Abstract

The majority of rail vehicles worldwide use diesel as a primary fuel source. Diesel engine carbon emissions harm the environment and human health. Although railway electrification can reduce emissions, it is not always the most economical option, especially on routes with low vehicle demand. As a result, interest in hydrogen-powered trains as a way to reduce greenhouse gas (GHG) emissions has steadily grown in recent years. In this paper, we discuss advancements made in hydrogen-powered freight and commuter trains, as well as the technology used in some aspects of hydrogen-powered vehicles. It was observed that hydrogen-powered trains are already in use in Europe and Asia, unlike most developing countries in Africa. Commuter trains have received most of the research and development (R&D) attention, but interest in hydrogen-powered freight trains has recently picked up momentum. Despite the availability and use of gray and blue hydrogen, green hydrogen is still the preferred fuel for decarbonizing the rail transport sector.

1. Introduction

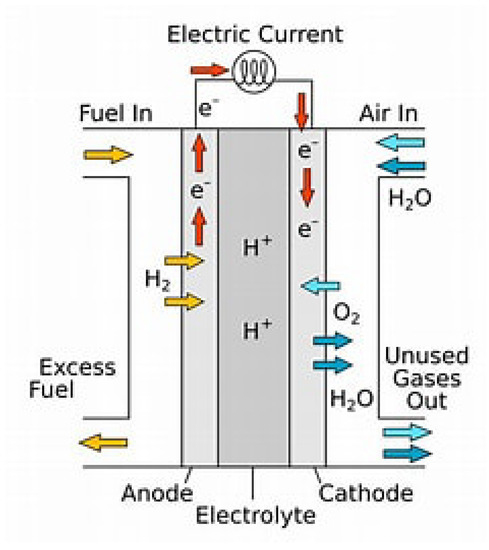

The transport sector accounts for 25% of the worlds energy consumption in developed countries, showing a strong connection between energy use and economic growth [1,2]. Passenger and freight transportation consume roughly 40 to 60% of the energy used in transportation-related activities [2]. As a result, the transport sector is responsible for 15 to 31% of global man-made carbon emissions [3]. Trains use diesel fuel and or electricity for propulsion systems, with each having its pros and cons [4]. According to [5], diesel engines currently account for 70% of all locomotive power used in rail transport worldwide, with electric locomotives making up the remaining 30%. Electricity is generated from a variety of sources, including renewables such as hydro, solar, wind, biomass, and geothermal energy, as well as fossil fuels such as coal, natural gas, and oil. Diesel fuel is a refined crude oil used in an internal combustion engine (ICE). It ignites by compressing inlet air and injecting it into a combustion chamber [6]; it enables trains to run continuously and ensures trains travel over routes where electrification is not cost-effective or routes that have not yet been electrified. However, diesel emissions harm human health, the environment, and global climate change. Today, science and technology have made it possible to reduce carbon emissions by utilizing a clean energy carrier such as hydrogen to eliminate the use of fossil fuels in the railway transport industry. Fuel cell technology is the appropriate technology to be used with hydrogen to generate clean electricity for vehicles [4,5]. A fuel cell uses a chemical reaction to convert the chemical energy of hydrogen fuel and oxygen into electrical energy. It offers a clean and sustainable form of energy. If fuel and oxygen are supplied to the electrodes, fuel cells can continuously produce electricity. FCs have a variety of applications, including railway vehicles. There are various types of fuel cells, all having three main components: an anode, a cathode, and an electrolyte. A catalyst at the anode causes the hydrogen fuel to go through oxidation reactions that produce ions and electrons [7]. The electrolytes facilitate the movement of the ions from the anode to the cathode. A direct current electricity is generated concurrently as electrons move from the anode to the cathode in the external circuit. As ions, electrons, and oxygen interact at the cathode, a different catalyst triggers the formation of water and heat.

There are various types of hydrogen fuel cell technologies, the following are the ones frequently used: Polymeric Electrolyte Membrane Fuel Cell (PEMFC), Alkaline Fuel Cell (AFC), Phosphoric Acid Fuel Cell (PAFC), Solid Oxide Fuel Cell (SOFC), and Molten Carbonate Fuel Cell (MCFC) [7]. PEMFCs are the best suited for automotive and railway applications due to their high power densities, low operating temperatures, and lack of dependence on potentially dangerous fluids [8]. Due to their many advantages over other FC types, including their relatively quick startup and shutdown times, PEMFCs are generally the most widely used FC technology. The use of expensive metal catalysts drives up the cost of these products, and the poisoning effect of platinum catalysts is one of their main disadvantages [9]. The AFC is another low-temperature FC technology that is less expensive than PEMFCs, but because of its sensitivity to molecules, it performs significantly more poorly than PEMFCs [9]. According to the US Department of Energy, due to lower efficiency and higher operating temperatures (200 °C) than earlier FCs, PAFCs have longer lifetimes and less platinum catalyst poisoning. They are primarily used in systems for stationary power and heat generation [9]. SOFCs operate on higher temperatures, allowing for high power output (up to 2 MW) and high efficiency but also resulting in low performance at lower temperatures, a lengthy start-up process, higher material costs, and complex design and assembly [10]. Another high-temperature FC, MCFCs, are used primarily in stationary power generation systems and have high output power (up to 3 MW) [9]. Hydrogen could reduce GHG emissions by 5 to 6 gigatons annually by the year 2050 [11]. Hydrogen can burn in air and has a flammability range of 4% to 75% [4], making it suitable for use in some types of combustion engines, where it burns similarly to fossil fuels [4]. The vehicle efficiency for a hydrogen-powered car is 41%, and 45% for hydrogen hybrid, compared with 25% for a diesel–electric train [12]. In this paper, a review of technical advances in hydrogen-powered trains internationally is carried out. This will assist decision makers, heads of state, politicians, policy makers, and train operators around the world when deciding on hydrogen to decarbonize the rail sector. Previous research had a strong emphasis on topics like environmental performance, hydrogen production, prototype designs and analysis, feasibility, and economic assessment. However, it omitted the analysis of the advancements in hydrogen trains. Scholarly works published between 2009 and 2023 are used to review the advances in commuter trains and hydrogen freight locomotives. This paper is outlined as follows: Section 2 provides a brief literature on hydrogen as a fuel. Section 3 and Section 4 deals with fuel cell technology and advances in hydrogen-powered trains. Section 5 discusses the retrofitting of the existing trains, while Section 6 deals with hydrogen refueling infrastructure. This study does not include trams.

2. Hydrogen Fuel

Hydrogen is a flammable gas that is odorless, colorless, and tasteless. According to [13], fossil fuels are the primary source of hydrogen synthesis, with natural gas contributing 75% of total production. Then, coal accounts for 23% of hydrogen generation, while oil and electrolysis contribute the remainder of the supply. Hydrogen has the most energy content by weight of any fuel but the least by volume [14]. It is frequently denoted as the missing link in energy transformation. Hydrogen is used as fuel-on-fuel cells and spaceships because of its high energy content. Although hydrogen exists naturally, it must be synthesized in one of these three methods to be useful: (1) electrolysis, (2) gasification, and (3) pyrolysis. Electrolysis is where water is separated into chemical elements: hydrogen and oxygen. The hydrogen gas produced through electricity supplied by renewable energy is referred to as “green hydrogen”. Green hydrogen accounts for approximately 1% of global hydrogen generation. Coal gasification, mostly a methane transformation to produce and , is referred to as “gray hydrogen”, but if is stored, the hydrogen generated is referred to as “blue hydrogen”. This technology currently accounts for nearly 99% of global hydrogen, which is 70 million tons. Clean energy from renewable sources can be used to power this “turquoise hydrogen” process.

Water electrolysis, coal, natural gas, and plant materials are all used to create hydrogen on a massive scale. As a result, while the final product produces less pollution, the benefits are diluted if fossil fuels and are used in the manufacturing process. The term “green” refers to hydrogen derived from biogenic sources or electrolysis powered by zero-carbon electricity. Green hydrogen is created by breaking water into and using suitable energy sources such as solar photovoltaic (solar PV) and wind power. All these green hydrogen-generating methods are not widely used at the moment. However, solar and wind are becoming more widely available and less expensive, which will lead to green electrolytic hydrogen becoming more popular in the future [15]. Electrolysers are a modest and slow-growing market, with growth rates significantly lower than technologies such as solar photovoltaic [16]. In some areas of the transportation, industrial, and power sectors, green hydrogen could replace higher-carbon fuels. It can operate as an anchor for recycling carbon dioxide and offer low-carbon feedstock, as well as reduce gas for chemical processes. Increasing demand for green hydrogen will necessitate significant investment and construction of electricity transmission, distribution, and storage networks, as well as much larger volumes of zero-carbon power generation, electrolyser production systems, hydrogen pipelines, and hydrogen fueling systems [15]. A proliferation of green hydrogen and hydrogen fuels could enhance local economies and the environment in numerous ways, including a reduction in particulate and sulfur pollution, the maintenance or expansion of high-wage jobs, and new opportunities for export [15]. In a fuel cell, hydrogen is burned with oxygen to create electricity, making it a clean source of energy. Burning hydrogen in a boiler or furnace produces no direct emissions. Hydrogen fuel cell technology offers the advantage of having a minimal carbon footprint, which contributes to cleaner air and improved human health. During hydrogen combustion in the air, nitrogen oxide is produced, while many other pollutants are avoided, including carbon monoxide, soot, and partially burned hydrocarbons [17].

3. Fuel Cell Technology

A fuel cell is an energy conversion device that generates electricity through an electrochemical reaction. It is considered reliable compared with a traditional combustion engine, with the advantage of high efficiency and being pollution-free. It is not a new concept; it was originally discovered in 1839 [18]. In 1960, the primary hydrogen fuel cell vehicle was developed, and the National Aeronautics and Space Administration (NASA) utilized fuel cells for both Apollo and the space shuttle [19]. Most fuel cells are in various development stages. The most commonly used are Alkaline Fuel Cell (AFC), Solid Oxide Fuel Cell (SOFC), Polymer Electrolyte Fuel Cell (PEFC), Phosphoric Acid Fuel Cell (PAFC), and Molten Carbonate Fuel Cell (MCFC). A fuel cell is made up of two electrodes, an anode, and a cathode sandwiched together with an electrolyte layer. Figure 1 shows a diagram of a fuel cell with a reaction of gases and the flow of ions through the cell. Fuel is continuously supplied to the anode side, and oxygen is drawn from outside through the cathode. Typically, a single fuel cell produces 1V of electricity or less. To produce more electricity, stacked fuel cells are realized by connecting them in series. The term “fuel cell” refers to both a stack and individual cells under the fuel cell umbrella. Depending on the application, it may require a few cells or up to a hundred cells stacked together to achieve the required output power. The versatility of fuel cells makes them ideal for a wide array of applications.

Figure 1.

Fuel cell diagram [20].

In general, fuel cell categorization is determined by the electrolyte material used, size, and pressure at which gas is supplied. Electrolytes play an important role in the kind of chemical reaction that occurs in a fuel cell, the operating temperature range, and other variables that determine its use.

Table 1 presents a comparison of FC parameters from a literature review. PEMFC is a preferred technology for automotive transport and railway application [21]. It is viewed as an optimal choice for application in vehicles, light rail, trams, locomotives, and underground mining locomotives due to its moderate operating temperatures (50–100 °C). Solid Oxide Fuel Cells (SOFCs), on the other hand, are more efficient than any other type of FC but operate at higher temperatures between 600–1000 °C. The disadvantages of the fuel cells are the use of expensive metal catalysts, which drives up the cost of these products, and the poisoning effect of platinum catalysts [9]. The scientific community continues to search for cheaper alternative catalysts for fuel cells that can replace platinum, which is expensive. As a result of the constant duty cycle of locomotives, SOFC specification is considered a promising technology for heavy rail transport, except that it operates at higher temperatures [10]. SOFCs can run on a wide range of fuels and under a variety of operational circumstances [22].

Table 1.

Fuel Cell (FC) Technology Parameter comparison [23].

4. Advances in Hydrogen-Powered Trains

Around the world, there are 16 hydrogen commuter trains deployed, 61 more in manufacturing stages, and 2 or more hydrogen locomotive projects; see Table 2. While the research and development for several alternative propulsion concepts is still in its infancy, hydrogen for rail use is already available around the world. Cummins Inc. (Columbus, OH, USA) collaborated with Alstom, la Rochelle, France, a French Railway Company, in 2016 to engineer, deliver, and integrate a hydrogen fuel cell solution in its Coradia iLint trains [24]. Coradia iLint is the first hydrogen fuel-cell-powered passenger train. A total of two prototype trains went through field tests on the Elbe–Weser network in Lower Saxony, Germany in September 2018 and traveled over 180,000 km on a regular passenger service track [25,26]. A record of 1175 km without refueling was set by the German Coradia iLint. Additionally, a total of 14 fuel cell trains were deployed in Bremervörde, Lower Saxony in August 2022, following the success of hydrogen-fueled passenger train tests in Germany [26,27]. Additional trials outside Germany were carried out in UK, Denmark, Norway, Sweden, Italy, the Netherlands, Canada, Austria, and France [26]. The Japanese railway company Hitachi Ltd., in collaboration with Toyota Motor Corporation, has designed, built, and tested a hydrogen-powered passenger train (Hybari) in Japan with a top speed of 100 km/h that can travel up to 140 km on a single filling [28]. The China Railway Rolling Stock Corporation (CRRC) in China has also designed, manufactured, and tested a hydrogen fuel-cell-powered passenger train with a top speed of 160 km/h, and it covers a distance of 600 km before refueling. In addition, the train adopted the most cutting-edge automatic driving technology. The hybrid hydrogen fuel cell locomotive was also manufactured at the CRRC Datong plant in Shanxi province [29,30]. This is the first hybrid locomotive (Hyrail) made in China, and it represents a significant development for the country’s use of hydrogen energy technology by enabling locomotives to achieve zero emissions of carbon and other pollutants [29,31]. On flat, straight roads, this locomotive can travel at a design speed of 80 km/h, with a maximum traction load of more than 5000 metric tons. On a full tank of hydrogen, it can operate continuously for 24.5 h [29,32]. This makes China the second nation in the world and the first in Asia to develop hydrogen trains. In other nations, R&D is being conducted as well. In Lower Saxony, Germany, a public transport operator has decided to move forward with the plans to replace all diesel trains on that line with hydrogen fuel cell trains as a result of the success of the region’s hydrogen fuel cell train trials. Of the 41 trains ordered in Germany, 14 were delivered by Alstom and deployed to Lower Saxony [29,33]. France ordered 12 dual-mode trains (electric and hydrogen traction) from Alstom, and Italy also ordered 6 hydrogen fuel cell trains [29,33]. In a contract that is signed with Alstom, a Polish company, PKN Orlen, agreed to supply and distribute hydrogen, while Alstom would provide the trains. Within two years, their first hydrogen trains are anticipated to begin operating on regional lines. Along with Alstom, Siemens Mobility has created a hydrogen-powered passenger train and a mobile trailer for hydrogen storage. According to Siemens, testing of their train will start in the middle of 2023, with the start of full service in Germany planned for January 2024 [24,33]. Siemens and Alstom both manufacture hydrogen-powered trains with fuel cells mounted on the roofs of passenger cars. Stadler unveiled its hydrogen-powered passenger train, which will start running in California in 2024 [29,34]. The San Bernardino County Transportation Authority ordered the two-car train-set in 2019. To bring hydrogen to European rail freight, Alstom and Engie have partnered [27,33]. A two-stroke locomotive with blended ammonia fuel was successfully combusted during testing of zero-emission locomotives by Fortescue Future Industries, a division of Fortescue Metals Group, [29]. This is an integral part of Fortescue’s bold goal to achieve the climate goals for Scope 1 and 2 emissions by 2030. As they concentrate on investing in renewable energy and phasing out the use of diesel across the mining fleets, their target is supported by a pathway to decarbonization. To enable the conversion of diesel trains to hydrogen operation, Talgo in Spain has designed its fuel cell technology in a modular way that can be installed on all types of trains. But Talgo’s solution was created with the Vittal platform in mind. With this commuter and regional train, Talgo hopes to win several bids in Spain and other nations [29]. Talgo, a Spanish manufacturer of rolling stock, claims that its hydrogen train will be ready in 2023. In May 2012, Anglo American unveiled a prototype fuel cell hydrogen mining locomotive. TransNamib has announced that they have received funding from the German Federal Ministry of Education and Research for a hydrogen locomotive project. The Namibian National Railways intends to build Africa’s first dual-fuel hydrogen–diesel locomotives. For academic studies, the University of Birmingham designed and built the narrow-gauge locomotive “Hydrogen Pioneer”, which was used to test the capabilities of a hydrogen hybrid railway traction vehicle [35]. Numerous scientific tests were carried out to accomplish this project. The power plants total duty cycle efficiency was reported to range between 28% and 40% [35]. A prototype hydrogen-fueled fuel cell–battery hybrid shunt locomotive for city and military base rail applications has been created by a North American consortium consisting of BNSF Railway Company (Fort Worth, TX, USA), the US Army Engineers, and Vehicle Projects Inc. (Golden, CO, USA) [36].

Table 2.

Deployed hydrogen trains and trains under development.

4.1. The Advantages of Hydrogen-Powered Trains

Compared with internal combustion engines (ICE), FCs have several benefits, namely high efficiency, low noise, and emission-free operations at the point of use, with the only waste products being water vapor and heat [10]. According to [41], hydrogen-powered trains are flexible to levels of hybridization, zero emissions, quick refueling, reduced downtime, absence of any operational restrictions, and lower operating costs [41]. However, they have a slow dynamic response, which necessitates the hybridization of a vehicle with an energy storage system (ESS) and coordinating energy management and control strategies to smooth out power fluctuations and enable the recovery of braking energy [42]. Nevertheless, in areas where track electrification is not financially viable, hydrogen-powered trains hold the promise of meeting the operational needs of rail transportation. Furthermore, because hydrogen-powered trains have fewer moving parts in a fuel cell system, downtime, repair, and maintenance costs are predicted to be lower than diesel counterparts [25].

4.2. Limitations of Hydrogen-Powered Trains

There are already practical commercial uses for hydrogen-powered trains, which is very promising. Nevertheless, a few potential obstacles came to light as important challenges that the scientific community is busy addressing, such as the transportation and onboard storage of hydrogen [43]. In order to operate safely and within time constraints for charging, hydrogen refueling stations (HRS) and tankers must meet safety standards that have not yet been incorporated into railroad regulations [43].

5. Retrofitted Existing Trains

In the United Kingdom (UK), an existing electric train class, 319001, has been retrofitted with hydrogen modules. The train is called Hydro-Flex, which is a result of collaboration between Poterbrook and the University of Birmingham. This was achieved by integrating a hydrogen fuel tank, fuel cells, batteries, electric motors, and a control system [44]. According to Professor Stephen Jarvis, Hydro-Flex is an illustration of how cutting-edge R&D combined with the appropriate industry partnerships can produce decarbonization technologies. The project proved that it is possible to fully decarbonize train propulsion systems by using hydrogen as an alternative fuel. Canadian Pacific (CP) has launched its first hydrogen locomotive (H2OEL), which is still being in-service tested. The H2OEL is a diesel–electric heavy haul locomotive that was retrofitted with hydrogen modules [29]. The pioneering Canadian pilot program will launch in 2024 and last through the end of 2026. India’s first hydrogen-powered trains will be developed by Medha Ballard’s most recent fuel cell technology, which offers better efficiency and power density than earlier module generations, and they will be integrated into the two retrofitted diesel–electric commuter trains in the form of eight units of 100 kW fuel cells [45,46]. The first deployment of the trains is expected to happen in 2024, with the potential for subsequent retrofits. An electric multiple units retrofitted with hydrogen fuel cells was tested in Scotland as part of a project involving the University of St Andrews, Transport Scotland, Scottish Enterprise, Ballard Motive Solutions, Abbott Risk Consulting, ARUP, Aegis, and Angel Trains [45,46].

6. Hydrogen Refueling Infrastructure

No matter how trains are propelled, rail transport systems and equipment are essential for the efficient and safe transportation of commuters and goods throughout the world. However, managing safety issues becomes a significantly more difficult task when it comes to hydrogen train equipment and systems. Hydrogen is an extremely combustible fuel that if incorrectly stored or managed, can result in the creation of an explosive environment [47]. There are currently no applicable rail-specific regulations and standards for the use of hydrogen [27]. The majority of risks can be controlled by combining the existing standards for railways with the existing regulations for other uses of hydrogen. Even though the respective procedure is currently not universally regulated, uncertainty and risks must be addressed by individual actions up to an acceptable level [47]. For illustration, type approval is required in accordance with Regulation (EC) No. 79/2009 of the European Parliament and Council of the European Union, which was replaced by R134 after July 2022 for hydrogen pressure storage systems used on hydrogen-powered motor vehicles [27]. With an increase in hydrogen vehicles, there is a significant increase in the amount of hydrogen infrastructure required to connect regions with abundant resources to produce low-emission hydrogen with markets, as production volumes and transport distances increase to meet rising demand. The energy density of hydrogen is very low; one cubic meter of hydrogen only contains a third of the energy of a cubic meter of natural gas at the same pressure and temperature, and its boiling point is as low as −253 °C, compared with −162 °C for natural gas, making the development of the infrastructure for hydrogen transmission a difficult task [33]. Similarly, natural gas is currently transported through pipelines, and hydrogen can also be transported using pipelines. In the United States, there are currently about 2600 km of hydrogen pipelines in use, and there are about 2000 km in Europe. These pipelines are situated where major hydrogen consumers, such as petroleum refineries and chemical plants, are concentrated and are owned by commercial hydrogen producers, such as Air Liquide, Air Products, and Linde [27,33]. In the case where the pipelines are not economically viable due to relatively low volumetric flows, hydrogen gas can be transported to consumers with relatively low demands in multielement gas container trailers, such as steel high-pressure tubes, in lighter composite pressure vessels, or in thermoinsulated cryogenic vessel trailers as liquid hydrogen for consumers with medium-sized demand [27,33]. The PNW 9-2697 International Electrotechnical Commission (IEC) plans to complete the international standardization of work on fuel cell systems for propulsion (Part 2: Hydrogen storage system) in February 2024 for railway rolling stock application [48].

7. Summary and Discussion

A multitude of prospective technologies for clean rail vehicles have emerged because of research and development (R&D); one of the promising alternatives is hydrogen. Although green hydrogen is the preferred option, the industry is currently using gray hydrogen. Over the previous 16 years, the rail industry, in collaboration with universities, has produced prototype trains and demonstrations that have been tested in operation, and more recently, a series of FC hydrogen commuter trains have entered the commercial market. The deployment of FC hydrogen rail vehicles will not only improve energy efficiency but also significantly reduce carbon emissions. The SOFC and PEMFC technologies are strong contenders to address environmental issues because of the high infrastructure cost of electrification. Due to low operating temperatures, high efficiency, and quick start-up, PEMFC appears more suitable for commuter rail applications than SOFC, which has a higher efficiency and the potential to be used on heavy haul locomotives. According to previous scholars, hydrogen FC trains are more efficient than diesel trains. In addition, there are a lot of positive developments in heavy haul locomotives; however, they have received little attention. Currently, there are no rail-specific regulations or standards in place for the use of hydrogen. Most safety risks are mitigated by combining existing railway standards with the existing regulations for other uses of hydrogen. The key issue to be addressed includes developing a network of hydrogen refueling infrastructures. This study examines the literature and activity reports on progress made in the field of hydrogen FC technologies, highlighting the advancement of hydrogen-powered trains around the world.

8. Conclusions and Recommendations

Over the past 16 years, the technology for hydrogen and FC has advanced significantly. The majority of European and Asian nations have included FCs and hydrogen in their road maps for energy production strategies. Hydrogen FC trains will provide a solution when rail operators are experiencing problems with their high-voltage infrastructure, such as cable theft, and the distances are too great for battery–electric trains to travel. Therefore, the use of hydrogen-powered rolling stock will aid in the growth of a low-carbon society by reducing global warming and diversifying energy sources. Hydrogen is no longer a fuel of the future; it is a reality and has arrived. The majority of countries have expressed an interest in purchasing hydrogen trains to combat climate change, and some have already signed memorandums of understanding (MoU’s) with hydrogen train manufacturers. Hydrogen implementation has advanced significantly in the last six years, particularly in European countries. The African nations have not made much progress in hydrogen technology, except for the mining sector, such as Anglo-Americans in South Africa. The African nations are supposed to be better positioned to contribute significantly to the development of hydrogen trains compared with other countries due to their platinum mines, as well as the abundance of wind and sun for renewable energy generation. Even though the African countries have made little progress in the implementation of hydrogen trains and hydrogen technology at large, it is part of the governments’ energy strategy and will be incorporated into state policies. Hydrogen trains can easily replace diesel locomotives and commuter trains. For nations that see hydrogen as a future transportation option, the sky is the limit. Even though hydrogen is already used in the rail sector in countries such as Europe and Asia, the African continent lags. The conclusions above offers some recommendations for decision makers on how to implement hydrogen trains to reduce GHG emissions in the global rail sector:

- Countries that are lagging in the adoption of hydrogen trains should collaborate with nations like Asia and Europe that have expertise in the technology.

- Feasibility studies on the infrastructure required for hydrogen trains, as well as the deployment strategy, should be conducted in all the countries that are lagging.

- Increase spending for research and development (R&D) in order to achieve economic strategic goals.

- Globally, state policies should be changed to enable the deployment of hydrogen technology.

Author Contributions

Conceptualization A.N., T.C.M. and A.A.Y.; writing—original draft preparation, A.N.; writing—review and editing, A.N., T.C.M. and A.A.Y.; supervision, T.C.M. and A.A.Y. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by National Research Foundation South Africa grant number 150572.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Mohsin, M.; Abbas, Q.; Zhang, J.; Ikram, M.; Iqbal, N. Integrated effect of energy consumption, economic development, and population growth on CO2 based environmental degradation: A case of transport sector. Environ. Sci. Pollut. Res. 2019, 26, 32824–32835. [Google Scholar] [CrossRef] [PubMed]

- Rodrigue, J.-P. The Geography of Transport Systems; Routledge: New York, NY, USA, 2020. [Google Scholar]

- Fuglestvedt, J.; Berntsen, T.; Myhre, G.; Rypdal, K.; Skeie, R.B. Climate forcing from the transport sectors. Proc. Natl. Acad. Sci. USA 2008, 105, 454–458. [Google Scholar] [CrossRef] [PubMed]

- Din, T.; Hillmansen, S. Energy consumption and carbon dioxide emissions analysis for a concept design of a hydrogen hybrid railway vehicle. IET Electr. Syst. Transp. 2018, 8, 112–121. [Google Scholar] [CrossRef]

- Hoffrichter, A. Hydrogen as an Energy Carrier for Railway Traction. Ph.D. Thesis, University of Birmingham, Birmingham, UK, 2013. [Google Scholar]

- Wang, Y.; Wang, H.; Meng, X.; Tian, J.; Wang, Y.; Long, W.; Li, S. Combustion characteristics of high pressure direct-injected methanol ignited by diesel in a constant volume combustion chamber. Fuel 2019, 254, 115598. [Google Scholar] [CrossRef]

- Ahmed, H.; Adebayo, P.; Ahmed, M.; Arbab, A.I. Hydrogen Fuel Cell Technology: Benefits, Challenges, and Future Potential. J. Energy Technol. Policy 2023, 13. [Google Scholar] [CrossRef]

- Giorgi, L.; Leccese, F. Fuel cells: Technologies and applications. Open Fuel Cells J. 2013, 6, 1–20. [Google Scholar] [CrossRef]

- Kapetanović, M.; Nunez, A.; van Oort, N.; Goverde, R.M. Analysis of hydrogen-powered propulsion system alternatives for diesel-electric regional trains. J. Rail Transp. Plan. Manag. 2022, 23, 100338. [Google Scholar] [CrossRef]

- Sun, Y.; Anwar, M.; Hassan, N.; Spiryagin, M.; Cole, C. A review of hydrogen technologies and engineering solutions for railway vehicle design and operations. Railw. Eng. Sci. 2021, 29, 212–232. [Google Scholar] [CrossRef]

- Ludwig, M.; Lüers, M.; Lorenz, M.; Hegnsholt, E.; Kim, M.; Pieper, C.; Meidert, K. The Green Tech Opportunity in Hydrogen; Boston Consulting Group: Boston, MA, USA, 2021. [Google Scholar]

- Hoffrichter, A.; Hillmansen, S.; Roberts, C. Conceptual propulsion system design for a hydrogen-powered regional train. IET Electr. Syst. Transp. 2016, 6, 56–66. [Google Scholar] [CrossRef]

- Patel, M. Green Hydrogen: A Potential Export Commodity in a New Global Marketplace; Trade & Industrial Policy Strategies (TIPS): Pretoria, South Africa, 2020. [Google Scholar]

- Thapa, B.S.; Thapa, B. Green hydrogen as a future multi-disciplinary research at Kathmandu university. J. Phys. Conf. Ser. 2020, 1608, 012020. [Google Scholar] [CrossRef]

- Fan, Z.; Ochu, E.; Braverman, S.; Lou, Y.; Smith, G.; Bhardwaj, A.; Brouwer, J.; McCormick, C.; Friedmann, J. Green Hydrogen in a Circular Carbon Economy: Opportunities and Limits; Columbia Center for Global Energy Policy: New York, NY, USA, 2021. [Google Scholar]

- Grimm, A.; de Jong, W.A.; Kramer, G.J. Renewable hydrogen production: A techno-economic comparison of photoelectrochemical cells and photovoltaic-electrolysis. Int. J. Hydrogen Energy 2020, 45, 22545–22555. [Google Scholar] [CrossRef]

- Frassoldati, A.; Faravelli, T.; Ranzi, E. A wide range modeling study of NOx formation and nitrogen chemistry in hydrogen combustion. Int. J. Hydrogen Energy 2006, 31, 2310–2328. [Google Scholar] [CrossRef]

- Thomas, J.M.; Edwards, P.P.; Dobson, P.J.; Owen, G.P. Decarbonising energy: The developing international activity in hydrogen technologies and fuel cells. J. Energy Chem. 2020, 51, 405–415. [Google Scholar] [CrossRef]

- Singh, M.; Zappa, D.; Comini, E. Solid Oxide Fuel Cell: Decade of progress, future perspectives and challenges. Int. J. Hydrogen Energy 2021, 46, 27643–27674. [Google Scholar] [CrossRef]

- Motylinski, K.; Skrzypkiewicz, M.; Naumovich, Y.; Wierzbicki, M.; Kupecki, J. Effects of gas velocity on formation of carbon deposits on AS-SOFC fuel electrodes. J. Power Technol. 2018, 98, 322–328. [Google Scholar] [CrossRef]

- Peng, F.; Chen, W.; Liu, Z.; Li, Q.; Dai, C. System integration of China’s first proton exchange membrane fuel cell locomotive. Int. J. Hydrogen Energy 2014, 39, 13886–13893. [Google Scholar] [CrossRef]

- Cinti, G.; Desideri, U. SOFC fuelled with reformed urea. Appl. Energy 2015, 154, 242–253. [Google Scholar] [CrossRef]

- Fan, L.; Tu, Z.; Chan, S.H. Recent development of hydrogen and fuel cell technologies: A review. Energy Rep. 2021, 7, 8421–8446. [Google Scholar] [CrossRef]

- Saeed, M.; Briz, F.; Guerrero, J.M.; Larrazabal, I.; Ortega, D.; Lopez, V.; Valera, J.J. Onboard energy storage systems for railway: Present and trends. IEEE Open J. Ind. Appl. 2023, 4, 238–259. [Google Scholar] [CrossRef]

- Norman, H. Tomorrow’s World. Electr. Hybrid Rail Technol. 2021, 2021, 4–66. [Google Scholar] [CrossRef]

- Gjerdingen, I.K. Hydrogen Technology Experimentation for Sustainable Mobility–A Case Study of Hydrogen Fuel Cell Experimentation in Lower Saxony in Germany. Master’s Thesis, University of Oslo, Oslo, Norway, 2020. [Google Scholar]

- Böhm, M.; Del Rey, A.F.; Pagenkopf, J.; Varela, M.; Herwartz-Polster, S.; Calderón, B.N. Review and comparison of worldwide hydrogen activities in the rail sector with special focus on on-board storage and refueling technologies. Int. J. Hydrogen Energy 2022, 47, 38003–38017. [Google Scholar] [CrossRef]

- Pielecha, I.; Dimitrov, R.; Mihaylov, V. Energy flow analysis based on a simulated drive of a hybrid locomotive powered by fuel cells. Rail Veh. Szyn. 2022, 1–2, 68–76. [Google Scholar] [CrossRef]

- Herwartz, S.; Pagenkopf, J.; Streuling, C. Sector coupling potential of wind-based hydrogen production and fuel cell train operation in regional rail transport in Berlin and Brandenburg. Int. J. Hydrogen Energy 2021, 46, 29597–29615. [Google Scholar] [CrossRef]

- Verheul, B. Overview of Hydrogen and Fuel Cell Developments in China; Holland Innovation Network China: Beijing, China, 2019. [Google Scholar]

- Zimmerman, J.A.; Hensley, M. H2@ RailSM Workshop; Technical report; Sandia National Lab. (SNL-CA): Livermore, CA, USA; Sandia National Lab. (SNL-NM): Albuquerque, NM, USA, 2019.

- Asimeng, E.T.; Altenburg, T. Urban Rail Implementation in Emerging Economies: An Opportunity for Industrial Development and Technological Learning? German Institute of Development and Sustainability (IDOS): Bonn, Germany, 2022. [Google Scholar]

- Agency, I.E. Global Hydrogen Review 2022; OECD Publishing: Paris, France, 2022. [Google Scholar]

- Hosseini, S.E. Hydrogen fuel, a game changer for the world’s energy scenario. Int. J. Green Energy 2023, 13, 1–17. [Google Scholar] [CrossRef]

- Hoffrichter, A.; Fisher, P.; Tutcher, J.; Hillmansen, S.; Roberts, C. Performance evaluation of the hydrogen-powered prototype locomotive ‘Hydrogen Pioneer’. J. Power Sources 2014, 250, 120–127. [Google Scholar] [CrossRef]

- Miller, A.R.; Hess, K.S.; Erickson, T.L.; Dippo, J.L. Fuelcell-hybrid shunt locomotive: Largest fuelcell land vehicle. In Proceedings of the IET Conference on Railway Traction Systems (RTS 2010), Birmingham, UK, 13–15 April 2010. [Google Scholar]

- Xu, Z.; Zhao, N.; Hillmansen, S.; Roberts, C. Techno-economic analysis of hydrogen storage technologies for railway engineering. Energies 2022, 15, 6467. [Google Scholar] [CrossRef]

- Mast, T. Advances in Railway Mechanical Engineering 2020–2021 Survey–Locomotives. In Proceedings of the ASME/IEEE Joint Rail Conference, Online, 20–21 April 2022; American Society of Mechanical Engineers: New York, NY, USA, 2022; Volume 85758, p. V001T08A001. [Google Scholar]

- Palmer, C. Hydrogen-Powered Trains Start to Roll. Engineering 2022, 11, 9–11. [Google Scholar] [CrossRef]

- Stobnicki, P.; Gallas, D. Adoption of modern hydrogen technologies in rail transport. J. Ecol. Eng. 2022, 23, 84–91. [Google Scholar]

- Fúnez Guerra, C.; Reyes-Bozo, L.; Vyhmeister, E.; Salazar, J.L.; Caparrós, M.J.; Clemente-Jul, C. Sustainability of hydrogen refuelling stations for trains using electrolysers. Int. J. Hydrogen Energy 2021, 46, 13748–13759. [Google Scholar] [CrossRef]

- Siddiqui, O.; Dincer, I. A review on fuel cell-based locomotive powering options for sustainable transportation. Arab. J. Sci. Eng. 2019, 44, 677–693. [Google Scholar] [CrossRef]

- Gandini, L.M.; Ricci, S.; Verrascina, F. Hydrogen powered trains challenges: Normative constraints and operational assessment. In Proceedings of the Resource Efficient Vehicles Conference, Online, 14–16 June 2021. [Google Scholar]

- Manoharan, Y.; Hosseini, S.E.; Butler, B.; Alzhahrani, H.; Senior, B.T.F.; Ashuri, T.; Krohn, J. Hydrogen fuel cell vehicles; current status and future prospect. Appl. Sci. 2019, 9, 2296. [Google Scholar] [CrossRef]

- Norman, H. Put to the Testing Test. Electr. Hybrid Rail Technol. 2022, 2022. [Google Scholar] [CrossRef]

- Murray-Smith, D.J.; Fisher, P. Hybrid Trains for the Highlands? Computer Simulations of Fuel-Cell/Battery-Electric Trains on Secondary Routes in Scotland; Technical Report; University of Glasgow: Glasgow, UK, 2021. [Google Scholar]

- Wichmann, T.; Heyn, J. Risk and regulation-based safety verification of hydrogen technology for rail vehicles. ZEVrail Tagungsband Schienenfahrzeugtagung Graz 2021, 2021, 57e63. [Google Scholar]

- International Electrotechnical Commission (IEC). PNW 9-2697 ED1 Railway Applications–Rolling Stock–Fuel Cell Systems for Propulsion-Part 2: Hydrogen Storage System. 2021. Available online: https://www.iec.ch/dyn/www/f?p=103:38:9548088943215::::FSP_ORG_ID,FSP_APEX_PAGE,FSP_PROJECT_ID:1248,23,105233 (accessed on 15 August 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).