Development of a Biomass Component Prediction Model Based on Elemental and Proximate Analyses

Abstract

1. Introduction

2. Methodology

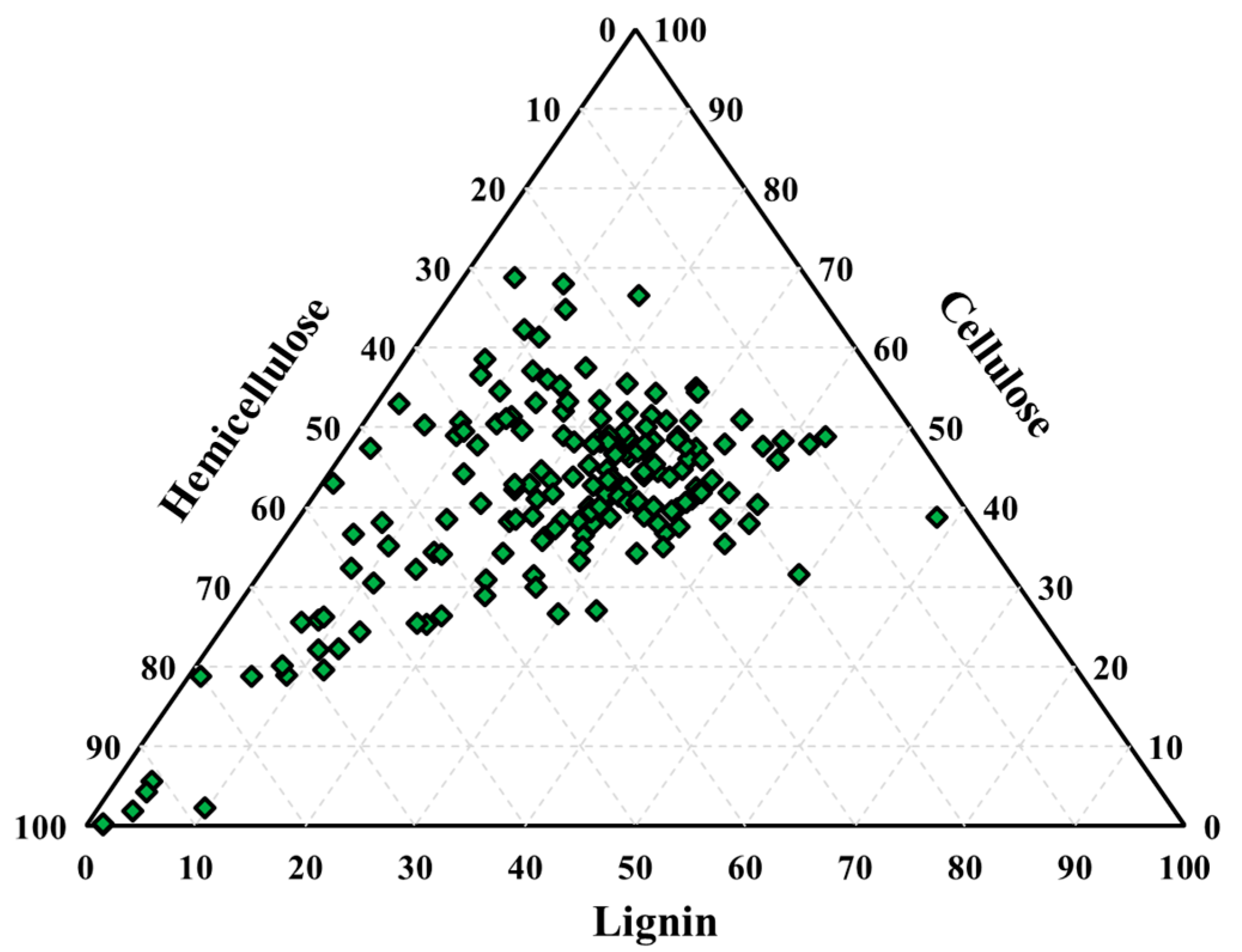

2.1. Collection of Data

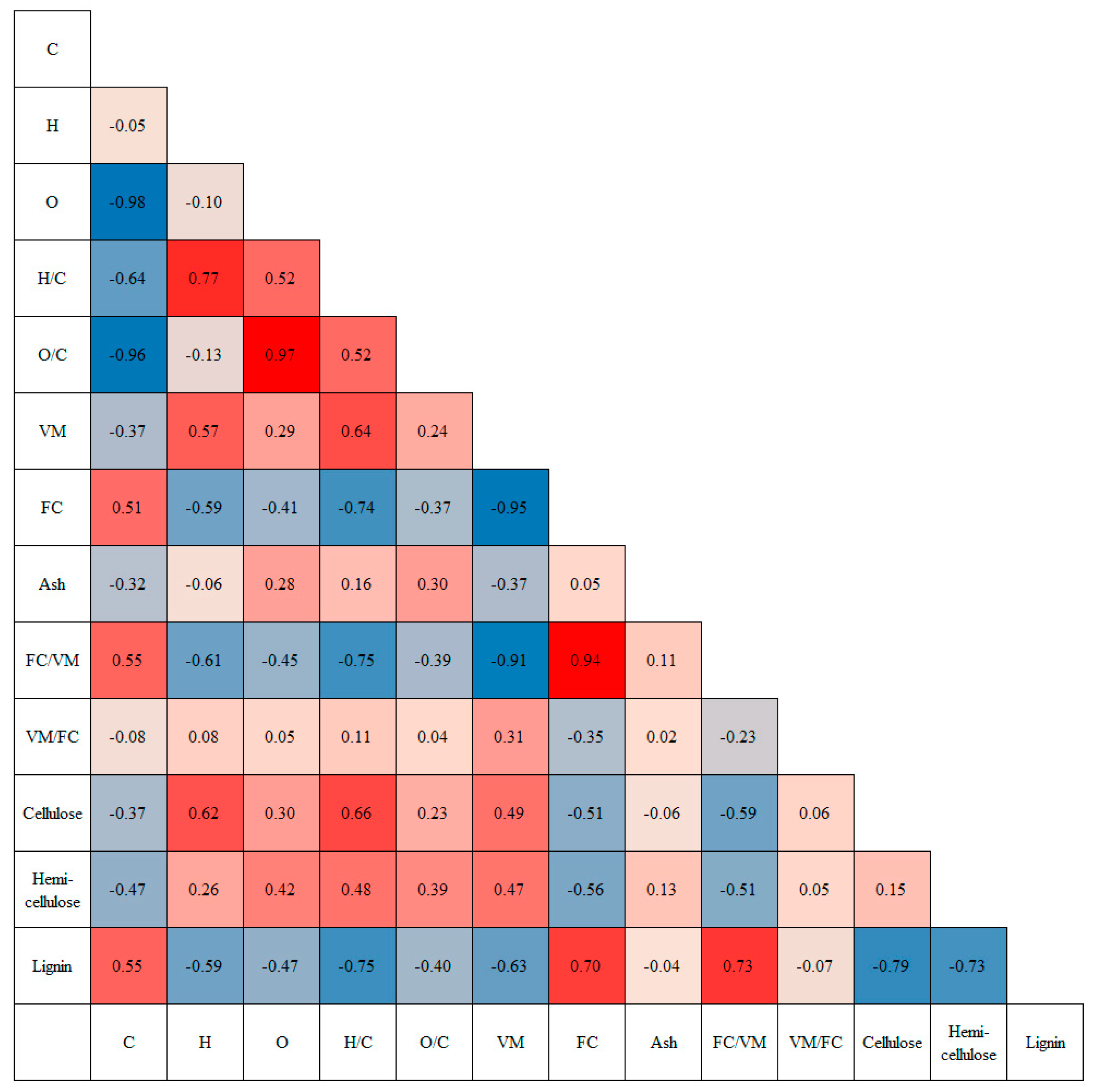

2.2. Pearson Correlation Coefficient

2.2.1. Linear Regression

2.2.2. Polynomial Regression

2.3. Model Evaluation

3. Results & Discussions

3.1. Result of Pearson Correlation Coefficient

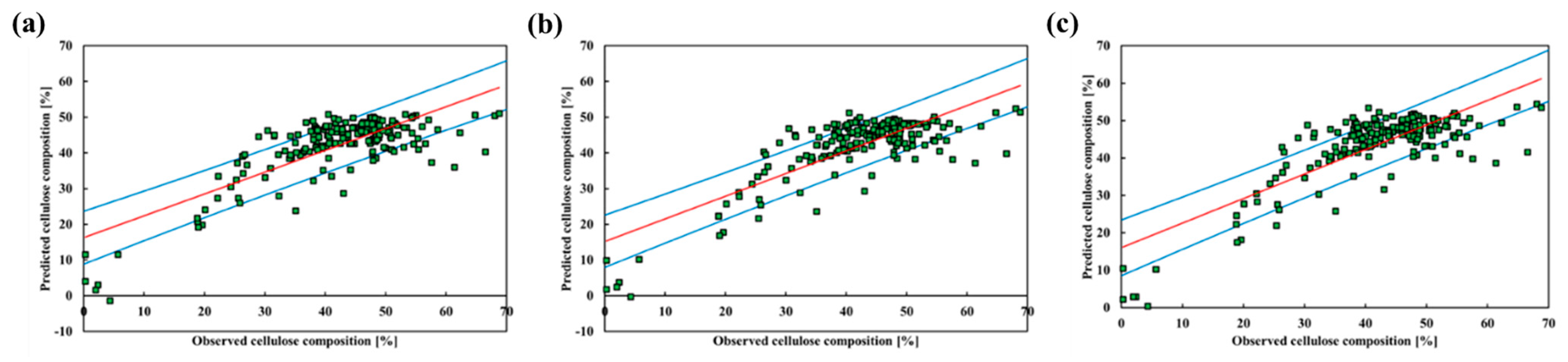

3.2. Prediction Model for Cellulose

3.3. Prediction Model for Hemicellulose

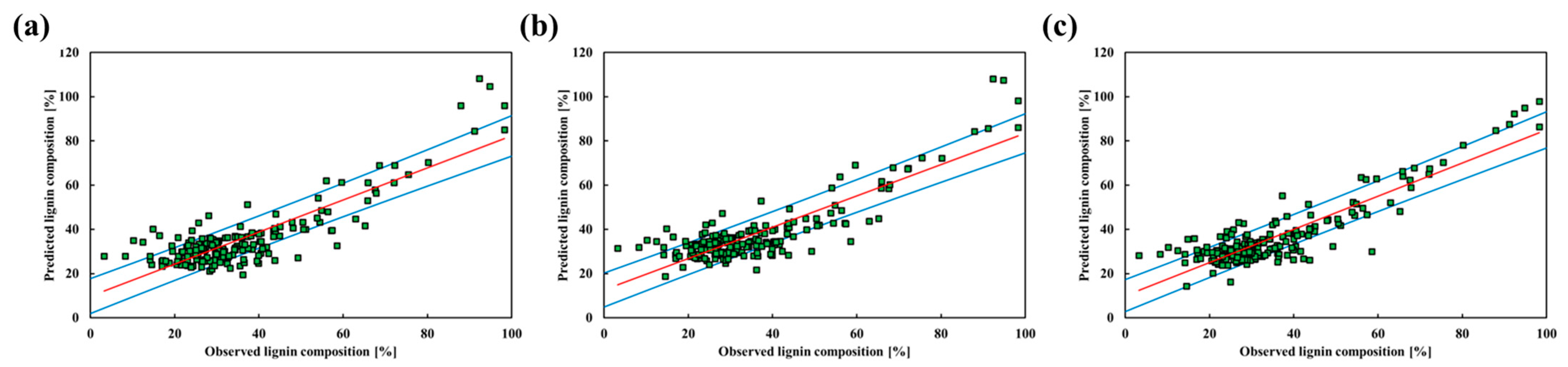

3.4. Prediction Model for Lignin

3.5. Cross-Validation Results for Cellulose

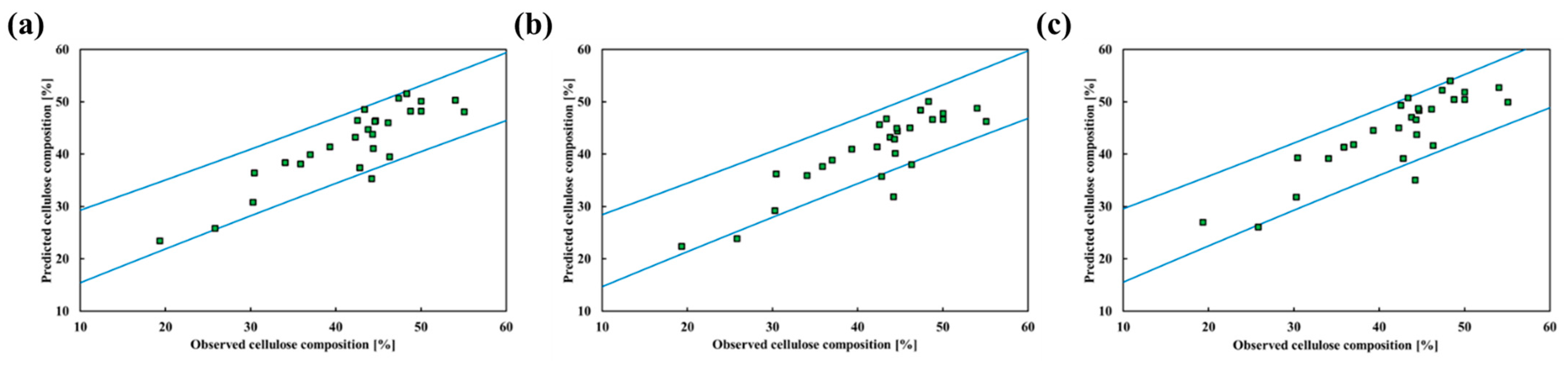

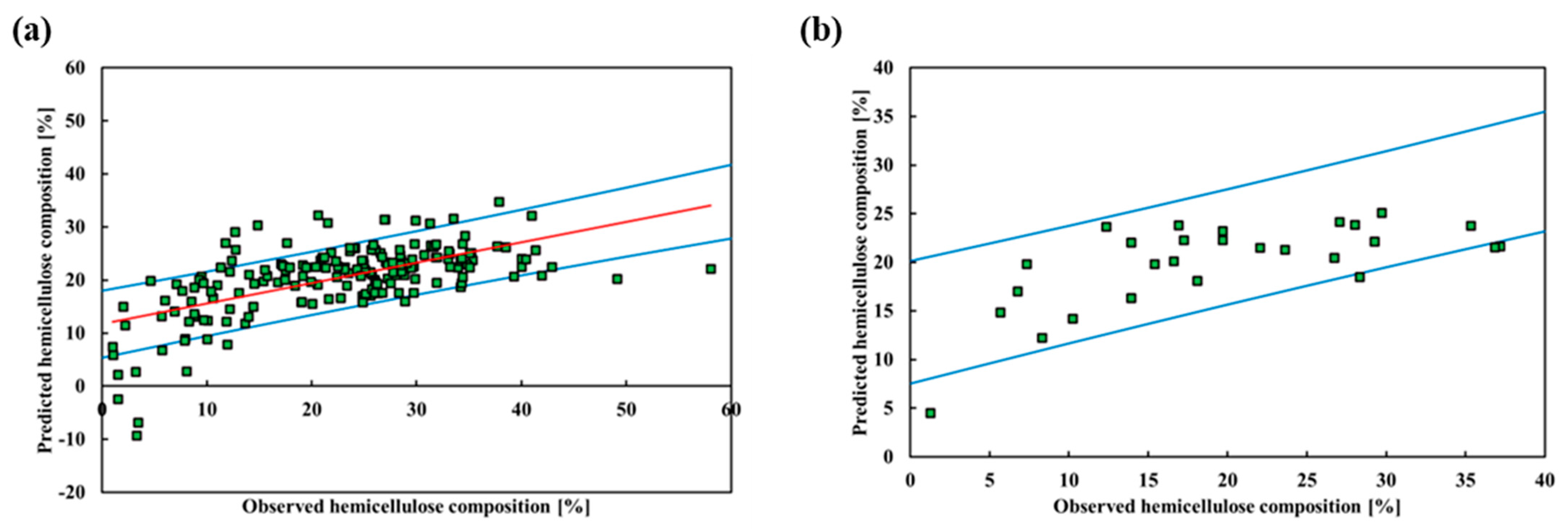

3.6. Cross-Validation Results for Hemicellulose

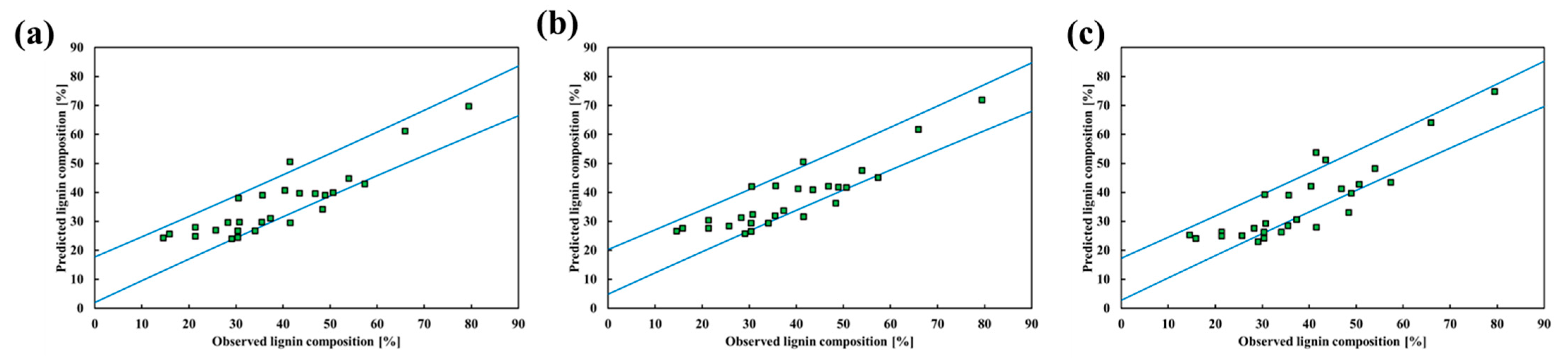

3.7. Cross-Validation Results for Lignin

3.8. Prediction and Cross-Validation of Hemicellulose Using Cellulose and Lignin

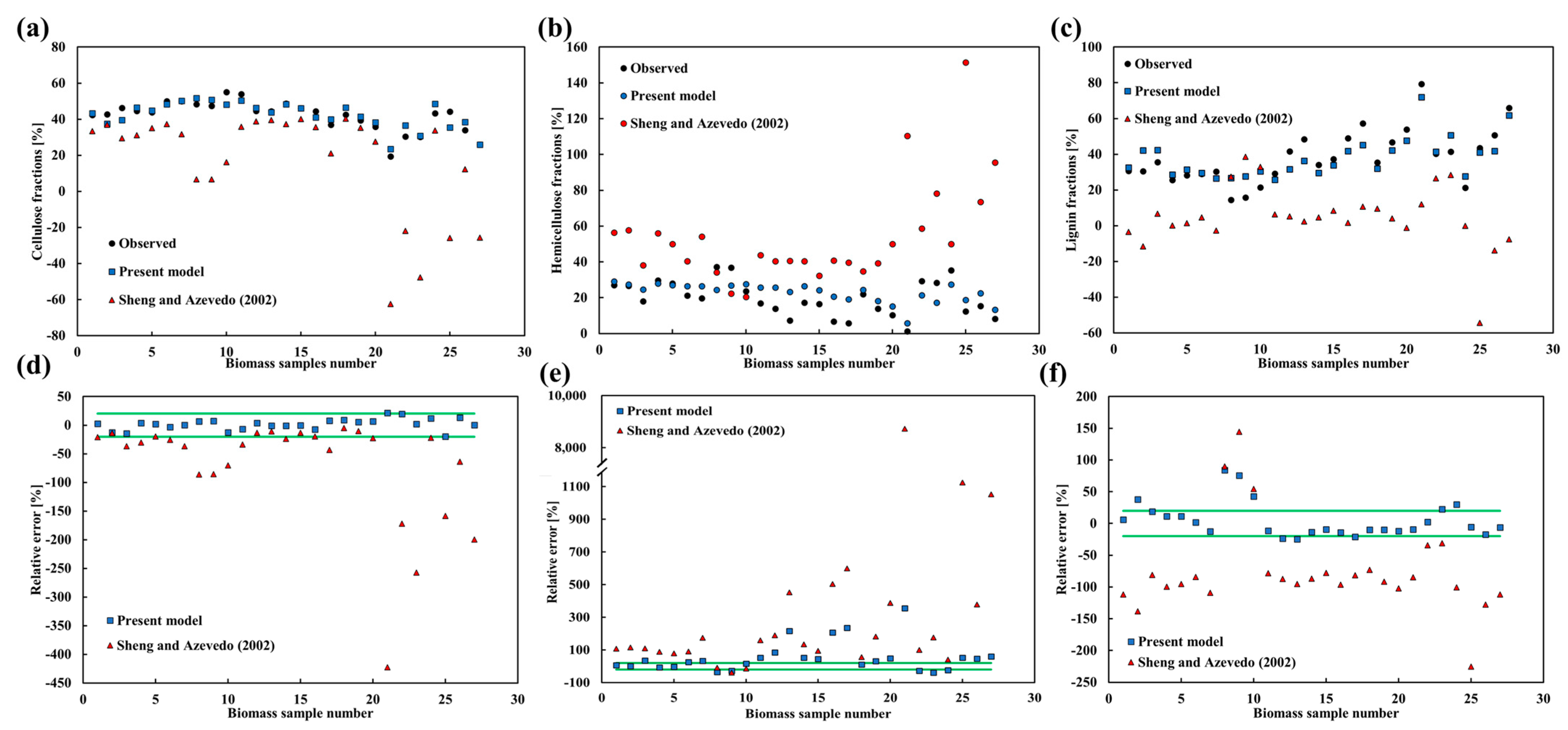

3.9. Application Performance

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- O’sullivan, A.C. Cellulose: The Structure Slowly Unravels. Cellulose 1997, 4, 173–207. [Google Scholar] [CrossRef]

- Rao, J.; Lv, Z.; Chen, G.; Peng, F. Hemicellulose: Structure, Chemical Modification, and Application. Prog. Polym. Sci. 2023, 140, 101675. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Ragauskas, A.J. Current Understanding of the Correlation of Lignin Structure with Biomass Recalcitrance. Front. Chem. 2016, 4, 45. [Google Scholar] [CrossRef] [PubMed]

- Smoot, L.D.; Baxter, L.L. Fossil Fuel Power Stations—Coal Utilization. In Encyclopedia of Physical Science and Technology, 3rd ed.; Meyers, R.A., Ed.; Academic Press: New York, NY, USA, 2003; pp. 121–144. ISBN 9780122274107. [Google Scholar]

- Basu, P. Chapter 13—Analytical Techniques. In Biomass Gasification, Pyrolysis and Torrefaction: Practical Design and Theory; Basu, P., Ed.; Biomass Gasification, Pyrolysis and Torrefaction (Second Edition); Academic Press: Boston, MA, USA, 2013; pp. 439–455. ISBN 9780123964885. [Google Scholar]

- Ozbayoglu, G. 3.19 Energy Production From Coal. In Comprehensive Energy Systems; Dincer, I., Ed.; Elsevier: Oxford, UK, 2018; pp. 788–821. ISBN 9780128149256. [Google Scholar]

- Qu, T.; Guo, W.; Shen, L.; Xiao, J.; Zhao, K. Experimental Study of Biomass Pyrolysis Based on Three Major Components: Hemicellulose, Cellulose, and Lignin. Ind. Eng. Chem. Res. 2011, 50, 10424–10433. [Google Scholar] [CrossRef]

- Zhao, C.; Jiang, E.; Chen, A. Volatile Production from Pyrolysis of Cellulose, Hemicellulose and Lignin. J. Energy Inst. 2017, 90, 902–913. [Google Scholar] [CrossRef]

- Kim, D.; Lee, K.; Park, K.Y. Upgrading the Characteristics of Biochar from Cellulose, Lignin, and Xylan for Solid Biofuel Production from Biomass by Hydrothermal Carbonization. J. Ind. Eng. Chem. 2016, 42, 95–100. [Google Scholar] [CrossRef]

- Technical Association of the Pulp and Paper Industry (TAPPI). Solvent Extractives of Wood and Pulp, Test Method T 204 Cm-97. 2007. Available online: https://www.astm.org/d1106-96r01.html (accessed on 1 July 2023).

- Technical Association of the Pulp and Paper Industry (TAPPI). Standard Test Method for Acid-Insoluble Lignin in Wood. 2007. [Google Scholar]

- Technical Association of the Pulp and Paper Industry (TAPPI). Alpha-, Beta- and Gamma-Cellulose in Pulp, Test Method T 203 Cm-22. 1999. Available online: https://imisrise.tappi.org/TAPPI/Products/01/T/0104T203.aspx (accessed on 1 July 2023).

- Sluiter, A.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Extractives in Biomass: Laboratory Analytical Procedure (LAP); National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass: Laboratory Analytical Procedure (LAP); National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP); National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- Sheng, C.; Azevedo, J.L.T. Modeling Biomass Devolatilization Using the Chemical Percolation Devolatilization Model for the Main Components. Proc. Combust. Inst. 2002, 29, 407–414. [Google Scholar] [CrossRef]

- Burhenne, L.; Messmer, J.; Aicher, T.; Laborie, M.P. The Effect of the Biomass Components Lignin, Cellulose and Hemicellulose on TGA and Fixed Bed Pyrolysis. J. Anal. Appl. Pyrolysis 2013, 101, 177–184. [Google Scholar] [CrossRef]

- Díez, D.; Urueña, A.; Piñero, R.; Barrio, A.; Tamminen, T. Determination of Hemicellulose, Cellulose, and Lignin Content in Different Types of Biomasses by Thermogravimetric Analysis and Pseudocomponent Kinetic Model (TGA-PKM Method). Processes 2020, 8, 1048. [Google Scholar] [CrossRef]

- Xing, J.; Luo, K.; Wang, H.; Fan, J. Estimating Biomass Major Chemical Constituents from Ultimate Analysis Using a Random Forest Model. Bioresour. Technol. 2019, 288, 121541. [Google Scholar] [CrossRef]

- Peng, J.; Bi, X.T.; Lim, J.; Sokhansanj, S. Development of Torrefaction Kinetics for British Columbia Softwoods. Int. J. Chem. React. Eng. 2012, 10, 1–40. [Google Scholar] [CrossRef]

- Chen, W.H.; Kuo, P.C. A Study on Torrefaction of Various Biomass Materials and Its Impact on Lignocellulosic Structure Simulated by a Thermogravimetry. Energy 2010, 35, 2580–2586. [Google Scholar] [CrossRef]

- Rousset, P.; Aguiar, C.; Labbé, N.; Commandré, J.M. Enhancing the Combustible Properties of Bamboo by Torrefaction. Bioresour. Technol. 2011, 102, 8225–8231. [Google Scholar] [CrossRef]

- Granados, D.A.; Ruiz, R.A.; Vega, L.Y.; Chejne, F. Study of Reactivity Reduction in Sugarcane Bagasse as Consequence of a Torrefaction Process. Energy 2017, 139, 818–827. [Google Scholar] [CrossRef]

- Cahyanti, M.N.; Doddapaneni, T.R.K.C.; Madissoo, M.; Pärn, L.; Virro, I.; Kikas, T. Torrefaction of Agricultural and Wood Waste: Comparative Analysis of Selected Fuel Characteristics. Energies 2021, 14, 2774. [Google Scholar] [CrossRef]

- Chen, W.H.; Hsu, H.C.; Lu, K.M.; Lee, W.J.; Lin, T.C. Thermal Pretreatment of Wood (Lauan) Block by Torrefaction and Its Influence on the Properties of the Biomass. Energy 2011, 36, 3012–3021. [Google Scholar] [CrossRef]

- Chen, W.H.; Cheng, W.Y.; Lu, K.M.; Huang, Y.P. An Evaluation on Improvement of Pulverized Biomass Property for Solid Fuel through Torrefaction. Appl. Energy 2011, 88, 3636–3644. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, Y.; Shen, Y.; Wang, J.; Yang, Y.; Zhang, W.; Wang, S. Oxygen Migration Characteristics during Bamboo Torrefaction Process Based on the Properties of Torrefied Solid, Gaseous, and Liquid Products. Biomas. Bioenergy 2019, 128, 105300. [Google Scholar] [CrossRef]

- Kanwal, S.; Chaudhry, N.; Munir, S.; Sana, H. Effect of Torrefaction Conditions on the Physicochemical Characterization of Agricultural Waste (Sugarcane Bagasse). Waste Manag. 2019, 88, 280–290. [Google Scholar] [CrossRef]

- Jiang, H.; Ye, Y.; Lu, P.; Zhao, M.; Xu, G.; Chen, D.; Song, T. Effects of Torrefaction Conditions on the Hygroscopicity of Biochars. J. Energy Inst. 2021, 96, 260–268. [Google Scholar] [CrossRef]

- Li, M.F.; Chen, C.Z.; Li, X.; Shen, Y.; Bian, J.; Sun, R.C. Torrefaction of Bamboo under Nitrogen Atmosphere: Influence of Temperature and Time on the Structure and Properties of the Solid Product. Fuel 2015, 161, 193–196. [Google Scholar] [CrossRef]

- Rodriguez Alonso, E.; Dupont, C.; Heux, L.; Da Silva Perez, D.; Commandre, J.M.; Gourdon, C. Study of Solid Chemical Evolution in Torrefaction of Different Biomasses through Solid-State 13C Cross-Polarization/Magic Angle Spinning NMR (Nuclear Magnetic Resonance) and TGA (Thermogravimetric Analysis). Energy 2016, 97, 381–390. [Google Scholar] [CrossRef]

- Saffe, A.; Fernandez, A.; Mazza, G.; Rodriguez, R. Prediction of Regional Agro-Industrial Wastes Characteristics by Thermogravimetric Analysis to Obtain Bioenergy Using Thermal Process. Energy Explor. Exploit. 2019, 37, 544–557. [Google Scholar] [CrossRef]

- Zhou, H.; Long, Y.; Meng, A.; Li, Q.; Zhang, Y. The Pyrolysis Simulation of Five Biomass Species by Hemi-Cellulose, Cellulose and Lignin Based on Thermogravimetric Curves. Thermochim. Acta 2013, 566, 36–43. [Google Scholar] [CrossRef]

- Wang, H.; Wang, X.; Cui, Y.; Xue, Z.; Ba, Y. Slow Pyrolysis Polygeneration of Bamboo (Phyllostachys Pubescens): Product Yield Prediction and Biochar Formation Mechanism. Bioresour. Technol. 2018, 263, 444–449. [Google Scholar] [CrossRef]

- Naik, S.; Goud, V.V.; Rout, P.K.; Jacobson, K.; Dalai, A.K. Characterization of Canadian Biomass for Alternative Renewable Biofuel. Renew Energy 2010, 35, 1624–1631. [Google Scholar] [CrossRef]

- Wang, S.; Zou, C.; Yang, H.; Lou, C.; Cheng, S.; Peng, C.; Wang, C.; Zou, H. Effects of Cellulose, Hemicellulose, and Lignin on the Combustion Behaviours of Biomass under Various Oxygen Concentrations. Bioresour. Technol. 2021, 320, 124375. [Google Scholar] [CrossRef]

- Pasangulapati, V.; Ramachandriya, K.D.; Kumar, A.; Wilkins, M.R.; Jones, C.L.; Huhnke, R.L. Effects of Cellulose, Hemicellulose and Lignin on Thermochemical Conversion Characteristics of the Selected Biomass. Bioresour. Technol. 2012, 114, 663–669. [Google Scholar] [CrossRef]

- Sengupta, D.; Pike, R.W. Chemicals from Biomass: Integrating Bioprocesses into Chemical Production Complexes for Sustainable Development; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Krerkkaiwan, S.; Buranatrevedhya, S.; Sanduang, J.; Fukuda, S. Combustion Characteristics and Fouling Tendency of Co-Combustion between Sub-Bituminous Coal and Thai Biomass. In Proceedings of the Combustion Charazcteristics and Fouling Tendency of Co-Combustion between Sub-Bituminous Coal and Thai Biomass, 9th i-CIPEC, Kyoto, Japan, 21–23 September 2016. [Google Scholar]

- Raj, T.; Kapoor, M.; Gaur, R.; Christopher, J.; Lamba, B.; Tuli, D.K.; Kumar, R. Physical and Chemical Characterization of Various Indian Agriculture Residues for Biofuels Production. Energy Fuels 2015, 29, 3111–3118. [Google Scholar] [CrossRef]

- Dhyani, V.; Bhaskar, T. A Comprehensive Review on the Pyrolysis of Lignocellulosic Biomass. Renew Energy 2018, 129, 695–716. [Google Scholar] [CrossRef]

- Mohammed, I.Y.; Abakr, Y.A.; Kazi, F.K.; Yusup, S.; Alshareef, I.; Chin, S.A. Comprehensive Characterization of Napier Grass as a Feedstock for Thermochemical Conversion. Energies 2015, 8, 3403–3417. [Google Scholar] [CrossRef]

- Singh, Y.D.; Mahanta, P.; Bora, U. Comprehensive Characterization of Lignocellulosic Biomass through Proximate, Ultimate and Compositional Analysis for Bioenergy Production. Renew Energy 2017, 103, 490–500. [Google Scholar] [CrossRef]

- Wannapeera, J.; Worasuwannarak, N.; Pipatmanomai, S. Product Yields and Characteristics of Rice Husk, Rice Straw and Corncob during Fast Pyrolysis in a Drop-Tube/Fixed-Bed Reactor. Songklanakarin J. Sci. Technol. 2007, 30, 393–404. [Google Scholar]

- Nanda, S. Conversion of Lignocellulosic Feedstocks to Renewable Fuels; York University: Toronto, ON, Canada, 2013. [Google Scholar]

- Hernandez-Mena, L.E.; Pecora, A.A.B.; Beraldo, A.L. Slow Pyrolysis of Bamboo Biomass: Analysis of Biochar Properties. Chem. Eng. Trans. 2014, 37, 115–120. [Google Scholar] [CrossRef]

- Greenhalf, C.E.; Nowakowski, D.J.; Bridgwater, A.V.; Titiloye, J.; Yates, N.; Riche, A.; Shield, I. Thermochemical Characterisation of Straws and High Yielding Perennial Grasses. Ind. Crops Prod. 2012, 36, 449–459. [Google Scholar] [CrossRef]

- Halder, P.; Kundu, S.; Patel, S.; Parthasarathy, R.; Pramanik, B.; Paz-Ferreiro, J.; Shah, K. TGA-FTIR Study on the Slow Pyrolysis of Lignin and Cellulose-Rich Fractions Derived from Imidazolium-Based Ionic Liquid Pre-Treatment of Sugarcane Straw. Energy Convers. Manag. 2019, 200, 112067. [Google Scholar] [CrossRef]

- Guida, M.Y.; Lanaya, S.; Rbihi, Z.; Hannioui, A. Thermal Degradation Behaviors of Sawdust Wood Waste: Pyrolysis Kinetic and Mechanism. J. Mater. Environ. Sci. 2019, 10, 742–755. [Google Scholar]

- Rahardjo, B.S. Effect of gasifiyng agent (air+steam) injection towards syngas quality from rice husk gasification. Int. J. Eng. 2013, 4, 8269. [Google Scholar]

- Aydinli, B.; Caglar, A. The Catalytic Effects of Potassium Dichromate on the Pyrolysis of Polymeric Mixtures Part II: Hazelnut Shell and Ultra-High Molecular Weight Polyethylene and Their Blend Cases. World Acad. Sci. Eng. Technol. Int. J. Mater. Metall. Eng. 2010, 4, 462–466. [Google Scholar]

- Villegas, J.M.; Avila, H. Quick-Scan Estimating Model of Higher Heating Value of Oil Palm Empty Fruit Bunches Based on Ash from Proximate Analysis Data. Ing. Investig. 2014, 34, 33–38. [Google Scholar] [CrossRef]

- Camacho, Y.M.; Bensaid, S.; Ruggeri, B.; Restuccia, L.; Ferro, G.; Mancini, G.; Fino, D. Valorisation of By-Products/Waste of Agro-Food Industry by the Pyrolysis Process. J. Adv. Catal. Sci. Technol. 2016, 3, 1–11. [Google Scholar]

- Guida, M.Y.; Hannioui, A. Properties of Bio-Oil and Bio-Char Produced by Sugar Cane Bagasse Pyrolysis in a Stainless Steel Tubular Reactor. Prog. Agric. Eng. Sci. 2017, 13, 13–33. [Google Scholar] [CrossRef]

- Lyu, G.; Wu, S.; Zhang, H. Estimation and Comparison of Bio-Oil Components from Different Pyrolysis Conditions. Front. Energy Res. 2015, 3, 28. [Google Scholar] [CrossRef]

- Ramos-Carmona, S.; Martínez, J.D.; Pérez, J.F. Torrefaction of Patula Pine under Air Conditions: A Chemical and Structural Characterization. Ind. Crops Prod. 2018, 118, 302–310. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.J.; Oh, K.C.; Cho, L.H.; Kim, D.H. Developing a Proximate Component Prediction Model of Biomass Based on Element Analysis. Energies 2023, 16, 509. [Google Scholar] [CrossRef]

- Majumder, A.K.; Jain, R.; Banerjee, P.; Barnwal, J.P. Development of a New Proximate Analysis Based Correlation to Predict Calorific Value of Coal. Fuel 2008, 87, 3077–3081. [Google Scholar] [CrossRef]

- Elmaz, F.; Yücel, Ö.; Mutlu, A.Y. Makine Öğrenmesi Ile Kısa ve Elemental Analiz Kullanarak Katı Yakıtların Üst Isı Değerinin Tahmin Edilmesi. Int. J. Adv. Eng. Pure Sci. 2020, 32, 145–151. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, Q.; Wang, Q. Model Detection for Functional Polynomial Regression. Comput. Stat. Data Anal. 2014, 70, 183–197. [Google Scholar] [CrossRef]

- Gendy, T.S.; El-Shiekh, T.M.; Zakhary, A.S. A Polynomial Regression Model for Stabilized Turbulent Confined Jet Diffusion Flames Using Bluff Body Burners. Egypt. J. Pet. 2015, 24, 445–453. [Google Scholar] [CrossRef]

- Ivanovski, M.; Goricanec, D.; Krope, J.; Urbancl, D. Torrefaction Pretreatment of Lignocellulosic Biomass for Sustainable Solid Biofuel Production. Energy 2022, 240, 122483. [Google Scholar] [CrossRef]

- Feng, Y.; Qiu, K.; Zhang, Z.; Li, C.; Rahman, M.M.; Cai, J. Distributed Activation Energy Model for Lignocellulosic Biomass Torrefaction Kinetics with Combined Heating Program. Energy 2022, 239, 122228. [Google Scholar] [CrossRef]

- Zhang, Z.; Duan, H.; Zhang, Y.; Guo, X.; Yu, X.; Zhang, X.; Rahman, M.M.; Cai, J. Investigation of Kinetic Compensation Effect in Lignocellulosic Biomass Torrefaction: Kinetic and Thermodynamic Analyses. Energy 2020, 207, 118290. [Google Scholar] [CrossRef]

- Garba, M.U.; Gambo, S.U.; Musa, U.; Tauheed, K.; Alhassan, M.; Adeniyi, O.D. Impact of Torrefaction on Fuel Property of Tropical Biomass Feedstocks. Biofuels 2018, 9, 369–377. [Google Scholar] [CrossRef]

- Phanphanich, M.; Mani, S. Impact of Torrefaction on the Grindability and Fuel Characteristics of Forest Biomass. Bioresour. Technol. 2011, 102, 1246–1253. [Google Scholar] [CrossRef]

- Meng, J.; Park, J.; Tilotta, D.; Park, S. The Effect of Torrefaction on the Chemistry of Fast-Pyrolysis Bio-Oil. Bioresour. Technol. 2012, 111, 439–446. [Google Scholar] [CrossRef]

- Chan, Y.H.; Yusup, S.; Quitain, A.T.; Uemura, Y.; Sasaki, M. Bio-Oil Production from Oil Palm Biomass via Subcritical and Supercritical Hydrothermal Liquefaction. J. Supercrit. Fluids 2014, 95, 407–412. [Google Scholar] [CrossRef]

- Manatura, K. Inert Torrefaction of Sugarcane Bagasse to Improve Its Fuel Properties. Case Stud. Therm. Eng. 2020, 19, 100623. [Google Scholar] [CrossRef]

- Yang, W.; Shimanouchi, T.; Iwamura, M.; Takahashi, Y.; Mano, R.; Takashima, K.; Tanifuji, T.; Kimura, Y. Elevating the Fuel Properties of Humulus Lupulus, Plumeria Alba and Calophyllum inophyllum L. through Wet Torrefaction. Fuel 2015, 146, 88–94. [Google Scholar] [CrossRef]

| Element Analysis | Proximate Analysis | Composition Analysis | Ref | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | H | O | VM | FC | Ash | Cell | Hemi | Lig | ||

| Mixed waste wood | 48.08 | 5.69 | 45.8 | 86.15 | 10.44 | 3.41 | 42.27 | 27.05 | 30.68 | [62] |

| Torrefied mixed waste wood (200 °C) | 51.76 | 5.34 | 42.47 | 83.03 | 10.6 | 6.36 | 42.78 | 26.71 | 30.51 | |

| Torrefied mixed waste wood (250 °C) | 52.46 | 5.55 | 41.46 | 74.24 | 18.82 | 6.94 | 46.32 | 18.07 | 35.61 | |

| Oak waste wood | 47.26 | 5.95 | 46.46 | 87.3 | 12.05 | 0.65 | 44.64 | 29.72 | 25.64 | |

| Torrefied Oak waste wood (200 °C) | 48.78 | 5.86 | 44.94 | 86.52 | 12.62 | 0.86 | 43.77 | 28.01 | 28.22 | |

| Logging residue | 47.72 | 6.26 | 45.6 | 82.18 | 16.07 | 1.75 | 49.94 | 21.12 | 28.94 | [63] |

| pine wood | 45.83 | 6.35 | 47.51 | 83.1 | 16.3 | 0.6 | 50 | 19.67 | 30.33 | [64] |

| Rice husk | 44.91 | 6.93 | 47.21 | 68.55 | 22.95 | 8.5 | 48.32 | 37.17 | 14.52 | [65] |

| Corn cob | 46.29 | 6.69 | 46.69 | 67.68 | 22.29 | 10.03 | 47.37 | 36.84 | 15.79 | |

| Groundnut shell | 47.51 | 6.32 | 45.64 | 69.69 | 21.11 | 9.2 | 55.06 | 23.6 | 21.35 | |

| Pine chip | 47.31 | 6.65 | 45.86 | 85.97 | 13.76 | 0.27 | 54.01 | 16.89 | 29.09 | [66] |

| Torrefied pine chip (225 °C) | 49.61 | 6.09 | 44.15 | 84.42 | 14.89 | 0.7 | 44.56 | 13.91 | 41.53 | |

| Torrefied pine chip (250 °C) | 51.73 | 5.89 | 42.24 | 82.51 | 17.24 | 0.25 | 44.32 | 7.33 | 48.34 | |

| Logging residue chip | 47.72 | 6.26 | 45.6 | 82.16 | 16.07 | 1.77 | 48.75 | 17.24 | 34.01 | |

| Torrefied logging residue chip (225 °C) | 50.51 | 6.14 | 43.05 | 80.73 | 17.9 | 1.37 | 46.11 | 16.59 | 37.30 | |

| Torrefied logging residue chip (250 °C) | 53.81 | 5.75 | 40.14 | 78.14 | 20.37 | 1.49 | 44.37 | 6.75 | 48.88 | |

| Torrefied logging residue chip (275 °C) | 53.75 | 5.44 | 40.5 | 71.43 | 26.69 | 1.88 | 37 | 5.68 | 57.32 | |

| Loblolly pine | 50.78 | 6.29 | 42.84 | 84.6 | 14.8 | 0.6 | 42.52 | 22.03 | 35.45 | [67] |

| Torrefied loblolly pine (270 °C 2.5 min) | 55.36 | 5.98 | 38.55 | 78.6 | 20.8 | 0.6 | 39.29 | 13.92 | 46.79 | |

| Torrefied loblolly pine (300 °C 2.5 min) | 57.74 | 5.83 | 36.28 | 76.4 | 22.8 | 0.8 | 35.85 | 10.22 | 53.93 | |

| Torrefied loblolly pine (330 °C 2.5 min) | 66.77 | 4.94 | 28.01 | 59.96 | 38.64 | 1.4 | 19.33 | 1.25 | 79.42 | |

| Palm mesocarp fiber | 46.29 | 4.67 | 47.37 | 63.29 | 29.49 | 7.22 | 30.43 | 29.25 | 40.32 | [68] |

| Palm kernel shell | 47.77 | 4.06 | 47.55 | 59.07 | 34.36 | 6.57 | 30.28 | 28.31 | 41.41 | |

| Sugarcane bagasse sample | 46.32 | 6.28 | 46.74 | 83.55 | 14.28 | 2.17 | 43.35 | 35.33 | 21.32 | [69] |

| Torrefied sugarcane bagasse (200 °C) | 41.88 | 4.21 | 53.59 | 71.26 | 26.97 | 1.77 | 44.19 | 12.35 | 43.46 | |

| Torrefied sugarcane bagasse (225 °C) | 47.1 | 4.72 | 47.79 | 71.95 | 25.55 | 2.49 | 34.03 | 15.39 | 50.58 | |

| Torrefied sugarcane bagasse (250 °C) | 52.63 | 3.79 | 43.16 | 62.27 | 34.5 | 3.22 | 25.82 | 8.29 | 65.89 | |

| No. | Proposed Models | R2P [-] | RMSEP [%] | MAEP [%] | AAEP [%] |

|---|---|---|---|---|---|

| C1 | 0.6104 | 7.3666 | 5.6839 | 49.2202 | |

| C2 | 0.6342 | 7.3013 | 5.4302 | 32.7348 | |

| C3 | 0.6362 | 7.3263 | 5.8115 | 43.1320 |

| No. | Proposed Models | R2P [-] | RMSEP [%] | MAEP [%] | AAEP [%] |

|---|---|---|---|---|---|

| H1 | 0.4901 | 7.4899 | 6.1396 | 53.1694 | |

| H2 | 0.4803 | 7.5634 | 5.6556 | 45.8770 | |

| H3 | 0.5112 | 7.7173 | 5.7038 | 48.7658 |

| No. | Proposed Models | R2P [-] | RMSEP [%] | MAEP [%] | AAEP [%] |

|---|---|---|---|---|---|

| L1 | 0.7247 | 9.0426 | 7.0424 | 28.6080 | |

| L2 | 0.7348 | 9.1532 | 7.1781 | 31.1764 | |

| L3 | 0.7914 | 7.9857 | 5.9868 | 26.3036 |

| R2CV [-] | RMSECV [%] | MAECV [%] | AAECV [%] | |

|---|---|---|---|---|

| C1 | 0.7837 | 3.8149 | 3.0291 | 7.5647 |

| C2 | 0.7458 | 4.3132 | 3.2023 | 7.7781 |

| C3 | 0.7387 | 4.8125 | 4.1379 | 6.9634 |

| R2CV [-] | RMSECV [%] | MAECV [%] | AAECV [%] | |

|---|---|---|---|---|

| H1 | 0.3292 | 8.6098 | 7.2671 | 61.0694 |

| H2 | 0.4004 | 8.2683 | 7.2084 | 66.4448 |

| H3 | 0.3280 | 9.8534 | 8.7032 | 66.0180 |

| R2CV [-] | RMSECV [%] | MAECV [%] | AAECV [%] | |

|---|---|---|---|---|

| L1 | 0.7728 | 7.7483 | 6.7726 | 19.8385 |

| L2 | 0.7757 | 7.2735 | 6.3054 | 20.2150 |

| L3 | 0.7427 | 7.7133 | 6.6112 | 19.7636 |

| R2P [-] | RMSEP [%] | MAEP [%] | AAEP [%] | R2CV [-] | RMSECV [%] | MAECV [%] | AAECV [%] |

|---|---|---|---|---|---|---|---|

| 0.3770 | 8.5612 | 6.7581 | 50.3295 | 0.4292 | 7.5979 | 6.3346 | 51.9966 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.Y.; Oh, K.C.; Kim, S.J.; Cho, L.H.; Jeon, Y.K.; Kim, D. Development of a Biomass Component Prediction Model Based on Elemental and Proximate Analyses. Energies 2023, 16, 5341. https://doi.org/10.3390/en16145341

Park SY, Oh KC, Kim SJ, Cho LH, Jeon YK, Kim D. Development of a Biomass Component Prediction Model Based on Elemental and Proximate Analyses. Energies. 2023; 16(14):5341. https://doi.org/10.3390/en16145341

Chicago/Turabian StylePark, Sun Yong, Kwang Cheol Oh, Seok Jun Kim, La Hoon Cho, Young Kwang Jeon, and DaeHyun Kim. 2023. "Development of a Biomass Component Prediction Model Based on Elemental and Proximate Analyses" Energies 16, no. 14: 5341. https://doi.org/10.3390/en16145341

APA StylePark, S. Y., Oh, K. C., Kim, S. J., Cho, L. H., Jeon, Y. K., & Kim, D. (2023). Development of a Biomass Component Prediction Model Based on Elemental and Proximate Analyses. Energies, 16(14), 5341. https://doi.org/10.3390/en16145341