Evaluation of Growth and Energy Parameters of One-Year-Old Raspberry Shoots, Depending on the Variety

Abstract

1. Introduction

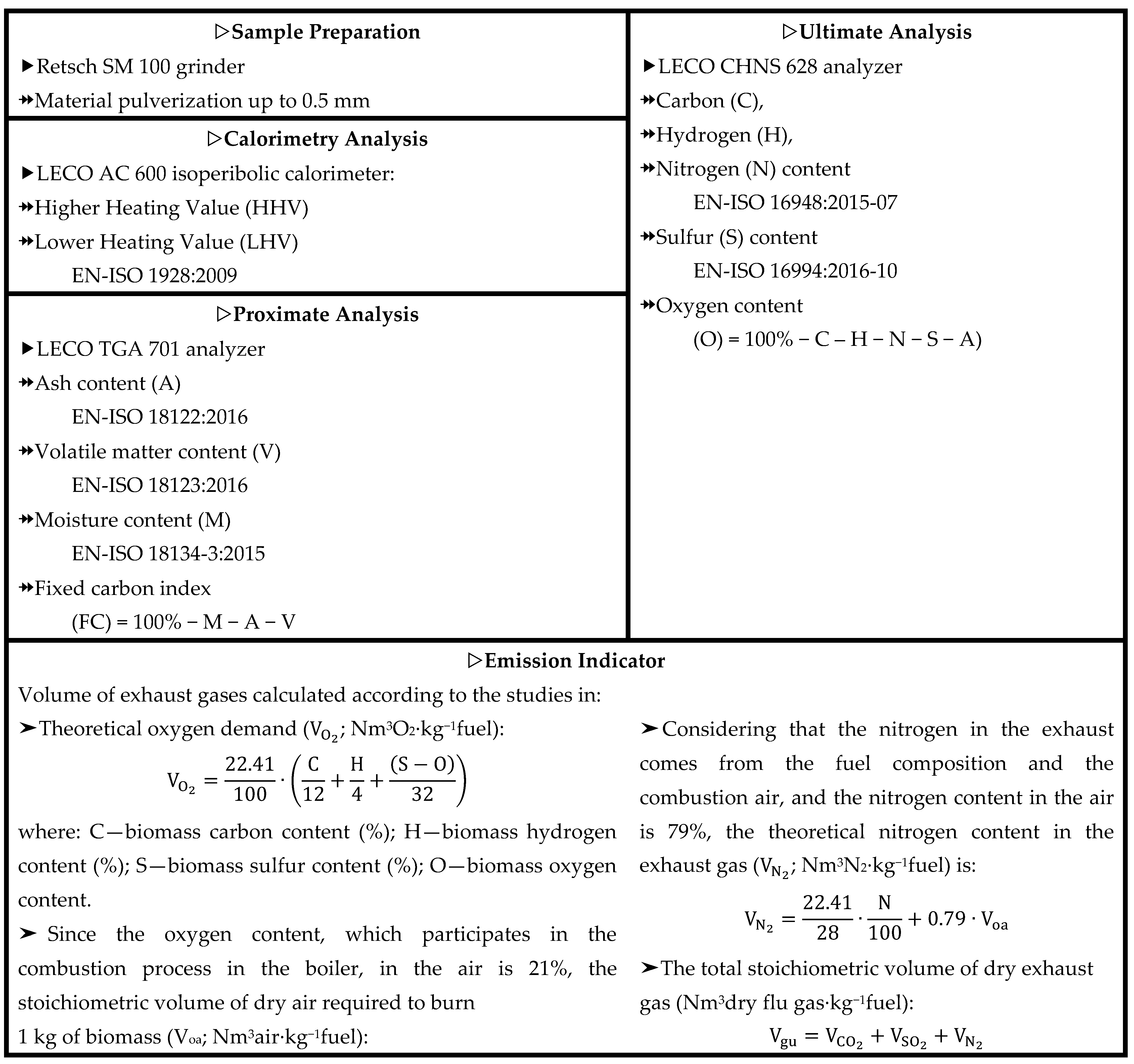

2. Materials and Methods

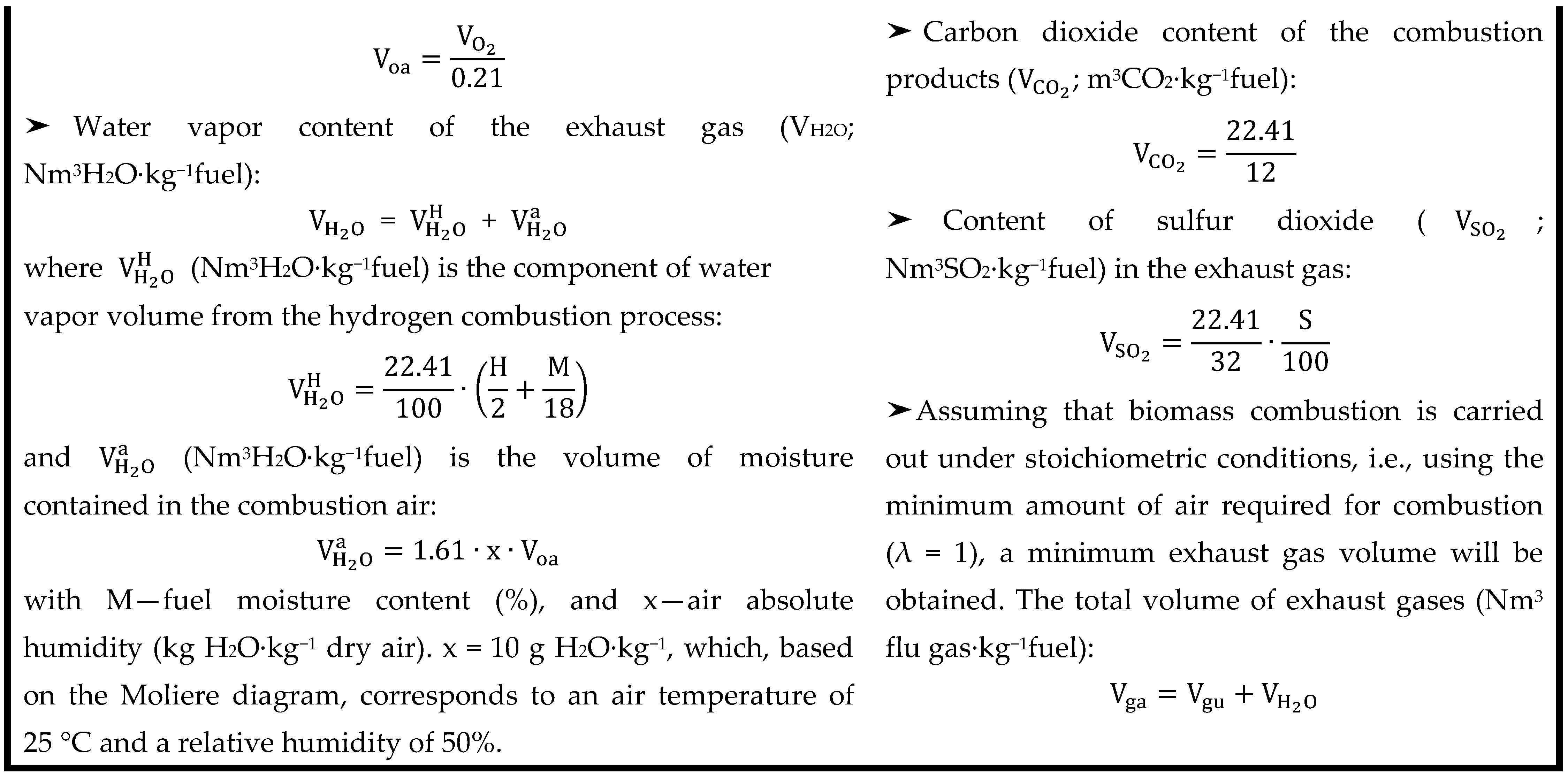

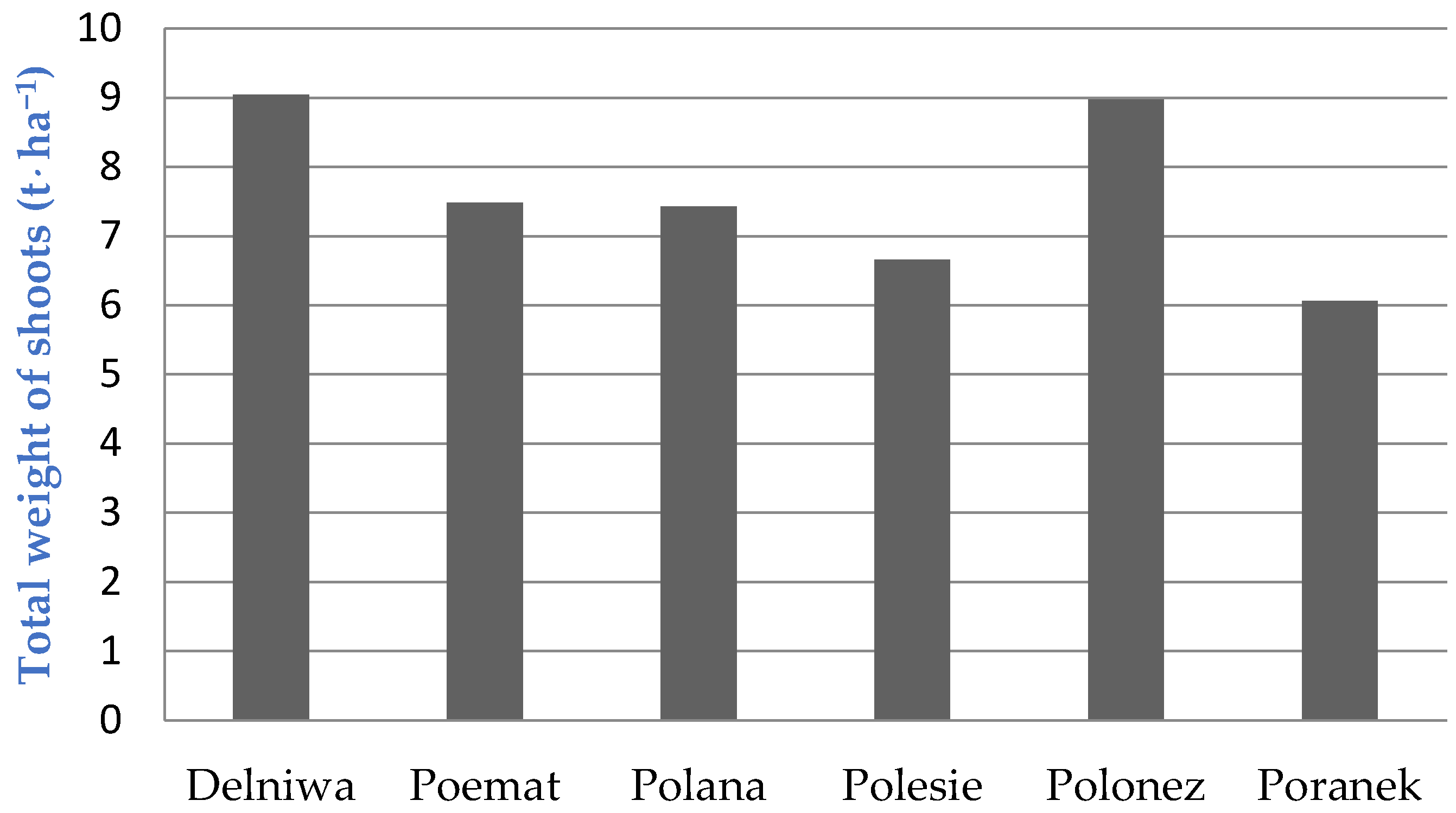

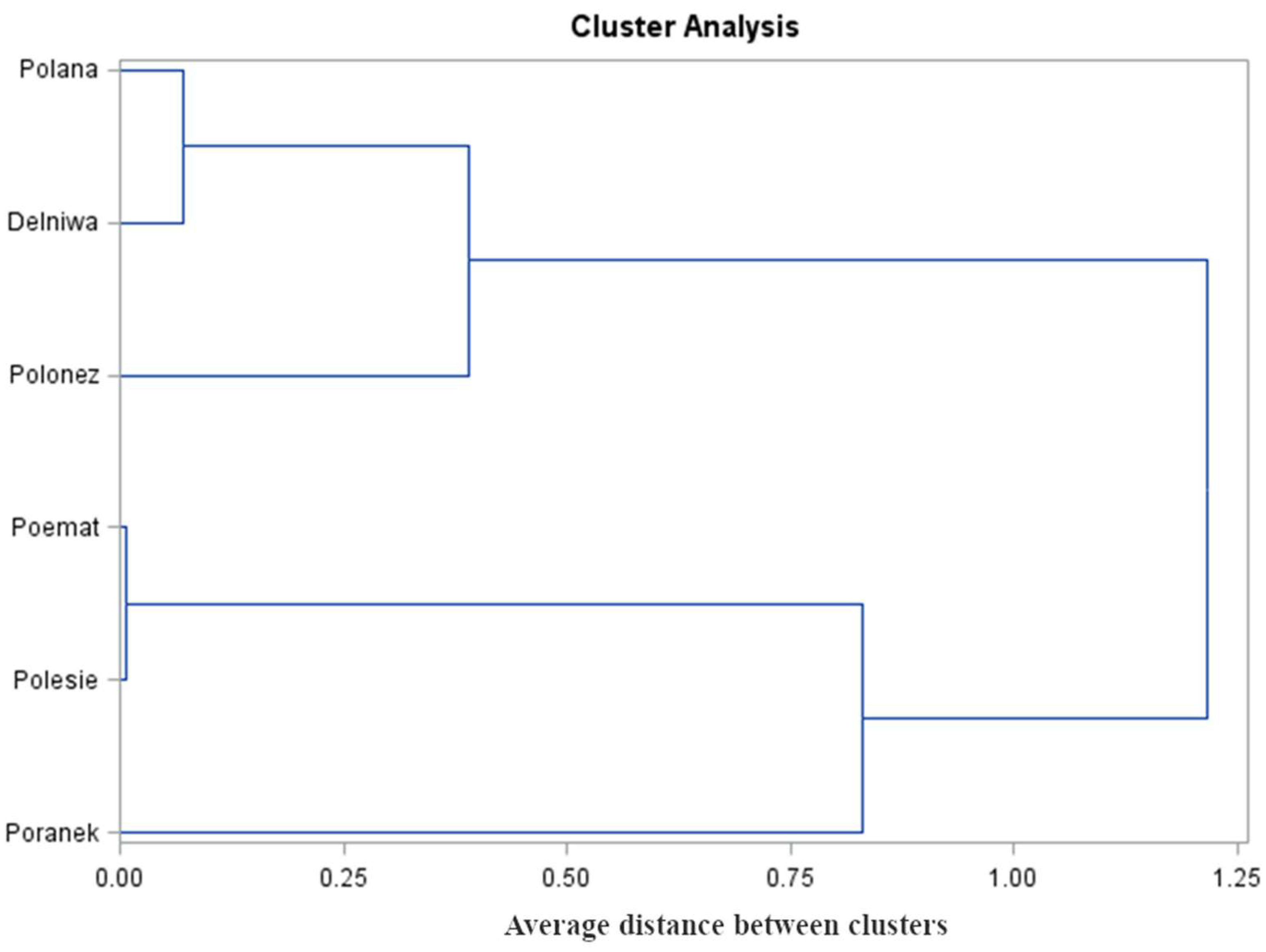

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Borowski, P.F. Management of Energy Enterprises in Zero-Emission Conditions: Bamboo as an Innovative Biomass for the Production of Green Energy by Power Plants. Energies 2022, 15, 1928. [Google Scholar] [CrossRef]

- Obi, O.F.; Pecenka, R.; Clifford, M.J. A Review of Biomass Briquette Binders and Quality Parameters. Energies 2022, 15, 2426. [Google Scholar] [CrossRef]

- Aboelela, D.; Saleh, H.; Attia, A.M.; Elhenawy, Y.; Majozi, T.; Bassyouni, M. Recent Advances in Biomass Pyrolysis Processes for Bioenergy Production: Optimization of Operating Conditions. Sustainability 2023, 15, 11238. [Google Scholar] [CrossRef]

- Ujados Lorenzo, C.; Paredes Sánchez, J.P.; Laine Cuervo, G.; Xiberta Bernat, J. Bioenergy as an Environmental Alternative in Energy Systems: A Case Study. Proceedings 2018, 2, 1481. [Google Scholar] [CrossRef]

- Roudneshin, M.; Sosa, A. Optimising Agricultural Waste Supply Chains for Sustainable Bioenergy Production: A Comprehensive Literature Review. Energies 2024, 17, 2542. [Google Scholar] [CrossRef]

- Yogalakshmi, K.N.; Poornima Devi, T.; Sivashanmugam, P.; Kavitha, S.; Yukesh Kannah, R.; Varjani, S.; AdishKumar, S.; Kumar, G.; Rajesh Banu, J. Lignocellulosic Biomass-Based Pyrolysis: A Comprehensive Review. Chemosphere 2022, 286, 131824. [Google Scholar] [CrossRef]

- United Nations Department of Economic and Social Affairs. The Sustainable Development Goals Report 2023: Special Edition; The Sustainable Development Goals Report; United Nations: New York, NY, USA, 2023; ISBN 978-92-1-002491-4. Available online: https://unstats.un.org/sdgs/report/2023/The-Sustainable-Development-Goals-Report-2023.pdf (accessed on 11 June 2024).

- Ahmed, H.; Abolore, R.S.; Jaiswal, S.; Jaiswal, A.K. Toward Circular Economy: Potentials of Spent Coffee Grounds in Bioproducts and Chemical Production. Biomass 2024, 4, 286–312. [Google Scholar] [CrossRef]

- Lee, S.Y.; Sankaran, R.; Chew, K.W.; Tan, C.H.; Krishnamoorthy, R.; Chu, D.-T.; Show, P.-L. Waste to Bioenergy: A Review on the Recent Conversion Technologies. BMC Energy 2019, 1, 4. [Google Scholar] [CrossRef]

- Havrysh, V.; Kalinichenko, A.; Brzozowska, A.; Stebila, J. Life Cycle Energy Consumption and Carbon Dioxide Emissions of Agricultural Residue Feedstock for Bioenergy. Appl. Sci. 2021, 11, 2009. [Google Scholar] [CrossRef]

- Kalak, T. Potential Use of Industrial Biomass Waste as a Sustainable Energy Source in the Future. Energies 2023, 16, 1783. [Google Scholar] [CrossRef]

- Tshikovhi, A.; Motaung, T.E. Technologies and Innovations for Biomass Energy Production. Sustainability 2023, 15, 12121. [Google Scholar] [CrossRef]

- Vaskalis, I.; Zabaniotou, A. Comparative Feasibility and Environmental Life Cycle Assessment of Cotton Stalks Gasification and Pyrolysis. Biomass 2024, 4, 23–48. [Google Scholar] [CrossRef]

- Bijarchiyan, M.; Sahebi, H.; Mirzamohammadi, S. A Sustainable Biomass Network Design Model for Bioenergy Production by Anaerobic Digestion Technology: Using Agricultural Residues and Livestock Manure. Energ. Sustain. Soc. 2020, 10, 19. [Google Scholar] [CrossRef]

- Wang, K.; Tester, J.W. Sustainable Management of Unavoidable Biomass Wastes. Green Energy Resour. 2023, 1, 100005. [Google Scholar] [CrossRef]

- Suman, S.; Mohan Yadav, A.; Tomar, N.; Bhushan, A. Combustion Characteristics and Behaviour of Agricultural Biomass: A Short Review. In Renewable Energy—Technologies and Applications; Taner, T., Tiwari, A., Selim Ustun, T., Eds.; IntechOpen: London, UK, 2021; ISBN 978-1-83881-000-9. [Google Scholar]

- George, O.S.; Dennison, M.S.; Yusuf, A.A. Characterization and Energy Recovery from Biomass Wastes. Sustain. Energy Technol. Assess. 2023, 58, 103346. [Google Scholar] [CrossRef]

- Ochieng, R.; Gebremedhin, A.; Sarker, S. Integration of Waste to Bioenergy Conversion Systems: A Critical Review. Energies 2022, 15, 2697. [Google Scholar] [CrossRef]

- Zucaro, A.; Ansanelli, G.; Cerbone, A.; Picarelli, A.; Rinaldi, C.; Beltrani, T.; Sbaffoni, S.; Fiorentino, G. Life Cycle Assessment of Electricity Production from Different Biomass Sources in Italy. Energies 2024, 17, 2771. [Google Scholar] [CrossRef]

- Saletnik, B.; Bajcar, M.; Saletnik, A.; Zaguła, G.; Puchalski, C. Effect of the Pyrolysis Process Applied to Waste Branches Biomass from Fruit Trees on the Calorific Value of the Biochar and Dust Explosivity. Energies 2021, 14, 4898. [Google Scholar] [CrossRef]

- FAO (Food and Agriculture Organization of the United Nations). 2024. Available online: https://www.fao.org/faostat/en/#data/qcl (accessed on 11 June 2024).

- Samoraj, M.; Izydorczyk, G.; Krawiec, P.; Moustakas, K.; Chojnacka, K. Biomass-Based Micronutrient Fertilizers and Biofortification of Raspberries Fruits. Environ. Res. 2022, 215, 114304. [Google Scholar] [CrossRef]

- Wu, L.; Yang, J.; Wang, C.; Li, N.; Liu, Y.; Duan, A.; Wang, T. Chemical Compositions of Raspberry Leaves Influenced by Growth Season, Cultivars and Leaf Position. Sci. Hortic. 2022, 304, 111349. [Google Scholar] [CrossRef]

- Kapłan, M.; Maj, G.; Klimek, K.E. The Analysis of Energy Potential in Vine Leaves of the ‘Regent’ Cultivar as Bio-Waste Depending on the Year of Cultivation and the Type of Rootstock Used. J. Water Land Dev. 2023, 58, 171–177. [Google Scholar] [CrossRef]

- Amine, D.; Abdeltif, A.; Tounsia, A.; Naima, B. Characterization of Cardinal Vine Shoot Waste as New Resource of Lignocellulosic Biomass and Valorization into Value-Added Chemical Using Plackett–Burman and Box Behnken. Biomass Conv. Bioref. 2023, 13, 6331–6344. [Google Scholar] [CrossRef]

- Rahimi, Z.; Anand, A.; Gautam, S. An Overview on Thermochemical Conversion and Potential Evaluation of Biofuels Derived from Agricultural Wastes. Energy Nexus 2022, 7, 100125. [Google Scholar] [CrossRef]

- Enes, T.; Aranha, J.; Fonseca, T.; Matos, C.; Barros, A.; Lousada, J. Residual Agroforestry Biomass–Thermochemical Properties. Forests 2019, 10, 1072. [Google Scholar] [CrossRef]

- Maj, G.; Najda, A.; Klimek, K.; Balant, S. Estimation of Energy and Emissions Properties of Waste from Various Species of Mint in the Herbal Products Industry. Energies 2020, 13, 55. [Google Scholar] [CrossRef]

- Maj, G.; Szyszlak-Bargłowicz, J.; Zając, G.; Słowik, T.; Krzaczek, P.; Piekarski, W. Energy and Emission Characteristics of Biowaste from the Corn Grain Drying Process. Energies 2019, 12, 4383. [Google Scholar] [CrossRef]

- Greinert, A.; Mrówczyńska, M.; Szefner, W. The Use of Waste Biomass from the Wood Industry and Municipal Sources for Energy Production. Sustainability 2019, 11, 3083. [Google Scholar] [CrossRef]

- Chojnacka, K.; Moustakas, K. Anaerobic Digestate Management for Carbon Neutrality and Fertilizer Use: A Review of Current Practices and Future Opportunities. Biomass Bioenergy 2024, 180, 106991. [Google Scholar] [CrossRef]

- Lee, M.E.; Steiman, M.W.; Angelo, S.K.S. Biogas Digestate as a Renewable Fertilizer: Effects of Digestate Application on Crop Growth and Nutrient Composition. Renew. Agric. Food Syst. 2021, 36, 173–181. [Google Scholar] [CrossRef]

- Zając, G.; Maj, G.; Szyszlak-Bargłowicz, J.; Słowik, T.; Krzaczek, P.; Gołębiowski, W.; Dębowski, M. Evaluation of the Properties and Usefulness of Ashes from the Corn Grain Drying Process Biomass. Energies 2020, 13, 1290. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial Management of Biomass Combustion Ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Ertuğrul, Ö.; Daher, B.; Özgünaltay Ertuğrul, G.; Mohtar, R. From Agricultural Waste to Energy: Assessing the Bioenergy Potential of South-Central Texas. Energies 2024, 17, 802. [Google Scholar] [CrossRef]

- EN-ISO 16948:2015-07; Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen. ISO: Geneva, Switzerland, 2015.

- ISO 16994:2016; Solid Biofuels—Determination of Total Content of Sulphur and Chlorine. ISO: Geneva, Switzerland, 2016.

- Alves, J.L.F.; da Silva, J.C.G.; Mumbach, G.D.; Domenico, M.D.; da Silva Filho, V.F.; de Sena, R.F.; Machado, R.A.F.; Marangoni, C. Insights into the Bioenergy Potential of Jackfruit Wastes Considering Their Physicochemical Properties, Bioenergy Indicators, Combustion Behaviors, and Emission Characteristics. Renew. Energy 2020, 155, 1328–1338. [Google Scholar] [CrossRef]

- EN-ISO 1928:2009; Solid Mineral Fuels—Determination of Gross Calorific Value by the Bomb Calorimetric Method and Calculation of Net Calorific Value. ISO: Geneva, Switzerland, 2010.

- EN-ISO 18122:2016-01; Solid Biofuels. Determination of Ash Content. ISO: Geneva, Switzerland, 2016.

- EN-ISO 18123:2016-01; Solid Fuels—Determination of Volatile Content by Gravimetric Method. ISO: Geneva, Switzerland, 2016.

- EN-ISO 18134-3:2015; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. ISO: Geneva, Switzerland, 2015.

- Choudhury, N.D.; Saha, N.; Phukan, B.R.; Kataki, R. Characterization and Evaluation of Energy Properties of Pellets Produced from Coir Pith, Saw Dust and Ipomoea Carnea and Their Blends. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–18. [Google Scholar] [CrossRef]

- Kovacs, H.; Szemmelveisz, K.; Koós, T. Theoretical and Experimental Metals Flow Calculations during Biomass Combustion. Fuel 2016, 185, 524–531. [Google Scholar] [CrossRef]

- Paraschiv, L.S.; Serban, A.; Paraschiv, S. Calculation of Combustion Air Required for Burning Solid Fuels (Coal / Biomass / Solid Waste) and Analysis of Flue Gas Composition. Energy Rep. 2020, 6, 36–45. [Google Scholar] [CrossRef]

- Orzeł, A.; Król-Dyrek, K.; Jagła, J.; Lech, W.; Bieniasz, M.; Krośniak, M. Recent Progress in Polish Black Raspberry Breeding at the Niwa Berry Breeding Ltd. Acta Hortic. 2020, 1277, 55–64. [Google Scholar] [CrossRef]

- Dávila, J.A.; Rosenberg, M.; Cardona, C.A. A Biorefinery for Efficient Processing and Utilization of Spent Pulp of Colombian Andes Berry (Rubus Glaucus Benth): Experimental, Techno-Economic and Environmental Assessment. Bioresour. Technol. 2017, 223, 227–236. [Google Scholar] [CrossRef]

- Marian, G.; Ianuș, G.; Istrate, B.; Banari, A.; Nazar, B.; Munteanu, C.; Măluțan, T.; Gudîma, A.; Ciolacu, F.; Daraduda, N.; et al. Evaluation of Agricultural Residues as Organic Green Energy Source Based on Seabuckthorn, Blackberry, and Straw Blends. Agronomy 2022, 12, 2018. [Google Scholar] [CrossRef]

- Ighalo, J.O.; Adeniyi, A.G. Biomass to Biochar Conversion for Agricultural and Environmental Applications in Nigeria: Challenges, Peculiarities and Prospects. Mater. Int. 2020, 2, 111–116. [Google Scholar] [CrossRef]

- Siddiqi, H.; Bal, M.; Kumari, U.; Meikap, B.C. In-Depth Physiochemical Characterization and Detailed Thermo-Kinetic Study of Biomass Wastes to Analyze Its Energy Potential. Renew. Energy 2020, 148, 756–771. [Google Scholar] [CrossRef]

- Lo, S.-L.; Huang, Y.-F.; Chiueh, P.-T.; Kuan, W.-H. Microwave Pyrolysis of Lignocellulosic Biomass. Energy Procedia 2017, 105, 41–46. [Google Scholar] [CrossRef]

- Dorokhov, V.V.; Nyashina, G.S.; Romanov, D.S.; Strizhak, P.A. Combustion and Mechanical Properties of Pellets from Biomass and Industrial Waste. Renew. Energy 2024, 228, 120625. [Google Scholar] [CrossRef]

- Gupta, R. Analysis of Solid and Liquid Fuel Calorific Value. J. Sci. Technol. (JST) 2021, 6, 20–24. [Google Scholar]

- Pérez, S.; Renedo, C.J.; Ortiz, A.; Delgado, F.; Fernández, I. Energy Potential of Native Shrub Species in Northern Spain. Renew. Energy 2014, 62, 79–83. [Google Scholar] [CrossRef]

- Cavalaglio, G.; Cotana, F.; Nicolini, A.; Coccia, V.; Petrozzi, A.; Formica, A.; Bertini, A. Characterization of Various Biomass Feedstock Suitable for Small-Scale Energy Plants as Preliminary Activity of Biocheaper Project. Sustainability 2020, 12, 6678. [Google Scholar] [CrossRef]

- Maj, G. Emission Factors and Energy Properties of Agro and Forest Biomass in Aspect of Sustainability of Energy Sector. Energies 2018, 11, 1516. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An Overview of the Chemical Composition of Biomass. Fuel 2010, 89, 913–933. [Google Scholar] [CrossRef]

- Hossain, T.; Jones, D.S.; Godfrey, E.; Saloni, D.; Sharara, M.; Hartley, D.S. Characterizing Value-Added Pellets Obtained from Blends of Miscanthus, Corn Stover, and Switchgrass. Renew. Energy 2024, 227, 120494. [Google Scholar] [CrossRef]

- Maj, G.; Krzaczek, P.; Stamirowska-Krzaczek, E.; Lipińska, H.; Kornas, R. Assessment of Energy and Physicochemical Biomass Properties of Selected Forecrop Plant Species. Renew. Energy 2019, 143, 520–529. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G.; Vassilev, V.S. Advantages and Disadvantages of Composition and Properties of Biomass in Comparison with Coal: An Overview. Fuel 2015, 158, 330–350. [Google Scholar] [CrossRef]

- Williams, O.; Eastwick, C.; Kingman, S.; Giddings, D.; Lormor, S.; Lester, E. Investigation into the Applicability of Bond Work Index (BWI) and Hardgrove Grindability Index (HGI) Tests for Several Biomasses Compared to Colombian La Loma Coal. Fuel 2015, 158, 379–387. [Google Scholar] [CrossRef]

| Parameter | Variety of Raspberry | p-Value | |||||

|---|---|---|---|---|---|---|---|

| Delniwa | Poemat | Polana | Polesie | Polonez | Poranek | ||

| HHV, MJ·kg−1 | 17.32 c* ± 0.12 | 17.49 b ± 0.12 | 17.33 c ± 0.07 | 17.49 b ± 0.14 | 17.39 bc ± 0.13 | 17.63 a ± 0.11 | <0.0001 |

| LHV, MJ·kg−1 | 16.07 d ± 0.12 | 16.28 bc ± 0.15 | 16.19 bcd ± 0.07 | 16.24 bc ± 0.14 | 16.13 bcd ± 0.13 | 16.39 a ± 0.10 | <0.0001 |

| C,% | 43.86 b ± 0.35 | 43.76 b ± 0.18 | 43.44 c ± 0.17 | 43.87 b ± 0.15 | 44.40 a ± 0.33 | 44.18 a ± 0.18 | <0.0001 |

| H, % | 7.55 a ± 0.03 | 7.55 a ± 0.04 | 7.47 a ± 0.02 | 7.49 a ± 0.03 | 7.53 a ± 0.03 | 7.45 a ± 0.04 | 0.1065 |

| N, % | 1.12 a ± 0.13 | 1.06 ab ± 0.07 | 0.98 bc ± 0.08 | 1.15 a ± 0.08 | 0.96 c ± 0.07 | 1.03 bc ± 0.06 | <0.0001 |

| S, % | 0.43 a ± 0.04 | 0.29 c ± 0.06 | 0.29 c ± 0.04 | 0.35 b ± 0.03 | 0.41 a ± 0.09 | 0.04 d ± 0.01 | <0.0001 |

| M, % | 7.68 bc ± 0.23 | 7.46 d ± 0.13 | 7.61 cd ± 0.11 | 7.99 a ± 0.16 | 7.80 b ± 0.12 | 7.60 cd ± 0.14 | <0.0001 |

| O, % | 44.16 c ± 0.35 | 44.94 a ± 0.23 | 44.76 ab ± 0.41 | 44.75 ab ± 0.27 | 44.76 ab ± 0.51 | 44.43 bc ± 0.45 | <0.0001 |

| A, % | 2.88 a ± 0.46 | 2.39 b ± 0.20 | 3.05 a ± 0.39 | 2.38 b ± 0.31 | 1.94 c ± 0.20 | 2.88 a ± 0.43 | <0.0001 |

| V, % | 71.40 bc ± 0.67 | 72.00 ab ± 0.31 | 72.16 a ± 0.38 | 70.88 c ± 0.65 | 71.07 c ± 0.81 | 71.23 c ± 0.62 | <0.0001 |

| FC, % | 18.03 c ± 0.37 | 18.15 c ± 0.17 | 17.19 d ± 0.36 | 18.76 b ± 0.45 | 19.19 a ± 0.53 | 18.30 c ± 0.36 | <0.0001 |

| Parameter | Variety of Raspberry | p-Value | |||||

|---|---|---|---|---|---|---|---|

| Delniwa | Poemat | Polana | Polesie | Polonez | Poranek | ||

| , Nm3·kg−1 | 0.82 b* ± 0.01 | 0.82 b ± 0.00 | 0.81 c ± 0.00 | 0.82 b ± 0.00 | 0.83 a ± 0.01 | 0.83 a ± 0.00 | <0.0001 |

| , Nm3·kg−1 | 0.0030 a ± 0.0003 | 0.0021 c ± 0.0004 | 0.0020 c ± 0.0003 | 0.0025 b ± 0.0002 | 0.0029 a ± 0.0006 | 0.0002 d ± 0.0009 | <0.0001 |

| , Nm3·kg−1 | 0.94 a ± 0.00 | 0.94 a ± 0.01 | 0.93 a ± 0.00 | 0.94 a ± 0.02 | 0.94 a ± 0.02 | 0.93 a ± 0.02 | 0.0799 |

| , Nm3·kg−1 | 0.72 ab ± 0.01 | 0.71 bc ± 0.00 | 0.70 c ± 0.00 | 0.71 bc ± 0.01 | 0.72 a ± 0.01 | 0.71 ab ± 0.01 | <0.0001 |

| , Nm3·kg−1 | 1.66 a ± 0.01 | 1.65 ab ± 0.01 | 1.64 b ± 0.01 | 1.65 ab ± 0.02 | 1.66 a ± 0.03 | 1.64 ab ± 0.03 | 0.0107 |

| , Nm3·kg−1 | 4.41 a ± 0.09 | 4.34 ab ± 0.05 | 4.24 bc ± 0.07 | 4.41 c ± 0.07 | 4.31 cd ± 0.08 | 4.33 d ± 0.07 | <0.0001 |

| , Nm3·kg−1 | 6.51 ab ± 0.05 | 6.46 bc ± 0.03 | 6.39 c ± 0.04 | 6.46 bc ± 0.06 | 6.55 a ± 0.11 | 6.49 ab ± 0.10 | <0.0001 |

| Vga, Nm3·kg−1 | 6.89 a ± 0.08 | 6.80 bc ± 0.05 | 6.69 d ± 0.07 | 6.89 ab ± 0.08 | 6.80 bc ± 0.10 | 6.79 c ± 0.10 | <0.0001 |

| Vgu, Nm3·kg−1 | 5.24 a ± 0.08 | 5.16 b ± 0.05 | 5.05 c ± 0.07 | 5.23 a ± 0.07 | 5.14 b ± 0.08 | 5.15 b ± 0.07 | <0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maj, G.; Buczyński, K.; Klimek, K.E.; Kapłan, M. Evaluation of Growth and Energy Parameters of One-Year-Old Raspberry Shoots, Depending on the Variety. Energies 2024, 17, 3153. https://doi.org/10.3390/en17133153

Maj G, Buczyński K, Klimek KE, Kapłan M. Evaluation of Growth and Energy Parameters of One-Year-Old Raspberry Shoots, Depending on the Variety. Energies. 2024; 17(13):3153. https://doi.org/10.3390/en17133153

Chicago/Turabian StyleMaj, Grzegorz, Kamil Buczyński, Kamila E. Klimek, and Magdalena Kapłan. 2024. "Evaluation of Growth and Energy Parameters of One-Year-Old Raspberry Shoots, Depending on the Variety" Energies 17, no. 13: 3153. https://doi.org/10.3390/en17133153

APA StyleMaj, G., Buczyński, K., Klimek, K. E., & Kapłan, M. (2024). Evaluation of Growth and Energy Parameters of One-Year-Old Raspberry Shoots, Depending on the Variety. Energies, 17(13), 3153. https://doi.org/10.3390/en17133153