Optimal Dispatch Strategy for a Flexible Integrated Energy Storage System for Wind Power Accommodation

Abstract

1. Introduction

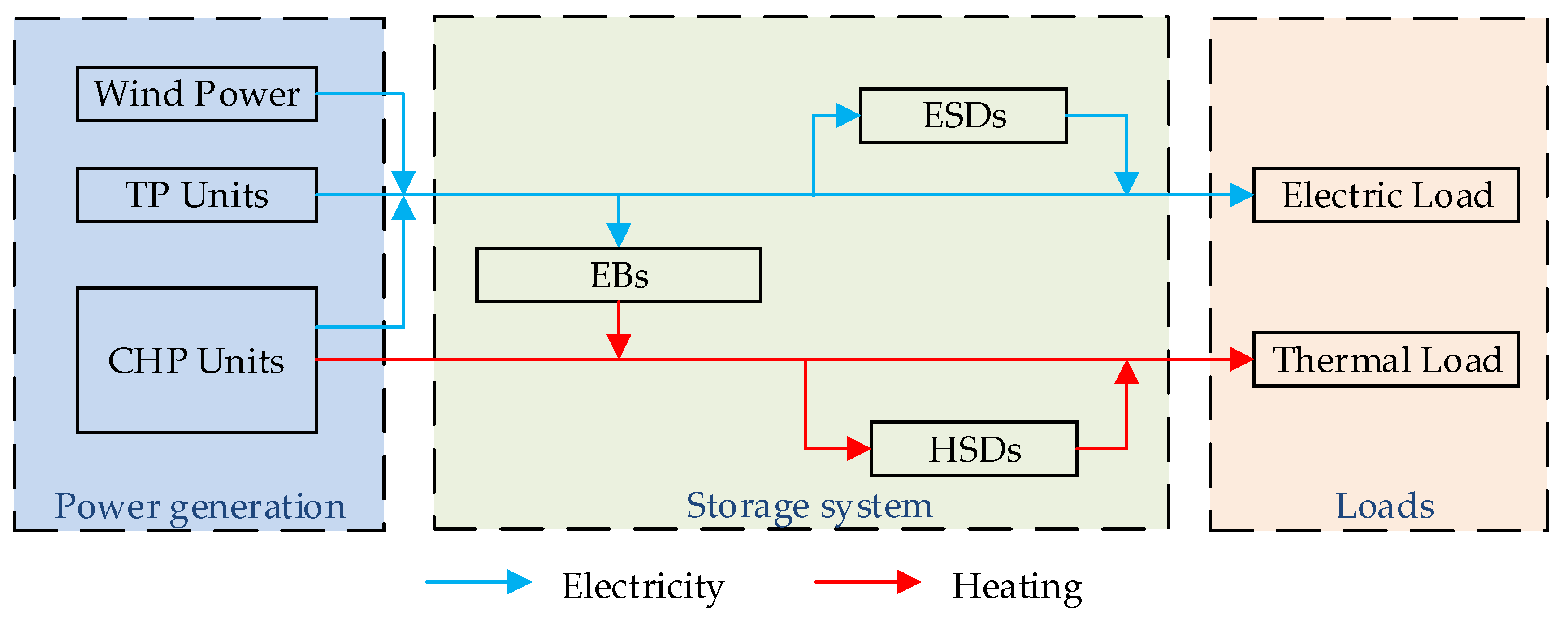

2. Electric-Heat Integrated Energy System

3. Powers Sources and Devices Models

3.1. Conventional Thermal Power Units

3.1.1. Operation Costs Model

3.1.2. Constraints

3.2. CHP Units

3.2.1. Operation Costs Model

3.2.2. Constraints

3.3. Heat Storage Devices

3.3.1. Operation Costs Model

3.3.2. Constraints

3.4. Electric Storage Devices

3.4.1. Operation Costs Model

3.4.2. Constraints

3.5. Electric Boilers

3.5.1. Operation Costs Model

3.5.2. Constraints

4. Overall Optimal Scheduling Model

4.1. Objective Function

4.2. Constraints

4.3. Solution Method

5. Case Study

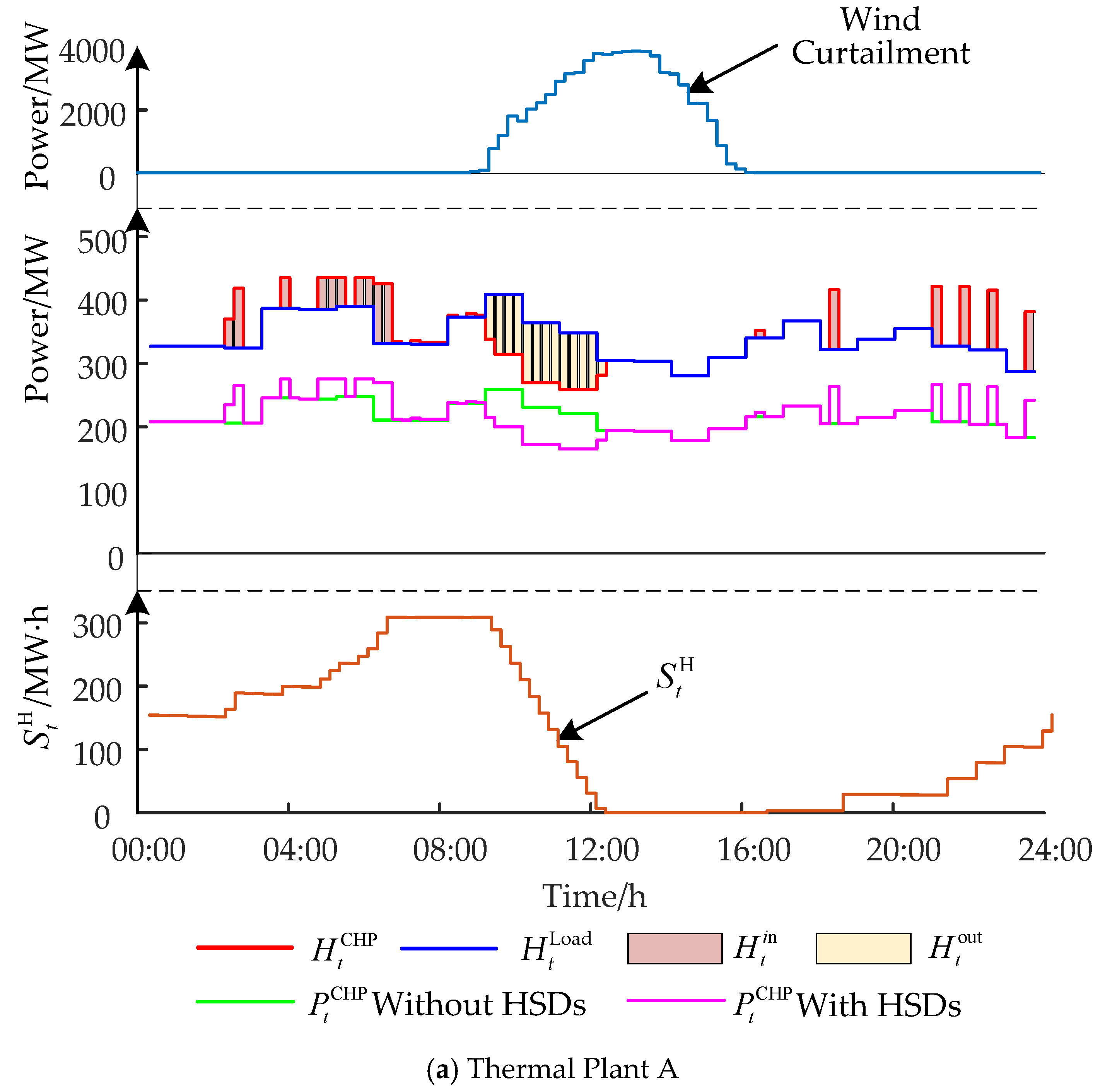

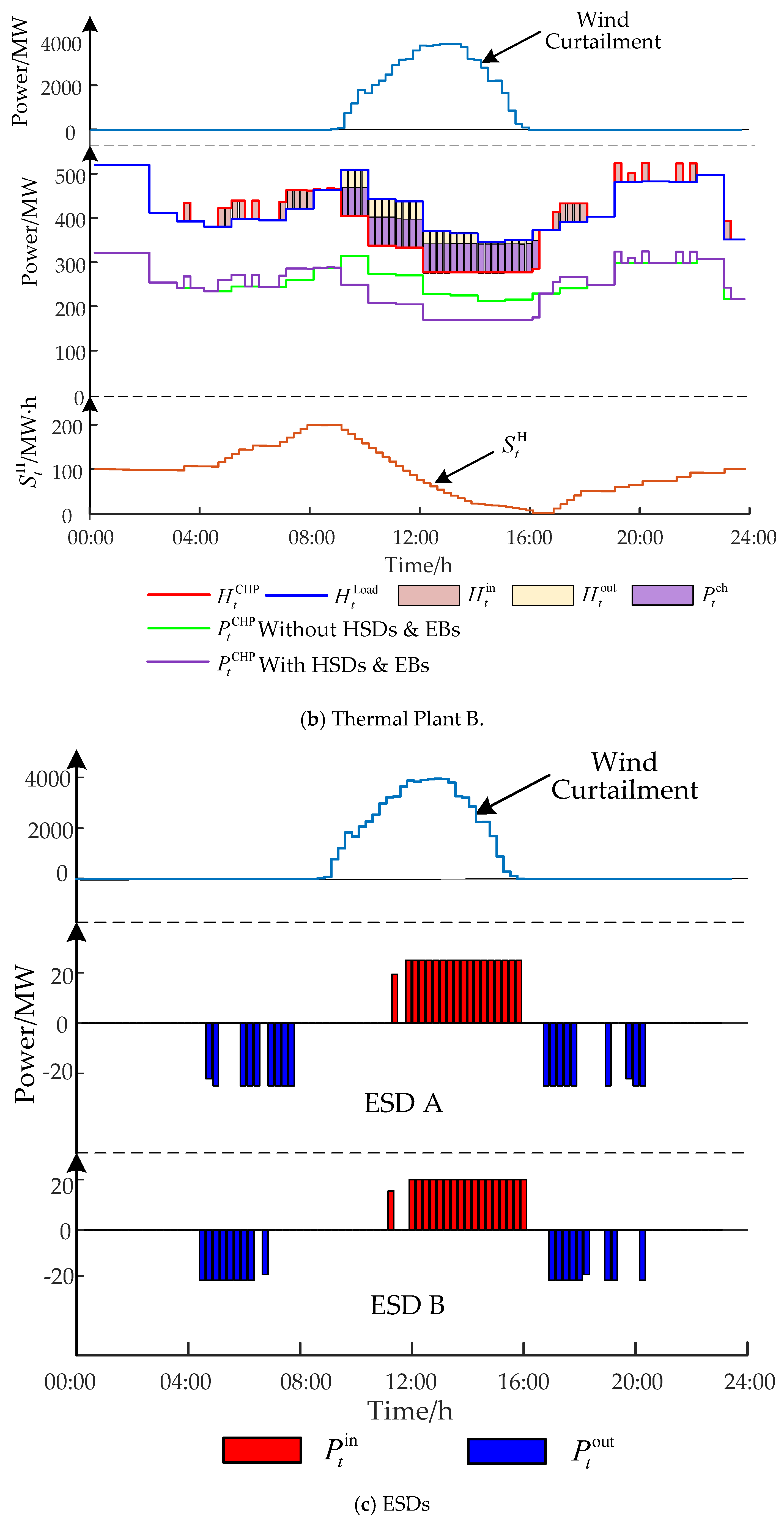

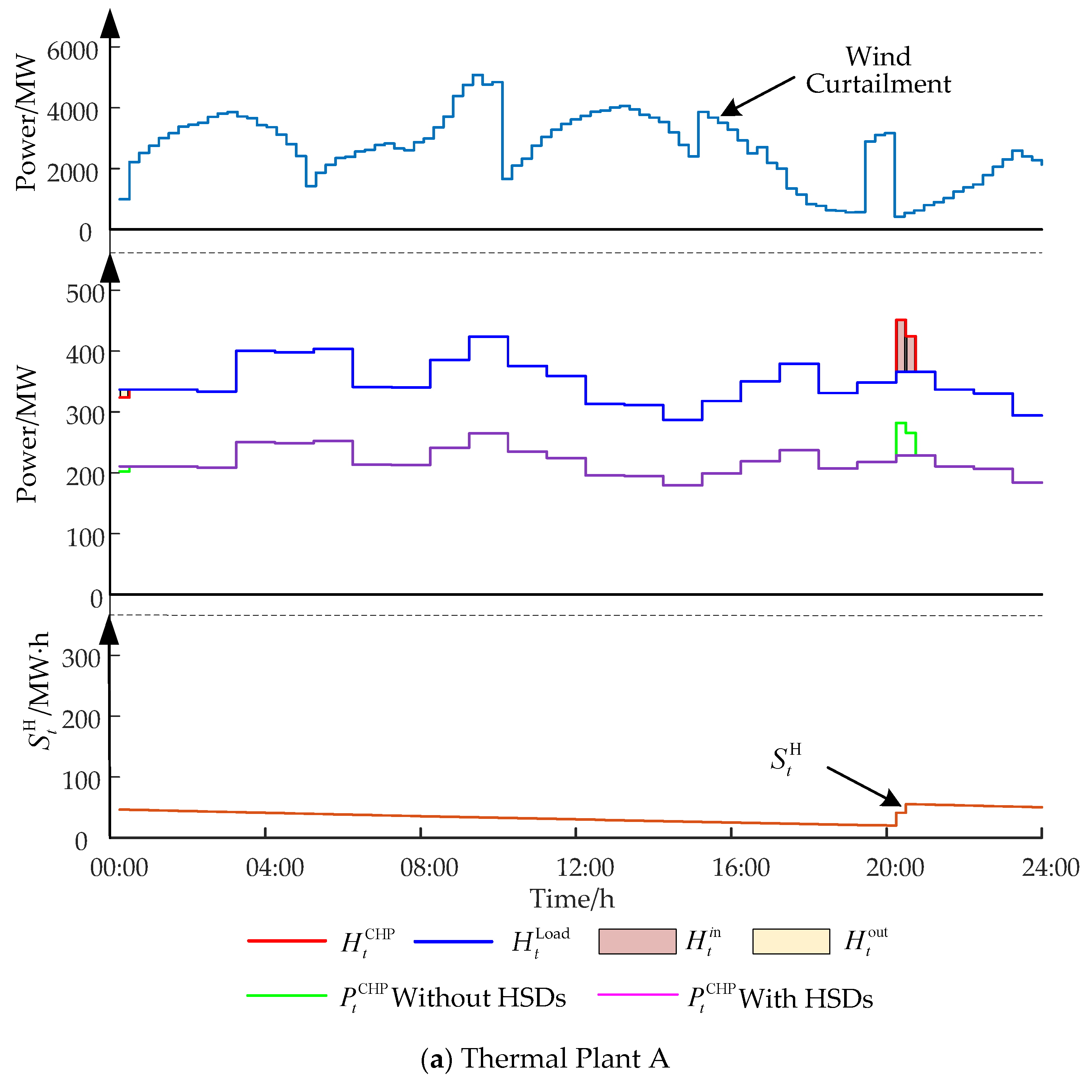

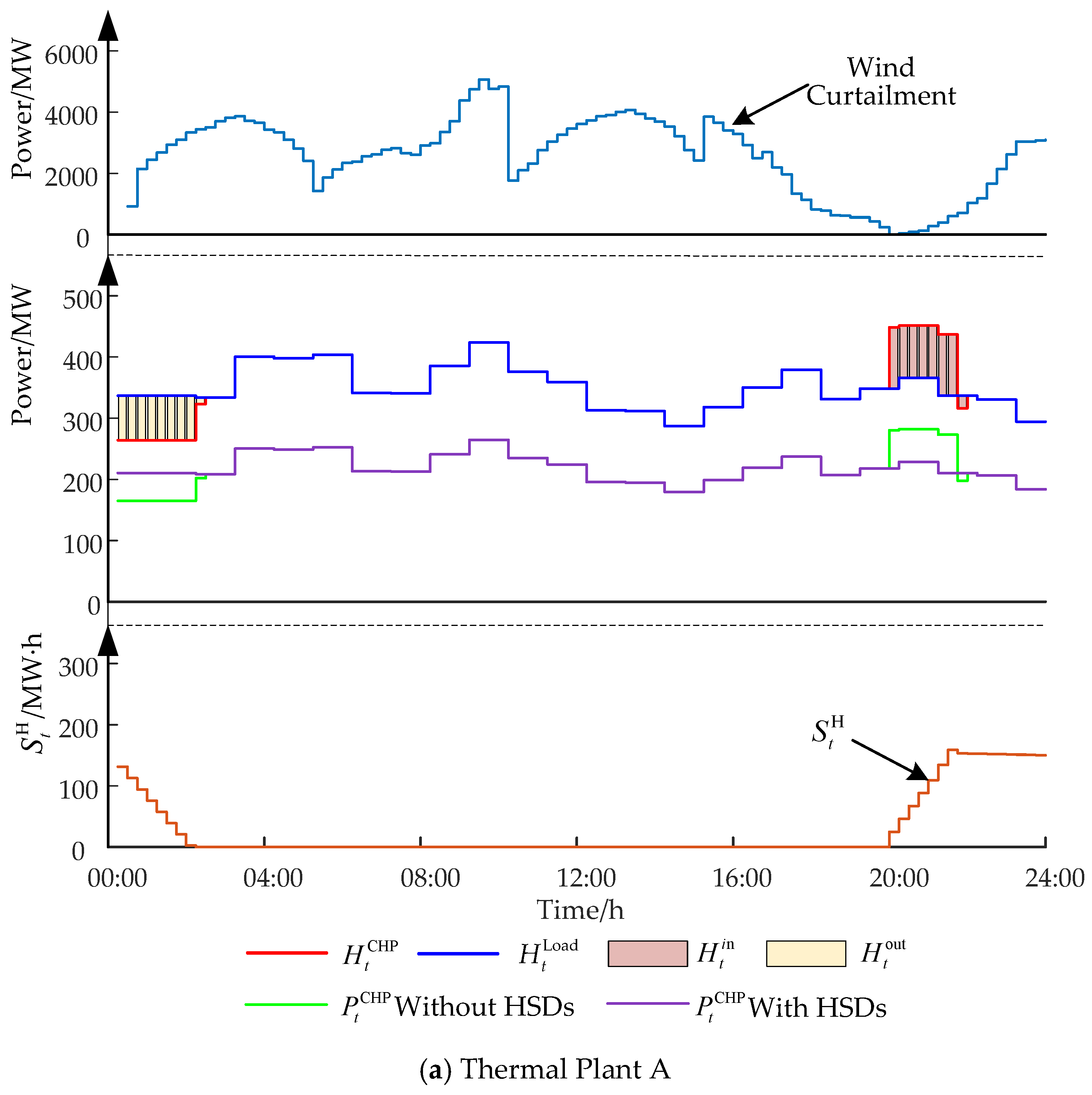

5.1. Ordinary Operating Conditions

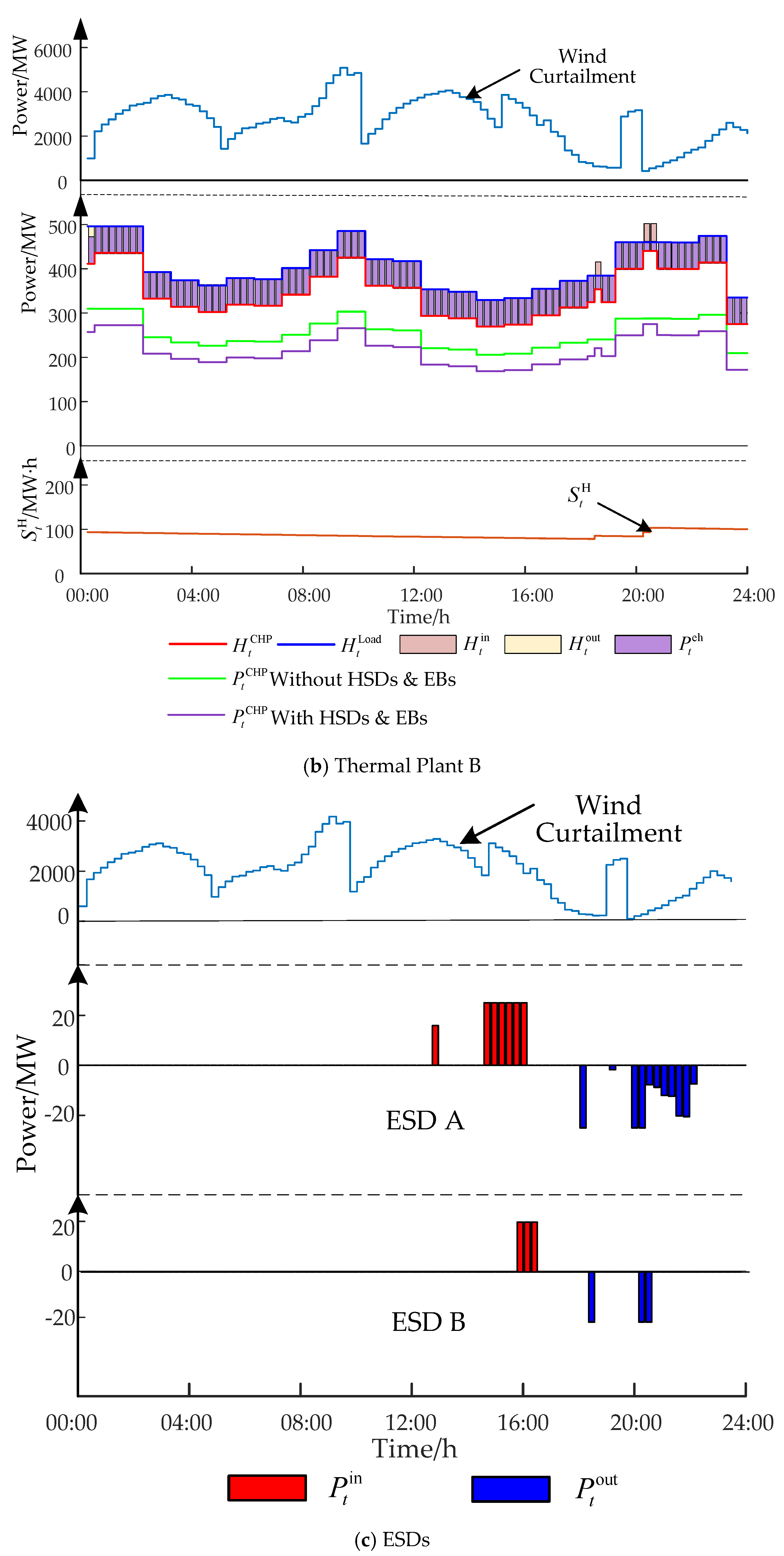

5.2. All-day Wind Curtailment Conditions

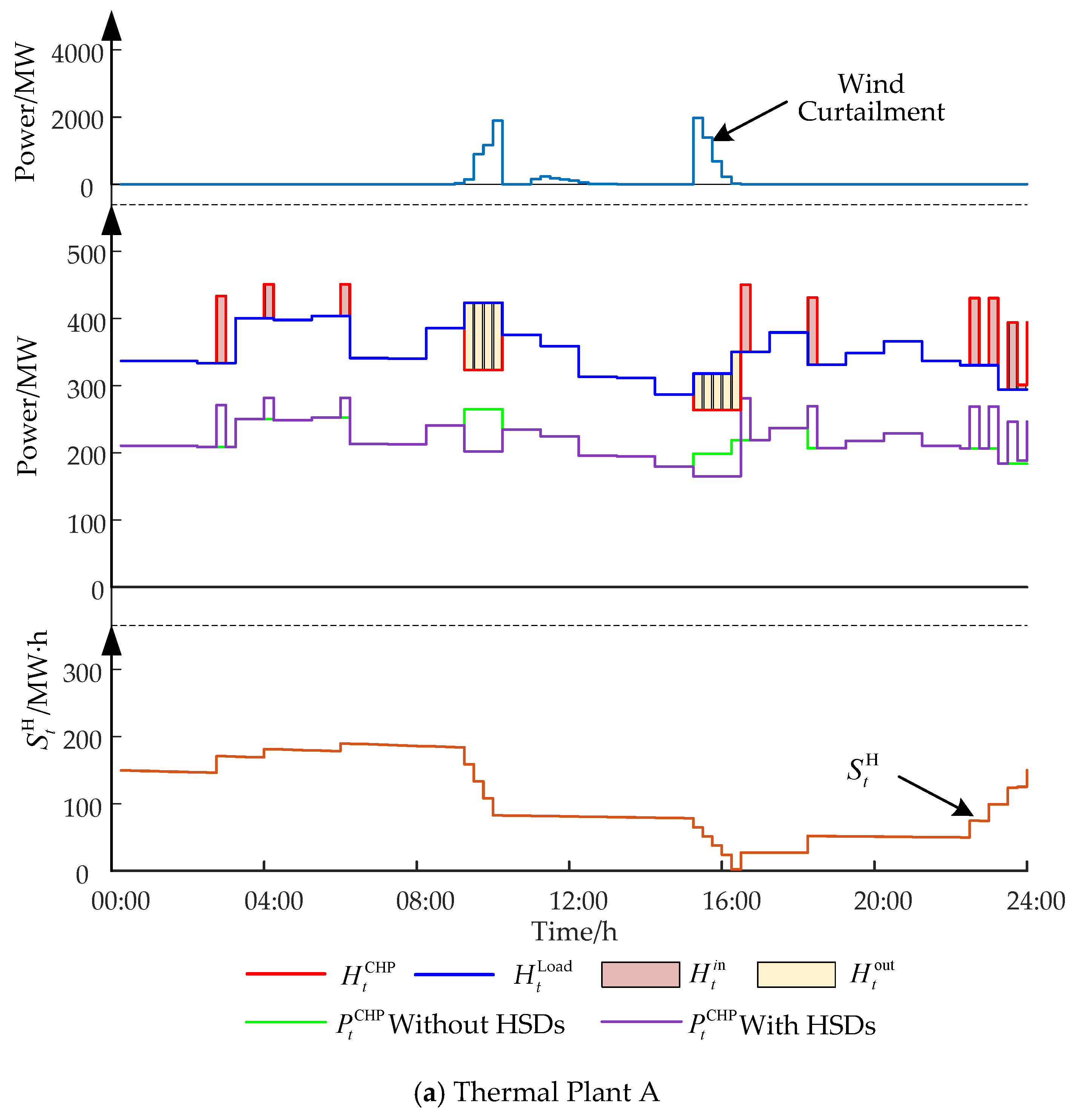

5.3. A Small Amount of Wind Curtailment Conditions

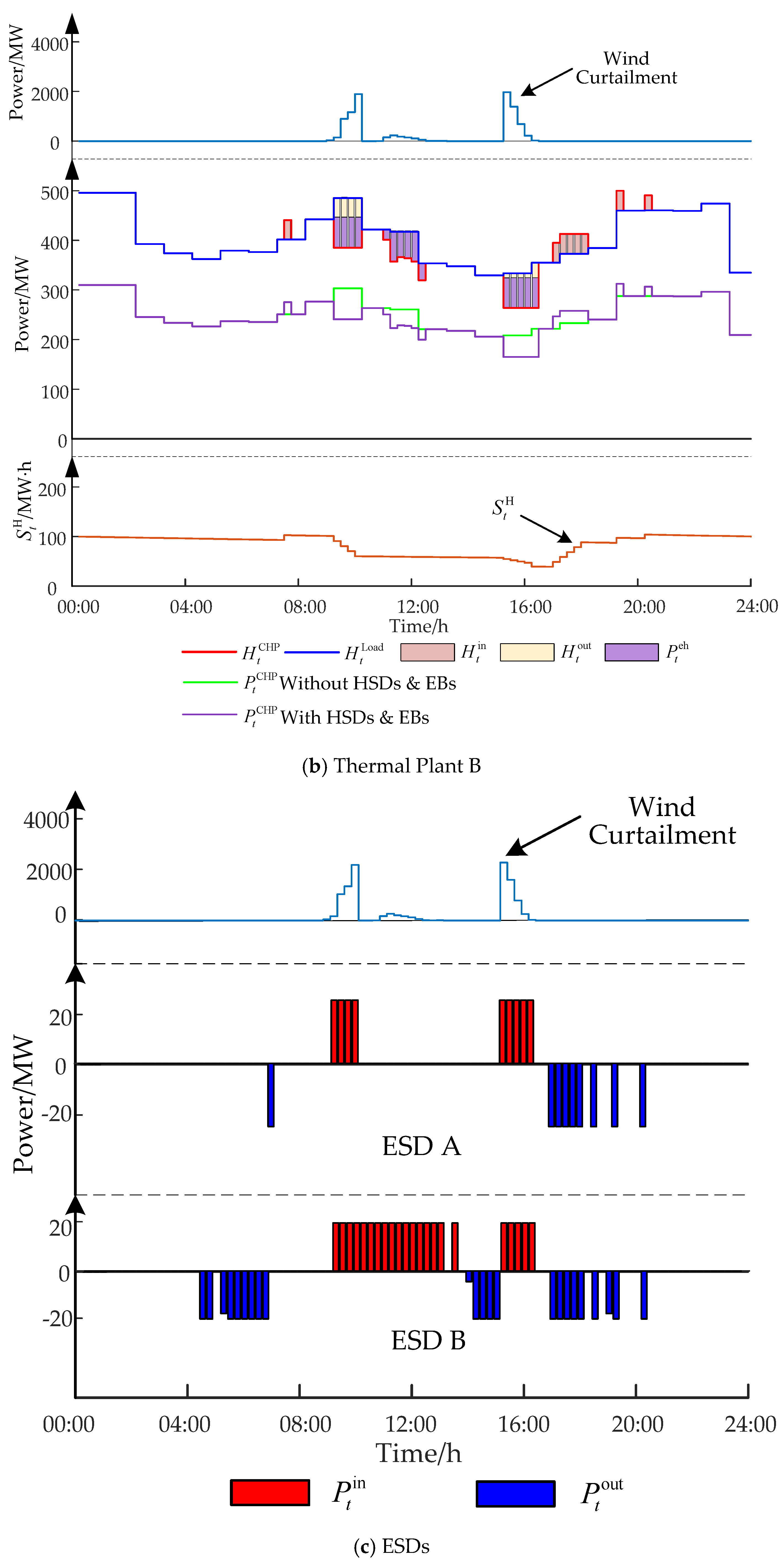

5.4. Conditions Where the Wind Curtailment Period Is Not Long Enough to Fill HSDs

5.5. Case Study Conclusions

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Full Name | Acronym |

|---|---|

| Combined heat and power | CHP |

| Following the thermal load | FTL |

| Thermal power | TP |

| Heat storage device | HSD |

| Electric boiler | EB |

| Energy storage device | ESD |

References

- Bai, J.H.; Xin, S.X.; Liu, X.; Zheng, K. Roadmap of Realizing the High Penetration Renewable Energy in China. Proc. CSEE 2015, 35, 3699–3705. [Google Scholar] [CrossRef]

- Chen, X.; Kang, C.; O’Malley, M.; Xia, Q.; Bai, J.; Chun, L.; Sun, R.; Wang, W.; Li, H. Increasing the flexibility of combined heat and power for wind power integration in China: Modeling and implications. IEEE Trans. Power Syst. 2015, 30, 1848–1857. [Google Scholar] [CrossRef]

- Wu, Y.T.; Fu, L.; Zhang, S.G.; Tang, D.K. Study On A Novel Co-operated Heat and Power System for Improving Energy Efficiency and Flexibility of Cogeneration Plants. Appl. Therm. Eng. 2019, 163, 1–13. [Google Scholar] [CrossRef]

- Luo, Y.H.; Yin, Z.X.; Yang, D.S.; Zhou, B.W. A New Wind Power Accommodation Strategy for Combined Heat and Power System Based on Bi-Directional Conversion. Energies 2019, 12, 2458. [Google Scholar] [CrossRef]

- Lin, C.H.; Wu, W.C.; Zhang, B.M.; Sun, Y. Decentralized Solution for Combined Heat and Power Dispatch Through Benders Decomposition. IEEE Trans. Sustain. Energy 2017, 8, 1361–1372. [Google Scholar] [CrossRef]

- Shin, D.U.; Ryu, S.R.; Kim, K.W. Simultaneous Heating and Cooling System with Thermal Storage Tanks Considering Energy Efficiency and Operation Method of The System. Energy Build. 2019, 20, 1–14. [Google Scholar] [CrossRef]

- Lesko, M.; Bujalski, W.; Futyma, K. Operational Optimization in District Heating Systems with the Use of Thermal Energy Storage. Energy 2018, 165, 902–915. [Google Scholar] [CrossRef]

- Huo, D.; Wei, W.; Simon, L.B. Optimisation for Interconnected Energy Hub System with Combined Ground Source Heat Pump and Borehole Thermal Storage. Front. Energy 2018, 12, 529–539. [Google Scholar] [CrossRef]

- Lv, Q.; Chen, T.Y.; Wang, H.X.; Yu, T.; Li, Q.; Tang, W. Analysis on Peak-load Regulation Ability of Cogeneration Unit with Heat Accumulator. Autom. Electr. Power Syst. 2014, 38, 34–41. [Google Scholar] [CrossRef]

- Lv, Q.; Chen, T.Y.; Wang, H.X.; Li, L.; Lv, Y.; Li, W.D. Combined Heat and Power Dispatch Model for Power System With Heat Accumulator. Electr. Power Autom. Equip. 2014, 34, 79–85. [Google Scholar] [CrossRef]

- Xu, F.; Min, Y.; Chen, L.; Chen, Q.; Hu, W.; Zhang, W.L.; Wang, X.H.; Hou, Y.H. Combined Electricity-Heat Operation System Containing Large Capacity Thermal Energy Storage. Proc. CSEE 2014, 34, 5063–5072. [Google Scholar] [CrossRef]

- Ge, W.C.; Gao, M.L.; Zhang, Y.J.; Li, J.; Che, X.T.; Liu, Y.Y. Optimal Economic Dispatch of Integrated Energy System Based on Electric Boiler for Wind Power Accommodation. South. Power Syst. Technol. 2019, 13, 59–66. [Google Scholar] [CrossRef]

- Meibom, P.; Kiviluoma, J.; Barth, R.; Brand, H.; Weber, C.; Larsen, H.V. Value of Electric Heat Boilers and Heat Pumps for Wind Power Integration. Wind Energy 2010, 10, 321–337. [Google Scholar] [CrossRef]

- Lv, Q.; Jang, H.; Chen, T.Y.; Wang, H.X.; Lv, Y.; Li, W.D. Wind Power Accommodation by Combined Heat and Power Plant with Electric Boiler and Its National Economic Evaluation. Autom. Electr. Power Syst. 2014, 38, 6–12. [Google Scholar] [CrossRef]

- Yuan, X.M.; Cheng, S.J.; Wen, J.Y. Prospects Analysis of Energy Storage Application in Grid Integration of Large-scale Wind Power. Autom. Electr. Power Syst. 2013, 37, 14–18. [Google Scholar] [CrossRef]

- Shi, J.; Wang, L.H.; Lee, W.J.; Cheng, X.G.; Zong, X.J. Hybrid Energy Storage System (HESS) Optimization Enabling Very Short-term Wind Power Generation Scheduling Based On Output Feature Extraction. Appl. Energy 2019, 256, 1–10. [Google Scholar] [CrossRef]

- Wu, W.; Lin, B.Q. Application Value of Energy Storage In Power Grid: A Special Case of China Electricity Market. Energy 2018, 165, 1191–1199. [Google Scholar] [CrossRef]

- Kia, M.; Nazar, M.S.; Sepasian, M.S.; Heidari, A.; Siano, P. Optimal Day Ahead Scheduling of Combined Heat and Power Units with Electrical and Thermal Storage Considering Security Constraint of Power System. Energy 2017, 120, 241–252. [Google Scholar] [CrossRef]

- Kose, F.; Kaya, M.N. Wind-Hydro Pumped Storage Power Stations to Meet the Energy Demands of Irrigation: Feasibility, Optimal Design and Simulation of a System. J. Chin. Soc. Mech. Eng. 2018, 39, 223–232. [Google Scholar]

- Wu, X.S.; Zhang, B.H.; Yuan, X.M.; Li, G.W.; Luo, G.; Zhou, Y. Solutions to Unit Commitment Problems in Power Systems With Wind Farms Using Advanced Quantum-inspired Binary PSO. Proc. CSEE 2013, 33, 45–52. [Google Scholar] [CrossRef]

- Tian, K. Unit Commitment Model and Solution in the Hybrid Power System Based on Chaos Embedded Particle Swarm Optimization-Scenario Reduction Algorithms. Power Syst. Technol. 2013, 37, 1019–1024. [Google Scholar] [CrossRef]

- Hussain, S.; Al-Hitmi, M.; Khaliq, S.; Hussain, A.; Saqib, M.A. Implementation and Comparison of Particle swarm Optimization and Genetic Algorithm Techniques In Combined Economic Emission Dispatch of An Independent Power Plant. Energies 2019, 12, 2037. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L.D.; Yin, M.H.; Zhang, X.L.; Zou, Y. Fuzzy decision-making based unit commitment of power grid integrated with wind farms. Power Syst. Technol. 2013, 37, 2480–2485. [Google Scholar] [CrossRef]

- Guan, X.H.; Zhai, Q.Z.; Gao, F. Short-term Hydrothermal Scheduling Using Mixed-integer Linear Programming. Proc. CSEE 2009, 29, 82–88. [Google Scholar] [CrossRef]

- Fischetti, M.; Monaci, M. Proximity Search for 0–1 Mixed-integer Convex Programming. J. Heuristics 2014, 20, 709–731. [Google Scholar] [CrossRef]

| Software | Fortran and GLPK |

|---|---|

| Date source | Partial data of a provincial power grid |

| Scale of scheduling | Two thermal power plants with CHP units, HSDs and EBs, two power storage plants with ESDs |

| Number of variables | About 500,000 |

| Working scenarios | Condition 1: ordinary operating condition Condition 2: all-day wind curtailment Condition 3: a small amount of wind abandoning Condition 4: the wind abandoning period is not long enough to fill HSDs |

| Working Scenarios | Increased Accommodation Rate | |||

|---|---|---|---|---|

| Condition 1 | 182,911.00 | 181,880.00 | 1031.00 | 0.56% |

| Condition 2 | 636,658.64 | 634,269.83 | 2388.81 | 0.38% |

| Condition 3 | 2388.81 | 1901.93 | 486.88 | 20.38% |

| Condition 4 | 611,873.52 | 609,432.45 | 2441.07 | 0.39% |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, Y.; Zhao, P.; Xu, F.; Cui, D.; Ge, W.; Chen, X.; Gu, B. Optimal Dispatch Strategy for a Flexible Integrated Energy Storage System for Wind Power Accommodation. Energies 2020, 13, 1073. https://doi.org/10.3390/en13051073

Zhou Y, Zhao P, Xu F, Cui D, Ge W, Chen X, Gu B. Optimal Dispatch Strategy for a Flexible Integrated Energy Storage System for Wind Power Accommodation. Energies. 2020; 13(5):1073. https://doi.org/10.3390/en13051073

Chicago/Turabian StyleZhou, Yunhai, Pinchao Zhao, Fei Xu, Dai Cui, Weichun Ge, Xiaodong Chen, and Bo Gu. 2020. "Optimal Dispatch Strategy for a Flexible Integrated Energy Storage System for Wind Power Accommodation" Energies 13, no. 5: 1073. https://doi.org/10.3390/en13051073

APA StyleZhou, Y., Zhao, P., Xu, F., Cui, D., Ge, W., Chen, X., & Gu, B. (2020). Optimal Dispatch Strategy for a Flexible Integrated Energy Storage System for Wind Power Accommodation. Energies, 13(5), 1073. https://doi.org/10.3390/en13051073