Abstract

Greenhouse gas emissions are one of the most critical worldwide concerns, and multiple efforts are being proposed to reduce these emissions. Shipping represents around 2% of global CO emissions. Since ship power systems have a high dependence on fossil fuels, hybrid systems using diesel generators and batteries are becoming an interesting solution to reduce CO emissions. In this article, we analyze the potential implementation of Li-ion batteries in a platform supply vessel system through simulations using HOMER software (Hybrid Optimization Model for Multiple Energy Resources). We evaluate the impact of battery characteristics such as round trip efficiency, rated power, and energy capacity. We also evaluate the potential CO emissions reduction that could be achieved with two of the most common types of Li-ion batteries (lithium titanate, lithium iron phosphate). Furthermore, we consider that the Li-ion batteries are installed in a 20 ft container. Results indicate that the lithium iron phosphate battery has a better performance, even though the difference between both technologies is lower than 1% of total emissions. We also analyze the potential emissions reduction for different parts of a mission to an offshore platform for different configurations of the ship power system. The most significant potential CO emissions reduction among the analyzed cases is 8.7% of the total emissions, and it is achieved by the configuration including the main and auxiliary diesel engines as well as batteries. Finally, we present managerial implications of these results for both companies operating ships and ship building companies.

1. Introduction

In recent years, concerns about greenhouse gas emissions have risen and discussions took place to decide each country’s strategy to reduce these emissions. Kyoto Protocol and Paris Agreement are the results of these discussions.

The Kyoto protocol was adopted in 1997 at the Kyoto conference. This protocol was the first to introduce emissions limits and an agenda to prevent further global warming [1]. Moreover, the Kyoto protocol brought in some mechanisms such as the International Emission Trading (IET), the Joint Implementation Mechanism, and the Clean Development Mechanism (CDM) [2]. IET allowed industrialized countries, included in Annex B of the protocol, to buy and sell their assigned emissions.

The Joint Implementation Mechanism allowed governments to develop projects that reduced emissions in other countries to earn emission reduction units (ERUs). In addition, the Clean Development Mechanism focuses on the relations between countries of Annex B and developing countries. Thanks to this mechanism, developing countries could sell Certified Emission Reduction (CER) units to an industrialized nation. Certified Emission Reduction units could be earned by obtaining the certification that a given project, promoted by a developing country, reduced emissions. Unfortunately, the final deal did not set an objective for emissions reduction in the international shipping sector.

The Paris agreement entered into force on the 4th of November 2016; its main ambition is to keep the temperature increase below 2 [3]. Countries have presented their national situation and their target to reduce global greenhouse gases in the intended nationally determined contributions [4]. Moreover, the International Panel on Climate Change (IPCC) also wrote a report about the impacts that would be caused by an increase of of the global temperature. Every potential solution is required to attain this reduction level.

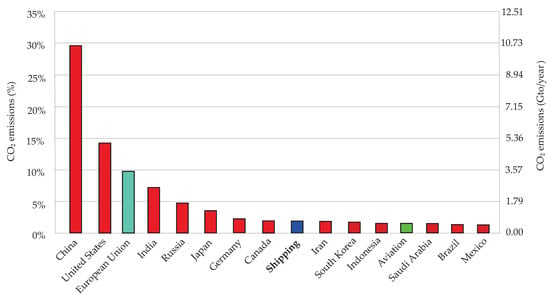

These international agreements helped to bring out the discussion about emissions in the transports sector and more particularly shipping emissions, which are the focus of this work. As can be seen in Figure 1, shipping accounts for 2% of global CO emissions, shipping emissions are equivalent to the ones of Canada, and shipping emits 20% more than aviation. A recent study by the European Parliament shows that shipping emissions should be reduced of 13% by 2030 and 63% by 2050 from 2005 level, in order to stay below 2 . However, maritime emissions have increased by 3% per year between 1990 and 2010 [5], this is higher than the increase of global Greenhouse Gas (GHG) emissions, which is of 1.1%.

Figure 1.

Global CO emissions ranking according to the Emission Database for Global Atmospheric Research (EDGAR) report [6].

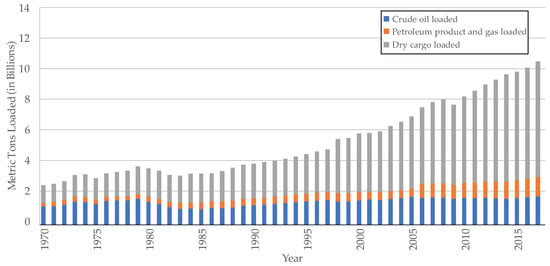

Figure 2 shows the rise of the world seaborne trade. We observe that the crude oil loaded trade has remained stable during the 37 years analyzed and that the trade involving petroleum products and gas has slightly increased. We also observe that the dry cargo ship loaded trade has increased very significantly.

Figure 2.

Annual world seaborne trade from 1970 to 2017 according to the United Nations Conference on Trade and Development [7].

The fact that ships are responsible for 90% of global trade [8] combined with the rapid growth in maritime trade (Figure 2) highlights the urgency of lowering CO emissions from this sector.

The following articles have studied the potential CO emissions reduction in the shipping sector, notably by investigating energy dispatch strategies in ships.

In [9], Miyasaki et al. proposed a model to calculate fuel savings and the emissions reduction potential, considering various constraints. Even though this article presents good results, such as a fuel consumption reduction of around 45%, it neither clearly describes the missions that are considered nor evaluates CO emissions for a full routine of the ship. Compared to [9], our article presents a mission routine with a load curve that clearly shows the power variations that the generators need to support during the whole mission. Moreover, we pursue the analysis for each part of the mission highlighting the parts that present the highest CO emissions reduction potential.

In [10], Miyasaki et al. presented a model of a hybrid power system and validated it experimentally. The authors evaluated the effect of the battery efficiency, considering a variation of the efficiency from 80% to 100%. However, since there is no commercially available battery for ships that achieves 100% efficiency and battery efficiency can drop below 80%, we consider a variation of the round trip efficiency from 70 to 96%. Moreover, our article also studies the impact of different C-rates and discharge times on emissions reduction.

In [11], Kanellos presented an algorithm to optimize the energy dispatch in an all-electric ship considering some constraints such as power balance, generator loading, GHG emissions, and ramp rates. The article included a cost to start the generators, which is not considered in our article. On the other hand, [11] neither studied the potential of hybrid power systems nor investigated the influence of the minimum load level of generators.

Section 2 presents the methodology used in this work. In Section 3, sensitivity analyses are performed showing the effects on CO emissions reduction of changes in power system characteristics such as round trip efficiency, battery power, battery capacity, and minimum generators load level. Section 4 presents a comparison between two Li-ion battery technologies (i.e., lithium-titanate, lithium iron phosphate). In Section 5, the potential reduction in CO emissions that can be achieved for each part of a mission is evaluated. We notably study the potential impact of using auxiliary generators during low load parts of the mission, since they could allow to disconnect bigger generators which are working at lower efficiency points.

The originalities of this article include the consideration of different technologies of batteries, a sensitivity analysis over parameters that were not considered previously, the study of new power system architectures including batteries and auxiliary generators, and the computation of CO emissions reduction during different parts of a mission to an offshore platform.

These aspects are worth considering since there are multiple battery technologies with different round trip efficiencies and several ship power system architectures. In addition, requirements for each part of the mission are different, which implies that the use of batteries and auxiliary generators could also differ for each part.

2. Methodology

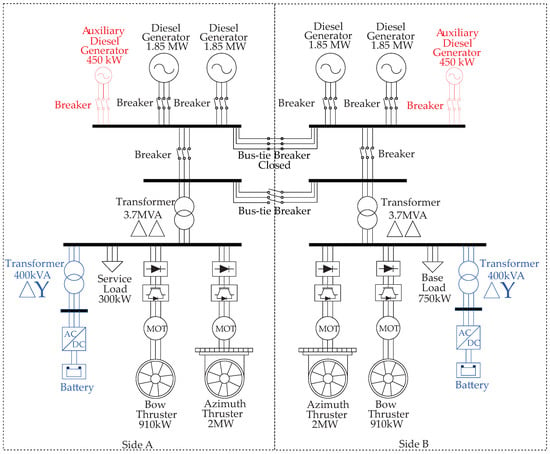

This section presents the general methodology for the simulations, the software used and the range of analyzed parameters. The different architectures used in the simulation cases are shown in Figure 3.

Figure 3.

Power system diagram of the Platform Supply Vessel (PSV) considered. The base case analyzed is in black. The components connected to the base case to evaluate the potential of auxiliary generators are in red. The ones related to batteries are in blue. The last analysis pursued (auxiliary generators + batteries) comprises all the elements of this figure.

2.1. Simulation Cases

The performance of a generic Platform Supply Vessel (PSV) is analyzed by simulating multiple architectures of a hybrid system including diesel generators, energy storage systems, and auxiliary generators. Figure 3 shows the electrical diagram of the hybrid system [12]. The main group of generators is composed of four 1850 kW diesel generators and is connected to a bus-bar providing energy to different types of loads such as thrusters (bow and azimuth thrusters), base load, service load, and to batteries.

The optimal dispatch of the available energy to supply the demand is performed using HOMER (Hybrid Optimization Model for Multiple Energy Resources) software. HOMER uses a proprietary derivative-free optimization method to find the system with the lowest cost considering combinations of available energy sources and the load profile.

Following general procedures to analyze isolated systems such as island electrical systems [13,14] and general recommendations to implement Li-ion batteries in ships [15], we developed a general methodology to evaluate CO emissions.

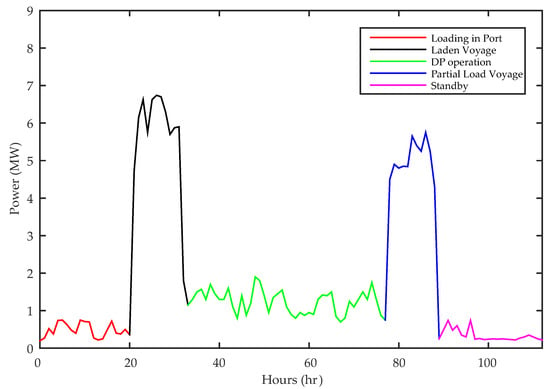

A base case is defined using the load demand profile shown in Figure 4. The minimum load level for three 1850 kW diesel generators is set at 50%, for the other diesel generator the minimum load level is set at 10%. Minimum load means that the generator will be switched on only if the power it would produce is higher than 50% or 10% of its rated power. No batteries or auxiliary generators are used in the base case. In this article, we use “Diesel” to refer to the main generators and “Diesel Aux” to refer to the auxiliary ones. We simulate four identical 1850 kW diesel generators, two additional auxiliary generators (450 kW) and multiple Li-ion batteries with different round trip efficiency, rated power, rated capacity, and C-rate. CO emissions are evaluated for all cases. The time step of the simulations is 30 min.

Figure 4.

Power demand during the different parts of the mission.

Sensitivity analyses compare CO emissions reduction potential that can be achieved by four main parameters:

- Round trip efficiency. The total round trip efficiency of batteries and charge converter is combined under one parameter which varies from 70% to 96%.

- Minimum load level of diesel generators. We simulate minimum load levels of 30%, 40%, and 50%.

- Battery C-rate. The energy capacity of the battery system is fixed at 1000 kWh to simulate multiple cases with different C-rates from 0.2 to 2.

- Battery energy capacity. The energy storage system is fixed at 1000 kW of rated power. Multiple cases are simulated for different energy capacities, therefore influencing the time that the storage would last if we discharge it at the rated power. This discharge time varies from 12 min to 120 min.

We investigate the implementation of lithium iron phosphate and lithium titanate batteries in a typical 20 ft container. Some considerations are taken into account to estimate the effective volume available for batteries inside the container.

In Section 5, we present the results of the individual simulations for each part of the mission (loading in port, laden voyage, DP operation, partial load voyage, standby). It allows the evaluation of the CO emissions reduction potential of each configuration proposed in this article for each part of the mission.

The following configurations including auxiliary generators and batteries are evaluated:

- Diesel + Battery. There are four 1850 kW diesel generators and a 1000 kW–1000 kWh battery system.

- Diesel + Diesel Aux. There are four 1850 kW diesel generators and two 450 kW auxiliary generators at minimum load level 50%, which are included only during loading in port and standby operations.

- Diesel + Battery + Diesel Aux. There are four 1850 kW diesel generators, a 1000 kW–1000 kWh battery system, and two 450 kW generators during loading in port and standby.

The full mission and individual mission parts are simulated for each configuration. For configurations including batteries, the state of charge at the end of one part of the mission is used as initial state of charge for the next part of the mission.

2.2. Mission Profile Considered

The power demand during the different parts of the mission is presented in Figure 4. This load profile is considered for the different simulations performed in this article. The mission starts in the port, where the ship is fully loaded with goods that should be transported to the offshore platform. Then it begins a voyage to the platform and, since the vessel is fully loaded, this part of the mission is called “laden voyage”. When the ship stops at the platform, if the climate conditions are appropriate, the ship starts the Dynamically Positioned (DP) operation. During this operation, the DP control system receives all the information about wind and tidal current speed and calculates the power that each thruster should dispatch to keep the ship steady.

The thrusters of this PSV are the bow thrusters, that only move the ship forward and backward, and the azimuth thrusters, that can drive the vessel in any direction. The DP control system sends the exact direction towards which the azimuth thrusters should move the ship to counterbalance the forces that tend to make the ship drift, keeping the ship steady.

After the DP operation the ship starts a voyage back to the port. During this voyage, the ship is not fully loaded and it is therefore called partial load voyage. As can be seen in Figure 4, the partial load voyage requires less power than the laden voyage. Finally, the ship arrives close to the port area but receives a message to wait because the port does not have a space available to receive the vessel. During this time, the vessel is in standby operation.

As shown in Figure 4, even though the ship is keeping a position in DP operation and standby, the restriction of movement during DP operation is more power demanding. Indeed, the tidal and wind forces are stronger during the DP operation than during the standby operation, as the ship is further away from the shore. Moreover, the ship does not have to remain completely steady during the standby operation.

2.3. Batteries Charge-Discharge Cycles

An additional consideration related to batteries is their total number of full charge-discharge cycles. Since batteries present erratic states of charge (SoC) through the whole mission, it is difficult to directly determine the total number of cycles for a battery. We decided to estimate the number of cycles by calculating equivalent battery cycles per mission. For this step we take the total energy cycled through the battery and divide it by the actual available battery energy. The result, shown in Equation (1), is an equivalent of total full charge-discharge cycles during the mission and is one of the variables evaluated for multiple cases in this article.

where:

- : Total cycled energy through the battery (kWh)

- : Battery capacity at 90% SoC (kWh)

- : Battery capacity at 20% SoC (kWh)

Battery states of charge 90% and 20% are selected to increase battery life, following the recommendations provided by Xu et al. [16]. Indeed, using batteries at very high state of charge increases their capacity loss and deeply discharging batteries decreases their lifetime.

2.4. Optimization Performed with HOMER

HOMER [17] is a software for modeling and optimizing small grids connected or not connected to the main grid. HOMER software is a commercial program developed by the National Renewable Energy Laboratory (NREL) and now managed by HOMER Energy LLC. HOMER uses available information about:

- Energy resources (e.g., fuel-powered generators, solar photovoltaic, wind turbine, biomass power, fuel cell);

- Energy storage (e.g., batteries, flywheel, hydrogen);

- Loads (i.e., load demand profile)

Figure 5 shows the 1850 kW generators efficiency curve used in HOMER simulations. HOMER allows the evaluation of multiple system configurations, which combine elements of these three types, calculating energy balance for each time step and then calculating the energy flow for each component ensuring that the demand is always met.

Figure 5.

Efficiency curve for the 1850 kW diesel generators used in simulations.

To determine which element is dispatched at each time step, HOMER compares the energy cost of each element considered in the configuration, dispatching elements with the lowest energy cost first. For example, for fuel generators [18], the required data include the capital cost ($) the replacement cost ($), the O&M cost ($/h/year), and the fuel cost ($/l). With this information, HOMER calculates fixed and marginal costs. Fixed energy cost is the cost of running the generator for one hour. Marginal energy cost is the cost of every kilowatt-hour produced. A similar procedure to generators is followed for batteries, calculating fixed and marginal costs (from capital cost, replacement cost, O&M cost, cost of stored energy when it comes from a fuel generator). However, in this article battery fixed costs and O&M costs are not considered.

Thanks to all these information, HOMER performs an optimization to find the cheapest configuration amongst all simulated cases. HOMER also provides the CO emissions associated to the different simulated cases. In this article, we always select the cheapest configuration and give the associated CO emissions.

3. Sensitivity Analysis

3.1. Round Trip Efficiency

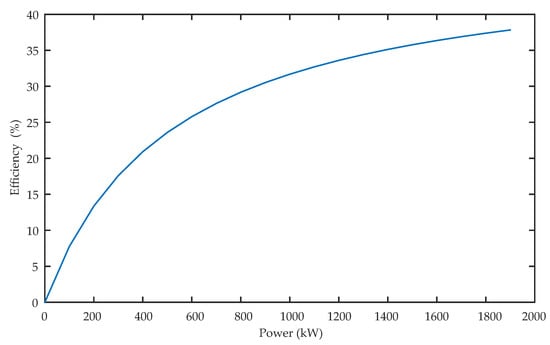

This section describes a sensitivity analysis considering a variation from 70% to 96% in the battery round trip efficiency. The minimum load of diesel generators for simulations is 50%, since it is recommended to operate generators above this level [19]. The sensitivity analysis aims at finding out a round trip efficiency value which presents better results in comparison to the base case of vessel operation without battery. Figure 6 shows CO emissions comparing the with and without battery cases.

Figure 6.

Changes in CO emissions and number of cycles caused by a variation in the round trip efficiency. Battery power and capacity fixed at 1000 kW–1000 kWh. In red: CO emissions reduction in the case of four diesel generators with batteries in comparison to the base case (four diesel generators and no batteries). In black: Number of battery cycles.

CO emissions reduction vary from 4.5% to 8.6%. The number of battery cycles remains almost constant for the whole range.

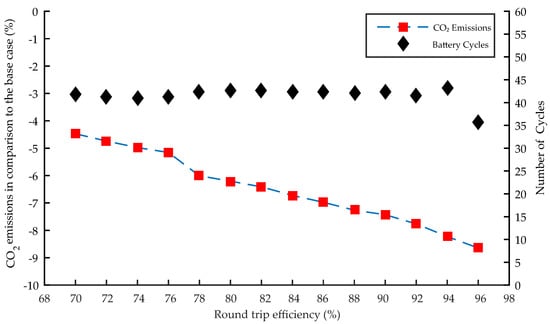

The total energy generated varies with the round trip efficiency, as can be seen in Figure 7. Even though the total energy generated is higher in the case of the hybrid system than in the case with diesel only, batteries enable the operation of generators at higher efficiency points. This explains why the introduction of batteries allows to reduce fuel consumption and CO emissions.

Figure 7.

Total generation variation with the round trip efficiency for the case of four diesel generators with batteries in comparison to the base case.

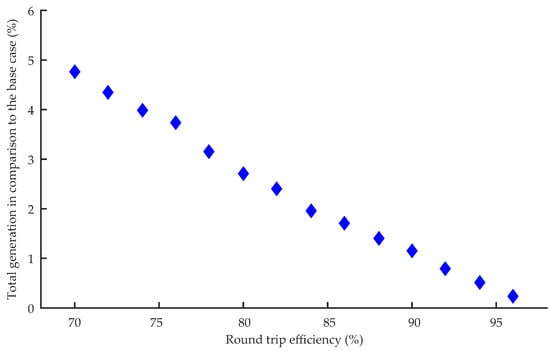

3.2. Minimum Load Level of Diesel Generators

Diesel generators have predefined minimum load levels below which they cannot operate. To evaluate the effect of minimum load level on CO emissions reduction, full mission simulations for three cases are performed. These simulations consider minimum load operation of 30%, 40%, and 50% for the 1850 kW diesel generators. Moreover, the batteries parameters are set as following: power 1000 kW, capacity 1000 kWh, round trip efficiency 92%. A value of 92% is considered for the efficiency because it is the average between the round trip efficiencies of lithium titanate and lithium iron phosphate batteries (see Table 2), two very common battery technologies. We compare the results with the base case.

According to Tufte [19], marine engineers sometimes operate with diesel generator load lower than 50%, even though low-load operations (i.e., under 50%) for more than 8 hours are not recommended by some engine manufacturers. There is evidence that operating under that limit can cause a negative impact related with the incomplete combustion of fuel in the inner part of the engine components due to low cylinder pressure [19]. If the low-load operation lasts for a long time, it is recommended to operate for at least 30 min at 50% after the low-load operation. Results on CO emissions and the total energy produced for the three minimum loads are shown in Figure 8.

Figure 8.

CO emissions reduction and total energy generated increase for the case with four diesel generators and batteries in comparison to the case with four diesel generators without battery. The round trip efficiency is kept at 92% for the three minimum load levels simulated. The generators minimum load levels simulated are 30%, 40%, and 50%, the equivalent number of battery cycles during the operation are 43.8, 41.9, and 41.6, respectively.

The evolution of CO emissions with the load level is explained by the fact that, for lower minimum levels, generators operate more frequently at lower power resulting in overall higher fuel consumption and CO emissions. Indeed, generators efficiency decreases as operating power decreases (see Figure 5). In any case, results do not show a high impact of the generators minimum load level on CO emissions and generated energy. Given this result and the problems that may be caused by running at a low load level, lowering the minimum load level does not appear to be an interesting strategy.

3.3. Battery C-rate and Energy Capacity

Another sensitivity analysis is made in order to account for the impact of battery power and energy capacity. First, the energy capacity of the battery is fixed at 1000 kWh to simulate multiple cases with different C-rates from 0.2 to 2. Results of this evaluation are shown in Figure 9.

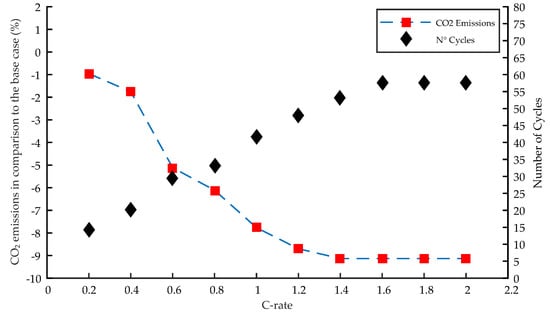

Figure 9.

CO emissions reduction in the case of four diesel generators with batteries in comparison to the base case (four diesel generators and no battery). The energy capacity of the battery system is fixed at 1000 kWh and the round trip efficiency at 92%. Multiple cases with C-rates from 0.2 to 2 are simulated.

A 0.2 C-rate is equivalent to a rated power of 200 kW for the current battery capacity of 1000 kWh. Similarly, a 2.0 C-rate is equivalent to a rated power of 2000 kW. For C-rates under 0.6, CO emissions reduction is lower than 2%. However, emissions reduction is higher than 5% for C-rates higher or equal to 0.6.

Figure 10 shows the CO emissions variation with rated battery energy capacity. Indeed, as the rated power is fixed at 1000 kW, a rated energy capacity of 200 kWh is equivalent to 12 min of discharge time and 2000 kWh to 120 min.

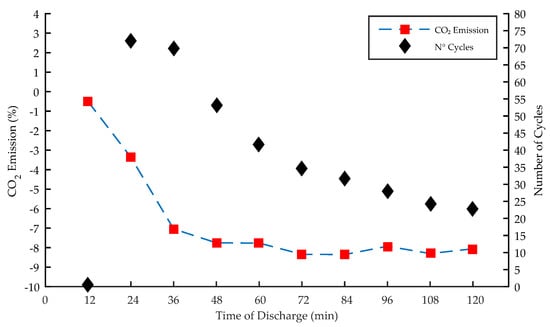

Figure 10.

CO emissions reduction in the case of four diesel generators with batteries in comparison to the base case (four diesel generators and no battery). Battery rated power is fixed at 1000 kW. Multiple cases are simulated for different energy capacities, varying the time that the storage would last if we discharge it at the rated power. Every 12 min of discharge time is equivalent to 200 kWh of battery capacity.

As can be seen in Figure 10, the reduction of CO emissions considerably increases from 12 to 36 min, but after that the rate of increase is reduced. The gain obtained by the increase of the discharge time after 36 min is triggered by the reduction of the number of cycles. The reduction of the number of cycles has a significant impact on the increase of the battery life. Results show that a battery with 12 min capacity of discharging at rated power is almost not used, indicating that for the current load demand a 200 kWh–1000 kW battery system is considered not worth to dispatch by the optimization method. At the same time, since energy is limited by feasible generators and load demand, it is expected that there is a saturation level over which increasing battery energy capacity and rated power would not affect CO emissions.

4. Lithium Iron Phosphate and Lithium Titanate Batteries Comparison

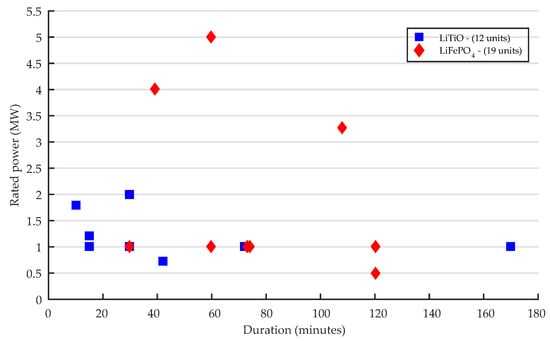

With the increasing installation and use of energy storage systems in PSV and other ship power systems, space and standardization of batteries have become relevant to minimize their time for installation and maintenance. Overall, the most suitable installation method of batteries that has also gained popularity in the last years is their installation in a 20 ft container. Li-ion batteries are among the preferred technologies used in power systems around the world. Figure 11 shows examples of rated power and operating duration of Li-ion battery systems connected to the grid in operation worldwide [20].

Figure 11.

Li-ion battery technologies from 500 kW to 5 MW of power and 10 to 180 min of operating duration that are in operation worldwide [20].

Zubi, Dufo-López, Carvalho and Pasaoglu [21] highlight that the production structure of lithium-ion batteries can be divided into three tiers. Tier 1 includes the battery cells and the battery pack usually used in Battery Management Systems (BMS). Tier 2 comprises the cell components such as: Cathode, anode, separator, and electrolyte. Tier 3 covers materials such as lithium, aluminum, graphite, and cobalt. Valence Technology, Sony, ATL, Panasonic, A123 System, GS Yuasa, Lishen, Hitachi Vehicle Energy, Samsung, Kokam, SK Innovation, BYD Company, Tesla, Johnson Controls, EnerDel, and LG Chem are the major manufacturers of the Li-ion battery industry [21].

For our analysis, a standard 20 ft container is used with the following dimensions: L × W × H 6.058 × 2.438 × 2.591 m. Li-ion batteries used are lithium titanate (LiTiO) and lithium iron phosphate (LiFePO4). The main characteristics of these batteries are given in Table 1.

Table 1.

Parameters of Li-ion batteries.

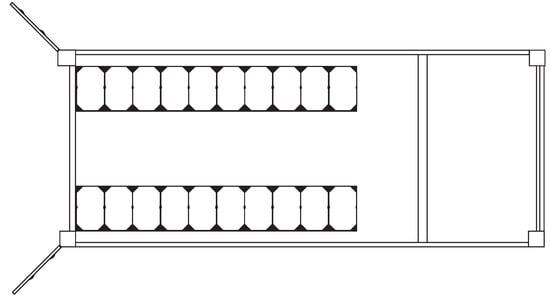

The effective container volume used is estimated to determine the characteristics of these two Li-ion batteries containers. Considering distribution [26,27,28] and arrangement of battery racks in a container [29,30,31], a typical battery container layout is shown in Figure 12.

Figure 12.

Plane view of a typical arrangement of battery racks in a 20 ft container.

Two volume factors are used to calculate the rated power and energy of Li-ion batteries inside the 20 ft container. One factor represents the space occupied by cells in the battery rack, and the other factor considers the space occupied by the battery racks in the container. Since battery cells inside racks need additional space for proper electrical and thermal installation [32], the effectively utilized rack volume by battery cells is of 57%. The estimated effective volume occupied by battery racks varies from 30% for layouts similar to Figure 12 with two battery racks up to 52% for containers with three battery racks [29,30,31]. A layout with two battery racks is used with a volume factor of 30%. Considering these two factors and the parameters of lithium iron phosphate and lithium titanate batteries, the rated parameters of the energy storage system in a 20 ft container, used in simulations, are shown in Table 2.

Table 2.

Rated parameters of Li-ion batteries in a 20 ft container.

Additionally, efficiency losses due to the converter are considered. It is estimated that for different topologies, converter losses vary from 0.4% up to 1.56% [33]. A conservative value of 2.0% for efficiency losses is therefore used in simulations. This explains why the round trip efficiencies presented in Table 2 are 2.0% lower than the ones of Table 1. Similar to the analysis in previous sections, an entire mission is considered and a minimum load of 50% for the diesel generators is chosen.

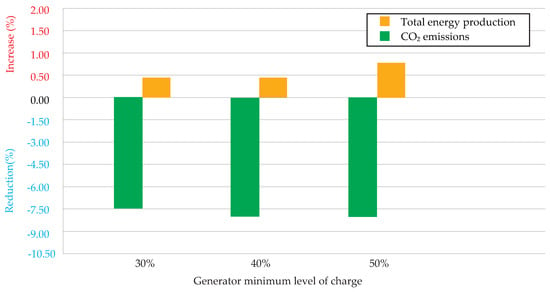

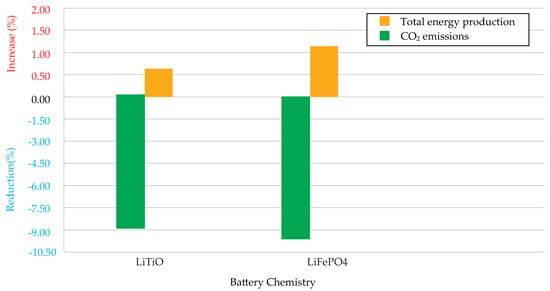

CO emissions and total energy produced by the diesel generators are shown in Figure 13.

Figure 13.

Variation of CO emissions and total energy production using Lithium Titanate (LiTiO) and Lithium Iron Phosphate (LiFePO4) batteries in a 20 ft container.

LiFePO4 battery presents better results compared to LiTiO battery. For the considered ship load demand, although lithium titanate has the highest round trip efficiency, the lithium iron phosphate battery with higher capacity and power presents lower CO emissions. All things considered, the difference between these two batteries is relatively small; other elements should be taken into consideration when selecting a suitable battery for a ship system. For instance, maintenance and replacement cost may also play essential roles in the choice of a battery technology and they are out of the scope of this article.

5. Evaluation of CO Emissions Reduction per Part of the Mission

In this section, an analysis is performed to evaluate the CO emissions reduction that can be achieved in each part of the mission pursued by the platform supply vessel.

Figure 4 shows the variation in power demand of each part of the mission of the PSV. This mission load demand is designed according to [34].

Four cases are simulated considering each part of the PSV routine, separately. The first case considers the elements shown in black in Figure 3. These elements include 4 × 1850 kW diesel generators, one service load, one base load, 2 × 910 kW bow thrusters, and 2 × 2 MW azimuth thrusters. This configuration is based on a real platform supply vessel [12]. It is used to measure the difference in CO emissions triggered by adding components highlighted in blue and red in Figure 3.

The real configuration, in black in Figure 3, is not optimal for the different missions that a standard PSV pursues. Considering that during a 112 hours mission, the ship pursues low power demand 35% of the time (loading in port and standby) and that the rated power of the PSV’s main diesel engines is 1850 kW, one of the generators is forced to operate with the minimum load set at 10%. This operation at low load is not advisable [19]. Battery connection allows all diesel generators to operate with minimum load of 50% since the excess of power generation can be used to charge the batteries. Later, the stored energy can be used to power the ship, which allows to disconnect diesel generator for some time.

The second case considers the inclusion of batteries, shown in blue in Figure 3. The battery system considered in this analysis has 1000 kW of rated power and 1000 kWh of energy. During the missions that require a low level of power from generators, this battery system allows generators to operate at higher efficiency points. It also permits to disconnect generators at times when the battery can run the operation alone. Moreover, batteries can offer support of reliability for the ship power system during DP operation.

The third case evaluates the connection of two small auxiliary diesel generators of 450 kW each, in red in Figure 3, that will operate only during loading in port and standby. This case does not include batteries since the focus is to analyze the potential of the small auxiliary diesel generators to reduce CO emissions.

The last case appraises the reduction capacity that two auxiliary diesel generators of 450 kW each can offer when combined with a 1000 kW/1000 kWh battery system. It comprises all the elements shown in Figure 3.

Battery and Auxiliary Generators Configurations

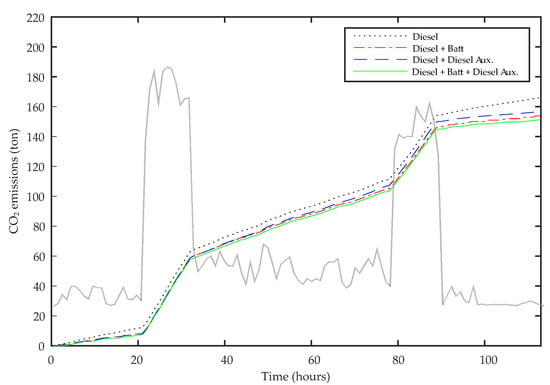

Results for the three additional cases per part of the mission are shown in Figure 14.

Figure 14.

Accumulated CO emissions for the four cases simulated in contrast to the demand curve. The most inclined segments represent the mission parts that have the highest CO emissions, while the difference between the curves at the beginning and at the end of the mission part shows the periods that have the highest reduction of CO emissions. The round trip efficiency of the battery is kept at 92%. In the case that includes only the diesel generators, the minimum load level of the generators is 10% for one diesel generator and 50% for the other three diesel generators when the ship is in loading in port and standby and 50% for all diesel generators when the ship is in laden voyage, DP operation, and partial load voyage. In the case that includes diesel generators and batteries, the minimum load level is 50% for all generators. The case considering diesel generators and auxiliary diesel generators has a minimum load level fixed at 50% for all generators. In the case that considers the diesel generators, batteries, and the auxiliary diesel generators, the minimum load level is also 50%.

As can be seen in Figure 14, batteries have a higher potential to reduce CO emissions when used in loading in port and standby. When we compare the difference of slope in the loading in port and standby operations, we can see that the case that considers the connection of auxiliary diesel generators and batteries to the real PSV power system has the lowest slope, on the other hand the real PSV that only considers the four 1850 kW diesel generators has the highest slope. Implementation of batteries and auxiliary generators decreases CO emissions growth over time. However, batteries have a lower impact on CO emissions during laden voyage, partial load voyage and DP operation. During loading in port and standby, the use of the batteries allows the disconnection of generators during a period of time. When these generators are connected they operate at a higher power than the power required by the load in order to charge the batteries. Figure 14 also indicates that the operations that require more power, laden voyage and partial load voyage, are also the missions that generate the largest share of the CO emissions, considering the slope of both lines.

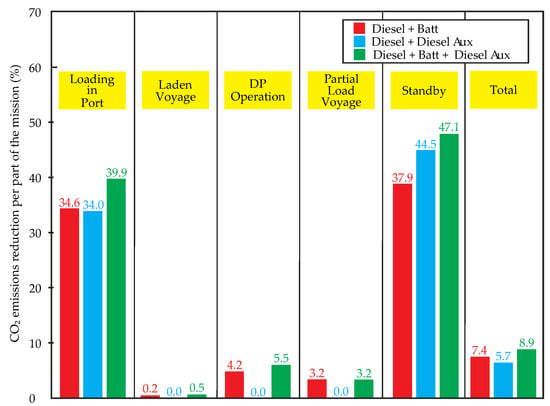

A results summary for the three cases is shown in Figure 15.

Figure 15.

Reduction of CO emissions in each mission part of the ship routine. Loading in port and standby, which are the operations with the lowest power requirements, also present the highest reduction when the batteries and/or auxiliary generators are used. When only diesel generators are used (base case), these mission parts are run at low efficiency points in the specific fuel oil consumption curve of the 1850 kW diesel generators. The impact of the reduction in these mission on the total reduction remains small because the sum of the CO emitted during loading in port and standby represents less than 15% of the total CO emitted during the mission. The low reduction during laden voyage and partial load voyage pulls the total emissions results down since these operations represents more than 56% of the emissions in all of the cases simulated.

Loading in port and standby have the highest reduction in CO emissions compared to other parts of the mission. However, despite the fact that the use of batteries and auxiliary generators achieves a reduction of 34%, these two parts of the mission have overall low energy demand resulting in a low impact on the total reduction for the whole mission (lower than 9%).

Figure 15 also shows that the system using diesel + auxiliary generators has a lower reduction of the CO emissions when compared to the case that comprises diesel + batteries. When auxiliary generators and batteries are combined, they present the highest CO emissions reduction. However, the reduction achieved by this combination is much lower when compared to the sum of the reductions achieved independently by the auxiliary generators and by the batteries. The CO emissions reduction achieved are: 5.7% for diesel + auxiliary generators; 7.4% for diesel + battery system; and 8.9% for a diesel + battery + diesel aux.

For the PSV mission studied in this article, during laden voyage and partial load voyage the four diesel generators operate close to their full rated power; hence there is no available energy to charge batteries and generators already operate at high-efficiency points. This explains why the presence of batteries does not affect CO emissions during laden voyage and partial load voyage (see Figure 15).

6. Conclusions, Managerial Implications and Discussion

We investigated several CO emissions mitigation strategies in a platform supply vessel. We simulated several architectures of the power system including batteries and auxiliary generators. In addition, we performed sensitivity analysis considering several battery parameters: battery power ranging from 200 kW to 2000 kW, battery capacity ranging from 200 kWh to 2000 kWh, and round trip efficiency (70% to 96%). We also considered the use of two Li-ion technologies: LiTiO and LiFePO4. Additional analyses for the different parts of the mission (e.g., loading-in-port, DP operation, etc) were performed to evaluate CO emissions with batteries and auxiliary generators on every segment separately.

Batteries can reduce CO emissions by enabling a more efficient use of diesel generators. Indeed, diesel generators can charge batteries at times of low demand (where generators had to operate at lower power low-efficiency points) allowing generators to operate at higher power high-efficiency points. Although the total energy generated by diesel generators is higher using batteries compared to a system with no batteries, energy storage elements allow generators to operate at higher efficiency points, reducing fuel consumption and therefore CO emissions. Later, this stored energy is released allowing the disconnection of generators.

Sensitivity analysis show the impact on CO emissions of different characteristics such as battery round trip efficiency, minimum generators load, rated battery power, and rated battery capacity. Our simulations indicate that round trip efficiency has a direct impact on CO emissions. The analyses on generators minimum load level do not show a high impact on generated energy and reduction of CO emissions, although at lower load levels it is more likely that generators operate at lower efficiency points.

Evaluating impact of maximum battery C-rate shows that for 0.2 and 0.4 C-rate there is a small reduction of CO emissions (lower than 2%). However, for C-rates higher than 0.6, CO emissions reduction is higher than 5%. For C-rates higher than 1.4, CO emissions reduction begins to stabilize around 9%. Low rated power batteries have a lower number of total cycles during the mission since they take more time to complete a full charge discharge cycle. The total number of cycles per mission varies from 15 to 55 approximately.

Energy capacity variation shows increments of CO reduction at higher available discharge times. However for discharge times higher than 60 min, CO emissions variation remains lower than 1%. At this energy capacity level, the rated power of the battery restricts the amount of energy that can be dispatched by the energy storage system during each cycle. The total number of cycles per mission varies from 22 to 75 approximately, not taking into account the 200 kWh battery that does not have a significant number of equivalent cycles.

Two Li-ion technologies were studied and simulated. Lithium iron phosphate and lithium titanate batteries were used as if they were installed in a 20 ft container. Although both batteries present reduction of CO emissions compared to the base case, lithium iron phosphate battery (1289 kW-kWh) has higher CO emissions reduction compared to its lithium titanate counterpart (948 kW-kWh). Overall, Li-ion batteries present benefits for all of the studied cases and represent a viable solution to reduce CO emissions in ship power systems.

During parts of the mission of low demand such as loading-in-port and standby, configurations using batteries and auxiliary generators present a reduction of CO emissions ranging from 34.6% to 47%. However, since these two part of the mission have lower energy consumption compared to other parts of the mission, the total CO emissions reduction varies from 5.7% to 8.9%. The use of auxiliary generators increases the reduction of CO emissions, allowing the disconnection of the main generators during times of low load. However, when auxiliary generators and batteries are combined, their impacts on CO emissions do not add up linearly.

The results provided in this study have significant managerial implications for both companies operating ships and ship building companies. This article shows that the use of batteries and/or auxiliary generators reduces fuel consumption, equipment renewal and CO emissions. Moreover, auxiliary generators and batteries can be easily integrated into current ship power systems, notably since batteries can be installed in 20 ft containers.

The reduction of fuel consumption and equipment renewal allows to lower ship operational cost. In addition, low levels of CO emissions is now a requirement in many ports. Therefore hybrid power systems, including batteries and auxiliary generators, may allow companies operating ships to increase their revenue. It may also give them the opportunity to enter more ports and extend their operations. As a result, the demand for ships powered by hybrid systems may increase. Ship building companies may therefore be interested in retrofitting existing ships by integrating batteries and/or auxiliary generators in their power system or in building new ships with hybrid power systems. To this end, this article highlights the influence of key design parameters of hybrid power systems on fuel consumption.

Future work could consider different load mission profiles, diesel generators efficiencies, and operating times for batteries, allowing shorter charge-discharge time while operating generators during longer times to avoid frequent connections and disconnections. All these elements align toward our mutual goal to reduce global CO emissions.

Author Contributions

Conceptualization, C.O.P.P., G.T.T.V., M.B.C.S., B.S.C., S.M.; methodology, C.O.P.P., M.B.C.S.; software, C.O.P.P.; validation, C.O.P.P., S.M., M.B.C.S.; formal analysis, C.O.P.P. and G.T.T.V.; investigation, C.O.P.P., G.T.T.V. and R.J.V.; resources, C.O.P.P. and G.T.T.V.; data curation, C.O.P.P.; writing—original draft preparation, C.O.P.P. and G.T.T.V.; writing—review and editing, C.O.P.P. and S.M.; visualization, G.T.T.V.; supervision, M.B.C.S.; project administration, B.S.C. and M.B.C.S.; funding acquisition, B.S.C.

Funding

This research was funded by FAPESP and Shell through the Research Centre for Gas Innovation, FAPESP Grant Processes 2014/50279-4 and 2014/05261, TOSHIBA Scholarship Program—grant 2014/Dr-01 (TOSHIBA-EPUSP), the French National research Agency (ANR) as part of the « Investissement d’Avenir » program, through the “IDI 2015” project funded by the IDEX Paris-Saclay, ANR-11-IDEX0003-02 and the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brazil (CAPES)—Finance Code 001.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in the collection, analysis, or interpretation of data; in the writing of the manuscript, and in the decision to publish the results.

Abbreviations

The following abbreviations are used in this manuscript:

| CDM | Clean Development Mechanism |

| CER | Certified Emission Reduction |

| IET | International Emission Trading |

| GHG | Greenhouse Gas |

| HOMER | Hybrid Optimization Model for Multiple Energy Resources |

| ERU | Emission Reduction Unit |

| IPCC | International Panel on Climate Change |

| DP | Dynamically Positioned |

| PSV | Platform Supply Vessel |

| SoC | State of Charge |

| LiTiO | Lithium Titanate |

| LiFePO4 | Lithium Iron Phosphate |

References

- Springer, U. The market for tradable GHG permits under the Kyoto Protocol: A survey of model studies. Energy Econ. 2003, 25, 527–551. [Google Scholar] [CrossRef]

- Böhringer, C. The Kyoto protocol: A review and perspectives. Oxf. Rev. Econ. Policy 2003, 19, 451–466. [Google Scholar] [CrossRef]

- Rogelj, J.; Den Elzen, M.; Höhne, N. Paris Agreement climate proposals need a boost to keep warming well below 2 C. Nature 2016, 534, 631. [Google Scholar] [CrossRef] [PubMed]

- Hulme, M. 1.5 C and climate research after the Paris Agreement. Nat. Clim. Chang. 2016, 6, 222. [Google Scholar] [CrossRef]

- Cames, M.; Graichen, J.; Siemons, A. Emission Reduction Targets for International Aviation and Shipping; Technical Report; European Parliament: Brussels, Belgium, 2015. [Google Scholar]

- Janssens-Maenhout, G.; Crippa, M.; Guizzardi, D. Fossil CO2 & GHG Emissions of All World Countries; Technical Report; European Commission: Brussels, Belgium, 2017. [Google Scholar]

- United Nations Conference on Trade and Development. World Seaborne Trade by Types of Cargo and by Group of Economies, Annual. Available online: http://unctadstat.unctad.org/wds/TableViewer/tableView.aspx?ReportId=32363 (accessed on 26 October 2018).

- Green, J.F. Why do We Need New Rules on Shipping Emissions? Well, 90 Percent Of Global Trade Depends on Ships. Available online: https://www.washingtonpost.com/news/monkey-cage/wp/2018/04/17/why-do-we-need-new-rules-on-shipping-emissions-well-90-of-global-trade-depends-on-ships/?noredirect=on&utm_term=.2b5726dc9e76 (accessed on 5 October 2018).

- Miyazaki, M.R.; Sørensen, A.J.; Vartdal, B.J. Reduction of Fuel Consumption on Hybrid Marine Power Plants by Strategic Loading With Energy Storage Devices. IEEE Power Energy Technol. Syst. J. 2016, 3, 207–217. [Google Scholar] [CrossRef]

- Miyazaki, M.R.; Sørensen, A.J.; Lefebvre, N.; Yum, K.K.; Pedersen, E. Hybrid modeling of strategic loading of a marine hybrid power plant with experimental validation. IEEE Access 2016, 4, 8793–8804. [Google Scholar] [CrossRef]

- Kanellos, F.D. Optimal Power Management With GHG Emissions Limitation in All-Electric Ship Power Systems Comprising Energy Storage Systems. IEEE Trans. Power Syst. 2014, 29, 330–339. [Google Scholar] [CrossRef]

- Fujian Shipbuilding. 87M Platform Supply Vessel. Available online: http://www.fujianshipbuilding.com/87m-platform-supply-vessel (accessed on 26 September 2018).

- Peralta, C.; Salles, M. Advanced energy storage systems to increase the penetration of renewable energies in Fernando de Noronha Island. In Proceedings of the 2017 6th International Conference on Clean Electrical Power (ICCEP), Santa Margherita Ligure, Italy, 27–29 June 2017; pp. 392–396. [Google Scholar]

- Kroposki, B.; Burman, K.; Keller, J.; Kandt, A.; Glassmire, J.; Lilienthal, P. Integrating high levels of renewables into the lanai electric grid. Contract 2012, 303, 275–3000. [Google Scholar]

- Lloyd, D.N.V.G. Handbook for Maritime and Offshore Battery Systems; Technical Report; DNV-GL: Oslo, Norway, 2016. [Google Scholar]

- Xu, B.; Oudalov, A.; Ulbig, A.; Andersson, G.; Kirschen, D.S. Modeling of lithium-ion battery degradation for cell life assessment. IEEE Trans. Smart Grid 2018, 9, 1131–1140. [Google Scholar] [CrossRef]

- HOMER Energy. HOMER Pro User Manual. 2016. Available online: https://www.homerenergy.com/pdf/HOMERHelpManual.pdf (accessed on 15 November 2018).

- Lambert, T.; Gilman, P.; Lilienthal, P. Micropower system modeling with HOMER. Integr. Alternative Sources Energy 2005, 379–418. [Google Scholar] [CrossRef]

- Tufte, E.D. Low Load Operation of Modern Four-Stroke Diesel Engines in Generator Configuration. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2014. [Google Scholar]

- Department of Energy of the United States of America. Global Energy Storage Database. Available online: https://www.energystorageexchange.org/ (accessed on 27 October 2018).

- Zubi, G.; Dufo-López, R.; Carvalho, M.; Pasaoglu, G. The lithium-ion battery: State of the art and future perspectives. Renew. Sustain. Energy Rev. 2018, 89, 292–308. [Google Scholar] [CrossRef]

- Linden, D.; Reddy, T.B. Handbook of Batteries; McGraw-Hill Education: New York, NY, USA, 2002. [Google Scholar]

- International Renewable Energy Agency IRENA. Electricity Storage and Renewables: Costs and Markets to 2030. Technical Report. 2017. Available online: http://www.irena.org/-/media/Files/IRENA/Agency/Publication/2017/Oct/IRENA_Electricity_Storage_Costs_2017.pdf (accessed on 5 October 2018).

- DNV GL. Battery Energy Storage Study for the 2017 IRP. Technical Report. 2016. Available online: http://www.pacificorp.com/content/dam/pacificorp/doc/Energy_Sources/Integrated_Resource_Plan/2017_IRP/10018304_R-01-D_PacifiCorp_Battery_Energy_Storage_Study.pdf (accessed on 20 September 2018).

- EEMB CO., LTD. Lithium Iron Phosphate Battery Specification. Technical Report. 2014. Available online: https://datasheetspdf.com/pdf-file/1281808/EEMB/LP903395F/1 (accessed on 14 September 2018).

- Corvus Energy. Containerized Energy Storage System. Available online: https://corvusenergy.com/containerized-energy-storage-system (accessed on 14 November 2018).

- Delta Electronics Inc. Delta Lithium-ion Battery Energy Storage Container. Available online: http://www.deltaww.com/filecenter/Products/Download/18/1805/0803%20DM05-Container-201807.pdf (accessed on 14 November 2018).

- Sonoda, M. Development of Containerized Energy Storage System with Lithium-ion batteries. In Mitsubishi Heavy Industries Technical Review; 2013; pp. 36–41. Available online: https://www.mhi.co.jp/technology/review/pdf/e503/e503036.pdf (accessed on 18 November 2018).

- Tesvolt. Tesvolt TPS 200-864kWh Lithium Battery Storage. Available online: https://zerohomebills.com/product/tesvolt-tps-200-864kwh-lithium-battery-storage-all-in-one-20ft-container (accessed on 15 November 2018).

- Corvus Energy. Containerized: Energy Storage System. Available online: https://corvusenergy.com/wp-content/uploads/2016/04/Corvus-Energy_Containerized-Solution_Nov2015.pdf (accessed on 17 November 2018).

- Dudek. Technical Memorandum. Available online: https://www.sandiegocounty.gov/content/dam/sdc/pds/ceqa/Soitec-Documents/Final-EIR-Files/00_AIS_Combined_OPT_January%202015_Part3.pdf (accessed on 13 November 2018).

- Avo Reinap, IEA/LU. Battery Pack Design. Available online: http://www.ht.energy.lth.se/fileadmin/ht/Kurser/MVKF25/MVKF25-vt17_BatPackDes.pdf (accessed on 17 November 2018).

- Trintis, I. Grid Converters for Stationary Battery Energy Storage Systems. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 2011. [Google Scholar]

- Morales Vásquez, C.A. A methodology to select the electric propulsion system for Platform Supply Vessels (PSV). Master’s Thesis, Universidade de São Paulo, São Paulo, Brazil, 2014. [Google Scholar]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).