Abstract

This review examines recent advances in the extraction of valuable compounds from seaweed biomass, focusing on practical feasibility and environmental sustainability. There is a growing importance of seaweed biomass in terms of the study and acknowledgment of its untapped biotechnological potential (multiple compounds and biological activities) and in terms of economic impact. Conventional extraction techniques largely fail to address this challenge, even if optimized. This has led to the development and testing of innovative technologies as solutions for a ‘green’ and effective extraction of components from seaweed biomass and to biorefinery processes. There are large differences in outcomes between alternative processes, depending on the matrix, operational parameters, and targeted compounds and activities. Despite the positive results of some techniques, such as those based on physical mechanisms, namely Microwave-Assisted Extraction (MAE) and Ultrasound-Assisted Extraction (UAE), and on enzymatic selectivity, i.e., Enzyme-Assisted Extraction (EAE), there is no universally effective technique and approach, thus justifying integrated approaches combining different techniques. The application of ‘green’ solvents was also assessed and proven to harbor a large potential, just as the wet route. Although technical difficulties, outcome variability, and economic viability problems are relevant, recent progress in seaweed processing paves the way for a future blue economy.

1. Introduction

Among the wide variety of marine life forms, seaweeds are a group of photosynthetic organisms with an important role in the capture of carbon and oxygen production, thereby constituting a significant share of the marine biomass. There are three main seaweed groups, which differ genetically, biochemically, and in their overall phenotype: Chlorophyta (green algae), Rhodophyta (red algae), and Phaeophyta (brown algae) [1].

Research has shown that the photosynthetic efficiency of marine seaweeds is substantially higher than that of terrestrial plants [2,3]. On the other hand, their biomass is rich in a wide variety of nutrients and biologically active compounds [4]. In particular, their biomass contains valuable polysaccharides, lipids, and proteins as well as micronutrients, such as vitamins, minerals, or sterols, but also secondary metabolites, such as polyphenols and pigments [5,6]. Some species, such as Enteromorpha intestinalis, Palmaria palmata, and Vertebrata lanosa, have been pointed out as containing high-quality profiles of essential amino acids and lipids [7,8]. Moreover, biological activities, such as anticoagulant, antidiabetic, anti-inflammatory, antimicrobial, antioxidant, anti-tumoral, antiviral, hypocholesterolemic, immunomodulatory, and prebiotic, have been found in seaweed [4,9].

Extracting these biologically active compounds and attaining extracts with high activity is a major challenge [10]. The usual extraction processes, still much applied by the industry worldwide, may lead to relatively low yields and/or decomposition of some valuable substances as a result of excessive temperature and processing time, notwithstanding permanent optimization efforts, for instance, using Response Surface Methodology (RSM) and similar approaches [10]. Cell disruption and, in particular, destruction of the cell wall barrier, is a key factor, but also other physicochemical phenomena affect, modulate, and thwart the release of the bioactive components [11,12,13].

Usual methods for extracting bioactive compounds from seaweed biomass typically involve several steps, being affected by factors such as temperature, extraction time, solvent choice, liquid-to-solid ratio, and flow rate [14,15,16]. The most common extractive process, Solid–Liquid Extraction (SLE), involves the direct utilization of liquid solvents as extracting agents [16]. There is also percolation (PE), which is an extraction technique that is distinguished from SLE by its continuous mode of operation. A third usual technique is Reflux Extraction (RE), which is based on a continuous reflux (repeated solvent evaporation and condensation) [8,15].

However, traditional methods are quite time consuming and may have safety and toxicity issues associated depending on the extractive solvents, as well as negative environmental impacts at an industrial scale [17]. These environmental sustainability concerns have to be considered together with efficiency/yield issues in the development of a seaweed-based industry viable in the long-term [18,19].

In this context, alternative and so-called ‘green’ solvents and processing techniques [20,21] are emerging, undergoing research and development, and, in some instances, already maturing and being introduced into the seaweed processing industry. In many cases, these alternatives can consistently bring about higher process yields, shorter processing times, and ensure higher biological activity in the final extracts/fractions [19]. Such innovative extracting techniques correspond to a wide variety of processes of physical, chemical, and/or biological nature, comprising Microwave-Assisted Extraction (MAE), Ultrasound-Assisted Extraction (UAE), Pulsed Electric Field (PEF), Sub-critical Water Extraction (SWE), Pressurized Liquid Extraction (PLE), Supercritical Fluid Extraction (SFE), High Hydrostatic Pressure (HHP), Solid-Phase Extraction (SPE), Solid-Phase MicroExtraction (SPME), Enzyme-Assisted Extraction (EAE), Osmotic Lysis (OL), Alkali Extraction (AlE), pH-shift Extraction (pHE), and other technologies [8,16,19,22,23,24,25,26,27,28,29].

Beyond the application of novel extractive methodologies and operational conditions, there are also innovative approaches and transforming concepts. Among these, biorefinery is a key concept whose gist is the integral valorization of the whole seaweed biomass through a thorough knowledge of all its components and the clever alignment and articulation of extractive and separation processes in order to maximize each specific extractive yield and enlarge each output in the form of varied applications in the fields of feed, food, cosmetic, pharmaceutical or specialty biotechnology [25,30,31,32]. Seaweed is considered one of the most promising bio-feedstocks for renewable fuel production [33], requiring sunlight, water, nutrients, and carbon dioxide (CO2) to generate energy [3], but not demanding precious arable land. There have been some relevant recent studies [34] concerning biorefinery and its zero-waste approach to specific seaweed species, such as the green seaweed Codium sp., thereby showing their potential [34,35].

Another innovative approach with the purpose of environmental sustainability is the Wet Route (WR) extraction of targeted compounds, which has been proposed as a less energy-intensive and operative way to have a biorefinery approach in the case of algal biomass [29,36]. In this approach, cell disruption operations are performed before extraction, thus improving the release of valuable molecules from the disrupted algal biomass [36]. In addition, dewatering and drying operations—usually performed before extraction—are rendered unnecessary. This is important since these are energy-intensive procedures. The energy required for dewatering/drying represents more than 80% of the total energy consumption in the extractive process.

Nonetheless, it should be noted that most of these novel technologies, approaches, and concepts have neither stood the test of time nor met a large-scale implementation. In many instances, they cannot yet be performed at an industrial scale. This reality has also led to a substantial number of studies using Life Cycle Analysis (LCA) as a means to assess the sustainability of the proposed value chains [37]. In this regard, it has been pointed out that seaweed biorefineries have the ability to stimulate the growth of the blue economy and are a promising economic opportunity within the higher-value products market [37].

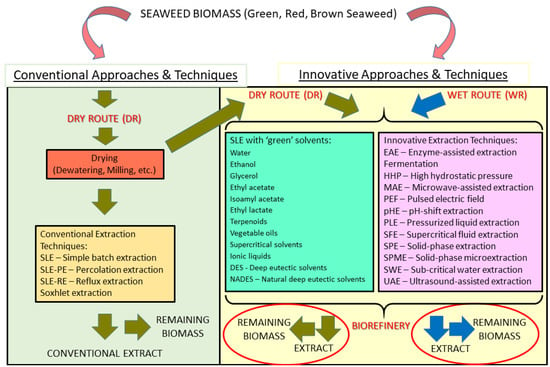

The objective of this review was to produce a thorough assessment of the state-of-the-art regarding not only extractive methods and processing approaches already applied to the seaweed biomass, but also emerging innovative techniques and new concepts/approaches that may represent an advancement to the current state of affairs, especially if taken under a new perspective of biorefinery and blue economy (Figure 1).

Figure 1.

Overview diagram of possible alternative strategies and extraction techniques to be applied to seaweed biomass.

Literature Search Procedure

A thorough literature search was planned, systematically carried out, and critically assessed at each step. The literature screening included books, scientific papers in peer-reviewed and indexed journals, official reports, communications in congresses and other conferences or seminars, as well as other publications considered scientifically significant. Important databases comprising the field of phycology and related fields were searched, namely, ScienceDirect, SpringerLink, PubMed, among several others. In addition, broad web searches (encompassing official bodies) were performed, but were circumscribed to publications (books, papers, etc.) written in English. Keywords used were seaweed, algal biomass, phycology, extraction, extractive techniques, extractive yield, conventional techniques, emerging technologies, purification, separation, refining, nutrients, bioactive compounds, biological activity, biorefinery, blue economy, sustainability, biotechnology, and high-value-added applications. Approximately 800 papers and documents were assessed. A short list of 305 most significant publications was attained after screening the abstracts.

2. Conventional Extractive Routes and Techniques

Seaweed biomass already has a long history of extraction aiming at specific components, such as carrageenan or agar [25,38]. However, as already stressed above, seaweeds also contain a variety of other components with invaluable nutritional, functional, and biological properties. This has led to the application of conventional extraction technologies—usually already applied to terrestrial plants and other matrices—to seaweed biomass. Extraction in its broader sense also encompasses processes for concentrating specific components. Indeed, for instance, secondary metabolites with biological activity may need to be concentrated; that is, they may have to be extracted from the seaweed biomass and, at least, partially isolated in a more purified fraction, which is then appropriate for various applications. All these aspects raise questions about how to choose effective, safe, reliable, and sustainable methods for seaweed extraction. It is critical that employed techniques do not cause loss of the compounds targeted by the extractive method (e.g., as a result of high temperature) or lead to the generation of dangerous compounds. Furthermore, it should be remarked that extraction processes able to be scaled up to an industrial-scale level may entail condition sets that are more drastic and, also, automatically exclude expensive technologies used for microextraction and/or analytical purposes [39]. Accordingly, there is a balance between sustainability, product quality, practicality, and technological and commercial viability that must always be carefully considered. In this context, the so-called conventional approaches and methods [16] offer the advantage of having already proved their worth in various circumstances and for many different matrices and compounds.

2.1. Main Conventional Routes

2.1.1. The Conventional Approach

There is a traditional way of thinking and tackling the issue of extracting specific components from a biological matrix, and this has also been applied to seaweed biomass in several instances [16]. Indeed, seaweeds are usually subjected to a pre-treatment that involves drying and grinding prior to any extraction procedure. This corresponds to a DR approach, which is the most conventional route [16]. Though seaweed biomass can be sun-dried in favorable latitudes and places as well as propitious seasons that allow for this procedure, the most common drying technique involves the operation of ovens, which may be solar or, most often, electrical, and may involve only heating, or heating and forced air circulation, thereby entailing a high energy consumption and carbon footprint [16]. Another conventional procedure involves prior mechanical dewatering as a way to stabilize seaweed and reduce the cost of downstream transport and drying [40]. However, this also has drawbacks, since some water-soluble components may be lost instead of remaining deposited on the biomass after heat-driven drying. Regarding mechanical processes for reducing particle size and other purposes, grinding, milling, and extrusion may also be mentioned as relevant, and a previous mechanical treatment is always critical for the optimization of extraction, thereby setting the stage for more advanced and efficient seaweed processing techniques [41,42]. Indeed, these mechanical pre-treatments are usually carried out prior to chemical and biological processing, being employed with the purpose of reducing seaweed biomass to approximately 2 mm, resulting in powdered samples [41,43]. Furthermore, extrusion is another possible mechanical technology, which can be integrated into the seaweed processing flowsheet as a pre-treatment step when conversion of cellulosic material into biogas is an objective [42]. There are other pre-treatments that may be applied to seaweed biomass, but these concern specific extraction purposes. Namely, there are physicochemical pre-treatments for preparing biomass to enzymatic action [44,45]. Overall, these technologies that aim to prepare raw materials for downstream extraction have been previously developed for cultivated land plants and then applied to a wide variety of matrices, including seaweed.

The conventional approach to seaweed extraction and valorization of the biomass main fractions can be generalized to some extent, being divided into pre-treatment of the raw material, extraction in single or multiple stages (depending on the existence of one or various compounds with significant commercial value), separation of the valuable compounds from residues, and downstream recovery and concentration of the final products [19]. This conventional route also leads to large amounts of waste—wherein the remaining biomass after extraction of the valuable components is a major part—and by-products. Most of these materials are typically treated as waste, being frequently sent to landfills or incinerated, or given low-value-added applications, for instance, as an undifferentiated component of soil fertilizers [46]. This type of single-purpose extraction aiming at one component (or a few components) is still ubiquitous and it is quite deleterious for the environment and the sustainable use of marine resources.

2.1.2. Conventional Thermal Pre-Treatments

There has been little progress in minimizing a wasteful approach, which may be explained by the difficulties and hurdles associated with introducing any major change into the conventional flow diagram. A first major hurdle lies in overcoming thermal pre-treatment. In fact, one of the main reasons for performing an energy-consuming process such as seaweed drying lies in the risks of degradation of the biomass due to a high level of water activity [47]. For instance, sugar kelp (Saccharina latissima), a brown seaweed species, is highly perishable as a result of its high moisture content (approximately 92%, w/w), thus being dried for industrial processing. For achieving this, the biomass is either conventionally sun-dried or dried with hot air [47]. However, the previous approach is quite slow, requires adequate weather conditions, and, unless special measures are taken, it may result in the exposure of seaweed biomass to pest or animal infestation [48]. On the other hand, the latter approach is energy-intensive while having been shown to be better than sun-drying regarding nutrient retention and hygiene [49]. Another important example concerns eucheumatoid (red) seaweeds that are a source of carrageenan and, after harvesting, need to be dried from a moisture content surpassing 90%, w/w, to the industry standard of less than 38% moisture [50]. The drying process is crucial since the reduction in water activity inhibits microbial growth, thereby preventing a deterioration of carrageenan quality [51]. Seaweed dried to an adequate moisture level can be kept for years without any loss of the gel-forming properties. Given this main advantage, various drying alternatives, ranging from solar dryers to powered ovens, have been employed in order to decrease drying time in an economically feasible and environmentally sustainable way, while protecting seaweed from environmental factors [50].

In this context, optimization efforts have been undertaken concerning drying and, especially, the technology of hot air drying [47]. Any optimization endeavor requires good knowledge and control of key operational parameters affecting drying, necessarily comprising temperature, moisture diffusion coefficient, difference in water vapor partial pressure between biomass and the environment, thickness, or surface area [52]. If air is circulated, the type and velocity of air circulation are also factors to be taken into account in any optimization effort. Though more energy-expensive, since hot dry air is usually circulated by a fan or blower into a chamber in order to guarantee a uniform heat distribution, this kind of drying technique provides for a higher rate of drying [53]. Using such a technique, samples of the green seaweed Ulva rigida were dried at up to 150 °C, and final moisture levels of nearly 10% were attained by Thunyawanichnondh et al. (2020) [54]. In comparison to solar drying, it has been reported that higher recovery of carotenoids and chlorophyll is achievable [55]. Therefore, oven drying has been selected as the most suitable solution for drying pre-treatment of seaweed biomass, for instance, with the purpose of extracting vitamin B12 [56]. Furthermore, the oven-dried brown seaweed Durvillaea antarctica was found to have a higher retention of phytochemicals than that prepared with solar, vacuum, freeze, and infrared drying [57]. However, higher drying temperatures and lengthier processing times negatively affected chlorophyll and phenolic compounds in D. antarctica [57]. Another relatively recent study [58] showed that brown seaweed species (Ascophyllum nodosum, Fucus vesiculosus, and Fucus distichus), after being subjected to air drying, could be stored for up to a year without any loss of important nutrients and biologically active compounds.

Optimized drying procedures are thus essential to reduce costs, minimize waste, and enhance the profitability of seaweed drying techniques. Combining different drying techniques can also be a solution by making the best of the merits of each individual technology and thus helping to achieve efficient and sustainable drying processes [53]. Each drying method has advantages and disadvantages, being critical to evaluate the optimal method for specific seaweed types and to take into account the intended product quality, processing costs, and targeted market [53].

2.1.3. Conventional Mechanical and Other Pre-Treatments

Regarding mechanical extraction processes, such as grinding and milling, these are pre-treatment solutions that are more environmentally friendly and safe—in terms of safety to human consumers—than the thermal techniques [59,60]. This has to do with their general absence of waste generation. Bead Milling (BeM), Mammer Milling (HaM), Ball Milling (BaM), and High-Pressure Cell Disruption (HPCD) are paradigmatic cases of such mechanical methods [59,60,61]. However, there may be practical hurdles in the employment of these methods. Namely, Teo and Wahab (2020) [60] have reported that the application of HPCD to seaweed biomass can lead to clogging problems, and BaM has been deemed unsuitable due to its relatively low rotating speed and downstream low extraction yields. Hence, BeM has been argued to be a better solution—for instance, it has been pointed out that it causes a rapid cell disintegration through this mechanical procedure, with the additional advantage of being an energy-saving process [62]. In addition, BeM does not raise safety issues, being a contamination-free process that does not generate any waste stream [59]. It is also possible to scale up BeM to an industrial-scale production and further increase extraction yields [63]. The technique has also been tested in Kappaphycopsis cottonii and concluded that its total operating cost was lower than alternative methods [59].

Mechanical pre-treatments require further study, and their optimal operational parameters must be found. Namely, a study by Vanegas et al. (2014) [64] that targeted the extraction of reducing sugars, lipids, and proteins from two relevant seaweed species in Ireland (Laminaria digitata and Saccharina latissima), analyzed several thermal, mechanical, and chemical pre-treatments and their conditions. This study observed that each pre-treatment enhanced the release of macromolecules to a different extent when compared to non-treated control batches. The authors concluded that, among the pre-treatments studied, a combination of milling without beads and under cryogenic (liquid nitrogen) conditions, and a chemo-thermal procedure ensured the strongest effect in releasing sugars and lipids from both seaweed species [64]. Precisely, such findings highlight the relevance of seaweed pre-treatment and the need to perform optimization studies. This was also performed in a study that aimed to optimize a mechanical pre-treatment to destroy the seaweed’s physical barriers to extraction [42]. In particular, a Hollander beater mechanical pre-treatment was applied to a batch of Laminariaceae and assessed by Tedesco et al. (2014) [42]. The derived biogas yield was used as a response in order to identify the optimal input variables in a specific RSM design [42]. In this case, the best results were achieved after 10 min using the minimum gap (76 mm) in the Hollander beater and incubation at 50 °C. Hjorth et al. (2011) [65] tested extrusion pre-treatment in different biomass materials with the purpose of increasing biogas production further downstream. It was observed that extrusion accelerated the degradation of slowly degradable organic compounds, being the methane yield significantly increased, up to 70% after 28 days [65]. More such studies on different pre-treatments with potential practical industrial applications are needed.

2.2. Conventional Extractive Techniques

2.2.1. General Overview

The conventional routes of processing seaweed, which are outlined above, are usually associated with typical extractive techniques. These are mostly variations on a solid–liquid interaction and separation process, encompassing SLE, PE, and RE [8,16]. Though the procedure may vary, ranging from simple batch mixture to percolation and reflux, solvents, such as water (and aqueous solutions), ethanol, methanol, ethyl acetate, chloroform, and acetone at room or higher temperature, are common to these processes. The choice of a particular process depends on factors such as the chemical nature of the targeted biologically active compounds, the specific characteristics of the algal matrix, intended yields for achieving commercial viability, and the type of application—whenever there is a final human consumer, standards are higher, and safety issues are of paramount importance [22]. Regarding the solid–liquid interaction with utilization of seaweed biomass as starting material, it should be remarked that many solutes are found inside algal cells, while others are part of the cell walls (usually in polymerized form), thereby also affecting extracting technique choice [66]. As a consequence, the degradation of cell walls, which act as a barrier to component release, enhances mass transfer. Usual stages in the solid–liquid interaction are as follows: (i) solvent diffusion within the seaweed matrix; (ii) hydrolysis and solubilization of targeted component(s); (iii) diffusion of the component(s) through the seaweed matrix; and (iv) mass transfer to the bulk solution [66]. It has often been reported that the third stage is the rate-limiting step and that a smaller particle size and effective cell wall degradation are essential for a successful extraction [66]. Any solid–liquid extraction process is limited by the capability of sorbent sorption of the targeted component(s) and requires a small particle solid-phase separation, which conventionally is performed by centrifugation or filtration [67,68]. Indeed, in the conventional techniques, key operational parameters typically involve the type of solvent, particle size of the solid (in general, powdered seaweed biomass), time and temperature, number of extractive cycles, or stirring velocity. All these can significantly impact extraction efficiency as well as the quality of the attained biologically active substances [69]. Therefore, selecting suitable extractive technology and having fine-tuned operational parameters is fundamental for achieving the intended outcome [22].

More specifically, for extracting phenolic compounds, polar solvents with low boiling points, such as ethanol, methanol, acetone, or a mixture of acetone and water, are generally considered the standard choice [68]. In addition, for water-soluble amino acids, peptides, simple carbohydrates, and nucleotides, water or aqueous extractions are advised [70]. On the other hand, for moderate hydrophobic products, with low or intermediate polarity, an ethyl acetate extraction is frequently advocated [71]. In the case of lipophilic and totally hydrophobic substances—for instance, sterols and other lipid groups—, acetone, chloroform, or, alternatively, chloroform in combination with methanol are conventional choices [72,73]. Indeed, in the specific case of lipid extraction, the Folch [74] and Bligh and Dyer [75] techniques have been traditionally employed, taking advantage of polarity differences between chloroform, methanol, and water to form an extraction system comprising both an SLE phase and a liquid–liquid partition phase. More recent experimental work [76] has shown that the substitution of dichloromethane (CH2Cl2) for chloroform (CHCl3) kept acceptable yields—similar to the older methods—while mitigating detrimental health and environmental effects. For carotenoids, a lipophilic group of substances, ethanol extraction at 100 °C has been shown to be effective in extracting, for instance, fucoxanthin from the brown seaweed Himanthalia elongata [77]. An overview is provided in Table 1.

Table 1.

Overview of scientific studies concerning conventional extraction techniques and approaches applied to seaweed biomass.

2.2.2. Specific Case of Seaweed Polysaccharides

For polysaccharides, a key component of seaweed biomass, given the practical complications of extracting polysaccharides by a single technique, a combination of extraction and purification techniques has usually been adopted as the best strategy [95]. The chemical composition and biological activity of polysaccharides necessarily play a major role in selecting the most adequate extraction procedure [96]. Aqueous extractions, comprising diluted acidic extraction, as well as other chemical-based techniques, have been employed and are considered the conventional first approach of extracting seaweed polysaccharides [95,97]. These techniques are generally inexpensive, compatible for functional food preparation, and friendly to the environment, but their efficiency is considered to be too low [95,98]. Additionally, it should be noted that hot solvent and extended periods of extraction are often necessary in such conventional methodologies, leading to the degradation of natural biologically active compounds [99]. Rioux et al. (2007) [100] proposed a stepwise process beginning with crude extraction using ethanol, t-butanol, petroleum ether, and chloroform solvents—to separate proteins, pigments, and other components—and followed by residue treatment with diluted acid/water, thermal hydrolysis, and, if necessary, calcium chloride-induced precipitation of alginic acid (and other polysaccharides). Isolation of polysaccharides is usually achieved with polar solvent precipitation, such as ethanol and acetone, in which polysaccharides are insoluble, followed by polysaccharide separation with downstream techniques like membrane filtration or centrifugation [100].

The extraction of fucoidan from brown seaweed offers a paradigmatic example of a conventional process applied to seaweed biomass [66]. The biomass is firstly subjected to pre-treatment (washing, milling, and drying), then to filtration/centrifugation resulting in a defatted intermediate product, to an extraction that may use water, acid, alkali or ethanol, again to filtration/centrifugation, and, finally, to a purification step—through either ethanol/acetone precipitation, liquid–liquid fractionation, ion-exchange chromatography, size-exclusion chromatography, affinity chromatography or membrane filtration [66]. There are plenty of studies [66] on variations in the conventional extraction of fucoidan, ranging from aqueous extraction applied to dried Ecklonia cava at 70 °C [101], to alkaline extraction from Sargassum stenophyllum with 4 M potassium hydroxide (KOH) at room temperature [102] and to acid extraction from Saccharina japonica with 0.05 M hydrochloric acid (HCl) at 25 °C [103].

This panorama can also be found in the extraction of other seaweed carbohydrate components, such as carrageenan in red seaweed [104] or ulvan in green seaweed [105]. For carrageenan, after a prior drying step to prevent degradation, subsequent steps comprise washing to remove impurities, a hot alkali extraction process to release carrageenan from cells, clarification, and reduction to powder [104,106]. Further downstream, different techniques are used to isolate carrageenan from solution, either freeze–thawing—also used for agar [107]—or alcohol precipitation or potassium chloride precipitation. In freeze–thawing, carrageenan-containing solution is subjected to gelling with different salts, resulting in freezing [104]. Afterwards, thawing enables water separation, resulting in a product composed of carrageenan and its salt and requiring grinding to attain the intended particle size. If the alcohol precipitation method is used, the carrageenan solution is subjected to precipitation by 2-propanol or other alcohols, followed by alcohol evaporation, drying, and grinding to the targeted particle size [104]. Potassium chloride precipitation encompasses volume reduction through evaporation, extrusion, washing of the attained gel threads, pressing, drying, and milling to obtain carrageenan powder [104]. With respect to ulvan, dried seaweed biomass undergoes a solid–liquid interaction treatment, a kind of RE technique (utilization of Soxhlet extractors), followed by static batch extraction with water, filtration, concentration, deproteinization, and, finally, precipitation and freeze-drying of the polymer [105].

2.2.3. Utilization of Conventional Extraction Techniques at an Industrial Scale

The seaweed industry is still largely based on these conventional extractive technologies, especially in the case of algal hydrocolloid polysaccharides, such as agar, alginate, and carrageenan, traditionally used by Western countries as stabilizing, thickening, and gelling agents in the food industry [108]. Meanwhile, France has authorized the utilization of seaweed for human consumption as vegetables/condiments, thus creating new opportunities for the industry [109]. Currently, the seaweed processing industry is a multi-billion-dollar business, of which 85% corresponds to food products for human consumption, representing agar, alginate, and carrageenan almost 40% of the global hydrocolloids market [108]. However, it should be noted that less than 1% of total seaweed production is directly used as food, hydrocolloids being the major final products [108].

Conventional industrial production of these hydrocolloids is still dominant and involves large equipment, such as huge mixing vessels and potent filtration units, for performing multi-stage processes, with washing, pre-treatment, solid–liquid interaction, precipitation and filtration, final drying and milling as main steps [107,110]. Hot water is the most usual industrial solvent for extracting hydrocolloids from seaweed biomass, since these polysaccharides are water-soluble with the noteworthy exception of alginate/alginic acid, which demands a hot alkali solution as an extracting agent [110,111]. Indeed, alginate in the seaweed biomass is found in the form of water-insoluble salts, requiring the presence of an alkali medium to convert them into water-soluble alginate salts. Alkali treatment is also applied by the industry in the agar and carrageenan processes because hot water extraction leads to hydrocolloids with a lower gel strength [110]. The alkali treatment can be performed before or during extraction and converts the 6-sulfated macromolecules into 3,6-anhydrogalactose polymers with a concomitant improvement of the gelling properties [110]. Furthermore, a very dilute-acid treatment is sometimes coupled with heat to improve water penetration, for instance, in the case of the industrial process of agar extraction from the red seaweed belonging to the genus Gelidium [107]. Industry favors the alkali procedure, despite its lower yields—a consequence of polysaccharide degradation under alkali conditions and inability of alcohol addition to induce precipitation of the formed low molecular weight polymers—, given the commercial demand for high gel strength hydrocolloids [106,112,113,114]. In spite of this and other problems, these chemically driven processes are still most commonly used in factories that process seaweed worldwide [110].

2.2.4. Optimization of Conventional Extraction Techniques

All the above-described conventional techniques have important drawbacks, flaws, and limitations that have thwarted the development of the seaweed processing sector and, as based on older technologies and approaches, are unable to meet the current high standards in product quality, safety to the end consumer, and environmental protection. In fact, conventional techniques have failed to achieve high recovery rates of several biologically active compounds from seaweed biomass, including lipophilic substances, specific carbohydrates, or terpenoids [115]. This difficulty is related to the rigidity of the seaweed matrix, which hinders the release of many substances, and remains an unresolved problem in seaweed processing with conventional technologies [116]. The chemical composition of the seaweed matrix also has a major influence on the disruption efficiency and yield in targeted compounds [117]. Moreover, these older techniques are very often time consuming, may require large quantities of polluting solvents (as described above), which can result in environmental problems and safety issues with the presence of contaminants in the end products, losses due to volatilization during concentration stages, large quantities of waste and undervalued by-products, loss of functionality of sensitive molecules, and lower purity levels [14,19,21,72,118,119,120]. These reasons have led to a search for alternative techniques with higher efficiency/selectivity or to efforts toward an upgraded and optimized utilization of conventional technologies.

Indeed, given the shortcomings and flaws of conventional techniques, in order to maximize yield in the targeted component(s), it is of critical importance to optimize operational parameters (Table 1), in particular, to have optimal conditions for the applied solvent and the solid–liquid interaction [99,121,122]. In particular, within solid–liquid processes, it has been considered that RE, such as the Soxhlet extraction, may represent a progress with respect to simple maceration, since it consumes less solvent, while enabling higher purity and greater yields [14,123]. Though the reduction in utilized solvent quantities and generated waste also represents an advance in favor of the environment (with respect to SLE and PE), RE is still a technique that may use solvents harmful to the environment and human health.

In any case, even the simplest seaweed biomass SLE maceration with heat under agitation can undergo meaningful improvement [124]. These authors studied polyphenol extraction from the brown seaweed Sargassum fluitans and its optimization. For this purpose, they performed a complete factorial design 32 with replicates in the center of the plane, being extraction time and ethanol concentration as independent variables [124]. While higher ethanol concentration had a deleterious effect on yield, lengthier extraction time did not matter so much. Based on coefficients provided by the mathematical model, optimal conditions for polyphenol extraction were established [124]. Under such conditions, 8.66 mg of total polyphenols was obtained per g of dry seaweed.

Moreover, the choice of extracting solvent is a critical parameter of almost all conventional techniques, being dependent on the targeted component(s)—whose solubilization must be maximized—, desirable selectivity, efficiency, and velocity of mass transfer as well as other processual aspects [125,126]. The heating component of conventional extractions is also crucial for a successful outcome. It requires a thorough analysis not only of the temperature–time binomial, but also of the type of heat transfer—considering the usual combination in conventional processes of convection through the solvent and conduction from the solid surface to the core of the biomass particles [72,125]. In fact, all the various operational parameters deserve thorough analysis and are optimizable. However, this multiplies the number of trials and the overall research investment that is needed to deliver meaningful advances, thus justifying the application of RSM and similar methodologies. Indeed, RSM and RSM-equivalents have been used to optimize conventional processes [10,42]. Namely, extraction conditions for Gracilaria gracilis were optimized with the help of such an experimental design technique for achieving high biological activity in the extracts [10]. Furthermore, the mechanical pre-treatment of Laminariaceae spp. biomass was also subjected to an RSM-supported optimization [42].

Even after optimization, the processes currently used present serious problems with high consumption of solvents, energy, and time as well as potentially damaging effects on nutrients and biologically active compounds whenever high temperature and lengthy extraction time conditions are required [125]. On the other hand, optimization itself is difficult because of the large variability of seaweed biomass as a raw material. This is particularly the case when initial contents and extraction outcomes are highly dependent on geographical source, harvesting season, maturity/life cycle phase, pre-treatment applied, storage history, particle size, among other not fully controlled factors [110,125]. Accordingly, due to common weaknesses of conventional techniques and approaches, other methodologies and strategies have been examined, including so-called ‘green’ or ‘alternative’ technologies, which may conjugate environmental sustainability and commercial viability [19,125].

3. Innovative Extractive Routes and Techniques

The problems and insufficiencies associated with the conventional approaches and technologies used for extracting nutrients and valuable components from the seaweed biomass have been a limiting factor in the full valorization of this marine resource, thus restricting the development of the industry and keeping a huge gap between the potential ascribed to seaweed and the current reality. For this reason, novel technological solutions and innovative strategies with upscaling possibilities and commercial viability are required. Precisely, commercial operation needs high recovery of the targeted components on the one hand, but concomitantly also the preservation of biological activity on the other, a combination that conventional techniques and approaches have failed to achieve [19]. In order to overcome all these limitations and also ensure a more environmentally friendly processing of seaweed biomass, alternative greener procedures and strategies have been developed, as presented in the sections below.

3.1. Biorefinery, Wet Route, and Other Innovative Approaches

3.1.1. The Current Challenge

Firstly, the whole approach to the extraction of components from seaweed biomass must be rethought, and a full utilization of the biomass should be a key objective, not only from an environmental point of view (sustainability), but also in order to add more processual efficiency and economic value to this precious marine resource. These objectives demand processes with superior ability in overcoming the algal cell wall as well as other hurdles associated with the peculiar features of seaweed biomass [36]. Indeed, effective cell disruption methods are critically important for a high extraction yield of intracellular compounds, and it should be remarked that commercial extraction from seaweed biomass has been hampered by a lack of a comprehensive understanding of the cell disruption methods. High extractive yields are essential for an adequate separation of the components present in the biomass, regardless of being hydrocolloids, other polysaccharides, lipids, lipophilic substances, proteins and peptides, polyphenols, or other secondary metabolites. This separation, in turn, is indispensable for a rational and full utilization of all the biomass components to the utmost of their inherent value, that is, a biorefinery strategy. This is related to the aim of a zero-waste approach to seaweed biomass and the pursuit of a blue circular economy [34]. Moreover, besides reducing waste generation and other environmental impacts, a smaller carbon footprint with a lower level of energy consumption in the extraction process is a key goal. This may be reached with a rethinking of the whole extractive approach, namely through the avoidance of energy-intensive technologies, in particular thermal drying or hot extraction. The application of innovative cell disruption methodologies to wet biomass may also represent a gain in terms of yield and enable the implementation of a biorefinery approach—this may be called the WR approach, in contrast to the conventional DR. This new way of processing seaweed biomass requires not only novel technologies, but also a new way of thinking and a different underlying philosophy. Moreover, this is part of a larger whole, where economic activities and value are created from the sustainable and smart use of aquatic resources, which is the definition of blue bioeconomy by the European Commission [127].

3.1.2. The Biorefinery Approach

The biorefinery approach is of critical importance for rethinking the future of seaweed valorization. It presupposes the integral valorization of the whole seaweed biomass through a thorough knowledge of all its components and the smart articulation of extraction/separation processes, thus maximizing each specific extractive yield and creating novel value-added products [25,30,128]. Additionally, the biorefinery approach is central to the bioeconomy concept, with seaweed presenting a huge potential to be used as a feedstock for it [129]. A recent systematic review has shown an overview of possible seaweed-based biorefinery chains and accompanying technical and non-technical difficulties to overcome for biorefinery to be successful in the realm of seaweed [130]. Full utilization of the seaweed biomass and minimization of environmental impacts are two sides of the same coin. In particular, seaweed biorefinery can substantially contribute to sustainable development by adding value to the original feedstock [32]. This involves transforming all seaweed biomass into a broad spectrum of applications/products using cascade conversion that may be adjusted to specific conditions.

In comparison to the situation of terrestrial biomass, the application of the biorefinery approach to seaweed biomass is less advanced, thus warranting further study [30]. As in many cases of terrestrial biomass, after extracting a valuable nutrient or biologically active component, there remains a large quantity of undervalued material. Just as with many instances of plant biomass, the conversion into biofuel and biogas may be an option and provide a route to a full biorefinery. Indeed, bioethanol production is more advantageous than aiming at lignocellulosics since it requires only hydrolysis and fermentation [30]. In this regard, it must be noted that, in general, seaweed fermentation requires specific microorganism strains with higher galactose metabolism ability than those used for terrestrial plants [131]. However, the crux of the matter is the rather high salt concentrations in seaweed material, leading to fermentation inhibition [30,132]. In any case, there are already some practical successful examples of attaining several commercially relevant components from seaweed biomass—encompassing case-studies of red, green, and brown seaweed species—, which may represent a meaningful step towards a biorefinery approach [29,30,34].

Biorefinery in Red Seaweed Species

In particular, red seaweed species have been considered an excellent raw material for this approach due to their valuable components, such as polysaccharides (including valuable hydrocolloids) and protein [25,30]. This biomass has the highest protein content among seaweeds, up to 45% w/dw, and its digestibility is higher than in other seaweeds [25,30]. Red seaweeds have also developed photo-protective defense mechanisms against UV radiation with the synthesis of pigmented compounds, such as carotenoids and phycobiliproteins, and mycosporine-like amino acids [133]. In the case of red seaweed processed for hydrocolloid extraction, it is common to only use 15–30% of the total dry biomass, leaving 70–85% as by-product or even waste [134]. For accomplishing a biorefinery approach, this material should be further processed to yield commercial products, taking advantage of its disrupted state for microbiological conversion or used to extract its protein—rich in essential amino acids—for multiple nutraceutical or food technological purposes [30]. Two case-studies on red seaweed species, Gracilaria corticata (agarophyte) and Kappaphycus alvarezii (carragenophyte), illustrate the potential and viability of biorefinery in this seaweed group [30].

For G. corticata, the spent biomass can be used to produce ethanol [135], thereby requiring a previous hydrolysis, hydrolysate separation by filtration after pH adjustment to 5.3, and nutrient supplementation for Saccharomyces cerevisiae fermentation. However, this fermentation would take 5 days at 30–34 °C, leading to an ethanol yield of 0.02 g/g [135]. Baghel et al. (2015; 2016) [136,137] went further and managed to design and propose one of the most thorough biorefinery strategies for red seaweed. The cascading process enabled a thorough utilization of the biomass, solvent recycling, absence of solid waste, and recovery of six different products, with a market value four times higher than the costs [137]. In detail, after pigment extraction, the remaining biomass was dried and lipids were extracted with a chloroform–methanol mixture—recovered and reused—, leaving a dried solid material whose agar contents were extracted with water at 120 °C for 1.5 h. Then, the spent biomass was hydrolyzed with a commercial cellulase to yield 0.27 g reducing sugar/g material and fermented with S. cerevisiae at 28 °C for 12 h [137]. This fermentation ensured a conversion into ethanol of approximately 90%, leaving a residue representing 12% of the starting material and usable as soil conditioner in accordance with its favorable C:H:N:S ratio [137]. In a global mass balance, for a ton of fresh biomass, that is 122 kg dry biomass, approximately 1 kg of pigments (R-phycoerythrin and R-phycocyanin), 2 kg lipids, 28 kg of agar, 15 kg of soil conditioner, and 4 kg ethanol would be attainable [137]. Hence, in dry matter terms, this biorefinery strategy would find, at least, a useful application for 40% of the biomass.

In the case of K. alvarezii, different biorefinery strategies have been proposed [138,139]. A WR strategy to support a biorefinery of K. alvarezii has been developed and aimed to extract an agricultural bio-stimulant and a semi-refined form of carrageenan [139]. Basically, fresh seaweed was washed and a sap was removed by filtration, leaving the solid material to be subjected to an alkali treatment with 8%, w/w, KOH solution in a proportion 1:1, v/w, at 70–80 °C for 1.5–3.0 h, and then filtrated and washed for the attainment of carrageenan [139]. The total process yields of the agricultural bio-stimulant and carrageenan were in the ranges 2.0–2.4% and 2.4–4.2%, respectively. This is still very insufficient, and the whole process is only a step away from a single-purpose conventional use of the biomass. On the other hand, it was possible to develop a K. alvarezii biorefinery with four end products: fertilizer, carrageenan, ethanol, and biogas [138]. This process started with a homogenization step coupled to a filtration for attaining a sap to be used as fertilizer, followed by drying, carrageenan extraction, two-step fermentation—a first step with S. cerevisiae for treating the spent biomass and a second step with Escherichia coli to convert the fermentation leftovers and the produced S. cerevisiae biomass—at 28 °C for 12 h, filtration/distillation to obtain ethanol, and final anaerobic digestion to yield the biogas [138]. The mass balance showed a ton of fresh seaweed, 670 kg of sap, and 73 kg dry biomass, from which 7 kg of carrageenan, 6 kg of ethanol, 6 kg of released CO2, and 7800 L of methane were measured. This represents progress with respect to previous research [139].

Biorefinery in Green Seaweed Species

Representative case-studies on green seaweed species’ biorefineries can be found especially for the genera Codium and Ulva [34,126,140,141,142].

For Codium sp., at the beginning of a recently proposed process [34], there was a hydroethanolic extraction, which enabled the separation of biologically active compounds (anti-inflammatory, anti-enzymatic, and photo-protective), and the remaining biomass was subjected to different carbonization processes, leading to a so-called biochar, that is, to a kind of biofuel. Since this remaining biomass had only been subjected to a single extraction, this whole approach seems to be unsatisfactory in terms of maximizing the value of the biomass components. For Ulva sp., a processing strategy was tested that was much nearer to a true biorefinery concept, thereby comparing a classical thermochemical hydrolysis followed by an enzymatic hydrolysis with a SWE hydrolysis [142]. In a nutshell, this biorefinery comprised drying and grinding Ulva sp., then the hydrolysis with separation of a solid phase (biochar) from a hydrolyzed phase that was further processed by subjecting it to a two-step fermentation—with a S. cerevisiae step followed by an Escherichia coli step, similar to the fermentation in the K. alvarezii biorefinery described above [142]. The utilization of SWE is a much better use of a green seaweed biomass, especially if considering that HMF is included in the list of the 12 most promising biobased molecules and a potential precursor of pharmaceuticals and bioplastics [143]. Recently, a biorefinery-like process for U. fasciata has been developed, thereby separating pigments (total of ~3% of the biomass dw), starch (13%, dw), lipids (3%, dw), protein (13%, dw), cellulose (11%, dw), and ulvan (22%, dw) [140]. This required quite an elaborate process, entailing several steps of Soxhlet extractions, filtrations, centrifugations, isopropanol extraction, bleaching, and various chemical treatments, under both alkali and acid conditions [140]. While this complexity and the associated technological and economic cost of upscaling bring difficulties, this process separated ulvan, a sulfated polysaccharide with biotechnological potential [144], using chilled isopropanol, 2.5:1, v/v, at −40 °C for 24 h [140]. Hence, though less studied, there is also significant progress towards a green seaweed biorefinery concept.

Biorefinery in Brown Seaweed Species

As to brown seaweed species, which are considered an outstanding source of biologically active components [16,145,146], there are plenty more examples of biorefinery approaches, comprising a large variety of species, such as Alaria esculenta, A. nodosum, Durvillaea potatorum, Fucus vesiculosus, Laminaria digitata, S. latissima, Sargassum tenerrimum (and other species of the same genus) or Undaria pinnatifida [147,148,149,150,151,152,153,154,155]. This diversity of case studies offers the possibility of comparing different strategies and technological articulations for achieving a proper and effective biorefinery.

A biorefinery aiming at the production of alginate, fucoidan, and laminarin from D. potatorum has been studied, and, in particular, it was found advantageous an acid extraction step before alkaline extraction in order to attain such multiple valuable polysaccharides from a single seaweed feedstock [147]. Indeed, the process was initiated with an acid extraction (up to 0.1 M HCl solution, 1:20 w/v, at 60 °C for 3 h) for extracting fucoidan, laminarin, and acid-extractable alginate, which were separated from a supernatant after centrifugation, thus leaving a residual biomass still rich in alginate [147]. Moreover, the supernatant was subjected to a selective precipitation with 20%, v/v, ethanol and 0.5%, w/v, calcium chloride, followed by overnight stirring at 4 °C and centrifugation, resulting in a pellet rich in calcium alginate, which was further treated and enabled the production of sodium alginate, and in a supernatant rich in fucoidan and laminarin. This supernatant was subjected to precipitation with the addition of twice its volume in ethanol, followed by centrifugation to separate a solid residue and a novel supernatant whose ethanol was evaporated and, finally, freeze-dried, thereby achieving a product rich in fucoidan and laminarin [147]. The residual biomass after the acid extraction was subjected to an alkaline extraction (28%, w/v, sodium carbonate solution, at 60 °C for 2 h) and centrifuged, yielding a supernatant—the extracted material—rich in alginate, which was then neutralized and precipitated with 10%, w/v, calcium chloride solution. The precipitated calcium alginate was further processed which led to a second product composed of sodium alginate [147]. The yields were 7%, w/dw, in fucoidan+laminarin, and 37%, w/dw, sodium alginate in two final products. This process may still be improved, since there are various by-products without a proper valorization, for instance, the solid residual after the alkaline extraction.

For two of the most important brown seaweed species, A. esculenta and S. latissima, important advances in the direction of a multicomponent biorefinery have already taken place using a combination of mild chemical extraction techniques [148]. In this other case-study, besides alginate, fucoidan, and laminarin, a fourth polysaccharide, usually abundant in brown seaweed, cellulose, was separated. The first step was a slightly acidic extraction with diluted HCl (pH 4.5) of fucoidan and laminarin, which were dialyzed for separation [148]. Afterwards, calcium alginate in the solid material was converted first to alginic acid by the action of a 0.2 M HCl solution treatment and then to sodium alginate with 0.2 M sodium hydrogenocarbonate solution. The soluble sodium alginate was washed and precipitated with a strong acidic 3 M HCl solution, and this step was followed by neutralization and further precipitation with ethanol until isolating alginate [148]. On the other hand, the spent biomass (after alginate extraction) was treated with ethanol and water as well as solutions of hydrogen peroxide, sodium hydroxide (NaOH), and HCl, thereby removing multiple types of other components according to their chemical affinities and leaving a final solid residue much enriched in cellulose [148]. This process represents an advance regarding other previous and comparable processes using brown seaweed as starting material, thereby yielding 70 kg of cellulose, 90 kg of fucoidan+laminarin, and 140 kg of alginate per ton of organic matter in the biomass—corresponding to ~70% dw [148]. Nonetheless, these mass balance results mean that there is still a large fraction of wasted organic material, which is chiefly present in the washing waste streams.

Another brown seaweed species that is very important as a source of biologically active compounds, namely laminarin, is L. digitata, for which a biorefinery for the production of specialty chemicals, biofuel, and bioactive substances was developed [151]. This biorefinery has a dilute-acid extraction—0.1 M HCl solution (pH 2–2.5) at 70 °C for 1 h—as its first operation. This was followed by centrifugation and by calcium chloride precipitation and another centrifugation for separation of alginate, and then by absolute ethanol precipitation and centrifugation for attaining a fucoidan-rich fraction. The waste liquor resulting from these operations was evaporated and used to prepare fractions with antioxidant and antimicrobial activity [151]. The solid residue was treated with a diluted acid solution (1.5 N H2SO4 at 121 °C for 24 min in an autoclave), its pH adjusted with sodium citrate buffer, and subjected to enzyme saccharification, thus forming glucose and other simple sugars, which were fermented with S. cerevisiae to produce ethanol. However, this biorefinery strategy had shortcomings, as more than 40% of the starting material was not valorized, and there was still fucoidan in the residue, a problem that warrants further optimization to maximize recovery of this polysaccharide [151].

Finally, a fourth and very recent case-study involving A. nodosum and F. vesiculosus aimed at the development of an efficient ‘green’ biorefinery [154]. This biorefinery strove to go beyond the usual brown seaweed polysaccharides—alginate, fucoidan, and laminarin—and isolate mannitol and protein, two other major components in this biomass. Except for ultrafiltration for attaining a fucoidan-rich fraction and ultrasound treatment in the route for alginate separation, the various separation processes and principles were similar to those already described above [154]. The ultrafiltration permeate was enriched in mannitol, 8–13%, w/dw, in A. nodosum and 15–17%, w/dw, in F. vesiculosus, and laminarin, 21–31%, w/dw, in A. nodosum and 25–36%, w/dw, in F. vesiculosus [154]. Though protein was recovered in this approach, cellulose and other polysaccharides were left behind. Hence, a saccharification and fermentation component would be advantageous in this process and help in bringing it closer to a full-fledged biorefinery.

Biorefinery in Seaweed

All these biorefinery case-studies covering a significant diversity of seaweed species show that the overarching goal of achieving a full utilization of all major biomass components with a conjugation of maximal valorization, technological viability, commercial profitability, and environmental sustainability is still somewhat distant and requires further research and optimization. Based on LCA, it has been concluded that though seaweed has the potential to become a sustainable raw material for biorefinery purposes, technologies still require maturing and improvements [129]. In fact, other novel approaches, especially concerning the minimization of environmental impacts and innovative processing technologies, are needed for a successful application of the biorefinery concept to seaweed.

3.1.3. Wet Route and Other Sustainable Approaches

Wet Route

Precisely for achieving a sustainable and environmentally friendly biorefinery of the seaweed biomass, WR has been proposed as a possible alternative [154]. This approach entails waiving any drying or rehydrating step in the overall process, thus saving expensive thermal energy, which usually also translates into a large carbon footprint in the DR approach [29,36]. It may also be a technologically advantageous approach, since cell disruption operations in fresh seaweed matrix could enhance the release of bioactive compounds [36]. In this respect, it has been advocated that disrupting seaweed cell walls by mechanical and/or non-mechanical methods may be eased with the expected improvement in yields [36].

Ummat et al. (2024) [154] in their biorefinery study also compared the WR and DR approaches by utilizing both dry and fresh A. nodosum and F. vesiculosus. Namely, these authors reported that the highest amount of fucoidan was extracted from fresh F. vesiculosus seaweed using an acidic solution as a separating agent—a conventional treatment. It has been argued that whereas the high moisture content in fresh seaweed helps in extraction by acting as a co-solvent and enhancing solvent diffusion in the algal matrix, in dry seaweed, algal structure becomes compact and difficult for the efficient mass transfer of the biomolecules to be extracted [154]. The drying temperature itself can cause degradation of any thermally sensitive compounds present in the biomass and thus depress final yields. Moreover, it was observed that a lower number of solids in the ultrafiltration retentate obtained from fresh F. vesiculosus than in that from dry seaweed, but protein content was higher in retentate from fresh compared to dry biomass [154]. Regarding the potential of WR, it has been demonstrated the feasibility of a process for attaining laminarin along with fucoidan from fresh seaweed [156].

The application of a WR approach to green seaweed has also been tested [157], involving the extraction of both carbohydrates and protein from Ulva sp. biomass. This is challenging because protein is a component of the seaweed cell wall, and it is closely associated with the carbohydrate macromolecules, which increase viscosity and limit access to the proteins. For this purpose, protein alkaline extraction (pH 8.5) followed by isoelectric precipitation (pH 4.0) and, alternatively, carbohydrate/ulvan enzymatic hydrolysis has been proposed for achieving a protein-enriched fraction as outcome [157], this second strategy being more successful. These authors also observed that sugar release from fresh seaweed was much higher than from freeze-dried material, thus also suggesting a relative advantage of WR. Another factor against alkaline extraction may be its induction of aminoacyl cross-linking [158]. However, according to Juul et al. (2021) [159], this does not affect its in vitro digestibility. In any case, further research is warranted as cross-links—occurring both between and within proteins—alter protein conformation and hamper access of proteases to peptide bonds, thus curtailing protein digestibility [158]. Indeed, it has been claimed that amino acid bioavailability may be lowered by cross-linking [160].

In general, protein extraction from typical green seaweed biomass involves either targeted protein extraction [158,161,162] or protein concentration in the sequence of other compounds’ extraction [158,163,164]. This second option is often an outcome of choosing a biorefinery strategy and is also applicable to WR. Protein extraction presupposes a first step of physical destruction, by either High Speed Homogenization (HSH) or Screw Pressing (SP) [159], usually coupled with an alkaline solution extraction [165,166] and/or enzymatic hydrolysis [165,167]. Afterwards, in order to achieve a higher protein concentration, isoelectric or heat precipitation are among the most effective solutions [158,168]. Regarding brown seaweed and WR, it has been investigated whether fresh or dried biomass is better as feedstock in a biorefinery [169]. These authors concluded that, for the specific case of bioenergy production and a solid/water ratio of 1:4, the efficiency of extraction from fresh biomass was higher than that from dried biomass, 13.8 vs. 1.3, thus indicating that fresh kelp (Saccharina japonica) is a better feedstock than dried seaweed. The removal of inorganic matter, which interferes with the full utilization of the organic component of biomass [170], seems to be favored in a WR approach [169]. Research on WR application to red seaweed has also been carried out, for instance, in a K. alvarezii biorefinery that extracted an agricultural bio-stimulant and a semi-refined form of carrageenan [139] (see above in Section 3.1.2). The conducted literature review showed that studies on WR, regardless of the particular seaweed group considered, remain few and sparse.

There are also technological and efficiency problems concerning WR. In fact, the high water content of the biomass along the process may also hinder the diffusion of some chemicals or solvents in the matrix, thereby encumbering or delaying the release of relevant molecules from algal cells [171]. This has led to the application of novel technologies in combination with wet matrices [72]. On the other hand, fresh seaweed is highly perishable as a result of high moisture and water activity levels [157]. For tackling this issue without applying dehydration/drying, alternative storage concepts have been proposed, such as silage [157]. Indeed, this technique was tested, and while minerals, mannitol, and glucose contents were reduced, there was a relative enrichment in protein and alginate [157]. In particular, the lower mannitol content was partly assigned to a possible consumption of mannitol by lactic acid (LA) bacteria grown during storage. Nevertheless, Bikker et al. (2016) [157] were of the opinion that opting for silage is an effective way to preserve the major structural components of seaweed biomass. Therefore, WR may be advantageous with respect to DR, but there are still operational issues that require study (and new ideas) in order to reap the environmental benefits of avoiding energetically expensive processes, such as drying.

Application of ‘Green’ Solvents

For achieving environmental sustainability, a choice for the so-called ‘green’ solvents in the various operational instances where a solvent is needed is also a major current trend, and with the potential to deliver positive results [21,172]. This trend has been reinforced by regulations and legislation seeking to reduce solvent emissions [173,174]. A ‘green’ solvent should be a nonflammable and biodegradable substance (and able to be recycled) with no inhalation hazards and displaying a low volatility [174,175]. In addition, any such solvent must have a set of physicochemical properties that enable it to be used in diverse types of extraction methodologies [174]. Finding an ideal ‘green’ solvent is difficult, as the choice is a compromise depending on the process, the particular seaweed characteristics, and the components to be extracted [20].

Such solvents encompass a wide variety of substances, ranging from water to the more complex and specific Ionic Liquids (ILs), Deep Eutectic Solvents (DESs), and Natural Deep Eutectic Solvents (NADESs) [14,176,177,178]. In fact, ‘green’ solvents may be ascribed to three major groups: (i) biobased solvents (with a natural origin and presence, such as water, ethanol, glycerol, eucalyptol, limonene, other terpenoids or vegetable oils, fitting ethyl acetate, isoamyl acetate, and ethyl lactate better in a different group of ‘low toxicity’ solvents); (ii) supercritical solvents (including natural substances, but in an unnatural state, such as CO2); and (iii) neoteric solvents (including synthesized substances, such as DES, and naturally existing substances, NADES) [176].

Water can be regarded as the ultimate ‘green’ solvent, since it is cheap, non-toxic, and the friendliest to the environment [14]. It can be applied in a wide variety of seaweed processing operations, such as maceration, decoction, infusion, or percolation. However, water is unsuitable to extract non-polar substances [179]. This can be partially tackled by applying water at high temperature and pressure because its polarity is lower under these circumstances. The downside is the deleterious effect of these conditions upon thermolabile bioactive compounds [179].

Ethanol is also a usual ‘green’ solvent, and it is typically applied together with water in variable proportions in hydroethanolic extractions [176,180]. As an example, a 30% ethanol hydroalcoholic solution has been combined with a novel extractive technology, PLE (see Section 3.2), in targeting polyphenols in red seaweed, and this technical solution has been shown to yield the most efficient extraction of phenolic compounds [180]. Antioxidant and antidiabetic compounds were effectively extracted with a relatively mild process, thereby providing a framework for future industrial applications [180]. There are also cases of higher ethanol ratios in the hydroalcoholic solution [181]. These authors used a Timatic extractor—a solid–liquid extractor that, in its extraction cycle, alternates a dynamic phase with a static phase for the transfer of extract into the solvent, in winning biomolecules from Zonaria tournefortii. The authors used an RSM to conclude that the optimal parameters would be 96% ethanol, 14.4 Timatic cycles, and 20 min sonication [181].

Within biobased solvents, there are also less-known solvents, but exhibiting a significant extraction potential [176]. For instance, Hamiche et al. (2018) [182] used eucalyptol (1,8-cineole, a terpenoid) as a solvent in the preparation of extracts from Z. tournefortii. The eucalyptol extracts were distinguished by being rich in phlorotannins. There was an additional advantage in the possibility of solvent recovery through recycling by steam distillation [182]. However, it was found that the phenolic content and antioxidant properties of the ‘green’ extract attained with eucalyptol were not so favorable for future applications as those of a conventional extract (e.g., higher Half Maximal Effective Concentration, EC50, 140 vs. 58 μg/mL) [182]. Indeed, the efficiency and yields of these biobased solvents are frequently unsatisfactory, and this represents a major hurdle to their application by the industry. For instance, Savira et al. (2021) [183] compared several solvents with respect to the extraction of fucoxanthin, a carotenoid, from a brown seaweed (Sargassum duplicatum) and found that extracts attained with ethanol and ethyl acetate were less antioxidant than those obtained with methanol, a solvent that poses safety risks and to be avoided.

Supercritical fluids have also been explored and are considered promising as alternative ‘green’ solvents for extracting variable components from seaweed [184]. Examples of application of supercritical CO2 as a ‘green’ alternative extracting agent include the brown seaweeds Dictyopteris polypodioides [185] and Fucus serratus [186] or the green seaweed Ulva flexuosa [187]. Since these solvents involve the application of a relatively novel technology to seaweed biomass, SFE, more details are given below (see Section 3.2).

Within neoteric ‘green’ solvents and regarding their application to seaweed biomass, IL utilization has been restricted to a few studies [62,188]. The combination of IL and mild extraction conditions is relatively recent and circumscribed to very few studies, such as phycobiliproteins from the red seaweed Gracilaria sp. [189] or protein from the green seaweed Ulva lactuca [62]. Synthetic IL, such as 1-butyl-3-methylimidazolium acetate (BMIA), 1-ethyl-3-methyl-imidazolium dibutyl phosphate (EMIDP), 1-butyl-3-methylimidazolium dibutyl phosphate (BMIDP), 1-butyl-3-methylimidazolium chloride (BMIC) or choline chloride (ChC), have been tested, for instance in U. lactuca [62]. It was reported that EMIDP was strongly selective to proteins, enabling extraction yields up to 80% for proteins and 30% for carbohydrates [62]. Additionally, gel electrophoresis showed that the native structure of the extracted protein was maintained during the whole process, which proves its relative mildness. It has been found that, after optimization of all operational parameters, a maximum extraction yield from Ulva spp. of 5.96 mg chlorophyll/g dw was attainable with tributyltetradecylphosphonium chloride (TBTDPC)—a surface active IL [190]. Martins et al. (2021) [190] concluded the possibility of the development of a cost-effective process without compromising the stability of the final product. In fact, the main hurdle for the utilization of IL is the associated high economic cost [191] and remaining uncertainty regarding toxicity [62]. Sequeira et al. (2021) [153] used tetramethylammonium hydroxide (TMAH) for the extraction of alginic acid from brown seaweeds belonging to the genus Sargassum. The process delivered promising results and encompassed an acid treatment followed by the application of TMAH [153]. The application of IL to red seaweed can be exemplified with the extraction of carrageenan from K. alvarezii [192]. Results showed that the carrageenan extracted through this process had worse gel strength and viscosity, but a higher emulsification index than that of the conventional process [192]. According to these authors, though monosaccharide composition was similar to the usual carrageenan, antioxidant activity was low as a result of decreased sulfate content. Evidence of thermal degradation and IL dissolution was found in the profiling of molecular weights, but this was claimed to enhance bioavailability and functional properties of the produced hydrocolloid [192].

Beyond IL, there is the group of DES, which are fluids composed of two or three substances that can interact through hydrogen bonds in a way that results in a eutectic effect (with melting temperature below that of the individual components). Just as IL, DESs have already been used in the extraction of seaweed polysaccharides and bioactive compounds [193]. Despite the effectiveness of DES (and IL), there is a current trend toward aqueous solutions of DES (and IL) and away from concentrated solutions [193]. It has been claimed that hydrated DES may be better at extracting carrageenan from K. alvarezii than non-hydrated DES, highlighting the importance of solvent hydration in optimizing such extractive processes [194]. Nonetheless, it should be noted that some components may present relevant risks [193,195].

Hence, alternative neoteric solvents that already exist in nature (and in foods) may be a better choice due to the absence of unforeseen toxicological aspects. Indeed, NADES may be preferable, given their natural origin and the fact that they have already been tested to some extent in seaweed [176,196]. For instance, phenolics from powdered seaweeds (Gelidium corneum, a red seaweed, and Sargassum muticum, a brown seaweed) have been extracted using maceration combined with NADES [196]. They reported that the combination of L-LA and fructose (5:1) was the most effective, enabling a final extract phenolic concentration of 2099 mg Gallic Acid Equivalent GAE/L. Moradiya et al. (2024) [193] used neoteric solvents that are naturally present in biological systems—choline glycolate, choline acetate, choline formate, and their DES counterparts, choline chloride/glycolic acid (1:2), choline chloride/acetic acid (1:2), and choline chloride/formic acid (1:2)—in the extraction of alginate from Sargassum tenerrimum. It was observed that a hydrated IL was more effective than its non-hydrated form, being the yield maximized up to 54%, which exceeds the equivalent value in a conventional approach [193]. Moreover, physicochemical and rheological features of the alginate extracted by IL compared well with the alginate produced by a conventional method [193].

In any case, there are still big challenges hampering the widespread utilization of ‘green’ solvents. In many instances, the unsatisfactory or less favorable results in comparison to conventional solvents may be ascribed to the novelty of ‘green’ solvents and the dearth of optimization experiences. The convergence to optimal operational parameters can be accelerated by using time- and test-sparing strategies, being RSM quite useful [181,197]. This and other tools may help in addressing the technological viability challenge. Other technical innovations, including innovative extraction technologies (see Section 3.2), or simply new ideas, such as adding water to NADES for reducing the viscosity of these neoteric solvents and enabling a higher extraction efficiency as a result of accelerated mass transfer phenomena [196], may provide solutions to the challenges posed by such novel and untested ‘green’ solvents. Other issues may be related to the commercial viability of the ‘green’ solvents. Namely, the high costs of some neoteric solvents may be addressed by synthesizing new ILs from inexpensive raw materials [198] and by putting in place technologies—based on phase induction, adsorption, or membrane processes—that allow solvent recovery and reutilization [62,199].

3.2. Novel Extractive Techniques

3.2.1. General Overview