Abstract

Hydrogel sweat cooling is one of the leading areas in the study of multiphase heat transfer. In this study, the principles, applications, current research status, and future trends of hydrogel sweat cooling technology are comprehensively reviewed. By combing through and analyzing the relevant literature, the research progress in hydrogel sweat cooling is presented from the application perspective, including its use in electronic devices, buildings, and clean-energy facilities. The principle of each application is illustrated, the research status is established, and pros and cons are proposed. To provide inspiration for future research, the development trend is set out. Our literature review indicates that research on advanced hydrogels is the most promising research direction, including studies on the effect of environmental and indoor factors on sweat cooling performance through numerical, experimental, and theoretical means. Challenges for future research mainly include conducting hydrogel numerical analysis which can be experimentally verified, developing advanced hydrogels in a green way, and achieving the precise regulation of hydrogel control through intelligent methods. Interdisciplinary integration might be promising as well due to the fact that it can reveal the hydrogel sweat cooling mechanism from a different perspective. This study aims to promote multiphase cooling technology in exploring the application of hydrogels in energy utilization criteria.

1. Introduction

The importance of cooling technology to human life and production is self-evident. In daily life, cooling technology helps us to preserve food, extend the shelf life of food, and ensure dietary safety [1]; in the medical field, cooling technology plays a vital role in drug preservation, organ transplantation, and other key links [2]; and in industrial production, cooling technology ensures the normal operation of machines and equipment and prevents damage and failures caused by overheating [3]. In addition, cooling technology also plays an important role in energy [4], aerospace [5], electronic information [6], and many other fields. The development and application of cooling technology have greatly promoted the progress and development of human society.

Multiphase flow cooling technology, also known as phase change cooling technology, occupies an important position in the cooling field. Multiphase flow cooling refers to the utilization of phase change materials, such as in solid–liquid or liquid–gas forms, to effectively absorb heat and store energy, thereby realizing the purpose of heat dissipation. Compared with traditional single-phase flow cooling, multiphase flow cooling significantly improves the cooling effect by introducing media with different phases (e.g., liquids, gases, and solid particles) to form a complex multiphase flow system during the flow process [7], which absorbs or releases the huge amount of latent heat during the phase change process and realizes the heat transfer and distribution more efficiently. In addition, the multiphase flow cooling technology also has the advantages of strong adaptability and flexible operation, meaning that it can be widely used in a variety of complex environments and working conditions according to the cooling needs. Whether it is used in the industrial production of large equipment cooling [8] or in the aerospace field of high-performance material cooling [9], multiphase flow cooling technology can show its unique advantages and application value.

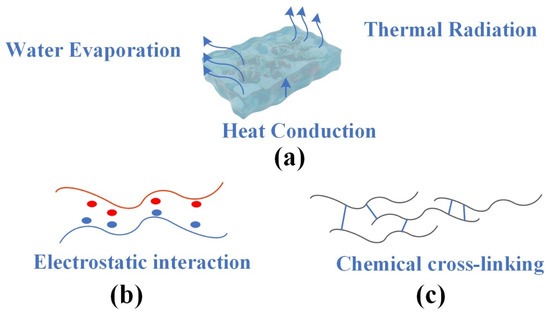

Hydrogel sweat cooling technology is a multiphase flow cooling technology that has emerged in the last 20 years [10]. As shown as Figure 1a, hydrogels are an innovative material, composed of a network of hydrophilic cross-linked polymer chains, including electrostatic interaction and chemical cross-linking, as shown in Figure 1b,c. Due to the abundance of hydrophilic groups, hydrogels have a great capacity to retain water, at approximately 90%. During the sweat cooling process, it can release water when heated and extract a substantial amount of heat by evaporating water, thus producing effective cooling [11]. This technology is not only suitable for small-equipment heat dissipation, but also can be applied to the cooling of large industrial equipment, and has broad application potential.

Figure 1.

(a) Main heat transfer processes in hydrogel sweating; (b) electrostatic interaction type (c) chemical cross-linking type.

In contrast to traditional cooling strategies, hydrogel has a widespread, straightforward, and efficient ability to accommodatively adjust object temperature. Recently, notable growth has been spurred in this particular field, including experimental, theoretical, and computational investigations. Nevertheless, though existed reviews have summarized areas like the environment [12], agriculture [13] and molecular dynamics simulations [14], there still remains a deficiency in reviews on the hydrogel sweat cooling field specifically, which might be inconvenient for this field. To capture this rapidly evolving research trend and provide systematic indications for potential applications, it is essential to conduct an overall review for hydrogels used in the sweat cooling field. The present review establishes the groundwork for this particular issue. The principles, applications, current research status, and future trends of hydrogel sweat cooling technology are summarized, with the aim of promoting multiphase cooling technology in exploring applications of hydrogels in energy utilization criteria.

2. Research Status of Hydrogel Sweat Cooling

2.1. Electronic Device Heat Dissipation

With the increasing performance and miniaturization of electronic devices, cores exhibit increasingly high heat flow density, and the thermal design of electronic devices is becoming more and more challenging [15]. Studies have shown [16,17] that those excessive temperatures can lead to core damage, and even may lead to hazards such as burning, combustion, or explosion [18].

Traditional heat dissipation methods, such as heat conduction based on the heat source components in contact with the back panel material, or the use of structurally dense materials like plastic, glass, metal and ceramics, are not sufficiently efficient. Most of the heat is concentrated on the exterior surface of the product, which leads to the degradation of the product’s operating performance and problems such as hot hands [19,20]. Furthermore, the implementation of active heat dissipation techniques, such as air-cooling or liquid-cooling, necessitates the consumption of extra energy, which increases the burden of structural design and generates noise [21]. Therefore, the development of novel heat dissipation materials is significantly important.

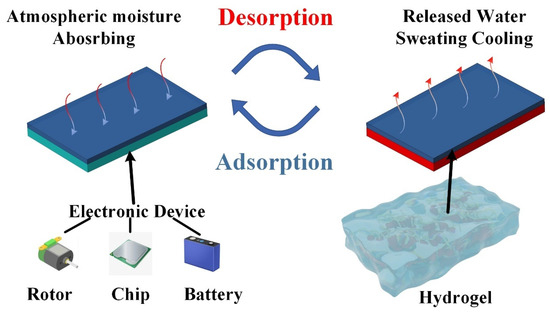

To solve this problem, practical hydrogel is an appropriate material to be introduced. Hydrogel used in electronic devices mainly contains two stages [22,23]. One is the sweat cooling stage, where the hydrogel would release water and absorb heat during the time electronic devices are working; the other is the recover stage, where hydrogel would absorb water from environment, which is illustrated as Figure 2. Currently, a number of studies have been carried with hydrogels as the dominant heat dissipation scheme.

Figure 2.

Working principle of hydrogel used in electronic device thermal management.

Inspired by the effective and simple characteristics of hydrogel sweat cooling, various studies have been devoted to cooling battery systems. Zhao et al. [24] developed a flexible BTM system based on a cost-effective poly(sodium acrylate) (PAAS) hydrogel, which can be customized and easily mounted according to any shape of the lithium-ion battery stack. They discovered that the PAAS hydrogel BTM system was superior in regulating the temperature of the battery pack, ensuring it remained stable within the acceptable range. Nan et al. [25] developed the hydrogel thermal management system containing superabsorbent polymer (SAP-50) hydrogel, which effectively improves the temperature uniformity of lithium batteries and reduces the temperature difference, which is an effective method for the passive thermal management of large lithium batteries. Zhang et al. [26] proposed the use of PAAS hydrogel for the passive thermal management of lithium-ion batteries; through the construction of thermal models and experimental validation, it was proved that the system can effectively reduce the temperature rise rate and temperature difference of the battery pack in the process of discharging, improving the stability and safety of the batteries. Pu et al. [27] used hydrogel to lower mobile phone battery temperatures by 20 °C and recover 5 µW of power for improved energy efficiency and reliability.

Furthermore, hydrogel is also beneficial for high-power electronic device thermal management. Hamid et al. [28] found that the addition of sodium polyacrylate hydrogel to a 500 Wh industrial battery pack reduced the maximum temperature by 3.9 °C, 7.5 °C, and 10.9 °C at 1C, 2C, and 3C discharge rates, respectively; the gel was completely filled, especially at the edges, which was preferable to increasing the cell spacing only. It was also found that cell density and specific heat capacity had a significant effect on the thermal characteristics of the battery pack. Mehryan et al. [29] proposed a BTMS design using hydrogel to significantly reduce the temperature of Li-ion batteries under forced convection and improve battery performance and safety. Pu et al. [30] developed a PNIPA hydrogel composite thermal film to mimic human perspiration, which effectively dissipates heat from VR devices and improves its performance; this provides a new way to dissipate heat from electronic devices. Pu et al. [17] developed lithium bromide-containing PAAm hydrogels, which reduce semiconductor device temperatures through evaporative cooling, increasing solar cell efficiency and the maximum output power of mobile phone chips.

Some researchers used the adaptive and shapable characteristics for hydrogel and applied it in the cooling for electronic chips. Massimiliano et al. [31] designed a novel heat sink (HHS) based on polyvinyl alcohol (PVA) hydrogel for the thermal management of electronic chips. They mold casted the PVA hydrogel blocks (size 50 mm × 50 mm × 5 mm) and tested its performance. The cooling performance of the HHS was experimentally measured and analyzed based on the water flow rate; it is found that this HHS could reach 340 to 1012 W/m2, demonstrating the efficient heat dissipation potential of the HHS utilizing perspiration cooling. Mu et al. [32] introduced a smart color-changing hydrogel to improve the efficiency of electronic devices and contribute to sustainable development by indicating cooling performance through color change.

Apart from single hydrogels, compounding hydrogels with another cooling strategy has also been explored. Xiu et al. [33] proposed an adaptive microchannel cooling scheme based on thermosensitive nanocomposite hydrogel, which can adjust the flow rate according to the dynamic thermal load of electronic chips. It has been experimentally proven to be effective and economical, providing a new way for the liquid cooling of modern electronic devices. Li et al. [34] developed a smart fractal microchannel heat sink with integrated thermo-responsive hydrogel that senses random hot spots and adaptively cools microelectronic devices for a lower and more uniform temperature distribution. Zeng et al. [35] developed a hydrogel-based moisture thermal battery (MTB) to provide passive cooling for high-power electronic devices. The MTB can automatically absorb water from the atmosphere and is used during periods of low energy consumption; it has been proven that its high-thermal conductivity and heat capacity can provide stable cooling for electronic devices during prolonged testing. Miao et al. [36] developed a polyimide (PI)-based biomimetic hydrogel thermal film that mimics the human skin perspiration mechanism to dissipate heat from electronic devices. Experiments show that the film significantly cools down by 25.4 °C under high-power laser heating, as well as in mobile phone and battery applications, exhibiting excellent heat dissipation (269.3 W/m2) and high humidity adsorption (0.062 g/min). Pu et al. [37] created smart metal fins and smart hydrogels to efficiently control the temperature of heat-generating electronic devices through evaporation and regeneration mechanisms. Simulations and experiments show that smart fins can efficiently cool high-power integrated electronic devices.

With the above literature, it could be indicated that though hydrogel shows some unique advantages for cooling electronic devices, there are still some limitations, which have been concluded as follows:

- Limited cooling effect: Although hydrogels can reduce the temperature of electronic devices through evaporation, their cooling effect is limited by a number of factors, such as ambient temperature, humidity, and power consumption of the electronic devices. Under extreme conditions, hydrogels may not provide sufficient cooling, resulting in overheating of electronic devices.

- Moisture replenishment problem: Although the hydrogel can automatically take water from the air, in some special environments (e.g., dry, closed environments), the moisture content in the air may not be sufficient to meet the hydrogel’s needs. In such cases, manual replenishment of water is required, adding to the complexity and cost of use.

- Gel adhesion and stability: The adhesion of hydrogels to the surface of electronic devices requires a certain level of skill and equipment, and it is necessary to ensure that the gel remains stable over a long period of time. If the gel is not firmly attached or has poor stability, it may affect its cooling effect and increase the risk of damage to the electronic device.

- Limited applicability: Hydrogels are mainly suitable for low- or medium-power electronic devices and may not be effective enough for cooling high-power electronic devices. In addition, hydrogels have a limited temperature range and are not suitable for extreme high- or low-temperature environments.

Table 1 is presented to summarize the conclusions according to time clues. Though hydrogel has certain advantages and potential in electronic equipment cooling through the sweating evaporation process, there are some limitations. In future, a more advanced, suitable cooling study should be conducted according to the specific needs and conditions.

Table 1.

Summary table for hydrogel sweat cooling used in electronic devices.

2.2. Building Energy Consumption Saving

Apart from its effective application in electronics, hydrogel has also been utilized in building cooling as a highly efficient material [38,39]. Due to the ability for maintaining and storing large amounts of water, it can absorb heat from the environment during night-time or low-temperature hours and release that heat during daytime or high-temperature hours, thereby lowering indoor temperatures [40,41]; this mechanism is shown in Figure 3. This process can help regulate indoor temperatures [42,43], reduce the use of cooling equipment such as air conditioners, and lower energy consumption and carbon emissions. Several studies have been applied in this field and have been concluded in this section.

Figure 3.

Hydrogel sweat cooling used in a building.

On the one hand, several studies have indicated that hydrogel sweat cooling has the ability to be directly used in building cooling. Rotzetter et al. [44] developed thermosensitive hydrogels (PNIPAM) that can be used to cool buildings by mimicking the action of bio sweat. These hydrogels release stored water under pressure when the ambient temperature goes over the lower critical solution temperature (LCST). The results indicated a decrease of 25 °C in surface temperature when compared to uncovered ground. Feng et al. [45] developed a hydrogel-based building material that reflects sunlight and dissipates heat through the atmosphere during the day and spontaneously absorbs moisture from the air at night for energy-efficient cooling. Ji et al. [46] prepared an interpenetrating polymer network hydrogel that mimics human perspiration. This hydrogel releases moisture during the day to lower the building temperature; their experiments show that it can effectively reduce the temperature of glass panels. Roisul et al. [47] fabricated a polyacrylate membrane prepared from a self-absorbing hygroscopic hydrogel for houses to reduce solar radiation cooling; it is found that this hydrogel can absorb moisture, is cost-effective and has the potential to advance the development of passive cooling applications.

On the other hand, known as an excellent environment green material, several studies have been carried to improve building efficiency and save cost. Inspired by desert animals, Lu et al. [42] designed a hydrogel–aerogel bilayer structure that mimics animal fur and sweat, significantly extending the cooling time and making it more efficient than the single-layer design. The structure has the potential for food and drug preservation and the temperature regulation of building structures in areas with limited power resources. Another study provided by Arslan et al. [48] found that polyacrylamide hydrogels can effectively cool timber structures and masonry houses without relying on active cooling. They enhanced the mechanical strength of the hydrogels by adding nanoparticles and found that dual-network hydrogels provided better strength and cooling over extended periods of time. Yang et al. [49] developed a novel poly(n -isopropylacrylamide) (PNIPAM)-based hydrogel and verified that this on-demand thermal management can be combined with water recovery systems to develop sustainable passive thermostats for buildings with high efficiency, controllable power, low cost and aesthetic appearance. Mao et al. [50] suggested a combination of evaporative and radiative cooling strategies based on hydrophilic hydrogel. It is found that this triple-structured hydrogel–PEA membrane achieves both evaporative and radiative cooling to effectively reduce ambient temperatures; tests on human cooling equipment have shown its efficient performance.

In conclusion, Table 2 is constructed through time clues to conclude that hydrogel sweat cooling can be used in building and construction areas. Hydrogel has shown obvious potential applications in building cooling. However, there are some limitations, which are as follows:

Table 2.

Summary table for hydrogel sweat cooling used in building energy consumption saving.

- Poor mechanical properties: Hydrogels inherently have poor mechanical properties, which means that they may not be able to withstand the various pressures and stresses in the building environment. This can lead to hydrogels breaking or failing during long-term use, compromising the cooling effect.

- Light ageing: Hydrogels are prone to ageing when exposed to constant light, leading to a reduction in performance. In the built environment, hydrogels need to be exposed to sunlight for long periods of time, which can accelerate the ageing process and reduce their cooling effect.

- Stability issues: The cooling effect of hydrogels is affected by a number of factors, such as ambient temperature, humidity and wind speed. The cooling effect of hydrogels may vary under different climatic conditions. In addition, hydrogels can change their morphology considerably during water absorption, which may cause problems in practical use, such as the need for regular replacement or maintenance.

- Cost issues: Although hydrogels are relatively inexpensive to manufacture, they may need to be used in large quantities to achieve effective cooling in building cooling applications. This may increase building costs and require additional maintenance and management.

2.3. Clean Energy Utilization

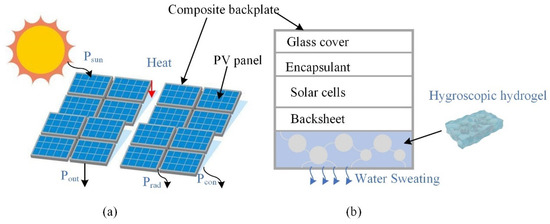

In recent years, hydrogels have garnered significant interest in the field of clean energy use, particularly in the areas of atmospheric water harvesting and solar energy collecting [51,52]. The very basic principle for hydrogel sweat cooling is illustrated in Figure 4. An innovative composite backplate has been developed based on hydrogel, which supports high-efficiency cooling performance during the working time. In addition, according to the hydrogel-commendable hygroscopic capacity, various studies have been explored, which indicate that hydrogel has the strong potential to be used as passive cooling of photovoltaic panels, solar evaporation and other energy conversion management devices [53]. This section will conclude the latest research in this field and review the useful outcomes.

Figure 4.

(a) PV panel energy conversion illustration; (b) schematic depiction of PV panel with the composite backplate.

Several researchers have paid attention to the adhesive ability of hydrogel and used it in solar panel cooling. Su et al. [54] found that the addition of graphene oxide and nitrogen-doped graphene (GO) to the composite hydrogel consisting of protonated g-C3N4 (g-C3N4) could effectively improve the self-floating and evaporation ability of the hydrogel, resulting in an increase in the solar thermal conversion efficiency. Abdo et al. [55] used hydrogel as a coolant for solar panels to effectively reduce their temperature through evaporative cooling technology, and experiments showed that the hydrogel bed configuration can significantly improve the power generation efficiency of solar panels, and has the advantages of being lightweight, easy to install, and low cost. Lv et al. [56] developed hydrogels with all-weather adhesion and cooling properties. It was demonstrated that the hydrogel had excellent adhesion and cooling effects on solar photovoltaic panels under a variety of humidity conditions and could be prepared at low cost. Further [53], they fabricated a highly hygroscopic and adhesive hydrogel by adding CaCl2 to polyacrylamide and used it for the passive cooling of photovoltaic panels, which was found to significantly improve cooling efficiency and energy output under hot and humid environments.

At the same time, some researchers have indicated the potential for hydrogel to be used in energy consumption saving. Li et al. [57] achieved the passive cooling of solar panels using a composite hydrogel containing polyacrylamide (PAM), carbon nanotubes (CNT), and calcium chloride (PAM-CNT-CaCl2), which proved to be effective and feasible under both laboratory and outdoor conditions. It is pointed out that the cooling system not only cools the panels, but also produces clean water in arid and semi-arid regions, solving the problems of dust-covered panels and the difficulty of accessing liquid water, and providing a valuable solution for combating climate change. Zheng et al. [58] designed a double-layer hydrogel evaporator by 3D printing technology, and experimentally demonstrated that the double-layer hydrogel evaporator exhibits excellent evaporation rates and energy efficiency under simulated solar radiation, providing a new and efficient solution in the field of wastewater treatment and solar energy utilization. Liu et al. [59] developed a novel hydrogel cooling layer based on polyacrylamide, carbon black and lithium chloride for the passive cooling of solar photovoltaic panels. The cooling method was proven to be effective in outdoor experiments during the summer in Beijing, and the performance can be optimized by adjusting the hygroscopic salt content and thickness, which is expected to improve the efficiency of photovoltaic power plants and reduce carbon emissions.

In conclusion, Table 3 is presented to summarize researchers’ contributions to this field. Based on this table, it could be indicated that hydrogel is also highly advocated in clean energy utilization.

Table 3.

Summary table for hydrogel sweat cooling used in clean energy utilization.

3. Development Trend of Hydrogel Sweat Cooling

During the last section, the research status of hydrogel sweat cooling technology has been concluded based on its main application Though hydrogel shows capability in the thermal management of these field, there are still some challenges that need to be solved, such as the stability, durability, and cost [60]. Researchers have carried out a lot of work by improving the preparation process of hydrogels and optimizing their structural properties based on the cooling principle of whole process [61]. By reviewing the related latest study, this section is presented to track the potential research orientation in the hydrogel sweat cooling field, which includes the preparation of high-thermal-performance hydrogels, improvement in hydrogel hygroscopicity and a new way to study the cooling principle of hydrogel.

3.1. Research on the Preparation of Advanced Performance Hydrogel

The most popular, spotted area is the preparation of high-performance hydrogels [62]. When hydrogel is applied in the electronic devices, due to the large amount of water contained in hydrogels, their mechanical and electrochemical properties have potential to cause the side effects of the devices. The temperature characteristics of hydrogels have a significant impact on the functionality of flexible electrical devices. Hence, it is crucial to investigate the temperature characteristics of hydrogels employed in flexible electrical devices. Furthermore, hydrogels typically exhibit reduced heat conductivity as a result of their polymer composition [63]; the study and understanding of the thermal behavior of hydrogels for advanced thermal design of electronic devices with high heat flux are also important [64,65]. Hence, this section presents the findings and recommendations for enhancing the thermal and mechanical performance of hydrogel.

Sun et al. [66] developed a solar vapor generator by utilizing copper sulfide–microporous polyacrylamide hydrogel (CuS-m-PAM) as a material that converts sunlight into heat. The researchers discovered that the combination of the surface plasmon resonance effect of CuS nanoparticles and the rough porous structure of m-PAM resulted in an increased evaporation rate of the hydrogel.

Zhao et al. [67] prepared a novel solar evaporator based on ionic hydrogel. The evaporator employed a functional layer consisting of a composite hydrogel made of sodium polyvinyl alginate (SA) and poly(3,4-ethylenedioxythiophene): polystyrene sulfonate (PEDOT: PSS) for the purpose of photothermal conversion and in situ heating. The study revealed that adjusting the proportion of hydrogels can enhance the evaporation of interfacial water. Zhou et al. [68] prepared polyacrylamide (PAM) hydrogels by the polymerization freeze-drying process. They enhanced the mechanical properties of the hydrogel by adding carbon nanotubes and hydrophilic polymer networks to the hydrogel. It was found that the hydrogel contained a large number of hydrophilic functional groups; these were able to form intermediate water (IW), which had weak hydrogen bonding, thus reducing the enthalpy of the evaporation of water.

Lv et al. [69] prepared an efficient carbon nanotube (CNT) @ polyvinyl alcohol (PVA) nanofiber hydrogel evaporator. They modulated the evaporation capacity of this hydrogel by the electrospinning technique and subsequent chemical cross-linking treatment. Chun-lei et al. [70] prepared a temperature-sensitive hydrogel with N-isopropylacrylamide (PNIPAm) and sodium acrylate (AA-Na) as the main components by the free-radical polymerization method, considering the sufficient water content in the hydrogel as well as the potential of the immense latent heat of water in gasoline fire extinguishing. They measured the thermal properties and viscosity of the hydrogel solutions with different mass fractions by a differential scanning calorimeter (DSC) and viscometer, and applied them in gasoline fire extinguishing experiments. The results showed that the hydrogel had a short extinguishing time, a fast cooling rate and a good cooling effect on burning objects.

Liang et al. [71] suggested a novel hydrogel packaging solution to address the lack of a transportation cold chain system in developing areas. This packaging utilizes its sweat cooling and daylight sunlight chilling capabilities to minimize the deterioration of polyphenols and enzymes during transit. Through various experiments, it was discovered that the containers made of polyacrylamide/poly(vinyl alcohol) hydrogel packaging with nanoparticles were capable of achieving a cooling effect at different temperatures and humidity levels. Additionally, they were found to effectively safeguard anthocyanins and trypsin from degradation caused by intense sunlight and high temperatures. The study evaluated the process of preparing hydrogel packaging, the swelling behavior of hydrogel, the mechanical strength characteristics, and the cooling effect of daytime radiation. It concluded that using hydrogel could offer an alternative solution for transporting non-cold-chained biologics.

Because the cooling behavior directly depends on the amount of water the hydrogel contains, the effect of the hygroscopicity of hydrogels obviously affects the effectiveness of sweat cooling [72,73]. Several studies have been undertaken to investigate the effects of different factors on the hygroscopic properties of hydrogels, with the aim of enhancing their ability to gather atmospheric water or meet the requirements for sweat cooling applications.

Mathesan et al. [74] conducted a molecular dynamics simulation to study hydrogels based on chitosan polymers. Their findings demonstrated that the incorporation of hydroxyapatite (HAP) into the hydrogel augmented its mechanical robustness. Abudabbus et al. [75] created composite hydrogels by using silver-doped poly(vinyl alcohol)/graphene oxide (Ag/PVA/Gr). Thermogravimetric analysis (TGA) revealed that the inclusion of graphene enhances the thermal stability of composite hydrogels based on polyvinyl alcohol (PVA). Zhao et al. [76] developed a composite hydrogel electrolyte (BPCE) by combining bacterial cellulose (BC) and poly(vinyl alcohol) (PVA) to create flexible solid-state zinc–air batteries. The addition of BC microfibers to the PVA matrix resulted in a significant increase in the mechanical strength of the composite hydrogel. Specifically, the strength was enhanced by a factor of 9, with the pure PVA having a strength of 0.102 MPa and the 6-BPCE having a strength of 0.951 MPa. This improvement can be attributed to the formation of a dual-network structure in the hydrogel, where the BC microfibers interact with the PVA matrix through hydrogen bonds. Park et al. [77] reported a wearable flexible thermoelectric cooling device. Lu et al. [78] synthesized LiCl (lithium chloride) and polyacrylamide (PAM) hygroscopic hydrogels, and prepared hydrogels with high hygroscopic properties by modulating the water state inside the hydrogel polymer network. The findings indicated that the water absorption and release properties of PAM-LiCl were controlled by the interaction between the hydrogel structure and water molecules.

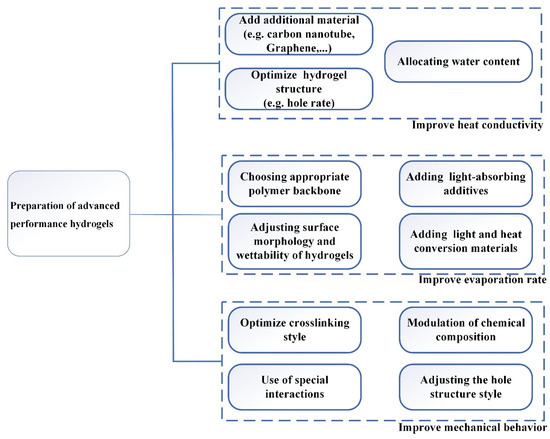

In summary, Figure 5 presents the overall review in this section. It has been shown that the addition of nanoscale fillers to polymers can modify the mechanical, thermal, barrier and hygroscopicity properties of hydrogels [79,80]. However, these studies mainly use experiments, which cost lots of time, money and are complex to undertake. Furthermore, the mechanism of how and why the property is influenced by some factors cannot be well explained. Subsequently, a more convenient, time-saving, and precise method is urgently needed.

Figure 5.

Summary of the advanced hydrogel preparation method.

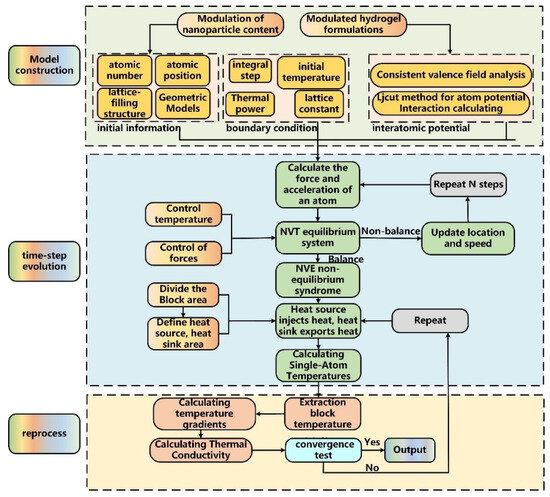

3.2. Research on Molecular Dynamics Used in Thermal and Mechanical Property Analysis of Hydrogel

The advancement of computational tools has led to the growing utilization of molecular dynamics simulations in the analysis of the nano- and micrometer structure and properties of hydrogels. These simulations are particularly useful in studying the thermophysical properties of hydrogels. Molecular dynamics simulation utilizes the principles of classical mechanics, quantum mechanics, and statistical mechanics to examine the interactions between hydrogels and molecules at the nano- and micrometer scale. It computationally replicates the macroscopic features of the system [81].

The core principle of the molecular dynamics simulation is Newton’s laws of motion. During the simulation, the positions and velocities of the molecules are updated by solving Newton’s equations over a certain time step to obtain the evolutionary trajectory of the system. In order to ensure the accuracy and stability of the simulation results, appropriate force fields and algorithms need to be selected. The force field includes the type of force field, parameter selection, etc. Different force fields are suitable for different molecular systems. For instance, Figure 6 illustrates an example of the PAAM hydrogel molecular structure; the bond between each molecule should be calculated separately, and the configuration of molecules should be discussed carefully. The PAAM hydrogel molecular structure controls the evolutionary behavior of molecules during the simulation process [82].

Figure 6.

Box model illustration of MD simulation.

Ni et al. [83] investigated the variables that influence the heat conductivity of polyacrylamide (PAAm) hydrogels using both experimental measurements and equilibrium molecular dynamics simulations. The researchers discovered that the thermal conductivity of PAAm hydrogels may be controlled by manipulating the effective crosslink density and water content. Experimental studies demonstrated that modifying the cross-linking density led to a significant 54% increase in thermal conductivity, ranging from 0.33 to 0.51 Wm−1K−1. While the water content was controlled within a range of 23 to 88 weight percent, the thermal conductivity could be adjusted between 0.41 and 0.57 Wm−1K−1.

Xu et al. [84] created a molecular dynamics (MD) model of randomly crosslinked PAAm hydrogels with varying water volume fractions using a reaction technique. An et al. [85] conducted simulations using non-equilibrium molecular dynamics (NEMD) and equilibrium molecular dynamics (EMD) to examine the thermo-mechanical characteristics of cross-linked polyacrylamide (PAAm) hydrogels. The researchers used equilibrium molecular dynamics (EMD) simulations to forecast the thermal conductivity of the hydrogels based on their water content and cross-linking degree. Juan et al. [86] offered insights on the potential of MD investigations in elucidating the hydrogelation process, mechanical characteristics, and encapsulation/adsorption phenomena of diverse materials. Li et al. [87] conducted molecular dynamics simulation studies on hyaluronic acid hydrogels, focusing on the effect of water content on the mechanical and tribological properties of hydrogels. They found that the mechanical and tribological properties of hydrogels gradually improved with increasing water content.

Jomary et al. [88] applied experimental and molecular simulation methods to investigate the structural characteristics of poly (ethylene glycol) diacrylate (PEGDA) hydrogels, revealing the existence of a link between chain–chain interactions, hydrogel structure, and the equilibrium swelling behavior of this hydrogel polymer solution. Duan et al. [89] prepared poly(vinyl alcohol) (PVA) hydrogels with tunable anisotropy ratios by the bidirectional ice template method and investigated their structural and mechanical properties. Narges et al. [90] employed molecular dynamics simulations to examine the impact of three distinct types of crosslinked hydrogels (polyacrylamide (PAM), polyvinyl alcohol (PVA), and polyethylene glycol (PEG) hydrogels), as well as the volume fraction of PAM hydrogels (ranging from 5% to 15%), on the swelling and thermal characteristics of simulated samples. Fei et al. [91] investigated the toughening mechanism of physico-chemical hybrid hydrogels consisting of hydrophilic–hydrophobic–hydrophilic triblock copolymers by coarse-grained molecular dynamics simulations and obtained the stress–strain curves of the hydrogel systems by tensile simulations. They concluded that the hybrid hydrogels had the best mechanical properties when the chain length ratio was 7:1:7.

To sum up, additional nano material is usually added to improve the thermal and mechanical behavior of hydrogel. In addition, based on a review of the study of MD simulations in hydrogel property, Figure 7 is constructed to describe the flow scheme of the heat conductivity analysis of hydrogel, which works as the example of how to use MD simulation in the property improvement of hydrogel. This could be helpful for researchers when applying this method.

Figure 7.

Flow diagram of MD simulation in the thermal conductivity analysis of composite hydrogel.

3.3. Research on Computational Fluid Dynamics Applied to Hydrogel

Recently, computational fluid dynamics (CFD) simulation is gradually coming into the view of researchers and scholars. The use of CFD to simulate the heat dissipation characteristics of hydrogels is an effective method, especially in situations where the internal complexity cannot be experimentally measured [92,93]. CFD simulation can help us to understand and optimize the performance of hydrogels in heat dissipation applications, which is crucial for analyzing heat transfer and fluid dynamics behaviors in the heat dissipation structures of hydrogels. The application of CFD to hydrogels mainly involves geometric modeling, mesh partitioning, and setting up the physical model; setting up the boundary and initial conditions; and setting up the boundary and initial conditions. The application of CFD to hydrogels mainly includes geometric modeling, meshing, and setting up the physical model; setting up boundary and initial conditions; running the simulation; post-processing the results; and optimization and iteration. A number of studies have been carried out, which mainly include the application of CFD to compute the structural, solubility, and thermal conductivity of hydrogels, as well as to regulate the critical transition temperature, LCST, to enhance the thermal properties of hydrogels and gel’s thermal properties.

Chester et al. [94] numerically solved the coupled thermochemical–mechanical properties of elastic gels under isothermal conditions based on the commercial finite element software ABAQUS 6.10. Mazaheri et al. [95] also presented numerical and analytical solutions for temperature-sensitive FG micro-valves. They modeled cylindrical FG hydrogels with different crosslink densities along the radius. Furthermore, in another study, Mazaheri et al. [96] investigated the swelling of photo-thermal-sensitive cylindrical polyelectrolyte hydrogel micro-valves and proposed an analytical solution for the swelling of hydrogel cylinders under temperature variations and different light intensities. Ayra et al. [97] studied the behavior of a temperature-sensitive hydrogel microchannel. The researchers employed the finite element method (FEM) and computational fluid dynamics (CFD) to analyze the behavior of the microchannel under various operating conditions.

Boschetti et al. [98] proposed a three-dimensional lattice Boltzmann model to simulate the swelling properties of IPN (interpenetrating polymer network) hydrogel implants. In their study, they discussed in detail the implementation, experimental methodology, and computational procedure of the method and proved the validity of the multiple-relaxation-time lattice Boltzmann model (MRT LB model). In the same year, the group [99] used computational simulations using the lattice Boltzmann method to complement the assessment of the swelling behavior of hydrogel samples of cylindrical and parallel hexagonal shapes. Later, Boschetti et al. [100] utilized finite elements and FDM to simulate the free swelling of 3D hydrogels. Toro et al. [101] computationally simulated the dehydration behavior of IPN (interpenetrating polymer network) hydrogel tablets. Their study demonstrated that the computational fluid dynamics approach can effectively characterize the dehydration process of this hydrogel polymer.

Based on previous reviews, it could be concluded that CFD simulations allow for the analysis of the heat dissipation performance of hydrogel heat sink materials under specific conditions, such as heat conduction, convection and radiation. This helps to determine the optimal design and layout of the heat sink material to achieve higher thermal efficiency and lower temperatures.

4. Conclusions

In this review, the recent research progress of hydrogel sweat cooling has been summarized, including its use in electronic devices, building and clean-energy facilities. The principle of each application has been illustrated, the research status has been concluded, and pros and difficulties have been proposed. Subsequently, the development trend has been discussed, which might provide useful inspiration for future research. The pivotal findings of this review and areas for future investigation are concluded as follows:

- As a simple, efficient, affordable, and adaptive technology, hydrogel sweat cooling has emerged as an encouraging alternative to traditional cooling strategies. To certificate the necessity and indicate innovation and practicability of this technology, this review summarizes the recent research progress of hydrogel sweat cooling from the application direction, which might inspire innovation in multiphase flow cooling technology for future research.

- Although plenty of research has been conducted to improve the mechanical and thermal behavior of hydrogels during the cooling process, due to the increasing need for thermal management, this trend can never be halted, and novel hydrogels need to be developed from generation to generation. Based on the requirements of hydrogels used in the sweat cooling process, future research may focus on the influencing factors and how to produce hydrogels with higher thermal conductivity, better hydrophobicity, greater mechanical strength, and better environmental adaptability. In addition, the formation of composite hydrogels is encouraged. Based on previous reviews, compounding hydrogels with other good thermal behavior materials can also produce better thermal storage composites. Single and composite hydrogels both indicate high potential to be studied.

- Numerical studies on the hydrogel sweat cooling process, especially CFD simulations, may lead to enhanced high-performance hydrogel fabrication techniques. To improve the sweat cooling efficiency and find out which factors influence the performance of hydrogels, understanding the comprehensive heat transfer process is of paramount significance. Simultaneously, the CFD method is incredibly powerful as a target tool. However, based on previous reviews, the heat and mass transfer of this process is still in its initial stage. On the one hand, due to the fact that sweat cooling mainly depends on water evaporation, the comprehensive process involves multiphase flow heat transfer, and the corresponding numerical modeling is thus still a great challenge. On the other hand, due to its porous behavior, recognizing the heat and mass transfer inside the hydrogel is also troublesome. This is an interesting but challenging area; more research should thus be conducted in this field.

- To make hydrogels more practical, intelligent and controllable, enhancements should be explored. Currently, although some types of hydrogels show intelligent adaptive cooling effects, the controllability of hydrogel sweat cooling technology is still poor, which makes it difficult to meet the demands of complex application scenarios. Future research may introduce intelligent elements, such as the use of sensors and microprocessors to monitor and control the temperature and humidity of the hydrogel in real time, to achieve precise regulation of the cooling performance. In addition, the exploration of how to reduce the environmental impact of hydrogels during the production and use stages might also be a pragmatic issue. Because hydrogels are known as green materials, optimizing the production and use stages of hydrogels to make sure that these processes are completely clean is of vital importance for the green economy and sustainable development.

- To deeply and comprehensively analyze hydrogel sweat cooling, interdisciplinary integration is suggested, as it involves knowledge like material science, chemistry, physics, and biomedicine. Based on previous reviews, existing research mainly focuses on studying this process from one viewpoint. Future research might pay more attention to interdisciplinary integration, combining the advantages of different disciplines to jointly promote the development of hydrogels in the field of sweat cooling.

Author Contributions

Conceptualization, L.X. (Liang Xu) and J.L.; methodology, J.L.; validation, Y.L. and L.X. (Lei Xi); formal analysis, J.L.; investigation, J.L.; resources, L.X. (Liang Xu) and J.G.; data curation, J.L.; writing—original draft preparation, J.L.; writing—review and editing, L.X. (Liang Xu) and L.X. (Lei Xi); visualization, J.L.; supervision, Y.L. and L.X. (Liang Xu); project administration, J.G. and Y.L.; funding acquisition, L.X. (Liang Xu) and L.X. (Lei Xi). All authors have read and agreed to the published version of the manuscript.

Funding

This work was funded by the Natural Science Foundation of Shaanxi Province (2024JC-YBMS-345), the Fundamental Research Funds for the Central Universities (xzy022024097) and the China Postdoctoral Science Foundation (2021M702573).

Acknowledgments

This work was supported by the Natural Science Foundation of Shaanxi Province (2024JC-YBMS-345), the Fundamental Research Funds for the Central Universities (xzy022024097) and the China Postdoctoral Science Foundation (2021M702573).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ekka, J.P.; Kumar, D. A review of industrial food processing using solar dryers with heat storage systems. J. Stored Prod. Res. 2023, 101, 102090. [Google Scholar] [CrossRef]

- Mostafaeipour, A.; Bardel, B.; Mohammadi, K.; Sedaghat, A.; Dinpashoh, Y. Economic evaluation for cooling and ventilation of medicine storage warehouses utilizing wind catchers. Renew. Sustain. Energy Rev. 2014, 38, 12–19. [Google Scholar] [CrossRef]

- Palafox-Alcantar, P.G.; Khosla, R.; McElroy, C.; Miranda, N. Circular economy for cooling: A review to develop a systemic framework for production networks. J. Clean. Prod. 2022, 379, 134738. [Google Scholar] [CrossRef]

- Wang, H.; Xie, B.; Li, C. Review on operation control of cold thermal energy storage in cooling systems. Energy Built Environ. 2024. In Press. [Google Scholar] [CrossRef]

- Wang, J.-X.; Guo, W.; Xiong, K.; Wang, S.-N. Review of aerospace-oriented spray cooling technology. Prog. Aerosp. Sci. 2020, 116, 100635. [Google Scholar] [CrossRef]

- GaneshKumar, P.; Sivalingam, V.; Vigneswaran, V.S.; Ramalingam, V.; Seong Cheol, K.; Vanaraj, R. Spray cooling for hydrogen vehicle, electronic devices, solar and building (low temperature) applications: A state-of-art review. Renew. Sustain. Energy Rev. 2024, 189, 113931. [Google Scholar] [CrossRef]

- Hao, X.-Y.; Li, X.-B.; Zhang, H.-N.; Zhang, W.-H.; Li, F.-C. Review on multi-parameter simultaneous measurement techniques for multiphase flow—Part B: Basic physical parameters and phase characteristics. Measurement 2023, 220, 113397. [Google Scholar] [CrossRef]

- Li, H.; Zhang, W.; Hu, L.; Zhu, B.; Wang, F. Studies on Flow Characteristics of Gas–Liquid Multiphase Pumps Applied in Petroleum Transportation Engineering—A Review. Energies 2023, 16, 6292. [Google Scholar] [CrossRef]

- Chang, K.; Wang, Y.-Y.; Li, Y.-Z. A review of water sublimation cooling and water evaporation cooling in complex space environments. Prog. Aerosp. Sci. 2023, 140, 100930. [Google Scholar] [CrossRef]

- Wang, Q.; Li, S.; Wang, Z.; Liu, H.; Li, C. Preparation and Characterization of a Positive Thermoresponsive Hydrogel for Drug Loading and Release. J. Appl. Polym. Sci. 2009, 111, 1417–1425. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Khademhosseini, A. Advances in engineering hydrogels. Science 2017, 356, eaaf3627. [Google Scholar] [CrossRef]

- Dong, Y.; Ghasemzadeh, M.; Khorsandi, Z.; Sheibani, R.; Nasrollahzadeh, M. Starch-based hydrogels for environmental applications: A review. Int. J. Biol. Macromol. 2024, 269, 131956. [Google Scholar] [CrossRef] [PubMed]

- Mandal, S.; Chi, H.; Moss, R.E.; Dhital, P.; Babatunde, E.O.; Gurav, R.; Hwang, S. Seed gum-based polysaccharides hydrogels for sustainable agriculture: A review. Int. J. Biol. Macromol. 2024, 263, 130339. [Google Scholar] [CrossRef] [PubMed]

- Li, L.; Liu, Z.; Qi, R. Molecular dynamics simulations in hydrogel research and its applications in energy utilization: A review. Energy Rev. 2024, 3, 100072. [Google Scholar] [CrossRef]

- Jones-Jackson, S.; Rodriguez, R.; Yang, Y.; Lopera, L.; Emadi, A. Overview of Current Thermal Management of Automotive Power Electronics for Traction Purposes and Future Directions. IEEE Trans. Transp. Electrif. 2022, 8, 2412–2428. [Google Scholar] [CrossRef]

- Tianhu, W.; Zhigang, G.; Junhua, B.; Zhiqiang, W.; Keqiang, Q.; Peng, L.I. Thermal Performance of Mini Cooling Channels for High-Power Servo Motor with Non-Uniform Heat Dissipation. J. Therm. Sci. 2023, 32, 650–661. [Google Scholar]

- Pu, S.; Fu, J.; Liao, Y.; Ge, L.; Zhou, Y.; Zhang, S.; Zhao, S.; Liu, X.; Hu, X.; Liu, K.; et al. Promoting Energy Efficiency via a Self-Adaptive Evaporative Cooling Hydrogel. Adv. Mater. 2020, 32, 1907307. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Yu, J.; Wang, C.; Zeng, Z.; Poredoš, P.; Wang, R. Passive thermal management of electronic devices using sorption-based evaporative cooling. Device 2023, 1, 100122. [Google Scholar] [CrossRef]

- Zhang, Y.; Gao, J.; Zhu, S.; Li, J.; Lai, H.; Peng, Y.; Miao, L. Wearable Thermoelectric Cooler Based on a Two-Layer Hydrogel/Nickel Foam Heatsink with Two-Axis Flexibility. Acs Appl. Mater. Interfaces 2022, 14, 15317–15323. [Google Scholar] [CrossRef]

- Li, X.; Yao, R. Modelling heating and cooling energy demand for building stock using a hybrid approach. Energy Build. 2021, 235, 110740. [Google Scholar] [CrossRef]

- Faruk, M.O.; Ahmed, A.; Jalil, M.A.; Islam, M.T.; Shamim, A.M.; Adak, B.; Hossain, M.M.; Mukhopadhyay, S. Functional textiles and composite based wearable thermal devices for Joule heating: Progress and perspectives. Appl. Mater. Today 2021, 23, 101025. [Google Scholar] [CrossRef]

- Park, H.; Kim, D.; Eom, Y.; Wijethunge, D.; Hwang, J.; Kim, H.; Kim, W. Mat-like flexible thermoelectric system based on rigid inorganic bulk materials. J. Phys. D Appl. Phys. 2017, 50, 494006. [Google Scholar] [CrossRef]

- Liang, J.; Wang, T.; Qiu, P.; Yang, S.; Ming, C.; Chen, H.; Song, Q.; Zhao, K.; Wei, T.-R.; Ren, D.; et al. Flexible thermoelectrics: From silver chalcogenides to full-inorganic devices. Energy Environ. Sci. 2019, 12, 2983–2990. [Google Scholar] [CrossRef]

- Zhao, R.; Zhang, S.; Gu, J.; Liu, J.; Carkner, S.; Lanoue, E. An experimental study of lithium ion battery thermal management using flexible hydrogel films. J. Power Sources 2014, 255, 29–36. [Google Scholar] [CrossRef]

- Wu, N.; Ye, X.; Li, J.; Lin, B.; Zhou, X.; Yu, B. Passive thermal management systems employing hydrogel for the large-format lithium-ion cell: A systematic study. Energy 2021, 231, 120946. [Google Scholar] [CrossRef]

- Zhang, S.; Zhao, R.; Liu, J.; Gu, J. Investigation on a hydrogel based passive thermal management system for lithium ion batteries. Energy 2014, 68, 854–861. [Google Scholar] [CrossRef]

- Pu, S.; Liao, Y.; Chen, K.; Fu, J.; Zhang, S.; Ge, L.; Conta, G.; Bouzarif, S.; Cheng, T.; Hu, X.; et al. Thermogalvanic Hydrogel for Synchronous Evaporative Cooling and Low-Grade Heat Energy Harvesting. Nano Lett. 2020, 20, 3791–3797. [Google Scholar] [CrossRef] [PubMed]

- Jannesari, H.; Khalafi, V.; Mehryan, S.A.M. Experimental and numerical study of employing Potassium poly acrylate hydrogel for thermal management of 500 Wh cylindrical LiFePO4 battery pack. Energy Convers. Manag. 2019, 196, 581–590. [Google Scholar] [CrossRef]

- Mehryan, S.A.M.; Jannesari, H. Improving Li-ion battery thermal management via hydrogel evaporative cooling. Appl. Therm. Eng. 2024, 248, 123173. [Google Scholar] [CrossRef]

- Pu, S.; Su, J.; Li, L.; Wang, H.; Chen, C.; Hu, X. Bioinspired sweating with temperature sensitive hydrogel to passively dissipate heat from high-end wearable electronics. Energy Convers. Manag. 2019, 180, 747–756. [Google Scholar] [CrossRef]

- Zamengo, M.; Morikawa, J. Evaluation of cooling ability for a novel heat sink made of polyvinyl alcohol hydrogel. Int. J. Heat. Mass. Transf. 2019, 143, 118523. [Google Scholar] [CrossRef]

- Mu, X.; Shi, X.-L.; Zhou, J.; Chen, H.; Yang, T.; Wang, Y.; Miao, L.; Chen, Z.-G. Self-hygroscopic and smart color-changing hydrogels as coolers for improving energy conversion efficiency of electronics. Nano Energy 2023, 108, 108177. [Google Scholar] [CrossRef]

- Li, X.; Xuan, Y.; Li, Q. Self-adaptive chip cooling with template-fabricated nanocomposite P(MEO2MA-co-OEGMA) hydrogel. Int. J. Heat. Mass. Transf. 2021, 166, 120790. [Google Scholar] [CrossRef]

- Xie, L.; Wang, X.; Zou, X.; Bai, Z.; Liang, S.; Wei, C.; Zha, S.; Zheng, M.; Zhou, Y.; Yue, O.; et al. Engineering Self-Adaptive Multi-Response Thermochromic Hydrogel for Energy-Saving Smart Windows and Wearable Temperature-Sensing. Small 2023, 19, 2304321. [Google Scholar] [CrossRef]

- Zeng, J.; Zhang, X.; Chung, K.M.; Feng, T.; Zhang, H.; Prasher, R.S.; Chen, R. Moisture thermal battery with autonomous water harvesting for passive electronics cooling. Cell Rep. Phys. Sci. 2023, 4, 101250. [Google Scholar] [CrossRef]

- Jiang, M.; Xiao, C.; He, X.; Du, H.; Wang, Y.; Ding, X.; Zhang, X.; Li, X.; Zheng, K.; Liu, X.; et al. Skin mimicking-sweating evaporation polyimide cooling film for electronic devices. Sci. China Technol. Sci. 2023, 66, 2797–2807. [Google Scholar] [CrossRef]

- Pu, S.; Xia, Y.; Qiu, X.; Lu, C. Smart fin with automatic evaporation and regeneration for thermal management of high heat flux electronics. Case Stud. Therm. Eng. 2024, 56, 104271. [Google Scholar] [CrossRef]

- Zhao, B.; Yue, X.; Tian, Q.; Qiu, F.; Li, Y.; Zhang, T. Bio-inspired BC aerogel/PVA hydrogel bilayer gel for enhanced daytime sub-ambient building cooling. Cellulose 2022, 29, 7775–7787. [Google Scholar] [CrossRef]

- Fu, J.; Feng, C.; Liao, Y.; Mao, M.; Liu, H.; Liu, K. Broadband light management in hydrogel glass for energy efficient windows. Front. Optoelectron. 2022, 15, 33. [Google Scholar] [CrossRef]

- Gao, Y.; Liang, S.; Zhao, S.; Gao, W.; Li, Z.; Wang, M.; Li, H.; He, X.; Cong, R.; Diao, H.; et al. An intelligent cooling material modified with carbon dots for evaporative cooling and UV absorption. Nanoscale Adv. 2022, 4, 4169–4174. [Google Scholar] [CrossRef]

- Ishikawa, Y.; Saito, T.; Mitsusaka, I.; Oka, H.; Mizutani, K. Water Evaporative-Cooling Roof Wall Structure for Low-Load Type Building, Has Layered Structure, Which Includes Layer That Contains Hydrogel, Whose Outer Surface Receives Rain Water; Kohjin Co., Ltd.: Osaka, Japan, 2018. [Google Scholar]

- Lu, Z.; Strobach, E.; Chen, N.; Ferralis, N.; Grossman, J.C. Passive Sub-Ambient Cooling from a Transparent Evaporation-Insulation Bilayer. Joule 2020, 4, 2693–2701. [Google Scholar] [CrossRef]

- Kim, Y.S.; Liu, M.; Ishida, Y.; Ebina, Y.; Osada, M.; Sasaki, T.; Hikima, T.; Takata, M.; Aida, T. Thermoresponsive actuation enabled by permittivity switching in an electrostatically anisotropic hydrogel. Nat. Mater. 2015, 14, 1002–1007. [Google Scholar] [CrossRef] [PubMed]

- Rotzetter, A.C.C.; Schumacher, C.M.; Bubenhofer, S.B.; Grass, R.N.; Gerber, L.C.; Zeltner, M.; Stark, W.J. Thermoresponsive Polymer Induced Sweating Surfaces as an Efficient Way to Passively Cool Buildings. Adv. Mater. 2012, 24, 5352–5356. [Google Scholar] [CrossRef] [PubMed]

- Feng, C.; Yang, P.; Liu, H.; Mao, M.; Liu, Y.; Xue, T.; Fu, J.; Cheng, T.; Hu, X.; Fan, H.J.; et al. Bilayer porous polymer for efficient passive building cooling. Nano Energy 2021, 85, 105971. [Google Scholar] [CrossRef]

- Ji, Y.; Sun, Y.; Javed, M.; Xiao, Y.; Li, X.; Jin, K.; Cai, Z.; Xu, B. Skin inspired thermoresponsive polymer for constructing self-cooling system. Energy Convers. Manag. 2022, 254, 115251. [Google Scholar] [CrossRef]

- Galib, R.H.; Tian, Y.; Lei, Y.; Dang, S.; Li, X.; Yudhanto, A.; Lubineau, G.; Gan, Q. Atmospheric-moisture-induced polyacrylate hydrogels for hybrid passive cooling. Nat. Commun. 2023, 14, 6707. [Google Scholar] [CrossRef] [PubMed]

- Riaz, M.A.B.; Nasir, M.A.; Nauman, S.; Amin, S.; Mehmood, F.; Anwar, O.B.; Hafeez, O.; Abid, T. Passive cooling performance of polyacrylamide hydrogel on wooden and brick houses and effect of nanoparticle integration on its mechanical strength. Plast. Rubber Compos. 2021, 50, 340–350. [Google Scholar] [CrossRef]

- Yang, M.; Zou, W.; Luo, H.; Liu, Y.; Zhao, N.; Xu, J. Bright-white hydrogels for on-demand passive cooling. Sci. China Chem. 2023, 66, 1511–1519. [Google Scholar] [CrossRef]

- Mao, M.; Feng, C.; Pei, J.; Liu, H.; Jiang, H. A Triple-Layer Membrane with Hybrid Evaporation and Radiation for Building Cooling. Energies 2023, 16, 2750. [Google Scholar] [CrossRef]

- Shi, Y.; Ilic, O.; Atwater, H.A.; Greer, J.R. All-day fresh water harvesting by microstructured hydrogel membranes. Nat. Commun. 2021, 12, 2797. [Google Scholar] [CrossRef]

- Lei, C.; Guo, Y.; Guan, W.; Lu, H.; Shi, W.; Yu, G. Polyzwitterionic Hydrogels for Efficient Atmospheric Water Harvesting. Angew. Chem. 2022, 134, e202200271. [Google Scholar] [CrossRef]

- Li, Z.; Ma, T.; Ji, F.; Shan, H.; Dai, Y.; Wang, R. A Hygroscopic Composite Backplate Enabling Passive Cooling of Photovoltaic Panels. ACS Energy Lett. 2023, 8, 1921–1928. [Google Scholar] [CrossRef]

- Su, H.; Zhou, J.; Miao, L.; Shi, J.; Gu, Y.; Wang, P.; Tian, Y.; Mu, X.; Wei, A.; Huang, L.; et al. A hybrid hydrogel with protonated g-C3N4 and graphene oxide as an efficient absorber for solar steam evaporation. Sustain. Mater. Technol. 2019, 20, e00095. [Google Scholar] [CrossRef]

- Abdo, S.; Saidani-Scott, H.; Benedi, J.; Abdelrahman, M.A. Hydrogels beads for cooling solar panels: Experimental study. Renew. Energy 2020, 153, 777–786. [Google Scholar] [CrossRef]

- Lv, T.; Sun, L.; Yang, Y.; Huang, J. Bio-inspired hydrogel with all-weather adhesion, cooling and reusability functions for photovoltaic panels. Sol. Energy 2021, 216, 358–364. [Google Scholar] [CrossRef]

- Li, R.; Shi, Y.; Wu, M.; Hong, S.; Wang, P. Photovoltaic panel cooling by atmospheric water sorption–evaporation cycle. Nat. Sustain. 2020, 3, 636–643. [Google Scholar] [CrossRef]

- Zheng, X.; Bao, Y.; Huang, A.; Qin, G.; He, M. 3D printing double-layer hydrogel evaporator with surface structures for efficient solar steam generation. Sep. Purif. Technol. 2023, 306, 122741. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Z.; Wang, Z.; Sun, W.; Kong, F. Photovoltaic passive cooling via water vapor sorption-evaporation by hydrogel. Appl. Therm. Eng. 2024, 240, 122185. [Google Scholar] [CrossRef]

- Hasan, A.; Sarwar, J.; Alnoman, H.; Abdelbaqi, S. Yearly energy performance of a photovoltaic-phase change material (PV-PCM) system in hot climate. Sol. Energy 2017, 146, 417–429. [Google Scholar] [CrossRef]

- Yin, X.; Ren, J.; Lan, W.; Chen, Y.; Ouyang, M.; Su, H.; Zhang, L.; Zhu, J.; Zhang, C. Microfluidics-assisted optimization of highly adhesive haemostatic hydrogel coating for arterial puncture. Bioact. Mater. 2022, 12, 133–142. [Google Scholar] [CrossRef]

- Peng, B.; Yu, S.; Li, J.; Xing, J. Droplet photopolymerization as new strategy for the rapid preparation of hydrogel beads for malachite green removal. Sep. Purif. Technol. 2024, 342, 127013. [Google Scholar] [CrossRef]

- Park, H.; Guo, X.; Temenoff, J.S.; Tabata, Y.; Caplan, A.I.; Kasper, F.K.; Mikos, A.G. Effect of swelling ratio of injectable hydrogel composites on chondrogenic differentiation of encapsulated rabbit marrow mesenchymal stem cells in vitro. Biomacromolecules 2009, 10, 541–546. [Google Scholar] [CrossRef] [PubMed]

- Deng, Z.; Liu, P.-F.; Zhou, J.; Miao, L.; Peng, Y.; Su, H.; Wang, P.; Wang, X.; Cao, W.; Jiang, F.; et al. A Novel Ink-Stained Paper for Solar Heavy Metal Treatment and Desalination. Sol. Rrl 2018, 2, 1800073. [Google Scholar] [CrossRef]

- Xin, F.; Lyu, Q. A Review on Thermal Properties of Hydrogels for Electronic Devices Applications. Gels 2023, 9, 7. [Google Scholar] [CrossRef]

- Sun, Y.; Gao, J.; Liu, Y.; Kang, H.; Xie, M.; Wu, F.; Qiu, H. Copper sulfide-macroporous polyacrylamide hydrogel for solar steam generation. Chem. Eng. Sci. 2019, 207, 516–526. [Google Scholar] [CrossRef]

- Zhao, X.; Liu, C. Overcoming salt crystallization with ionic hydrogel for accelerating solar evaporation. Desalination 2020, 482, 114385. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, Z.; Mu, X.; Zhang, J.; Wang, P.; Chen, Y.; Wang, X.; Gao, J.; Miao, L.; Sun, L. Highly efficient and long-term stable solar-driven water purification through a rechargeable hydrogel evaporator. Desalination 2022, 537, 115872. [Google Scholar] [CrossRef]

- Lv, B.; Song, C.; Liu, Y.; Xu, Y.; Fan, X. A novel, flexible porous nanofibrous hydrogel interfacial solar evaporator for highly efficient seawater and wastewater purification. Chemosphere 2022, 309, 136818. [Google Scholar] [CrossRef] [PubMed]

- Jia, C.L.; Tang, K. A Temperature-Sensitive Hydrogel for Suppressing Oil Fire. Adv. Mater. Res. 2013, 785-786, 724–728. [Google Scholar] [CrossRef]

- Xu, L.; Sun, D.-W.; Tian, Y.; Zhu, Z. Minimizing polyphenols and enzymes degradation using hydrogel packaging with combined evaporative and daytime radiative cooling functions during ambient transportation. Food Chem. 2024, 437, 137804. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, H.; Hou, Z.; Chen, Q.; Xie, Z.; Zhu, J.; Xu, J.; Zhang, L. Light-responsive bilayered hydrogel for freshwater production from surface soil moisture. EcoMat 2021, 3, e12144. [Google Scholar] [CrossRef]

- Liu, L.; Dou, Q.; Sun, Y.; Lu, Y.; Zhang, Q.; Meng, J.; Zhang, X.; Shi, S.; Yan, X. A moisture absorbing gel electrolyte enables aqueous and flexible supercapacitors operating at high temperatures. J. Mater. Chem. A 2019, 7, 20398–20404. [Google Scholar] [CrossRef]

- Mathesan, S.; Rath, A.; Ghosh, P. Molecular mechanisms in deformation of cross-linked hydrogel nanocomposite. Mater. Sci. Eng. C 2016, 59, 157–167. [Google Scholar] [CrossRef] [PubMed]

- Nesovic, K.; Abudabbus, M.M.; Rhee, K.Y.; Miskovic-Stankovic, V. Graphene Based Composite Hydrogel for Biomedical Applications. Croat. Chem. Acta 2017, 90, 207–213. [Google Scholar] [CrossRef]

- Gu, Z.; Xie, J.; Zhao, Y. Hydrogel Material Used for Skin Radiation Protection, Comprises Carbon Nanoparticles and Sodium Hyaluronate Hydrogel; National Center for Nanoscience and Technology, China: Beijing, China, 2020. [Google Scholar]

- Kim, H.; Song, H.; Cakmakci, N.; Kang, H.; Park, J.; Shin, M.; Jeong, Y. A Flexible Supercapacitor Prepared with Surface Modified Carbon Nanotube Film Electrode and Hydrogel Electrolyte. Fibers Polym. 2021, 22, 2673–2679. [Google Scholar] [CrossRef]

- Lu, H.; Shi, W.; Zhang, J.H.; Chen, A.C.; Guan, W.; Lei, C.; Greer, J.R.; Boriskina, S.V.; Yu, G. Tailoring the Desorption Behavior of Hygroscopic Gels for Atmospheric Water Harvesting in Arid Climates. Adv. Mater. 2022, 34, 2205344. [Google Scholar] [CrossRef] [PubMed]

- Dubey, D.K.; Tomar, V. Role of hydroxyapatite crystal shape in nanoscale mechanical behavior of model tropocollagen–hydroxyapatite hard biomaterials. Mater. Sci. Eng. C 2009, 29, 2133–2140. [Google Scholar] [CrossRef]

- Wu, C.J.; Gaharwar, A.K.; Chan, B.K.; Schmidt, G. Mechanically tough Pluronic F127/Laponite nanocomposite hydrogels from covalently and physically cross-linked networks. Macromolecules 2011, 44, 8215–8224. [Google Scholar] [CrossRef]

- Xu, J.; Chen, X.; Yang, G.; Niu, X.; Chang, F.; Lacidogna, G. Review of research on micromechanical properties of cement-based materials based on molecular dynamics simulation. Constr. Build. Mater. 2021, 312, 125389. [Google Scholar] [CrossRef]

- Maximiano, P.; Durães, L.; Simões, P. Overview of Multiscale Molecular Modeling and Simulation of Silica Aerogels. Ind. Eng. Chem. Res. 2019, 58, 18905–18929. [Google Scholar] [CrossRef]

- Tang, N.; Peng, Z.; Guo, R.; An, M.; Chen, X.; Li, X.; Yang, N.; Zang, J. Thermal Transport in Soft PAAm Hydrogels. Polymers 2017, 9, 688. [Google Scholar] [CrossRef]

- Xu, S.; Cai, S.; Liu, Z. Thermal Conductivity of Polyacrylamide Hydrogels at the Nanoscale. ACS Appl. Mater. Interfaces 2018, 10, 36352–36360. [Google Scholar] [CrossRef] [PubMed]

- An, M.; Demir, B.; Wan, X.; Meng, H.; Yang, N.; Walsh, T.R. Predictions of Thermo-Mechanical Properties of Cross-Linked Polyacrylamide Hydrogels Using Molecular Simulations. Adv. Theory Simul. 2019, 2, 1800153. [Google Scholar] [CrossRef]

- Alegre-Requena, J.V.; Saldias, C.; Inostroza-Rivera, R.; Diaz Diaz, D. Understanding hydrogelation processes through molecular dynamics. J. Mater. Chem. B 2019, 7, 1652–1673. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, R.; Zhou, B.; Dong, Y.; Liu, D. Rational Design of DNA Hydrogels Based on Molecular Dynamics of Polymers. Adv. Mater. 2024, 36, 2307129. [Google Scholar] [CrossRef] [PubMed]

- Mercado-Montijo, J.; Anstine, D.M.; Rukmani, S.J.; Colina, C.M.; Andrew, J.S. PEGDA hydrogel structure from semi-dilute concentrations: Insights from experiments and molecular simulations. Soft Matter 2022, 18, 3565–3574. [Google Scholar] [CrossRef] [PubMed]

- Duan, S.; Liu, Z.; Wu, S.; Hua, M.; He, X. Tuning structural and mechanical anisotropy of PVA hydrogels. Mech. Mater. 2022, 172, 104411. [Google Scholar] [CrossRef]

- Dehkordi, N.K.; Shojaei, S.; Asefnejad, A.; Hassani, K.; Benisi, S.Z. The effect of three types of cross-linked hydrogels and volume fraction of polyacrylamide on the swelling and thermal behavior using molecular dynamics simulation. J. Mater. Res. Technol. 2023, 24, 4627–4638. [Google Scholar] [CrossRef]

- Liu, F.; Wu, D.; Hong, W. Mechanism Study on Mechanical Properties of Physical–Chemical Hybrid Hydrogels by Coarse-Grained Molecular Dynamics Simulations. ACS Appl. Polym. Mater. 2023, 5, 1707–1714. [Google Scholar] [CrossRef]

- Lee, S.; Son, M.; Lee, J.; Byun, I.; Kim, J.-W.; Kim, J.; Seonwoo, H. Computational Fluid Dynamics Analysis and Empirical Evaluation of Carboxymethylcellulose/Alginate 3D Bioprinting Inks for Screw-Based Microextrusion. Polymers 2024, 16, 1137. [Google Scholar] [CrossRef]

- Yan, Y.; He, Z.; Wu, G.; Xu, F.; Li, L.; Zhang, L. Automatically adaptive cooling of hotspots by a fractal microchannel heat sink embedded with thermo-responsive hydrogels. Int. J. Energy Res. 2022, 46, 3132–3144. [Google Scholar] [CrossRef]

- Chester, S.A.; Di Leo, C.V.; Anand, L. A finite element implementation of a coupled diffusion-deformation theory for elastomeric gels. Int. J. Solids Struct. 2015, 52, 1–18. [Google Scholar] [CrossRef]

- Namdar, A.H.; Mazaheri, H. Kinetics of Swelling of Cylindrical Temperature-Responsive Hydrogel: A Semi-Analytical Study. Int. J. Appl. Mech. 2020, 12, 2050090. [Google Scholar] [CrossRef]

- Mazaheri, H.; Khodabandehloo, A. FSI and non-FSI studies on a functionally graded temperature-responsive hydrogel bilayer in a micro-channel. Smart Mater. Struct. 2022, 31, 015007. [Google Scholar] [CrossRef]

- Amiri, A.; Mazaheri, H. Study on the behavior of a temperature-sensitive hydrogel micro-channel via FSI and non-FSI approaches. Acta Mech. 2020, 231, 2799–2813. [Google Scholar] [CrossRef]

- Boschetti, P.J.; Pelliccioni, O.; Da Costa, K.; Sabino, M.A. Lattice Boltzmann simulation of swelling of an implant for microtia manufactured with IPN hydrogel. Comput. Methods Biomech. Biomed. Eng. 2020, 23, 491–499. [Google Scholar] [CrossRef]

- Boschetti, P.J.; Pelliccioni, O.; Sabino, M.A.; Vera, N.; Ontiveros, A.; Pappaterra, M.F. Swelling behavior of IPN and copolymer hydrogels by lattice Boltzmann method. In Proceedings of the AIAA Scitech 2020 Forum, Orlando, FL, USA, 6–10 January 2020; p. 13. [Google Scholar]

- Boschetti, P.J.; Toro, D.J.; Ontiveros, A.; Pelliccioni, O.; Sabino, M.A. Lattice Boltzmann method simulations of swelling of cuboid-shaped IPN hydrogel tablets with experimental validation. Heat Mass Transf. 2022, 58, 763–777. [Google Scholar] [CrossRef]

- Toro, D.J.; Boschetti, P.J.; Vera, N.; Pelliccioni, O.; Sabino, M.A. The Deswelling of IPN Hydrogel Tablets by Lattice Boltzmann Method. Transp. Porous Media 2023, 148, 559–576. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).