The Applications and Challenges of Nanofluids as Coolants in Data Centers: A Review

Abstract

1. Introduction

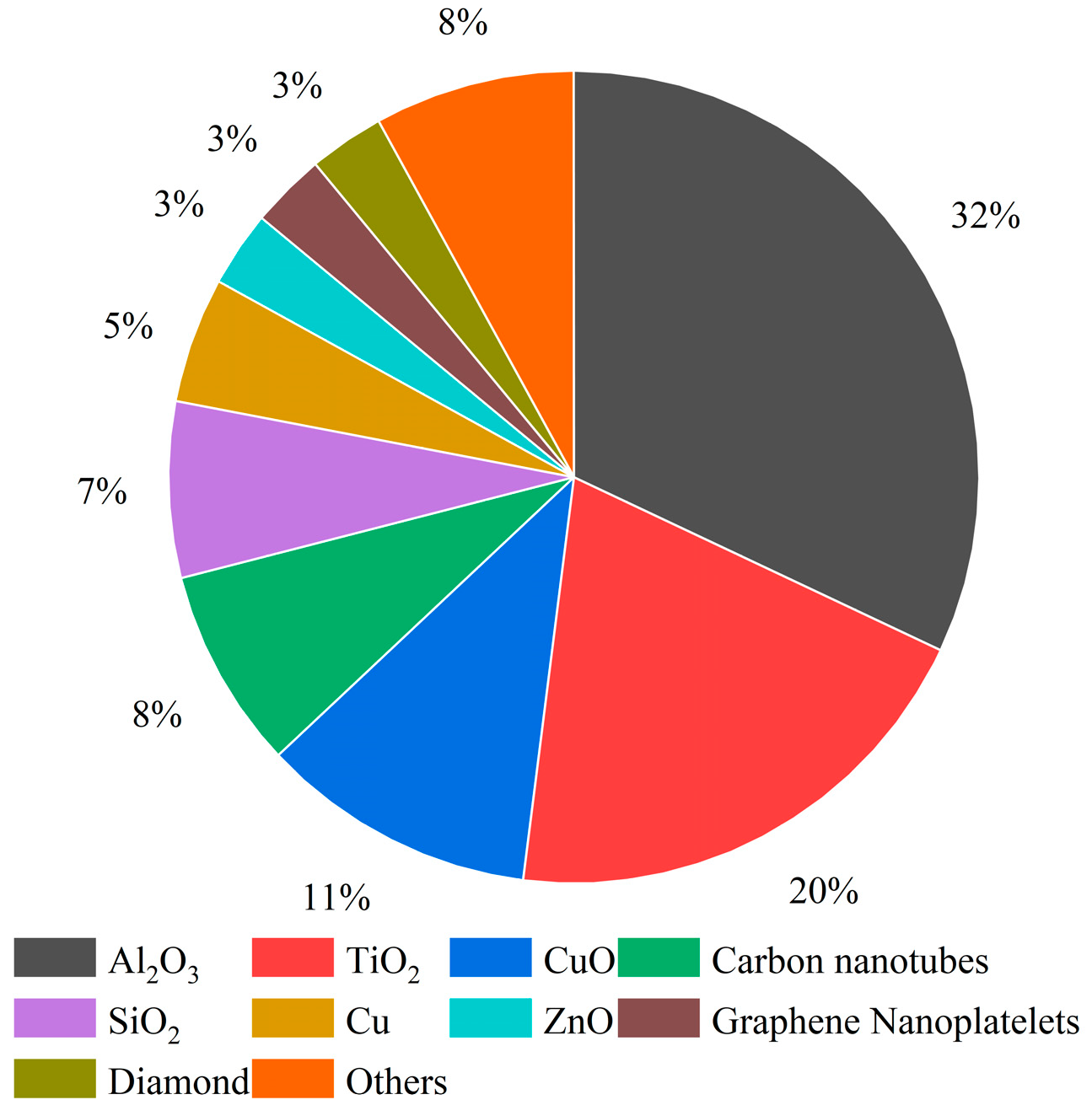

2. Types of Nanofluids Used in Liquid Cooling

2.1. Metal Nanoparticles

2.2. Metal Oxide Nanoparticles

2.3. Non-Metallic Nanoparticles

2.4. Magnetic Nanoparticles

3. Experimental Studies of Liquid Cooling with Nanofluids

3.1. Thermophysical Properties and Rheological Properties of Nanofluids

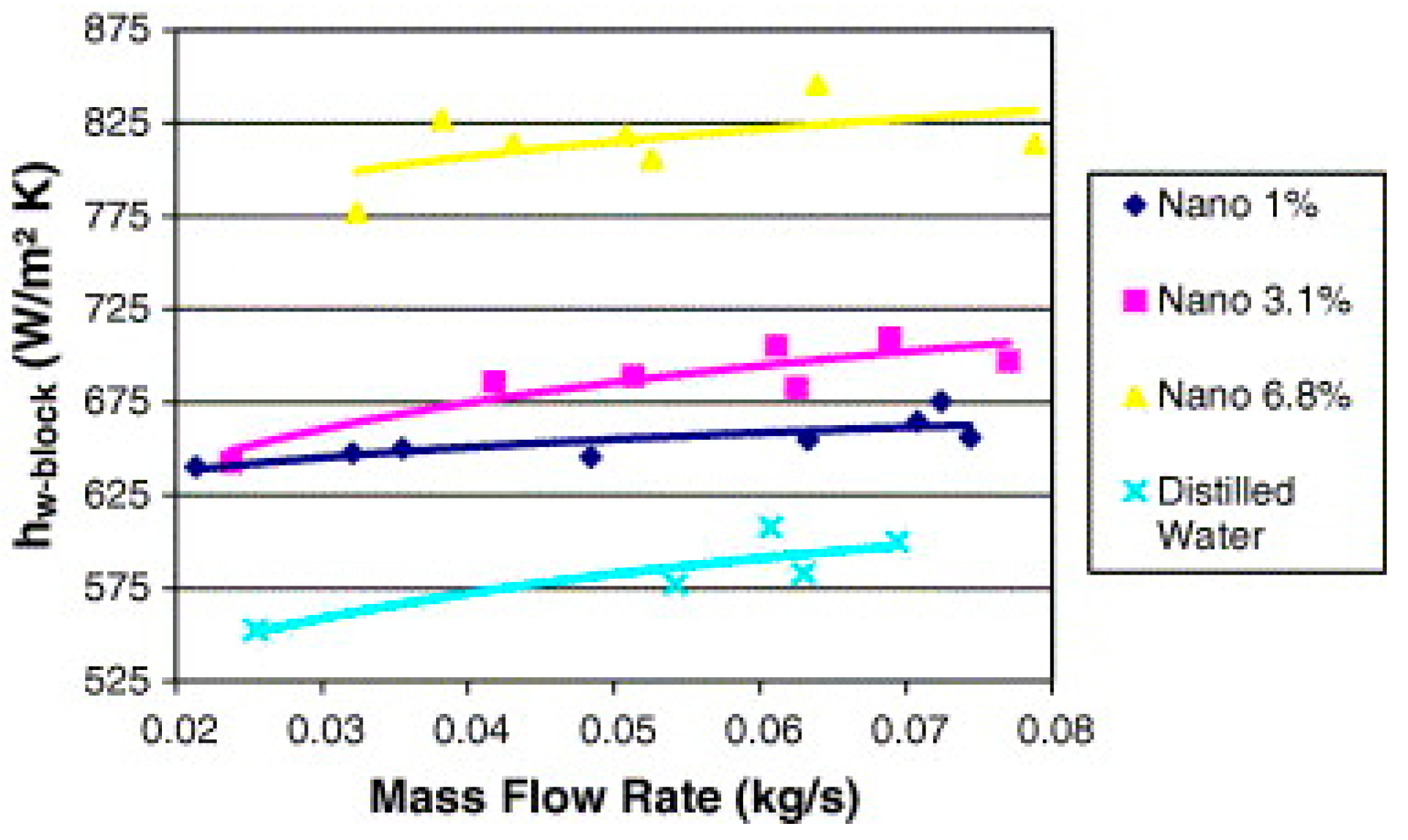

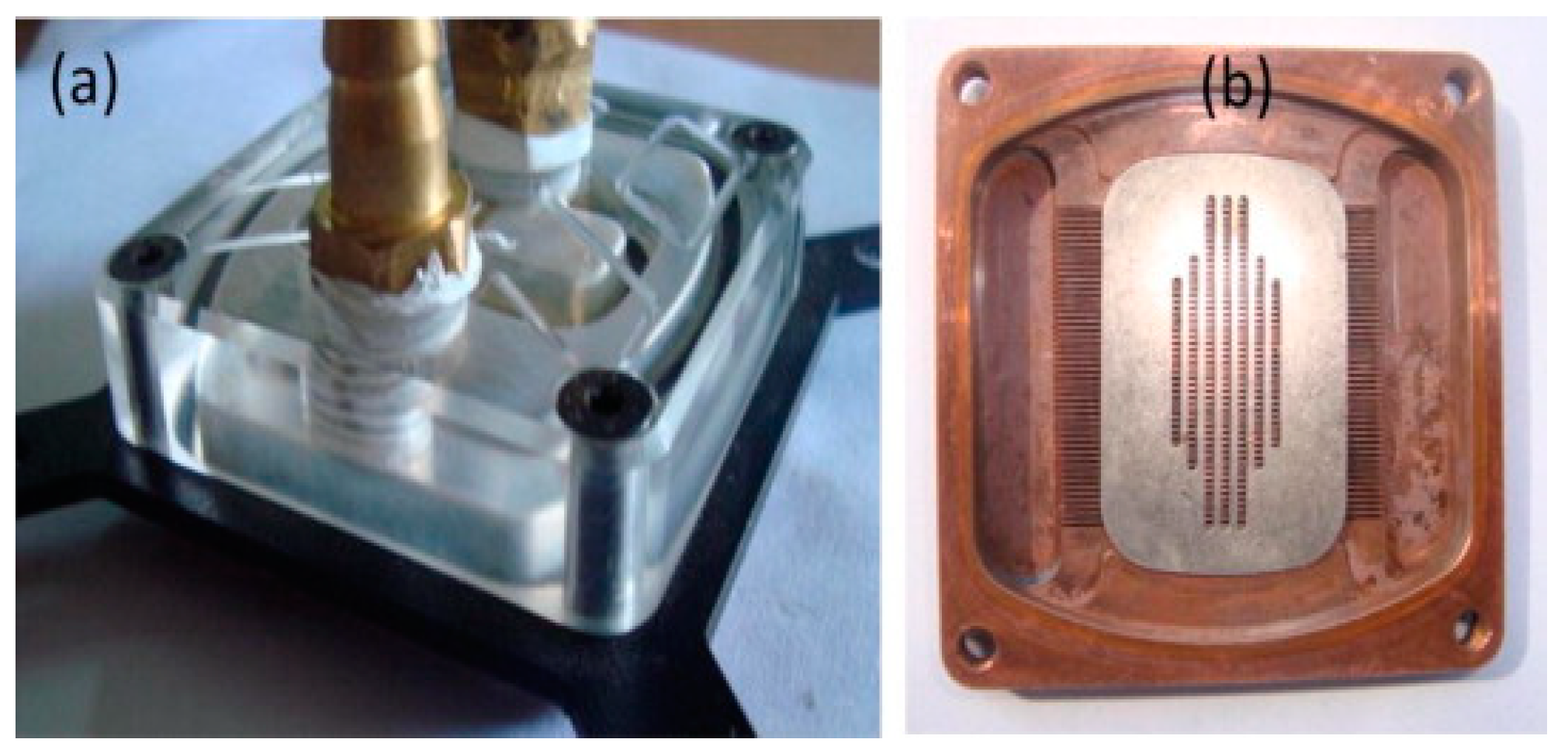

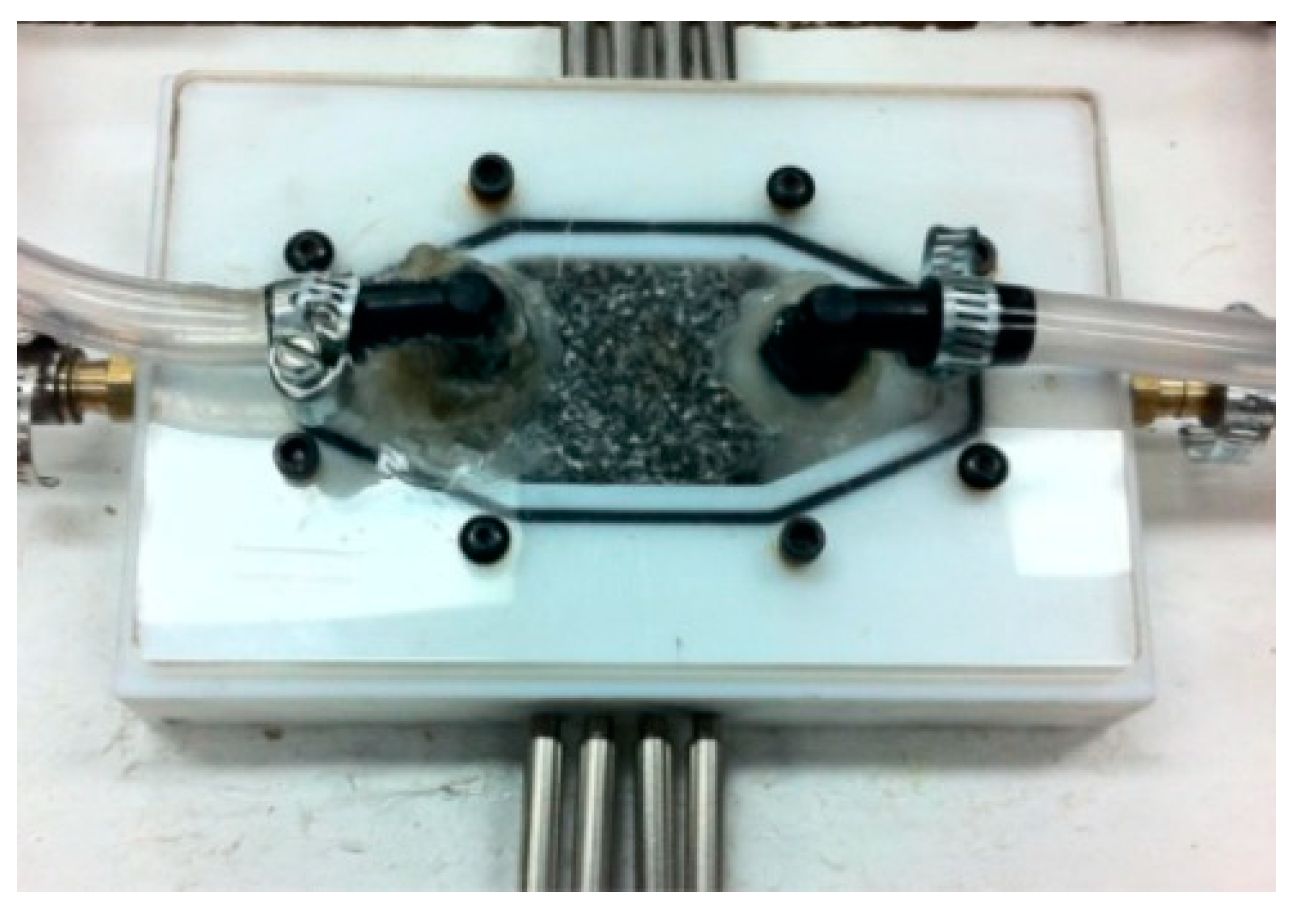

3.2. Nanofluids as Coolant in Microchannel Heat Sinks

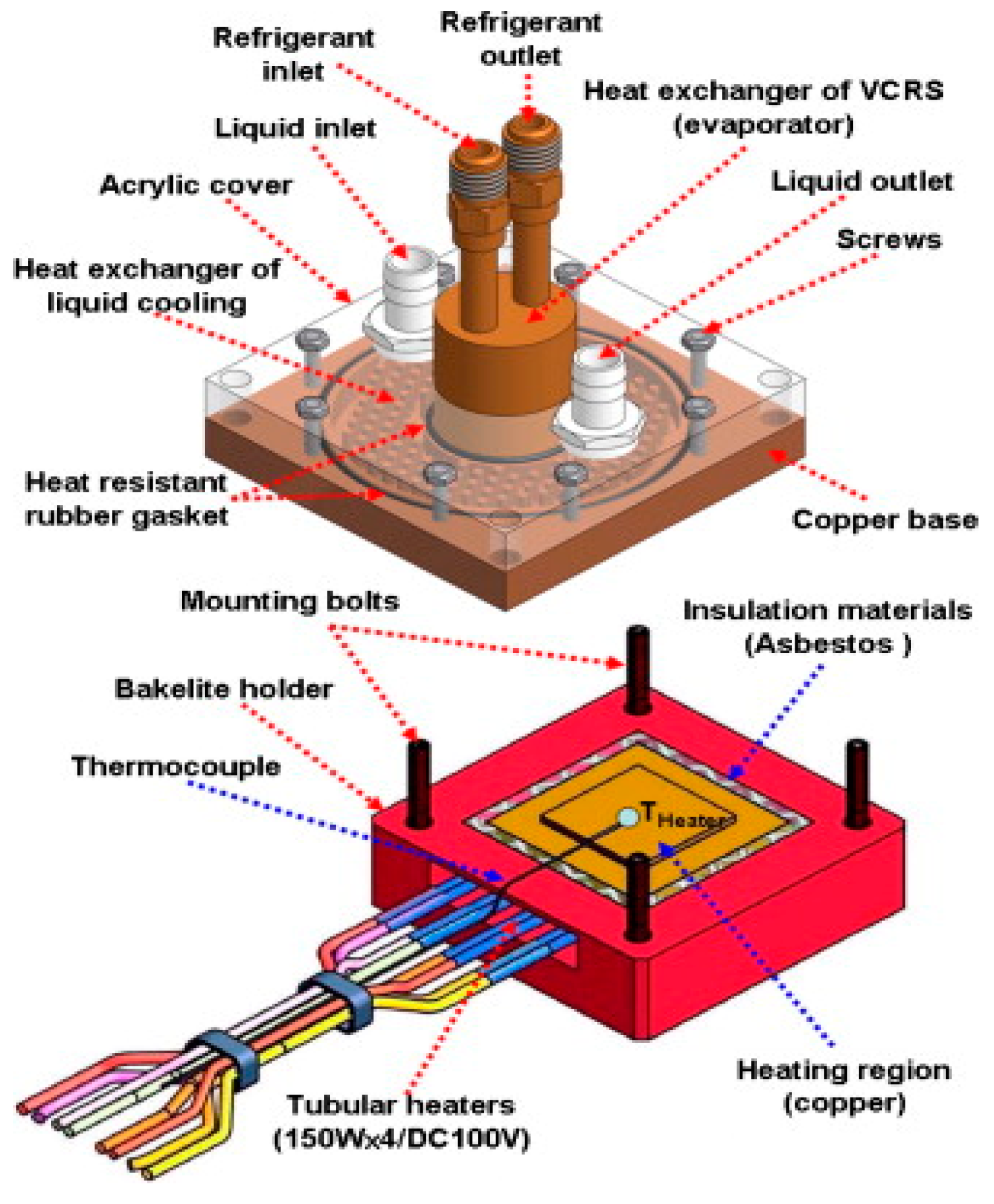

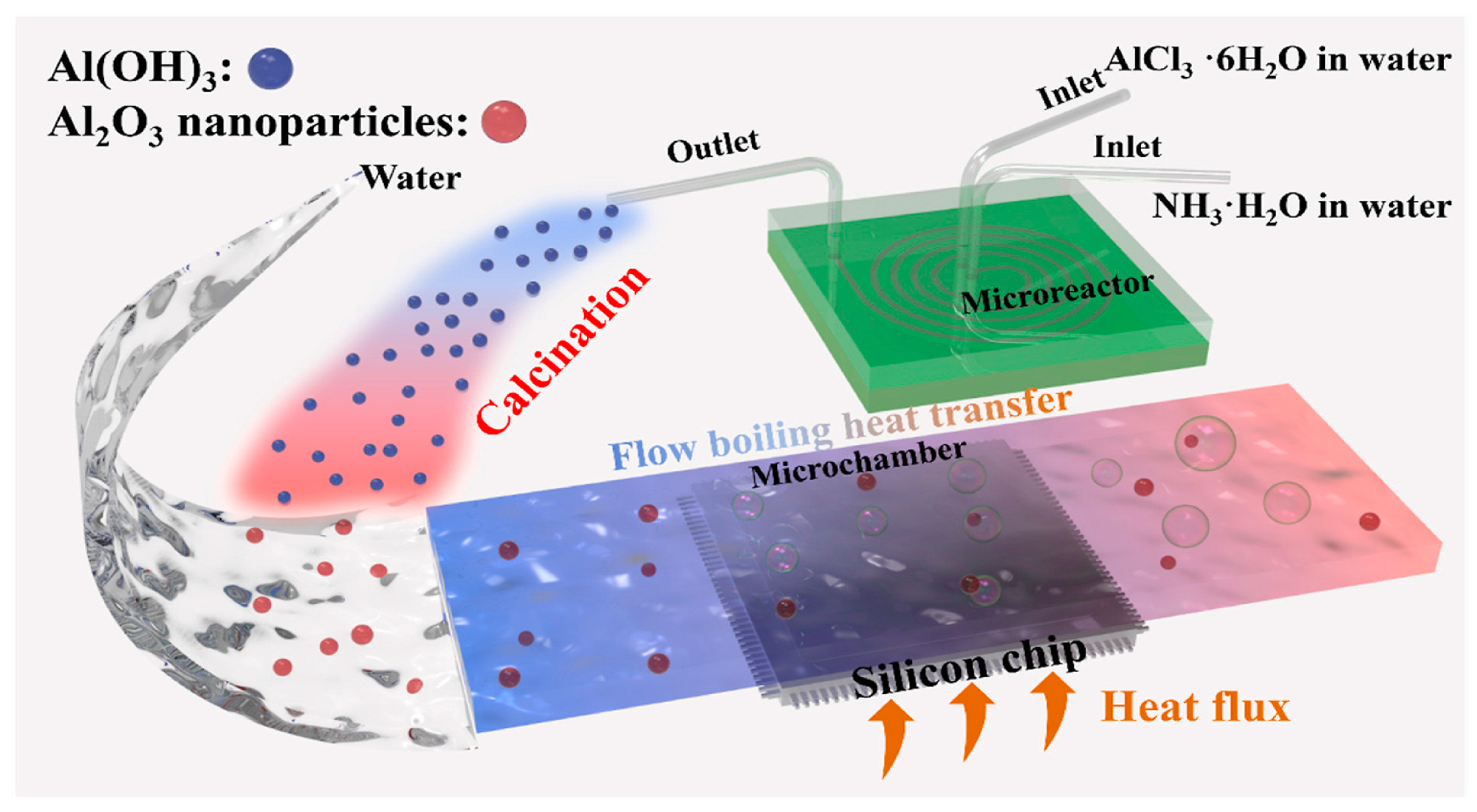

3.3. Phase Change Heat Transfer of Nanofluids

4. Simulations and Theoretical Studies of Liquid Cooling with Nanofluids

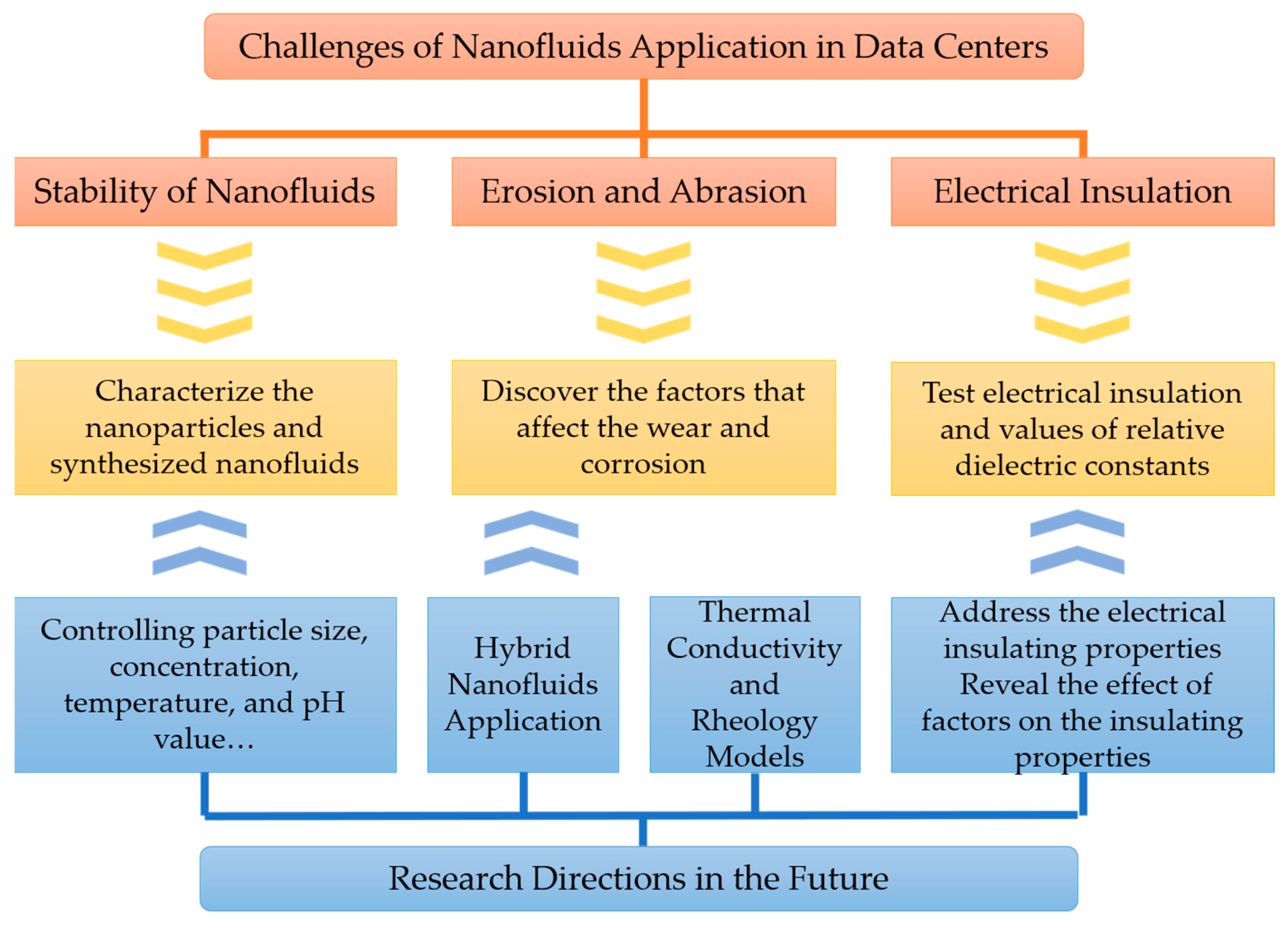

5. The Challenges of Nanofluids Application in Data Centers

5.1. Stability of Nanofluids

5.2. The Erosion and Abrasion of Nanofluids

5.3. Electrical Insulation of Nanofluids

6. Research Directions in the Future

6.1. Nanofluids Stability Improvement

6.2. Hybrid Nanofluids Application

6.3. Reversal of Erosion and Abrasion in the Application of Nanofluids

6.4. Thermal Conductivity Models and Rheology Models

6.5. Electrical Conductivity Characteristics

7. Conclusions and Perspectives

- Numerous studies have demonstrated that the thermal conductivity of nanofluids can be greatly enhanced by incorporating nanoparticles. These studies confirm the enormous potential of nanofluids as data center coolants. The current studies only focus on the nanofluids themselves, lacking evaluation of their effectiveness in cooling systems;

- Different types of nanofluids, including metal, metal oxide, non-metallic, and magnetic nanofluids, and various cooling systems, such as microchannel heat sinks, have been analyzed in different categories. There are different techniques to investigate the application of nanofluids in data centers, including experimental research, numerical simulation, and theoretical models;

- Currently, there is a significant amount of research focused on the thermal and physical characteristics of nanofluids, including their specific heat and thermal conductivity. However, there has been relatively limited investigation into the rheological properties of nanofluids. This article focuses on the analysis of the thermal and physical characteristics as well as the rheological parameters of commonly used nanofluids such as Al2O3, TiO2, and CuO and compares them with traditional coolants. Nanofluids can significantly improve thermal conductivity, while some studies suggest that nanofluids do not cause an obvious increase in viscosity;

- The literature suggests that using nanofluids as coolants in data centers presents some challenges, including the stability of nanofluids, particle erosion and wear on electronic devices and solid surfaces, and the limitations of nanofluid electrical conductivity. Among these, the stability of nanofluids has significant limitations on their use in data center liquid cooling. Hence, it is essential to uncover the factors influencing the stability of nanofluids, enhance production techniques for nanofluids, and ultimately boost the stability of nanofluids;

- Finally, concerning the potential areas for future investigation into the application of nanofluids as cooling agents in data centers, our article proposes following five suggestions, including improving their stability, employing hybrid nanofluids, developing more accurate thermal conductivity and rheology models, and decreasing electrical conductivity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| Al2O3 | Aluminum oxide |

| AgO | Silver oxide |

| Cu | Cuprum |

| CuO | Copper oxide |

| CFD | Computational fluid dynamics |

| CNT | Carbon nanotubes |

| EG | Ethylene glycol |

| Fe2O3 | Ferric oxide |

| Fe3O4 | Ferric oxide |

| MWCNT | Multiwalled carbon nanotube |

| SiC | Silicon carbide |

| SiO2 | Silicon dioxide |

| SWCNT | Single-walled carbon nanotube |

| TiO2 | Titanium oxide |

| Zn | Zinc |

| ZnO | Zinc oxide |

| Symbols | |

| Nanofluid thermal conductivity (W/m·K) | |

| Base fluid thermal conductivity (W/m·K) | |

| Nanoparticle thermal conductivity (W/m·K) | |

| K | Heat transfer coefficient (W/(m²·K)) |

| L | Nanoparticle length (nm) |

| Nanoparticle diameter (nm) | |

| n | Shape factor |

| Constant | |

| Constant | |

| Nanofluid viscosity (Pa·s) | |

| Base fluid viscosity (Pa·s) | |

| Density (g/cm3) | |

| Nanofluid volume fraction | |

| Sphericity degree | |

References

- Luo, Y.; Andrensen, J.; Clarke, H.; Rajendra, M.; Maroto-Valer, M. A decision support system for waste heat recovery and energy efficiency improvement in data centres. Appl. Energy 2019, 250, 1217–1224. [Google Scholar] [CrossRef]

- Kanbur, B.B.; Wu, C.L.; Duan, F. Multi-criteria thermoeconomic and thermodynamic assessments of the desalination-integrated two-phase liquid-immersion data center cooling system. Int. J. Energy. Res. 2020, 44, 10453–10470. [Google Scholar] [CrossRef]

- Hua, C.; Wen, L.C.; Wei, W.Z.; Yu, H.P.; Li, J.J. Energy saving evaluation of a novel energy system based on spray cooling for supercomputer center. Energy 2017, 141, 304–315. [Google Scholar]

- Zhou, W.; Dong, K.; Sun, Q.; Luo, W.; Zhang, B.; Guan, S.; Wang, G. Research progress of the liquid cold plate cooling technology for server electronic chips: A review. Int. J. Energy Res. 2022, 46, 11574–11595. [Google Scholar] [CrossRef]

- Jones, N. The information factories. Nature 2018, 561, 163–166. [Google Scholar] [CrossRef] [PubMed]

- Jin, C.; Bai, X. The study of servers’ arrangement and air distribution strategy under partial load in data centers. Sust. Cities Soc. 2019, 49, 101617. [Google Scholar] [CrossRef]

- Oro, E.; Depoorter, V.; Garcia, A.; Salom, J. Energy efficiency and renewable energy integration in data centres: Strategies and modeling review. Renew. Sust. Energy Rev. 2015, 42, 429–445. [Google Scholar] [CrossRef]

- Rong, H.; Zhang, H.; Xiao, S.; Li, C.; Hu, C. Optimizing energy consumption for data centers. Renew. Sust. Energy Rev. 2016, 58, 674–691. [Google Scholar] [CrossRef]

- Ding, T.; Chen, X.; Cao, H.; He, Z.; Wang, J.; Li, Z. Principles of loop thermosyphon and its application in data center cooling systems: A review. Renew. Sust. Energy Rev. 2021, 150, 111389. [Google Scholar] [CrossRef]

- Greenberg, S.; Mill, E.; Tschudi, B.; Rumsey, P.; Myatt, B. Best practices for data centers: Lessons learned from benchmarking 22 data centers. In Proceedings of the 14th ACEEE Summer Study on Energy Efficiency in Buildings, Pacific Grove, CA, USA, 13–18 August 2006. [Google Scholar]

- Ebrahimi, K.; Jones, G.F.; Fleischer, A.S. A review of data center cooling technology, operating conditions and the corresponding low-grade waste heat recovery opportunities. Renew. Sust. Energy Rev. 2014, 31, 622–638. [Google Scholar] [CrossRef]

- Afsharpanah, F.; Cheraghian, G.; Akbarzadeh, H.F.; Shokri, E.; Mousavi, A.S.S. Utilization of Carbon-Based Nanomaterials and Plate-Fin Networks in a Cold PCM Container with Application in Air Conditioning of Buildings. Nanomaterials 2022, 12, 1927. [Google Scholar] [CrossRef] [PubMed]

- Hassan, O.; Seyed, S.S.A.; Mohamadreza, E. Development on evacuated tube solar collectors: A review of the last decade results of using nanofluids. Sol. Energy 2020, 211, 265–282. [Google Scholar]

- Mousavi, A.S.S.; Mojtaba, S.; Saman, R.; Li, K.B.L. Heat transfer performance of a nanofluid-filled tube with wall corrugations and center-cleared twisted-tape inserts. Energy Source Part A 2020, 2020, 1841860. [Google Scholar]

- Mohammad, Z.; Seyfolah, S.; Seyed, S.M.A.; Mehdi, N. Numerical evaluation of the heat transfer in a shell and corrugated coil tube heat exchanger with three various water-based nanofluids. Heat Transf. 2021, 50, 6043–6067. [Google Scholar]

- Saboura, Y.; Mostafa, M.; Seyed, S.M.A.; Mohsen, S. Hydrothermal behavior of nanofluid flow in a microscale backward-facing step equipped with dimples and ribs; Lattice Boltzmann method approach. Therm. Sci. Eng. Prog. 2023, 43, 101987. [Google Scholar]

- Mohammad, Z.; Mousavi, A.S.S.; Seyfolah, S.; Behnam, K. Hybrid nanofluid flow and heat transfer in a parabolic trough solar collector with inner helical axial fins as turbulator. Eur. Phys. J. Plus 2021, 136, 841. [Google Scholar]

- Farzam, A.H.; Seyed, S.M.A.; Seyed, A.H. Numerical evaluation of the effect of geometrical and operational parameters on thermal performance of nanofluid flow in convergent–divergent tube. J. Therm. Anal. Calorim. 2020, 140, 1483–1505. [Google Scholar]

- Seyed, S.M.A.; Mohammad, Z.; Mehdi, N. Numerical evaluation of turbulence heat transfer and fluid flow of hybrid nanofluids in a pipe with innovative vortex generator. J. Therm. Anal. Calorim. 2021, 143, 1583–1597. [Google Scholar]

- Shchegolkov, A.V.; Shchegolkov, A.V. Synthesis of Carbon Nanotubes Using Microwave Radiation: Technology, Properties, and Structure. Russ. J. Gen. Chem. 2022, 92, 1168–1172. [Google Scholar] [CrossRef]

- Sardarabadi, H.; Heris, S.Z.; Ahmadpour, A.; Passandideh, F.M. Experimental investigation of a novel type of two-phase closed thermosyphon filled with functionalized carbon nanotubes/water nanofluids for electronic cooling application. Energy Convers. Manag. 2019, 188, 321–332. [Google Scholar] [CrossRef]

- Zhao, N.; Guo, L.; Qi, C.; Chen, T.; Cui, X. Experimental study on thermo-hydraulic performance of nanofluids in CPU heat sink with rectangular grooves and cylindrical bugles based on exergy efficiency. Energy Convers. Manag. 2019, 181, 235–246. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, Z.; Zheng, B. A new 3D chip cooling technology using micro-channels thermosyphon with super-moist fluids and nanofluids. Energy Convers. Manag. 2016, 128, 44–56. [Google Scholar] [CrossRef]

- Tang, H.; Tang, Y.; Zhuang, B.; Chen, G.; Zhang, S. Experimental investigation of the thermal performance of heat pipes with double-ended heating and middle–cooling. Energy Convers. Manag. 2017, 148, 1332–1345. [Google Scholar] [CrossRef]

- Zhao, N.; Qi, C.; Chen, T.; Tang, J.; Cui, X. Experimental study on influences of cylindrical grooves on thermal efficiency, exergy efficiency and entropy generation of CPU cooled by nanofluids. Int. J. Heat Mass. Tran. 2019, 135, 16–32. [Google Scholar] [CrossRef]

- Wu, J.; Zhao, J.; Lei, J.; Liu, B. Effectiveness of nanofluid on improving the performance of microchannel heat sink. Appl. Therm. Eng. 2016, 101, 402–412. [Google Scholar] [CrossRef]

- Khaleduzzaman, S.S.; Sohel, M.R.; Mahbubul, I.M.; Saidur, S.; Selvaraj, J. Exergy and entropy generation analysis of TiO2-water nanofluid flow through the water block as an electronics device. Int. J. Heat Mass. Tran. 2016, 101, 104–111. [Google Scholar] [CrossRef]

- Al-Rashed, M.H.; Dzido, G.; Korpys, M.; Smolka, J.; Wojcik, J. Investigation on the CPU nanofluid cooling. Microelectron. Reliab. 2016, 63, 159–165. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Optimizing energy efficiency of a specific liquid block operated with nanofluids for utilization in electronics cooling: A decision-making based approach. Energy Convers. Manag. 2017, 154, 180–190. [Google Scholar] [CrossRef]

- Vishnuprasad, S.; Haribabu, K.; Perarasu, V.T. Experimental study on the convective heat transfer performance and pressure drop of functionalized graphene nanofluids in electronics cooling system. Heat Mass. Transf. 2019, 55, 2221–2234. [Google Scholar]

- Yunus, T.A.; Hendrik, C.; Pinar, E.; Maria, R.V. Spray cooling investigation of TiO2–Water nanofluids on a hot surface. Energies 2023, 16, 2938. [Google Scholar] [CrossRef]

- Sarafraz, M.M.; Arya, A.; Hormozi, F.; Nikkhah, V. On the convective thermal performance of a CPU cooler working with liquid gallium and CuO/water nanofluid: A comparative study. Appl. Therm. Eng. 2017, 112, 1373–1381. [Google Scholar] [CrossRef]

- Chen, J.; Jia, J. Experimental study of TiO2 nanofluid coolant for automobile cooling applications. Mater. Res. Innov. 2017, 21, 177–181. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Nachtane, M.; Stanishevskiy, Y.M.; Dodina, E.P.; Rejepov, D.T.; Vetcher, A.A. The Effect of Multi-Walled Carbon Nanotubes on the Heat-Release Properties of Elastic Nanocomposites. J. Compos. Sci. 2022, 6, 333. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Shchegolkov, A.V.; Zemtsova, N.V.; Vetcher, A.A.; Stanishevskiy, Y.M. Properties of Organosilicon Elastomers Modified with Multilayer Carbon Nanotubes and Metallic (Cu or Ni) Microparticles. Polymers 2024, 16, 774. [Google Scholar] [CrossRef]

- Leong, K.Y.; Saidur, R.; Kazi, S.N.; Mamun, A.H. Performance investigation of an automotive car radiator operated with nano fluid-based coolants (nanofluid as a coolant in a radiator). Appl. Therm. Eng. 2010, 30, 2685–2692. [Google Scholar] [CrossRef]

- Nishant, K.; Shriram, S.S. Experimental study of thermal conductivity and convective heat transfer enhancement using CuO and TiO2 nanoparticles. Int. Commun. Heat Mass. 2016, 76, 98–107. [Google Scholar]

- Wadd, M.S.; Warkhedkar, R.M.; Choudhari, V.G. Comparing performance of nanofluids of metal and nonmetal as coolant in automobile radiator. IJARSE 2015, 4, 182–190. [Google Scholar]

- Sheikhzadeh, G. Analysis of thermal performance of a car radiator employing nanofluid. Int. J. Mech. Eng. Appl. 2014, 4, 47–51. [Google Scholar] [CrossRef]

- Behrangzade, A.; Heyhat, M.M. The effect of using nano-silver dispersed water based nanofluid as a passive method for energy efficiency enhancement in a plate heat exchanger. Appl. Therm. Eng. 2016, 102, 311–317. [Google Scholar] [CrossRef]

- Tsai, C.Y.; Chien, H.T.; Ding, P.P.; Chan, B.; Luh, T.Y.; Chen, P.H. Effect of structural character of gold nanoparticles in nanofluid on heat pipe thermal performance. Mater. Lett. 2004, 58, 1461–1465. [Google Scholar] [CrossRef]

- Hassani, S.M.; Khoshvaght, A.M.; Mazloumi, S.H. Influence of chevron fin interruption on thermo-fluidic transport characteristics of nanofluid-cooled electronic heat sink. Chem. Eng. Sci. 2018, 191, 436–447. [Google Scholar] [CrossRef]

- Nguyen, C.T.; Roy, G.; Gauthier, C.; Galanis, N. Heat transfer enhancement using Al2O3–water nanofluid for an electronic liquid cooling system. Appl. Therm. Eng. 2007, 27, 1501–1506. [Google Scholar] [CrossRef]

- Nnanna, A.G.A.; Rutherford, W.; Elomar, W.; Sankowski, B. Assessment of thermoelectric module with nanofluid heat exchanger. Appl. Therm. Eng. 2009, 29, 491–500. [Google Scholar] [CrossRef]

- Ambreen, T.; Kim, M.H. Effect of fin shape on the thermal performance of nanofluid cooled micro pin-fin heat sinks. Int. J. Heat Mass. Transf. 2018, 126, 245–256. [Google Scholar] [CrossRef]

- Nitiapiruk, P.; Mahian, O.; Dalkilic, A.S.; Wongwises, S. Performance characteristics of a microchannel heat sink using TiO2/water nanofluid and different thermophysical models. Int. Commun. Heat Mass. Transf. 2013, 47, 98–104. [Google Scholar] [CrossRef]

- Nakharintr, L.; Naphon, P. Magnetic field effect on the enhancement of nanofluids heat transfer of a confined jet impingement in mini-channel heat sink. Int. J. Heat Mass. Transf. 2017, 110, 753–759. [Google Scholar] [CrossRef]

- Chein, R.; Chuang, J. Experimental microchannel heat sink performance studies using nanofluids. Int. J. Therm. Sci. 2007, 46, 57–66. [Google Scholar] [CrossRef]

- Guo, W.W.; Li, G.N.; Zheng, Y.Q.; Dong, C. Numerical study of nanofluids thermal and hydraulic characteristics considering Brownian motion effect in micro fin heat sink. J. Mol. Liq. 2018, 264, 38–47. [Google Scholar] [CrossRef]

- Duangthongsuk, W.; Wongwises, S. An experimental study on the thermal and hydraulic performances of nanofluids flow in a miniature circular pin fin heat sink. Exp. Therm. Fluid. Sci. 2015, 66, 28–35. [Google Scholar] [CrossRef]

- Mare, T.; Halelfadl, S.; Sow, O.; Estelle, P.; Duret, S.; Bazantay, F. Comparison of the thermal performances of two nanofluids at low temperature in a plate heat exchanger. Exp. Therm. Fluid. Sci. 2011, 35, 1535–1543. [Google Scholar] [CrossRef]

- Sarafraz, M.; Hormozi, F. Experimental Thermal and Fluid Science Heat Transfer, Pressure Drop and Fouling Studies of Multi-walled Carbon Nanotube nanofluids inside a plate heat exchanger. Exp. Therm. Fluid. Sci. 2016, 72, 1–11. [Google Scholar] [CrossRef]

- Kumar, V.; Tiwari, A.K.; Ghosh, S.K. Effect of variable spacing on performance of plate heat exchanger using nanofluids. Energy 2016, 114, 1107–1119. [Google Scholar] [CrossRef]

- Hasan, M.I. Investigation of flow and heat transfer characteristics in micro pin fin heat sink with nanofluid. Appl. Therm. Eng. 2014, 63, 598–607. [Google Scholar] [CrossRef]

- Aich, W.; Hilali-Jaghdam, I.; Alshahrani, A.; Maatki, C.; Alshammari, B.M.; Kolsi, L. Control of Three-Dimensional Natural Convection of Graphene–Water Nanofluids Using Symmetrical Tree-Shaped Obstacle and External Magnetic Field. Symmetry 2024, 16, 692. [Google Scholar] [CrossRef]

- Shchegolkov, A.V.; Jang, S.H.; Shchegolkov, A.V.; Rodionov, Y.V.; Glivenkova, O.A. Multistage Mechanical Activation of Multilayer Carbon Nanotubes in Creation of Electric Heaters with Self-Regulating Temperature. Materials 2021, 14, 4654. [Google Scholar] [CrossRef] [PubMed]

- Gandomkar, A.; Saidi, M.H.; Shafii, M.B.; Vandadi, M.; Kalan, K. Visualization and comparative investigations of pulsating Ferro-fluid heat pipe. Appl. Therm. Eng. 2017, 116, 56–65. [Google Scholar] [CrossRef]

- Jahani, K.; Mohammadi, M.; Shafii, M.B. Promising technology for electronic cooling: Nanofluidic micro pulsating heat pipes. J. Electron. Packag. 2013, 135, 021005. [Google Scholar] [CrossRef]

- Yu, C.C.; Huei, C.W. A brief note on the magnetowetting of magnetic nanofluids on AAO surfaces. Nanomaterials 2018, 8, 118. [Google Scholar] [CrossRef] [PubMed]

- Yu, C.C.; Huei, C.W. Magnetic nanofluid droplet impact on an AAO surface with a magnetic field. Appl. Sci. 2018, 8, 1059. [Google Scholar] [CrossRef]

- Al-Yaari, A.; Ching, D.L.; Sakidin, H.; Muthuvalu, M.S.; Zafar, M.; Haruna, A.; Merican, Z.M.; Yunus, R.B.; Al-dhawi, B.N.; Jagaba, A.H. The effects of nanofluid thermophysical properties on enhanced oil recovery in a heterogenous porous media. Case. Stud. Chem. Environ. Eng. 2024, 9, 100556. [Google Scholar] [CrossRef]

- Pavía, M.; Alajami, K.; Estellé, P.; Desforges, A.; Vigolo, B. A critical review on thermal conductivity enhancement of graphene-based nanofluids. Adv. Colloid. Interface. Sci. 2021, 294, 102452. [Google Scholar] [CrossRef] [PubMed]

- Xie, H.; Yu, W.; Li, Y.; Chen, L. Discussion on the thermal conductivity enhancement of nanofluids. Nanoscale Res. Lett. 2011, 6, 124. [Google Scholar] [CrossRef] [PubMed]

- Keblinski, P.; Eastman, J.A.; Cahill, D.G. Nanofluids for thermal transport. Mater. Today 2005, 8, 36–44. [Google Scholar] [CrossRef]

- Luo, Q.Y.; Wang, C.H.; Wu, C.L. Study on heat transfer performance of immersion system based on SiC/white mineral oil composite nanofluids. Int. J. Therm. Sci. 2023, 187, 108203. [Google Scholar] [CrossRef]

- Luo, Q.Y.; Wang, C.H.; Wen, H.P.; Liu, L.D. Research and optimization of thermophysical properties of sic oil-based nanofluids for data center immersion cooling. Int. Commun. Heat Mass. 2022, 131, 105683. [Google Scholar] [CrossRef]

- Jamei, M.; Olumegbon, I.A.; Karbasi, M.; Ahmadianfar, I.; Asadi, A.; Dehkordi, M.M. On the thermal conductivity assessment of oil-based hybrid nanofluids using extended Kalman filter integrated with feed-forward neural network. Int. J. Heat Mass. Transf. 2021, 172, 121159. [Google Scholar] [CrossRef]

- Shubhankar, S.; Nanda, K.G. Effect of silver nanoparticle volume fraction on thermal conductivity, specific heat and viscosity of ethylene glycol base silver nanofluid: A molecular dynamics investigation. J. Mol. Liq. 2023, 378, 121635. [Google Scholar]

- Ambreen, T.; Kim, M.H. Influence of particle size on the effective thermal conductivity of nanofluids: A critical review. Appl. Energy 2020, 264, 114684. [Google Scholar] [CrossRef]

- Wei, B.; Zou, C.; Yuan, X.; Li, X. Thermo-physical property evaluation of diathermic oil based hybrid nanofluids for heat transfer applications. Int. J. Heat Mass. Transf. 2017, 107, 281–287. [Google Scholar] [CrossRef]

- Li, Z.X.; Asadi, S.; Karimipour, A.; Abdollahi, A.; Tlili, I. Experimental study of temperature and mass fraction effects on thermal conductivity and dynamic viscosity of SiO2-oleic acid/liquid paraffin nanofluid. Int. Commun. Heat Mass. Transf. 2020, 110, 104436. [Google Scholar] [CrossRef]

- Sahoo, R.R.; Kumar, V. Development of a new correlation to determine the viscosity of ternary hybrid nanofluid. Int. Commun. Heat Mass. Transf. 2020, 111, 104451. [Google Scholar] [CrossRef]

- Hassan, M.; Mebarek-Oudina, F.; Faisal, A.; Ghafar, A.; Ismail, A.I. Thermal energy and mass transport of shear thinning fluid under effects of low to high shear rate viscosity. Int. J. Thermofluids 2022, 15, 100176. [Google Scholar] [CrossRef]

- Wei, M.; Lin, K.; Sun, L. Shear thickening fluids and their applications. Mater. Des. 2022, 216, 110570. [Google Scholar] [CrossRef]

- Sun, L.; Geng, J.F.; Dong, K.J.; Sun, Q. An experimental study on the effect of nanofluids on the thermal conductivity and rheological properties of a coolant for liquids. Energies 2024, 17, 1313. [Google Scholar] [CrossRef]

- Madhusree, K.; Dey, T.K. Viscosity of alumina nanoparticles dispersed in car engine coolant. Exp. Therm. Fluid. Sci. 2010, 34, 677–683. [Google Scholar]

- Eneren, P.; Aksoy, Y.T.; Vetrano, M.R. Experiments on single-phase nanofluid heat transfer mechanisms in microchannel heat sinks: A review. Energies 2022, 15, 2525. [Google Scholar] [CrossRef]

- Li, H.; Chiang, M.H.; Lee, C.I.; Yang, W.J. Thermal performance of plate-fin vapor chamber heat sinks. Int. Commun. Heat Mass. Transf. 2010, 37, 731–738. [Google Scholar] [CrossRef]

- Sui, Y.; Lee, P.S.; Teo, C.J. An experimental study of flow friction and heat transfer in wavy microchannels with rectangular cross section. Int. J. Therm. Sci. 2011, 50, 2473–2482. [Google Scholar] [CrossRef]

- Gong, L.; Kota, K.; Tao, W.; Joshi, Y. Parametric numerical study of flow and heat transfer in microchannels with wavy walls. J. Heat Transf. Trans. ASME 2011, 133, 051702. [Google Scholar] [CrossRef]

- Lu, G.; Zhao, J.; Lin, L.; Wang, X.D.; Yan, W.M. A new scheme for reducing pressure drop and thermal resistance simultaneously in microchannel heat sinks with wavy porous fins. Int. J. Heat Mass. Transf. 2017, 111, 1071–1078. [Google Scholar] [CrossRef]

- Nemati, H.; Moghimi, M.A.; Meyer, J.P. Shape optimisation of wavy mini-channel heat sink. Int. Commun. Heat Mass. Transf. 2021, 122, 105172. [Google Scholar] [CrossRef]

- Yang, K.S.; Li, S.L.; Chen, I.Y.; Chien, K.H.; Huc, R.; Wang, C.C. An experimental investigation of air-cooling thermal module using various enhancements at low Reynolds number region. Int. J. Heat Mass. Transf. 2010, 53, 5675–5681. [Google Scholar] [CrossRef]

- Kim, D.K.; Kim, S.J.; Bae, J.K. Comparison of thermal performances of plate-fin and pin-fin heat sinks subject to an impinging flow. Int. J. Heat Mass. Transf. 2009, 52, 3510–3517. [Google Scholar] [CrossRef]

- Li, H.Y.; Chen, K.Y.; Chiang, M.H. Thermal-fluid characteristics of plate-fin heat sinks cooled by impingement jet. Energy Convers. Manag. 2009, 50, 2738–2746. [Google Scholar] [CrossRef]

- Kuppusamy, N.R.; Mohammed, H.A.; Lim, C.W. Numerical investigation of trapezoidal grooved microchannel heat sink using nanofluids. Thermochim. Acta 2013, 573, 39–56. [Google Scholar] [CrossRef]

- Jang, S.P.; Choi, S.U.S. Cooling performance of a microchannel heat sink with nanofluids. Appl. Therm. Eng. 2006, 26, 2457–2463. [Google Scholar] [CrossRef]

- Jung, Y.; Oh, S.H.; Kwak, H.Y. Forced Convective heat transfer of nanofluids in microchannels. Int. J. Heat Mass. Transf. 2009, 52, 466–472. [Google Scholar] [CrossRef]

- Kuppusamy, N.R.; Mohammed, H.A.; Lim, C.W. Thermal and hydraulic characteristics of nanofluid in a triangular grooved microchannel heat sink (TGMCHS). Appl. Math. Comput. 2014, 246, 168–183. [Google Scholar] [CrossRef]

- Anbumeenakshi, C.; Thansekhar, M.R. On the effectiveness of a nanofluid cooled microchannel heat sink under non-uniform heating condition. Appl. Therm. Eng. 2017, 113, 1437–1443. [Google Scholar] [CrossRef]

- Sivakumar, A.; Alagumurthi, N.; Senthilvelan, T. Experimental investigation of forced convective heat transfer performance in nanofluids of Al2O3/water and CuO/water in a serpentine shaped micro channel heat sink. Heat Mass. Transf. 2016, 52, 1265–1274. [Google Scholar] [CrossRef]

- Sakanova, A.; Keian, C.C.; Zhao, J. Performance improvements of microchannel heat sink using wavy channel and nanofluids. Int. J. Heat Mass. Transf. 2015, 89, 59–74. [Google Scholar] [CrossRef]

- Selvakumar, P.; Suresh, S. Convective performance of CuO/water nanofluid in an electronic heat sink. Exp. Therm. Fluid. Sci. 2012, 40, 57–63. [Google Scholar] [CrossRef]

- Bayomy, A.M.; Saghir, M.Z. Experimental study of using c-Al2O3–water nanofluid flow through aluminum foam heat sink: Comparison with numerical approach. Int. J. Heat Mass. Transf. 2017, 107, 181–203. [Google Scholar] [CrossRef]

- Jeng, L.Y.; Teng, T.P. Performance evaluation of a hybrid cooling system for electronic chips. Exp. Therm. Fluid. Sci. 2013, 45, 155–162. [Google Scholar] [CrossRef]

- Sohel, M.R.; Saidur, R.; Khaleduzzaman, S.S.; Ibrahim, T.A. Cooling performance investigation of electronics cooling system using Al2O3-H2O nanofluid. Int. Commun. Heat Mass. Transf. 2015, 65, 89–93. [Google Scholar] [CrossRef]

- Li, H.; Fan, Z.; Lai, Q.; Xie, Y.; Qiao, L.; Tan, J. The effect of pulse heating on saturated boiling heat transfer in rough surfaces. Case Stud. Therm. Eng. 2023, 42, 102772. [Google Scholar] [CrossRef]

- Chhetri, A.; Kashyap, D.; Mali, A.; Agarwal, C.; Ponraj, C.; Gobinath, N. Numerical simulation of the single-phase immersion cooling process using a dielectric fluid in a data server. Mater. Today Proc. 2022, 51 Pt 3, 1532–1538. [Google Scholar] [CrossRef]

- Zhou, G.H.; Zhou, J.Z.; Huai, X.L.; Zhou, F.; Jiang, Y.W. A two-phase liquid immersion cooling strategy utilizing vapor chamber heat spreader for data center servers. Appl. Therm. Eng. 2022, 210, 118289. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Arik, M.; Ohadi, M. Direct liquid cooling of high flux micro and nano electronic components. Proc. IEEE 2006, 94, 1549–1570. [Google Scholar] [CrossRef]

- Lee, Y.T. Heat transfer of bubbly flows in microchannels at varied aspect ratios and hydraulic diameters. Int. J. Heat Mass. Transf. 2023, 216, 124573. [Google Scholar] [CrossRef]

- Soleimani, A.; Sattari, A.; Hanafizadeh, P. Thermal analysis of a microchannel heat sink cooled by two-phase flow boiling of Al2O3 HFE-7100 nanofluid. Therm. Sci. Eng. Prog. 2020, 20, 100693. [Google Scholar] [CrossRef]

- Hou, J.S.; Wu, J.J.; Zhao, X.; Ma, L.; Huang, L.; Qiu, Y.N.; Li, D.Y.; Ding, Z.H.; Chen, Z.Z.; Wei, J.J.; et al. Microfluidic flow synthesis of Al2O3 nanofluids for efficient phase-change boiling heat transfer enhancement of electronic devices. Case Stud. Therm. Eng. 2024, 58, 104458. [Google Scholar] [CrossRef]

- Suja, S.B.; Islam, S.R.; Ahmed, Z.U. Numerical investigation of thermal and hydraulic characteristics in porous pin fin heat sinks using single phase nanofluids. Int. J. Therm. Sci. 2024, 22, 100677. [Google Scholar] [CrossRef]

- Heidarshenas, B.; Abidi, A.; Sajadi, S.M.; Yuan, Y.J.; El-Shafay, A.S.; Aybar, H.S. Numerical study and optimization of thermal efficiency for a pin fin heatsink with nanofluid flow by modifying heatsink geometry. Case Stud. Therm. Eng. 2024, 55, 104125. [Google Scholar] [CrossRef]

- Castillo, E.; Santos, A.; Gonzales, A. Numerical study of the use of shear-thinning nanofluids in a microchannel heat sink with different pin densities and including vortex generator. Case Stud. Therm. Eng. 2024, 57, 104328. [Google Scholar] [CrossRef]

- Aguirre, I.; González, A.; Castillo, E. Numerical study on the use of shear-thinning nanofluids in a micro pin-fin heat sink including vortex generators and changes in pin shapes. J. Taiwan. Inst. Chem. Eng. 2022, 136, 104400. [Google Scholar] [CrossRef]

- Kavitha, C.; Mukeshkumar, P.C.; Arun Kumar, C.M. Numerical study on the performance of Al2O3/water nanofluids as a coolant in the fin channel heat sink for an electronic device cooling. Mater. Today Proc. 2023, in press.

- Islam, M.R.; Shabani, B.; Andrews, J.; Rosengarten, G. Experimental investigation of using ZnO nanofluids as coolants in a PEM fuel cell. Int. J. Hydrog. Energy 2017, 42, 19272–19286. [Google Scholar] [CrossRef]

- Hamilton, R.L.; Crosser, O.K. Thermal conductivity of heterogeneous two-component systems. Ind. Eng. Chem. Res. Fundam. 1962, 1, 187–191. [Google Scholar] [CrossRef]

- Yamada, E.; Ota, T. Effective thermal conductivity of dispersed materials. Heat Mass. Transf. 1980, 13, 27–37. [Google Scholar] [CrossRef]

- Davis, R. The effective thermal conductivity of composite material spherical inclusions. Int. J. Thermophys. 1986, 7, 609–620. [Google Scholar] [CrossRef]

- Sun, L.; Zhao, Q.; Zhang, Y.; Gao, W.; Jing, D. Insights into the rheological behavior of ethanol-based metal oxide nanofluids. J. Mol. Liq. 2021, 323, 115006. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, Y.; Gao, W.; Li, X.; Jing, D. Rheology of methanol-based metal oxide nanofluids: The effect of temperature and particle type and mass fraction. Interfacial Phenom. Heat Transf. 2020, 8, 165–181. [Google Scholar] [CrossRef]

- Einstein, A. Eine neue bestimmung der moleküldimensionen. Ann. Phys. 1906, 324, 289–306. [Google Scholar] [CrossRef]

- Brinkman, H. The viscosity of concentrated suspensions and solutions. J. Chem. Phys. 1952, 20, 571. [Google Scholar] [CrossRef]

- Batchelor, G.K. The effect of Brownian motion on the bulk stress in a suspension of spherical particles. J. Fluid. Mech. 1977, 83, 97. [Google Scholar] [CrossRef]

- Wang, X.; Xu, X.; Choi, S.U. Thermal conductivity of nanoparticle-fluid mixture. J. Thermophys. Heat Transf. 1999, 13, 474–480. [Google Scholar] [CrossRef]

- Tao, Q.; Zhong, F.; Deng, Y.; Wang, Y.; Su, C. A Review of Nanofluids as Coolants for Thermal Management Systems in Fuel Cell Vehicles. Nanomaterials 2023, 13, 2861. [Google Scholar] [CrossRef] [PubMed]

- Kuznetsova, Y.V.; Balyakin, I.A.; Popov, I.D.; Schummer, B.; Sochor, B.; Rempel, S.V.; Rempel, A.A. Ag2S interparticle interaction in an aqueous solution: Mechanism of steric and electrostatic stabilization. J. Mol. Liq. 2021, 335, 116130. [Google Scholar] [CrossRef]

- Alam, H.S.; Sutikno, P.; Soelaiman, T.A.F.; Sugiarto, A.T. A diffused double-layer model of bulk nanobubbles in aqueous NaCl solutions. Therm. Sci. Eng. Prog. 2024, 50, 102590. [Google Scholar]

- Li, X.Y.; Sun, L.; Jin, J.Y.; Ding, Y.; Jing, D.W. Combined effects of surface tension and thermal conductivity on the methane hydrate formation in the presence of both nanoparticles and surfactant. J. Disper Sci. Technol. 2020, 41, 92–101. [Google Scholar] [CrossRef]

- Bhat, D.K.; Kumar, S.P.; Shenoy, U.S. Design, synthesis, and characterization of stable copper nanofluid with enhanced thermal conductivity. Mater. Today Commun. 2024, 39, 109129. [Google Scholar] [CrossRef]

- Peng, C.; Song, Y.Y.; Deng, J.; Wu, J.; Chen, H.L.; Liu, F. The influence of suspension and deposition on pool boiling heat transfer of nanofluids: Experiment and engineering model study. Int. J. Heat Mass. Transf. 2024, 227, 125614. [Google Scholar] [CrossRef]

- Bhavani, J.D.; Gopal, T.S.; Gnanasekar, S.; Pandiaraj, S.; Muthuramamoorthy, M.; Alodhayb, A.N.; Andrews, N.G. Ultrasonic interferometry and physiothermal properties of Al2O3/CuO nanofluids. Case Stud. Therm. Eng. 2024, 55, 104120. [Google Scholar]

- Aich, W.; Khlissa, F.; Alshammari, B.M.; Kolsi, L. Experimental study of graphene-based nanofluid dispersions stability for efficient heat transmission within a concentric tube heat exchanger. Case Stud. Therm. Eng. 2024, 59, 104523. [Google Scholar] [CrossRef]

- Li, Y.Q.; Zou, C.J.; Kang, J.X.; You, J.W.; Liu, E.X.; Wang, Y.Z.; Cao, Y.X. β-Cyclodextrin modified SiO2 nanofluid for enhanced oil recovery. Colloids Surf. A Physicochem. Eng. Asp. 2024, 688, 133655. [Google Scholar] [CrossRef]

- Vallejo, J.P.; Febrero-Garrido, L.; Cacabelos, A.; González-Gil, A.; Lugo, L. Influence of crystal structure on the thermophysical properties and figures-of-merit of propylene glycol: Water-based SiC nanofluids. Powder Technol. 2024, 433, 119299. [Google Scholar] [CrossRef]

- Yu, J.; Grossiord, N.; Koning, C.E.; Loos, J. Controlling the dispersion of multi-wall carbon nanotubes in aqueous surfactant solution. Carbon 2007, 45, 618–623. [Google Scholar] [CrossRef]

- Tang, Q.Y.; Shafiq, I.; Chan, Y.C.; Wong, N.B.; Cheung, R. Study of the dispersion and electrical properties of carbon nanotubes treated by surfactants in dimethylacetamide. Nanotechnology 2010, 10, 4967–4974. [Google Scholar] [CrossRef]

- Brzóska, K.; Golba, A.; Kuczak, M.; Mrozek-Wilczkiewicz, A.; Boncel, S.; Dzida, M. Bio-Based Nanofluids of Extraordinary Stability and Enhanced Thermal Conductivity as Sustainable Green Heat Transfer Media. ACS Sustain. Chem. Eng. 2021, 9, 7369–7378. [Google Scholar]

- Mehta, B.; Subhedar, D.; Panchal, H.; Said, Z. Synthesis, stability, thermophysical properties and heat transfer applications of nanofluid—A review. J. Mol. Liq. 2022, 364, 120034. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. 11-Abrasive, Erosive and Cavitation Wear. In Engineering Tribology, 3rd ed.; Stachowiak, G.W., Batchelor, A.W., Eds.; Butterworth-Heinemann: Burlington, VT, USA, 2006; pp. 501–551. [Google Scholar]

- Chakraborty, S.; Shukla, D.; Panigrahi, P.K. A review on coolant selection for thermal management of electronics and implementation of multiple-criteria decision-making approach. Appl. Therm. Eng. 2024, 245, 122807. [Google Scholar] [CrossRef]

- Mohapatra, S.C.; Loikits, D. Advances in liquid coolant technologies for electronics cooling. In Proceedings of the Semiconductor Thermal Measurement and Management IEEE Twenty First Annual IEEE Symposium, 2005, San Jose, CA, USA, 15–17 March 2005; pp. 354–360. [Google Scholar]

- Khdher, A.M.; Sidik, N.A.C.; Hamzah, W.A.W.; Mamat, R. An experimental determination of thermal conductivity and electrical conductivity of bio glycol based Al2O3 nanofluids and development of new correlation. Int. Commun. Heat Mass. Transf. 2016, 73, 75–83. [Google Scholar] [CrossRef]

- Ganguly, S.; Sikdar, S.; Basu, S. Experimental investigation of the effective electrical conductivity of aluminum oxide nanofluids. Powder Technol. 2009, 196, 326–330. [Google Scholar] [CrossRef]

- Kalpana Sarojini, K.G.; Manoj, S.V.; Singh, P.K.; Pradeep, T.; Das, S.K. Electrical conductivity of ceramic and metallic nanofluids. Colloids Surf. A Physicochem. Eng. Asp. 2013, 417, 39–46. [Google Scholar] [CrossRef]

- Subramaniyan, A.; Sukumaran, L.P.; Ilangovan, R. Investigation of the dielectric properties of TiO2 nanofluids. J. Taibah Univ. Sci. 2016, 10, 403–406. [Google Scholar] [CrossRef]

- Selvakumar, P.; Suresh, S. Use of Al2O3–Cu/water hybrid nanofluid in an electronic heat sink. IEEE Trans. Compon. Packag. Manuf. Technol. 2012, 2, 1600–1607. [Google Scholar] [CrossRef]

- Bahiraei, M.; Heshmatian, S. Efficacy of a novel liquid block working with a nanofluid containing graphene nanoplatelets decorated with silver nanoparticles compared with conventional CPU coolers. Appl. Therm. Eng. 2017, 127, 1233–1245. [Google Scholar] [CrossRef]

- Khaleduzzaman, S.S.; Saidur, R.; Selvaraj, J.; Mahbubul, I.M.; Sohel, M.R.; Shahrul, I.M. Nanofluids for thermal performance improvement in cooling of electronic device. Adv. Mater. Res. 2014, 832, 218–223. [Google Scholar] [CrossRef]

| Type of Nanoparticles | Nanoparticles | Base Fluids | Author/Reference | Results |

|---|---|---|---|---|

| Non-metallic oxide | SiO2 | H2O | Duangthongsuk [50] | Nanofluid cooling allows a 4–14% enhancement in heat transfer coefficient |

| Carbon materials | carbon nanotubes (CNT) | H2O | Mare et al. [51] | Convective heat transfer coefficient enhanced by about 50% |

| Carbon materials | Multi-walled carbon nanotube (MWCNT) | H2O | Sarafraz and Hormozi [52] | MWCNT can enhance the thermal conductivity coefficient up to 68% |

| Carbon materials | Multi-walled carbon nanotube/graphene nanoplate | H2O | Kumar et al. [53] | MWCNT improved relative thermal conductivity by 11.42–22.67% |

| Carbon materials | Diamond | H2O | Hasan [54] | Diamond–water improved the heat transfer rate by 9.12–9.9% |

| Metal | Copper | ethylene glycol | Leong [36] | Heat transfer rate showed a 45.2% enhancement |

| Metal | TiO2/copper | H2O | Wadd et al. [38] | Heat transfer coefficient enhancement of 10–15% |

| Metal | Copper | ethylene glycol | Sheikhzadeh et al. [39] | Heat transfer rate enhanced by 29.6% |

| Metal | Ag | H2O | Behrangzade and Heyhat [40] | Overall heat transfer coefficient improved by 16.79% |

| Metal | Au | H2O | Tsai et al. [41] | Thermal resistance of heat pipe reduced by 20–25% |

| Metal oxide | Al2O3 | H2O | Hassani et al. [42] | Performance index of improved by 14.7% and 28.3% |

| Metal oxide | Al2O3 | H2O | Nguyen [43] | Heat transfer coefficient enhanced by 40% |

| Metal oxide | Al2O3 | H2O | Nnanna [44] | Effective thermal conductivity enhanced by more than 30%, |

| Metal oxide | TiO2 | H2O | Ambreen and Kim [45] | 26%, 44%, and 62% Raises in Nusselt numbers |

| Metal oxide | TiO2 | H2O | Nitiapiruk [46] | Heat transfer coefficient enhanced by over 500 W/m2·K |

| Metal oxide | TiO2 | H2O | Nakharintr and Naphon [47] | Heat transfer coefficient improved by 12.5% |

| Metal oxide | TiO2 | H2O | Maria [31] | TiO2 nanoparticles did not alter the spray characteristics substantially |

| Metal oxide | CuO | H2O | Chein [48] | Thermal conductivity improved by 1.8–8% |

| Metal oxide | CuO | H2O | Sarafraz [32] | Convective heat transfer coefficient did noy surpass that of the gallium |

| Metal oxide | ZnO | H2O | Guo et al. [49] | Heat transfer coefficient improved by 25.6–38.3% |

| Material | Thermal Conductivity (W/M·K) | Dynamic Viscosity (mPa·s) | Specific Heat (J/kg·K) |

|---|---|---|---|

| SiC | 165 | - | 422.0 |

| Mineral oil | 0.13 | 5.6 | 2197.8 |

| Nanofluid | 0.135 | 5.8 | 2009.8 |

| Type | Reference | Main Method | Result |

|---|---|---|---|

| P25 TiO2 | Our previous work [122] | SEM, XRD | The TiO2 nanoparticles exhibit a spherical shape with an average size of approximately 21 nm |

| Copper | Bhat [123] | TEM | TEM images provided visual proof of the development of particles exhibiting spherical shape |

| Al2O3 | Peng [124] | AFM, UV–vis | The presence of nanoparticles on the heating surfaces was demonstrated |

| Al2O3–CuO | Bhavani [125] | XRD, FTIR | The characteristic peaks confirmed the presence of CuO and Al2O3 |

| Graphene oxide | Aich [126] | FTIR, DSC | The existence of C=O stretching vibrations and a highly organized honeycomb-like structure in the graphene architecture was denoted |

| AP–SiO2, β-CD–SiO2 | Li [127] | TGA | β-CD was successfully loaded on the surface of SiO2 |

| SiC | Vallejo [128] | DSC | The isobaric heat capacities for the base fluid and nanofluids were obtained |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, L.; Geng, J.; Dong, K.; Sun, Q. The Applications and Challenges of Nanofluids as Coolants in Data Centers: A Review. Energies 2024, 17, 3151. https://doi.org/10.3390/en17133151

Sun L, Geng J, Dong K, Sun Q. The Applications and Challenges of Nanofluids as Coolants in Data Centers: A Review. Energies. 2024; 17(13):3151. https://doi.org/10.3390/en17133151

Chicago/Turabian StyleSun, Le, Jiafeng Geng, Kaijun Dong, and Qin Sun. 2024. "The Applications and Challenges of Nanofluids as Coolants in Data Centers: A Review" Energies 17, no. 13: 3151. https://doi.org/10.3390/en17133151

APA StyleSun, L., Geng, J., Dong, K., & Sun, Q. (2024). The Applications and Challenges of Nanofluids as Coolants in Data Centers: A Review. Energies, 17(13), 3151. https://doi.org/10.3390/en17133151