Abstract

Standalone photovoltaic (PV) systems are crucial for providing reliable, cost-effective, and sustainable energy to remote or off-grid locations with limited or no access to the traditional electrical grid. In this context, the sizing of a standalone PV system for a remote health clinic involves determining the clinic’s power requirements and matching them with an appropriate PV system’s capacity. Maximum power point tracking (MPPT) is a critical aspect of standalone PV systems, as it optimizes the PV system’s power output by adjusting the PV array’s operating point to the maximum power point (MPP) of the PV module. However, the non-linear behavior of PV systems due to exposure to changing climate conditions and partial shading can hide some faults, making traditional protection devices incapable of detecting them. Therefore, the design of an optimal simulation model of a properly sized standalone PV system is important for simulating and collecting the necessary data to diagnose faults. In this study, a standalone PV system for a hypothetical clinic in Malaysia is proposed, and it is sized based on peak sun hours. Its simulation model is built using MATLAB/Simulink (R2018b). The proposed simulation system’s performance was evaluated considering the proper design of the PV system’s boost converter within the changing conditions, and its ability to harvest maximum power points is considered a criterion for evaluating the performance. Various scenarios of uniform irradiance, uniform temperatures, shading effects, and sequential partial shading scenarios were implemented to evaluate the proposed simulation model. Results show that the proposed simulation model is suited to simulating different tests as it can harvest maximum power in all test scenarios.

1. Introduction

Over the last few decades, it has become clear that environmental pollution problems are becoming worse due to the generation of energy from non-renewable energy sources and that fossil fuels and other non-renewable natural resources are running out [1].

Researchers’ focus has turned to the need for stable and secure alternative energy sources as a result of technological advancement and rising energy consumption. Due to their benefits, including a long lifespan that requires little maintenance over many years and their lack of pollution, photovoltaic solar energy sources are a viable renewable alternative to employ in place of fossil fuels. According to the findings of research on global energy consumption conducted by the International Energy Agency, it will rank as one of the most significant renewable energy sources in the future [2].

Despite all the advantages, solar power systems do not offer the desired efficiency because the amount of output power changes with the weather conditions. The external light intensity and temperature are the most critical elements impacting the output characteristics of photovoltaic modules. The output characteristics of photovoltaic modules will alter in response to changes in light intensity and temperature, so the overall output of the PV array will change. The maximum amount of energy may be extracted from the PV array under various conditions by using the maximum power tracking algorithm (MPPT) between the PV system and the load with a DC-DC boost converter, boosting the efficiency of the overall system. The MPPT works as a regulator and controls the input voltage of the PV module at its highest power point by adjusting the boost converter’s duty cycle. Various MPPT techniques have been proposed by researchers in the literature, such as the perturb and observe (P&O) and the incremental conductance (INC) methods, whose main advantages are that they are generic, suitable for any PV array, they require no information about the PV array, and they work reasonably well under most conditions [3], fuzzy logic control (FLC) [4], and an Artificial Neural Network (ANN) [5].

PV systems can be designed as standalone or grid-connected systems [6]. Standalone photovoltaic (PV) systems refer to off-grid systems that generate electricity from solar panels and store it in batteries for later use. These systems are ideal for remote areas where access to the grid is limited or non-existent. The advantages of standalone PV systems are their reliability and ability to provide all electrical needs for a building, such as clean and cost-effective electricity, in areas where traditional grid-tied systems are not feasible. Additionally, they are easy to install and maintain, and they offer energy independence and protection against power failures [7,8].

The sizing of a photovoltaic (PV) system is crucial in ensuring the accuracy of the simulation model. A proper sizing of the system is necessary to avoid an oversized system, which can result in unnecessary expenses, and an undersized system that cannot meet the energy demands. If the system is not sized correctly, the simulation results will be inaccurate, making it challenging to predict the system’s performance.

Many researchers presented procedures to design standalone photovoltaic systems [8,9]. The sizing of standalone PVS in this work is based on the Watt-Hour demand and peak sun hour, two crucial factors in determining the efficiency and performance of a standalone photovoltaic system.

The contributions of this work can be summarized as the following points:

- Sizing of a standalone photovoltaic system (SAPVS) for a proposed case study.

- Modeling a 3.2 kW PV array system simulation model for the proposed case with a resistive load and considering the DC-DC boost converter’s optimal design and P&O technique to harvest MPP under different conditions.

- Verification of the proposed model under a different scenario of irradiance and temperature changing and shading.

- Evaluation of the proposed model with sequence partial shading.

The rest of the paper is structured as follows: Section 2 contains the description of the sizing of the standalone photovoltaic system, followed by Section 3 which describes the PV System Proposed simulation model; Section 4 describes the simulation part, while Section 5 is the validation of the proposed PV simulation model. Section 6 contains the discussion of the simulation results. Finally, Section 7 provides the conclusion.

2. Standalone Photovoltaic System Sizing

Case study: A Health Care Facility in Malaysia

This section aims to size and select standalone photovoltaic system equipment based on the Watt-hour demand and peak sun hours. As a case study, we propose a clinic with medium energy consumption as the hypothetical case located at the same location proposed by [6]. These medium-sized health clinics have an average daily energy consumption of 10–20 kWh/day and will tend to offer a wide range of health services, catering to larger populations than rural health posts (WHO, 2015) [10].

For sizing the PV system, the following steps are used:

2.1. Load Analysis of the Health Care Center

Table 1 illustrates clinic devices proposed with their power ratings and time of operation during the day to calculate the energy consumption in Watt-hour per day.

Table 1.

Electrical devices and their load calculation.

2.2. PV Modules’ Calculation (Sizing of PV Solar Panels)

From a Global Solar Power Map that is developed by Solarex, it is obtained that Malaysia has an average PSH value of 4–5 h [6] and for the case study location, the PSH value is 4.5 h. The efficiency of the overall system is 80%. The selected PV module is illustrated in Table 2.

Table 2.

Specifications of the KC200GT solar module at 25 °C, 1000 W/m2 from the datasheet [11].

The SAPV system proposed to generate a DC at a nominal voltage of 96 V.

The PV sizing is 4 × 4 modules to generate 3.2 kW power.

2.3. Battery Sizing Storage

Total Average Energy Use = 11.49 kWh. Days of autonomy or the no-sun days = 3 days. According to the selected battery (lead-type batteries of 250 AH, 12V-DC):

the number of continuous cloudy days in the selected region (3 days), kWh/day = 11.49, DC system voltage = 96 V, and D.O.D = 75%

So, using lead-type batteries of 250 Ah, 12 V:

which equals to 16 batteries.

During extended periods of low sunlight, the system may not generate enough surplus energy to recharge the batteries fully. To address this, we consider recharging the batteries during inactive periods and during the weekends.

2.4. Sizing of a Charge Controller

The maximum power point tracker (MPPT) charge controller is installed between the PV array and the batteries to match the output of the PV array to the battery voltage to ensure maximum charge ampere, prevent overcharging of the batteries, or limit excessive discharge and harvest the MPP.

The charge controller sizing is based on the following parameters;

- Voltage rating:

The rating of the charge controller input voltage should be greater than the PV voltage. Voc of a 4 × 4 PV array at 5 °C (worst case) = 140.9 V.

- b.

- current rating:

2.5. Sizing of the Inverter

The inverter must be able to handle about 3.2 kW at 220-Vac. The input rating of the inverter should be larger than the total watt of the appliances requirement, adding a 25% safety margin to account for surge requirements, which are equal to 1.25 × 3.2 kW = 4 kW, and it must have the same nominal voltage as the battery (96 V). So, we chose a DC to AC inverter with 4 kW and 96 V.

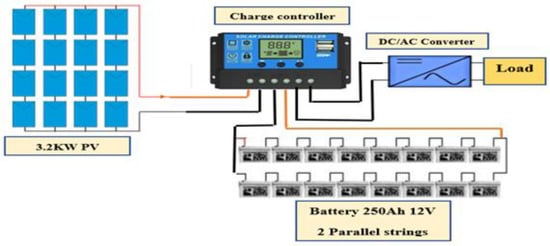

The sizing results show, for the Malaysian clinic proposal case study that has about 11.49 kWh of daily electricity load, that the photovoltaic system requirements are a 3.2 kW (4 × 4) photovoltaic array, 3830 Ah battery capacity for a 96 V system, 150 V 40 A charge controller, and 4 kW DC/AC converter. Figure 1 illustrates the overall standalone PV system sizing for the proposed case study.

Figure 1.

Sizing of the standalone PV system for the case studied.

3. Description of the PV System Proposed Simulation Model

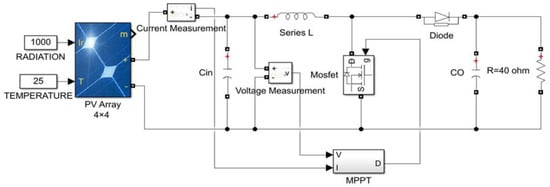

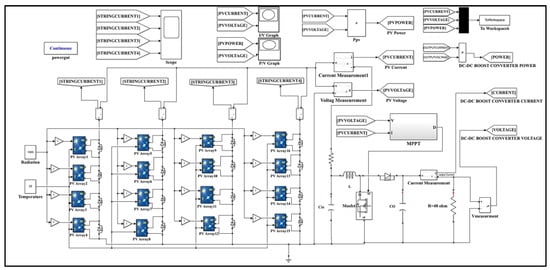

The overall PV simulation model that was considered in this work based on the sizing of the proposed case study in the previous section, which was developed and implemented using MATLAB/Simulink (R2018b), is shown in Figure 2. The 16 PV modules were connected to a DC-DC boost converter connected with MPPT. The modeling of each stage is described in detail in this section.

Figure 2.

PV System.

3.1. PV Array Model

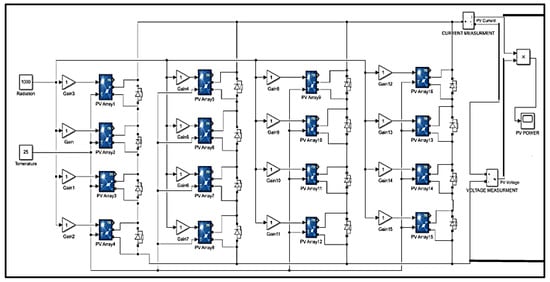

Figure 3 illustrates the PV array configuration considered in this work. It is configured as four parallel strings of four PV modules in series to produce the required power for the proposed clinic, which is 3.2 kW maximum output power under solar irradiance of 1000 W/m2 at standard test conditions (STC). The chosen module type was the KC200GT; it is made up of 54 solar cells connected in series, and its specifications are as reported in Table 2.

Figure 3.

The PV array proposed model configuration.

3.2. DC-DC Boost Converter

The non-linear properties of the PV modules and the variation of radiation and temperature make the design of the boost converter to keep track of the maximum power under different operating conditions difficult. We followed the approach suggested in [12,13], which is based on maximum power point resistance, to simplify the design of the boost converter. The photovoltaic model and the P&O MPPT algorithm were applied in the simulation using MATLAB/Simulink (R2018b). The three main parameters we need to calculate for the DC-DC boost converter are load resistance, inductor, and capacitor.

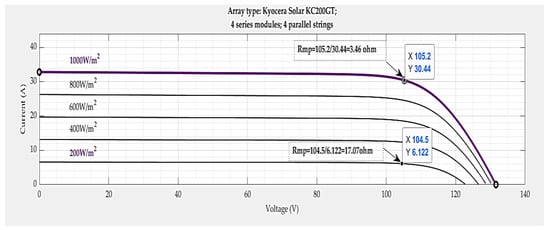

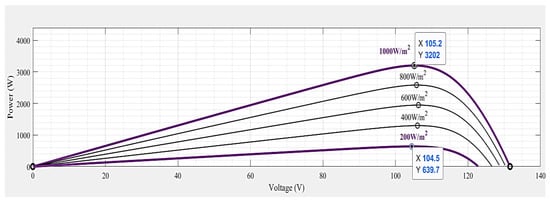

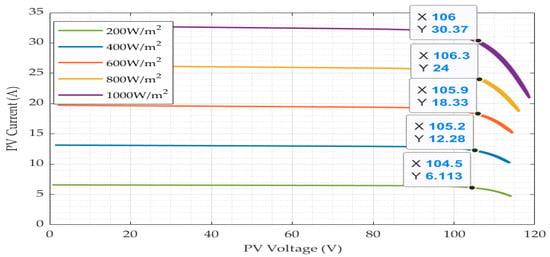

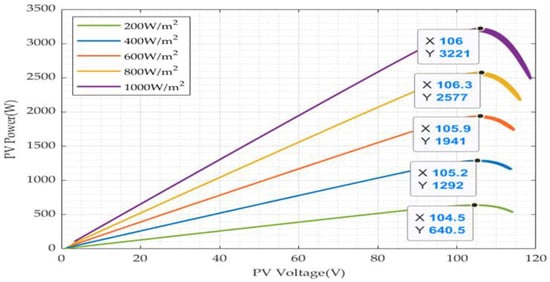

Two different levels of irradiance, the highest (G = 1000 W/m2) and the lowest (G = 200 W/m2) are considered, as shown in Figure 4, to simulate different conditions and calculate a maximum power point resistance. The maximum power point resistance is the entire resistance seen by the source. As it is clear from the characteristics of P/V the RMPP increased from 3.46 Ω at 1000 w/m2 to 17.07 Ω at 200 W/m2; for this study, a load resistance value of 40 Ω was chosen so that it would be more than RMPP in the event of the lowest irradiation. Since the range of duty ratio is from 0 to 1, therefore, RL ≥ Rpv and the tracking of maximum power will fail if this condition is not met [14].

where Rmpp is the PV resistance at MPP, Vmpp, and Impp are the voltage and current at MPP, respectively [15].

Figure 4.

Power-Voltage and Current-Voltage characteristics of 4 × 4 PV array.

In this study, the switching frequency (fs) is set at 20 kHz, and the input and output filter capacitor and inductor are chosen to meet the voltage ripple and current ripple requirements of 0.2% and 40%, respectively [13].

After several simulations are conducted in MATLAB/Simulink (R2018b) to set the values of the inductor, input capacitor, and output capacitor, Table 3 summarizes the overall PV proposed model and boost converter characteristics in the lowest (200 W/m2) and highest (1000 W/m2) irradiance.

Table 3.

PV proposed model and boost converter characteristics.

- Where Vout (V): Output voltage of the DC-DC boost converter.

- Iout (A): Output current of the DC-DC boost converter.

- RL (Ω): Load resistance of boost converter.

- L (mH): Inductor value of DC-DC boost converter.

- C (μF): Output capacitor value of DC-DC boost converter.

- Dmpp: The duty cycle of the converter at MPP.

3.3. Maximum Power Point Tracking (MPPT)

Implementing maximum power point tracking (MPPT) helps extract a PV system’s maximum output power more effectively.

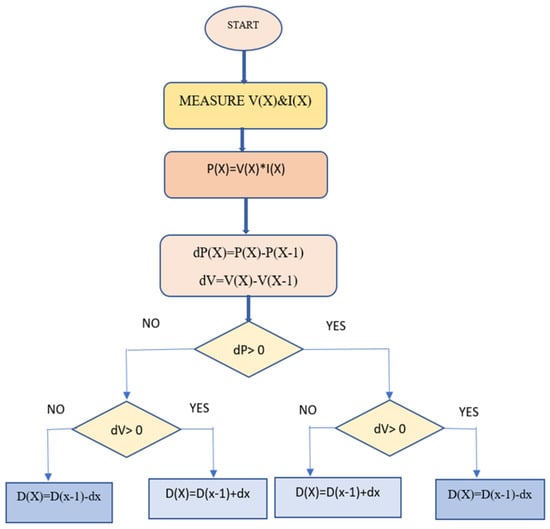

To harvest the maximum power, the perturb and observe (P&O) technique is applied in this work. P&O is called direct control MPPT because current and voltage inputs to the model are system parameters. P&O is the most commonly used technique in commercial products because of its simplicity, ease of use, and low cost [16,17].

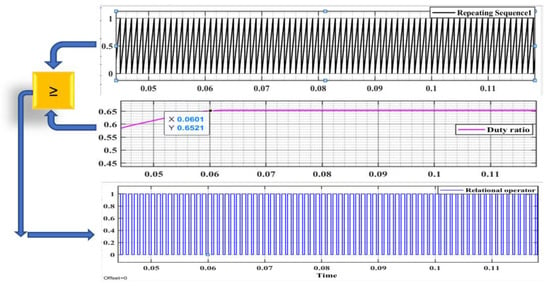

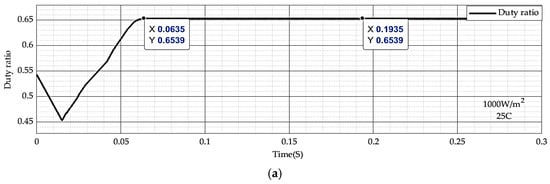

Figure 5 shows the simplest form of the algorithm, which works as discussed by several researchers [18,19,20]. P&O generates the duty cycle which changes according to the increase or decrease of voltage and power. The modified duty cycle is compared by a saw tooth waveform using the relational operator and repeating sequence to produce a Pulse Width Modulation (PWM) signal for controlling the IGBT switch and keeping the converter operating at Vmp. Figure 6 shows the simulation result of duty ratio and PWM signal. In our work, the controlled variable is the duty cycle. The initial values of the duty cycle and perturbation step (∆X) are taken as 0.54 and 0.0006, respectively.

Figure 5.

Flowchart of perturb and observe algorithm.

Figure 6.

The simulation result of duty ratio and PWM signal.

4. Simulation

The simulation of the DC-DC boost converter and the PV array coupled with a resistive load and connected with the MPPT and IGBT is used as a switch to validate the proposed PV system, and its ability to harvest maximum power in different conditions was conducted using the MATLAB/Simulink (R2018b) environment. A complete Simulink model of the proposed PV system is shown in Figure 7.

Figure 7.

Standalone PV simulation model.

5. Validation of the Proposed PV System

The verification of the PV array model’s ability to track MPP for different scenarios is shown in the following sections.

5.1. Verification under Different Scenarios of Uniform Irradiations

The PV array characteristic curves simulation at 200 W/m2 to 1000 W/m2 and 25 °C when connected to the MPPT boost converter are shown in Figure 8 and Figure 9, which provide good correspondence to data from the manufacturer’s datasheet of the PV module.

Figure 8.

Current-Voltage characteristics of Photovoltaic proposed model (Module KC200GT) at various irradiance levels.

Figure 9.

Power-Voltage characteristics of the proposed photovoltaic model (Module KC200GT) at various irradiance levels.

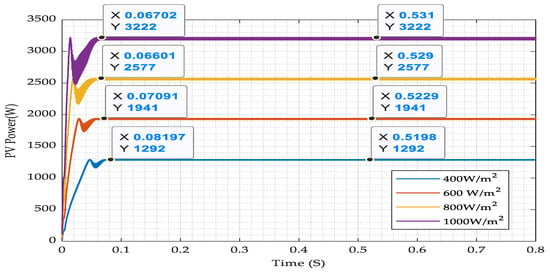

Figure 10 illustrates the ability of the proposed simulation model to harvest MPP at different irradiance.

Figure 10.

PV power of the PV proposed model under various irradiance levels.

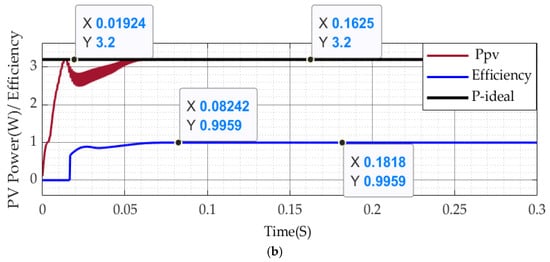

Figure 11 illustrates the duty ratio and PV proposed array model efficiency at 1000 W/m2 irradiation and a temperature of 25 °C.

Figure 11.

(a) Duty ratio; (b) Efficiency of PV proposed array model at 1000 W/m2, 25 °C.

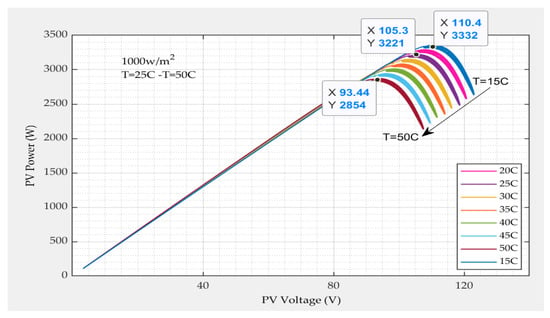

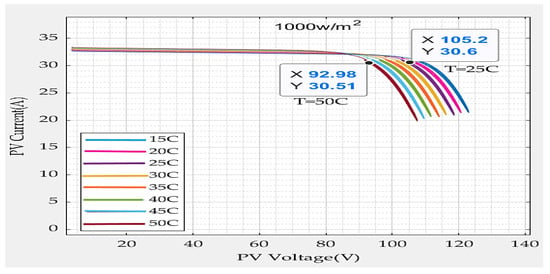

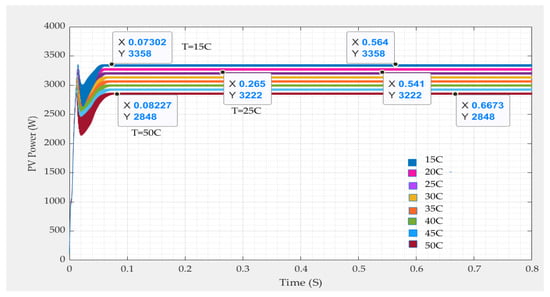

5.2. Verification under Different Scenarios of Uniform Temperatures

The Ppv/Vpv and Ipv/Vpv of the proposed PV array model characteristics simulation under uniform temperatures starting from 15 °C to 50 °C and 1000 W/m2 are illustrated in Figure 12 and Figure 13. Figure 14 illustrates the simulation result of PV power under different temperatures.

Figure 12.

Power-Voltage characteristics of the proposed photovoltaic model (Module KC200GT) under various temperature levels.

Figure 13.

Current-voltage characteristics of the proposed photovoltaic model (Module KC200GT) under various temperature levels.

Figure 14.

PV power of the proposed model under various temperature levels.

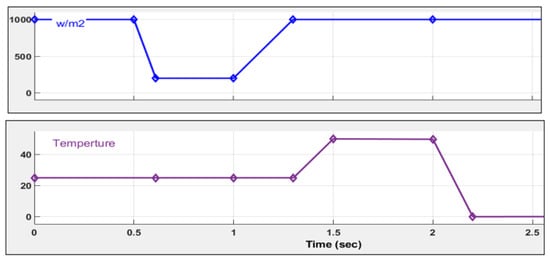

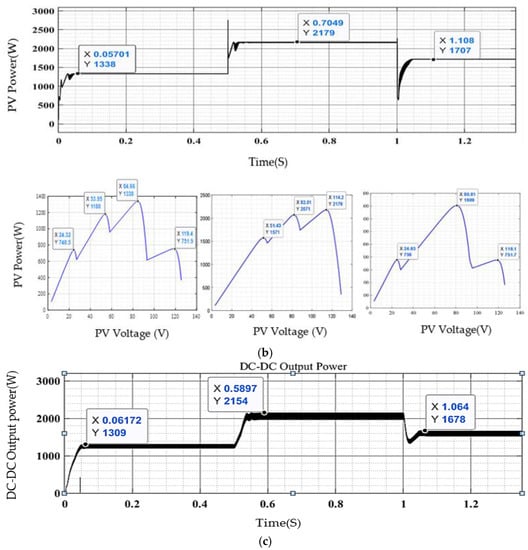

5.3. Verification of Changing Temperature and Irradiation Level States in a Single Simulation Run

Figure 15 shows the variation of irradiance concerning the time at constant temperature states (25 °C) from 0 to 1.3 s, and all PV modules receive equal irradiance levels. The variation of temperature concerning the time at constant irradiation (1000 W/m2) states from 1.3 s to the end of the simulation time, so we proposed a quick variation of temperature magnitude since it is practical and more time-efficient, it can help ensure the reproducibility of results, and it is useful for testing the sensitivity of the PV system model as well as ensuring its accuracy and reliability under various conditions. The test verification results are given in Table 4, and Figure 16 shows the plot of PV array power and duty ratio. Due to this change, the global maximum power point (GMPP) is updated by the irradiance and temperature since it is positioned on the knee of this I/V and P/V curve. Between 0 and 0.5 s, the initial level is 1000 W/m2, which drops to 200 watts at 0.5 s, remains constant until 1 s, and then increases to 1000 W/m2. Starting from the last change of irradiation, the temperature begins to vary with the constant irradiation. The initial level is 25 °C at 1.3 s, increases to 50 °C, and remains constant until the 2 s drops to zero and continues to the end of the simulation test.

Figure 15.

The variation of irradiance and temperature with respect to time.

Table 4.

Verification result of the fast-varying condition of temperature and irradiance.

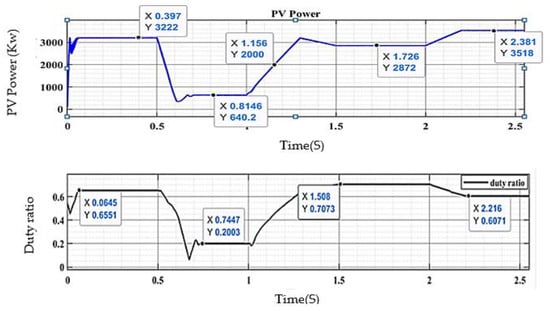

Figure 16.

PV array power and duty ratio under variation of irradiance and temperature.

Figure 16 illustrates that from ts = 0 to ts = 0.5, the proposed PV system operates at standard test conditions (1000 W/m2, 25 °C), and PV power reaches 3.2 kW as estimated from PV unit specifications. The duty cycle varies to track the MPP, and the MPPT controller produces maximum power when the irradiance is constant, as in the four periods of time in Table 4.

5.4. Verification of the PV Model for the Ability to Track GMPP under Different Scenarios of Partial Shading

The performance evaluation of the proposed PV system was carried out in MATLAB/Simulink to show the GMPP tracking capabilities under various partial shade conditions. To test the effectiveness of the system, different cases were considered in simulations where the GMPP position changes in P/V characteristics for different partial shading patterns.

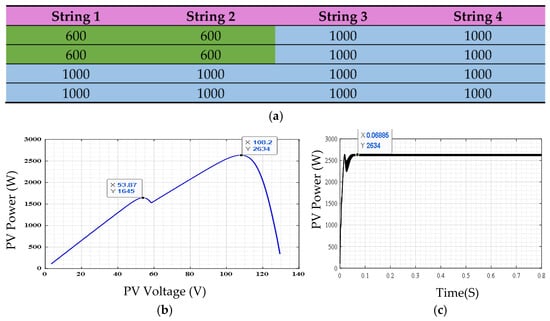

5.4.1. Shading Scenario 1

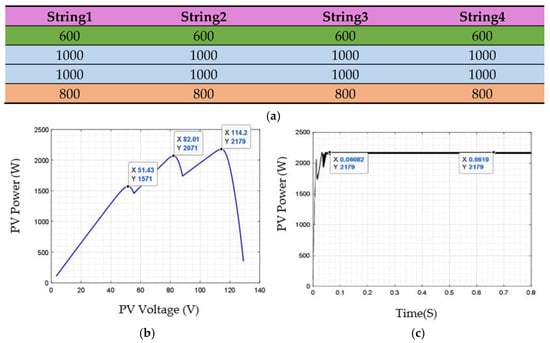

In this scenario, twelve connected modules get uniform radiation (1000 W/m2), whereas four receive 600 W/m2. The configuration is seen in Figure 17a. In the PV power-voltage characteristics, there are two maximum power points: global and local maximum power. The points in the figure illustrate where the MPP is located. The simulation results for this case are shown in Figure 17b, and the performance of the PV proposed system for harvesting GMMP is shown in Figure 17c.

Figure 17.

The simulation results of the proposed model: (a) shading pattern; (b) PV power-voltage; (c) performance of the PV proposed system for harvesting GMMP.

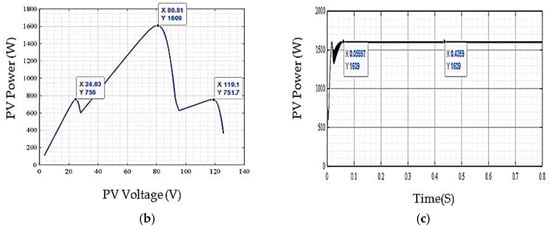

5.4.2. Shading Scenario 2

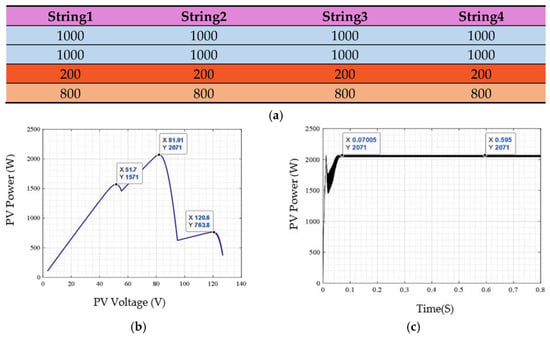

This scenario tests long-narrow shading through shading of the upper first module of each string of an array that gets 200 W/m2, 500 W/m2 for the third and fourth modules of the second and third strings, and 800 W/m2 for the last two modules of string 4. The simulation results and figuration for this situation are shown in Figure 18a–c.

Figure 18.

The simulation results of the proposed model: (a) shading pattern; (b) PV power/voltage; (c) performance of the PV proposed system for harvesting GMMP.

5.4.3. Shading Scenario 3

Long-narrow shading by receiving 600 W/m2 and 800 W/m2 for the first and last module in each string of the PV array, respectively, with a balance of 1000 W/m2 radiation for the remaining modules. The simulation results and figure for this situation are shown in Figure 19a–c.

Figure 19.

The simulation results of the proposed model: (a) shading pattern; (b) PV power/voltage; (c) performance of the PV proposed system for harvesting GMMP.

5.4.4. Shading Scenario 4

This scenario tests long-narrow shading by shading the last two modules in each string of an array with 200 W/m2 and 800 W/m2, respectively, and the rest of the modules with 1000 W/m2. The figure and simulation results for this scenario are shown in Figure 20a–c.

Figure 20.

The simulation results of the proposed model: (a) shading pattern; (b) PV power/voltage; (c) performance of the PV proposed system for harvesting GMMP.

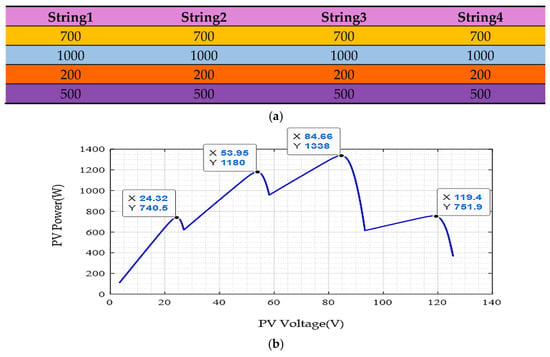

5.4.5. Complex Scenario

In this scenario, 700 W/m2, 1000 W/m2, 200 W/m2, and 500 W/m2 were received for modules in each string, respectively, as illustrated in Figure 21 to build long-narrow shading.

Figure 21.

The simulation results of the eighth scenario: (a) shading pattern; (b) PV voltage/power; (c) performance of the PV proposed system for harvesting GMMP; (d) output power of DC-DC boost converter.

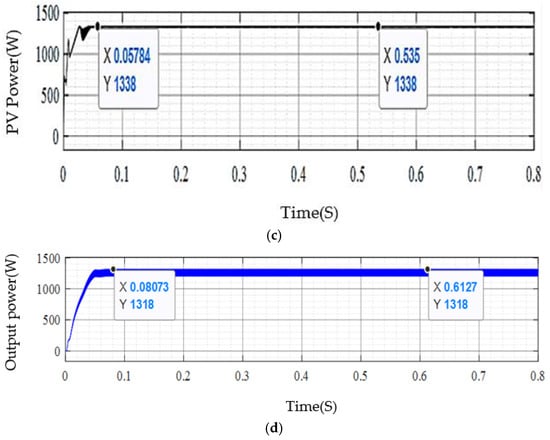

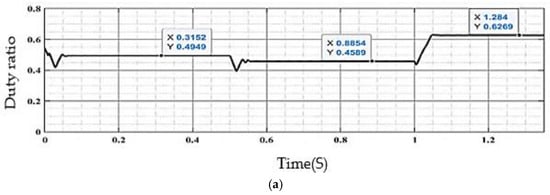

5.4.6. Verifying under the Sequence of Partial Shading Scenarios

For more support for the effectiveness of the proposed system, the proposed model was tested under the sequence of three cases of partial shading. Figure 22 shows an assessment of the proposed simulation model’s performance under the sequence of the last scenario of shading (the complex scenario), followed by the sixth and fourth scenarios.

Figure 22.

Performance of the combined sequence of shading scenarios, in terms of (a) the duty cycle; (b) the PV output power, and (c) the boost converter’s output power.

6. Discussion of the Simulation Results

Simulation of the proposed model of the 3.2 kW PV system under different conditions of irradiance and temperature was implemented to verify its performance under the following conditions:

- Changing the radiation from 200 W/m2 to 1000 W/m2 with a constant temperature of 25 °C in separate simulations for each irradiance level under the period time of the simulation.

- Changing the temperature from 15 °C to 50 °C with constant irradiance at 1000 W/m2 in separate simulations for each irradiance level under the period time of the simulation.

- The variation of irradiance with respect to time at constant temperature states 25 °C and the variation of temperature with respect to time at constant irradiation (1000 W/m2) states under one run of the simulation, respectively.

- Simulation under partial shading scenarios was performed to test the effectiveness of the MPPT to harvest MPP.

- Verifying under the sequential partial shading scenarios.

Figure 8 and Figure 9 show that the P/V and I/V characteristics of the proposed PV simulation model under different radiations match the characteristics of the manufacturer’s PV module. Figure 10 illustrates the ability to harvest MPP in this situation. Figure 12, Figure 13 and Figure 14 illustrate the effect of temperature changes on P/V and I/V characteristics, and their ability to reach MPP is clear.

Figure 16 shows how the MPPT re-tracked the new optimum MPP point by resetting the duty cycle to harvest a new optimum power. Table 4 illustrates the efficiency of tracking MPP of 100% for three periods of time for fast changes of irradiance with a constant temperature and changing of temperatures with constant irradiance, respectively, and 99.35% for the last period.

The simulation result summary for the shading situations related to harvesting maximum power point and tracking speed is shown in Table 5. The simulation results demonstrate MPPT’s ability to harvest GMPP in scenarios 2, 3, and 4, where there were three MPPs, two local and one global. The last scenario has three local maximum power points (LMPP), and as illustrated in its figure, the system can harvest MPP which supports the viability of the proposed model in various shading scenarios for maximum power extraction with high tracking speed and efficiency.

Table 5.

Detailed MPP tracking of the proposed model under shading scenarios.

The performance of the proposed simulation model under the sequence of the three shading scenarios is summarized in Table 6. The simulation of the boost converter, P&O, and PV array demonstrated good results in terms of oscillation; there were very few oscillations around the line of MPP, as shown in Figure 22, which led to the high efficiency of PV power. The duty cycle of all the scenarios was within the desired system requirements, and the model could harvest the MPP for different conditions by adjusting its duty cycle once there was any change in the pattern of shading to reach a new GMPP.

Table 6.

Performance analysis of the proposed simulation model under a sequence of three shading scenarios.

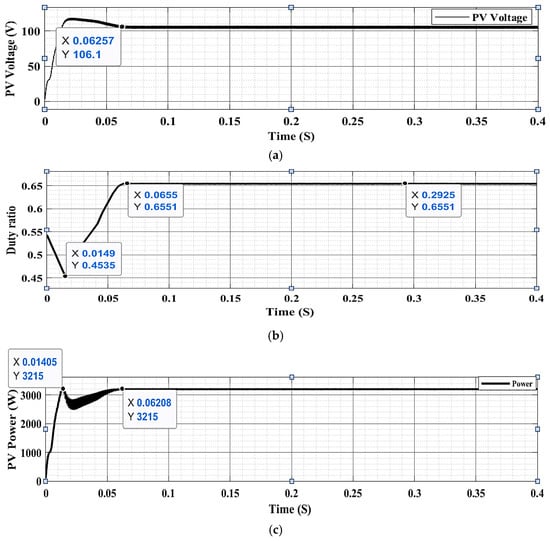

Figure 23 displays the boost converter duty cycle, PV voltage, and PV power at 1000 watts per square meter. The graphic shows that when MPPT is activated, the PV voltage begins to adjust by changing the duty cycle (D) to extract maximum power. From the figure, it is observed that from ts = 0 to ts = 0.014 s, the duty cycle of the boost converter decreased from the initial value of 0.54 to 0.45 as PV voltage and power increased; when D = 0.655, maximum power is obtained at 3.2 kW, and the system riches a steady state with a settling time of 0.062 s. This demonstrates the accuracy of the computed values for inductance, input capacitance, and output capacitance and the effectiveness of the overall model for use in other tests.

Figure 23.

(a) the duty cycle of the boost converter; (b) PV voltage, and (c) PV power.

7. Conclusions

This work proposed a 3.2 kW SAPV simulation model for a health center along with a P&O technique for maximum power point tracking in different conditions. The motivation of the work is to provide an early evaluation of the system’s performance under different conditions and to test the ability of the system to harvest MPP to extend the work later for other objectives. The simulation was carried out in MATLAB/Simulink (R2018b). The proposed model was tested under different variance conditions of irradiance and temperatures scenarios and the shading effect. The simulation results show that the simulation model was able to harvest MPP in all test scenarios. Under normal conditions, the model extracted 99.6% of the maximum power from the PV array, and it provides an efficient and reliable maximum power tracking performance under a rapid change in irradiance and temperature conditions. Additionally, the model was able to adjust its duty cycle once there was any change in the pattern of shading to reach a new global maximum power point (GMPP). The obtained results indicate that the proposed simulation model is suitable and can effectively be used for various simulation tests, as well as generate and collect data for other projects.

Author Contributions

Methodology, A.H.; validation, A.H. and W.R.; writing—original draft preparation, A.H.; writing—review and editing, A.H., H.H. and W.R.; supervision, H.H., N.I.A.W. and M.L.O.; performing the simulation of the work, A.H.; propose the hypothetical case study, W.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Liu, J. China’s renewable energy law and policy: A critical review. Renew. Sustain. Energy Rev. 2019, 99, 212–219. [Google Scholar] [CrossRef]

- Faranda, R.; Leva, S.; Maugeri, V. MPPT techniques for PV systems: Energetic and cost comparison. In Proceedings of the 2008 IEEE Power and Energy Society General Meeting—Conversion and Delivery of Electrical Energy in the 21st Century, Pittsburgh, PA, USA, 20–24 July 2008; pp. 1–6. [Google Scholar] [CrossRef]

- Sera, D.; Mathe, L.; Kerekes, T.; Spataru, S.V.; Teodorescu, R. On the perturb-and-observe and incremental conductance mppt methods for PV systems. IEEE J. Photovolt. 2013, 3, 1070–1078. [Google Scholar] [CrossRef]

- Kwan, T.H.; Wu, X. Maximum power point tracking using a variable antecedent fuzzy logic controller. Sol. Energy 2016, 137, 189–200. [Google Scholar] [CrossRef]

- Messalti, S.; Harrag, A.G.; Loukriz, A.E. A new neural networks MPPT controller for PV systems. In Proceedings of the IREC2015 The Sixth International Renewable Energy Congress, Sousse, Tunisia, 24–26 March 2015. [Google Scholar] [CrossRef]

- Al Riza, D.F.; Gilani, S.I.U.H. Standalone photovoltaic system sizing using peak sun hour method and evaluation by TRNSYS simulation. Int. J. Renew. Energy Res. 2014, 4, 109–114. [Google Scholar]

- Bhatia, A. Design and Sizing of Solar Photovoltaic Systems; Continuing Education and Development, Inc.: Woodcliff Lake, NJ, USA, 2018; pp. 2–125. [Google Scholar]

- Ali, W.; Farooq, H.; Rehman, A.U.; Awais, Q.; Jamil, M.; Noman, A. Design considerations of stand-alone solar photovoltaic systems. In Proceedings of the 2018 International Conference on Computing, Electronic and Electrical Engineering (ICE Cube), Quetta, Pakistan, 12–13 November 2018; pp. 8–13. [Google Scholar] [CrossRef]

- Al-shamani, A.N.; Yusof, M.; Othman, H.; Mat, S.; Ruslan, M.H.; Abed, A.M.; Sopian, K. Design & Sizing of Stand-alone Solar Power Systems A house Iraq. Recent Adv. Renew. Energy Sources 2013, 145–150. Available online: https://pdfs.semanticscholar.org/ac10/c05f8a9e233407132e0e86161f47c4840e98.pdf (accessed on 10 February 2023).

- Welland, A. Electrification of Health Clinics in Rural Areas: Challenges and Opportunities; Technical Report; Smart Villages: Cambridge, UK, 2017; p. 52. [Google Scholar]

- Hahm, J.; Baek, J.; Kang, H.; Lee, H.; Park, M. Matlab-based modeling and simulations to study the performance of different MPPT techniques used for photovoltaic systems under partially shaded conditions. Int. J. Photoenergy 2015, 2015, 1–11. [Google Scholar] [CrossRef]

- Ayop, R.; Tan, C.W. Design of boost converter based on maximum power point resistance for photovoltaic applications. Sol. Energy 2018, 160, 322–335. [Google Scholar] [CrossRef]

- Hashim, N.; Salam, Z.; Johari, D.; Nik Ismail, N.F. DC-DC Boost Converter Design for Fast and Accurate MPPT Algorithms in Stand-Alone Photovoltaic System. Int. J. Power Electron. Drive Syst. 2018, 9, 1038. [Google Scholar] [CrossRef]

- Nayak, B.; Mohapatra, A.; Mohanty, K.B. Selection criteria of dc-dc converter and control variable for MPPT of PV system utilized in heating and cooking applications. Cogent Eng. 2017, 4. [Google Scholar] [CrossRef]

- Batarseh, M.G.; Za’ter, M.E. Hybrid maximum power point tracking techniques: A comparative survey, suggested classification and uninvestigated combinations. Sol. Energy 2018, 169, 535–555. [Google Scholar] [CrossRef]

- Motahhir, S.; El Hammoumi, A.; El Ghzizal, A. The most used MPPT algorithms: Review and the suitable low-cost embedded board for each algorithm. J. Clean. Prod. 2020, 246, 118983. [Google Scholar] [CrossRef]

- Oi, A.; Anwari, M.; Taufik, M. Modeling and simulation of photovoltaic water pumping system. In Proceedings of the 2009 Third Asia International Conference on Modelling & Simulation, Bundang, Indonesia, 25–29 May 2009; pp. 497–502. [Google Scholar] [CrossRef]

- Reza Reisi, A.; Hassan Moradi, M.; Jamasb, S. Classification and comparison of maximum power point tracking techniques for photovoltaic system: A review. Renew. Sustain. Energy Rev. 2013, 19, 433–443. [Google Scholar] [CrossRef]

- Salman, S.; Ai, X.; Wu, Z. Design of a P-&-O algorithm based MPPT charge controller for a stand-alone 200W PV system. Prot. Control Mod. Power Syst. 2018, 3, 25. [Google Scholar] [CrossRef]

- Mohd Zainuri, M.A.A.; Mohd Radzi, M.A.; Soh, A.C.; Rahim, N.A. Development of adaptive perturb and observe-fuzzy control maximum power point tracking for photovoltaic boost dc-dc converter. IET Renew. Power Gener. 2014, 8, 183–194. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).