Assessment of Agro-Environmental Impacts for Supplemented Methods to Biochar Manure Pellets during Rice (Oryza sativa L.) Cultivation

Abstract

1. Introduction

2. Materials and Methods

2.1. Biochar Production

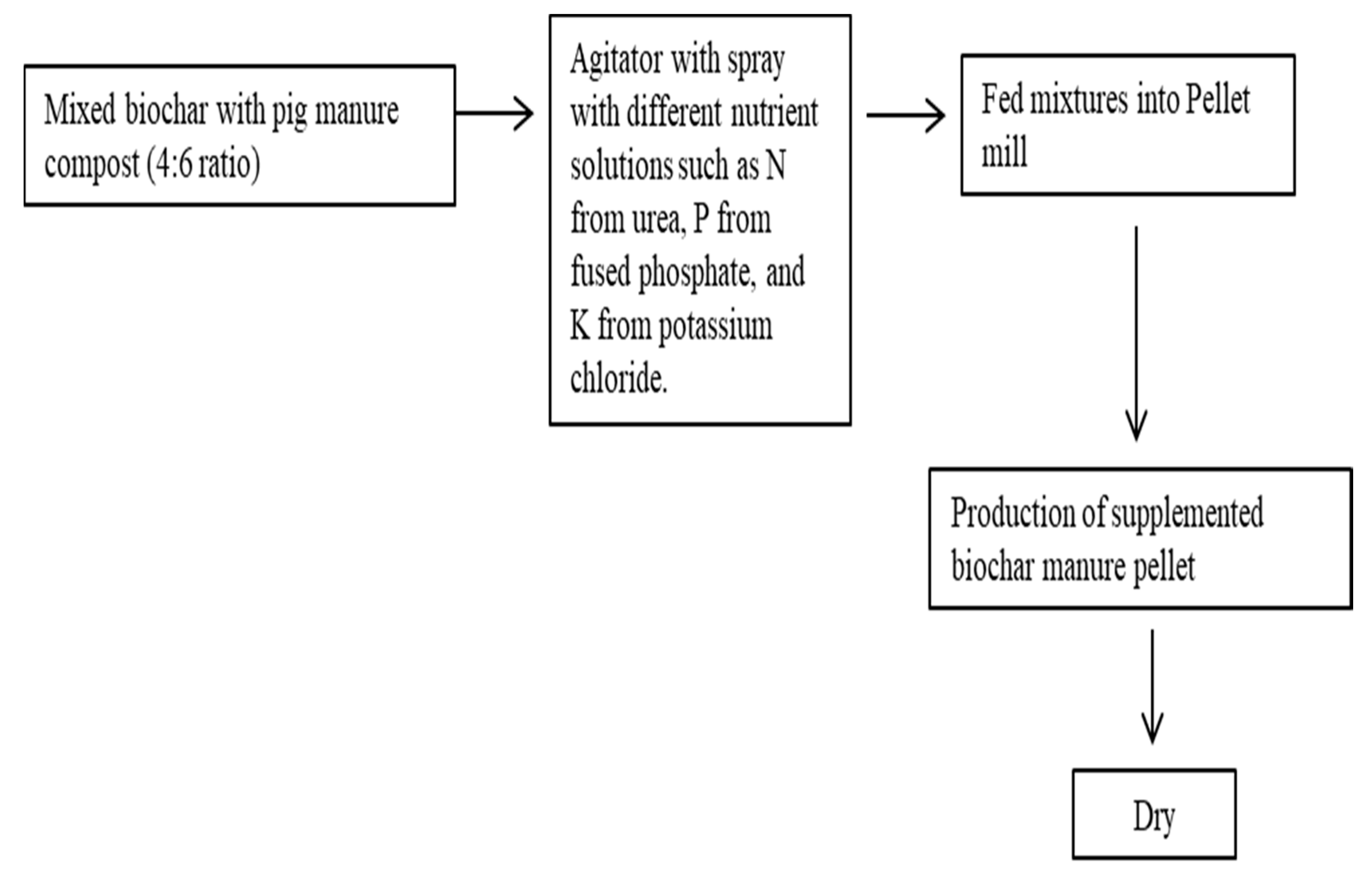

2.2. Production of Supplemented Biochar Manure Pellet

2.3. Field Experiment

2.4. Chemical Analysis of Paddy Soil and Water

2.5. Data Processing and Carbon Balance Calculations

2.6. Statistical Analysis

3. Results and Discussions

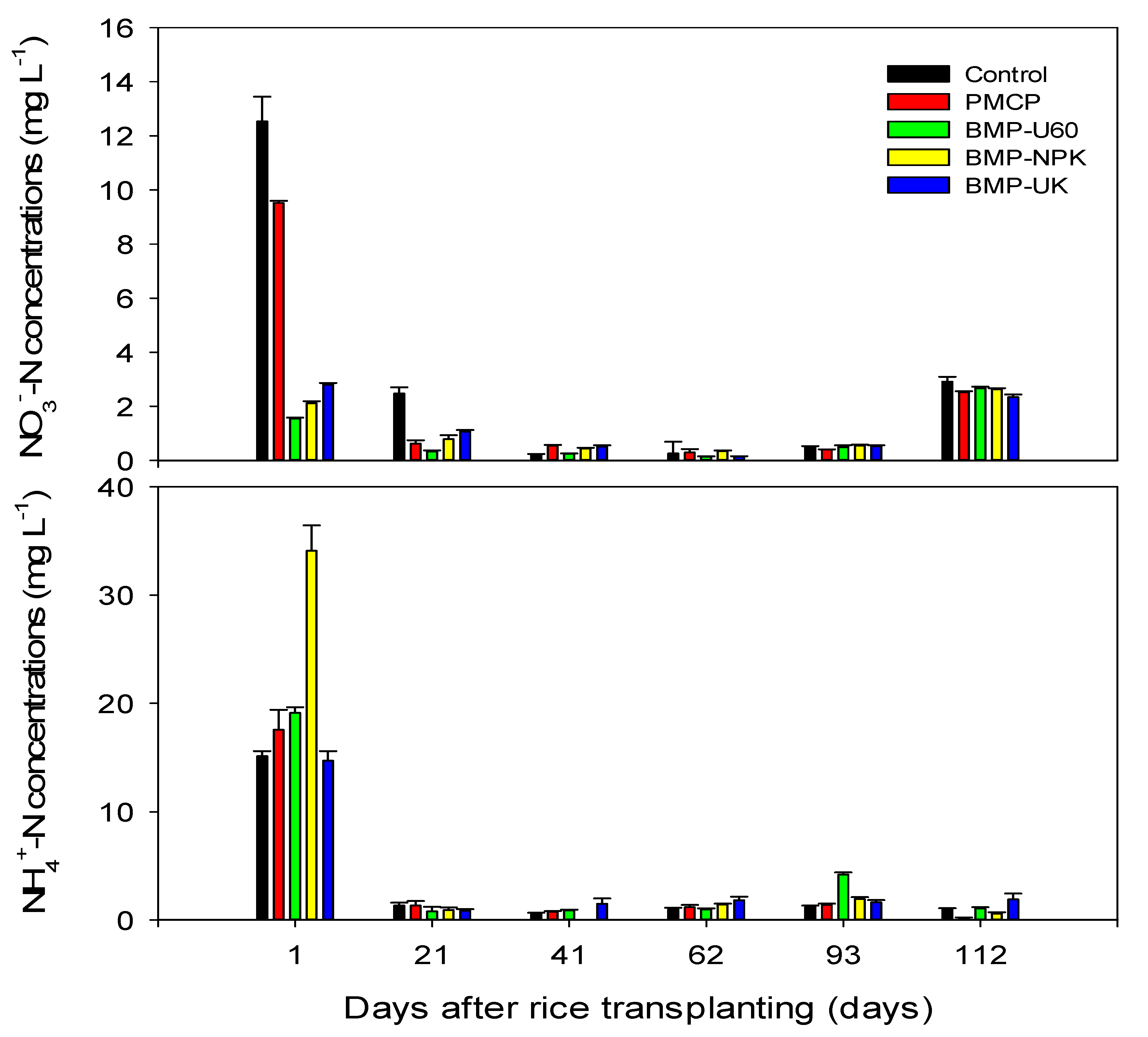

3.1. Effects of Essential Nutrients in the Paddy Water and Soil

3.1.1. Paddy Water Quality

3.1.2. Nutrients in Paddy Soil

3.2. Carbon Sequestration and Profit Analysis

3.3. Rice Growth Responses to Supplemented Biochar Manure Pellet

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Edgerton, M.D. Increasing crop productivity to meet global needs for feed, food, and fuel. Plant Physiol. 2009, 149, 7–13. [Google Scholar] [CrossRef] [PubMed]

- O’Connor, D.; Peng, T.; Zhang, J.; Tsang, D.C.W.; Alessi, D.S.; Shen, Z.; Bolan, N.S.; Hou, D. Biochar application for the remediation of heavy metal polluted land: A review of in situ field trials. Sci. Total Environ. 2018, 619, 815–826. [Google Scholar] [CrossRef] [PubMed]

- Zhao, B.; O’Connor, D.; Zhang, J.; Peng, T.; Shen, Z.; Tsang, D.C.W.; Hou, D. Effect of pyrolysis temperature, heating rate, and residence time on rapeseed stem derived biochar. J. Clean. Prod. 2018, 174, 977–987. [Google Scholar] [CrossRef]

- Min, H.; Liu, Y.; Qin, H.; Jiang, L.; Zou, Y. Quantifying the effect of biochar amendment on soil quality and crop productivity in Chinese rice paddies. Field Crops Res. 2013, 154, 172–177. [Google Scholar]

- Li, Z.; Gu, C.; Zhang, R.; Ibrahim, M.; Zhang, G.; Wang, L.; Zhang, R.; Chen, F.; Liu, Y. The benefic effect induced by biochar on soil erosion and nutrient loss of slopping land under natural rainfall conditions in central China. Agric. Water Manag. 2017, 185, 145–150. [Google Scholar] [CrossRef]

- Liu, X.; Zhou, J.; Chi, Z.; Zheng, J.; Li, L.; Zhang, X.; Zheng, J.; Cheng, K.; Bian, R.; Pan, G. Biochar provided limited benefits for rice yield and greenhouse gas mitigation six year following an amendment in a rice paddy. Catena 2019, 179, 20–28. [Google Scholar] [CrossRef]

- MIFAFF. Annual statistics in food, agriculture, fisheries and forestry in 2009. Korean Ministry for Food, Agriculture, Fisheries and Forestry. Environ. Sci. Pollut. Res. 2010, 16, 1–9. [Google Scholar]

- Lehmann, J.; Rillig, M.C.; Thies, J.; Masiello, C.A.; Hockaday, W.C.; Crowley, D. Biochar effects on soil biota —A review. Soil Biol. Biochem. 2011, 43, 1812–1836. [Google Scholar] [CrossRef]

- Cantrell, K.B.; Hunt, P.G.; Uchimiya, M.; Novak, J.M.; Ro, K.S. Impact of pyrolysis temperature and manure source on physicochemical characteristics of biochar. Bioresour. Technol. 2012, 107, 419–428. [Google Scholar] [CrossRef] [PubMed]

- Brewer, C.; Unger, R.; Schmidt-Rohr, K.; Brown, R. Criteria to select biochars for field studies based on biochar chemical properties. Bioenergy Res. 2011, 4, 312–323. [Google Scholar] [CrossRef]

- Xie, T.; Reddy, K.R.; Wang, C.; Yargicoglu, E.; Spokas, K. Characteristics and applications of biochar for environmental remediation: A review. Crit. Rev. Env. Sci. Tech 2015, 45, 939–969. [Google Scholar] [CrossRef]

- Kim, P.; Johnson, A.M.; Essington, M.E.; Radosevich, M.; Kwon, W.T.; Lee, S.H.; Rials, T.G.; Labbe, N. Effect of pH on surface characteristics of switchgrass-derived biochars produced by fast pyrolysis. Chemosphere 2013, 90, 2623–2630. [Google Scholar] [CrossRef] [PubMed]

- Blackwell, P.; Joseph, S.; Munroe, P.; Anawar, H.M.; Storer, P.; Gilkes, R.J.; Solaiman, Z.M. Influences of biochar and biochar-mineral complex on mycorrhizal colonization and nutrition of wheat and sorghum. Pedosphere 2015, 25, 686–695. [Google Scholar] [CrossRef]

- Chan, K.; van Zwieten, L.; Meszaros, I.; Downie, A.; Joseph, S. Agronomic values of green waste biochar as a soil amendment. Aust. J. Soil Res. 2007, 45, 629–634. [Google Scholar] [CrossRef]

- Deenik, J.L.; McClellan, T.; Uehara, G.; Antal, M.J.; Campbell, S. Charcoal volatile matter content influences plant growth and soil nitrogen transformations. Soil Sci. Soc. Am. J. 2010, 74, 1259–1270. [Google Scholar] [CrossRef]

- Solaiman, Z.M.; Murphy, D.V.; Abbott, L.K. Biochars influence seed germination and early growth of seedlings. Plant Soil 2012, 353, 273–287. [Google Scholar] [CrossRef]

- Husk, B.; Major, J. Commercial Scale Agricultural Biochar Field Trial in Quebec, Canada, over Two Years: Effects of Biochar on Soil Fertility, Biology, Crop Productivity and Quality; Blue Leaf: Quebec, QC, Canada, 2008. [Google Scholar]

- Major, J.; Lehmann, J.; Rondon, M.; Goodale, C. Fate of soil-applied black carbon: Downward migration, leaching and soil respiration. Glob. Chang. Biol. 2010, 16, 1366–1379. [Google Scholar] [CrossRef]

- Reza, M.T.; Lynam, L.G.; Vasquez, V.R.; Coronella, C.J. Pelletization of biochar from hydrothermally carbonized wood. Environ. Prog. Sustain. Energy 2012, 31, 225–234. [Google Scholar] [CrossRef]

- Khalil, M.; Gutser, R.; Schmidhalter, U. Effects of urease and nitrification inhibitors added to urea on nitrous oxide emissions from a loess soil. J. Plant Nutr. Soil Sci. 2009, 172, 651–660. [Google Scholar] [CrossRef]

- Harmel, R.D.; Torbert, H.A.; Haggard, B.E.; Haney, R.; Dozier, M. Water quality impacts of converting to a poultry litter fertilization strategy. J. Environ. Qual. 2004, 33, 2229–2242. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Y.; Chiu, P.C.; Imhoff, P.T.; Guo, M. Phosphorus release behaviors of poultry litter biochar as a soil amendment. Sci. Total Environ. 2015, 512, 454–463. [Google Scholar] [CrossRef] [PubMed]

- EPA. A Long-Term Vision for Assessment, Restoration, and Protection under the Clean Water Act Section 2013, 303(d) Program. Available online: https://19january2017snapshot.epa.gov/new-version-cwa-303d-program-updated-framework-implementing-cwa-303d-program-responsibilities_html (accessed on 14 April 2020).

- Cantrell, K.B.; Martin, J.H., II. Poultry litter and switchgrass blending and pelleting characteristics for biochar production. In Proceedings of the ASABE Annual International Meeting, Dallas, TX, USA, 29 July –1 August 2012. [Google Scholar]

- Hua, L.; Wu, W.X.; Liu, Y.X.; McBride, M.; Chen, Y.X. Reduction of nitrogen loss and Cu and Zn mobility during sludge composting with bamboo charcoal amendment. Environ. Sci. Pollut. Res. 2009, 16, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Ro, K.S.; Cantrell, K.B.; Hunt, P.G. High-temperature pyrolysis of blended animal manures for producing renewable energy and value-added biochar. Ind. Eng. Chem. Res. 2010, 49, 10125–10131. [Google Scholar] [CrossRef]

- Faloye, O.T.; Alatise, M.O.; Ajayi, A.E.; Ewulo, B.S. Synergistic effects of biochar and inorganic fertilizer on maize (zea mays) yield in an alfisol under drip irrigation. Soil Tillage Res. 2017, 174, 214–220. [Google Scholar] [CrossRef]

- Fernandez-Escobar, R.; Benlloch, M.; Herrera, E.; Garcia-Novelo, J.M. Effect of traditional and slow-release N fertilizers on growth of olive nursery plants and N losses by leaching. Sci. Hortic. 2004, 101, 39–49. [Google Scholar] [CrossRef]

- Mortain, L.; Dez, I.; Madec, P.J. Development of new composites materials, carriers of active agents from biodegradable polymers and wood. Comptes Rendus Chim. 2004, 7, 635–640. [Google Scholar] [CrossRef]

- Kim, J.; Yoo, G.; Kim, D.; Ding, W.; Kang, H. Combined application of biochar and slow-release fertilizer reduces methane emission but enhances rice yield by different mechanisms. Appl. Soil Ecol. 2017, 117, 57–62. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, X.; Zheng, W.; Kan, Y. Phosphorus-assisted biomass thermal conversion: Reducing carbon loss and improving biochar stability. PLoS ONE 2014, 9, e115373. [Google Scholar] [CrossRef]

- Brassard, P.; Godbout, S.; Raghavan, V. Soil biochar amendment as a climate change mitigation tool: Key parameters and mechanisms involved. J. Environ. Manage. 2016, 181, 484–497. [Google Scholar] [CrossRef]

- Harvey, O.R.; Kuo, L.J.; Zimmerman, A.R.; Louchouarn, P.; Amonette, J.E.; Herbert, B.E. An index-based approach to assessing recalcitrance and soil carbon sequestration potential of engineered black carbons (biochars). Environ. Sci. Technol. 2012, 46, 1415–1421. [Google Scholar] [CrossRef]

- Cross, A.; Sohi, S.P. A method for screening the relative long term stability of biochar. Gcb Bioenergy 2013, 5, 215–220. [Google Scholar] [CrossRef]

- Lehmann, J.; Joseph, S. Biochar for Environmental Management: Science, Technology and Implementation; Routledge: New York, NY, USA, 2015. [Google Scholar]

- Shin, J.; Hong, S.; Lee, S.; Hong, S.; Lee, J. Estimation of soil carbon sequestration and profit analysis on mitigation of CO2-eq. emission in cropland incorporated with compost and biochar. Appl. Biol. Chem. 2017, 60, 467–472. [Google Scholar] [CrossRef]

- Shin, J.; Choi, E.; Jang, E.S.; Hong, S.G.; Lee, S.; Ravindran, B. Adsorption characteristics of ammonium nitrogen and plant responses to biochar pellet. Sustainability 2018, 10, 1331. [Google Scholar] [CrossRef]

- Shin, J.; Jang, E.; Park, S.; Ravindran, B.; Chang, S. Agro-environmental impacts, carbon sequestration and profit analysis of blended biochar pellet application in the paddy soil-water system. J. Environ. Manag. 2019, 244, 92–98. [Google Scholar] [CrossRef] [PubMed]

- Thammasom, N.; Vityakon, P.; Lawongsa, P.; Saenjan, P. Biochar and rice straw have different effects on soil productivity, greenhouse gas emission and carbon sequestration in Northeast Thailand paddy soil. Agric. Nat. Resour. 2016, 50, 192–198. [Google Scholar] [CrossRef]

- NAAS. Recommended Application Amounts of Fertilizers for Crop Cultivation (eds); National Academy of Agricultural Sciences, Rural Development Administration: New Delhi, India, 2010; p. 16.

- Mehlich, A. Mehlich III soil test extractant: A modification of Mehlich II extractant. Commun. Soil Sci. Plant Anal. 1984, 15, 1409–1416. [Google Scholar] [CrossRef]

- EEX. EU Emission Allowances—Primary Market Auction. European Energy Exchange. 2017. Available online: https://www.eex.com/en/marketdata/environmental-markets/auction-market/ (accessed on 7 March 2017).

- KRX. Korea Allowance Unit. Korean Exchange. Available online: http://marketdata.krx.co.kr/mback; http://open.krx.co.kr/contents/OPN/01/01050401/OPN01050401.jsp#document=070301 (accessed on 7 March 2017).

- Kaneki, R.; Iwama, K.; Minagawa, A.; Sudo, M.; Odani, H.; Kobayashi, A.; Tanaka, A.; Ikeda, K.; Muranaga, M. Effect of mass balance in paddy fields and rice plant yields by reduced fertilizer use and non-puddling cultivation. J. Jpn. Soc. Hydrol. Water Resour. 2013, 26, 201–211. [Google Scholar] [CrossRef][Green Version]

- Epstein, F. Silicon: Its manifold roles in plants. Ann. Appl. Biol. 2009, 155, 155–160. [Google Scholar] [CrossRef]

- Wang, J.; Wang, D.; Zhang, G.; Wang, Y.; Wang, C.; Teng, Y.; Christie, P. Nitrogen and phosphorous leaching losses from intensively managed paddy fields with straw retention. Agri. Water Manag. 2014, 141, 66–73. [Google Scholar] [CrossRef]

- Hasegawa, K.; Kobayashi, M.; Nakada, H. Influence of applying organic matter in a paddy field on the water quality (2). Influence of applying rice-straw on the leaching of nitrate nitrogen from draining soil and on the denitrification of nitrate nitrogen in flooded soil. Bull. Shiga. Agric. Exp. Stn. 1981, 23, 30–37. [Google Scholar]

- Xu, G.; Wei, L.L.; Sun, J.N.; Shao, H.B.; Chang, S.X. What is more important for enhancing nutrient bioability with biochar application into a sandy soil: Direct or indirect mechanism? Ecol. Eng. 2013, 52, 119–124. [Google Scholar] [CrossRef]

- Major, J.; Steiner, C.; Downie, A.; Lehmann, J. Biochar effects on nutrient leaching. In Biochar for Environmental Management: Science and Technology; Lehmann, J., Joseph, S., Eds.; Earchscan Publ.: London, UK, 2009; pp. 271–287. [Google Scholar]

- Liu, Y.; Lu, H.; Yang, S.; Wang, Y. Impacts of biochar addition on rice yield and soil properties in a cold waterlogged paddy for two crop seasons. Field Crops Res. 2016, 191, 161–167. [Google Scholar] [CrossRef]

- Sebastian, D.; Rodrigues, H.; Kinsey, C.; KorndÖrfer, G.; Pereira, H.; Buck, G.; Datnoff, L.; Miranda, S.; Provance-Bowely, M. A 5-day method for determination of soluble silicon concentrations in non-liquid fertilizer materials using a sodium carbonate-ammonium nitrate extractant followed by visible spectroscopy with heteropoly blue analysis; single-laboratory validation. J. AOAC Int. 2013, 96, 251–259. [Google Scholar] [CrossRef] [PubMed]

- Xiao, X.; Chen, B.; Zhu, L. Transformation, morphology, and dissolution of silicon and carbon in rice straw-derived biochars under different pyroltytic temperatures. Environ. Sci. Technol. 2014, 28, 3411–3419. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Wang, J.; Wang, X. Effect of KOH-enhanced biochar on increasing soil plant-available silicon. Geoderma 2018, 321, 22–31. [Google Scholar] [CrossRef]

- Kan, T.; Strezov, V.; Evans, T.J. Lignocellulosic biomass pyrolysis: A review of product properties and effects of pyrolysis parameters. Renew. Sustain. Energy Rev. 2016, 57, 1126–1140. [Google Scholar] [CrossRef]

- MAFFa. Report of Road Map to Accomplish the Reduction Goal of Greenhouse Gas Emissions in Korea; Korean Ministry for Food, Agriculture, Fisheries and Forestry: Gwacheon, Korea, 2014; pp. 57–60.

- MAFFb. Annual Statistics in Food, Agriculture, Fisheries and Forestry in 2015; Korean Ministry for Food, Agriculture, Fisheries and Forestry: Sejong, Korea, 2015.

- Puga, A.P.; Grutzmacher, P.; Cerri CE, P.; Ribeirinho, V.S.; de Andrade, C.A. Biochar-based nitrogen fertilizers: Greenhouse gas emissions, use efficiency, and maize yield in tropical soils. Sci. Total Environ. 2020, 704, 135375. [Google Scholar] [CrossRef]

- Pokharel, P.; Chang, S.X. Manure pellet, woodchip and their biochars differently affect wheat yield and carbon dioxide emission from bulk and rhizosphere soils. Sci. Total Environ. 2019, 659, 463–472. [Google Scholar] [CrossRef]

| Materials Used | pH | EC (dS m−1) | TC (g kg−1) | TOC (g kg−1) | TIC (g kg−1) | TN (g kg−1) |

|---|---|---|---|---|---|---|

| Biochar | 9.67 ± 0.04 (1:10) | 1.4 ± 0.02 | 566 ± 5.2 | 533 ± 2.4 | 33.5 ± 0.8 | 2.0 ± 0.01 |

| Pig manure compost | 8.77 ± 0.02 (1:5) | 3.4 ± 0.03 | 289 ± 11.1 | 259 ± 20.7 | 30.2 ± 1.6 | 29.1 ± 0.3 |

| Treatments * | TC (g kg−1) | TN (g kg−1) | TP(g kg−1) | TK(g kg−1) |

|---|---|---|---|---|

| PMCP | 289.0 ± 0.3 | 29.1 ± 0.01 | 79.4 ± 0.3 | 20.8 ± 0.2 |

| BMP-U60 | 226.3 ± 0.2 | 102.0 ± 0.25 | 29.5 ± 0.2 | 11.8 ± 0.3 |

| BMP-NPK | 227.8 ± 0.3 | 75.2 ± 0.03 | 32.8 ± 0.4 | 57.2 ± 0.3 |

| BMP-UK | 224.7 ± 0.5 | 84.0 ± 0.05 | 35.4 ± 0.3 | 13.5 ± 0.1 |

| Soil Type | pH | EC (dS m−1) | NH4+–N (mg kg−1) | NO3–N (mg kg−1) | P2O5 (mg kg−1) | K2O (mg kg−1) | TC (g kg−1) | TOC (g kg−1) |

|---|---|---|---|---|---|---|---|---|

| Clay Loam | 7.0 ± 0.4 | 0.6 ± 0.03 | 10.6 ± 0.1 | ND | 97.8 ± 0.6 | 26.1 ± 0.1 | 20.7 ± 0.3 | 16.6 ± 0.2 |

| Treatments Control | First Day of Rice Transplant (g kg−1) | Day After Harvest (g kg−1) |

|---|---|---|

| 10.30 ± 0.02 a | 10.38 ± 0.02 c | |

| PMCP | 9.45 ± 0.07 d | 10.49 ± 0.07 c |

| BMP-U60 | 9.87 ± 0.13 b | 10.83 ± 0.13 b |

| BMP-NPK | 9.90 ± 0.06 b | 11.80 ± 0.09 a |

| BMP-UK | 9.66 ± 0.05 c | 11.83 ± 0.03 a |

| F-value | 55.33 | 235.30 |

| Pr > F | <0.001 | <0.001 |

| Treatments | Carbon Sequestration (Tonnes ha−1) | Mitigation of CO2 (Tonnes ha−1) | Profit ($ ha−1) | Additional Profit for SBMPF Application ($ ha−1) |

|---|---|---|---|---|

| Control | 1.28 ± 0.11 b | 4.70 ± 0.12 b | 63.59 ± 2.50 b | - |

| PMCP | 1.24 ± 0.08 b | 4.54 ± 0.29 b | 61.47 ± 3.96 b | - |

| BMP-U60 | 1.41 ± 0.12 b | 5.18 ± 0.44 b | 70.06 ± 5.98 b | 6.56 |

| BMP-NPK | 2.45 ± 0.18 a | 8.98 ± 0.66 a | 121.46 ± 8.92 a | 57.87 |

| BMP-UK | 2.67 ± 0.12 a | 9.78 ± 0.44 a | 132.36 ± 5.95 a | 68.77 |

| F-value | 55.06 | 55.06 | 55.06 | - |

| Pr > F | <0.001 | <0.001 | <0.001 | - |

| Treatments | Plant Height (cm) | Number of Tillers | Dry Weight of Rice Straw (Tonnes ha−1) | Grain Yield (Tonnes ha−1) |

|---|---|---|---|---|

| Control | 92.33 ± 0.58 b | 11.67 ± 1.53 b | 9.73 ± 0.51 a | 6.63 ± 0.14 b |

| PMCP | 100.00 ± 2.00 ab | 12.33 ± 2.52 ab | 9.55 ± 0.11 a | 6.68 ± 0.49 ab |

| BMP-U60 | 106.33 ± 8.15 a | 16.00 ± 2.65 ab | 6.85 ± 0.43 b | 7.67 ± 0.36 a |

| BMP-NPK | 103.67 ± 5.51 ab | 13.00 ± 3.46 ab | 5.96 ± 0.51 c | 7.13 ± 0.33 a |

| BMP-UK | 104.67 ± 5.03 ab | 17.67 ± 3.51 a | 5.32 ± 0.53 c | 6.52 ± 0.65 b |

| F-value | 3.69 | 2.49 | 63.02 | 3.69 |

| Pr > F | 0.043 | 0.110 | <0.001 | 0.043 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, J.; Park, S.; Jeong, C. Assessment of Agro-Environmental Impacts for Supplemented Methods to Biochar Manure Pellets during Rice (Oryza sativa L.) Cultivation. Energies 2020, 13, 2070. https://doi.org/10.3390/en13082070

Shin J, Park S, Jeong C. Assessment of Agro-Environmental Impacts for Supplemented Methods to Biochar Manure Pellets during Rice (Oryza sativa L.) Cultivation. Energies. 2020; 13(8):2070. https://doi.org/10.3390/en13082070

Chicago/Turabian StyleShin, JoungDu, SangWon Park, and Changyoon Jeong. 2020. "Assessment of Agro-Environmental Impacts for Supplemented Methods to Biochar Manure Pellets during Rice (Oryza sativa L.) Cultivation" Energies 13, no. 8: 2070. https://doi.org/10.3390/en13082070

APA StyleShin, J., Park, S., & Jeong, C. (2020). Assessment of Agro-Environmental Impacts for Supplemented Methods to Biochar Manure Pellets during Rice (Oryza sativa L.) Cultivation. Energies, 13(8), 2070. https://doi.org/10.3390/en13082070