 2024000000420, Cultivating Global Human Resources in Circular Resources Field).

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Conflicts of Interest

Author Soo Jin Yang was employed by Ecoeye Co. Author Jun Hee Nam was employed by GOODBYECAR Corp. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Hairabedian, J. The EU Adopts the Fit for 55 Road Map towards a 55% Reduction in Emissions by 2030. Available online: https://eco-act.com/emissions-reduction/fit-for-55/articles/news/16/08/2021 (accessed on 9 July 2023).

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Haque Sunny, M.S.; Mohammad, N.A. Comprehensive review on second-life batteries: Current state, manufacturing considerations, applications, impacts, barriers & potential solutions, business strategies, and policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Jihye, J.; Sora, L.; Jeongyoon, Y.; Incheol, K. Research on a Circular Economy Road Map by Securing the Interministerial Policy Linkages—Focusing on the Case of Electric Vehicle Batteries. Korea Environment Institute, Sejong Special Self-Governing City. 2020. Available online: https://www.riss.kr/search/detail/DetailView.do?p_mat_type=6b4a196b69d9bee2&control_no=d4b841b8a4c9851c (accessed on 9 July 2023).

- Fred, L. Tesla Significantly Increases Its Battery Recycling Capacity, but Only a Few Owner Battery Packs Are Coming Back. Electreck. Available online: https://electrek.co/2022/05/09/tesla-increase-battery-recycling-capacity-battery-packs/ (accessed on 9 July 2023).

- Duesenfeld. Ecofriendly Recycling of Lithium-Ion Batteries. Available online: https://www.duesenfeld.com/recycling_en.html (accessed on 9 July 2023).

- Meava, P.; Daniele, C.; Md Sazzad, H.; Anthony, S.; Erwin, B.; Elise, N.; Joeri, V.; Maarten, M. Environmental impact of the second life of an automotive battery: Reuse and repurpose based on ageing tests. J. Clean. Prod. 2022, 366, 132872. [Google Scholar] [CrossRef]

- Young Duk, L.; Kook Young, A.; Morosuk, T.; Tsatsaronis, G. Environmental impact assessment of a solid-oxide fuel-cell-based combined-heat-and power-generation system. Energy 2015, 79, 455–466. [Google Scholar] [CrossRef]

- Lee, G.; Jung, H.S.; Hyun, J.; Pak, C. The comparison of activation protocols for PEMFC MEA with PtCo/C catalyst. KHNES 2023, 34, 178–186. [Google Scholar] [CrossRef]

- Hyoungseok, K.; Seokjin, H.; Tak, H. Life cycle assessment (LCA) and energy efficiency analysis of fuel cell based energy storage system (ESS). Trans. Korean Hydrog. Energy Soc. 2017, 28, 156–165. [Google Scholar] [CrossRef]

- Jaehyung, J.; Kiman, K. Life cycle assessment of molten carbonate fuel cell system: A case study of 2.5 MW fuel cell system in Korea. New Renew. Energy 2017, 13, 45–53. [Google Scholar] [CrossRef]

- Jasper, F.B.; Späthe, J.; Baumann, M.; Peters, J.F.; Ruhland, J.; Weil, M. Life cycle assessment (LCA) of a battery home storage system based on primary data. J. Clean. Prod. 2022, 366, 132899. [Google Scholar] [CrossRef]

- Christos, S.I.; Alberto, M.; Ali, B.; Dimitrios, T.; Konstantinos, N. Life cycle assessment of a lithium iron phosphate (LFP) electric vehicle battery in second life application scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef]

- Leila, A.; Steven, B. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, B.; Shen, M.; Wu, Y.; Qu, S.; Hu, Y.; Feng, Y. Environmental impact assessment of second life and recycling for LiFePO4 power batteries in China. J. Environ. Manag. 2022, 314, 115083. [Google Scholar] [CrossRef] [PubMed]

- Maria Anna, C.; Francesco, G.; Sonia, L.; Marina, M.; Maurizio, C. Reuse of electric vehicle batteries in buildings: An integrated load match analysis and life cycle assessment approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life cycle assessment of repurposed electric vehicle batteries: An adapted method based on modelling energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Yu, M.; Bai, B.; Xiong, S.; Liao, X. Evaluating environmental impacts and economic performance of remanufacturing electric vehicle lithium-ion batteries. J. Clean. Prod. 2021, 321, 28935. [Google Scholar] [CrossRef]

- Kang, H.Y. Benefits of remanufacturing and its promoting policy. Geosyst. Eng. 2005, 8, 71–74. [Google Scholar] [CrossRef]

- Kampker, A.; Heimes, H.H.; Offermanns, C.; Frieges, M.H.; Graaf, M.; Soldan Cattani, N.; Späth, B. Cost-Benefit Analysis of Downstream Applications for Retired Electric Vehicle Batteries. World Electr. Veh. J. 2023, 14, 110. [Google Scholar] [CrossRef]

- Omrani, M.M.; Jannesari, H. Economic and environmental assessment of reusing electric vehicle lithium-ion batteries for load leveling in the residential, industrial and photovoltaic power plants sectors. Renew. Sustain. Energy Rev. 2019, 116, 109413. [Google Scholar] [CrossRef]

- Bai, B.; Xiong, S.; Song, B.; Xiaoming, M. Economic analysis of distributed solar photovoltaics with reused electric vehicle batteries as energy storage systems in China. Renew. Sustain. Energy Rev. 2019, 109, 213–229. [Google Scholar] [CrossRef]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Han, X.; Liang, Y.; Ai, Y.; Li, J. Economic evaluation of a PV combined energy storage charging station based on cost estimation of second-use batteries. Energy 2018, 165, 326–339. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/obp/ui/en/#iso:std:37456:en (accessed on 5 April 2023).

- Kim, J.; Park, K.; Hwang, Y.; Park, I. Sustainable manufacturing: A case study of the forklift painting process. Int. J. Prod. Res. 2010, 48, 3061–3078. [Google Scholar] [CrossRef]

- Transport Distance. Prod. Category Rules 2017 Annex 3. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs2&menuSn=2018400 (accessed on 27 December 2023).

- EPD 021(Portable Wireless Communication Devices for the Internet). Environ. Prod. Declar. 2021. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs1&menuSn=20018000 (accessed on 27 December 2023).

- A Survey of Camping Users as of 2020, 2021. Available online: https://datalab.visitkorea.or.kr/site/portal/ex/bbs/View.do?cbIdx=1127&bcIdx=305553&pageIndex=1&tgtTypeCd=SUB_CONT&searchKey=%EC%BA%A0%ED%95%91&searchKey2=&tabFlag=N&subFlag=N&cateCont=spt08 (accessed on 8 May 2023).

- EPD. PV Components: Invertors, Battery Energy Storage Systems, Combiner Boxes and Tracker Systems, 2023. Available online: https://www.environdec.com/pcr-library (accessed on 3 March 2023).

- Yi, Y.A.N.G.; Guo, Y.Q.; Zhu, W.S.; Huang, J.B. Environmental impact assessment of China’s primary aluminum based on life cycle assessment. Trans. Nonferrous Met. Soc. China 2019, 29, 1784–1792. [Google Scholar] [CrossRef]

- Ellingsen, L.A.W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life cycle assessment of a lithium-ion battery vehicle pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef]

- Bastro. Bastro Product Manual. 2021. Available online: http://goodbyecar.co.kr/ (accessed on 10 June 2023).

- Seafuture Inc. NETPAS—Smart Port Distance Table. Available online: https://www.netpas.net/ (accessed on 10 June 2023).

- National Waste Generation and Disposal Status. Ministry of the Environment, Korea Env Corp, 2019. 2020. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do?menuNo=M13020201&pageIndex=1&bbsId=BBSMSTR_000000000002&s_nttSj=KEC005&nttId=1090&searchBgnDe=&searchEndDe= (accessed on 2 June 2023).

- Ecoinvent Swiss Centre for Life Cycle Inventories, Final Report Ecoinvent Data. 2022. Available online: https://ecoinvent.org/ (accessed on 8 August 2023).

- KEITI (Korea Environmental Industry and Technology Institute) Guidelines for Environmental Declaration of Products. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs3&menuSn=20018500 (accessed on 27 December 2023).

- Lee, J.-H.; Kang, H.-Y.; Kim, Y.-W.; Hwang, Y.W.; Kwon, S.-G.; Park, H.-W.; Choi, J.-W.; Choi, H.-H. Analysis of the life cycle environmental impact reductions of remanufactured turbochargers. J. Remanuf. 2023, 13, 187–206. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).