Current and Expected Trends for the Marine Chitin/Chitosan and Collagen Value Chains

Abstract

:1. Introduction

- The extent of scientific knowledge along the marine-derived chitin/chitosan and collagen value chains.

- How stakeholders should interact within each value chain to narrow the gap between scientific knowledge on chitin/chitosan and collagen and their industrial application.

2. Results

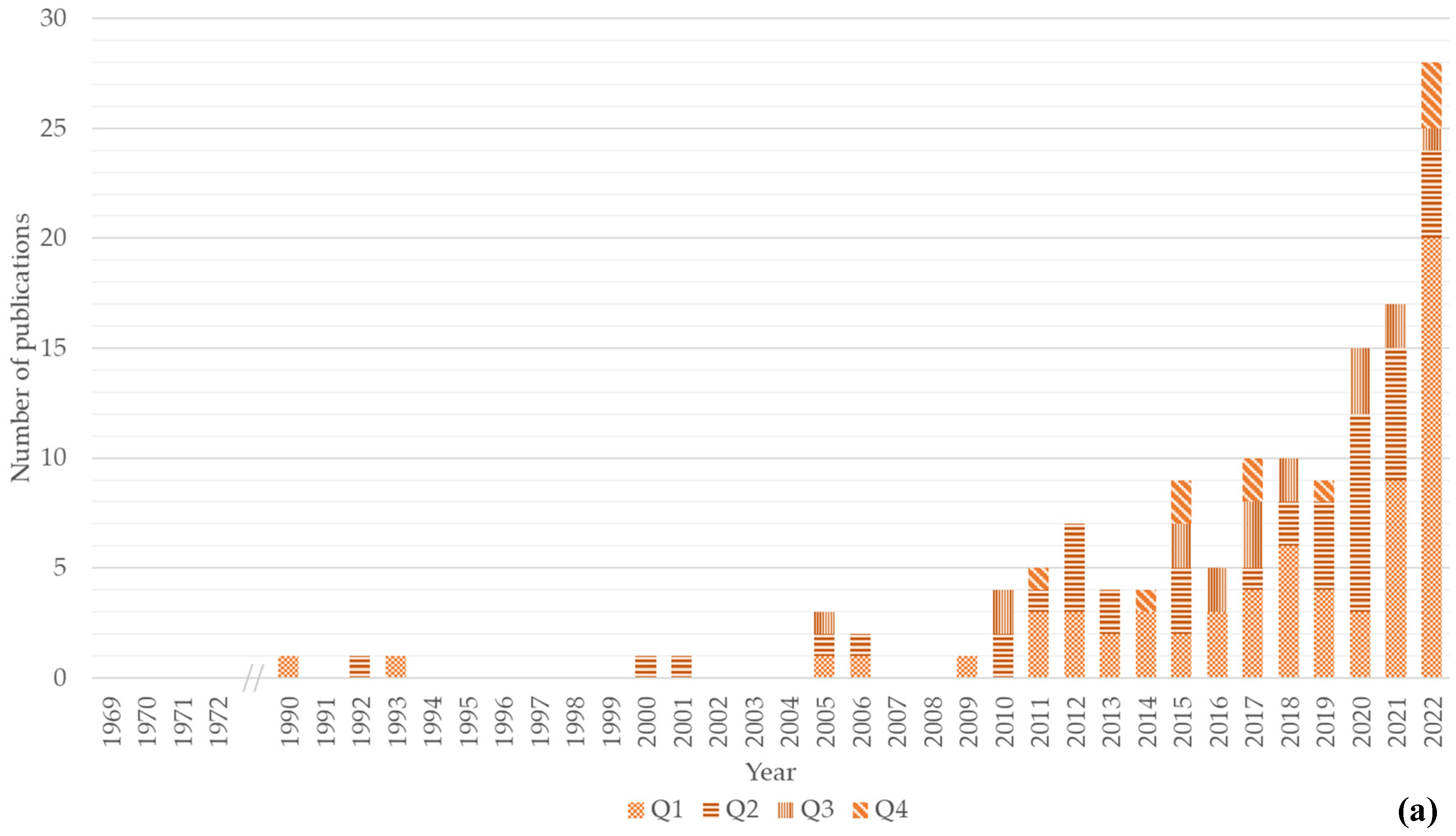

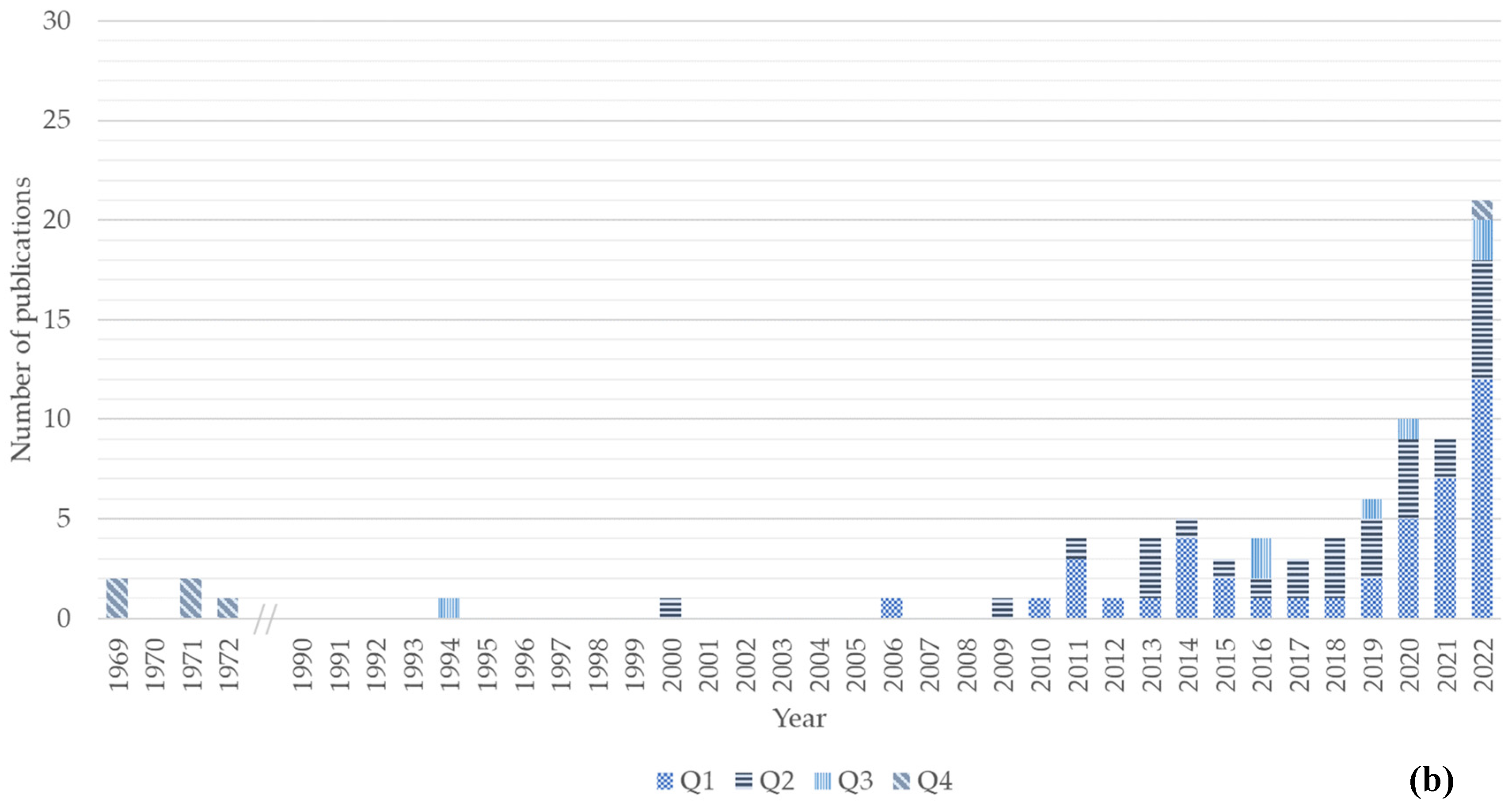

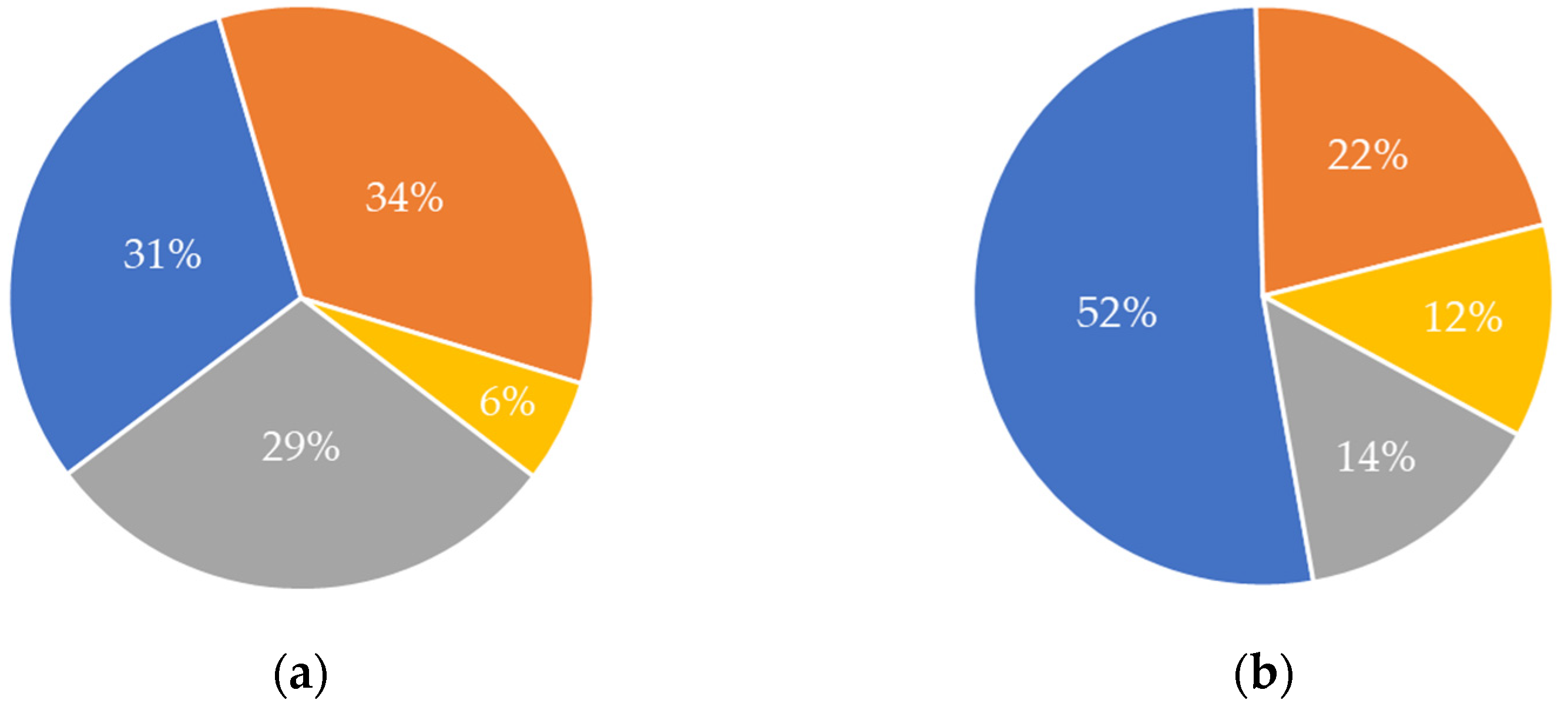

2.1. Trends in the Distribution and Number of Publications per Value Chain

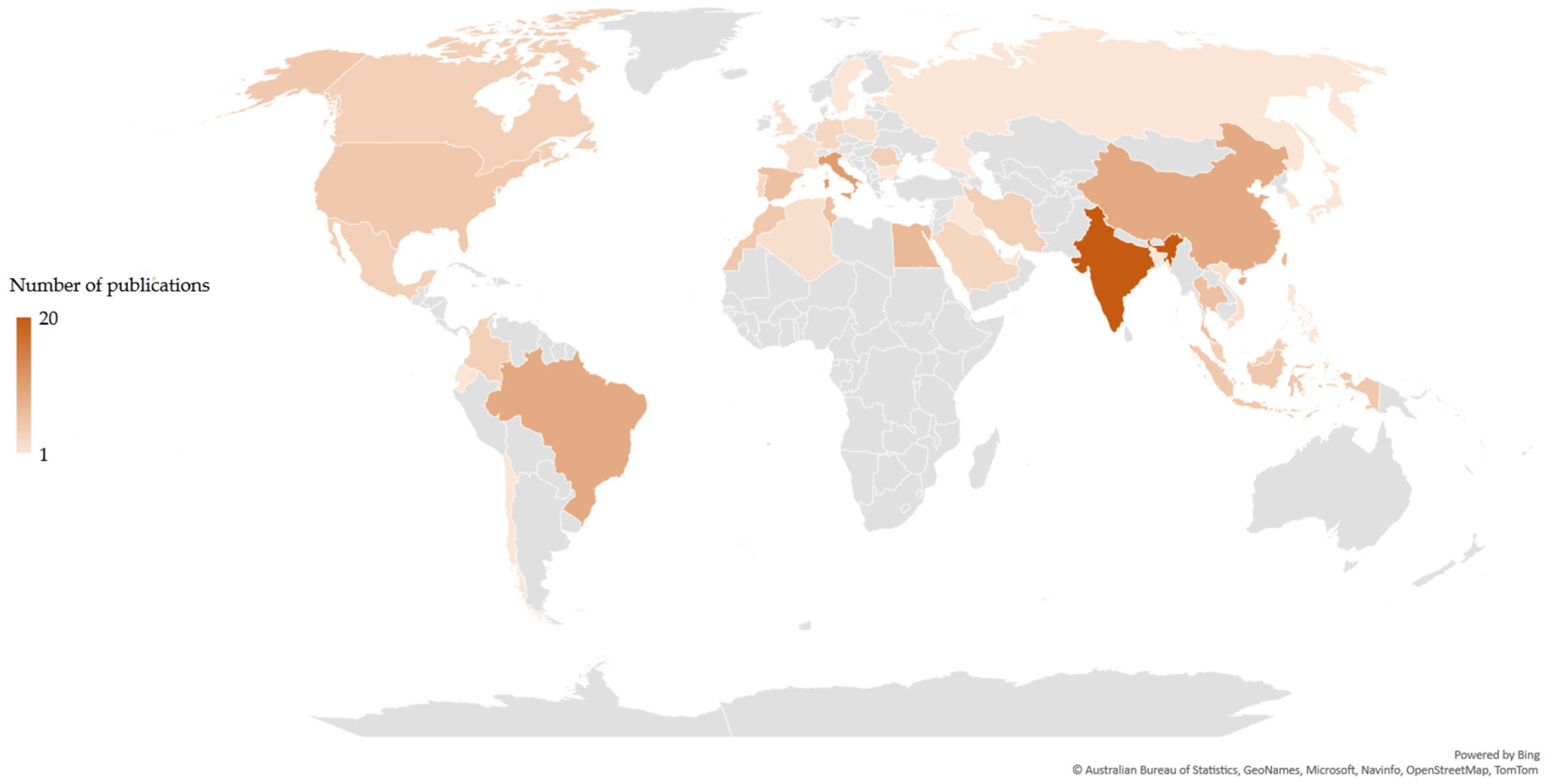

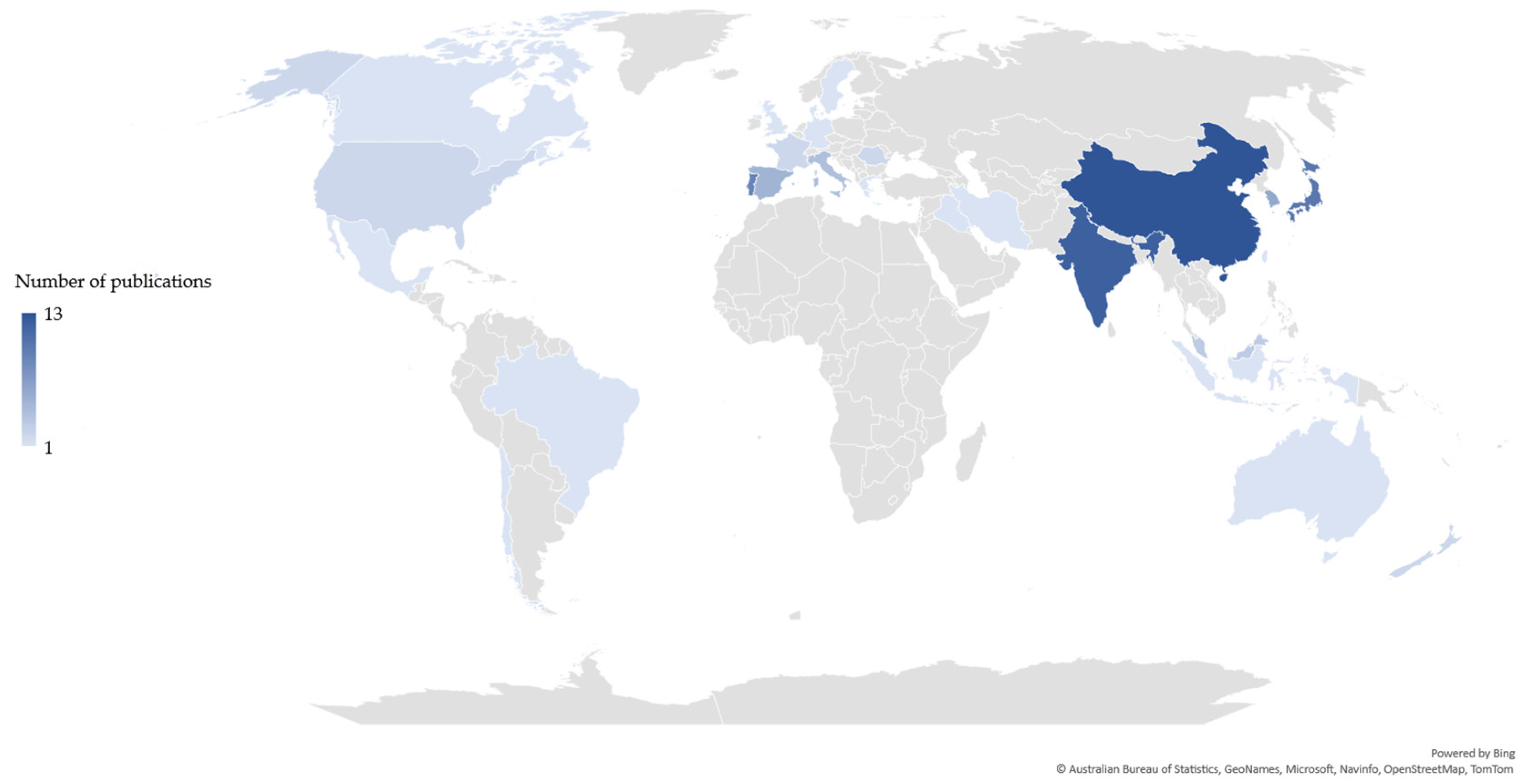

2.2. Trends in the Geographical Origin of Publications per Value Chain

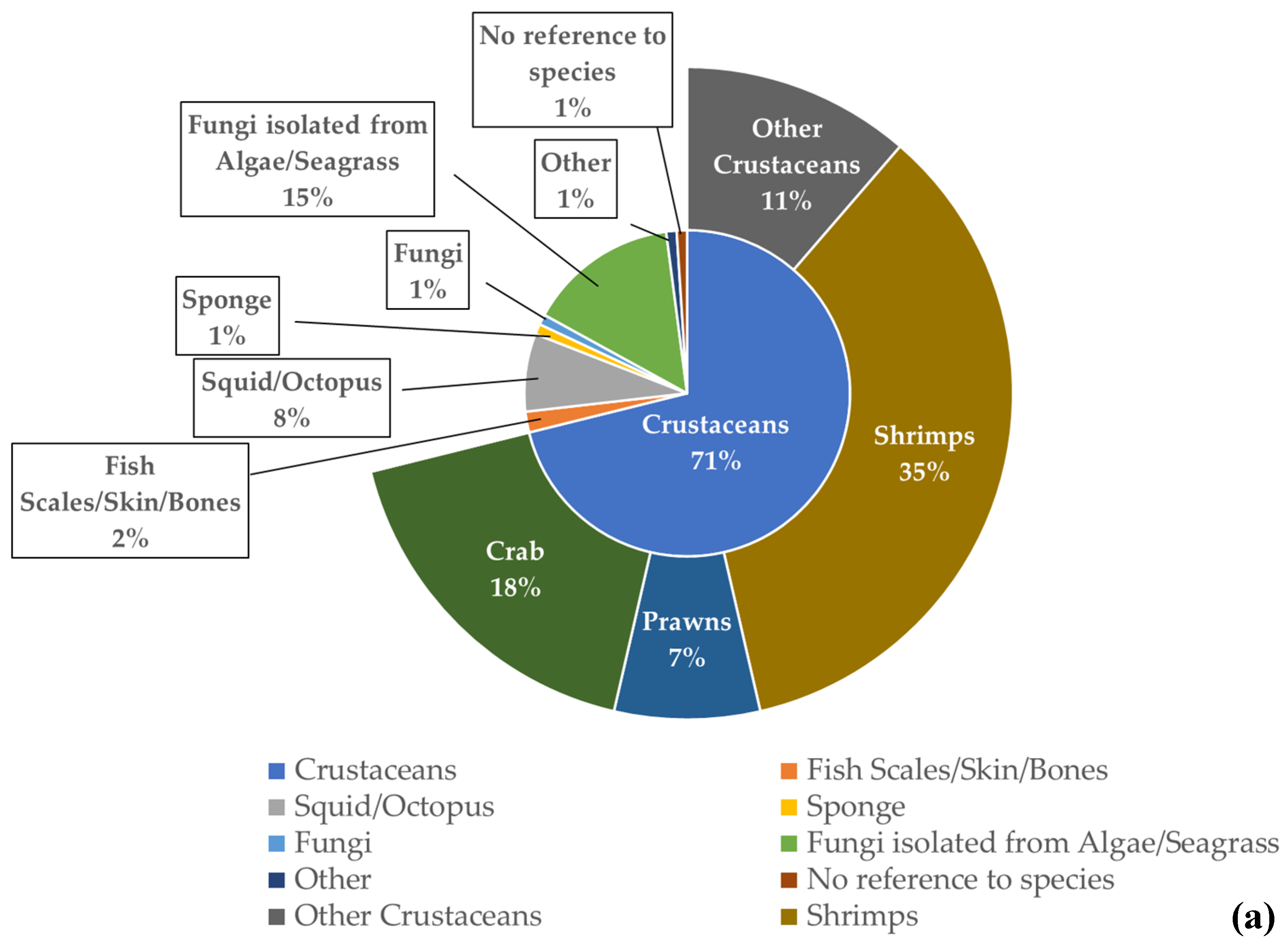

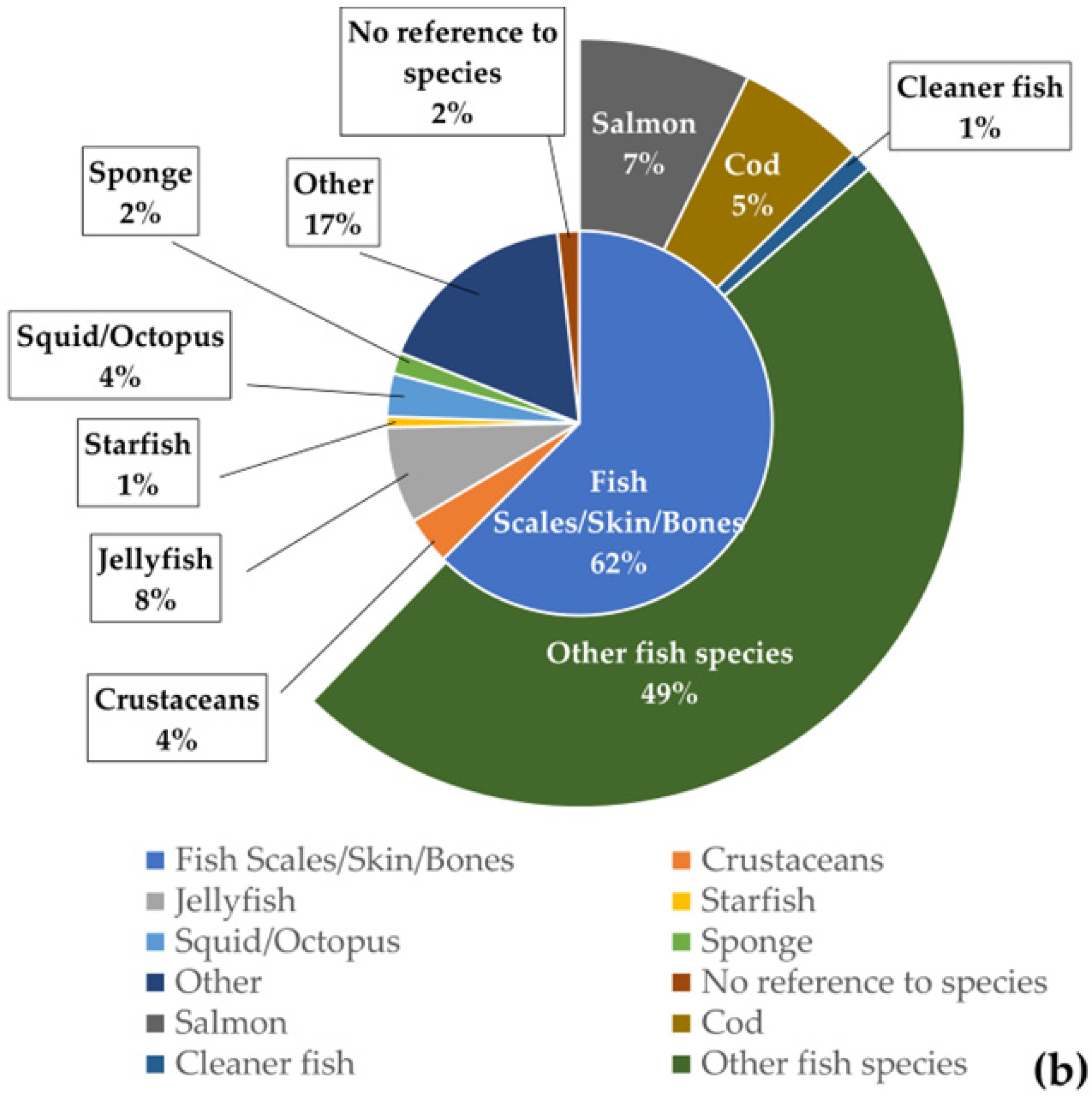

2.3. Trends in the Origin of the Marine Raw Materials and Feedstock per Value Chain

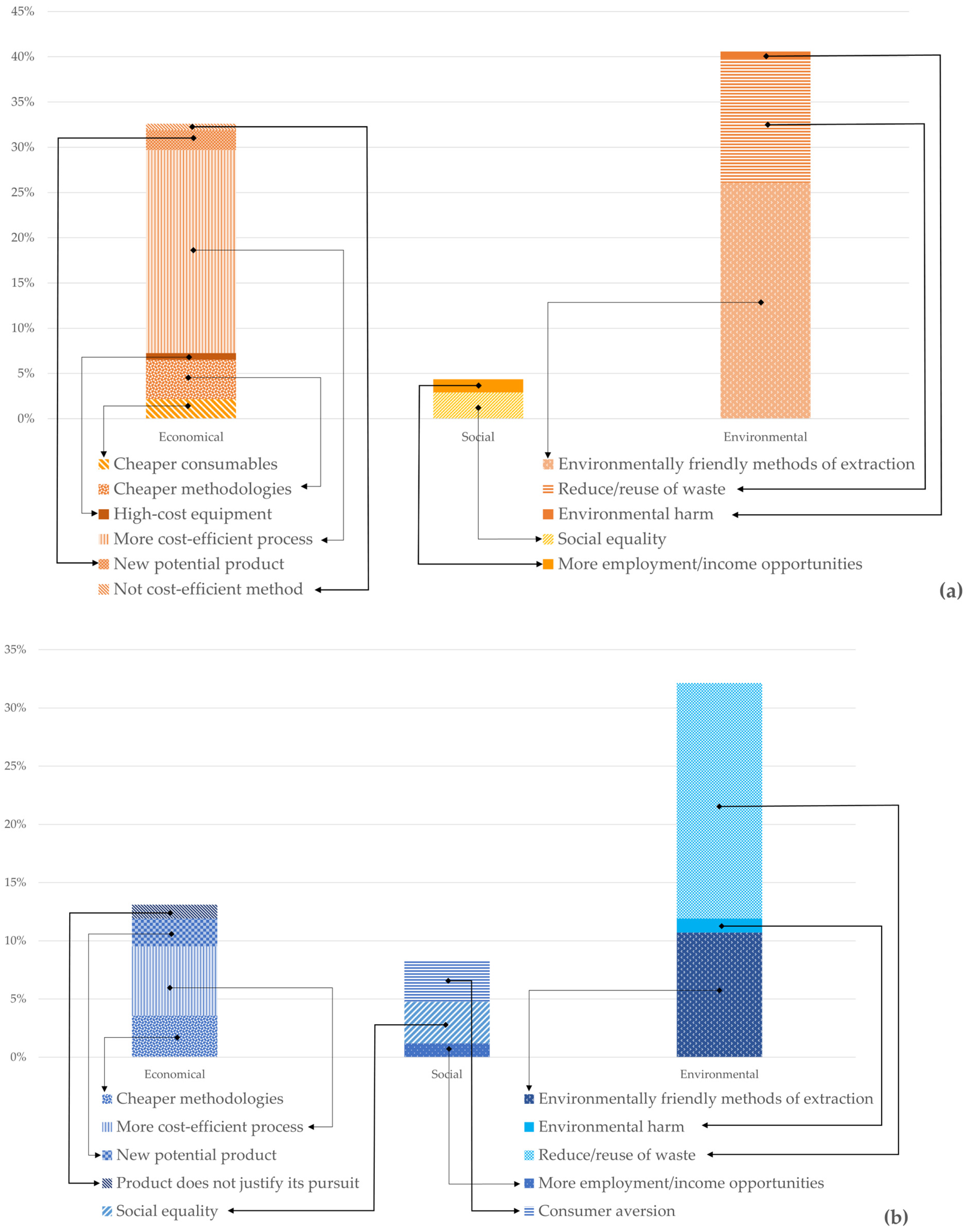

2.4. Trends in the Perception of Sustainability for Chitin/Chitosan and Collagen Value Chains

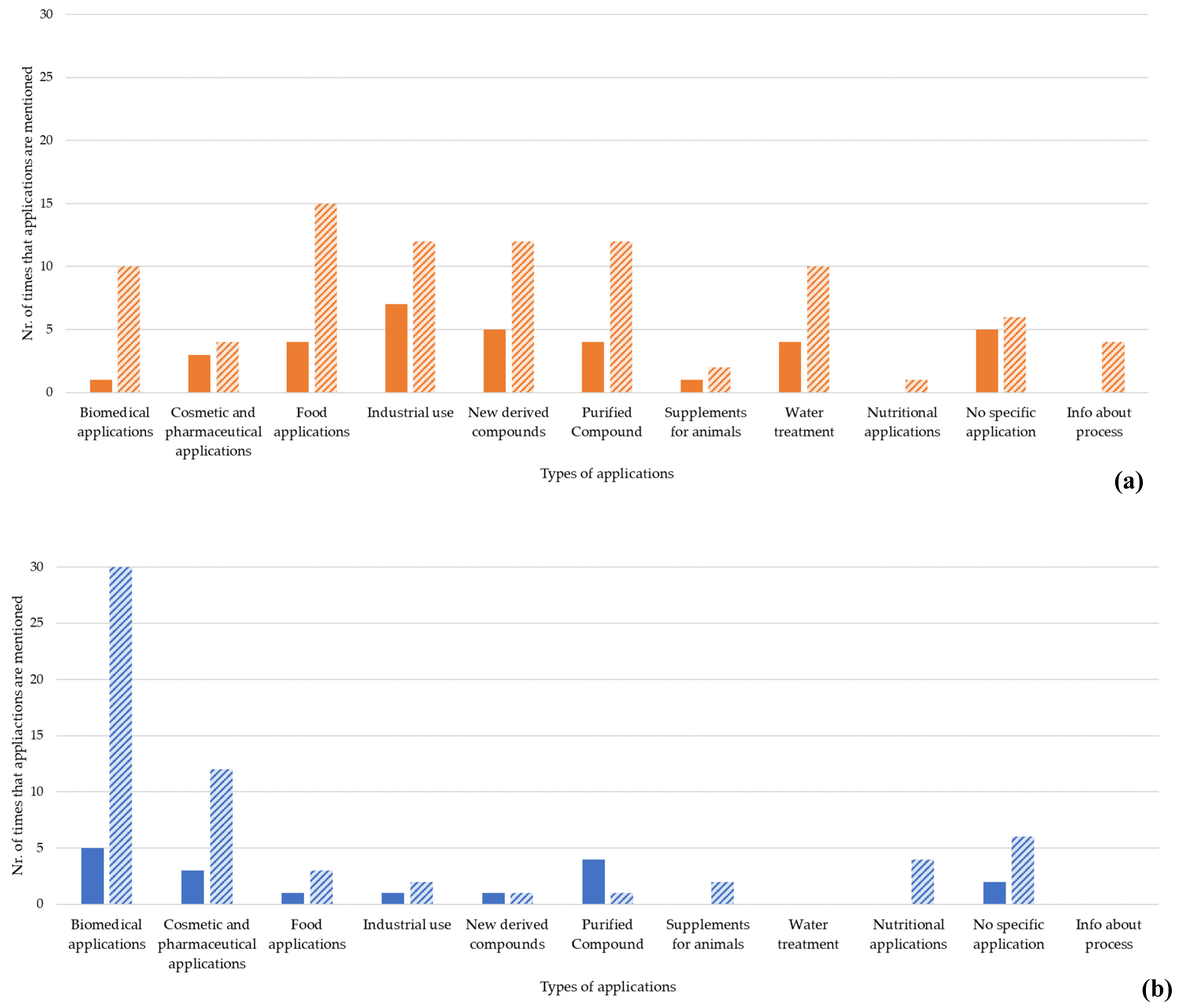

2.5. Trends in Market Applications for Each Value Chain

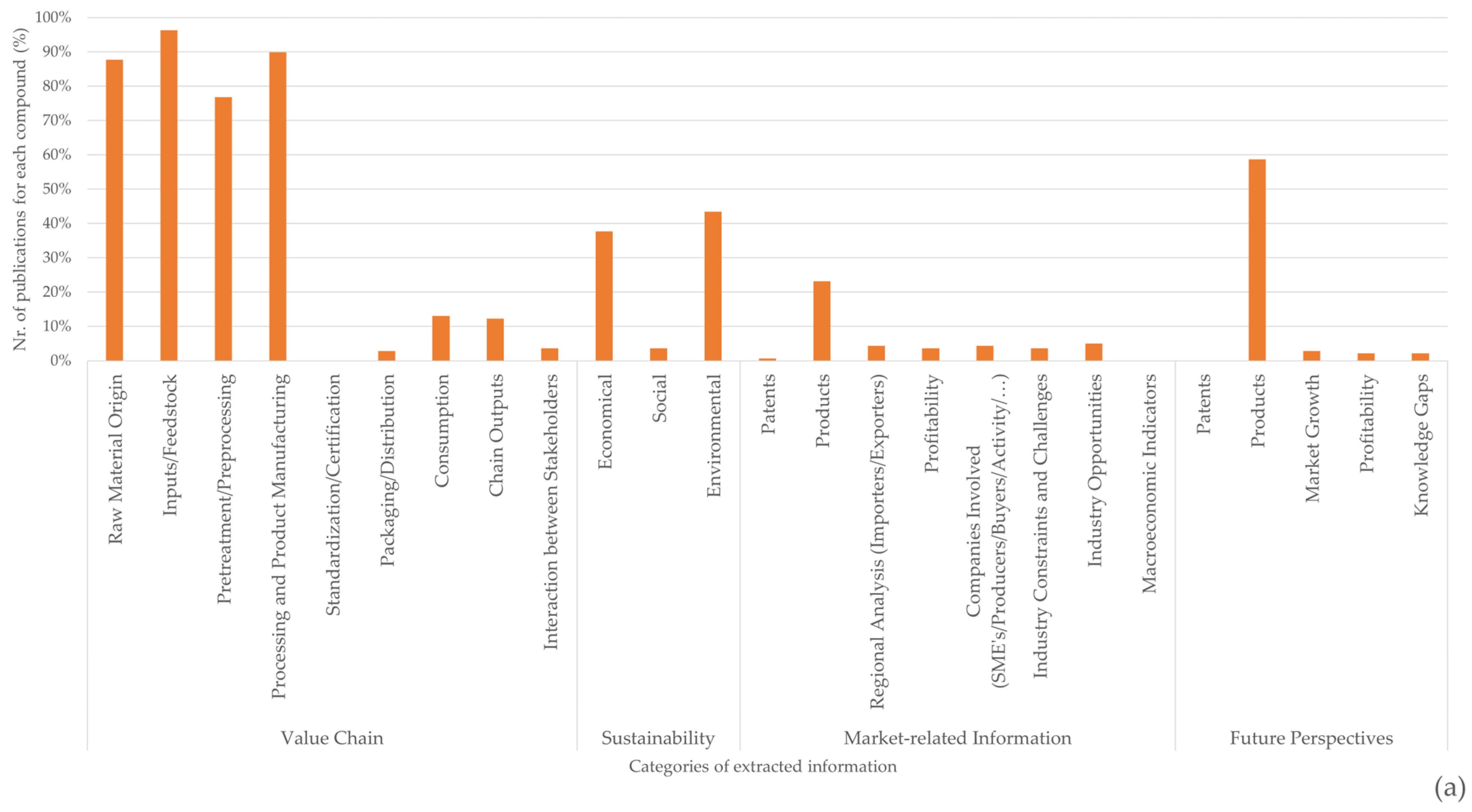

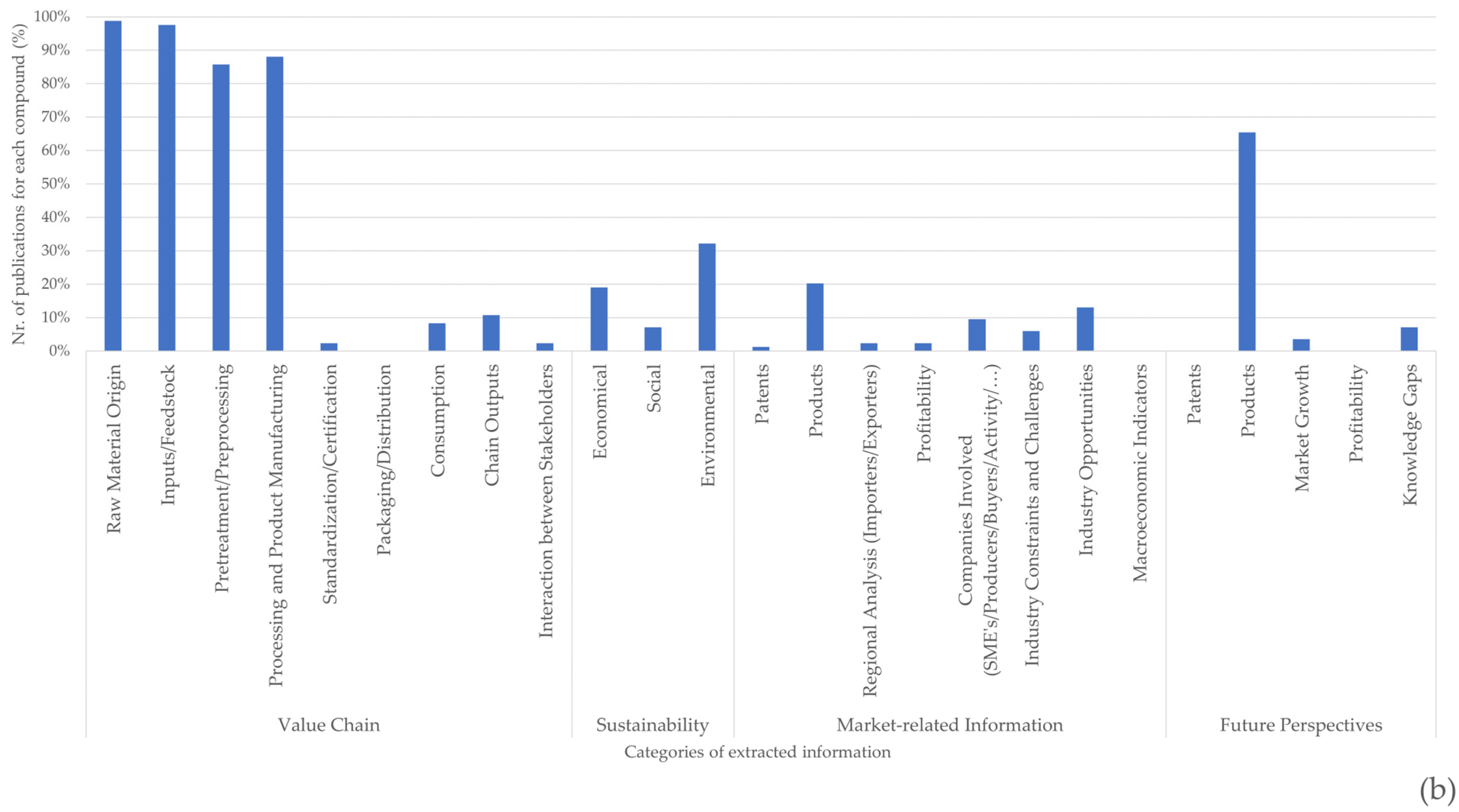

2.6. Trends in Data Distribution per Category of Information per Value Chain

3. Discussion

3.1. Trends in the Distribution and Number of Publications per Value Chain

3.2. Trends in the Geographical Origin of Publications per Value Chain

3.3. Trends in the Origin of the Marine Raw Materials and Feedstock per Value Chain

3.4. Trends in the Sustainability of Each Value Chain

3.5. Trends in Market Applications for Each Value Chain

3.6. Trends in Data Distribution along Each Value Chain

3.7. State-of-the-Art and Expressed Trends in the Chitin/Chitosan and Collagen Value Chains

| SWOT | Chitin/Chitosan | Collagen |

|---|---|---|

| Strengths | A high percentage (>80%) of scientific information is published in highly scored (Q1 and Q2) journals. The literature well documents the extraction processes to ensure consistency and standardisation. Coming from marine sources overcomes current barriers to land-based and/or animal-based counterparts and diet restrictions existing worldwide (halal, Muslim, Hindu, etc.). New, more efficient and more environmentally friendly methods are documented by several authors. Current extracted chitin, and its derivatives, already have an important role as components of advanced biomaterials. In this era of climate change, the strategy of producing chitin from wastes and converting it to value-added products is highly valued to mitigate the ecological and economic imbalances due to marine food wastes. | A high percentage (>80%) of scientific information is published in highly scored (Q1 and Q2) journals. The literature well documents the extraction processes to ensure consistency and standardisation. Coming from marine sources overcomes current barriers to land-based and/or animal-based counterparts and diet restrictions existing worldwide (halal, Muslim, Hindu, etc.). New, more efficient and more environmentally friendly methods are documented by several authors. One of the applications of collagen, collagen-based antioxidants, are highly valued, because unlike synthetic antioxidants, collagen-based ones are non-toxic and can also supply nutritional benefits to consumers. The extraction of collagen from marine wastes such as discards, and side streams helps to achieve one of the goals of EU fishing policies by reducing post-harvest losses. |

| Weaknesses | The lack of scientific studies considering macroeconomic factors. Social sustainability seems to be ignored or not integrated into available published data. The degree of dependence from raw materials sourced from the food processing industry (subject to fluctuations). The chemical processes used to obtain chitosan during recent decades are considered to have a big environmental footprint and the resulting chitosan does not meet the requirements of high-tech applications. Many of these new sources from which chitin/chitosan derived have yet to be proven to be adaptable and usable in many different markets. The eco-friendly method of chitin/chitosan extraction does not achieve the levels of yield and purity of the chemical methods and is still in a lab-scale phase. | The lack of scientific studies considering macroeconomic factors. Social sustainability seems to be ignored or not integrated into available published data. Traditional protocols applied to the extraction of collagen are outdated, mainly with respect to present demands to develop more sustainable processes. Literature data suggest a decreasing innovation tendency in developing new compounds and purified collagen products. The public perception of the origin of the product (marine wastes) may hinder its commercialisation. The adaptability of this marine-derived collagen to penetrate highly regulated markets is yet to be proven. |

| Opportunities | There is a vast number of possible applications for chitin and chitosan, with special focus on biomedical applications, food, industrial use, water treatment, and new applications in nutritional products are being exploited. The use of waste/discards raw materials is a new way of improving social equality, as well providing another stream of income for fishermen. More conscious consumers demanding sustainable and alternative food sources can be appeased by the marine-derived chitin/chitosan. | There is a vast number of possible applications for collagen, with special focus on biomedical applications, food applications, industrial use, cosmetic and pharmaceutical applications, and new applications in nutritional products and supplements for animals. Major sources for commercial collagen are the skin and bone of land animals, such as pigs and cows, and these sources are heavily associated with the risk of transference of diseases or religious issues; marine-originated collagen can help to tackle these challenges. More conscious consumers demanding sustainable and alternative food sources can be appeased by the marine-derived chitin/chitosan. |

| Threats | Current chitosan production methods and technologies experience a lack of quality in terms of potential purity and reproducibility, sustainability difficulties due to substantial pollutant emissions during the production process, or excessive production and storage costs. Challenges such as allergenic or viral contamination, normally related to animal originated products, are still to be properly addressed. The large quantities of food processing waste discarded could be used as a raw material for the extraction of chitin and may cause an enormous pollution problem. The high dependence on fisheries’ catches and supply is a risk. Many new sources of these products are being studied and competition is fierce. New applications with higher market values may be developed from waste and by-catch raw materials, making them competing uses of the same biomass. There is a disconnection between academic research outputs and market needs/applicability. | The constant discards of by-catches pose a serious threat to marine ecosystems, human health, and the sustainability and development of the fishing industries. Large quantities of food processing waste discarded could be used as a raw material for the extraction of collagen and may cause an enormous pollution problem. The high dependence on fisheries’ catches and supply is a risk. Many new sources of these products are being studied and competition is fierce. New applications with higher market values may be developed from waste and by-catch raw materials, making them competing uses of the same biomass. There is a disconnection between academic research outputs and market needs/applicability. |

| PESTEL | |

|---|---|

| Political [182,183,184,185,186] | Government regulations, such as import/export restrictions, marine conservation laws, tariff policies and safety regulations, can affect the global market. Regulations on fishing practices and marine biodiversity conservation can limit raw materials’ availability. Government incentives or funding for sustainable marine resources may influence the availability and cost of raw materials. The current political drive and initiatives to foster circular bioeconomy are accelerating the development of new value chains and strengthening the logistics and opportunities in current ones. |

| Economical [172,173,174] | Market demand, production costs, and currency exchange rates can affect profitability and competitiveness. Price fluctuations in raw materials, such as fish skins or crustacean shells, can affect the availability and cost of chitin/chitosan and collagen. The instability of countries (due to political tensions, armed conflicts, wars, or economic crisis) that supply or consume the raw materials or the finished products can impact the pricing and the stability of the supply chain. Economic recessions or economic growth effect consumer spending patterns, and consequently, the demand for products within both value chains. More suitable and higher value market applications for the same raw materials can hinder or alter dramatically these value chains’ development from these marine sources (e.g., focus on new bioactive compounds) |

| Social [12,162,176,177] | Consumer preferences, lifestyle trends, and culture effect the demand for marine-derived products. The growing interest in sustainable, cruelty-free, ethical, and eco-friendly products may increase the demand for marine-derived chitin/chitosan and collagen products. The growing world population is driving the demand for more marine food, which leads to more raw material for these value chains. The aging population demands new solutions to improve their quality of life, and collagen and chitin/chitosan play relevant roles in many aspects of healthy lifestyles. Globalisation can play a role in shaping consumer behaviours, with trends established by online personalities able to increase demand for products related to health and well-being. |

| Technological [100,122,150,164,175,178] | Advances in biotechnology and processing techniques can improve production and processing efficiency, as well as the development of new products and applications. The use of advanced extraction and purification techniques has enabled the use collagen and chitin/chitosan in biomedical applications. The inability to use the marine-derived products in certain market applications exists due to a lack of desired characteristics (e.g., lack of odour or colour for cosmetic applications; lack of unpleasant taste or odour for food applications). |

| Environmental [179,180] | Climate change and resource depletion effect the availability and sustainability of chitin/chitosan and collagen sources. Overfishing, biodiversity loss, and habitat destruction impact raw materials’ availability. Pollution, such as plastic waste and chemical pollutants, can contaminate the organisms that are the source of the raw material, impacting the quality and safety of the extracted chitin/chitosan and collagen. The growing demand for raw materials and industrial production of these new products may cause new sources of pollution or environmental load. |

| Legal [181,187] | Intellectual property laws, product liability regulations, and labour laws impose restrictions throughout the chitin/chitosan and collagen value chains. Existing intellectual property landscape makes it harder to innovate for collagen or chitin/chitosan new molecules. Superiority and best-in-class may need to be developed as cases for highly regulated markets such as pharmaceutical or food application industries. Stricter regulations can impact businesses’ practices, jeopardizing employment and the consequent well-being of employees and their families. |

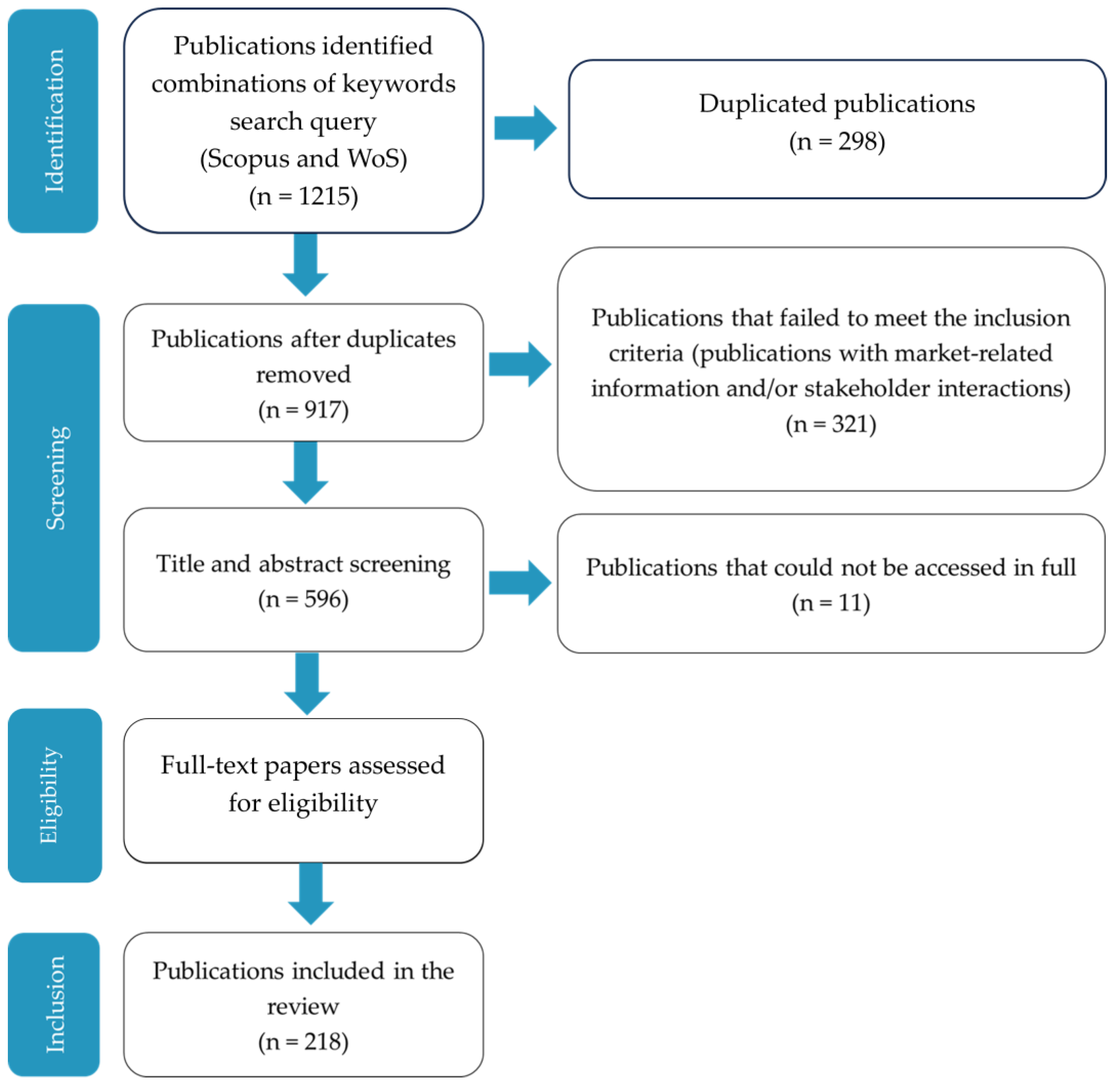

4. Materials and Methods

4.1. Literature Search and Database Construction

4.2. Inclusion Criteria and Data Extraction

4.3. Data Analyses

5. Conclusions

Supplementary Materials

Funding

Conflicts of Interest

References

- Estes, M.; Anderson, C.; Appeltans, W.; Bax, N.; Bednaršek, N.; Canonico, G.; Djavidnia, S.; Escobar, E.; Fietzek, P.; Gregoire, M.; et al. Enhanced Monitoring of Life in the Sea Is a Critical Component of Conservation Management and Sustainable Economic Growth. Mar. Policy 2021, 132, 104699. [Google Scholar] [CrossRef]

- CBD Oceans Contain a Wealth of Biodiversity. Available online: www.cbd.int (accessed on 24 October 2023).

- Golden, J.S.; Virdin, J.; Nowacek, D.; Halpin, P.; Bennear, L.; Patil, P.G. Making Sure the Blue Economy Is Green. Nat. Ecol. Evol. 2017, 1, 17. [Google Scholar] [CrossRef] [PubMed]

- Kvamsdal, S.; Hopland, A.O.; Li, Y.; Selle, S. Expert Opinions on Threats and Impacts in the Marine Environment. Mar. Policy 2023, 147, 105382. [Google Scholar] [CrossRef]

- The EU Blue Economy Report 2023; Publications Office of the European Union: Luxembourg, 2023; ISBN 9789268033456.

- FAO. The State of World Fisheries and Aquaculture 2022. Towards Blue Transformation; FAO: Roma, Italy, 2022. [Google Scholar]

- Hamed, I.; Özogul, F.; Özogul, Y.; Regenstein, J.M. Marine Bioactive Compounds and Their Health Benefits: A Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 446–465. [Google Scholar] [CrossRef]

- Romano, G.; Almeida, M.; Varela Coelho, A.; Cutignano, A.; Gonçalves, L.G.; Hansen, E.; Khnykin, D.; Mass, T.; Ramšak, A.; Rocha, M.S.; et al. Biomaterials and Bioactive Natural Products from Marine Invertebrates: From Basic Research to Innovative Applications. Mar. Drugs 2022, 20, 219. [Google Scholar] [CrossRef] [PubMed]

- Ambrosino, L.; Tangherlini, M.; Colantuono, C.; Esposito, A.; Sangiovanni, M.; Miralto, M.; Sansone, C.; Chiusano, M.L. Bioinformatics for Marine Products: An Overview of Resources, Bottlenecks, and Perspectives. Mar. Drugs 2019, 17, 576. [Google Scholar] [CrossRef] [PubMed]

- Carroll, A.R.; Copp, B.R.; Davis, R.A.; Keyzers, R.A.; Prinsep, M.R. Marine Natural Products. Nat. Prod. Rep. 2023, 40, 275–325. [Google Scholar] [CrossRef]

- Vasconcelos, V.; Moreira-Silva, J.; Moreira, S. Portugal Blue Bioeconomy Roadmap—BLUEandGREEN; CIIMAR: Matosinhos, Portugal, 2019. [Google Scholar]

- Amiri, H.; Aghbashlo, M.; Sharma, M.; Gaffey, J.; Manning, L.; Moosavi Basri, S.M.; Kennedy, J.F.; Gupta, V.K.; Tabatabaei, M. Chitin and Chitosan Derived from Crustacean Waste Valorization Streams Can Support Food Systems and the UN Sustainable Development Goals. Nat. Food 2022, 3, 822–828. [Google Scholar] [CrossRef]

- Collins, J.E.; Vanagt, T.; Huys, I.; Vieira, H. Marine Bioresource Development—Stakeholder’s Challenges, Implementable Actions, and Business Models. Front. Mar. Sci. 2020, 7, 62. [Google Scholar] [CrossRef]

- Leal, M.C.; Puga, J.; Serôdio, J.; Gomes, N.C.M.; Calado, R. Trends in the Discovery of New Marine Natural Products from Invertebrates over the Last Two Decades—Where and What Are We Bioprospecting? PLoS ONE 2012, 7, e30580. [Google Scholar] [CrossRef]

- Rocha, J.; Peixe, L.; Gomes, N.C.M.; Calado, R. Cnidarians as a Source of New Marine Bioactive Compounds—An Overview of the Last Decade and Future Steps for Bioprospecting. Mar. Drugs 2011, 9, 1860–1886. [Google Scholar] [CrossRef] [PubMed]

- Engku Noramalina Che Engku Chik, C.; Suryatie Kamaruzzan, A.; Ideris Abdul Rahim, A.; Lananan, F.; Endut, A.; Aslamyah, S.; Azman Kasan, N. Extraction and Characterization of Litopenaeus Vannamei’s Shell as Potential Sources of Chitosan Biopolymers. J. Renew. Mater. 2022, 11, 1181–1197. [Google Scholar] [CrossRef]

- Cutajar, N.; Lia, F.; Deidun, A.; Galdies, J.; Arizza, V.; Mangion, M.Z. Turning Waste into a Resource: Isolation and Characterization of High-Quality Collagen and Oils from Atlantic Bluefin Tuna Discards. Appl. Sci. 2022, 12, 1542. [Google Scholar] [CrossRef]

- Kumaran, S.; Perianaika Anahas, A.M.; Prasannabalaji, N.; Karthiga, M.; Bharathi, S.; Rajasekar, T.; Joseph, J.; Prasad, S.G.; Pandian, S.; Pugazhvendan, S.R.; et al. Chitin Derivatives of NAG and Chitosan Nanoparticles from Marine Disposal Yards and Their Use for Economically Feasible Fish Feed Development. Chemosphere 2021, 281, 130746. [Google Scholar] [CrossRef] [PubMed]

- Selvakumar, G.; Kuttalam, I.; Mukundan, S.; Lonchin, S. Valorization of Toxic Discarded Fish Skin for Biomedical Application. J. Clean. Prod. 2021, 323, 129147. [Google Scholar] [CrossRef]

- Ehrlich, H. Chitin and Collagen as Universal and Alternative Templates in Biomineralization. Int. Geol. Rev. 2010, 52, 661–699. [Google Scholar] [CrossRef]

- Khrunyk, Y.; Lach, S.; Petrenko, I.; Ehrlich, H. Progress in Modern Marine Biomaterials Research. Mar. Drugs 2020, 18, 589. [Google Scholar] [CrossRef]

- Dziedzic, I.; Voronkina, A.; Pajewska-Szmyt, M.; Kotula, M.; Kubiak, A.; Meissner, H.; Duminis, T.; Ehrlich, H. The Loss of Structural Integrity of 3D Chitin Scaffolds from Aplysina Aerophoba Marine Demosponge after Treatment with LiOH. Mar. Drugs 2023, 21, 334. [Google Scholar] [CrossRef]

- Tsurkan, D.; Wysokowski, M.; Petrenko, I.; Voronkina, A.; Khrunyk, Y.; Fursov, A.; Ehrlich, H. Modern Scaffolding Strategies Based on Naturally Pre-Fabricated 3D Biomaterials of Poriferan Origin. Appl. Phys. A Mater. Sci. Process. 2020, 126, 382. [Google Scholar] [CrossRef]

- Kritchenkov, A.S.; Egorov, A.R.; Volkova, O.V.; Zabodalova, L.A.; Suchkova, E.P.; Yagafarov, N.Z.; Kurasova, M.N.; Dysin, A.P.; Kurliuk, A.V.; Shakola, T.V.; et al. Active Antibacterial Food Coatings Based on Blends of Succinyl Chitosan and Triazole Betaine Chitosan Derivatives. Food Packag. Shelf Life 2020, 25, 100534. [Google Scholar] [CrossRef]

- Wysokowski, M.; Petrenko, I.; Stelling, A.; Stawski, D.; Jesionowski, T.; Ehrlich, H. Poriferan Chitin as a Versatile Template for Extreme Biomimetics. Polymers 2015, 7, 235–265. [Google Scholar] [CrossRef]

- Ehrlich, H.; Wysokowski, M.; Jesionowski, T. The Philosophy of Extreme Biomimetics. Sustain. Mater. Technol. 2022, 32, e00447. [Google Scholar] [CrossRef]

- Islam, N.; Hoque, M.; Taharat, S.F. Recent Advances in Extraction of Chitin and Chitosan. World J. Microbiol. Biotechnol. 2022, 39, 28. [Google Scholar] [CrossRef] [PubMed]

- Sun, C.; Wang, Z.; Zheng, H.; Chen, L.; Li, F. Biodegradable and Re-Usable Sponge Materials Made from Chitin for Efficient Removal of Microplastics. J. Hazard. Mater. 2021, 420, 126599. [Google Scholar] [CrossRef] [PubMed]

- Sagheer, F.A.A.; Al-Sughayer, M.A.; Muslim, S.; Elsabee, M.Z. Extraction and Characterization of Chitin and Chitosan from Marine Sources in Arabian Gulf. Carbohydr. Polym. 2009, 77, 410–419. [Google Scholar] [CrossRef]

- Muzzarelli, R.A.A.; Muzzarelli, C. Chitosan Chemistry: Relevance to the Biomedical Sciences. In Polysaccharides I: Structure, Characterization and Use; Heinze, T., Ed.; Springer: Berlin/Heidelberg, Germany, 2005; pp. 151–209. ISBN 9783540315834. [Google Scholar]

- Pellis, A.; Guebitz, G.M.; Nyanhongo, G.S. Chitosan: Sources, Processing and Modification Techniques. Gels 2022, 8, 393. [Google Scholar] [CrossRef] [PubMed]

- Tarique, J.; Sapuan, S.M.; Aqil, N.F.; Farhan, A.; Faiz, J.I.; Shahrizan, S. A Comprehensive Review Based on Chitin and Chitosan Composites. In Composites from the Aquatic Environment; Sapuan, S.M., Ahmad, I., Eds.; Springer Nature: Singapore, 2023; pp. 15–66. ISBN 9789811953279. [Google Scholar]

- Aranaz, I.; Alcántara, A.R.; Civera, M.C.; Arias, C.; Elorza, B.; Heras Caballero, A.; Acosta, N. Chitosan: An Overview of Its Properties and Applications. Polymers 2021, 13, 3256. [Google Scholar] [CrossRef]

- Sionkowska, A.; Skrzyński, S.; Śmiechowski, K.; Kołodziejczak, A. The Review of Versatile Application of Collagen: Versatile Application of Collagen. Polym. Adv. Technol. 2017, 28, 4–9. [Google Scholar] [CrossRef]

- Ehrlich, H.; Wysokowski, M.; Żółtowska-Aksamitowska, S.; Petrenko, I.; Jesionowski, T. Collagens of Poriferan Origin. Mar. Drugs 2018, 16, 79. [Google Scholar] [CrossRef]

- Pozzolini, M.; Tassara, E.; Dodero, A.; Castellano, M.; Vicini, S.; Ferrando, S.; Aicardi, S.; Cavallo, D.; Bertolino, M.; Petrenko, I.; et al. Potential Biomedical Applications of Collagen Filaments Derived from the Marine Demosponges Ircinia Oros (Schmidt, 1864) and Sarcotragus Foetidus (Schmidt, 1862). Mar. Drugs 2021, 19, 563. [Google Scholar] [CrossRef]

- Carvalho, A.M.; Marques, A.P.; Silva, T.H.; Reis, R.L. Evaluation of the Potential of Collagen from Codfish Skin as a Biomaterial for Biomedical Applications. Mar. Drugs 2018, 16, 495. [Google Scholar] [CrossRef] [PubMed]

- Alves, A.L.; Marques, A.L.P.; Martins, E.; Silva, T.H.; Reis, R.L. Cosmetic Potential of Marine Fish Skin Collagen. Cosmetics 2017, 4, 39. [Google Scholar] [CrossRef]

- Rigogliuso, S.; Campora, S.; Notarbartolo, M.; Ghersi, G. Recovery of Bioactive Compounds from Marine Organisms: Focus on the Future Perspectives for Pharmacological, Biomedical and Regenerative Medicine Applications of Marine Collagen. Molecules 2023, 28, 1152. [Google Scholar] [CrossRef] [PubMed]

- Rajabimashhadi, Z.; Gallo, N.; Salvatore, L.; Lionetto, F. Collagen Derived from Fish Industry Waste: Progresses and Challenges. Polymers 2023, 15, 544. [Google Scholar] [CrossRef] [PubMed]

- Geahchan, S.; Baharlouei, P.; Rahman, A. Marine Collagen: A Promising Biomaterial for Wound Healing, Skin Anti-Aging, and Bone Regeneration. Mar. Drugs 2022, 20, 61. [Google Scholar] [CrossRef]

- Abdullah, J.A.A.; Yemişken, E.; Guerrero, A.; Romero, A. Marine Collagen-Based Antibacterial Film Reinforced with Graphene and Iron Oxide Nanoparticles. Int. J. Mol. Sci. 2022, 24, 648. [Google Scholar] [CrossRef] [PubMed]

- Klüver, E.; Baltzer, M.; Langer, A.; Meyer, M. Additive Manufacturing with Thermoplastic Collagen. Polymers 2022, 14, 974. [Google Scholar] [CrossRef]

- Harussani, M.M.; Sapuan, S.M.; Iyad, M.; Wong, H.K.A.; Farouk, Z.I.; Nazrin, A. Collagen Based Composites Derived from Marine Organisms: As a Solution for the Underutilization of Fish Biomass, Jellyfish and Sponges. In Composites from the Aquatic Environment; Springer Nature: Singapore, 2023; pp. 245–274. ISBN 9789811953262. [Google Scholar]

- Rahman, A.; Silva, T.H. Collagens from Marine Organisms towards Biomedical Applications. Mar. Drugs 2022, 20, 170. [Google Scholar] [CrossRef]

- Rudovica, V.; Rotter, A.; Gaudêncio, S.P.; Novoveská, L.; Akgül, F.; Akslen-Hoel, L.K.; Burlakovs, J. Valorization of Marine Waste: Use of Industrial By-Products and Beach Wrack Towards the Production of High Added-Value Products. Front. Mar. Sci. 2021, 8, 723333. [Google Scholar] [CrossRef]

- Markets andMarkets. Collagen Market by Product Type (Gelatin, Hydrolyzed Collagen, Native Collagen), Application, Source (Bovine, Porcine, Poultry, Marine, and Plant Sources), Form, Type, Extraction Process and Region—Global Forecast to 2030; Research and Markets: Dublin, Ireland, 2023. [Google Scholar]

- Lv, L.-C.; Huang, Q.-Y.; Ding, W.; Xiao, X.-H.; Zhang, H.-Y.; Xiong, L.-X. Fish Gelatin: The Novel Potential Applications. J. Funct. Foods 2019, 63, 103581. [Google Scholar] [CrossRef]

- Ricciotti, F. From Value Chain to Value Network: A Systematic Literature Review. Manag. Rev. Q. 2020, 70, 191–212. [Google Scholar] [CrossRef]

- Lokesh, K.; Ladu, L.; Summerton, L. Bridging the Gaps for a ‘Circular’ Bioeconomy: Selection Criteria, Bio-Based Value Chain and Stakeholder Mapping. Sustain. Sci. Pract. Policy 2018, 10, 1695. [Google Scholar] [CrossRef]

- Mathew, G.M.; Mathew, D.C.; Sukumaran, R.K.; Sindhu, R.; Huang, C.-C.; Binod, P.; Sirohi, R.; Kim, S.-H.; Pandey, A. Sustainable and Eco-Friendly Strategies for Shrimp Shell Valorization. Environ. Pollut. 2020, 267, 115656. [Google Scholar] [CrossRef] [PubMed]

- Newton, R.; Telfer, T.; Little, D. Perspectives on the Utilization of Aquaculture Coproduct in Europe and Asia: Prospects for Value Addition and Improved Resource Efficiency. Crit. Rev. Food Sci. Nutr. 2014, 54, 495–510. [Google Scholar] [CrossRef] [PubMed]

- Nisticò, R. Aquatic-Derived Biomaterials for a Sustainable Future: A European Opportunity. Resources 2017, 6, 65. [Google Scholar] [CrossRef]

- Regenstein, J.M.; Zhou, P. 13—Collagen and Gelatin from Marine by-Products. In Maximising the Value of Marine By-Products; Shahidi, F., Ed.; Woodhead Publishing: Sawston, UK, 2007; pp. 279–303. ISBN 9781845690137. [Google Scholar]

- European Commission. A New Circular Economy Action Plan for a Cleaner and More Competitive Europe; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Ambayeram, V.; Rajulu, G.; Thirunavukkarasu, N.; Suryanarayanan, T.S. Endophytic Fungi of Marine Algae and Seagrasses: A Novel Source of Chitin Modifying Enzymes. Mycosphere 2015, 6, 345–355. [Google Scholar]

- Bradić, B.; Novak, U.; Likozar, B. Crustacean Shell Bio-Refining to Chitin by Natural Deep Eutectic Solvents. Green Process. Synth. 2019, 9, 13–25. [Google Scholar] [CrossRef]

- Bisht, M.; Martins, M.; Dias, A.C.R.V.; Ventura, S.P.M.; Coutinho, J.A.P. Uncovering the Potential of Aqueous Solutions of Deep Eutectic Solvents on the Extraction and Purification of Collagen Type I from Atlantic Codfish (Gadus Morhua). Green Chem. 2021, 23, 8940–8948. [Google Scholar] [CrossRef]

- Carrera, M.; Ezquerra-Brauer, J.M.; Aubourg, S.P. Characterization of the Jumbo Squid (Dosidicus Gigas) Skin By-Product by Shotgun Proteomics and Protein-Based Bioinformatics. Mar. Drugs 2019, 18, 31. [Google Scholar] [CrossRef]

- Blanco, M.; Vázquez, J.A.; Pérez-Martín, R.I.; G Sotelo, C. Collagen Extraction Optimization from the Skin of the Small-Spotted Catshark (S. Canicula) by Response Surface Methodology. Mar. Drugs 2019, 17, 40. [Google Scholar] [CrossRef]

- Benedetto, C.D.; Barbaglio, A.; Martinello, T.; Alongi, V.; Fassini, D.; Cullorà, E.; Patruno, M.; Bonasoro, F.; Barbosa, M.A.; Carnevali, M.D.C.; et al. Production, Characterization and Biocompatibility of Marine Collagen Matrices from an Alternative and Sustainable Source: The Sea Urchin Paracentrotus Lividus. Mar. Drugs 2014, 12, 4912–4933. [Google Scholar] [CrossRef]

- Seixas, M.J.; Martins, E.; Reis, R.L.; Silva, T.H. Extraction and Characterization of Collagen from Elasmobranch Byproducts for Potential Biomaterial Use. Mar. Drugs 2020, 18, 617. [Google Scholar] [CrossRef] [PubMed]

- Bardakova, K.N.; Akopova, T.A.; Kurkov, A.V.; Goncharuk, G.P.; Butnaru, D.V.; Burdukovskii, V.F.; Antoshin, A.A.; Farion, I.A.; Zharikova, T.M.; Shekhter, A.B.; et al. From Aggregates to Porous Three-Dimensional Scaffolds through a Mechanochemical Approach to Design Photosensitive Chitosan Derivatives. Mar. Drugs 2019, 17, 48. [Google Scholar] [CrossRef] [PubMed]

- Batista, M.P.; Fernández, N.; Gaspar, F.B.; do Bronze, M.R.; Duarte, A.R.C. Extraction of Biocompatible Collagen from Blue Shark Skins through the Conventional Extraction Process Intensification Using Natural Deep Eutectic Solvents. Front. Chem. 2022, 10, 937036. [Google Scholar] [CrossRef] [PubMed]

- Miron, A.; Sarbu, A.; Zaharia, A.; Sandu, T.; Iovu, H.; Fierascu, R.C.; Neagu, A.-L.; Chiriac, A.-L.; Iordache, T.-V. A Top-Down Procedure for Synthesizing Calcium Carbonate-Enriched Chitosan from Shrimp Shell Wastes. Gels 2022, 8, 742. [Google Scholar] [CrossRef] [PubMed]

- Huang, C.-Y.; Kuo, C.-H.; Wu, C.-H.; Ku, M.-W.; Chen, P.-W. Extraction of Crude Chitosans from Squid (Illex Argentinus) Pen by a Compressional Puffing-Pretreatment Process and Evaluation of Their Antibacterial Activity. Food Chem. 2018, 254, 217–223. [Google Scholar] [CrossRef] [PubMed]

- Uranga, J.; Etxabide, A.; Cabezudo, S.; de la Caba, K.; Guerrero, P. Valorization of Marine-Derived Biowaste to Develop Chitin/Fish Gelatin Products as Bioactive Carriers and Moisture Scavengers. Sci. Total Environ. 2020, 706, 135747. [Google Scholar] [CrossRef] [PubMed]

- Acharya, P.P.; Kupendra, M.H.; Fasim, A.; More, S.S.; Murthy, V.K. A Comparative Assessment of Collagen Type 1 from Silver Carp (Fresh Water) and Milk Shark (Marine) Fish Waste. 3 Biotech 2022, 12, 82. [Google Scholar] [CrossRef]

- Singh, A.; Benjakul, S.; Prodpran, T. Ultrasound-Assisted Extraction of Chitosan from Squid Pen: Molecular Characterization and Fat Binding Capacity. J. Food Sci. 2019, 84, 224–234. [Google Scholar] [CrossRef]

- Amer, O.A.; Ali, S.S.; Azab, M.; El-Shouny, W.A.; Sun, J.; Mahmoud, Y.A.-G. Exploring New Marine Bacterial Species, Alcaligenes Faecalis Alca F2018 Valued for Bioconversion of Shrimp Chitin to Chitosan for Concomitant Biotechnological Applications. Int. J. Biol. Macromol. 2022, 196, 35–45. [Google Scholar] [CrossRef]

- Tan, Y.N.; Lee, P.P.; Chen, W.N. Microbial Extraction of Chitin from Seafood Waste Using Sugars Derived from Fruit Waste-Stream. AMB Express 2020, 10, 17. [Google Scholar] [CrossRef] [PubMed]

- Thomas, R.; Fukamizo, T.; Suginta, W. Bioeconomic Production of High-Quality Chitobiose from Chitin Food Wastes Using an in-House Chitinase from Vibrio Campbellii. Bioresour. Bioprocess. 2022, 9, 86. [Google Scholar] [CrossRef]

- Chiarelli, P.G.; Pegg, R.B.; Dev Kumar, G.; Mis Solval, K. Exploring the Feasibility of Developing Novel Gelatin Powders from Salted, Dried Cannonball Jellyfish (Stomolophus Meleagris). Food Biosci. 2021, 44, 101397. [Google Scholar] [CrossRef]

- Al-Ali, R.M.; Al-Hilifi, S.A.; Rashed, M.M.A. Fabrication, Characterization, and Anti-free Radical Performance of Edible Packaging-chitosan Film Synthesized from Shrimp Shell Incorporated with Ginger Essential Oil. J. Food Meas. Charact. 2021, 15, 2951–2962. [Google Scholar] [CrossRef]

- El Harmoudi, H.; El Gaini, L.; Daoudi, E.; Rhazi, M.; Boughaleb, Y.; El Mhammedi, M.A.; Migalska-Zalas, A.; Bakasse, M. Removal of 2,4-D from Aqueous Solutions by Adsorption Processes Using Two Biopolymers: Chitin and Chitosan and Their Optical Properties. Opt. Mater. 2014, 36, 1471–1477. [Google Scholar] [CrossRef]

- Akita, M.; Kono, T.; Lloyd, K.; Mitsui, T.; Morioka, K.; Adachi, K. Biochemical Study of Type I Collagen Purified from Skin of Warm Sea Teleost Mahi Mahi (Coryphaena Hippurus), with a Focus on Thermal and Physical Stability. J. Food Biochem. 2019, 43, e13013. [Google Scholar] [CrossRef] [PubMed]

- Wisser, D.; Wisser, F.M.; Raschke, S.; Klein, N.; Leistner, M.; Grothe, J.; Brunner, E.; Kaskel, S. Biological Chitin-MOF Composites with Hierarchical Pore Systems for Air-Filtration Applications. Angew. Chem. Int. Ed. Engl. 2015, 54, 12588–12591. [Google Scholar] [CrossRef]

- Sila, A.; Mlaik, N.; Sayari, N.; Balti, R.; Bougatef, A. Chitin and Chitosan Extracted from Shrimp Waste Using Fish Proteases Aided Process: Efficiency of Chitosan in the Treatment of Unhairing Effluents. J. Polym. Environ. 2014, 22, 78–87. [Google Scholar] [CrossRef]

- Wu, F.C.; Tseng, R.L.; Juang, R.S. Comparative Adsorption of Metal and Dye on Flake- and Bead-Types of Chitosans Prepared from Fishery Wastes. J. Hazard. Mater. 2000, 73, 63–75. [Google Scholar] [CrossRef]

- Magnacca, G.; Guerretta, F.; Vizintin, A.; Benzi, P.; Valsania, M.C.; Nisticò, R. Preparation, Characterization and Environmental/Electrochemical Energy Storage Testing of Low-Cost Biochar from Natural Chitin Obtained via Pyrolysis at Mild Conditions. Appl. Surf. Sci. 2018, 427, 883–893. [Google Scholar] [CrossRef]

- Mushi, N.E.; Kochumalayil, J.; Cervin, N.T.; Zhou, Q.; Berglund, L.A. Nanostructurally Controlled Hydrogel Based on Small-Diameter Native Chitin Nanofibers: Preparation, Structure, and Properties. ChemSusChem 2016, 9, 989–995. [Google Scholar] [CrossRef]

- Sinha, S.; Tripathi, P.; Chand, S. A New Bifunctional Chitosanase Enzyme from Streptomyces sp. and Its Application in Production of Antioxidant Chitooligosaccharides. Appl. Biochem. Biotechnol. 2012, 167, 1029–1039. [Google Scholar] [CrossRef]

- Eulálio, H.Y.C.; Vieira, M.; Fideles, T.B.; Tomás, H.; Silva, S.M.L.; Peniche, C.A.; Fook, M.V.L. Physicochemical Properties and Cell Viability of Shrimp Chitosan Films as Affected by Film Casting Solvents. I-Potential Use as Wound Dressing. Materials 2020, 13, 5005. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Yun, S.; Song, L.; Zhang, Y.; Zhao, Y. The Preparation and Characterization of Chitin and Chitosan under Large-Scale Submerged Fermentation Level Using Shrimp by-Products as Substrate. Int. J. Biol. Macromol. 2017, 96, 334–339. [Google Scholar] [CrossRef]

- Lopes, C.; Antelo, L.T.; Franco-Uría, A.; Alonso, A.A.; Pérez-Martín, R. Chitin Production from Crustacean Biomass: Sustainability Assessment of Chemical and Enzymatic Processes. J. Clean. Prod. 2018, 172, 4140–4151. [Google Scholar] [CrossRef]

- Aboudamia, F.Z.; Kharroubi, M.; Neffa, M.; Aatab, F.; Hanoune, S.; Bouchdoug, M.; Jaouad, A. Potential of Discarded Sardine Scales (Sardina Pilchardus) as Chitosan Sources. J. Air Waste Manag. Assoc. 2020, 70, 1186–1197. [Google Scholar] [CrossRef] [PubMed]

- Guerra, I.C.D.; de Oliveira, P.D.L.; Santos, M.M.F.; Lúcio, A.S.S.C.; Tavares, J.F.; Barbosa-Filho, J.M.; Madruga, M.S.; de Souza, E.L. The Effects of Composite Coatings Containing Chitosan and Mentha (Piperita L. or x Villosa Huds) Essential Oil on Postharvest Mold Occurrence and Quality of Table Grape Cv. Isabella. Innov. Food Sci. Emerg. Technol. 2016, 34, 112–121. [Google Scholar] [CrossRef]

- Mittal, A.; Singh, A.; Aluko, R.E.; Benjakul, S. Pacific White Shrimp (Litopenaeus Vannamei) Shell Chitosan and the Conjugate with Epigallocatechin Gallate: Antioxidative and Antimicrobial Activities. J. Food Biochem. 2021, 45, e13569. [Google Scholar] [CrossRef]

- Do Vale, D.A.; Vieira, C.B.; Vidal, M.F.; Claudino, R.L.; Andrade, F.K.; Sousa, J.R.; de Souza Filho, M.S.M.; da Silva, A.L.C.; de Souza, B.W.S. Chitosan-Based Edible Films Produced from Crab-Uçá (Ucides Cordatus) Waste: Physicochemical, Mechanical and Antimicrobial Properties. J. Polym. Environ. 2021, 29, 694–706. [Google Scholar] [CrossRef]

- Nunes, C.; Maricato, É.; Cunha, Â.; Rocha, M.A.M.; Santos, S.; Ferreira, P.; Silva, M.A.; Rodrigues, A.; Amado, O.; Coimbra, J.; et al. Chitosan–Genipin Film, a Sustainable Methodology for Wine Preservation. Green Chem. 2016, 18, 5331–5341. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Dehghan, A.; Najafpoor, A. Removing Reactive Red 120 and 196 Using Chitosan/Zeolite Composite from Aqueous Solutions: Kinetics, Isotherms, and Process Optimization. J. Ind. Eng. Chem. 2017, 51, 185–195. [Google Scholar] [CrossRef]

- Sun, W.Q.; Payne, G.F.; Moas, M.S.G.L.; Chu, J.H.; Wallace, K.K. Tyrosinase Reaction/Chitosan Adsorption for Removing Phenols from Wastewater. Biotechnol. Prog. 1992, 8, 179–186. [Google Scholar] [CrossRef]

- Rizzi, V.; Gubitosa, J.; Fini, P.; Romita, R.; Nuzzo, S.; Cosma, P. Chitosan Biopolymer from Crab Shell as Recyclable Film to Remove/Recover in Batch Ketoprofen from Water: Understanding the Factors Affecting the Adsorption Process. Materials 2019, 12, 3810. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, M.; Chauhan, D.; Sankararamakrishnan, N. Copper Chitosan Nanocomposite: Synthesis, Characterization, and Application in Removal of Organophosphorous Pesticide from Agricultural Runoff. Environ. Sci. Pollut. Res. Int. 2012, 19, 2055–2062. [Google Scholar] [CrossRef] [PubMed]

- Sun, T.-C.; Yan, B.-Y.; Ning, X.-C.; Tang, Z.-Y.; Hui, C.; Hu, M.-Z.; Ramakrishna, S.; Long, Y.-Z.; Zhang, J. A Nanofiber Hydrogel Derived Entirely from Ocean Biomass for Wound Healing. Nanoscale Adv. 2022, 5, 160–170. [Google Scholar] [CrossRef] [PubMed]

- Babeanu, N.; Radu, N.; Enascuta, C.-E.; Alexandrescu, E.; Ganciarov, M.; Mohammed, M.S.O.; Suica-Bunghez, I.R.; Senin, R.; Ursu, M.; Bostan, M. Obtaining and Characterizing Composite Biomaterials of Animal Resources with Potential Applications in Regenerative Medicine. Polymers 2022, 14, 3544. [Google Scholar] [CrossRef]

- El-Beltagi, H.S.; El-Mahdy, O.M.; Mohamed, H.I.; El-Ansary, A.E. Antioxidants, Antimicrobial, and Anticancer Activities of Purified Chitinase of Talaromyces Funiculosus Strain CBS 129594 Biosynthesized Using Crustacean Bio-Wastes. Agronomy 2022, 12, 2818. [Google Scholar] [CrossRef]

- Rodriguez-Veiga, I.; Acosta, N.; Aranaz, I.; Dobrzycka-Krahel, A. Exploring Saduria Entomon (Crustacea Isopoda) as a New Source for Chitin and Chitosan Isolation. Int. J. Mol. Sci. 2022, 23, 16125. [Google Scholar] [CrossRef]

- Abdullah, N.A.S.; Mohamad, Z. The Effect of Dynamic Vulcanization on the Morphological and Mechanical Properties of the Toughened Poly (Lactic Acid)/Epoxidized Natural Rubber. Malays. J. Fundam. Appl. Sci. 2018, 14, 348–352. [Google Scholar] [CrossRef]

- Balitaan, J.N.I.; Yeh, J.-M.; Santiago, K.S. Marine Waste to a Functional Biomaterial: Green Facile Synthesis of Modified-β-Chitin from Uroteuthis Duvauceli Pens (Gladius). Int. J. Biol. Macromol. 2020, 154, 1565–1575. [Google Scholar] [CrossRef]

- Gallo, N.; Natali, M.L.; Quarta, A.; Gaballo, A.; Terzi, A.; Sibillano, T.; Giannini, C.; De Benedetto, G.E.; Lunetti, P.; Capobianco, L.; et al. Aquaponics-Derived Tilapia Skin Collagen for Biomaterials Development. Polymers 2022, 14, 1865. [Google Scholar] [CrossRef]

- Ahmed, M.; Anand, A.; Verma, A.K.; Patel, R. In-Vitro Self-Assembly and Antioxidant Properties of Collagen Type I from Lutjanus Erythropterus, and Pampus Argenteus Skin. Biocatal. Agric. Biotechnol. 2022, 43, 102412. [Google Scholar] [CrossRef]

- Addad, S.; Exposito, J.-Y.; Faye, C.; Ricard-Blum, S.; Lethias, C. Isolation, Characterization and Biological Evaluation of Jellyfish Collagen for Use in Biomedical Applications. Mar. Drugs 2011, 9, 967–983. [Google Scholar] [CrossRef] [PubMed]

- Tziveleka, L.-A.; Kikionis, S.; Karkatzoulis, L.; Bethanis, K.; Roussis, V.; Ioannou, E. Valorization of Fish Waste: Isolation and Characterization of Acid- and Pepsin-Soluble Collagen from the Scales of Mediterranean Fish and Fabrication of Collagen-Based Nanofibrous Scaffolds. Mar. Drugs 2022, 20, 664. [Google Scholar] [CrossRef] [PubMed]

- Thulasisingh, A.; Venkatesan, S.A.; Kumar, S. Green Biopolysaccharides and Its Utilisation as Biodegradable Material in Diverse Fields: A Review. Polym. Bull. 2023, 1–23. [Google Scholar] [CrossRef]

- Junceda-Mena, I.; García-Junceda, E.; Revuelta, J. From the Problem to the Solution: Chitosan Valorization Cycle. Carbohydr. Polym. 2023, 309, 120674. [Google Scholar] [CrossRef] [PubMed]

- Cahú, T.B.; Santos, S.D.; Mendes, A.; Córdula, C.R.; Chavante, S.F.; Carvalho, L.B.; Nader, H.B.; Bezerra, R.S. Recovery of Protein, Chitin, Carotenoids and Glycosaminoglycans from Pacific White Shrimp (Litopenaeus Vannamei) Processing Waste. Process Biochem. 2012, 47, 570–577. [Google Scholar] [CrossRef]

- Beaney, P.; Lizardi-Mendoza, J.; Healy, M. Comparison of Chitins Produced by Chemical and Bioprocessing Methods. J. Chem. Technol. Biotechnol. 2005, 80, 145–150. [Google Scholar] [CrossRef]

- Coughlin, R.W.; Deshaies, M.R.; Davis, E.M. Chitosan in Crab Shell Wastes Purifies Electroplating Wastewater. Environ. Prog. 1990, 9, 35–39. [Google Scholar] [CrossRef]

- Mauro, M.; Pinto, P.; Settanni, L.; Puccio, V.; Vazzana, M.; Hornsby, B.L.; Fabbrizio, A.; Di Stefano, V.; Barone, G.; Arizza, V. Chitosan Film Functionalized with Grape Seed Oil—Preliminary Evaluation of Antimicrobial Activity. Sustainability 2022, 14, 5410. [Google Scholar] [CrossRef]

- Salazar, R.; Salas-Gomez, V.; Alvarado, A.A.; Baykara, H. Preparation, Characterization and Evaluation of Antibacterial Properties of Polylactide-Polyethylene Glycol-Chitosan Active Composite Films. Polymers 2022, 14, 2266. [Google Scholar] [CrossRef]

- Global Industry Analysts, Inc. Chitin and Chitosan Derivatives: Global Strategic Business Report; Research and Markets: Dublin, Ireland, 2023. [Google Scholar]

- GMI Marine Collagen Market Size. Available online: https://www.gminsights.com/industry-analysis/marine-collagen-market (accessed on 10 November 2023).

- Sultan, F.A.; Routroy, S.; Thakur, M. Understanding Fish Waste Management Using Bibliometric Analysis: A Supply Chain Perspective. Waste Manag. Res. 2023, 41, 531–553. [Google Scholar] [CrossRef] [PubMed]

- Kertmen, A.; Dziedzic, I.; Ehrlich, H. Patentology of Chitinous Biomaterials. Part II: Chitosan. Carbohydr. Polym. 2023, 301, 120224. [Google Scholar] [CrossRef] [PubMed]

- Kertmen, A.; Ehrlich, H. Patentology of Chitinous Biomaterials. Part I: Chitin. Carbohydr. Polym. 2022, 282, 119102. [Google Scholar] [CrossRef] [PubMed]

- Mo, W.Y.; Man, Y.B.; Wong, M.H. Use of Food Waste, Fish Waste and Food Processing Waste for China’s Aquaculture Industry: Needs and Challenge. Sci. Total Environ. 2018, 613–614, 635–643. [Google Scholar] [CrossRef] [PubMed]

- Olden, J.D.; Vitule, J.R.S.; Cucherousset, J.; Kennard, M.J. There’s More to Fish than Just Food: Exploring the Diverse Ways That Fish Contribute to Human Society. Fisheries 2020, 45, 453–464. [Google Scholar] [CrossRef]

- Rathore, V.K.; Parikh, J.K. Chitosan: Derivatives, Properties and Applications. In Proceedings of the Advances in Chemical, Bio and Environmental Engineering, Jalandhar, India, 20–22 August 2021; Springer International Publishing: Berlin/Heidelberg, Germany, 2022; pp. 759–770. [Google Scholar]

- Cooney, R.; de Sousa, D.B.; Fernández-Ríos, A.; Mellett, S.; Rowan, N.; Morse, A.P.; Hayes, M.; Laso, J.; Regueiro, L.; Wan, A.H.L.; et al. A Circular Economy Framework for Seafood Waste Valorisation to Meet Challenges and Opportunities for Intensive Production and Sustainability. J. Clean. Prod. 2023, 392, 136283. [Google Scholar] [CrossRef]

- Maliki, S.; Sharma, G.; Kumar, A.; Moral-Zamorano, M.; Moradi, O.; Baselga, J.; Stadler, F.J.; García-Peñas, A. Chitosan as a Tool for Sustainable Development: A Mini Review. Polymers 2022, 14, 1475. [Google Scholar] [CrossRef]

- Espinales, C.; Romero-Peña, M.; Calderón, G.; Vergara, K.; Cáceres, P.J.; Castillo, P. Collagen, Protein Hydrolysates and Chitin from by-Products of Fish and Shellfish: An Overview. Heliyon 2023, 9, e14937. [Google Scholar] [CrossRef]

- Nawaz, A.; Li, E.; Irshad, S.; Xiong, Z.; Xiong, H.; Shahbaz, H.M.; Siddique, F. Valorization of Fisheries By-Products: Challenges and Technical Concerns to Food Industry. Trends Food Sci. Technol. 2020, 99, 34–43. [Google Scholar] [CrossRef]

- Lucas, N.; Rode, C.V. Marine Waste Derived Chitin Biopolymer for N-Containing Supports, Catalysts and Chemicals. Tetrahedron Green Chem 2023, 2, 100013. [Google Scholar] [CrossRef]

- Nagai, T. Isolation of Collagen from Fish Waste Material—Skin, Bone and Fins. Food Chem. 2000, 68, 277–281. [Google Scholar] [CrossRef]

- Hou, E.-J.; Huang, C.-S.; Lee, Y.-C.; Han, Y.-S.; Chu, H.-T. A Method for the Process of Collagen Modified Polyester from Fish Scales Waste. MethodsX 2022, 9, 101636. [Google Scholar] [CrossRef] [PubMed]

- Joseph, J.; Manigundan, K.; Shamya Arokia Rajan, M.; Radhakrishnan, M.; Gopikrishnan, V.; Kumaran, S.; Thirunavukkarasu, R.; Aruni, W.; Shanmugam, V. Conversion of Aquaculture Waste into Biomedical Wealth: Chitin and Chitosan Journey. Adv. Mater. Sci. Eng. 2022, 2022, 2897179. [Google Scholar] [CrossRef]

- Little, D.C.; Newton, R.W.; Beveridge, M.C.M. Aquaculture: A Rapidly Growing and Significant Source of Sustainable Food? Status, Transitions and Potential. Proc. Nutr. Soc. 2016, 75, 274–286. [Google Scholar] [CrossRef] [PubMed]

- Little, D.C.; Young, J.A.; Zhang, W.; Newton, R.W.; Al Mamun, A.; Murray, F.J. Sustainable Intensification of Aquaculture Value Chains between Asia and Europe: A Framework for Understanding Impacts and Challenges. Aquaculture 2018, 493, 338–354. [Google Scholar] [CrossRef]

- Guran, S. Sustainable Waste-to-Energy Technologies: Gasification and Pyrolysis. In Sustainable Food Waste-to-Energy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 141–158. [Google Scholar]

- Leal, M.C.; Anaya-Rojas, J.M.; Munro, M.H.G.; Blunt, J.W.; Melian, C.J.; Calado, R.; Lürig, M.D. Fifty Years of Capacity Building in the Search for New Marine Natural Products. Proc. Natl. Acad. Sci. USA 2020, 117, 24165–24172. [Google Scholar] [CrossRef] [PubMed]

- Leal, M.C.; Pimentel, T.; Ricardo, F.; Rosa, R.; Calado, R. Seafood Traceability: Current Needs, Available Tools, and Biotechnological Challenges for Origin Certification. Trends Biotechnol. 2015, 33, 331–336. [Google Scholar] [CrossRef]

- Younes, I.; Rinaudo, M. Chitin and Chitosan Preparation from Marine Sources. Structure, Properties and Applications. Mar. Drugs 2015, 13, 1133–1174. [Google Scholar] [CrossRef]

- Jadhav, U.; Pillai, A. Preparation and Comparative Study of Chitosan from Shells of Different Marine and Freshwater Prawns. Biosci. Biotechnol. Res. Asia 2011, 8, 869–872. [Google Scholar] [CrossRef]

- Bedekar, A.N.; Pise, A.C.; Thatte, C.S.; Rathnam, M.V. Study on Optimization of Carboxymethylation of Chitosan Obtained from Squilla Chitin. Asian J. Chem. 2010, 22, 7675–7682. [Google Scholar]

- Silva, R.S.G.; Bandeira, S.F.; Pinto, L.A.A. Characteristics and Chemical Composition of Skins Gelatin from Cobia (Rachycentron Canadum). LWT Food Sci. Technol. 2014, 57, 580–585. [Google Scholar] [CrossRef]

- Nessa, F.; Khan, S.A.; Al Khatib, F.M.A. Production and Characterization of Chitosan from Shrimp (Penaeus Semisulcatus) Shell Waste of UAE. Biol. Sci. PJSIR 2010, 53, 52–58. [Google Scholar]

- Morganti, P. New Horizon in Cosmetic Dermatology. J. Appl. Cosmetol. 2016, 34, 15–24. [Google Scholar]

- Arias-Moscoso, J.L.; Soto-Valdez, H.; Plascencia-Jatomea, M.; Vidal-Quintanar, R.-L.; Rouzaud-Sández, O.; Ezquerra-Brauer, J.M. Composites of Chitosan with Acid-Soluble Collagen from Jumbo Squid (Dosidicus Gigas) by-Products. Polym. Int. 2011, 60, 924–931. [Google Scholar] [CrossRef]

- MMR Bioengineering Technology Market: Evaluation of the Modern Healthcare System to Drive the Market. Available online: https://www.maximizemarketresearch.com/market-report/bioengineering-technology-market/210041/ (accessed on 24 October 2023).

- Gitis, V.; Hankins, N. Water Treatment Chemicals: Trends and Challenges. J. Water Process Eng. 2018, 25, 34–38. [Google Scholar] [CrossRef]

- Ahmed, A.; Hassan, A.; Nour, M. Utilization of Chitosan Extracted from Shrimp Shell Waste in Wastewater Treatment as Low Cost Biosorbent. Egypt. J. Chem. 2020, 64, 981–988. [Google Scholar] [CrossRef]

- Cruz, M.A.; Fernandes, K.R.; Parisi, J.R.; Vale, G.C.A.; Junior, S.R.A.; Freitas, F.R.; Sales, A.F.S.; Fortulan, C.A.; Peitl, O.; Zanotto, E.; et al. Marine Collagen Scaffolds and Photobiomodulation on Bone Healing Process in a Model of Calvaria Defects. J. Bone Miner. Metab. 2020, 38, 639–647. [Google Scholar] [CrossRef]

- Jin, S.; Sun, F.; Zou, Q.; Huang, J.; Zuo, Y.; Li, Y.; Wang, S.; Cheng, L.; Man, Y.; Yang, F.; et al. Fish Collagen and Hydroxyapatite Reinforced Poly(Lactide-Co-Glycolide) Fibrous Membrane for Guided Bone Regeneration. Biomacromolecules 2019, 20, 2058–2067. [Google Scholar] [CrossRef]

- Chen, B.; Yu, L.; Wu, J.; Qiao, K.; Cui, L.; Qu, H.; Su, Y.; Cai, S.; Liu, Z.; Wang, Q. Effects of Collagen Hydrolysate from Large Hybrid Sturgeon on Mitigating Ultraviolet B-Induced Photodamage. Front. Bioeng. Biotechnol. 2022, 10, 908033. [Google Scholar] [CrossRef]

- Business Research Insigths. Pharma & Cosmetics Market Size, Share, Growth, and Industry Analysis, by Type (Ointments, Creams, Gels, and Others), by Application (Pharmaceuticals, OTC, and Cosmetics), COVID-19 Impact, Latest Trends, Segmentation, Driving Factors, Restraining Factors, Key Industry Players, Regional Insights, and Forecast from 2023 To 2030; Business Research Insigths: Pune, India, 2023. [Google Scholar]

- Das, J.; Dey, P.; Chakraborty, T.; Saleem, K.; Nagendra, R.; Banerjee, P. Utilization of Marine Industry Waste Derived Collagen Hydrolysate as Peroxide Inhibition Agents in Lipid-based Food. J. Food Process. Preserv. 2018, 42, e13430. [Google Scholar] [CrossRef]

- Guo, H.; Hong, Z.; Yi, R. Core-Shell Collagen Peptide Chelated Calcium/Calcium Alginate Nanoparticles from Fish Scales for Calcium Supplementation. J. Food Sci. 2015, 80, N1595-601. [Google Scholar] [CrossRef] [PubMed]

- Hajiali, F.; Vidal, J.; Jin, T.; de la Garza, L.C.; Santos, M.; Yang, G.; Moores, A. Extraction of Chitin from Green Crab Shells by Mechanochemistry and Aging. ACS Sustain. Chem. Eng. 2022, 10, 11348–11357. [Google Scholar] [CrossRef]

- Arulmoorthy, M.P.; Anbarasi, G.; Srinivasan, M.; Vishnupriya, B. Biosynthesis and Characterization of Chitosan Based Hydrogel: A Potential in Vitro Wound Healing Agent. Mater. Today Proc. 2022, 48, 263–275. [Google Scholar] [CrossRef]

- McReynolds, C.; Adrien, A.; de Fraissinette, N.B.; Olza, S.; Fernandes, S.C.M. Deep Eutectic Solvents for the Extraction of β-Chitin from Loligo Vulgaris Squid Pens: A Sustainable Way to Valorize Fishery by-Products. Biomass Convers. Biorefin. 2022, 1–13. [Google Scholar] [CrossRef]

- Jabeur, F.; Mechri, S.; Mensi, F.; Gharbi, I.; Naser, Y.B.; Kriaa, M.; Bejaoui, N.; Bachouche, S.; Badis, A.; Annane, R.; et al. Extraction and Characterization of Chitin, Chitosan, and Protein Hydrolysate from the Invasive Pacific Blue Crab, Portunus Segnis (Forskål, 1775) Having Potential Biological Activities. Environ. Sci. Pollut. Res. 2022, 29, 36023–36039. [Google Scholar] [CrossRef] [PubMed]

- Anouar, A.; Grirrane, A.; Álvarez, E.; Katir, N.; Primo, A.; Garcia, H.; El Kadib, A. Nanosized Copper Stabilized on Ternary P, N, S-Doped Graphene from Chitosan Shellfish Waste: Preparation and Catalysis of Single and Double A3-Type Amine Coupling. Mater. Today Sustain. 2022, 18, 100109. [Google Scholar] [CrossRef]

- Casanova, F.; Mohammadifar, M.A.; Jahromi, M.; Petersen, H.O.; Sloth, J.J.; Eybye, K.L.; Kobbelgaard, S.; Jakobsen, G.; Jessen, F. Physico-Chemical, Structural and Techno-Functional Properties of Gelatin from Saithe (Pollachius Virens) Skin. Int. J. Biol. Macromol. 2020, 156, 918–927. [Google Scholar] [CrossRef]

- De Wit-de Vries, E.; Dolfsma, W.A.; van der Windt, H.J.; Gerkema, M.P. Knowledge Transfer in University–Industry Research Partnerships: A Review. J. Technol. Transf. 2019, 44, 1236–1255. [Google Scholar] [CrossRef]

- Fletcher, C.A.; Niemenoja, K.; Hunt, R.; Adams, J.; Dempsey, A.; Banks, C.E. Addressing Stakeholder Concerns Regarding the Effective Use of Bio-Based and Biodegradable Plastics. Resources 2021, 10, 95. [Google Scholar] [CrossRef]

- Mohmood, H.; Tamyez, P.F.M. Researchers’ Motivation, Interaction Channels, and Strategies towards University-Industry Collaboration: A Case Study Approach. Int. J. Ind. Manag. 2022, 15, 17–25. [Google Scholar] [CrossRef]

- Grzegorczyk, M.A. The Role of Marketing in the Technology Transfer Process. In Marketing in University-Industry Technological Collaboration; Springer International Publishing: Cham, Switzerland, 2021; pp. 13–42. [Google Scholar]

- Kettunen, P.; Järvinen, J.; Mikkonen, T.; Männistö, T. Energizing Collaborative Industry-Academia Learning: A Present Case and Future Visions. Eur. J. Futures Res. 2022, 10, 8. [Google Scholar] [CrossRef]

- Singh, S.; Kaundal, B. Academia-Industry Linkages: Theoretical and Empirical Review Article. World J. Adv. Res. Rev. 2022, 15, 104–115. [Google Scholar] [CrossRef]

- Delannoy, J.-Y.P. Effective Industry-Academia Collaboration Driving Polymer Innovation. ACS Polym. Au 2022, 2, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Duasa, J.; Muhamad, H.A.; Mohamed, A.M.T.; Puspa, R.M. An Alternative Source of Collagen for Muslim Consumers: Halal and Environmental Concerns. J. Islam. Mark. 2021, 13, 2232–2253. [Google Scholar] [CrossRef]

- Susanto, A.; Satari, M.H.; Abbas, B.; Koesoemowidodo, R.S.A.; Cahyanto, A. Fabrication and Characterization of Chitosan-Collagen Membrane from Barramundi (Lates Calcarifer) Scales for Guided Tissue Regeneration. Eur. J. Dent. 2019, 13, 370–375. [Google Scholar] [CrossRef] [PubMed]

- Azaza, Y.B.; Van der lee, A.; Li, S.; Nasri, M.; Nasri, R. Chitosan/Collagen-Based Hydrogels for Sustainable Development: Phycocyanin Controlled Release. Sustain. Chem. Pharm. 2023, 31, 100905. [Google Scholar] [CrossRef]

- Aguirre-Cruz, G.; León-López, A.; Cruz-Gómez, V.; Jiménez-Alvarado, R.; Aguirre-Álvarez, G. Collagen Hydrolysates for Skin Protection: Oral Administration and Topical Formulation. Antioxidants 2020, 9, 181. [Google Scholar] [CrossRef]

- Altintzoglou, T.; Heide, M. Identifying Consumer Openness to New Ingredients: A Conjoint Study on Consumer Segments in the UK. Front. Aquac. 2023, 2, 1037014. [Google Scholar] [CrossRef]

- Buscaglia, M.; Guérard, F.; Roquefort, P.; Aubry, T.; Fauchon, M.; Toueix, Y.; Stiger-Pouvreau, V.; Hellio, C.; Le Blay, G. Mechanically Enhanced Salmo Salar Gelatin by Enzymatic Cross-Linking: Premise of a Bioinspired Material for Food Packaging, Cosmetics, and Biomedical Applications. Mar. Biotechnol. 2022, 24, 801–819. [Google Scholar] [CrossRef]

- Águila-Almanza, E.; Low, S.S.; Hernández-Cocoletzi, H.; Atonal-Sandoval, A.; Rubio-Rosas, E.; Violante-González, J.; Show, P.L. Facile and Green Approach in Managing Sand Crab Carapace Biowaste for Obtention of High Deacetylation Percentage Chitosan. J. Environ. Chem. Eng. 2021, 9, 105229. [Google Scholar] [CrossRef]

- Duan, B.; Huang, Y.; Lu, A.; Zhang, L. Recent Advances in Chitin Based Materials Constructed via Physical Methods. Prog. Polym. Sci. 2018, 82, 1–33. [Google Scholar] [CrossRef]

- Caruso, G.; Floris, R.; Serangeli, C.; Di Paola, L. Fishery Wastes as a Yet Undiscovered Treasure from the Sea: Biomolecules Sources, Extraction Methods and Valorization. Mar. Drugs 2020, 18, 622. [Google Scholar] [CrossRef] [PubMed]

- Ozogul, F.; Cagalj, M.; Šimat, V.; Ozogul, Y.; Tkaczewska, J.; Hassoun, A.; Kaddour, A.A.; Kuley, E.; Rathod, N.B.; Phadke, G.G. Recent Developments in Valorisation of Bioactive Ingredients in Discard/Seafood Processing by-Products. Trends Food Sci. Technol. 2021, 116, 559–582. [Google Scholar] [CrossRef]

- Zuorro, A.; Moreno-Sader, K.A.; González-Delgado, Á.D. Evaluating the Feasibility of a Pilot-Scale Shrimp Biorefinery via Techno-Economic Analysis. J. Clean. Prod. 2021, 320, 128740. [Google Scholar] [CrossRef]

- Aman, Z.; Mallick, S.; Nemlioglu, I. Currency Regimes and External Competitiveness: The Role of Institutions, Trade Agreements and Monetary Frameworks. J. Institutional Econ. 2022, 18, 399–428. [Google Scholar] [CrossRef]

- Kamakura, W.A.; Du, R.Y. How Economic Contractions and Expansions Affect Expenditure Patterns. J. Consum. Res. 2011, 39, 229–247. [Google Scholar] [CrossRef]

- Xu, S.; Zhao, Y.; Song, W.; Zhang, C.; Wang, Q.; Li, R.; Shen, Y.; Gong, S.; Li, M.; Sun, L. Improving the Sustainability of Processing By-Products: Extraction and Recent Biological Activities of Collagen Peptides. Foods 2023, 12, 1965. [Google Scholar] [CrossRef]

- Daszkiewicz, T. Food Production in the Context of Global Developmental Challenges. Collect. FAO Agric. 2022, 12, 832. [Google Scholar] [CrossRef]

- Liu, J.-K. Antiaging Agents: Safe Interventions to Slow Aging and Healthy Life Span Extension. Nat. Prod. Bioprospect. 2022, 12, 18. [Google Scholar] [CrossRef]

- Martins, E.; Diogo, G.S.; Pires, R.; Reis, R.L.; Silva, T.H. 3D Biocomposites Comprising Marine Collagen and Silica-Based Materials Inspired on the Composition of Marine Sponge Skeletons Envisaging Bone Tissue Regeneration. Mar. Drugs 2022, 20, 718. [Google Scholar] [CrossRef]

- Talukder, B.; Ganguli, N.; Matthew, R.; vanLoon, G.W.; Hipel, K.W.; Orbinski, J. Climate Change-Accelerated Ocean Biodiversity Loss & Associated Planetary Health Impacts. J. Clim. Chang. Health 2022, 6, 100114. [Google Scholar]

- Lee, S.-J.; Mamun, M.; Atique, U.; An, K.-G. Fish Tissue Contamination with Organic Pollutants and Heavy Metals: Link between Land Use and Ecological Health. Water 2023, 15, 1845. [Google Scholar] [CrossRef]

- Cai, W.; Ye, P. How Does Environmental Regulation Influence Enterprises’ Total Factor Productivity? A Quasi-Natural Experiment Based on China’s New Environmental Protection Law. J. Clean. Prod. 2020, 276, 124105. [Google Scholar] [CrossRef]

- CBD Convention on Biological Diversity. Available online: https://www.cbd.int/doc/legal/cbd-en.pdf (accessed on 10 November 2023).

- OSPAR OSPAR Convention. Available online: https://www.ospar.org/site/assets/files/1169/ospar_convention.pdf (accessed on 10 November 2023).

- EC Marine Strategy Framework Directive (Directive 2008/56/EC). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32008L0056 (accessed on 10 November 2023).

- EC European Circular Bioeconomy Policy Initiative. Available online: https://ecbpi.eu/wp-content/uploads/2021/02/ECBPI-manifesto.pdf (accessed on 10 November 2023).

- EC Green Deal. Available online: https://cor.europa.eu/en/engage/studies/Documents/European%20Green%20Deal%20Handbook.pdf (accessed on 10 November 2023).

- EPO Unitary Patent. Available online: https://www.epo.org/en/applying/european/unitary/unitary-patent (accessed on 10 November 2023).

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G. PRISMA Group Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vieira, H.; Lestre, G.M.; Solstad, R.G.; Cabral, A.E.; Botelho, A.; Helbig, C.; Coppola, D.; de Pascale, D.; Robbens, J.; Raes, K.; et al. Current and Expected Trends for the Marine Chitin/Chitosan and Collagen Value Chains. Mar. Drugs 2023, 21, 605. https://doi.org/10.3390/md21120605

Vieira H, Lestre GM, Solstad RG, Cabral AE, Botelho A, Helbig C, Coppola D, de Pascale D, Robbens J, Raes K, et al. Current and Expected Trends for the Marine Chitin/Chitosan and Collagen Value Chains. Marine Drugs. 2023; 21(12):605. https://doi.org/10.3390/md21120605

Chicago/Turabian StyleVieira, Helena, Gonçalo Moura Lestre, Runar Gjerp Solstad, Ana Elisa Cabral, Anabela Botelho, Carlos Helbig, Daniela Coppola, Donatella de Pascale, Johan Robbens, Katleen Raes, and et al. 2023. "Current and Expected Trends for the Marine Chitin/Chitosan and Collagen Value Chains" Marine Drugs 21, no. 12: 605. https://doi.org/10.3390/md21120605

APA StyleVieira, H., Lestre, G. M., Solstad, R. G., Cabral, A. E., Botelho, A., Helbig, C., Coppola, D., de Pascale, D., Robbens, J., Raes, K., Lian, K., Tsirtsidou, K., Leal, M. C., Scheers, N., Calado, R., Corticeiro, S., Rasche, S., Altintzoglou, T., Zou, Y., & Lillebø, A. I. (2023). Current and Expected Trends for the Marine Chitin/Chitosan and Collagen Value Chains. Marine Drugs, 21(12), 605. https://doi.org/10.3390/md21120605