Environmental and Economic Benefits Induced by a Remanufactured Portable Power Station

Abstract

1. Introduction

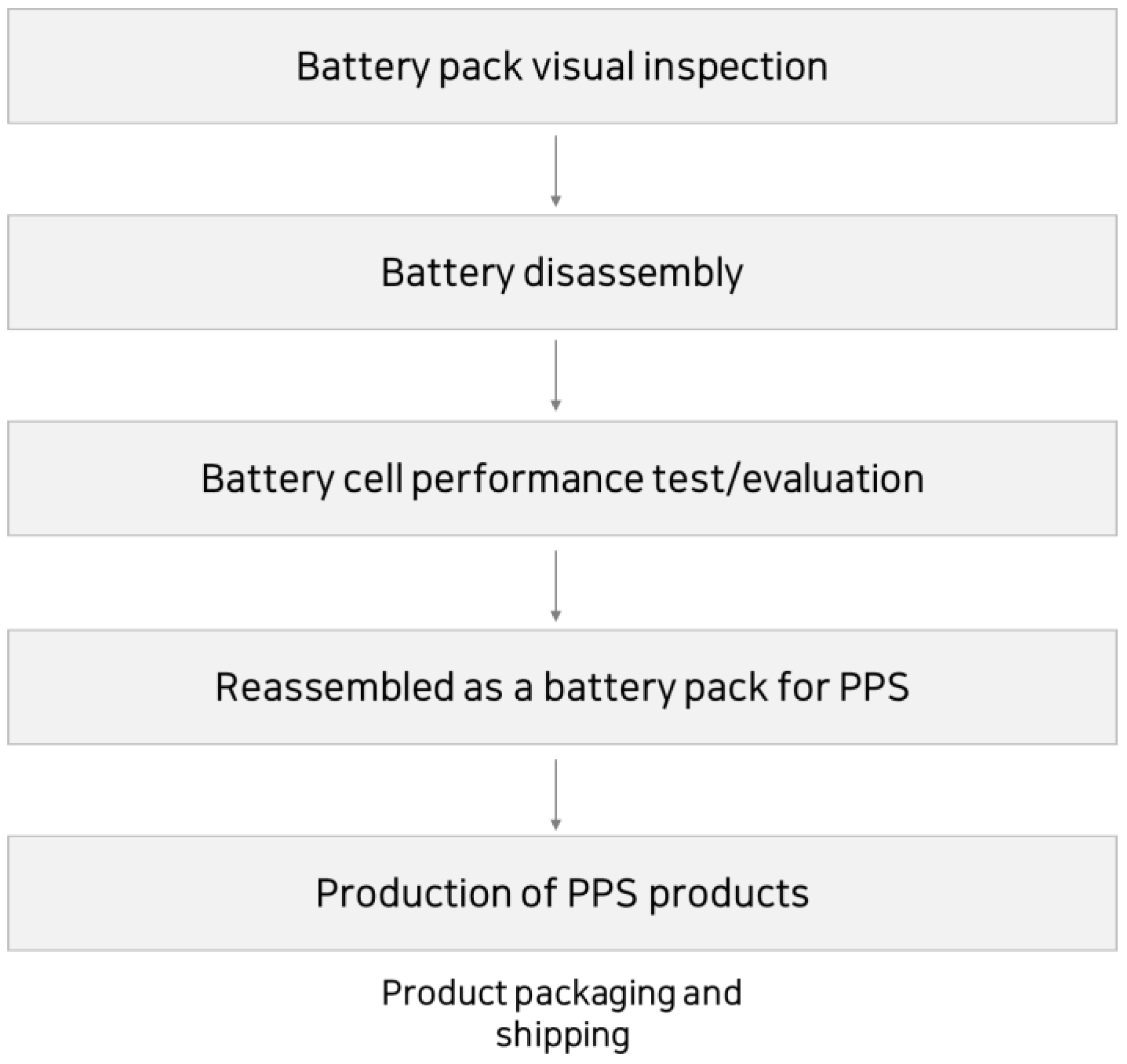

2. Remanufacturing Process of a Portable Power Station

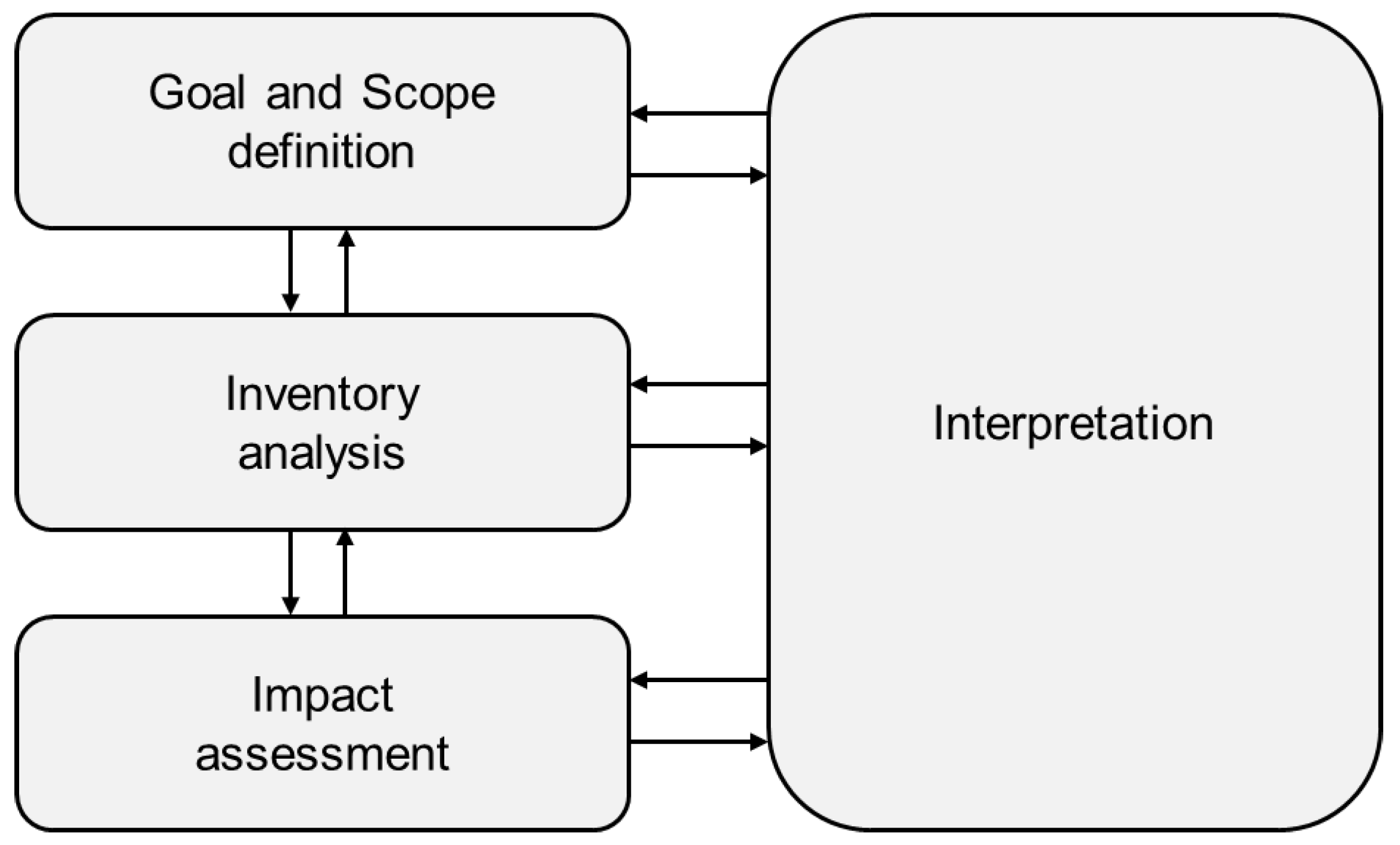

3. Environmental Impact Analysis Methods

3.1. Data Collection and Calculation

3.1.1. Premanufacturing

3.1.2. Manufacturing

3.1.3. Distribution

3.1.4. Use

3.1.5. End-of-Use/Life

3.2. Selection of Methodology for Impact Assessment and Impact Category

4. Economic Benefits Analysis Methods

5. Results

5.1. Setting Targets and Scope

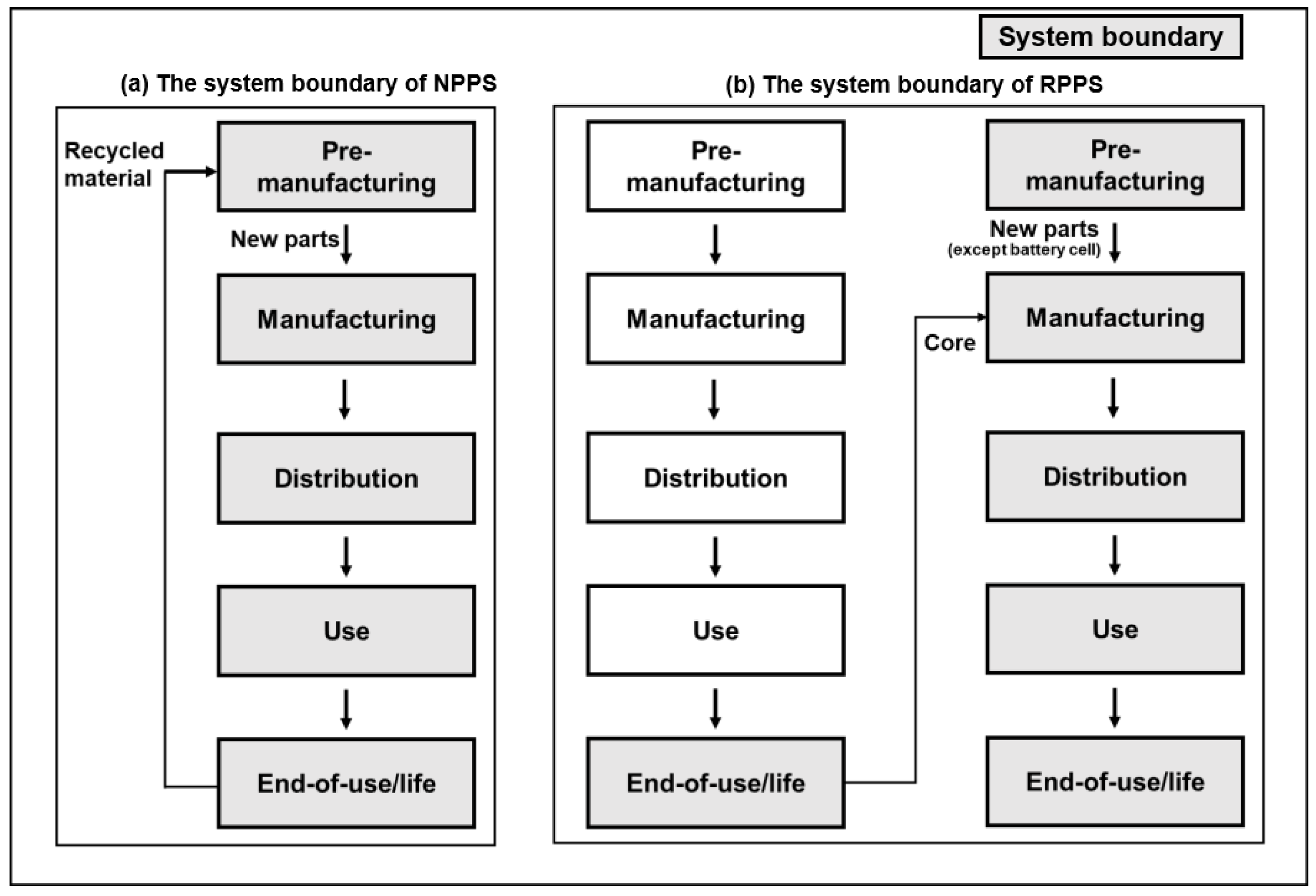

5.2. System Boundary

5.3. Data Collection and Calculation

5.3.1. Premanufacturing

5.3.2. Manufacturing

5.3.3. Distribution

5.3.4. Use

5.3.5. End-of-Use/Life

5.4. Applied Life Cycle Inventory Databases (LCI DBs)

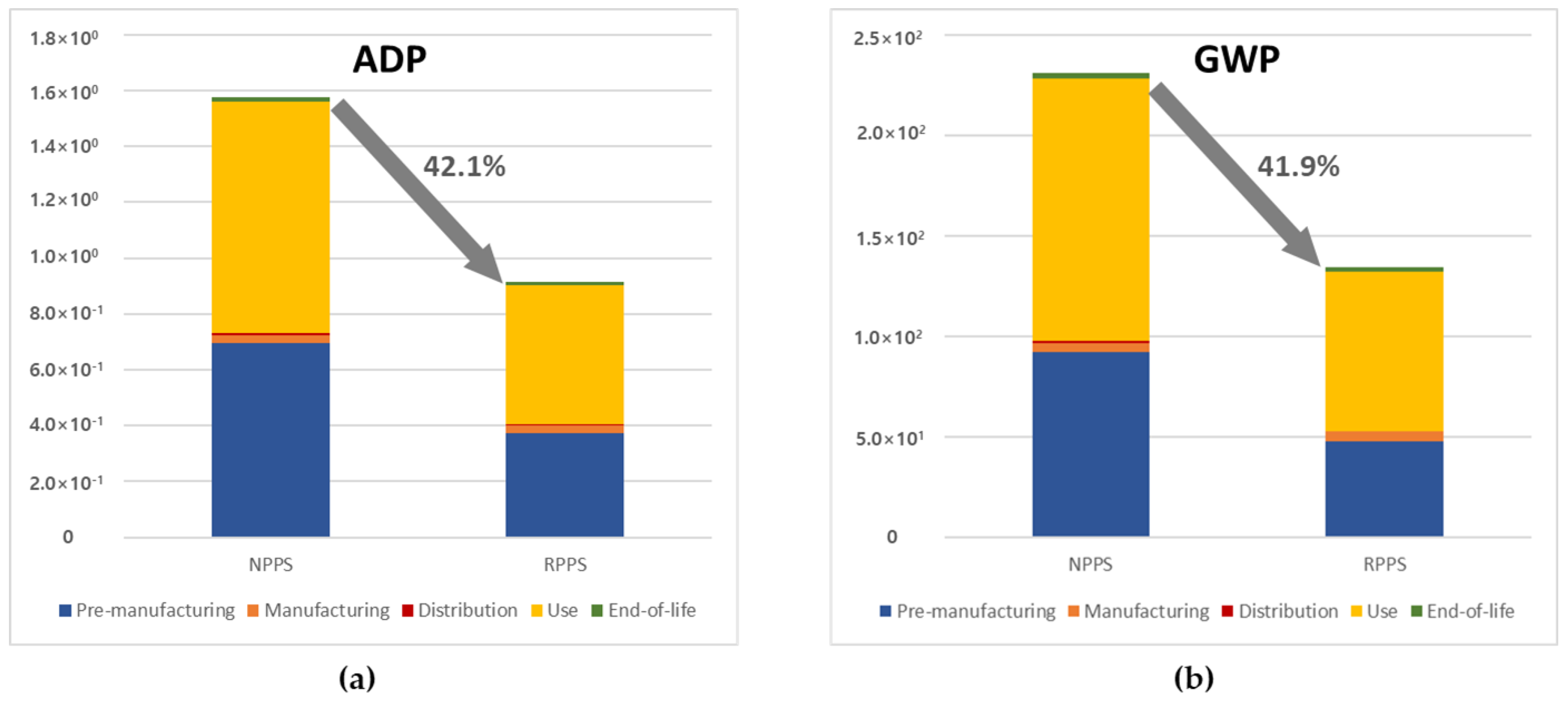

5.5. Environmental Impact Assessment of RPPS and NPPS

5.6. Economic Benefits Induced by Remanufactured Portable Power Stations

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hairabedian, J. The EU Adopts the Fit for 55 Road Map towards a 55% Reduction in Emissions by 2030. Available online: https://eco-act.com/emissions-reduction/fit-for-55/articles/news/16/08/2021 (accessed on 9 July 2023).

- Hossain, E.; Murtaugh, D.; Mody, J.; Faruque, H.M.R.; Haque Sunny, M.S.; Mohammad, N.A. Comprehensive review on second-life batteries: Current state, manufacturing considerations, applications, impacts, barriers & potential solutions, business strategies, and policies. IEEE Access 2019, 7, 73215–73252. [Google Scholar] [CrossRef]

- Jihye, J.; Sora, L.; Jeongyoon, Y.; Incheol, K. Research on a Circular Economy Road Map by Securing the Interministerial Policy Linkages—Focusing on the Case of Electric Vehicle Batteries. Korea Environment Institute, Sejong Special Self-Governing City. 2020. Available online: https://www.riss.kr/search/detail/DetailView.do?p_mat_type=6b4a196b69d9bee2&control_no=d4b841b8a4c9851c (accessed on 9 July 2023).

- Fred, L. Tesla Significantly Increases Its Battery Recycling Capacity, but Only a Few Owner Battery Packs Are Coming Back. Electreck. Available online: https://electrek.co/2022/05/09/tesla-increase-battery-recycling-capacity-battery-packs/ (accessed on 9 July 2023).

- Duesenfeld. Ecofriendly Recycling of Lithium-Ion Batteries. Available online: https://www.duesenfeld.com/recycling_en.html (accessed on 9 July 2023).

- Meava, P.; Daniele, C.; Md Sazzad, H.; Anthony, S.; Erwin, B.; Elise, N.; Joeri, V.; Maarten, M. Environmental impact of the second life of an automotive battery: Reuse and repurpose based on ageing tests. J. Clean. Prod. 2022, 366, 132872. [Google Scholar] [CrossRef]

- Young Duk, L.; Kook Young, A.; Morosuk, T.; Tsatsaronis, G. Environmental impact assessment of a solid-oxide fuel-cell-based combined-heat-and power-generation system. Energy 2015, 79, 455–466. [Google Scholar] [CrossRef]

- Lee, G.; Jung, H.S.; Hyun, J.; Pak, C. The comparison of activation protocols for PEMFC MEA with PtCo/C catalyst. KHNES 2023, 34, 178–186. [Google Scholar] [CrossRef]

- Hyoungseok, K.; Seokjin, H.; Tak, H. Life cycle assessment (LCA) and energy efficiency analysis of fuel cell based energy storage system (ESS). Trans. Korean Hydrog. Energy Soc. 2017, 28, 156–165. [Google Scholar] [CrossRef]

- Jaehyung, J.; Kiman, K. Life cycle assessment of molten carbonate fuel cell system: A case study of 2.5 MW fuel cell system in Korea. New Renew. Energy 2017, 13, 45–53. [Google Scholar] [CrossRef]

- Jasper, F.B.; Späthe, J.; Baumann, M.; Peters, J.F.; Ruhland, J.; Weil, M. Life cycle assessment (LCA) of a battery home storage system based on primary data. J. Clean. Prod. 2022, 366, 132899. [Google Scholar] [CrossRef]

- Christos, S.I.; Alberto, M.; Ali, B.; Dimitrios, T.; Konstantinos, N. Life cycle assessment of a lithium iron phosphate (LFP) electric vehicle battery in second life application scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef]

- Leila, A.; Steven, B. A cascaded life cycle: Reuse of electric vehicle lithium-ion battery packs in energy storage systems. Int. J. Life Cycle Assess. 2017, 22, 111–124. [Google Scholar] [CrossRef]

- Wang, Y.; Tang, B.; Shen, M.; Wu, Y.; Qu, S.; Hu, Y.; Feng, Y. Environmental impact assessment of second life and recycling for LiFePO4 power batteries in China. J. Environ. Manag. 2022, 314, 115083. [Google Scholar] [CrossRef] [PubMed]

- Maria Anna, C.; Francesco, G.; Sonia, L.; Marina, M.; Maurizio, C. Reuse of electric vehicle batteries in buildings: An integrated load match analysis and life cycle assessment approach. Energy Build. 2019, 186, 339–354. [Google Scholar] [CrossRef]

- Bobba, S.; Mathieux, F.; Ardente, F.; Blengini, G.A.; Cusenza, M.A.; Podias, A.; Pfrang, A. Life cycle assessment of repurposed electric vehicle batteries: An adapted method based on modelling energy flows. J. Energy Storage 2018, 19, 213–225. [Google Scholar] [CrossRef]

- Yu, M.; Bai, B.; Xiong, S.; Liao, X. Evaluating environmental impacts and economic performance of remanufacturing electric vehicle lithium-ion batteries. J. Clean. Prod. 2021, 321, 28935. [Google Scholar] [CrossRef]

- Kang, H.Y. Benefits of remanufacturing and its promoting policy. Geosyst. Eng. 2005, 8, 71–74. [Google Scholar] [CrossRef]

- Kampker, A.; Heimes, H.H.; Offermanns, C.; Frieges, M.H.; Graaf, M.; Soldan Cattani, N.; Späth, B. Cost-Benefit Analysis of Downstream Applications for Retired Electric Vehicle Batteries. World Electr. Veh. J. 2023, 14, 110. [Google Scholar] [CrossRef]

- Omrani, M.M.; Jannesari, H. Economic and environmental assessment of reusing electric vehicle lithium-ion batteries for load leveling in the residential, industrial and photovoltaic power plants sectors. Renew. Sustain. Energy Rev. 2019, 116, 109413. [Google Scholar] [CrossRef]

- Bai, B.; Xiong, S.; Song, B.; Xiaoming, M. Economic analysis of distributed solar photovoltaics with reused electric vehicle batteries as energy storage systems in China. Renew. Sustain. Energy Rev. 2019, 109, 213–229. [Google Scholar] [CrossRef]

- Rallo, H.; Benveniste, G.; Gestoso, I.; Amante, B. Economic analysis of the disassembling activities to the reuse of electric vehicles Li-ion batteries. Resour. Conserv. Recycl. 2020, 159, 104785. [Google Scholar] [CrossRef]

- Han, X.; Liang, Y.; Ai, Y.; Li, J. Economic evaluation of a PV combined energy storage charging station based on cost estimation of second-use batteries. Energy 2018, 165, 326–339. [Google Scholar] [CrossRef]

- ISO 14040:2006; Environmental Management-Life Cycle Assessment—Principles and Framework. Available online: https://www.iso.org/obp/ui/en/#iso:std:37456:en (accessed on 5 April 2023).

- Kim, J.; Park, K.; Hwang, Y.; Park, I. Sustainable manufacturing: A case study of the forklift painting process. Int. J. Prod. Res. 2010, 48, 3061–3078. [Google Scholar] [CrossRef]

- Transport Distance. Prod. Category Rules 2017 Annex 3. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs2&menuSn=2018400 (accessed on 27 December 2023).

- EPD 021(Portable Wireless Communication Devices for the Internet). Environ. Prod. Declar. 2021. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs1&menuSn=20018000 (accessed on 27 December 2023).

- A Survey of Camping Users as of 2020, 2021. Available online: https://datalab.visitkorea.or.kr/site/portal/ex/bbs/View.do?cbIdx=1127&bcIdx=305553&pageIndex=1&tgtTypeCd=SUB_CONT&searchKey=%EC%BA%A0%ED%95%91&searchKey2=&tabFlag=N&subFlag=N&cateCont=spt08 (accessed on 8 May 2023).

- EPD. PV Components: Invertors, Battery Energy Storage Systems, Combiner Boxes and Tracker Systems, 2023. Available online: https://www.environdec.com/pcr-library (accessed on 3 March 2023).

- Yi, Y.A.N.G.; Guo, Y.Q.; Zhu, W.S.; Huang, J.B. Environmental impact assessment of China’s primary aluminum based on life cycle assessment. Trans. Nonferrous Met. Soc. China 2019, 29, 1784–1792. [Google Scholar] [CrossRef]

- Ellingsen, L.A.W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life cycle assessment of a lithium-ion battery vehicle pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef]

- Bastro. Bastro Product Manual. 2021. Available online: http://goodbyecar.co.kr/ (accessed on 10 June 2023).

- Seafuture Inc. NETPAS—Smart Port Distance Table. Available online: https://www.netpas.net/ (accessed on 10 June 2023).

- National Waste Generation and Disposal Status. Ministry of the Environment, Korea Env Corp, 2019. 2020. Available online: https://www.recycling-info.or.kr/rrs/stat/envStatDetail.do?menuNo=M13020201&pageIndex=1&bbsId=BBSMSTR_000000000002&s_nttSj=KEC005&nttId=1090&searchBgnDe=&searchEndDe= (accessed on 2 June 2023).

- Ecoinvent Swiss Centre for Life Cycle Inventories, Final Report Ecoinvent Data. 2022. Available online: https://ecoinvent.org/ (accessed on 8 August 2023).

- KEITI (Korea Environmental Industry and Technology Institute) Guidelines for Environmental Declaration of Products. Available online: https://ecosq.or.kr/websquare.do#w2xPath=/ui/cer/ic/oh/ICOH110M01.xml&valVl=tabs3&menuSn=20018500 (accessed on 27 December 2023).

- Lee, J.-H.; Kang, H.-Y.; Kim, Y.-W.; Hwang, Y.W.; Kwon, S.-G.; Park, H.-W.; Choi, J.-W.; Choi, H.-H. Analysis of the life cycle environmental impact reductions of remanufactured turbochargers. J. Remanuf. 2023, 13, 187–206. [Google Scholar] [CrossRef]

| Study | LCA Target | System Boundary | LCI Data | Use of Primary Data |

|---|---|---|---|---|

| Philippot et al. [6] | Repurposed traction batteries after their use in EVs | Manufacturing, first use stage, repurposing, and reuse | Ecoinvent database | EV battery cells |

| Lee et al. [7] | A solid oxide fuel cell (SOFC)-based power generation system | Manufacturing, operation, and disposal | Ecoinvent database | Not considered |

| Kim et al. [9] | Molten carbonate fuel cell (MCFC) system and polymer electrolyte membrane fuel cell (PEMFC) system | Fuel production, manufacturing, and operation | Korean national LCI DB, Ecoinvent database | Fuel cell system |

| Kim et al. [10] | MCFC system | Pre-manufacturing, manufacturing, installation, and operation | Korean national LCI DB, Ecoinvent database | Not considered |

| Jasper et al. [11] | A photovoltaic (PV) home battery storage system | Primary material extraction, production, use phase, and recycling | Ecoinvent database | Battery system periphery |

| Loakimidis et al. [12] | A lithium iron phosphate (LFP) battery | Manufacturing, use, and disposal | Ecoinvent database | Not considered |

| Ahmadi et al. [13] | A Li-ion battery pack | Li-ion battery manufacturing, first use in the EV, re-purposing, second use in the ESS, and recycling | Ecoinvent database | Not considered |

| Wang et al. [14] | LFP batteries | Battery manufacturing, use, battery reuse and recycling | GaBi databases | Battery manufacturing |

| Cusenza et al. [15] | A BESS made by retired Li-ion EV batteries, a photovoltaic plant (20 kW), and the electricity grid | Operation | Ecoinvent database | Not considered |

| Bobba et al. [16] | Repurposed batteries | Manufacturing, repurposing, use, and end-of-life | Ecoinvent database | Not considered |

| Study | Contents |

|---|---|

| Kampker et al. [19] | Cos and benefit analysis of three chosen scenarios: reuse, repurpose, and recycle |

| Omrani et al. [20] | An economic evaluation of reusage of lithium-ion packs for load leveling in the residential, industrial, and photovoltaic power plant sectors |

| Bai et al. [21] | An economic performance evaluation by net present value of distributed solar photovoltaics (DSPV) with reused batteries as energy storage systems (RBESS) |

| Rallo et al. [22] | Investigates the current state of the art of disassembling activities by analyzing the Li-ion battery and provides insights into the costs of each disassembling operation, from battery level to cell level |

| Han et al. [23] | An economic estimation for a PV charging station based on the utilization of retired electric vehicle batteries |

| RPPS | NPPS | ||

|---|---|---|---|

| Premanufacturing | Bill of material (kg) | On-site data from RPPS manufacturer | Assumptions based on the RPPS on-site data and NPPS references |

| Manufacturing | Electricity use (kWh) | On-site data from RPPS manufacturer | Assumptions based on the RPPS on-site data |

| Distribution | Transport (km) | Average data from RPPS manufacturer | Assumptions based on the RPPS on-site data |

| Use | Electricity use (kWh) | Assumptions based on the statistical data | Assumptions based on the statistical data |

| End-of-use/life | Waste disposal rates | Statistical data | Statistical data |

| Battery Types Included for This PEFCR | |

|---|---|

| 1 | E-mobility (e.g., e-bikes, end-of-life vehicles (ELVs), plug-in hybrid electric vehicles (PHEVs), cars, bus/trucks), excluding charging units |

| 2 | Information and Communication Technologies (e.g., tablets and phones, computers, cameras, games), including charging units |

| 3 | Cordless power tools (e.g., drills, electric screwdrivers), including charging units |

| 4 | Battery technology: Li-ion and nickel–metal hydride (NiMH) |

| 5 | Battery chemistry for Li-ion technology includes lithium cobalt oxide [LCO (LiCoO2)], lithium–nickel–manganese–cobalt–oxide [NMC (LiNixMnyCozO2)], lithium–manganese [LiMn (LiMnO2)], lithium iron phosphate [LFP (LiFePO4)] |

| Impact Category | Unit |

|---|---|

| ADP (abiotic depletion potential) | kg Sb-eq. |

| GWP (global warming potential) | kg CO2-eq. |

| BOM | RPPS | NPPS | ||||

|---|---|---|---|---|---|---|

| Item | Weight (kg) | Material | Item | Weight (kg) | Material | |

| Input | Battery cell | 9 | Anode (NMC) Cathode (carbon) Copper Aluminum Electrolyte Separator (polypropylene) | Battery cell | 10.27 | Anode (LFP) Cathode (carbon) Copper Aluminum Electrolyte Separator (polypropylene) |

| Housing | 4 | Aluminum | Housing | 4.57 | Aluminum | |

| Controller | 0.6 | Printed circuit board (PCB) | Controller | 0.68 | PCB | |

| High-voltage parts, such as busbar/wiring | 0.8 | Bronze, iron | High-voltage parts, such as busbar/wiring | 0.91 | Bronze, iron | |

| Charger | 2.5 | Aluminum | Charger | 2.85 | Aluminum | |

| Carry bag | 1.5 | Nylon | Packaging box | 0.8 | Cardboard | |

| Packaging box | 0.7 | Cardboard | ||||

| Filling materials | 0.1 | Polypropylene | Filling materials | 0.11 | Polypropylene | |

| Instruction manual | 0.2 | Paper | Instruction manual | 0.23 | Paper | |

| Output | RPPS 1 set | 19.4 | Mixture | NPPS 1 set | 20.43 | Mixture |

| Departure | Arrival | Transportation Distance (km) | Transportation Method | Number of Units Sold per Year |

|---|---|---|---|---|

| Seoul Metropolitan Area (Seoul) | Seoul Metropolitan Area (Seoul) | 30 | Truck | 499 |

| Gangwon-do (Won-ju) | 125 | 37 | ||

| Chung-cheong bukdo (Cheongju) | 138 | 43 | ||

| Chungcheongnam-do (Daejeon) | 161 | 73 | ||

| Jeollabuk-do (Jeonju) | 212 | 27 | ||

| Jeollanam-do (Gwangju) | 212 | 66 | ||

| Gyeongsangbuk-do (Daegu) | 288 | 106 | ||

| Gyeongsangnam-do (Busan) | 395 | 124 | ||

| Jeju | 709 | Ship, truck | 25 |

| Average Transport Distance (km) | Number of Units Sold |

|---|---|

| 146.38 | 1 |

| Departure | Arrival | Transportation Distance (km) | Transportation Method | |

|---|---|---|---|---|

| Route 1 | Manufacturer of portable power station (China, Shenzhen) | Port (China, Shenzhen) | 20 | Truck |

| Route 2 | Port (China, Shenzhen) | Port (Republic of Korea, Incheon) | 2267 | Ship |

| Route 3 | Port (Republic of Korea, Incheon) | Supplier (vendor) of portable power station (Republic of Korea, Seoul) | 20 | Truck |

| Total | - | - | 2307 | - |

| Year | 2018 | 2019 | 2020 |

|---|---|---|---|

| Average number of camping trips per year | 3.6 | 3.8 | 5.1 |

| Average number of car camping trips per year | - | - | 2.8 |

| Waste Treatment | CPT + ICT | E-Mobility |

|---|---|---|

| Collection for recycling | 45% | 95% |

| Unidentified stream | 30% | 5% |

| Landfill | 16% | - |

| Incineration | 9% | - |

| List | LCI DB | |

|---|---|---|

| Name | Reference | |

| Anode | Anode production and graphite for Li-ion battery, China (CN) | Ecoinvent 3.8 [35] |

| Cathode | Carbon black | KEITI (2022) [36] |

| Copper | Copper | KEITI (2022) [36] |

| Electrolyte | Electrolyte production for Li-ion battery, global (GLO) | Ecoinvent 3.8 [35] |

| Aluminum | Aluminum alloy production | KEITI (2022) [36] |

| PCB | Hard-printed circuit board | KEITI (2022) [36] |

| Bronze | Bronze production, rest of world (RoW) | Ecoinvent 3.8 [35] |

| Iron | Sponge iron production, rest of world (RoW) | Ecoinvent 3.8 [35] |

| Nylon | Nylon 6-6 production, rest of world (RoW) | Ecoinvent 3.8 [35] |

| Cardboard | Cardboard | KEITI (2022) [36] |

| Polypropylene | Polypropylene | KEITI (2022) [36] |

| Paper | Printed paper | KEITI (2022) [36] |

| Pre-Manufacturing | Manufacturing | Distribution | Use | End of Use/Life | Total | |

|---|---|---|---|---|---|---|

| ADP (kg Sb-eq.) | 3.72 × 10−1 | 2.82 × 10−2 | 3.49 × 10−3 | 5.01 × 10−1 | 1.05 × 10−2 | 9.15 × 10−1 |

| 40.7% | 3.1% | 0.4% | 54.7% | 1.1% | 100% | |

| GWP (kg CO2-eq.) | 4.81 × 101 | 4.46 × 100 | 5.52 × 10−1 | 7.92 × 101 | 1.88 × 100 | 1.34 × 102 |

| 35.9% | 3.3% | 0.4% | 59% | 1.4% | 100% |

| Pre-Manufacturing | Manufacturing | Distribution | Use | End of Use/Life | Total | |

|---|---|---|---|---|---|---|

| ADP (kg Sb-eq.) | 6.97 × 10−1 | 2.82 × 10−2 | 6.87 × 10−3 | 8.26 × 10−1 | 1.90 × 10−2 | 1.58 × 100 |

| 44.2% | 1.8% | 0.4% | 52.4% | 1.2% | 100% | |

| GWP (kg CO2-eq.) | 9.22 × 101 | 4.46 × 100 | 1.01 × 100 | 1.31 × 102 | 2.73 × 100 | 2.31 × 102 |

| 39.9% | 1.9% | 0.4% | 56.6% | 1.2% | 100% |

| RPPS | NPPS | Environmental Impact Reduction | Reduction Rate (%) | |

|---|---|---|---|---|

| ADP (kg Sb-eq.) | 9.15 × 10−1 | 1.58 × 100 | 6.63 × 10−1 | 42.01% |

| GWP (kg CO2-eq.) | 1.34 × 102 | 2.31 × 102 | 9.68 × 101 | 41.91% |

| List | Cost Incurred in the Process of Disassembly of One Pack | Production Cost of One Product | Production Cost of 1000 Products |

|---|---|---|---|

| Labor cost | 1238.438 | - | 38,392 |

| Distribution cost | - | 270.908 | 270,908 |

| Administrative expenses | - | 154.805 | 154,805 |

| Sales Amount per Remanufactured Product | Annual Sales Revenue Based on 1000 Product Units |

|---|---|

| 1153 | 1,153,295 |

| Product Sales Revenue (A) | Cost of Purchasing Used Battery Pack (B1) | Operating Expenses of Remanufacturing Process (B2) | Economic Benefits (C = A − (B1 + B2)) |

|---|---|---|---|

| 1,153,295 | 95,979 | 464,105 | 593,212 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, S.J.; Hwang, Y.W.; Kim, Y.W.; Park, M.S.; Nam, J.H.; Kang, H.Y. Environmental and Economic Benefits Induced by a Remanufactured Portable Power Station. Energies 2024, 17, 793. https://doi.org/10.3390/en17040793

Yang SJ, Hwang YW, Kim YW, Park MS, Nam JH, Kang HY. Environmental and Economic Benefits Induced by a Remanufactured Portable Power Station. Energies. 2024; 17(4):793. https://doi.org/10.3390/en17040793

Chicago/Turabian StyleYang, Soo Jin, Yong Woo Hwang, Young Woon Kim, Mi Sook Park, Jun Hee Nam, and Hong Yoon Kang. 2024. "Environmental and Economic Benefits Induced by a Remanufactured Portable Power Station" Energies 17, no. 4: 793. https://doi.org/10.3390/en17040793

APA StyleYang, S. J., Hwang, Y. W., Kim, Y. W., Park, M. S., Nam, J. H., & Kang, H. Y. (2024). Environmental and Economic Benefits Induced by a Remanufactured Portable Power Station. Energies, 17(4), 793. https://doi.org/10.3390/en17040793