Development of a Conceptual Model for the Information and Control System of an Autonomous Underwater Vehicle for Solving Problems in the Mineral and Raw Materials Complex

Abstract

1. Introduction

1.1. Existing Challenges in the Field

- High risks for human personnel: The use of manned submersibles presents risks to the life and health of operators due to the extreme conditions of high depth, pressure, and temperature [12].

- Limited access to deepwater resources: Many promising mineral resources are located at depths inaccessible to conventional mining and exploration technologies [13].

1.2. Problem Statement

2. Materials and Methods

- “Good afternoon! I am, Dmitry Dmitriyevich Kotov, a graduate student at St. Petersburg Mining University, Department of System Analysis and Control, specializing in System Analysis, Control, Information Processing, and Statistics. As a part of my studies, I am conducting research in the field of developing autonomous underwater vehicles (AUVs). For my thesis, I am developing an Information and Control System (ICS) for AUVs. Before proceeding, I need to develop a conceptual model by determining the influence of various parameters through expert judgment, which will be used to calculate the correlation coefficient. I value the opinions of experts like you who are familiar with these challenges, and I would be grateful for your assistance in evaluating the attached table of parameters. Please assign a ranking to each parameter according to its influence on the technological process. If you believe I have missed any important parameters, I welcome your comments. Thank you in advance!”

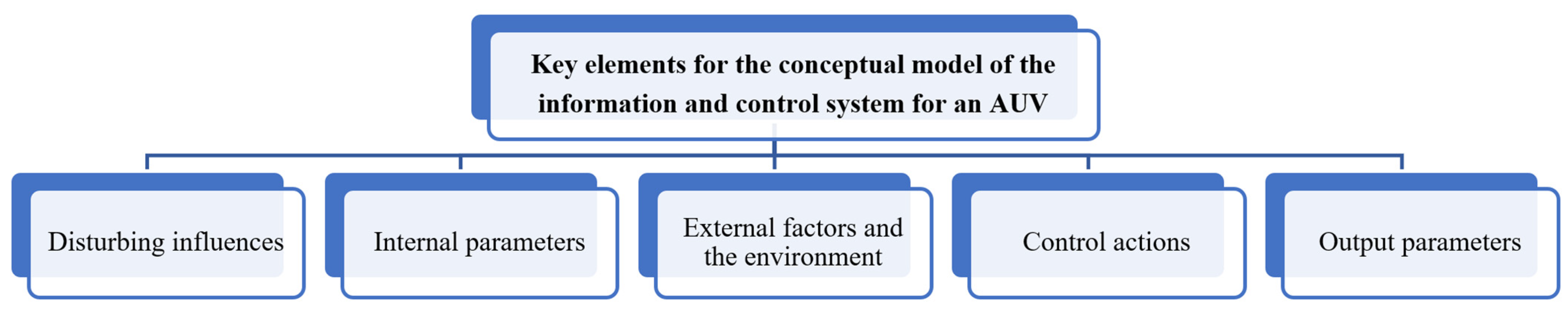

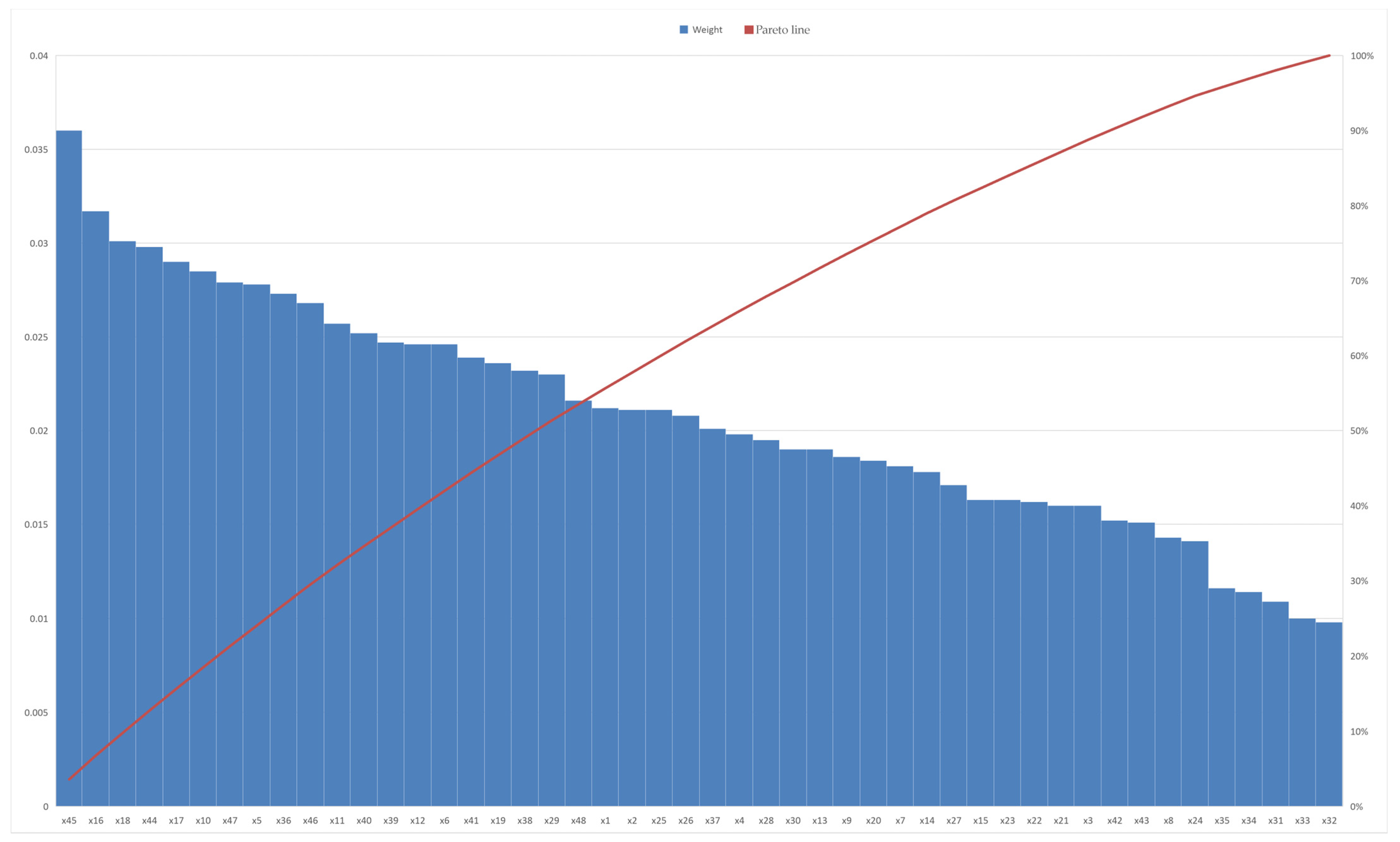

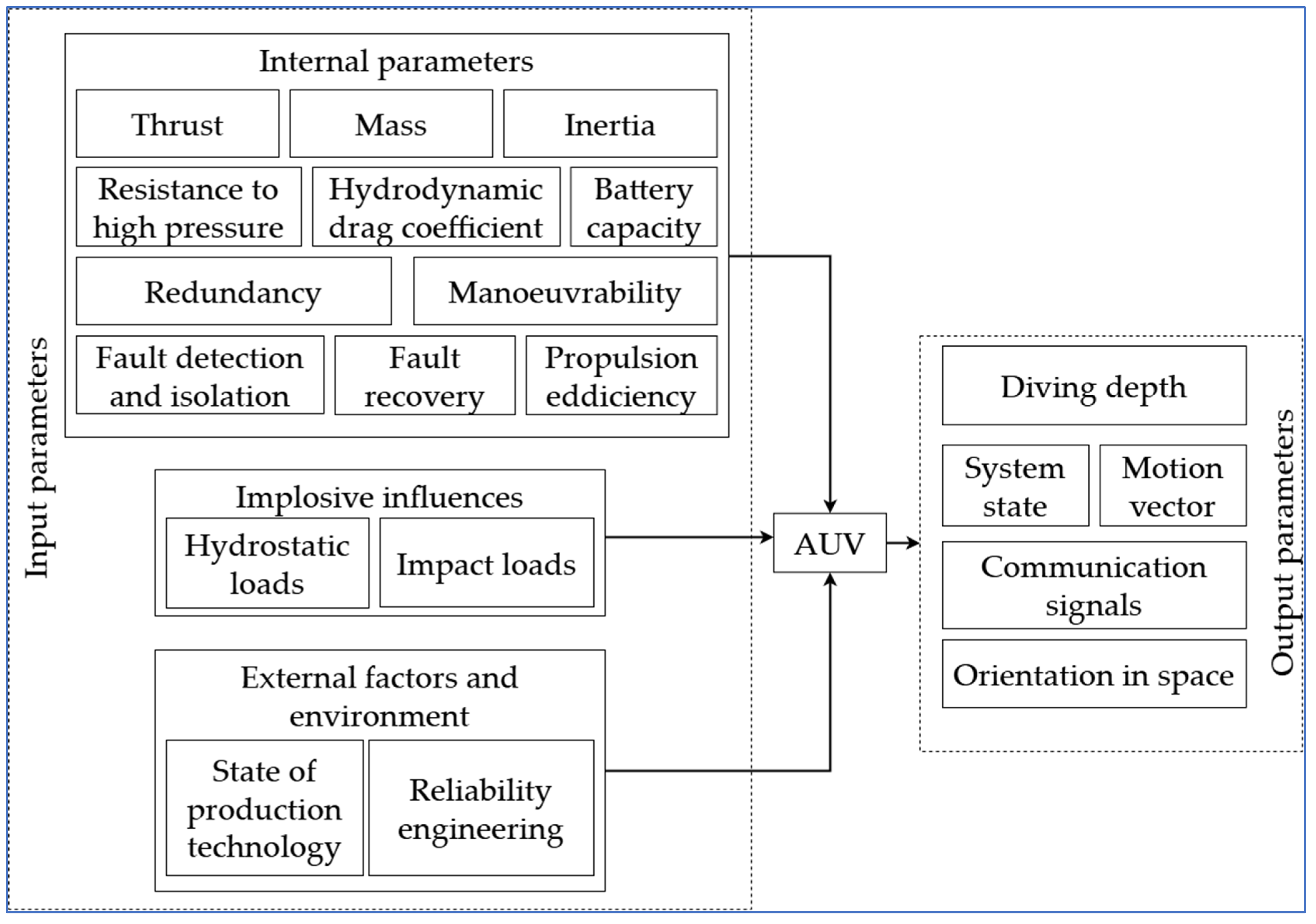

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| No. | AUV Parameters | Model Equation | Description | Ref. |

|---|---|---|---|---|

| 1 | Underwater currents | where is the fluid density, is the velocity field, is time, is pressure, is the dynamic viscosity, is the pressure gradient, is the Laplacian of the velocity field, and is the external body force per unit volume. | [41,42,43] | |

| 2 | Water density | is the density of water, is the reference density, is temperature, is the thermal expansion coefficient, is salinity, and is the salinity coefficient. | [44,45,46,47] | |

| 3 | Water salinity | where is salinity in parts per thousand, is the mass of salt, and is the mass of water. | [48,49] | |

| 4 | Water temperature | where is the current temperature, is the reference temperature, and is the temperature change. | [50,51] | |

| 5 | Hydrostatic loads | is hydrostatic pressure, is water density, is gravitational acceleration, and is depth. | [52,53] | |

| 6 | Shock loads | is the shock force, is the pressure change, and is the time interval. | [54,55] | |

| 7 | Chemical impact of water | is the corrosion rate, is a material constant, is current, is the exposed surface area, is time, and is the characteristic time constant. | [56] | |

| 8 | Biological impact of water | is the biofouling growth rate, is the growth rate constant, is the current population, and is the carrying capacity. | [57,58] | |

| 9 | Water resistance | where is the drag force, is the drag coefficient, is the water density, is the cross-sectional area, and is the velocity. | [59,60] | |

| 10 | Weight | where is the buoyant force, is the gravitational force, is the density of water, is the submerged volume, and is the object’s mass. | [61,62] | |

| 11 | Inertia | where represents the scalar moment of inertia with as the mass of the -th element and as its distance from the axis of rotation, is the inertia tensor with components representing moments and products of inertia, is angular velocity, is angular acceleration, and is torque. | [63,64] | |

| 12 | Resistance coefficient | is drag force, is drag coefficient, is fluid density, is velocity, and is area. | [65] | |

| 13 | Lift coefficient | is lift force, is lift coefficient, is fluid density, is velocity, and is area. | [66,67] | |

| 14 | Addition factors | is added mass force, is added mass coefficient, is density, is volume, and is acceleration. | [68,69] | |

| 15 | Pitch and yaw coefficients | where is coefficient, is moment, is velocity, is reference area, and is characteristic length. | [70] | |

| 16 | Traction | where is thrust force, is mass flow rate, and is exhaust velocity. | [71] | |

| 17 | Propulsion efficiency | where is efficiency, is thrust, is velocity, and is power. | [72] | |

| 18 | Maneuverability | where is the turn radius, is velocity, is gravitational acceleration, is the turning angle, is the angular velocity, is the applied moment, and is the moment of inertia about the -axis. | [73,74,75] | |

| 19 | Battery capacity | where is energy, is capacitance, is voltage, | [76,77] | |

| 20 | Power consumption | where is power, is current, and is voltage | [78] | |

| 21 | Accuracy and repeatability | where is accuracy, is the measured value, is the true value, is the root-mean-square deviation, are individual values, is the mean, is the number of observations, is the performance score, and are weighting coefficients. | [79,80] | |

| 22 | Sensitivity | where is sensitivity, is the change in output, and is the change in input. | [81,82,83] | |

| 23 | Range and resolution | where is resolution, is the measurement range, and is the number of bits. | [84] | |

| 24 | Response time | where is the time constant, is time, and is probability. | [85] | |

| 25 | Robustness | where is robustness, represents uncertainties in the set , and is the transfer function. | [86] | |

| 26 | Strength | where is stress, is force, and is the cross-sectional area. | [87] | |

| 27 | Fatigue | where is fatigue life, is the alternating stress, is fatigue strength coefficient, is the fatigue strength exponent, and is a material constant. | [88] | |

| 28 | Buckling resistance | where is the critical buckling load, is the modulus of elasticity, is the moment of inertia, is the effective length factor, and is the length. | [89,90] | |

| 29 | Resistance to high pressure | where is hoop stress, is the internal pressure, is the diameter, and is the wall thickness. | [91] | |

| 30 | Vibration resistance | where is the natural frequency, is stiffness, and is mass. | [92] | |

| 31 | Signal attenuation | where is amplitude, is the initial amplitude, is the attenuation factor, is the distance, and is frequency. | [93] | |

| 32 | Capacity constraints | where is the channel capacity, is the signal power, and is the noise power. | [94,95] | |

| 33 | Multipath distribution | where is the output, is the delayed input, is the impulse response, is noise, and is the number of components. | [96] | |

| 34 | Acoustic bandwidth | where is the channel capacity, is the signal power spectrum, and is the noise power spectrum. | [97] | |

| 35 | Probability of errors in digital communication | where is the bit error probability, is the bit energy, and is the noise power spectral density. | [98] | |

| 36 | Redundancy | where is the system reliability and is the reliability of the -th component. | [99,100,101,102] | |

| 37 | Variety | where is the reliability of a dependent system, is the reliability of the -th component in the -th subsystem, and is the number of subsystems. | [103] | |

| 38 | Fault detection and isolation | where is the output, is the state vector, is the control input, is noise, is the state matrix, is the input matrix, is the output matrix, is the direct transmission matrix, and is the observer gain. | [104] | |

| 39 | Disaster recovery | where is the state at the next time step, is the state transition matrix, is the control input matrix, is the control input, is the disturbance gain, and is the disturbance. | [105] | |

| 40 | Reliability Engineering | where is the mean time between failures, and is the failure rate. | [106] | |

| 41 | State of production technology | where is the total performance, is reliability, is cost, is efficiency, and are weighting factors. | [107] | |

| 42 | Lithium reserves | where is the behavior as a function of , is a proportionality constant, is the adjustment factor, is the current level, and is the reference level. | [108,109,110] | |

| 43 | Environmental safety | where is score, is efficiency, is energy, and is capacity | [111] | |

| 44 | Motion vector | where is mass, is velocity, is external force, is the pressure gradient, is the drag force, and is the body force. | [112] | |

| 45 | Diving depth | where is the rate of displacement, is vertical velocity, is water density, is volume, is mass, and is gravitational acceleration. | [113,114] | |

| 46 | Orientation in space | where is the time derivative of the quaternion, is the quaternion, and is the angular velocity vector. | [115] | |

| 47 | System status | where is the time derivative of the state vector , is the system matrix describing the dynamics, is the input matrix, and is the input vector at time . | [116] | |

| 48 | Communication signals | where is the observed signal, is the impulse response of the -th channel, is the input signal for the -th channel, is the total number of channels, and is the noise component at time . | [117] |

References

- Kotov, D.D.; Pervukhin, D.A.; Davardoost, H.; Afanasyeva, O.V. Prospects for the Use of Autonomous Underwater Vehicles (AUV) to Solve the Problems of the Mineral Resources Complex (MRC) of the Russian Federation. J. Marit. Res. 2024, 21, 309–317. [Google Scholar]

- Yoshida, H.; Hyakudome, T.; Ishibashi, S.; Sawa, T.; Nakano, Y.; Ochi, H.; Watanabe, Y.; Nakatani, T.; Ota, Y.; Sugesawa, M.; et al. An Autonomous Underwater Vehicle with a Canard Rudder for Underwater Minerals Exploration. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1571–1576. [Google Scholar]

- Kukharova, T.; Martirosyan, A.; Asadulagi, M.-A.; Ilyushin, Y. Development of the Separation Column’s Temperature Field Monitoring System. Energies 2024, 17, 5175. [Google Scholar] [CrossRef]

- Litvinenko, V.; Petrov, E.; Vasilevskaya, D.; Yakovenko, A.; Naumov, I.; Ratnikov, M. Assessment of the Role of the State in the Management of Mineral Resources. J. Min. Inst. 2022. Online first. [Google Scholar] [CrossRef]

- Wynn, R.B.; Huvenne, V.A.I.; Le Bas, T.P.; Murton, B.J.; Connelly, D.P.; Bett, B.J.; Ruhl, H.A.; Morris, K.J.; Peakall, J.; Parsons, D.R.; et al. Autonomous Underwater Vehicles (AUVs): Their Past, Present and Future Contributions to the Advancement of Marine Geoscience. Mar. Geol. 2014, 352, 451–468. [Google Scholar] [CrossRef]

- Fernandez, R.A.S.; Parra, R.E.A.; Milosevic, Z.; Dominguez, S.; Rossi, C. Design, Modeling and Control of a Spherical Autonomous Underwater Vehicle for Mine Exploration. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1513–1519. [Google Scholar]

- Kim, Y.J.; Kim, H.T.; Cho, Y.J.; Lee, K.W. Development of a Power Control System for AUVs Probing for Underwater Mineral Resources. J. Mar. Sci. Appl. 2009, 8, 259–266. [Google Scholar] [CrossRef]

- Kao, M.; Weitzel, G.; Zheng, X.; Black, M. A Simple Approach to Planning and Executing Complex AUV Missions. In Proceedings of the 1992 Symposium on Autonomous Underwater Vehicle Technology, Washington, DC, USA, 2–3 June 1992; IEEE: Piscataway, NJ, USA, 1992; pp. 95–102. [Google Scholar]

- Kuprikov, M.; Kuprikov, N.; Zaikov, K.; Zadorin, M.; Tsvetkova, A. Regional Climate Change Adaptation Plans in Russia: Legal Political Overview. J. Infrastruct. Policy Dev. 2024, 8, 5303. [Google Scholar] [CrossRef]

- Shinohara, M.; Yamada, T.; Ishihara, T.; Araya, A.; Kanazawa, T.; Fujimoto, H.; Uehira, K.; Tsukioka, S.; Omika, S.; Iizasa, K. Development of an Underwater Gravity Measurement System Using Autonomous Underwater Vehicle for Exploration of Seafloor Deposits. In Proceedings of the OCEANS 2015, Genova, Italy, 18–21 May 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–7. [Google Scholar]

- Golovina, E.I.; Tselmeg, B. Cost Estimate as a Tool for Managing Fresh Groundwater Resources in the Russian Federation. Geol. Miner. Resour. Sib. 2023, 4, 81–91. [Google Scholar] [CrossRef]

- McEwen, R.; Thomas, H.; Weber, D.; Psota, F. Performance of an AUV Navigation System at Arctic Latitudes. IEEE J. Ocean. Eng. 2005, 30, 443–454. [Google Scholar] [CrossRef]

- Asadulagi, M.-A.M.; Pershin, I.M.; Tsapleva, V.V. Research on Hydrolithospheric Processes Using the Results of Groundwater Inflow Testing. Water 2024, 16, 487. [Google Scholar] [CrossRef]

- Ishihara, T.; Shinohara, M.; Araya, A.; Yamada, T.; Kanazawa, T.; Uehira, K.; Mochizuki, M.; Fujimoto, H.; Tsukioka, S.; Omika, S.; et al. Development of an Underwater Gravity Measurement System with Autonomous Underwater Vehicle for Marine Mineral Exploration. In Proceedings of the 2016 Techno-Ocean (Techno-Ocean), Kobe, Japan, 6–8 October 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 127–133. [Google Scholar]

- Martirosyan, A.V.; Martirosyan, K.V.; Chernyshev, A.B. Calculation of the First Switch-on Time of Distributed Object’s Control Action. In Proceedings of the 2020 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (EIConRus), St. Petersburg and Moscow, Russia, 27–30 January 2020; IEEE: Piscataway, NJ, USA, 2020; pp. 750–754. [Google Scholar]

- Liu, T.; Hu, Y.; Xu, H. Deep Reinforcement Learning for Vectored Thruster Autonomous Underwater Vehicle Control. Complexity 2021, 2021, 6649625. [Google Scholar] [CrossRef]

- Millan, P.; Orihuela, L.; Jurado, I.; Rubio, F.R. Formation Control of Autonomous Underwater Vehicles Subject to Communication Delays. IEEE Trans. Control Syst. Technol. 2014, 22, 770–777. [Google Scholar] [CrossRef]

- Martins, A.; Almeida, J.; Almeida, C.; Dias, A.; Dias, N.; Aaltonen, J.; Heininen, A.; Koskinen, K.T.; Rossi, C.; Dominguez, S.; et al. UX 1 System Design—A Robotic System for Underwater Mining Exploration. In Proceedings of the 2018 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Madrid, Spain, 1–5 October 2018; IEEE: Piscataway, NJ, USA, 2018; pp. 1494–1500. [Google Scholar]

- Katysheva, E. Analysis of the Interconnected Development Potential of the Oil, Gas and Transport Industries in the Russian Arctic. Energies 2023, 16, 3124. [Google Scholar] [CrossRef]

- Che, G.; Yu, Z. Neural-Network Estimators Based Fault-Tolerant Tracking Control for AUV via ADP with Rudders Faults and Ocean Current Disturbance. Neurocomputing 2020, 411, 442–454. [Google Scholar] [CrossRef]

- Fujii, T.; Ura, T. Development of Motion Control System for AUV Using Neural Nets. In Proceedings of the Symposium on Autonomous Underwater Vehicle Technology, Singapore, 19–21 September 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 81–86. [Google Scholar]

- Di Vito, D.; De Palma, D.; Simetti, E.; Indiveri, G.; Antonelli, G. Experimental Validation of the Modeling and Control of a Multibody Underwater Vehicle Manipulator System for Sea Mining Exploration. J. Field Robot. 2021, 38, 171–191. [Google Scholar] [CrossRef]

- Khaykin, M.M.; Priyma, K.A. Digital Transformation Management Issues: An Oil-and-Gas Industry Example. In Navigating Digital Transformation: Original Research Across Smart Cities, Sustainable Development and Beyond; Nova Science Publishers: Hauppauge, NY, USA, 2024; pp. 99–112. [Google Scholar]

- Alam, K.; Ray, T.; Anavatti, S.G. Design and Construction of an Autonomous Underwater Vehicle. Neurocomputing 2014, 142, 16–29. [Google Scholar] [CrossRef]

- Ishibashi, S.; Yoshida, H.; Hyakudome, T.; Sugesawa, M.; Nakatani, T.; Ota, Y.; Ochi, H.; Watanabe, Y.; Sawa, T.; Nakano, Y.; et al. The Development of an Autonomous Underwater Vehicle “Otohime” with the Multiple Operation. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 1588–1593. [Google Scholar]

- Petit, A.; Paulo, C.; Carlucho, I.; Menna, B.; De Paula, M. Prediction of the Hydrodynamic Coefficients of an Autonomous Underwater Vehicle. In Proceedings of the 2016 3rd IEEE/OES South American International Symposium on Oceanic Engineering (SAISOE), Buenos Aires, Argentina, 15–17 June 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 1–6. [Google Scholar]

- Sahoo, A.; Dwivedy, S.K.; Robi, P.S. Dynamic Modelling and Control of a Compact Autonomous Underwater Vehicle. In Proceedings of the 6th International Conference on Robot Intelligence Technology and Applications, Kuala Lumpur, Malaysia, 16–18 December 2020; pp. 303–321. [Google Scholar]

- Polekhina, V.S.; Shestopalov, M.Y.; Ilyushin, Y.Y. Identification of Magnetic Field Strength Realisation as a Necessary Solution for High-Quality Metal Synthesis. In Proceedings of the 2022 Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg, Russia, 25–28 January 2022; IEEE: Piscataway, NJ, USA, 2022; pp. 831–833. [Google Scholar]

- Islamov, S.; Islamov, R.; Shelukhov, G.; Sharifov, A.; Sultanbekov, R.; Ismakov, R.; Agliullin, A.; Ganiev, R. Fluid-Loss Control Technology: From Laboratory to Well Field. Processes 2024, 12, 114. [Google Scholar] [CrossRef]

- Afanaseva, O.V.; Bezyukov, O.K.; Ignatenko, A.A. Method for Assessing the Relationship Between the Characteristics of Vibroactivity and the Design Parameters of a Marine Diesel. Proc. Eng. Sci. 2023, 5, 415–422. [Google Scholar] [CrossRef]

- Song, F.; An, P.; Folleco, A. Modeling and Simulation of Autonomous Underwater Vehicles: Design and Implementation. IEEE J. Ocean. Eng. 2003, 28, 283–296. [Google Scholar] [CrossRef]

- Saha, H.; Parhi. Conceptual Design of an Underwater Robot. In Proceedings of the 2015 International Conference on Man and Machine Interfacing (MAMI), Bhubaneswar, India, 17–19 December 2015; IEEE: Piscataway, NJ, USA, 2015; pp. 1–6. [Google Scholar]

- Petillot, Y.R.; Antonelli, G.; Casalino, G.; Ferreira, F. Underwater Robots: From Remotely Operated Vehicles to Intervention-Autonomous Underwater Vehicles. IEEE Robot. Autom. Mag. 2019, 26, 94–101. [Google Scholar] [CrossRef]

- Motta, D.; Andrade, L.; Mascarenhas, L.B.; Beal, V.E. Challenges for Deepwater Operations: An Industry Perspective. In AI Technology for Underwater Robots. Intelligent Systems, Control and Automation: Science and Engineering; Springer: Berlin/Heidelberg, Germany, 2020; pp. 37–48. [Google Scholar]

- Juran, J.M.; Gabriel, A.B. The Quality Control Process; McGraw-Hill: New York, NY, USA, 1999. [Google Scholar]

- Kendall, M.G. Rank Correlation Methods; Charles Griffin: London, UK, 1948. [Google Scholar]

- Marinina, O.; Nechitailo, A.; Stroykov, G.; Tsvetkova, A.; Reshneva, E.; Turovskaya, L. Technical and Economic Assessment of Energy Efficiency of Electrification of Hydrocarbon Production Facilities in Underdeveloped Areas. Sustainability 2023, 15, 9614. [Google Scholar] [CrossRef]

- Fetisov, V.G.; Nikolaev, A.K.; Lykov, Y.V. Experimental Studies for Determining Gas Flow Rate Accidental Release on Linear Part of Pipeline. IOP Conf. Ser. Earth Environ. Sci. 2017, 87, 062003. [Google Scholar] [CrossRef]

- Talanov, N.A.; Khloponina, V.S.; Fedorov, M.C. Systematic and Analytical Research of Methods for Analysing and Identifying the Technical Condition of Complex Technical Systems. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 92–95. [Google Scholar]

- Martirosyan, A.; Ilyushin, Y.; Afanaseva, O.; Kukharova, T.; Asadulagi, M.; Khloponina, V. Development of an Oil Field’s Conceptual Model. Int. J. Eng. 2025, 38, 381–388. [Google Scholar] [CrossRef]

- Mardashov, D.; Islamov, S.; Nefedov, Y. Specifics of Well Killing Technology during Well Service Operation in Complicated Conditions. Period. Tche Quim. 2020, 17, 782–792. [Google Scholar] [CrossRef]

- Nosova, V.A.; Pershin, I.M. Determining the Optimal Number of Wells during Field Development. In Proceedings of the 2021 IV International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 42–44. [Google Scholar]

- Kukulya, A.L.; Bellingham, J.G.; Kaeli, J.W.; Reddy, C.M.; Godin, M.A.; Conmy, R.N. Development of a Propeller Driven Long Range Autonomous Underwater Vehicle (LRAUV) for under-Ice Mapping of Oil Spills and Environmental Hazards: An Arctic Domain Center of Awareness Project (ADAC). In Proceedings of the 2016 IEEE/OES Autonomous Underwater Vehicles (AUV), Tokyo, Japan, 6–9 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 95–100. [Google Scholar]

- Nikolaev, A.K.; Samigullin, G.H.; Samigullina, L.G.; Fetisov, V.G. Non-Stationary Operation of Gas Pipeline Based on Selections of Travel. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 022074. [Google Scholar] [CrossRef]

- Pershin, I.M.; Nosova, V.A.; Tsapleva, V.V. Methodology for Designing Distributed Self-Tuning Control Systems. In Proceedings of the 2023 V International Conference on Control in Technical Systems (CTS), St. Petersburg, Russia, 21–23 September 2023; IEEE: Piscataway, NJ, USA, 2023; pp. 110–114. [Google Scholar]

- Aguirre, F.; Vargas, S.; Valdés, D.; Tornero, J. State of the Art of Parameters for Mechanical Design of an Autonomous Underwater Vehicle. Int. J. Ocean. Oceanogr. 2017, 11, 89–103. [Google Scholar]

- Allotta, B.; Conti, R.; Costanzi, R.; Fanelli, F.; Gelli, J.; Meli, E.; Monni, N.; Ridolfi, A.; Rindi, A. A Low Cost Autonomous Underwater Vehicle for Patrolling and Monitoring. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2017, 231, 740–749. [Google Scholar] [CrossRef]

- Gafur, S.; Andrey, S.; Liliya, S.; Vadim, F. Assessment of Damage of Metallic Elements in Oil and Gas Facilities Using Small Punch Test. Int. J. Appl. Eng. Res. 2017, 12, 11583–11587. [Google Scholar]

- Brito, M.P.; Griffiths, G.; Challenor, P. Risk Analysis for Autonomous Underwater Vehicle Operations in Extreme Environments. Risk Anal. 2010, 30, 1771–1788. [Google Scholar] [CrossRef]

- Fetisov, V.G.; Nikolaev, A.K.; Lykov, Y.V. Aggregative Simulation Method for Implementing Mathematical Models for Gas Transmission Systems. IOP Conf. Ser. Mater. Sci. Eng. 2018, 327, 022033. [Google Scholar] [CrossRef]

- Camilli, R.; Reddy, C.M.; Yoerger, D.R.; Van Mooy, B.A.S.; Jakuba, M.V.; Kinsey, J.C.; McIntyre, C.P.; Sylva, S.P.; Maloney, J.V. Tracking Hydrocarbon Plume Transport and Biodegradation at Deepwater Horizon. Science 2010, 330, 201–204. [Google Scholar] [CrossRef]

- Bakesheva, A.T.; Fetisov, V.G.; Pshenin, V.V. A Refined Algorithm for Leak Location in Gas Pipelines with Determination of Quantitative Parameters. Int. J. Eng. Res. Technol. 2019, 12, 2867–2869. [Google Scholar]

- Niu, H.; Adams, S.; Lee, K.; Husain, T.; Bose, N. Applications of Autonomous Underwater Vehicles in Offshore Petroleum Industry Environmental Effects Monitoring. J. Can. Pet. Technol. 2009, 48, 12–16. [Google Scholar] [CrossRef]

- Schipachev, A.; Fetisov, V.; Nazyrov, A.; Donghee, L.; Khamrakulov, A. Study of the Pipeline in Emergency Operation and Assessing the Magnitude of the Gas Leak. Energies 2022, 15, 5294. [Google Scholar] [CrossRef]

- González-García, J.; Gómez-Espinosa, A.; Cuan-Urquizo, E.; García-Valdovinos, L.G.; Salgado-Jiménez, T.; Cabello, J.A.E. Autonomous Underwater Vehicles: Localization, Navigation, and Communication for Collaborative Missions. Appl. Sci. 2020, 10, 1256. [Google Scholar] [CrossRef]

- Allotta, B.; Pugi, L.; Bartolini, F.; Ridolfi, A.; Costanzi, R.; Monni, N.; Gelli, J. Preliminary Design and Fast Prototyping of an Autonomous Underwater Vehicle Propulsion System. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2015, 229, 248–272. [Google Scholar] [CrossRef]

- Shchirova, E.; Tsvetkova, A.; Komendantova, N. Analysis of the Possibility of Implementing Carbon Dioxide Sequestration Projects in Russia Based on Foreign Experience. In Proceedings of the 21st International Multidisciplinary Scientific GeoConference SGEM 2021, Vienna, Austria, 16–22 August 2021; pp. 27–34. [Google Scholar]

- Guerrero, J.; Torres, J.; Creuze, V.; Chemori, A. Trajectory Tracking for Autonomous Underwater Vehicle: An Adaptive Approach. Ocean Eng. 2019, 172, 511–522. [Google Scholar] [CrossRef]

- Fadeev, A.; Komendantova, N.; Cherepovitsyn, A.; Tsvetkova, A.; Paramonov, I. Methods and Priorities for Human Resource Planning in Oil and Gas Projects in Russia and OPEC. OPEC Energy Rev. 2021, 45, 365–389. [Google Scholar] [CrossRef]

- Hwang, J.; Bose, N.; Nguyen, H.D.; Williams, G. Acoustic Search and Detection of Oil Plumes Using an Autonomous Underwater Vehicle. J. Mar. Sci. Eng. 2020, 8, 618. [Google Scholar] [CrossRef]

- Vasilev, Y.; Vasileva, P.; Batova, O.; Tsvetkova, A. Assessment of Factors Influencing Educational Effectiveness in Higher Educational Institutions. Sustainability 2024, 16, 4886. [Google Scholar] [CrossRef]

- Binney, J.; Krause, A.; Sukhatme, G.S. Informative Path Planning for an Autonomous Underwater Vehicle. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Via del Mar, Chile, 14–17 March 2010; IEEE: Piscataway, NJ, USA, 2010; pp. 4791–4796. [Google Scholar]

- Massel, L.; Komendantova, N.; Massel, A.; Tsvetkova, A.; Zaikov, K.; Marinina, O. Resilience of Socio-Ecological and Energy Systems: Intelligent Information Technologies for Risk Assessment of Natural and Technogenic Threats. J. Infrastruct. Policy Dev. 2024, 8, 4700. [Google Scholar] [CrossRef]

- Hwang, J.; Bose, N.; Nguyen, H.D.; Williams, G. Oil Plume Mapping: Adaptive Tracking and Adaptive Sampling From an Autonomous Underwater Vehicle. IEEE Access 2020, 8, 198021–198034. [Google Scholar] [CrossRef]

- Afanaseva, O. Analysis and Synthesis of Distributed Icedrill Heating Control System of Mountain Reconnaissance Drilling Rig. In Proceedings of the International Multidisciplinary Scientific GeoConference, Albena, Bulgaria, 2–8 July 2018. [Google Scholar]

- Tamitskiy, A.; Maltseva, L.; Zaikov, K.; Kuprikov, N.; Tsvetkova, A.; Kuprikov, M. Students’ Subjective Perceptions of Extremism in the Russian Arctic. J. Infrastruct. Policy Dev. 2024, 8, 7591. [Google Scholar] [CrossRef]

- Ilyushin, Y.; Afanaseva, O. Spatial Distributed Control System of Temperature Field: Synthesis and Modeling. ARPN J. Eng. Appl. Sci. 2021, 16, 1491–1506. [Google Scholar]

- Iakhiaev, D.; Grigorishchin, A.; Zaikov, K.; Bezdudnaya, A.; Ukhanova, A.; Tsvetkova, A.; Fadeev, A. Methodological Approach to Assessing the Digital Infrastructure of the Northern Regions of the Russian Federation. J. Infrastruct. Policy Dev. 2024, 8, 8747. [Google Scholar] [CrossRef]

- Joo, M.G.; Qu, Z. An Autonomous Underwater Vehicle as an Underwater Glider and Its Depth Control. Int. J. Control Autom. Syst. 2015, 13, 1212–1220. [Google Scholar] [CrossRef]

- Demenkov, P.A.; Trushko, O.V.; Potseshkovskaya, I.V. Numerical Experiments on the Modeling of Compensatory Injection for the Protection of Buildings during Tunneling. ARPN J. Eng. Appl. Sci. 2018, 13, 9161–9169. [Google Scholar]

- Potseshkovskaya, I.V.; Soroka, A.N. Revitalization of Urban Industrial Areas Based on Sustainable Development Principles. E3S Web Conf. 2021, 266, 08012. [Google Scholar] [CrossRef]

- Shapiro, S.L.; Kopkov, M.P.; Potseshkovskaya, I.V. Problems of the Organization of Surface and Underground Space (e.g., Historical Embankments of Saint Petersburg). E3S Web Conf. 2021, 266, 03016. [Google Scholar] [CrossRef]

- Zhang, B.; Ma, J.; Khan, M.A.; Repnikova, V.; Shidlovskaya, K.; Barykin, S.; Ahmad, M.S. The Effect of Economic Policy Uncertainty on Foreign Direct Investment in the Era of Global Value Chain: Evidence from the Asian Countries. Sustainability 2023, 15, 6131. [Google Scholar] [CrossRef]

- Lyakhov, D.G.; Smirnov, S.V.; Chudakov, M.I. The Application of Unmanned Underwater Vehicles in Marine Oil & gas Industry. Underw. Investig. Robot. 2013, 15, 23–32. [Google Scholar]

- Munafò, A.; Simetti, E.; Turetta, A.; Caiti, A.; Casalino, G. Autonomous Underwater Vehicle Teams for Adaptive Ocean Sampling: A Data-Driven Approach. Ocean Dyn. 2011, 61, 1981–1994. [Google Scholar] [CrossRef]

- Barykin, S.E.; Sergeev, S.M.; Vasilyevich Provotorov, V.; Lavskaya, K.; Shidlovskaya, K.A.; Dedyukhina, N.; Mikhov, O.; Buniak, V.; Dzhamaludinova, M.Y. Sustainability Analysis of Energy Resources Transport Based on A Digital N-D Logistics Network. Eng. Sci. 2024, 29, 1093. [Google Scholar] [CrossRef]

- Sadeq, A.M. Energy Storage Systems: A Comprehensive Guide, 1st ed.; Qatar Naval Academy: Khasooma, Qatar, 2023. [Google Scholar]

- Meshkov, A.A.; Korshunov, G.I.; Kondrasheva, N.K.; Eremeeva, A.M.; Seregin, A.S. Method of Reducing Air Pollution of the Coal Mines Working Areas with Diesel Locomotives Harmful Emissions. Occup. Saf. Ind. 2020, 1, 68–72. [Google Scholar] [CrossRef]

- Korshunov, G.I.; Eremeeva, A.M.; Seregin, A.S. Justification of Reduction in Air Requirement in Ventilation of Coal Roadways with Running Diesel Engines. Min. Informational Anal. Bull. 2022, 3, 47–59. [Google Scholar] [CrossRef]

- Hu, F.; Huang, Y.; Xie, Z.; Yu, J.; Wang, Z.; Qiao, J. Conceptual Design of a Long-Range Autonomous Underwater Vehicle Based on Multidisciplinary Optimization Framework. Ocean Eng. 2022, 248, 110684. [Google Scholar] [CrossRef]

- Kondrasheva, N.; Eremeeva, A. Production of Biodiesel Fuel from Vegetable Raw Materials. J. Min. Inst. 2023, 260, 248–256. [Google Scholar] [CrossRef]

- Kussat, N.H.; Chadwell, C.D.; Zimmerman, R. Absolute Positioning of an Autonomous Underwater Vehicle Using GPS and Acoustic Measurements. IEEE J. Ocean. Eng. 2005, 30, 153–164. [Google Scholar] [CrossRef]

- Zhang, Q.; Lin, J.; Sha, Q.; He, B.; Li, G. Deep Interactive Reinforcement Learning for Path Following of Autonomous Underwater Vehicle. IEEE Access 2020, 8, 24258–24268. [Google Scholar] [CrossRef]

- Eremeeva, A.M.; Khasanov, A.F.; Oleynik, I.L.; Kondrasheva, N.K.; Marinets, A.R. Development of Biofuel as Marine Low-Viscosity Fuels with Environmentally Friendly Components. Int. J. Eng. 2025, 38, 273–279. [Google Scholar] [CrossRef]

- Golovina, E.I.; Grebneva, A.V. Features of Groundwater Resources Management in the Transboundary Territories (on the Example of the Kaliningrad Region). Geol. Miner. Resour. Sib. 2022, 4, 85–94. [Google Scholar]

- Eremeeva, A.M.; Kondrasheva, N.K.; Korshunov, G.I. Method to Reduce Harmful Emissions When Diesel Locomotives Operate in Coal Mines. In Topical Issues of Rational Use of Natural Resources 2019; CRC Press: Boca Raton, FL, USA, 2019; pp. 10–15. [Google Scholar]

- Nechitailo, А.R.; Marinina, O.A. Analysis of Technological Directions of Electrification of Hydrocarbon Production Facilities in Poorly Developed Territories. Север И Рынoк: Фoрмирoвание Экoнoмическoгo Пoрядка 2022, 25, 45–57. [Google Scholar] [CrossRef]

- Kazanin, O.I.; Sidorenko, A.A.; Sidorenko, S.A.; Ivanov, V.V.; Mischo, H. High Productive Longwall Mining of Multiple Gassy Seams: Best Practice and Recommendations. Acta Montan. Slovaca 2022, 27, 152–162. [Google Scholar] [CrossRef]

- Marinin, M.A.; Marinina, O.A.; Rakhmanov, R.A. Methodological Approach to Assessing Influence of Blasted Rock Fragmentation on Mining Costs. Gornyi Zhurnal 2023, 9, 28–34. [Google Scholar] [CrossRef]

- Yu, R.; Shi, Z.; Huang, C.; Li, T.; Ma, Q. Deep Reinforcement Learning Based Optimal Trajectory Tracking Control of Autonomous Underwater Vehicle. In Proceedings of the 2017 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017; IEEE: Piscataway, NJ, USA, 2017; pp. 4958–4965. [Google Scholar]

- Kazanin, O.I.; Sidorenko, A.A.; Sidorenko, S.A.; Meshkov, A.A. Reproduction of the Longwall Panels: Modern Requirements for the Technology and Organization of the Development Operations at Coal Mines. Eurasian Min. 2020, 2, 19–23. [Google Scholar] [CrossRef]

- Brooks, R. A Robust Layered Control System for a Mobile Robot. IEEE J. Robot. Autom. 1986, 2, 14–23. [Google Scholar] [CrossRef]

- Martirosyan, A.V.; Martirosyan, K.V.; Grudyaeva, E.K.; Chernyshev, A.B. Calculation of the Temperature Maximum Value Access Time at the Observation Point. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg and Moscow, Russia, 26–29 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 1014–1018. [Google Scholar]

- Tabataba’i-Nasab, F.S.; Keymasi Khalaji, A.; Moosavian, S.A.A. Adaptive Nonlinear Control of an Autonomous Underwater Vehicle. Trans. Inst. Meas. Control 2019, 41, 3121–3131. [Google Scholar] [CrossRef]

- Ilyushin, Y.V.; Nosova, V.A. Methodology to Increase the Efficiency of the Mineral Water Extraction Process. Water 2024, 16, 1329. [Google Scholar] [CrossRef]

- Kukharova, T.V.; Utkin, V.A.; Pershin, I.M. Modeling of a Decision Support System for a Psychiatrist Based on the Dynamics of Electrical Conductivity Parameters. In Proceedings of the 2021 IEEE Conference of Russian Young Researchers in Electrical and Electronic Engineering (ElConRus), St. Petersburg and Moscow, Russia, 26–29 January 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 975–978. [Google Scholar]

- Bakovsky, V.B.; Golovkin, S.I.; Kukharova, T.V.; Utkin, V.A.; Chalaya, E.N.; Shabaldin, N.A. Acute Period of Polytrauma in Children in the Light of Discriminant Analysis. Russ. J. Pediatr. Surg. Anesth. Intensive Care 2021, 10, 145–156. [Google Scholar] [CrossRef]

- Arefiev, I.B.; Afanaseva, O.V. Implementation of Control and Forecasting Problems of Human-Machine Complexes on the Basis of Logic-Reflexive Modeling. In Proceedings of the International Conference System Analysis in Engineering and Control, St. Petersburg, Russia, 13–14 October 2022; pp. 187–197. [Google Scholar]

- Mal’Tsev, P.A.; Shatilova, N.A.; Abramkin, S.E.; Podkina, M.E. Designing a Digital Twin in Oil and Gas Technologies: Technology Integration. In Proceedings of the 2024 XXVII International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 22–24 May 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 352–355. [Google Scholar]

- Yokota, S.; Kim, K.; Imasato, M.; Sawada, K.; Tamura, K.; Nakane, K.; Koyama, H.; Nagahashi, K.; Obata, T.; Oyabu, Y. Development and Sea Trial of an Autonomous Underwater Vehicle Equipped with a Sub-Bottom Profiler for Surveying Mineral Resources. In Proceedings of the 2016 IEEE/OES Autonomous Underwater Vehicles (AUV), Tokyo, Japan, 6–9 November 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 81–84. [Google Scholar]

- Sun, S.; Zhang, X.; Zheng, C.; Fu, J.; Zhao, C. Underwater Acoustical Localization of the Black Box Utilizing Single Autonomous Underwater Vehicle Based on the Second-Order Time Difference of Arrival. IEEE J. Ocean. Eng. 2020, 45, 1268–1279. [Google Scholar] [CrossRef]

- Sahoo, A.; Dwivedy, S.K.; Robi, P.S. Advancements in the Field of Autonomous Underwater Vehicle. Ocean. Eng. 2019, 181, 145–160. [Google Scholar] [CrossRef]

- Marinina, O.; Parfenova, A.; Tsvetkova, A.; Komendantova, N. Assortment Strategy as a Driver of Fuel and Energy Complex Competitiveness. In Proceedings of the 21st International Multidisciplinary Scientific Geoconference: Ecology and Renewable Energy Sources, Albena, Bulgaria, 16–22 August 2021; pp. 665–672. [Google Scholar]

- Pavel, T.; Polina, S. Heterogeneity of the Impact of Energy Production and Consumption on National Greenhouse Gas Emissions. J. Clean. Prod. 2024, 434, 139638. [Google Scholar] [CrossRef]

- Pavel, T.; Polina, S.; Liubov, N. The Research of the Impact of Energy Efficiency on Mitigating Greenhouse Gas Emissions at the National Level. Energy Convers. Manag. 2024, 314, 118671. [Google Scholar] [CrossRef]

- Semenova, T.; Al-Dirawi, A.; Al-Saadi, T. Environmental Challenges for Fragile Economies: Adaptation Opportunities on the Examples of the Arctic and Iraq. Agronomy 2022, 12, 2021. [Google Scholar] [CrossRef]

- Semenova, T.; Martínez Santoyo, J.Y. Economic Strategy for Developing the Oil Industry in Mexico by Incorporating Environmental Factors. Sustainability 2023, 16, 36. [Google Scholar] [CrossRef]

- Kozyrev, B.A.; Sizyakov, V.M. Heap Leaching of Red Mud by the Formate Method. Obogashchenie Rud 2021, 4, 40–45. [Google Scholar]

- Tonacci, A.; Corda, D.; Tartarisco, G.; Pioggia, G.; Domenici, C. A Smart Sensor System for Detecting Hydrocarbon Volatile Organic Compounds in Sea Water. Clean 2015, 43, 147–152. [Google Scholar] [CrossRef]

- Pshikhopov, V.K.; Medvedev, M.Y.; Gaiduk, A.R.; Gurenko, B.V. Control System Design for Autonomous Underwater Vehicle. In Proceedings of the 2013 Latin American Robotics Symposium and Competition, Arequipa, Peru, 21–27 October 2013; IEEE: Piscataway, NJ, USA, 2013; pp. 77–82. [Google Scholar]

- Mal’Tsev, P.A.; Abramkin, S.E.; Plotnikov, A.V.; Martirosyan, K.V. A Conceptual Model of Controlled Gas Production Processes in Fields with a Complex Geological Structure. In Proceedings of the 2024 XXVII International Conference on Soft Computing and Measurements (SCM), St. Petersburg, Russia, 22–24 May 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 107–110. [Google Scholar]

- Boronko, E.A.; Novozhilov, I.M. Designing an Information System for Monitoring the Electromagnetic Field of a Power Plant. In Proceedings of the 2024 Conference of Young Researchers in Electrical and Electronic Engineering (ElCon), St. Petersburg, Russia, 29–30 January 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 331–334. [Google Scholar]

- Wakita, N.; Hirokawa, K.; Ichikawa, T.; Yamauchi, Y. Development of Autonomous Underwater Vehicle (AUV) for Exploring Deep Sea Marine Mineral Resources. Mitsubishi Heavy Ind. Tech. Rev. 2010, 47, 73–80. [Google Scholar]

- Li, W.; Farrell, J.A.; Pang, S.; Arrieta, R.M. Moth-Inspired Chemical Plume Tracing on an Autonomous Underwater Vehicle. IEEE Trans. Robot. 2006, 22, 292–307. [Google Scholar] [CrossRef]

- Romashin, D.V. Application of Artificial Intelligence to Improve the Efficiency of Monitoring and Diagnosing the Condition of Complex Technical Objects. In Proceedings of the 2024 Conference of Young Researchers in Electrical and Electronic Engineering (ElCon), St. Petersburg, Russia, 29–30 January 2024; IEEE: Piscataway, NJ, USA, 2024; pp. 485–488. [Google Scholar]

- Afanaseva, O.; Tulyakov, T.; Romashin, D.; Panova, A. Development of a Robotic Complex for the Manufacture of Parts Used in Civil Engineering. In Challenges and Advancements in Civil Engineering; Grinrey Publishing: Pune, India, 2023; pp. 51–58. [Google Scholar]

- Ilyushin, Y.; Golovina, E. Stability of Temperature Field of the Distributed Control System. ARPN J. Eng. Appl. Sci. 2020, 15, 664–668. [Google Scholar]

| Parameters | Scoring Band |

|---|---|

| Minor Importance | 1–3 |

| Moderate Importance | 4–5 |

| Significant | 6–7 |

| Important | 8–10 |

| No. | Expert Number | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| 1 | 9 | 6 | 5 | 7 | 7 |

| 2 | 8 | 5 | 7 | 4 | 8 |

| 3 | 7 | 4 | 5 | 3 | 9 |

| 4 | 7 | 5 | 6 | 4 | 10 |

| 5 | 10 | 7 | 9 | 8 | 6 |

| 6 | 9 | 7 | 8 | 7 | 5 |

| 7 | 6 | 4 | 7 | 3 | 8 |

| 8 | 5 | 3 | 6 | 2 | 7 |

| 9 | 9 | 6 | 5 | 7 | 4 |

| 10 | 8 | 8 | 10 | 9 | 5 |

| 11 | 7 | 8 | 7 | 10 | 4 |

| 12 | 9 | 7 | 6 | 8 | 5 |

| 13 | 8 | 6 | 5 | 9 | 3 |

| 14 | 7 | 6 | 5 | 8 | 4 |

| 15 | 7 | 5 | 4 | 9 | 3 |

| 16 | 8 | 10 | 7 | 10 | 5 |

| 17 | 8 | 10 | 6 | 10 | 4 |

| 18 | 8 | 9 | 6 | 10 | 5 |

| 19 | 7 | 10 | 5 | 8 | 4 |

| 20 | 6 | 9 | 4 | 7 | 3 |

| 21 | 5 | 8 | 4 | 8 | 3 |

| 22 | 5 | 8 | 4 | 8 | 3 |

| 23 | 5 | 8 | 4 | 8 | 3 |

| 24 | 4 | 9 | 3 | 7 | 2 |

| 25 | 5 | 8 | 6 | 8 | 4 |

| 26 | 5 | 4 | 10 | 6 | 6 |

| 27 | 4 | 3 | 9 | 5 | 5 |

| 28 | 5 | 4 | 10 | 6 | 5 |

| 29 | 6 | 4 | 10 | 6 | 6 |

| 30 | 5 | 4 | 9 | 5 | 5 |

| 31 | 4 | 7 | 3 | 6 | 2 |

| 32 | 4 | 6 | 3 | 6 | 2 |

| 33 | 4 | 6 | 3 | 6 | 2 |

| 34 | 4 | 7 | 3 | 6 | 2 |

| 35 | 4 | 7 | 3 | 6 | 2 |

| 36 | 6 | 9 | 5 | 10 | 4 |

| 37 | 5 | 8 | 4 | 9 | 3 |

| 38 | 5 | 9 | 4 | 10 | 3 |

| 39 | 6 | 8 | 4 | 10 | 4 |

| 40 | 7 | 6 | 5 | 9 | 5 |

| 41 | 6 | 7 | 6 | 8 | 4 |

| 42 | 3 | 4 | 2 | 3 | 9 |

| 43 | 3 | 2 | 3 | 2 | 10 |

| 44 | 8 | 7 | 5 | 9 | 6 |

| 45 | 10 | 7 | 8 | 9 | 7 |

| 46 | 8 | 6 | 5 | 10 | 4 |

| 47 | 6 | 8 | 5 | 9 | 5 |

| 48 | 5 | 8 | 4 | 8 | 4 |

| No. | AUV Parameters | Significance | Rank |

|---|---|---|---|

| 42 | Lithium reserves | 3 | 1 |

| 43 | Environmental safety | 3 | |

| 24 | Response time | 4 | 3 |

| 27 | Fatigue | 4 | |

| 31 | Signal attenuation | 4 | |

| 32 | Capacity constraints | 4 | |

| 33 | Multipath distribution | 4 | |

| 34 | Acoustic bandwidth | 4 | |

| 35 | Probability of errors in digital communication | 4 | |

| 8 | Biological impact of water | 5 | 10 |

| 21 | Accuracy and repeatability | 5 | |

| 22 | Sensitivity | 5 | |

| 23 | Range and resolution | 5 | |

| 25 | Robustness | 5 | |

| 26 | Strength | 5 | |

| 28 | Buckling resistance | 5 | |

| 30 | Vibration resistance | 5 | |

| 37 | Variety | 5 | |

| 38 | Fault detection and isolation | 5 | |

| 48 | Communication signals | 5 | |

| 7 | Chemical impact of water | 6 | 21 |

| 20 | Power consumption | 6 | |

| 29 | Resistance to high pressure | 6 | |

| 36 | Redundancy | 6 | |

| 39 | Disaster recovery | 6 | |

| 41 | State of production technology | 6 | |

| 47 | System status | 6 | |

| 3 | Water salinity | 7 | 28 |

| 4 | Water temperature | 7 | |

| 11 | Inertia | 7 | |

| 14 | Addition factors | 7 | |

| 15 | Pitch and yaw coefficients | 7 | |

| 19 | Battery capacity | 7 | |

| 40 | Reliability Engineering | 7 | |

| 2 | Water density | 8 | 35 |

| 10 | Weight | 8 | |

| 13 | Lift coefficient | 8 | |

| 16 | Traction | 8 | |

| 17 | Propulsion efficiency | 8 | |

| 18 | Maneuverability | 8 | |

| 44 | Motion vector | 8 | |

| 46 | Orientation in space | 8 | |

| 1 | Underwater currents | 9 | 43 |

| 6 | Shock loads | 9 | |

| 9 | Water resistance | 9 | |

| 12 | Resistance coefficient | 9 | |

| 5 | Hydrostatic loads | 10 | 47 |

| 45 | Diving depth | 10 |

| No. | Expert Number | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| 1 | 43 | 14 | 18 | 18 | 40 |

| 2 | 35 | 11 | 36 | 6 | 43 |

| 3 | 28 | 4 | 18 | 3 | 45 |

| 4 | 28 | 11 | 29 | 6 | 47 |

| 5 | 47 | 22 | 42 | 23 | 36 |

| 6 | 43 | 22 | 40 | 18 | 26 |

| 7 | 21 | 4 | 36 | 3 | 43 |

| 8 | 10 | 2 | 29 | 1 | 40 |

| 9 | 43 | 14 | 18 | 18 | 15 |

| 10 | 35 | 31 | 45 | 33 | 26 |

| 11 | 28 | 31 | 36 | 41 | 15 |

| 12 | 43 | 22 | 29 | 23 | 26 |

| 13 | 35 | 14 | 18 | 33 | 7 |

| 14 | 28 | 14 | 18 | 23 | 15 |

| 15 | 28 | 11 | 9 | 33 | 7 |

| 16 | 35 | 46 | 36 | 41 | 26 |

| 17 | 35 | 46 | 29 | 41 | 15 |

| 18 | 35 | 41 | 29 | 41 | 26 |

| 19 | 28 | 46 | 18 | 23 | 15 |

| 20 | 21 | 41 | 9 | 18 | 7 |

| 21 | 10 | 31 | 9 | 23 | 7 |

| 22 | 10 | 31 | 9 | 23 | 7 |

| 23 | 10 | 31 | 9 | 23 | 7 |

| 24 | 3 | 41 | 2 | 18 | 1 |

| 25 | 10 | 31 | 29 | 23 | 15 |

| 26 | 10 | 4 | 45 | 10 | 36 |

| 27 | 3 | 2 | 42 | 8 | 26 |

| 28 | 10 | 4 | 45 | 10 | 26 |

| 29 | 21 | 4 | 45 | 10 | 36 |

| 30 | 10 | 4 | 42 | 8 | 26 |

| 31 | 3 | 22 | 2 | 10 | 1 |

| 32 | 3 | 14 | 2 | 10 | 1 |

| 33 | 3 | 14 | 2 | 10 | 1 |

| 34 | 3 | 22 | 2 | 10 | 1 |

| 35 | 3 | 22 | 2 | 10 | 1 |

| 36 | 21 | 41 | 18 | 41 | 15 |

| 37 | 10 | 31 | 9 | 33 | 7 |

| 38 | 10 | 41 | 9 | 41 | 7 |

| 39 | 21 | 31 | 9 | 41 | 15 |

| 40 | 28 | 14 | 18 | 33 | 26 |

| 41 | 21 | 22 | 29 | 23 | 15 |

| 42 | 1 | 4 | 1 | 3 | 45 |

| 43 | 1 | 1 | 2 | 1 | 47 |

| 44 | 35 | 22 | 18 | 33 | 36 |

| 45 | 47 | 22 | 40 | 33 | 40 |

| 46 | 35 | 14 | 18 | 41 | 15 |

| 47 | 21 | 31 | 18 | 33 | 26 |

| 48 | 10 | 31 | 9 | 23 | 15 |

| No. | Expert Number | d | d2 | |||||

|---|---|---|---|---|---|---|---|---|

| No. 1 | No. 2 | No. 3 | No. 4 | No. 5 | ||||

| 1 | 43 | 14 | 18 | 18 | 40 | 134 | 2.63 | 6.89 |

| 2 | 35 | 11 | 36 | 6 | 43 | 133 | 1.63 | 2.64 |

| 3 | 28 | 4 | 18 | 3 | 45 | 101 | −30.38 | 922.64 |

| 4 | 28 | 11 | 29 | 6 | 47 | 125 | −6.38 | 40.64 |

| 5 | 47 | 22 | 42 | 23 | 36 | 175 | 43.63 | 1903.14 |

| 6 | 43 | 22 | 40 | 18 | 26 | 155 | 23.63 | 558.14 |

| 7 | 21 | 4 | 36 | 3 | 43 | 114 | −17.38 | 301.89 |

| 8 | 10 | 2 | 29 | 1 | 40 | 90 | −41.38 | 1711.89 |

| 9 | 43 | 14 | 18 | 18 | 15 | 117 | −14.38 | 206.64 |

| 10 | 35 | 31 | 45 | 33 | 26 | 180 | 48.63 | 2364.39 |

| 11 | 28 | 31 | 36 | 41 | 15 | 162 | 30.63 | 937.89 |

| 12 | 43 | 22 | 29 | 23 | 26 | 155 | 23.63 | 558.14 |

| 13 | 35 | 14 | 18 | 33 | 7 | 120 | −11.38 | 129.39 |

| 14 | 28 | 14 | 18 | 23 | 15 | 112 | −19.38 | 375.39 |

| 15 | 28 | 11 | 9 | 33 | 7 | 103 | −28.38 | 805.14 |

| 16 | 35 | 46 | 36 | 41 | 26 | 200 | 68.63 | 4709.39 |

| 17 | 35 | 46 | 29 | 41 | 15 | 183 | 51.63 | 2665.14 |

| 18 | 35 | 41 | 29 | 41 | 26 | 190 | 58.63 | 3436.89 |

| 19 | 28 | 46 | 18 | 23 | 15 | 149 | 17.63 | 310.64 |

| 20 | 21 | 41 | 9 | 18 | 7 | 116 | −15.38 | 236.39 |

| 21 | 10 | 31 | 9 | 23 | 7 | 101 | −30.38 | 922.64 |

| 22 | 10 | 31 | 9 | 23 | 7 | 102 | −29.38 | 862.89 |

| 23 | 10 | 31 | 9 | 23 | 7 | 103 | −28.38 | 805.14 |

| 24 | 3 | 41 | 2 | 18 | 1 | 89 | −42.38 | 1795.64 |

| 25 | 10 | 31 | 29 | 23 | 15 | 133 | 1.63 | 2.64 |

| 26 | 10 | 4 | 45 | 10 | 36 | 131 | −0.38 | 0.14 |

| 27 | 3 | 2 | 42 | 8 | 26 | 108 | −23.38 | 546.39 |

| 28 | 10 | 4 | 45 | 10 | 26 | 123 | −8.38 | 70.14 |

| 29 | 21 | 4 | 45 | 10 | 36 | 145 | 13.63 | 185.64 |

| 30 | 10 | 4 | 42 | 8 | 26 | 120 | −11.38 | 129.39 |

| 31 | 3 | 22 | 2 | 10 | 1 | 69 | −62.38 | 3890.64 |

| 32 | 3 | 14 | 2 | 10 | 1 | 62 | −69.38 | 4812.89 |

| 33 | 3 | 14 | 2 | 10 | 1 | 63 | −68.38 | 4675.14 |

| 34 | 3 | 22 | 2 | 10 | 1 | 72 | −59.38 | 3525.39 |

| 35 | 3 | 22 | 2 | 10 | 1 | 73 | −58.38 | 3407.64 |

| 36 | 21 | 41 | 18 | 41 | 15 | 172 | 40.63 | 1650.39 |

| 37 | 10 | 31 | 9 | 33 | 7 | 127 | −4.38 | 19.14 |

| 38 | 10 | 41 | 9 | 41 | 7 | 146 | 14.63 | 213.89 |

| 39 | 21 | 31 | 9 | 41 | 15 | 156 | 24.63 | 606.39 |

| 40 | 28 | 14 | 18 | 33 | 26 | 159 | 27.63 | 763.14 |

| 41 | 21 | 22 | 29 | 23 | 15 | 151 | 19.63 | 385.14 |

| 42 | 1 | 4 | 1 | 3 | 45 | 96 | −35.38 | 1251.39 |

| 43 | 1 | 1 | 2 | 1 | 47 | 95 | −36.38 | 1323.14 |

| 44 | 35 | 22 | 18 | 33 | 36 | 188 | 56.63 | 3206.39 |

| 45 | 47 | 22 | 40 | 33 | 40 | 227 | 95.63 | 9144.14 |

| 46 | 35 | 14 | 18 | 41 | 15 | 169 | 37.63 | 1415.64 |

| 47 | 21 | 31 | 18 | 33 | 26 | 176 | 44.63 | 1991.39 |

| 48 | 10 | 31 | 9 | 23 | 15 | 136 | 4.63 | 21.39 |

| Sum | 1022 | 1029 | 1027 | 1031 | 1021 | 6306 | 0 | 69,807.25 |

| Parameter Name | No. | Sum of Ranks |

|---|---|---|

| Capacity constraints | 32 | 62 |

| Multipath distribution | 33 | 63 |

| Signal attenuation | 31 | 69 |

| Acoustic bandwidth | 34 | 72 |

| Probability of errors in digital communication | 35 | 73 |

| Response time | 24 | 89 |

| Biological impact of water | 8 | 90 |

| Environmental safety | 43 | 95 |

| Lithium reserves | 42 | 96 |

| Water salinity | 3 | 101 |

| Accuracy and repeatability | 21 | 101 |

| Sensitivity | 22 | 102 |

| Pitch and yaw coefficients | 15 | 103 |

| Range and resolution | 23 | 103 |

| Fatigue | 27 | 108 |

| Addition factors | 14 | 112 |

| Chemical impact of water | 7 | 114 |

| Power consumption | 20 | 116 |

| Water resistance | 9 | 117 |

| Lift coefficient | 13 | 120 |

| Vibration resistance | 30 | 120 |

| Buckling resistance | 28 | 123 |

| Water temperature | 4 | 125 |

| Variety | 37 | 127 |

| Strength | 26 | 131 |

| Water density | 2 | 133 |

| Robustness | 25 | 133 |

| Underwater currents | 1 | 134 |

| Communication signals | 48 | 136 |

| Resistance to high pressure | 29 | 145 |

| Fault detection and isolation | 38 | 146 |

| Battery capacity | 19 | 149 |

| State of production technology | 41 | 151 |

| Shock loads | 6 | 155 |

| Resistance coefficient | 12 | 155 |

| Disaster recovery | 39 | 156 |

| Reliability Engineering | 40 | 159 |

| Inertia | 11 | 162 |

| Orientation in space | 46 | 169 |

| Redundancy | 36 | 172 |

| Hydrostatic loads | 5 | 175 |

| System status | 47 | 176 |

| Weight | 10 | 180 |

| Propulsion efficiency | 17 | 183 |

| Motion vector | 44 | 188 |

| Maneuverability | 18 | 190 |

| Traction | 16 | 200 |

| Diving depth | 45 | 227 |

| Parameter’s Name | No. | Sum of Ranks | Weight |

|---|---|---|---|

| Capacity constraints | 32 | 62 | 0.0098 |

| Multipath distribution | 33 | 63 | 0.0100 |

| Signal attenuation | 31 | 69 | 0.0109 |

| Acoustic bandwidth | 34 | 72 | 0.0114 |

| Probability of error in digital communication | 35 | 73 | 0.0116 |

| Response time | 24 | 89 | 0.0141 |

| Biological impact of water | 8 | 90 | 0.0143 |

| Environmental safety | 43 | 95 | 0.0151 |

| Lithium reserves | 42 | 96 | 0.0152 |

| Water salinity | 3 | 101 | 0.0160 |

| Accuracy and repeatability | 21 | 101 | 0.0160 |

| Sensitivity | 22 | 102 | 0.0162 |

| Pitch and yaw coefficients | 15 | 103 | 0.0163 |

| Range and resolution | 23 | 103 | 0.0163 |

| Fatigue | 27 | 108 | 0.0171 |

| Addition factors | 14 | 112 | 0.0178 |

| Chemical impact of water | 7 | 114 | 0.0181 |

| Power consumption | 20 | 116 | 0.0184 |

| Water resistance | 9 | 117 | 0.0186 |

| Lift coefficient | 13 | 120 | 0.0190 |

| Vibration resistance | 30 | 120 | 0.0190 |

| Buckling resistance | 28 | 123 | 0.0195 |

| Water temperature | 4 | 125 | 0.0198 |

| Variety | 37 | 127 | 0.0201 |

| Strength | 26 | 131 | 0.0208 |

| Water density | 2 | 133 | 0.0211 |

| Robustness | 25 | 133 | 0.0211 |

| Underwater currents | 1 | 134 | 0.0212 |

| Communication signals | 48 | 136 | 0.0216 |

| Resistance to high pressure | 29 | 145 | 0.0230 |

| Fault detection and isolation | 38 | 146 | 0.0232 |

| Battery capacity | 19 | 149 | 0.0236 |

| State of production technology | 41 | 151 | 0.0239 |

| Shock loads | 6 | 155 | 0.0246 |

| Resistance coefficient | 12 | 155 | 0.0246 |

| Disaster recovery | 39 | 156 | 0.0247 |

| Reliability Engineering | 40 | 159 | 0.0252 |

| Inertia | 11 | 162 | 0.0257 |

| Orientation in space | 46 | 169 | 0.0268 |

| Redundancy | 36 | 172 | 0.0273 |

| Hydrostatic loads | 5 | 175 | 0.0278 |

| System status | 47 | 176 | 0.0279 |

| Weight | 10 | 180 | 0.0285 |

| Propulsion efficiency | 17 | 183 | 0.0290 |

| Motion vector | 44 | 188 | 0.0298 |

| Maneuverability | 18 | 190 | 0.0301 |

| Traction | 16 | 200 | 0.0317 |

| Diving depth | 45 | 227 | 0.0360 |

| Parameter’s Name | No. | Sum of Ranks | Weight |

|---|---|---|---|

| Diving depth | 45 | 227 | 0.0360 |

| Traction | 16 | 200 | 0.0317 |

| Maneuverability | 18 | 190 | 0.0301 |

| Motion vector | 44 | 188 | 0.0298 |

| Propulsion efficiency | 17 | 183 | 0.0290 |

| Weight | 10 | 180 | 0.0285 |

| System status | 47 | 176 | 0.0279 |

| Hydrostatic loads | 5 | 175 | 0.0278 |

| Redundancy | 36 | 172 | 0.0273 |

| Orientation in space | 46 | 169 | 0.0268 |

| Inertia | 11 | 162 | 0.0257 |

| Reliability Engineering | 40 | 159 | 0.0252 |

| Disaster recovery | 39 | 156 | 0.0247 |

| Shock loads | 6 | 155 | 0.0246 |

| Resistance coefficient | 12 | 155 | 0.0246 |

| State of production technology | 41 | 151 | 0.0239 |

| Battery capacity | 19 | 149 | 0.0236 |

| Fault detection and isolation | 38 | 146 | 0.0232 |

| Resistance to high pressure | 29 | 145 | 0.0230 |

| Communication signals | 48 | 136 | 0.0216 |

| Key Indicators | Description of the Indicator |

|---|---|

| Communication signals | Determines the capability and quality of underwater communication |

| Resistance to high pressure and hydrostatic loads | Critical for underwater conditions |

| Fault detection and isolation | Ensures stable operation when issues arise |

| Battery capacity and propulsion efficiency | Essential for autonomy and mission duration |

| The state of manufacturing technology | Affects the quality and reliability of all components |

| Shock loads and reliability engineering | Ensures the durability of the apparatus |

| Drag coefficient and motion vector | Crucial for hydrodynamic performance |

| Disaster recovery | Essential for maintaining functionality |

| Inertia and spatial orientation | Determines maneuverability and positioning accuracy |

| Redundant systems | Improves overall reliability |

| Mass and thrust | Influences energy efficiency and dive depth |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pervukhin, D.; Kotov, D.; Trushnikov, V. Development of a Conceptual Model for the Information and Control System of an Autonomous Underwater Vehicle for Solving Problems in the Mineral and Raw Materials Complex. Energies 2024, 17, 5916. https://doi.org/10.3390/en17235916

Pervukhin D, Kotov D, Trushnikov V. Development of a Conceptual Model for the Information and Control System of an Autonomous Underwater Vehicle for Solving Problems in the Mineral and Raw Materials Complex. Energies. 2024; 17(23):5916. https://doi.org/10.3390/en17235916

Chicago/Turabian StylePervukhin, Dmitry, Dmitry Kotov, and Vyacheslav Trushnikov. 2024. "Development of a Conceptual Model for the Information and Control System of an Autonomous Underwater Vehicle for Solving Problems in the Mineral and Raw Materials Complex" Energies 17, no. 23: 5916. https://doi.org/10.3390/en17235916

APA StylePervukhin, D., Kotov, D., & Trushnikov, V. (2024). Development of a Conceptual Model for the Information and Control System of an Autonomous Underwater Vehicle for Solving Problems in the Mineral and Raw Materials Complex. Energies, 17(23), 5916. https://doi.org/10.3390/en17235916