Abstract

Achieving the required decarbonisation targets by the shipping industry requires a transition to technologies with zero or near-zero greenhouse gas (GHG) emissions. One promising shipping fuel with zero emission of exhaust gases (including CO2) is green hydrogen. This type of fuel, recognised as a 100% clean solution, is being investigated for feasible use on a service offshore vessel (SOV) working for offshore wind farms. This study aims to examine whether hydrogen may be used on an SOV in terms of the technical and economic challenges associated with the design process and other factors. In the analyses, a reference has been made to the current International Maritime Organization (IMO) guidelines and regulations. In this study, it was assumed that hydrogen would be directly combusted in a reciprocating internal combustion engine. This engine type was reviewed. In further research, hydrogen fuel cell propulsion systems will also be considered. The hydrogen demand was calculated for the assumed data of the SOV, and then the volume and number of high-pressure tanks were estimated. The analyses revealed that the SOV cannot undertake 14-day missions using hydrogen fuel stored in cylinders on board. These cylinders occupy 66% of the ship’s current volume, and their weight, including the modular system, accounts for 62% of its deadweight. The costs are over 100% higher compared to MDO and LNG fuels and 30% higher than methanol. The actual autonomy of the SOV with hydrogen fuel is 3 days.

1. Introduction

1.1. Research Background

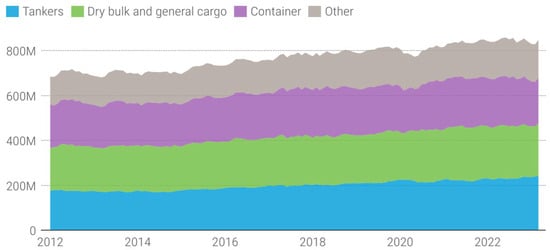

Nearly 60–70% of global CO2 emissions come from the combustion of fuels in various economic sectors, with maritime transport accounting for about 3.5% of all greenhouse gas emissions. According to the IMO [1], maritime transport emissions will continue to increase by up to 50% by 2050 if the current 99% of transport shipping fuel demand (covered by fossil fuels) is not drastically reduced in favour of alternative fuels. Without extensive action, emissions could reach up to 130% of 2008 levels by 2050 [2]. Figure 1 shows CO2 emissions from 2012 to 2023, expressed in tonnes, associated with maritime transport by major ship types [2].

Figure 1.

Carbon dioxide emissions by main vessel types, tons, 2012–2023, acc. [2]. Note: The group ‘other’ includes vehicles and roll-on/roll-off ships, passenger ships, offshore ships and service and miscellaneous ships.

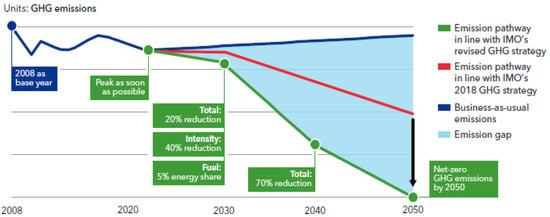

If maritime transport is to meet decarbonisation targets—whether set by the IMO [3], the EU or other national regulations—through a transition to technologies with zero or near-zero greenhouse gas (GHG) emissions (i.e., electric, hybrid or fuel cell drives), the requirements include using clean fuels (i.e., methanol, ammonia, hydrogen or biofuels) and/or alternative energy sources (i.e., solar and wind power or nuclear power). Figure 2 depicts the IMO’s current strategy for reducing GHGs from maritime transport, which uses 2008 as the baseline and should achieve net zero by 2050.

Figure 2.

Outline of ambitions and minimum indicative checkpoints in the revised IMO GHG strategy, acc. [3].

According to [4], hydrogen is currently becoming increasingly important in the shipping sector, although implementation is still at an early stage. The current fleet of hydrogen-powered vessels is relatively small, and most projects are in the demonstration or development phase [5]. However, orders for vessels with alternative propulsion systems represent an increasing share, with around 49% of new orders involving vessels using various forms of alternative fuels [4]. According to [6], 135 LNG-capable vessels have been ordered, and current orders also include 249 vessels adapted to use ammonia as fuel, 247 vessels adapted to use methanol and 14 vessels adapted to run on hydrogen.

Orders for new ships definitely show a clear trend towards alternative fuels, and the most promising zero-emission marine fuels include green hydrogen. For this reason, the authors have chosen to examine this new fuel, with great potential for SOV propulsion. Hydrogen can be produced from renewable energy sources, so the offshore wind farms in the Baltic Sea assumed in this study as the working area of the vessel could become a potential source of hydrogen, produced by electrolysis using the electricity generated by the offshore wind farms. This hydrogen could be used to power service vessels operating in the vicinity of these farms.

Recent studies indicate that global hydrogen demand has reached 97 Mt in 2023, an increase of 2.5% compared to 2022 [4], with the majority being met by hydrogen produced from fossil fuels. Green hydrogen is currently less available (its production was less than 1 Mt in 2023). Although the production costs are high relative to grey and black hydrogen, it is expected to be commercialised and have competitive prices [7].

According to these sources [8,9], the world’s first zero-emission, small passenger ferry using hydrogen fuel cells, batteries and electric propulsion, is the Switch Maritime-owned catamaran ‘Sea Change’, which began operating in the San Francisco Bay area in July 2024. It has 10 high-pressure (250 bar), onboard hydrogen tanks (from Hexagon) that store 246 kg of compressed hydrogen.

In Europe, the first certified vessel was a 14-metre-long passenger ship ‘Hydroville’, powered by hydrogen and diesel oil. Launched in 2017 for CMB Technologies, the ferry is equipped with two internal combustion engines running on hydrogen and diesel, with a total output of 441 kW. The hydrogen fuel is transported in 12,205-litre tanks at 200 bar pressure and two diesel tanks of 265 litres each [10].

According to [7,11], in recent years, several new and considerably larger hydrogen-powered vessels have entered the market, and a group of other vessels are at the design and research stage. One example, the passenger/car ferry MF ‘Hydra’, over 80 m long, made its first trip off the coast of Norway on liquid hydrogen fuel in March 2023. The vessel can accommodate up to 300 passengers and 80 vehicles. It carries 4000 kg of hydrogen fuel and is equipped with two 200 kW fuel cells, two 440 kW generating sets and two Shottel thrusters [12].

In addition, a new SOV concept has emerged, featuring a liquid hydrogen power plant, jointly developed by shipowner Louis Dreyfus Armateurs (LDA) and Norwegian company Salt Ship Design. It is estimated [13,14] that the ship will be able to operate 95% of the time with zero CO2 emissions and will only release water during standard operations. This would have a positive impact on the emissions associated with the operation of offshore wind farms, preventing the release of around 4000 tonnes of CO2 per year.

All the hydrogen-powered vessels built to date have resulted from new projects. There is no case in the literature of a vessel conversion or upgrade to run on hydrogen apart from this year’s publication by Melideo D. et al. [15]. The authors examined the possibilities of converting ro–ro and ro–pax ferries operating on a short route (about 27 km) off the Italian coast. The scenarios included the replacement of the main and auxiliary engines with fuel cells, together with an analysis of the hydrogen demand and other parameters associated with the use of this fuel. However, the authors did not attempt to explore feasible layouts of the ferry interior as required by the use of fuel cells or hydrogen tanks and their impact on the mass parameters of the entire vessel.

The publication [16] presents a draft scenario for the integrated use of offshore hydrogen-powered vessels with polymer membrane fuel cells (PEMFCs) and offshore wind energy and provides a technical and economic feasibility analysis. This project addresses problems associated with offshore hydrogen transport and offshore wind energy development, including hydrogen storage. Another publication [17] presents an overview of recent research on hydrogen ship propulsion systems and various aspects of the production, transport, storage and use of liquid/gas H2 and its derivatives as fuel in the shipping industry. The authors state that hydrogen propulsion in maritime transport is still in the experimental phase, and in most cases, these experiments serve as a kind of platform to evaluate the feasibility of different technological solutions. Panagiotis Karvounis et al. [18] made a comparative assessment of the potential for the use of alternative fuels for marine engines, in particular hydrogen, methanol and ammonia, as well as the associated environmental benefits. In addition, they assessed the required storage conditions, space and related costs, paying much attention to the safety issues and requirements for each alternative fuel. The results of this study show that the environmental benefits of alternative fuels are only visible when renewable energy is mainly used for fuel production, while the applicability of these fuels depends on the type of vessel and the relevant storage limitations. The article [19] analyses the possibility of replacing a conventional diesel generator installed on a small hybrid ferry with an innovative system based on PEMFC technology. To this end, the total energy/power demand of the vessel was considered using a typical operational profile, and a preliminary reconfiguration of the propulsion system was proposed along with an energy management strategy. The daily hydrogen consumption was determined. In addition, different storage technologies for compressed and liquefied phases were considered and compared to determine the ship’s mass and space requirements.

The overview of current research shows that assessments made to assess the required storage space on ships for alternative fuels used in their energy systems mainly relate to hydrogen fuel cell energy systems, to a lesser extent addressing internal combustion engines. This is probably due to the fact that the advantages of using hydrogen in shipping were only confirmed a few years ago, so there are more questions than clear answers when it comes to the design and construction of ships adapted to this type of fuel. International or class regulations are still in the process of creation. Not surprisingly, there is a lack of information in the literature on the impact of the use of hydrogen fuel on this important issue:

- Design and construction changes to the ship’s hull;

- Weight and volume of fuel tanks and their impact on the ship layout (engine room and adjacent compartments), as well as the possibility of installing them in the ship’s hull;

- Solutions and configuration of the ship’s energy system;

- Cargo carrying capacity and displacement of the vessel;

- Operational parameters, including vessel speed and range.

Over the last 10 years, considerations of alternative fuels in maritime transport, in terms of economic or environmental performance and the level of exhaust gas reduction, have been the subject of analyses presented in a number of publications [20,21,22,23,24,25]. However, these analyses are mainly concerned with transport vessels operating on established shipping routes. The use of hydrogen as a marine fuel for ships has only gained prominence in the past few years resulting in an increasing number of hydrogen-related topics in scientific publications as well as in the related industries.

One such example is the research [26] carried out on the experimental catamaran ‘Energy Observer’, which provided valuable information on the use of hydrogen fuel cells to propel this unit using renewable energy sources to produce hydrogen through electrolysis of seawater. On the other hand, the authors [27], using a coastal ferry (12,000 GT) as an example, presented the impact of several alternative fuels: LNG, MGO and hydrogen, by comparing them using a life cycle assessment (LCA) analysis. In the paper, they also made suggestions for a plan to use hydrogen for small coastal ships and to actually achieve a zero-emission ship. Similarly, in publication [28], the authors, using the LCA method, assessed the environmental impact of marine propulsion systems using hydrogen and ammonia as marine fuels. Selected for the study were two-stroke and four-stroke engines of tankers powered by conventional fuels and, for comparison, powered by ‘green’ and ‘blue’ hydrogen and ammonia with the support of pilot fuel. Whereas in [29], the authors broadly considered the safety of hydrogen storage. Discussing the advantages and disadvantages of hydrogen production technologies, the authors also highlighted the challenges that need to be overcome to safely use hydrogen as a marine fuel.

The key findings from the literature overview are as follows:

- Issues of using alternative fuels such as LNG or methanol (MeOH) are discussed, but the use of hydrogen fuel is still in an experimental phase, and research is limited to smaller coastal vessels;

- No information is available on the impact of fuel type on the design process and ship construction and performance, i.e., the main dimensions, functional–spatial layout of the hull, deadweight or total displacement of the ship;

- For special vessels, i.e., service vessels (apart from a few examples with design plans), there is a lack of scientific publications on the effects and possibilities of using hydrogen fuel with strict safety rules;

- There are no data on the use of hydrogen for direct combustion in reciprocating internal combustion engines used in ship energy systems and thus on the impact of such a solution on the functional and spatial parameters of the ship.

1.2. Hydrogen Properties, Storage and Maritime Transport

Hydrogen (H2) is the lightest and most common chemical element in the universe. It also has the lowest density of all elements, which depends on its state of aggregation; i.e., in the gaseous phase, it is only 0.00009 g/cm3; in the liquefied state, it is approx. 0.07 g/cm3 and in the solid state, 0.08 g/cm3 [30]. Under normal conditions (0 °C and 1013 hPa), hydrogen is an odourless and colourless gas. It is flammable and, with oxygen, forms an explosive mixture. However, its lightness means that rapid vaporisation occurs if the hydrogen tank is damaged—without posing a risk to humans. When burned in internal combustion engines, it does not pollute the air, as water is the only by-product when powering fuel cells.

The degree of purity of hydrogen, and thus its low or zero emissions, depends on the method of its production. In this research carried out, its purest form was considered, i.e., produced by electrolysis of water using electricity, which can be a ‘green source’ (when it comes, for example, from wind energy generated by an offshore wind farm). Other methods of production include processes based on steam reforming of natural gas or petrol reforming. These, however, result in by-products in the form of CO2 [31]. Methods of hydrogen production are discussed in many research publications; hence, this study does not discuss this subject. The method of hydrogen production corresponds to terms associated with its colour: green is the purest hydrogen derived from renewable sources, grey is hydrogen derived from fossil fuels, with high CO2 emissions, while blue denotes hydrogen derived like grey, with the process being combined with CO2 capture and storage technology.

Hydrogen storage and mode of transport are key issues related to hydrogen production. On ships, hydrogen as a fuel is most often used in the liquid or gaseous phase:

- Liquefied hydrogen transported in cryogenic tanks (−253 °C);

- Compressed hydrogen transported in metal, high-pressure tanks (older solution) and in composite tanks or high-pressure vessels, i.e., tanks (recent solution).

In this article, the authors focus on an analysis of the use of hydrogen as a gaseous propellant, as hydrogen compression technology has been known for a long time and is well-developed (widely used in both industrial and automotive applications). This technology is simpler, requiring only special pressure vessels, without the use of a complex cooling system during hydrogen storage and transport—as is the case with liquefied hydrogen. The whole process of compression of hydrogen counts as an energy-intensive and costly process—one of the disadvantages of this storage method. From an environmental point of view, the preparation for transport and the transport of compressed hydrogen itself consumes less energy (6–25% for a pressure range of 250–700 bar), as the preparation of liquefied hydrogen requires about 21–30% of the total energy contained in the fuel [31,32].

Of course, in the case of liquefied hydrogen, the hydrogen still needs to be kept in a liquefied state, which will increase the energy consumption by a few percent in relation to the total energy contained in the fuel.

According to literature sources, both types of hydrogen storage systems are crucial to its future as a marine fuel, with liquefied hydrogen being more efficient on long shipping routes and compressed hydrogen offering greater flexibility for smaller, short-range ships. According to [31], it is assumed that this form of hydrogen can be most competitive in coastal region markets and in inter-regional areas where pipelines are technically difficult or not economically justified.

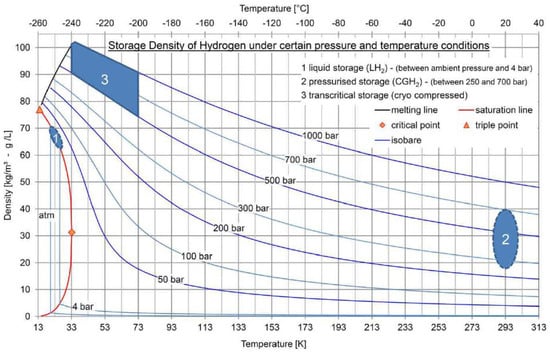

The low density of the gaseous form of hydrogen (under normal conditions) means that it requires a large volume for storage [33]. Compared to natural gas, hydrogen has as much as a three times lower energy content in the same volume. Therefore, when using hydrogen as an energy carrier in gaseous form, it is necessary to compress it in order to obtain a sufficiently large mass volume of hydrogen stored in a tank. Gaseous hydrogen is stored at room temperature (about 298 K) in the pressure range from 150 to 800 bar [34]. Increased pressures allow its energy density to be significantly raised, and thus, more fuel can be carried in a smaller volume, which in turn benefits the limited volume of the ship’s hull. Figure 3 shows the hydrogen storage conditions as a function of temperature and pressure [35]. Unfortunately, even so, the low density of hydrogen contributes to the fact that, even at high pressure, little useful energy is stored—which necessitates very large tank volumes and increased storage costs. Consequently, to increase the operating range of seagoing vessels, tanks are required to withstand such high pressures while not increasing the ship’s deadweight.

Figure 3.

Hydrogen storage conditions as a function of temperature and pressure [35].

For the storage and transport of pressurised hydrogen fuel by ship, containerised sets or independent cylindrical tanks are used, mounted in special racks/frames. When a ship requires larger volumes of hydrogen, companies offer a modular system, both in terms of the diameter and length of such tanks. The choice of how to store the transported hydrogen fuel on the SOV and a broader discussion of the above technologies will be presented further in this study.

There are currently four categories of standard cylinders (types I–IV) for the storage of compressed hydrogen. The fifth generation is in the experimental and research phase (intended mainly for space applications) [36].

The first three categories are tanks made mainly of steel, relatively heavy and not suitable for marine transport use. Type II has composite components to reduce their weight, and type III tanks have a metal liner (usually aluminium) inside, surrounded by full composite cover (e.g., carbon fibre). This offers greater weight reduction compared to type II tanks, which have a metal liner and only partial composite reinforcement. This group of tanks is mainly used in the transport and automotive sectors.

The latest developments, the fourth generation of pressure vessels, are constructed entirely of carbon composite materials. These materials provide high strength and resistance to rusting and fatigue, form a protective barrier to hydrogen, are much lighter than steel tanks and retain a correspondingly large gravimetric volume of fuel [35]. According to [37,38], they have up to 70% less weight compared to type I tanks, so this type of tank is particularly desirable in reducing the cargo carrying capacity as little as possible in the ship under study.

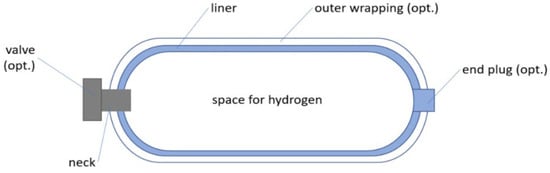

The type IV tank is made by winding or braiding carbon fibres in an epoxy resin matrix over a plastic liner. It allows hydrogen to be stored at a pressure of 700 bar, and the amount of gas stored is equal to 12% of the tank weight. When the gas is compressed to a pressure of 700 bar, it achieves a volumetric volume in the tank that reaches 40.2 g/L [39]. Typical structural elements of a composite hydrogen tank are shown in Figure 4 [37].

Figure 4.

Typical components of a hydrogen tank—source: [37].

Methods of manufacturing this type of vessel vary, and many companies already offer innovative solutions for the production lines. Of the global manufacturers of composite pressure vessels, only a few offer products for the maritime industry. This article focuses on two manufacturers with extensive experience and advanced technological solutions:

- NPROXX, based in the Netherlands;

- Hexagon Purus, with a seat in Ålesund, Norway.

In Poland, research work is also in progress to develop composite tanks for high-pressure hydrogen storage. For example, the Amargo company, in collaboration with the Warsaw University of Technology and the Wrocław University of Technology, is developing pressurised hydrogen tanks for industrial applications [40]. The result of this work is expected to be high-capacity composite hydrogen tanks with a liner of HDPE and PA plastic. Amargo tries to obtain the maximum achievable lifetime (service life) of its tanks. The firm uses original tank condition monitoring elements permanently installed in manufactured tanks and works on implementing a real-time tank condition monitoring system. All these activities are aimed at extending the life cycle of the tanks or predicting tank failures that could compromise the integrity of the chemical-resistant liner [40].

Carrying high-pressure hydrogen cylinders on a ship requires a number of strict safety requirements. For this reason, special structures in the form of containers or racks are used. Hexagon Purus already employs such comprehensive solutions. Table 1 shows examples from the specifications offered by the above-mentioned manufacturer of lightweight composite high-pressure containers for the carriage of hydrogen.

Table 1.

Type IV tank specification (nominal working pressure: 700 bar, 15 °C)—data from Hexagon Purus [41].

Table 2 presents some specifications for composite tanks (type IV) from NPROXX, the company that also specialises in high-pressure hydrogen tanks for the marine market. Data of the two largest tanks offered by the company are shown, currently undergoing certification (anticipated release in the last quarter of 2024) [42].

Table 2.

Specifications of selected hydrogen cylinders from NPROXX, source: [43].

Due to the greater availability of technical data on how to transport and store compressed hydrogen, this study used cylindrical cylinders from the manufacturer Hexagon Purus and a method of modular installation of the cylinders with frame protection on the service vessel.

1.3. The Use of Hydrogen in Internal Combustion Engines

Today, combustion engine technologies dominate the field of converting chemical energy into electricity. This may change when fuel cell technology achieves low overall costs, low recycling costs and high efficiency over a wide range of outputs. The achievement of these goals by fuel cells will make them truly competitive with reciprocating internal combustion engines, which are currently the most efficient devices for converting chemical energy into mechanical energy and indirectly into electrical energy. Considering the above and the well-developed technology of internal combustion engines, the author of the work [44] believes that reciprocating internal combustion engines will be widely used to generate electricity by burning hydrogen.

Hydrogen is more often used in four-stroke (medium- and high-speed) reciprocating engines used in ships operating over short distances (and in trucks) than in two-stroke (slow-speed) high-power piston engines used in deep-sea vessels [45].

Hydrogen can be burned directly in reciprocating internal combustion engines or burned in mixtures of hydrogen with other fuels to generate propulsion power by main engines and to generate electricity by generating sets. In addition, hydrogen can be used in hydrogen fuel cells to generate electricity for ship propulsion. The authors’ current research addresses the former solution, i.e., direct combustion of hydrogen in reciprocating internal combustion engines, while the use of hydrogen fuel cells on SOV vessels will be analysed in further stages of this research, including comparative studies of the two solutions from technical and economic points of view.

The market introduction of hydrogen-powered engines is currently underway. For example, the largest marine engine manufacturers, Wärtsilä Corporation (Helsinki, Finland) and MAN Energy Solutions SE (Augsburg, Germany), report that their hydrogen-powered engines will be launched in 2026, but orders may already be placed in early 2025 [45,46].

Wärtsilä Corporation (Helsinki, Finland) will initially offer two solutions for its engines [46]:

- The 31H2 dual-fuel engine, which can run on natural gas or hydrogen, as well as a mixture of these fuels;

- The 31SG-H2 engine, which can run on natural gas and a mixture of natural gas and hydrogen up to 25 per cent by volume; can also be adapted to run on hydrogen alone.

MAN Energy Solutions SE (Augsburg, Germany) is currently working on a hydrogen-powered dual-fuel H2 engine that will be fully flexible and require only pilot fuel, which can be derived from green synthetic diesel. MAN representatives believe that hydrogen-powered reciprocating internal combustion engines are an extremely attractive option compared to fuel cells due to the lower cost, power density, flexibility of fuel application and high reliability of these engines. Based on their long-term experience, they estimate a service life of more than 30 years for this type of engine (with regular maintenance), which far exceeds that of fuel cells. At the same time, they point out that fuel cells are a good solution in the lower power ranges but not as the main propulsion system solution for coastal and offshore vessels [45].

For its part, WinGD Ltd. (Winterthur, Switzerland), a manufacturer of slow-speed, high-power marine engines, is now betting on ammonia as a zero-emission hydrogen-based fuel that can be produced without greenhouse gas emissions using electricity generated from renewable energy sources. The first WinGD engine that can run on ammonia should be available in 2025. An ongoing project is developing a concept for the use of ammonia for both diesel-powered WinGD X-type engines and dual-fuel LNG X-DF engines [47].

To date, few hydrogen-fuelled engines are available. For example, the company BeHydro (Gent, Belgium) offers an off-the-shelf solution, the BEH2YDRO DZ H2 family of hydrogen-only engines (in which combustion of the air–hydrogen mixture is initiated by a spark, as in spark ignition engines). In addition, its BEH2YDRO DZD H2 dual-fuel engines are powered by diesel fuel and a fuel composed of 85% gaseous hydrogen and 15% liquid fuel (where the combustion of the air–hydrogen mixture is initiated by injection of liquid fuel, as in compression ignition engines) [48,49].

The company BeHydro (Gent, Belgium) offers the DZ H2 and DZD H2 engines with in-line cylinder layouts as 6- and 8-cylinder engines and in V-cylinder layouts as 12- and 16-cylinder engines [48,49].

Polish scientists are also involved in research into the use of hydrogen to power internal combustion engines. Researchers from the Krakow University of Technology presented a piston internal combustion engine adapted to run on hydrogen in January 2024. This is a Scania (Södertälje, Sweden) five-cylinder high-speed engine type DI09 074M, with 269 kW power, adapted for marine applications [50,51].

1.4. Research Aim

As a result of the literature review that revealed the lack of published data on analyses of using zero-emission alternative fuels on offshore vessels from the design-construction perspective, the aim of the current research is to analyse the feasibility of using compressed hydrogen fuel to propel an SOV vessel in terms of design and economic challenges. To achieve such an aim, the authors examined the existing design concept of the SOV, together with the ship’s operational profile—as well as the operating regime guidelines and corresponding power requirements. These were presented in detail in a publication by Bortnowska M. [52].

To achieve the main objective of this research, the following actions are needed:

- Analyse the physical and chemical properties of hydrogen and the challenges posed by the use of hydrogen on board as a fuel;

- Apply the technical requirements for the safe operation of hydrogen fuel (storage and transport) in accordance with current IMO guidelines;

- Carry out a power demand analysis for the main SOV operating regimes in the area of wind farms located in the Baltic Sea;

- Select the number and power of commercially available compressed hydrogen engines and analyse their configurations;

- Calculate fuel consumption for different ship operating regimes, select the storage and transport system and deploy their elements in the hull, meeting safety requirements;

- Analyse the impact of the use of hydrogen fuel on the design and structural elements and spatial layout of the ship;

- Identify what benefits will be achieved with the different fuels, taking into account the hull volume used, resulting from the volume of the fuel tanks selected;

- Conduct an economic analysis in terms of the cost of the hydrogen fuel used and make a rough comparison with other accepted fuels such as MDO, LNG and MeOH.

2. Initial Assumption and Methodology

2.1. Specification of the Service Vessel and Its Area of Work

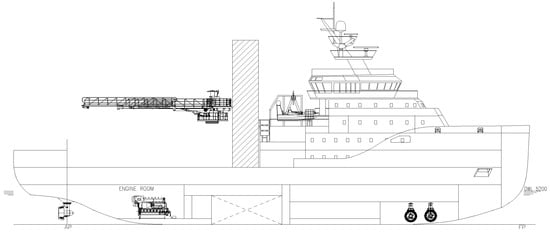

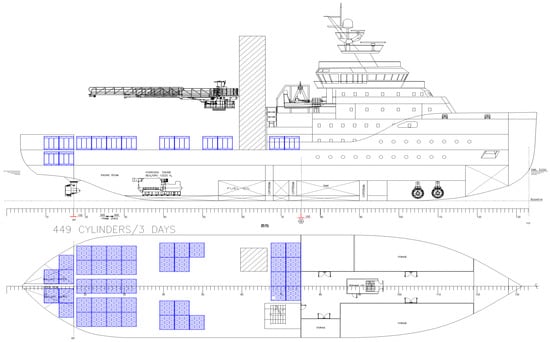

Table 3 contains the key data from the ship’s specifications that are important for this study, and Figure 5 depicts the sketch profile view of the ship.

Table 3.

Technical specifications of service vessel, adopted for further analysis [53].

Figure 5.

Sketch profile view of the SOV, source: [52].

A diesel–electric propulsion system was adopted for this study based on a database of similar vessels developed by the authors, in which four variants of reciprocating internal combustion engines powered by different types of fuel, i.e., diesel, LNG, methanol and hydrogen, drive generating sets to produce electricity for shipboard needs, including propulsion.

The following engine types used in the selected gensets were used:

- Wärtsilä 20 four-stroke diesel engine (Wärtsilä Corporation, Helsinki, Finland), which can run on marine diesel oil (MDO) and light and heavy fuel oil (LFO, HFO);

- Wärtsilä 20DF four-stroke dual-fuel diesel engine (Wärtsilä Corporation, Helsinki, Finland), that can run on liquified natural gas (LNG), MDO and HFO;

- Wärtsilä 20 methanol-fuelled four-stroke diesel engine (Wärtsilä Corporation, Helsinki, Finland), which, in addition to methanol, can run on MDO, LFO and HFO;

- BEH2YDRO DZD H2 four-stroke hydrogen-fuelled diesel engine (BeHydro, Gent, Belgium), which can run on MDO and LFO in addition to hydrogen.

The use of four engine power variants will allow a ship design analysis to be carried out for the estimation of the volume and weight of fuel tanks relative to the type of fuel used and the area occupied in the ship’s hull space. Thus, the analysis will allow an appropriate spatial layout of the ship’s power system (gensets and fuel tanks), taking into account the area of the engine room location, and an assessment of the impact of a given variant on the space occupied, displacement or deadweight of the ship.

The computational analysis was carried out for a vessel (Table 3) that was hypothetically planned to operate in a wind farm area in the Baltic Sea at a distance of approximately 80 km from the coastline. For the analysis, the vessel was assumed to operate for average weather conditions in that area: average significant wave height Hs = 2.5 m, and average wind speed vw = 10 m/s [53].

2.2. Hydrogen Fuel Storage and Transport on a Service Offshore Vessel

Based on the literature review, market analysis and current technologies in maritime transport of hydrogen fuel, the authors decided to use the following in the project:

- Technology for transporting hydrogen in compressed form at high pressure—700 bar;

- A cylindrical tank was selected—composite cylinder of type 4, made by Hexagon Purus, pressure 700 bar and ambient temperature;

- Technical data—H2-70-705X2078:

- –

- Outside diameter DH2 = 705 mm;

- –

- Overall length LH2 = 2078 mm;

- –

- Cylinder weight WH2 = 264 kg;

- –

- Volume V = 457 litres;

- –

- Hydrogen capacity VH2 = 18.4 kg;

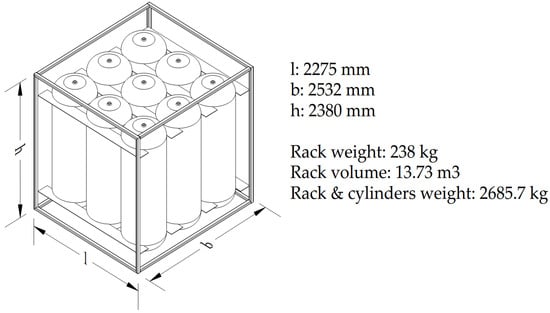

- Hydrogen fuel storage system on board the ship: the cylinders to be mounted on board in modular racks; each rack contains nine cylindrical cylinders, which can easily be combined; due to the limited manufacturer and regulatory guidelines on this issue, the authors chose the above concept as the preliminary one, which may be modified in the future.

The number of cylinders used, and thus the number of racks, will be determined later in this work, after an analysis of the mass and volume quantities of hydrogen required for the application.

2.3. Operational Profile of Service Vessel Work

The service vessel, in performing its tasks, is in various instantaneous operating states, during which it exhibits energy requirements in a variable range [52,53]. The specific nature of the SOV operation consists of several stages, which is why the entire cycle of its operation has been referred to as a mission. A single-ship mission consists of the following stages [52,53]:

- Normal operation: shipping to the working area;

- Service work in the offshore wind farms in the Baltic Sea;

- Normal operation: returning to port;

- Stopover in port.

The most common missions for a ship last 14 days. Due to the physical and chemical properties of compressed hydrogen fuel, it was found that a 14-day service period at sea would be feasible. It was therefore assumed that the maximum mission time Ts = 14 days.

Of all the mission phases, the main tasks of the vessel include service work around offshore wind farms, and, for this, the following was adopted: five regimes of ship operation marked (I–V) together with their duration in hours [52,53]:

- I—Operation with active working platform and DP2 dynamic positioning system (3.5 h);

- II—Manoeuvring (1.5 h);

- III—Operation with an inactive working platform and DP2 dynamic positioning system (3.5 h);

- IV—Low operation (1.0 h), vs = 6 knots;

- V—Night break using DP1 (14.5 h).

Each of the above service work phases is characterised by varying power demand. Table 4, based on [52,53], shows the input energy demand values for the particular service work regimes and for the round trip (to the offshore work area and back to port).

Table 4.

Power required for individual service work phases.

It follows from the data in Table 4 that the highest power demand occurs in operating regime (I)—with the DP2 system and working active platform, during normal ship operation, i.e., sailing to and from the wind farm, and in operating regime (III)—during operations using the dynamic positioning system.

2.4. Research Method

The new fuel type involves examining the effect of its use for service vessel propulsion and checking its feasibility in terms of safety criteria and volume design in the hull to provide storage space. These tasks can be carried out by analytical and computer-aided methods using CAD-type tools.

The computational research method was used to assess the feasibility of storing, transporting and bunkering hydrogen fuel on the vessel under study. The assessment also covered capabilities to provide demanded power under varying propulsion system load conditions during service work and estimation of the new fuel costs. The method was based on the following:

- Technical and operational data of the service vessel analysed in previous work—acc. [52];

- Latest IMO guidelines relating to hydrogen fuel;

- Available engine solutions adapted to run on this new fuel;

- A storage system that allows hydrogen to be transported under high-pressure conditions.

Using Autodesk Inventor Professional 2025 and AutoCAD Mechanical 2025, a 3D model of cylindrical tanks along with a transport module was utilised for research purposes. The model took into account parameters such as cylinder dimensions, the weight of the cylinder including the gas, and the volume occupied by the module with the cylinders. Thanks to the parameterization of the 3D models, modifications can be made more quickly and with precision. An additional advantage of CAD software is the visualisation of each element and the ability to verify the compatibility of individual modules with the cylinders on the ship, as well as the arrangement of power generators within the hull of the SOV.

However, the computational model is based on general formulas (presented later in this article) related to hourly and specific fuel consumption, enabling the determination of the required fuel reserves (in terms of mass and volume). It also relies on general formulas for calculating fuel consumption costs and engine loads under various operational conditions of the SOV.

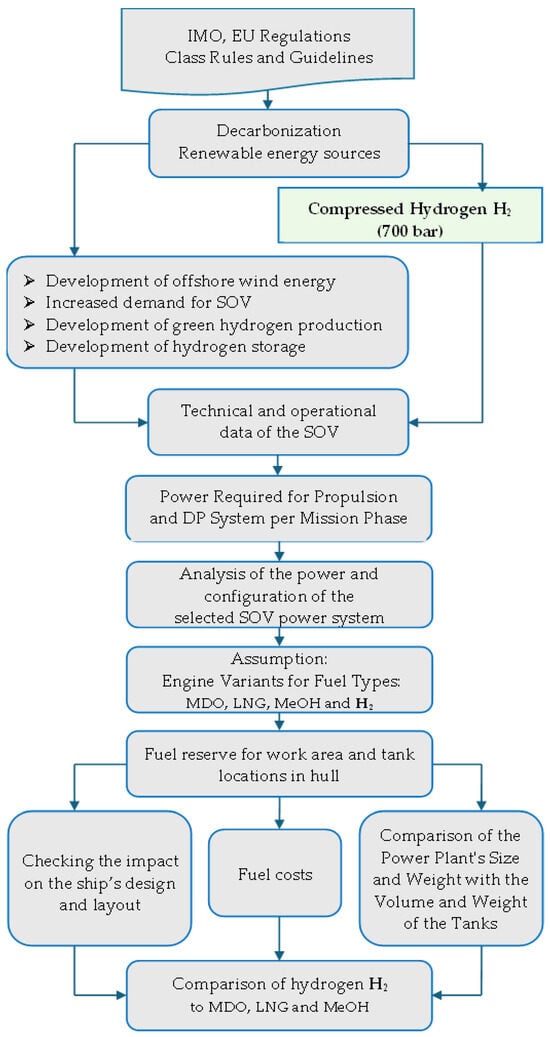

Figure 6 hierarchically depicts the main stages of the computational analyses, resulting from the initial assumptions and research background.

Figure 6.

Block diagram of the analysis of the size and mass of the power plant with fuel tanks and fuel costs for the SOV.

3. Design Analysis of the SOV for the Use of Alternative Propulsion Fuels

Taking into account the technical data of the analysed SOV, presented in Section 2, the vessel’s design analysis was carried out to estimate the volume and weight of the fuel tanks, depending on the type of fuel used, and to estimate the area occupied in the ship’s hull space. For comparison, methanol, LNG and conventional MDO fuel were used in addition to compressed hydrogen.

3.1. Selection of the Energy System Solution

3.1.1. Energy System Solutions for Service Offshore Vessels

From the SOV, CSOV (Construction Service Operation Vessel) and WSV (Windfarm Support Vessel) database of 20 similar vessels (authors’ collection used in this review), it can be seen that all vessels are equipped with diesel–electric propulsion or hybrid diesel-electric propulsion supported by a battery system.

In a diesel–electric propulsion system, electricity is produced by one common power station consisting of two, three or four gensets. The electric energy is then supplied to a propulsion system consisting of two electric motors driving two azimuthal thrusters and to the ship’s other loads such as the thrusters and all the equipment and facilities in the engine room, on deck, the bridge and accommodation.

In hybrid propulsion, two to four gensets that produce electricity for electric power receivers are supported by a battery bank system.

These considerations refer to combustion–electric propulsion, with reciprocating internal combustion engines powered by a variety of fuels: hydrogen, diesel, LNG and methanol.

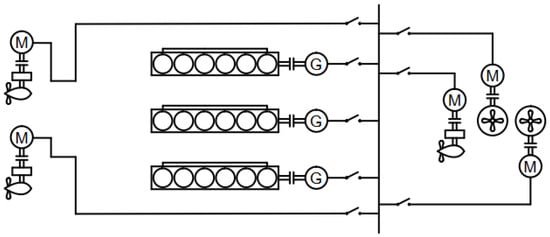

SOV power system solutions are dominated by a configuration of three gensets (12 vessels out of 20), with 11 vessels using gensets of the same power and only 1 using a configuration of two generating sets of higher power and one of lower power. For this reason, the authors adopt a configuration of three gensets of the same power for further study.

Considering the operational states of the service vessel (Table 3), we can conclude that the highest power demand occurs in operation mode (I)—with active DP2 system and active working platform. Taking into account the power demand in the different operating states of the examined SOV and the power values occurring on similar vessels (according to the database of service vessels developed by the authors), the total power of the power system was estimated at 5400 kW; i.e., each of the three gensets should have a power of 1800 kW. A diagram of the power system of the analysed ship is shown in Figure 7.

Figure 7.

The energy system of the SOV under analysis [authors’ drawing].

The database of similar vessels shows that two azimuth thrusters with an estimated power of 1000–1800 kW each and two bow thrusters with an estimated power of 750–1500 kW each are most commonly used for propulsion and manoeuvring on SOVs. In many cases, one retractable azimuth thruster with an estimated power of 800 kW is also used forward in addition to two thrusters.

3.1.2. DP2 Dynamic Positioning System

The high power output of the power system and appropriate propulsion and steering equipment provide the vessel with very good manoeuvring characteristics, typical of vessels equipped with the DP2 dynamic positioning system. Such vessels should meet two basic conditions [54,55]:

- (1)

- Maintain the position throughout the range of variations in hydrometeorological conditions specified in the design guidelines. This condition is met by installing generating sets and thrusters of sufficiently high power.

- (2)

- Maintain position even when a failure of any component occurs. This condition is met by adopting the redundancy concept, which is to maintain the dynamic positioning capability of the vessel in the event of a single failure of any component of the system.

In the current study, condition (1) is met, as the selected power system of 5400 kW is sufficient to drive two azimuth thrusters of approx. 1400 kW each and two bow thrusters of approx. 1200 kW each and one retractable azimuth bow thruster of about 800 kW.

In addition, the ship’s energy system can be equipped with an energy storage system consisting of, e.g., two battery units with a capacity of 300–600 kWh each and a maximum power of 800–1600 kW. This system will be able to support the ship’s energy system in situations of high demand for electricity, while at low demand the excess electricity from the generating sets will be able to charge battery banks. In addition, the battery banks can supply power to the ship’s systems when the gensets are not running, for instance when the ship stays in port.

In the present study, condition (2) is also met, as the power system consists of three gensets and two azimuth thrusters and three bow thrusters, guaranteeing that the dynamic positioning capability of the vessel is maintained even in the event of a single failure of any system component. The limit operating conditions of the SOV are determined by the power (generators, azimuth thrusters and bow thrusters) available once a failure of any system component occurs and not by the nominal power of the installed equipment. Thus, taking into account the power requirements for the engines in different operating states of the vessel estimated in Table 3, a failure of one of the gensets, azimuth thruster or one of the bow thrusters will provide the vessel with the required power to maintain position.

DP systems are equipped with a load-limiting function related to position maintenance priority. In certain situations, e.g., in severe weather conditions, the operation of the thrusters can consume the entire power reserve, thus limiting the power transmitted to other lower priority equipment, such as lifting equipment [55].

3.1.3. Selection of Generating Sets

Several variants of the gensets were adopted for this study. These machines, supplying electricity for the propulsion power of the ship, will be the study focus and will be fed with different fuels: hydrogen and, for comparison, methanol, LNG and conventional MDO fuel. The four gensets are composed of the following four-stroke reciprocating internal combustion engines to drive the generators:

- Wärtsilä 20 (Wärtsilä Corporation, Helsinki, Finland) powered by conventional MDO fuel;

- Wärtsilä 20 dual-fuel (Wärtsilä Corporation, Helsinki, Finland) fed with LNG preceded by a pilot dose of conventional MDO fuel;

- Wärtsilä 20 (Wärtsilä Corporation, Helsinki, Finland) fuelled with methanol (M);

- BEH2YDRO DZD H2 (BeHydro, Gent, Belgium) fuelled with a mixture of hydrogen (H2) and MDO in a ratio of 85/15.

A hydrogen-powered engine from BeHydro (Gent, Belgium) was included alongside the engines from Wärtsilä Corporation (Helsinki, Finland) because hydrogen-fuelled engines from the latter are expected on the market in 2026 [46]. MAN Energy Solutions SE (Augsburg, Germany) also plans to launch hydrogen-powered marine engines in 2026 [45].

Table 5 summarises the technical data of the gensets adopted for the analysis. The data relevant for design purposes include dimensions and mass. The space occupied by the gensets should account for the dimensions of the gensets themselves, as well as all the associated equipment and servicing (as defined by the regulations and the manufacturer’s requirements), which obviously increases the footprint. Assuming the ship breadth B = 18 m (Table 3), the gensets can be positioned side-by-side along the ship’s centre line. In this study, the approximate service space around the gensets was assumed to be 1 m around, with a 1.5 metre spacing between two gensets. Such space ensures convenient day-to-day servicing of the auxiliary engines and provides adequate service space during overhaul. For comparison, for the Wärtsilä 8L20 engine (Wärtsilä Corporation, Helsinki, Finland), the manufacturer recommends [56]:

Table 5.

Main technical data of auxiliary sets [48,49,57,58,59].

- Service space for generating set—500 mm;

- Distance needed to dismantle the pump cover with fitted pumps—650 mm;

- Width for dismantling lubricating oil module with lifting tool—approximately 500 mm.

The determined indicative space occupied by the gensets is summarised in Table 5.

A closer look at the data summarised in Table 5 shows that the main dimensions of the hydrogen-fuelled genset are similar to those of the other three Wärtsilä gensets (Wärtsilä Corporation, Helsinki, Finland) running on different fuels. Only the height is larger than the other machines (by 300 mm compared to the 9L20DF and 9L20M engines and 584 mm compared to the 9L20 engine). This will affect the need for more space above the hydrogen genset, while the footprint of all the gensets remains similar. In addition, the BEH2YDRO 12DZD H2 genset (BeHydro, Gent, Belgium) weighs 9–11 tons more than the other gensets, which, for three gensets, will increase the weight by approximately 30 t.

This research focuses on the BEH2YDRO 12DZD H2 hydrogen-fuelled engine solution (BeHydro, Gent, Belgium), a 12-cylinder engine in a V-cylinder arrangement. It is a four-stroke, medium-speed, dual-fuel H2 engine that is turbocharged, intercooled and built for multiple fuel execution; i.e., diesel, marine diesel oil (MDO), gasoil (GO), dual fuel (diesel and hydrogen), biofuel, vegetable oil, fuel cell grade or less purified H2 are possible [48]. According to the manufacturer [49], the engine is characterised by its ability to run on less purified hydrogen, its fast response to varying loads and an 85% CO2 reduction. It complies with EU Stage V requirements when combined with selective catalytic reduction, where a chemical reaction converts nitrogen oxides into nitrogen and oxygen, and a diesel particulate filter (DPF) removes particulate matter or soot from the exhaust gas. Other characteristics include a long life, easy maintenance and the availability of spare parts (rare materials not used). The engine runs on a fuel composed of 85% gaseous hydrogen and 15% liquid fuel, with an option for liquid fuel only. Combustion of the air–hydrogen mixture is initiated by liquid fuel injection, similar to compression–ignition engines.

In order to maintain the safety of the entire hydrogen combustion process, the engine is fitted with equipment for fuel treatment before it is delivered to the engine combustion chamber. The fuel preparation and delivery process are not relevant to the research discussed herein, so its description has been omitted.

3.1.4. Parameters of the Fuels Used

In order to dimension the fuel tanks, it is necessary to characterise the parameters of the fuels used in the selected engines (Table 5). The most relevant physical and chemical properties of the selected fuels are shown in Table 6, with one type of liquid fuel (MDO) selected for comparison, as this fuel does not require the treatment system nor the construction of the tank heating system using insulated fuel pipes routed to the engines, as is required for heavy fuel oil [60]. This will make the installation of liquid fuel less complex and less costly during the construction and operation of the vessel.

Table 6.

Comparison of the physical and chemical properties of hydrogen in relation to MDO, LNG fuel and methanol [31,61,62,63].

As low-carbon fuels, LNG and methanol have a lower carbon emission intensity compared to conventional petroleum-based marine fuels, while hydrogen has virtually zero carbon intensity. Since this study assumed a fuel consisting of 85% gaseous hydrogen and 15% liquid fuel as the fuel for the hydrogen-fuelled engine, carbon dioxide emissions will therefore occur but in much lower quantities.

For easier storage and use, LNG is liquefied by cooling to −163 °C, while hydrogen is compressed to a pressure of 700 bar. Like LNG-fuelled vessels, hydrogen-fuelled vessels use their own engine architecture and require specialised fuel storage systems. Hydrogen fuel has the lowest volumetric energy density, yet the highest specific density MJ/kg compared to other fuels used in vessel propulsion, including SOVs (Table 3), requiring larger tank volumes that will take up significantly more space on board.

3.2. Technical Requirements for Fuel Tanks on Ships

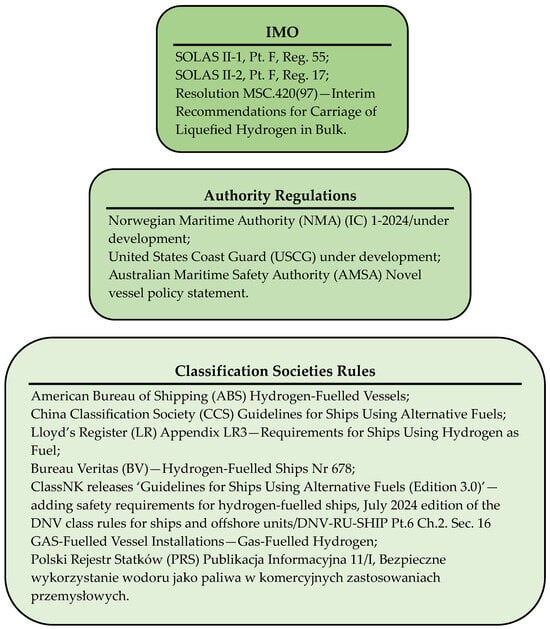

3.2.1. Current Regulations

The use of hydrogen as a fuel in maritime transport has gained prominence in recent decades, but only in 2019 did the International Maritime Organisation (IMO) approve and recognise hydrogen as a potentially safe and environmentally friendly fuel for ship propulsion. Still, hydrogen as an alternative fuel does not yet have full regulations. Work is still in progress, and the regulations are expected to be finalised by 2025. The IMO interim guidelines complement the most important regulation of the International Code of Safety for Ships Using Gases or Other Low-flashpoint Fuels (IGF Code)—concerning safety related to hydrogen storage, fuel systems and propulsion systems on board [64,65].

These regulations aim to provide an international standard for ships operating with gas or low flashpoint liquid. They set out criteria for the arrangement of equipment, machinery and installations on ships using low flashpoint liquids or gases for propulsion, such as hydrogen. There are also national (flagship) regulations and rules of classification societies that contain regulations for the use of hydrogen fuel in ships. Figure 8 illustrates the key rules and regulations relating to the use of hydrogen fuel in maritime transport [1,66].

Figure 8.

Current regulations for hydrogen fuel.

Many countries are strongly committed to the implementation of hydrogen as a fuel for marine use, which is evident in the development of the infrastructure and projects under development. Notably, at the IMO symposium [67], hydrogen fuel was announced as the long-term future, so it can be concluded that hydrogen has significant potential for the future energy economy.

3.2.2. Fuel Tanks with Compressed Hydrogen CH2 in the Ship’s Hull

Transporting hydrogen as a fuel on ships requires compliance with a number of stringent safety and design requirements due to its unique properties. Due to its characteristics, it increases the risk of leakage or penetration through the tank material, which can make it brittle, which in turn makes it difficult to store and transport. This article presents some of the most relevant design-related guidelines from DNV-RU-SHIP Pt.6 Ch.2. Sec. 16 Gas-Fuelled Vessel Installations—Gas-Fuelled Hydrogen:

- Use high-strength materials that are resistant to hydrogen permeability, hydrogen embrittlement and corrosion (this study uses composite containers with a lower weight and higher resistance to hydrogen diffusion compared to steel). Data on hydrogen embrittlement susceptibility of commonly used metallic materials are given in ISO/TR 15916: 2015, ANSI/AIAA G-095A-2017 or NASA TM-2016-218602;

- Locate the hydrogen fuel tanks in the ship’s hull and design the ship’s engine room along with the layout of other rooms containing the hydrogen fuel systems;

- Containers must be equipped with safety valves to discharge hydrogen in a controlled manner if the permitted pressure is exceeded (e.g., to the atmosphere via ventilation ducts);

- Hydrogen cylinders must be placed in separate technical rooms, away from heat sources (engines, boilers) and electrical equipment that could be a potential source of ignition;

- Tanks are to be separated from crew spaces by fire barriers (Class A-60);

- Tanks should be above the waterline (as high up in the hull as possible), and if not, very strict safety and access regulations must be met;

- Spaces where tanks are located must be equipped with ventilation systems with continuous air exchange to prevent the accumulation of hydrogen, which can be highly explosive, even at low concentrations, and equipped with hydrogen detector systems to detect its presence at very low concentrations and immediately raise an alarm if a leak is detected. The regulations require tanks to be located in open spaces or in enclosed spaces (equipped with an efficient ventilation system);

- Vessels inside the hull must be protected from mechanical damage, e.g., impacts or shocks, by additional protective covers or barriers;

- Bulkheads must be fire resistant and meet high fire insulation standards (Class A-60 according to IGF Code);

- Spaces with hydrogen tanks must be equipped with automatic fire detection systems and fixed fire extinguishing systems, i.e., water spray or powder extinguishing systems or gas extinguishing systems.

3.3. Calculation of Fuel Supply and Arrangement of Tanks in the Ship’s Hull

3.3.1. Estimation of Fuel Quantity

In order to estimate the required fuel supply in store for the analysed SOV, it is necessary to determine the overall efficiency of a piston internal combustion engine, which for modern medium-speed marine engines is 0.38–0.50. The overall efficiency is a measure of the engine’s utilisation of the heat flux supplied in the form of fuel and is the basic energy and economic indicator of internal combustion engines. It depends on a number of design and operating factors, as well as the engine’s condition and load level. It should also be taken into account that the highest overall efficiency is achieved by internal combustion engines in the load range of 70–90% of rated power [68]. Taking these factors into account, we can assume that the overall efficiency of the reciprocating internal combustion engines is ηDE = 0.44, with an average load of 80% of rated power. For simplicity, the efficiency of all engines was assumed to be the same regardless of the type of fuel burned.

In addition, the estimated power demand for the assumed SOV operating states in Table 4, including the duration of each operating state, was also taken into account to determine the required fuel supply.

The following relationships were used to calculate the maximum fuel supply required:

- Fuel consumption per hour Gfuel [kg/h]:where PR—rated power [kW], LHV—emergency content [kJ/kg], and ηDE—engine efficiency [-];

- Total fuel reserve MTfuel [t]:where Gfuel—the fuel consumption per hour [kg/h], and TS—mission duration [h];

- Fuel volume Vfuel [m3]:where MTfuel—total fuel reserve [t], and ρfuel—fuel density [kg/m3];

- Specific fuel consumption gfuel [g/kWh]:where Gfuel—the fuel consumption per hour [kg/h], and PR—rated power [kW].

The hydrogen-fuelled engine runs on a fuel composed of 85% gaseous hydrogen and 15% liquid fuel, with the combustion of the air–hydrogen mixture initiated by injection of MDO liquid fuel. Similarly, during LNG-fuelled dual-fuel engine operation, combustion of the air–gas mixture is initiated with a small amount of MDO pilot fuel, less than 1% of full-load fuel consumption [69]. The amount of this pilot fuel is optimised for optimum combustion using an onboard engine speed and load control and monitoring system [59,69]. The proportions of these fuels were further taken into account in determining the required maximum fuel reserve for the SOV (Table 7).

Table 7.

Estimated total fuel reserve and volume for a mission.

The data contained in Table 7 show that a very large volume of hydrogen is required to power the engines, more than the tripled amount of methanol required and more than seven times the amount of MDO fuel required. The use of liquid MDO in the BEH2YDRO 12DZD H2 engine (BeHydro, Gent, Belgium) makes it possible to reduce the required hydrogen supply by 158.42 m3, with the need to store 20.69 m3 of MDO fuel.

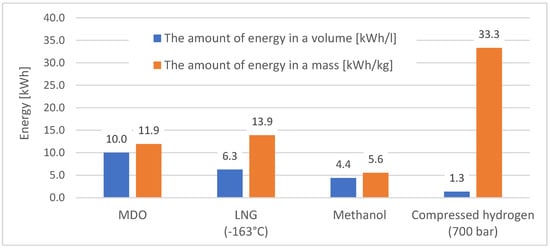

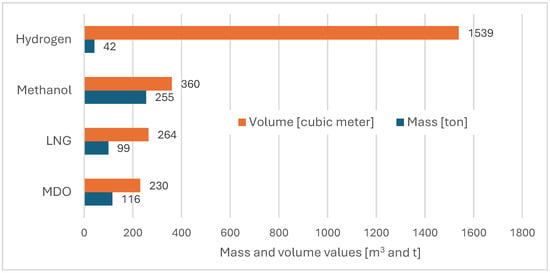

Also evident is the significantly lower weight of stored hydrogen fuel, six times less than that of methanol and more than twice less than that of LNG fuel. A comparison of the so-called ‘energy density’ of compressed hydrogen with the other fuels considered in this study is shown in Figure 9.

Figure 9.

Comparison of the so-called energy density for compressed hydrogen with respect to the other fuels considered in this study [authors’ research].

A more detailed picture of the variation in hydrogen fuel demand and volume occupied, depending on the possible variable service time, is presented in Table 8. These results provide the basis for conducting further design analyses regarding the layout of the hydrogen tanks in the SOV hull.

Table 8.

Calculated fuel reserve and hydrogen tank volume for ship autonomy (1–14 days).

3.3.2. Load Factor Analysis of Reciprocating Internal Combustion Engines

Table 9 shows the loads of the selected reciprocating internal combustion engines depending on the value of the power demand in the assumed operating states of the SOV (Table 4). As mentioned earlier, the highest overall efficiency of reciprocating internal combustion engines, and consequently the lowest specific fuel consumption, is achieved in the load range of 70–90% of rated power [68]. For this reason, the number and power of selected gensets should be such that, as far as possible, they will operate in these rated power ranges in particular operating conditions. This is particularly important in operating states that cover a longer period of time, such as states I, III and V, as the greatest amount of fuel is consumed during these operating states.

Table 9.

Degree of loading of the selected two combustion engine configurations depending on the value of the power demand in the assumed operating states SOV.

The following relationships were used to calculate the engine load:

- Engine load Eload [%]:where PR′—power requirement [kW], and PR—rated power [kW].

The data presented in Table 9 show that for the assumed operating states, the use of three gensets of equal engine power may not be economical, as in operating states III, IV and normal operation, the engines will consume more fuel due to their operation below the recommended loads. This should be taken into account in the calculation of the required fuel supply by increasing the amount accordingly.

For this reason, for the same operating conditions, three gensets of different powers of their four-stroke hydrogen-fuelled diesel engines BEH2YDRO DZD H2 (BeHydro—Gent, Belgium) [48] were used for the comparative analysis:

- The 8 DZD H2 with a power of 1200 kW;

- The 12 DZD H2 with a power of 1800 kW;

- The 16 DZD H2 with a power of 2400 kW.

The total power of these engines, 5400 kW, is the same as that of the three pre-selected 12 DZD H2 engines (BeHydro, Gent, Belgium). Similarly, the mass of the three gensets with different powers is practically the same as that of those with the same powers, as it is only 2.6 t, making them 2.5% heavier. However, this configuration of gensets will be troublesome with regard to their siting in the power plant due to their different dimensions and unit masses.

The use of a new configuration of three gensets with different powers improves the load factor of the engines for state III from 0.55 to 0.82, for state IV from 0.43 to 0.64 and for normal operation from 0.61 to 0.73. In the remaining states, i.e., I, II and V, the load factor of the engines remained unchanged. The apparent improvement in the degree of loading of the engines as a result power changes will certainly improve fuel consumption, but an accurate determination of this parameter for the purpose of comparing the two genset configurations requires the exact operating characteristics of the engines.

However, the use of the new configuration of three gensets of varied power output increases the hydrogen reserve by 5.91 t or 124.88 m3 (14%). This is a significant amount of hydrogen, but given the unfavourable load factor of the engines with the same power (Table 9), it can be assumed that the required hydrogen reserve will also increase in this configuration due to the increased fuel consumption in the three operating states.

A precise determination of the difference in the required hydrogen reserves for the two genset configurations is not possible at this stage of this study due to the lack of load characteristics or universal propulsion engines, so an average value from both configurations, i.e., 960 m3, was used for further analysis of the required hydrogen volume.

3.3.3. Hydrogen Fuel Volume and Arrangement of Cylinders in the Ship’s Hull

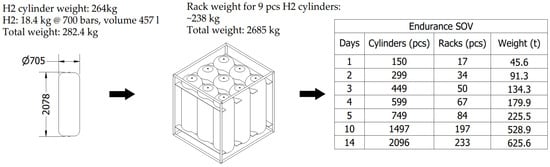

In order to store 960 m3 of hydrogen, 2096 Hydrogen high-pressure Type 4 cylinders (Table 1) from Hexagon Purus will be required, the parameters of which are outlined in Section 2. For the transport of hydrogen fuel cylinders in the ship’s hull, a preliminary initial rack structure was provided for the installation of nine cylinders—as illustrated in Figure 10.

Figure 10.

Modular rack for carrying hydrogen cylinders on an SOV [authors’ work].

The calculated weight of all the hydrogen-filled tanks was 592.19 t, and after adding the weight of the module frames, the figure rose to 625.6 t, a very high value considering the ship’s carrying capacity of 1005 t. It can therefore be seen that storing this amount of hydrogen significantly reduces the available deadweight of the vessel, and thus limits the transport of technical and service personnel and spare parts to offshore wind farms—the ship’s primary function.

In this situation, to use hydrogen as a fuel for the SOV, the reserve of hydrogen carried on the SOV must be limited. This can be achieved by the following:

- Reducing the service life of the vessel;

- Creating opportunities for offshore hydrogen refuelling, e.g., at an offshore hydrogen plant, which could ultimately be connected to an offshore wind farm;

- Employing an additional battery system for electricity storage;

- Replacing gensets with reciprocating internal combustion engine generators by hydrogen fuel cells supported by an electricity storage system.

In the latter two solutions, great emphasis is put on the energy efficiency of the vessel, which can be equipped with dual-fuel hydrogen-diesel engines, electric propulsion and a supporting energy storage system or with hydrogen fuel cells, electric propulsion and a supporting energy storage system. However, such SOV energy system solutions will be the subject of future research by the authors, as designs for such vessels are currently being developed.

One solution is based on setting up green hydrogen production facilities at sea in the form of electrolyser stations working in conjunction with offshore wind farms and offshore green hydrogen storage facilities. The availability of such solutions and the creation of an efficient hydrogen refuelling system can provide service vessels with increased service life using a dual-fuel hydrogen-diesel energy system.

In the current study, the authors focused on the analysis of an SOV energy system with hydrogen-fuelled dual-fuel reciprocating engines. To select and deploy the fuel tanks, it was necessary to limit the service life of the SOV analysed. Assuming its daily operation with the same profiles (Table 4), a linear increase in fuel demand was obtained from one operating day to another. Figure 11 shows the calculated demand for hydrogen cylinders (with the assumed parameters), the number of modules with cylinders, together with their total weight to ensure the ship’s endurance within the assumed range (1–14 days). At this point, it can be concluded that on an SOV with the assumed parameters, it will not be possible to transport a hydrogen supply providing a 14-day mission—contrary to the case of the same vessel with the other types of fuel (methanol, LNG and MDO).

Figure 11.

Diagram of the required number of hydrogen cylinders and the modules depending on the endurance of the SOV [authors’ work].

By calculating the required fuel mass (Table 7) and the resulting tank volumes for the four fuel types, it was possible to determine and compare the necessary footprint and volume in the ship’s hull. Table 10 shows the results of the above volumes for hydrogen fuel, transported in cylinders, over its full range of endurance (1–14 days).

Table 10.

Required area and volume for hydrogen cylinder modules in the SOV hull.

By analysing the results of the calculations (Table 10), we conclude that, in terms of footprint and volume, the service vessel will not have the technical capacity to store hydrogen fuel for a 14-day mission. The number of days for which the vessel can remain operational at sea running on hydrogen fuel is marked in green.

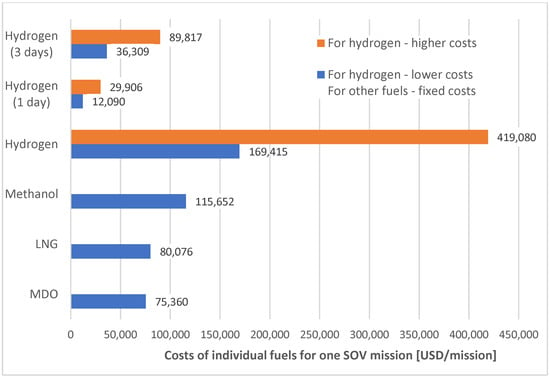

3.4. Fuel Costs

For estimated comparisons of the cost-effectiveness of the fuels, this study uses unit prices of the fuels based on price levels as of October 2024. Fuel costs related to the 14-day mission of the vessel, while hydrogen fuel calculations covered the time span of 1–14 days. In addition, annual fuel costs were calculated taking into account the number of voyages performed for the assumed TR = 250 operating days.

It is important to note that marine fuel prices have fluctuated significantly over the past year depending on the type of fuel and global economic factors. Comparing them to last year’s prices—adopted in this study, the prices of methanol fuel and LNG gas have fallen slightly, while traditional fuel has seen an increase of more than 30%—which are now relatively expensive fuel, dependent on global oil prices and emissions regulations. Hydrogen fuel is one of the most expensive marine fuels, with green hydrogen reaching a few thousand dollars per tonne. In addition, expensive high-pressure composite tanks and a hull-mounted system must be added as hydrogen-related costs, further increasing the ultimate hull value.

According to [70], the price of green hydrogen can vary from only EUR 1.12/kg to as much as EUR 16.06/kg depending on geographical location or the technology used. It varies widely; therefore, the authors assumed a value range of EUR 3.80–9.40/kg for the areas of Norway, the UK and Germany—European countries located close to the Baltic Sea. The authors of [70] suggest that by 2050, hydrogen may cost around 1 EUR/kg. The challenge in achieving this competitive price of green hydrogen calls for further technological and infrastructural advances, comprising hydrogen storage, transport and distribution, major factors affecting the cost of the entire supply chain.

This study is based on the price of Pfuel as of 14 October 2024, published in [71]:

- PMDO = 650.50 [USD/mt]—the unit price of MDO;

- PLNG = 806 [USD/mt]—the unit price of LNG;

- Pmethanol = 454 [USD/mt]—the unit price of methanol;

- PH2 = 3.80–9.40 [EUR/kg]—the unit price of hydrogen (at an average exchange rate of EUR 1 = USD 1.05, PH2 = 3990–9870 [USD/mt]).

The following relationships were used to calculate the fuel costs required:

- Fuel costs [USD/mission]:where MTfuel—total fuel reserve [mt], and Pfuel—fuel unit price (depending on the type of fuel assumed) [USD/mt];

- Number of voyages per year [-]:where TR—operating days [day], and TS—mission duration [day];

- Annual fuel costs [USD/year]:where nM—number of voyages per year [-], and Kfuel—fuel costs [USD/mission].

4. Results

4.1. Arrangement of Hydrogen Cylinders on the SOV

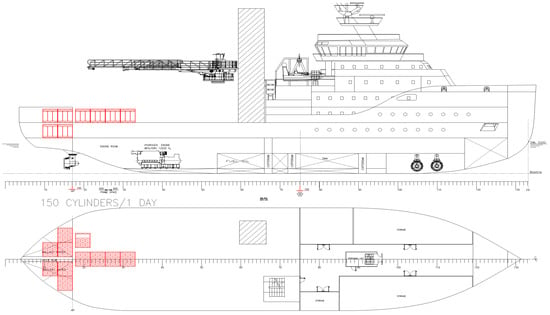

As a result of the calculation analyses, the vessel’s possible operating time is limited to about 3–4 days. Given the current limited regulations (Section 3.2) and the lack of clear guidance on the possibility of installing cylinders inside the ship’s hull, the authors have decided to locate hydrogen cylinders on the SOV working deck (significantly limiting the main working area of the ship) and in the afterpeak.

Figure 12.

Layout concept of cylindrical tanks, side and deck view—variant 1 (150 cylinders).

Figure 13.

Layout concept of cylindrical tanks, side and deck view—variant 2 (449 cylinders).

- Variant 1—150 cylinders deployed in 17 modules (red)—the case for a one-day mission. This option was considered a good reference for other cases considered;

- Variant 2—deployment of 449 cylinders in 50 modules (blue)—for a 3-day ship mission—the most likely and feasible option:

- –

- Total fuel reserve MTfuel—9.1 t;

- –

- Fuel volume Vfuel—205.75 m3;

- –

- Full cylinder weight (with hydrogen)—134.3 t.

The values obtained in the second variant are acceptable given the parameters of the ship under analysis. The weight of the full hydrogen tanks represents 13.4% of the ship’s deadweight, and the volume of hydrogen in the modules at 700 bar represents about 14.0% of the volume of the underwater part of the hull.

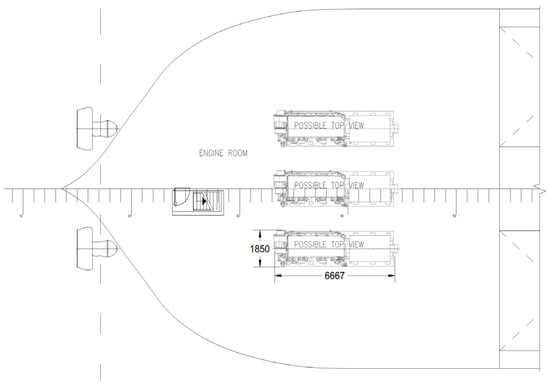

Figure 14 shows a section of a view of the power plant with H2 fuel generating sets.

Figure 14.

Fragment of a view of the ship’s engine room with generating sets.

The estimated floor area required for hydrogen fuel cylinders outside the engine room was 1539 m2, for methanol fuel and its required compartments 264 m2, for LNG 230 m2 and for MDO 360 m2 (Table 7). Considering that the area occupied by the gensets is very similar for all four of their types, the occupied space in the ship’s hull will be mainly determined by the fuel tanks and the additional compartments and facilities required when alternative fuels such as LNG, methanol and hydrogen are used, e.g., regulatory protective compartments, fuel treatment rooms, the so-called preparation room for methanol and the airlocks for both alternative fuels.

4.2. Needed Masses and Volumes of Hydrogen

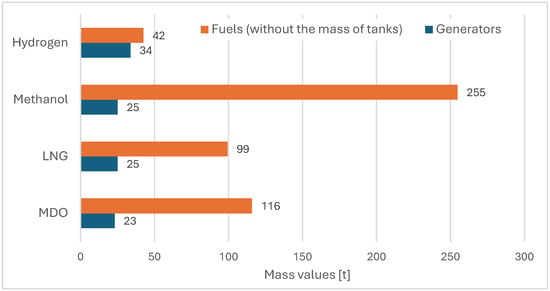

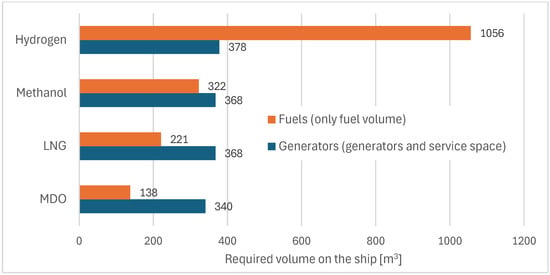

The results of the analyses are presented graphically in the charts below. Figure 15 and Figure 16 show the masses and occupied volumes of the generating sets, respectively, compared to the masses and volumes of the individual fuels required for a 14-day SOV mission.

Figure 15.

Comparison of the mass of generating sets with the mass of fuel required for a 14-day SOV mission.

Figure 16.

Comparison of the volume occupied by generating sets (including service volume) with the volume of fuel required for a 14-day SOV mission.

In the graphs shown, an inverse correlation between the mass and volume of the fuel itself is apparent: The mass of hydrogen is only slightly greater than that of the generating sets, but its volume is nearly three times larger than the space occupied by the generating sets, including the service bay. The situation is entirely different for the other fuels, as their mass is significantly greater than that of the generating sets, especially in the case of methanol, while the required volume is smaller than the volume occupied by the generating sets, particularly in the case of MDO.

The following chart (Figure 17) provides a summary of the required mass and volume of the various fuels for a 14-day SOV mission.

Figure 17.

Comparison of mass and volume of fuel required for a 14-day SOV mission.

In the diagram above, it is clear that the required amount of hydrogen has a significantly lower mass but a much greater volume compared to the other fuels. However, due to the very high mass of the compressed hydrogen tanks, its use for SOV propulsion on a 14-day mission is virtually impractical, as its reserves occupy excessive cargo space on the ship, significantly limiting the vessel’s carrying capacity.

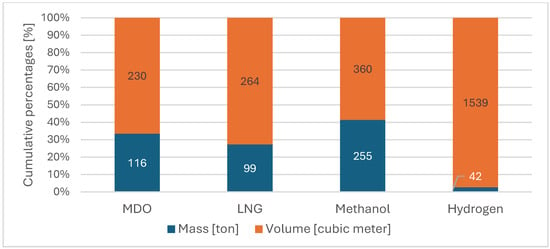

A comparative overview of the required reserves of various fuels for a 14-day SOV mission is presented in the graph showing the cumulative percentages of mass and volume of these fuels (Figure 18).

Figure 18.

Comparison of the cumulative percentage values of the mass and volume of the fuel required for a 14-day SOV mission.

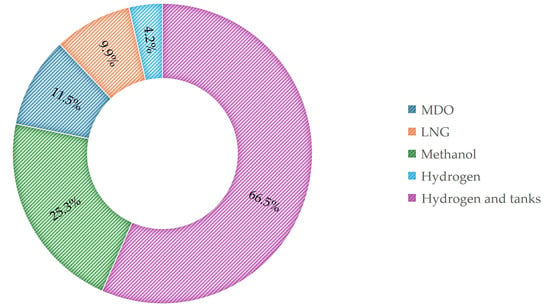

Figure 19 shows the percentage comparison of the mass of hydrogen-filled tanks in relation to the deadweight of the analysed SOV and, for comparison, the mass of the remaining fuels for a 14-day SOV mission.

Figure 19.

Percentage of mass of the fuel required for a 14-day SOV mission compared to a deadweight of the ship.

The drawing shows the very large mass of the hydrogen tanks, which takes up over 60% of the ship’s deadweight.

4.3. Calculated Fuel Costs

Figure 20 shows the estimated costs of the individual Kfuel for a single SOV mission and additionally, for comparison, the costs of hydrogen for a 1-day and a 3-day mission, which are related to the previously presented conclusion that the use of hydrogen for SOV propulsion for a 14-day mission is practically impossible (too large volume and mass of hydrogen tanks).

Figure 20.

Costs of individual fuels for one SOV mission.

If sailing on 14-day missions, in the assumed period of operations, one vessel may make 18 trips per year, which, after taking into account the fuel costs per mission, gives an estimate of annual fuel costs. For the hydrogen variant, it was assumed for economic justification that the SOV could carry out a 14-day mission, provided that it has the opportunity to replenish hydrogen fuel from hydrogen storage facilities located in the wind farm area to ensure mission continuity. Taking this into account, the significant cost of this fuel is apparent compared to the other fuels included in this study.

5. Summary and Conclusions

The present study appears to be relevant, as it presents the first results on the feasibility of using an innovative hydrogen fuel, transported under high pressure, on a small service vessel for operation in the area of wind farms in the Baltic Sea. For the purpose of this study, the analyses referred to a selected ship type, i.e., a service offshore vessel, and the power demand for the SOV’s assumed operating regimes. In addition, a comparison of hydrogen fuel is made to three fuel types, i.e., MDO, LNG and MeOH, which are presented in [52]. In order to achieve the main objective, the state-of-the-art in the application of hydrogen fuel in the marine industry was reviewed, including the capabilities of modern hydrogen storage tank, and marine hydrogen-fuelled engines, as well as the current regulations.

As a result of this research carried out, it has been concluded that the use of hydrogen fuel, carried and stored in the compressed form, burned directly in reciprocating internal combustion engines for propulsion, would not be viable for 14-day ship missions due to the technical problem of storing large volumes of hydrogen, as well as the significant weight of composite cylindrical cylinders because of the following:

- The weight of the hydrogen tanks and the modular system amounted to about 626 t, which is 62% of the ship’s current carrying capacity;

- The volume of the hydrogen tanks and the modular system occupies 3198 m3, which is 66% of the ship’s current volume.

Therefore, with regard to the other fuels (MDO, LNG and MeOH), hydrogen fuel and the ship’s transfer and storage system require a much larger, if not impossible, weight and volume.

Regarding fuel costs, with the currently estimated and rather complex unit hydrogen prices, the calculated costs of this fuel for SOVs (considering the minimum price) are as follows:

- More than 100% higher than MDO and LNG;

- More than 30% higher than MeOH.

The choice of hydrogen fuel for the service vessel would be justified in the case of a very short ship’s autonomy time allowing for up to three-day missions or the use of a solution that fits in with the zero-emission decarbonisation goal, i.e., the use of renewable energy. This means refuelling hydrogen from offshore storage facilities supplied with hydrogen generated from the electrolysis of seawater using electricity generated by an offshore wind farm. For the adopted scenarios, for one-day endurance (recharging from renewable energy at sea on the other mission days), the fuel costs are USD 12,090, and for three-day endurance, the costs are USD 36,309. With such high costs, it is necessary to stabilize the prices of hydrogen, especially its ‘green’ variety.

The analysis of the SOV design was limited to identifying and comparing the different engine and fuel options in the available hull space and identifying the differences in spatial layout, in line with the current regulations.