Simple Calibration of Three-Axis Accelerometers with Freely Rotating Vertical Bench

Abstract

1. Introduction

- Owing to the use of a vertical rotation plane, the calibration problem is fully determined in the present approach. In contrast, the method in [16] involves an underdetermined problem that requires the user to perform a manual measurement prior to calibration. In this work, no preliminary measurements are necessary; all parameters are identified directly through the calibration process.

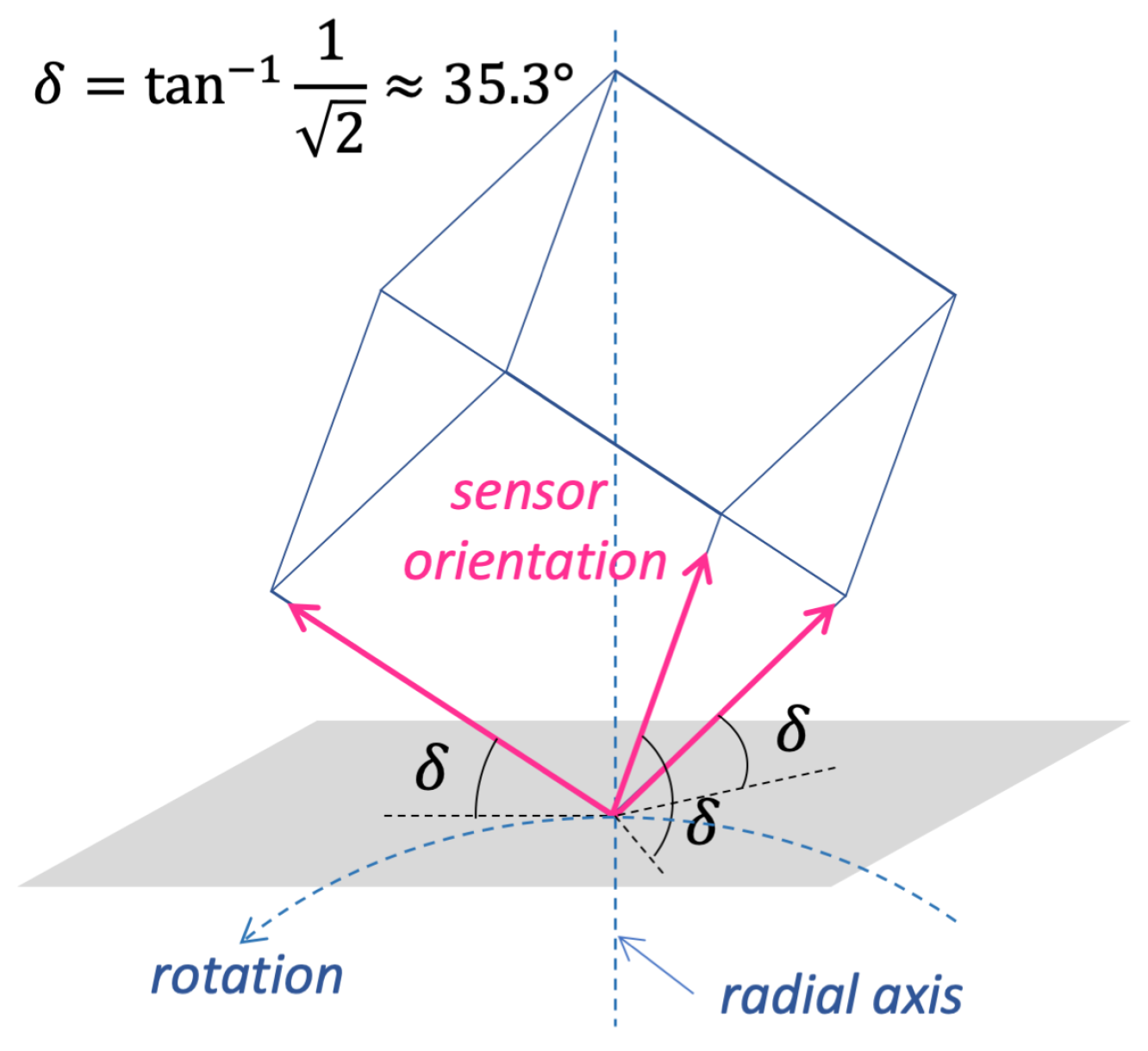

- The vertical rotation plane also allows us to address the problem of the optimal orientation with which the sensor should be positioned on the calibration bench. The analysis (in Section 3.2) leads to the proposal of a ‘good orientation’ that guarantees a valid and steady signal/noise ratio along all three axes.

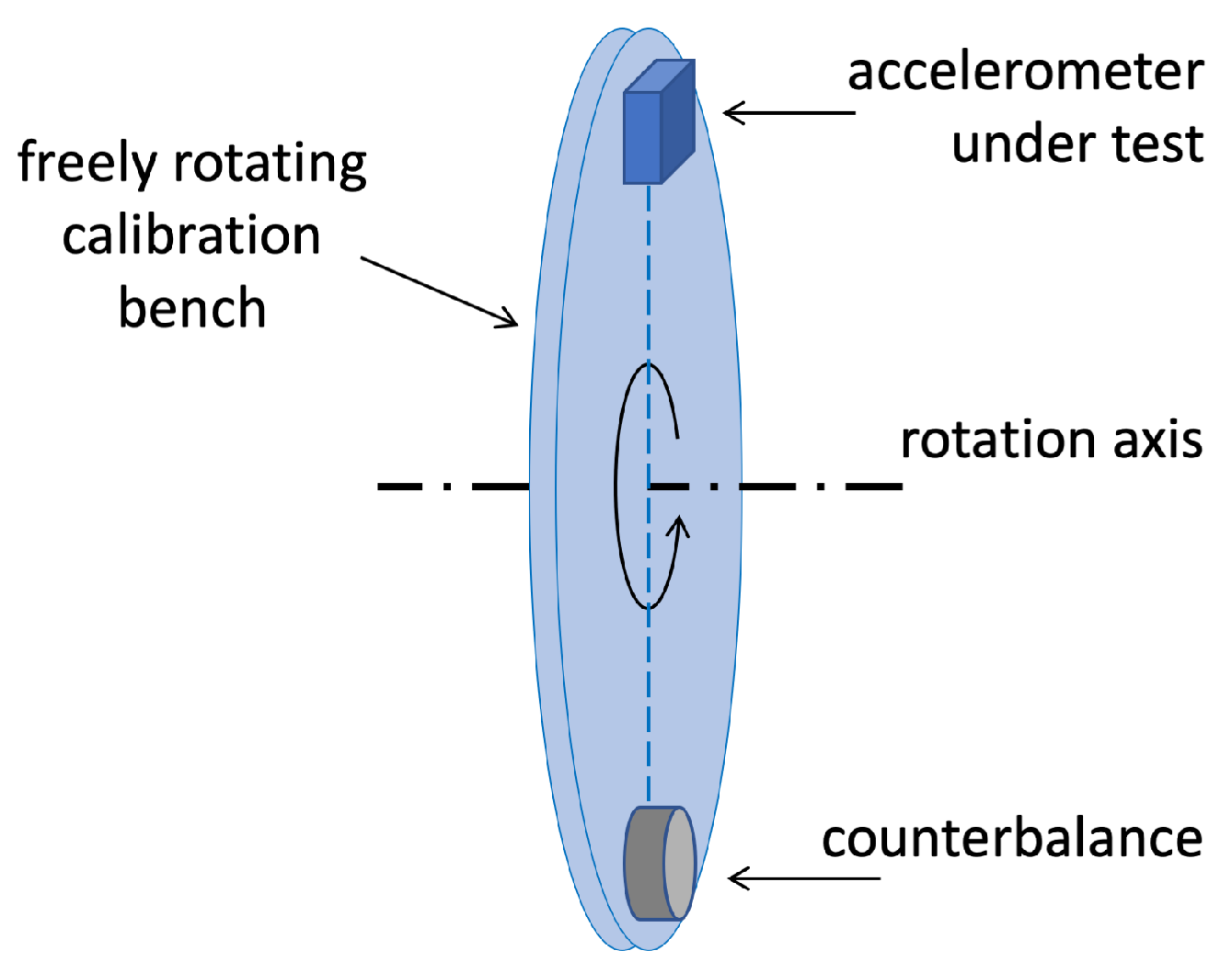

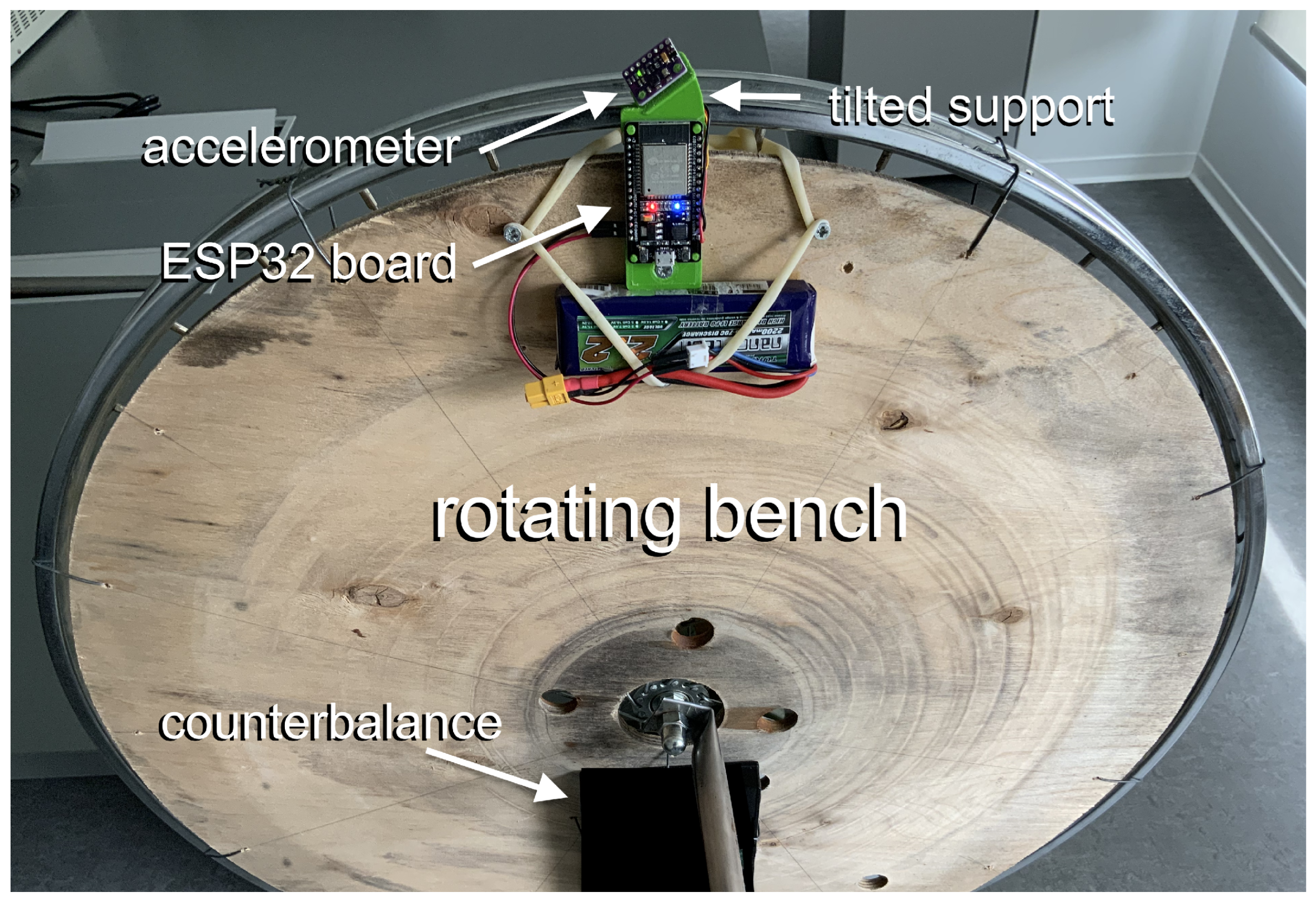

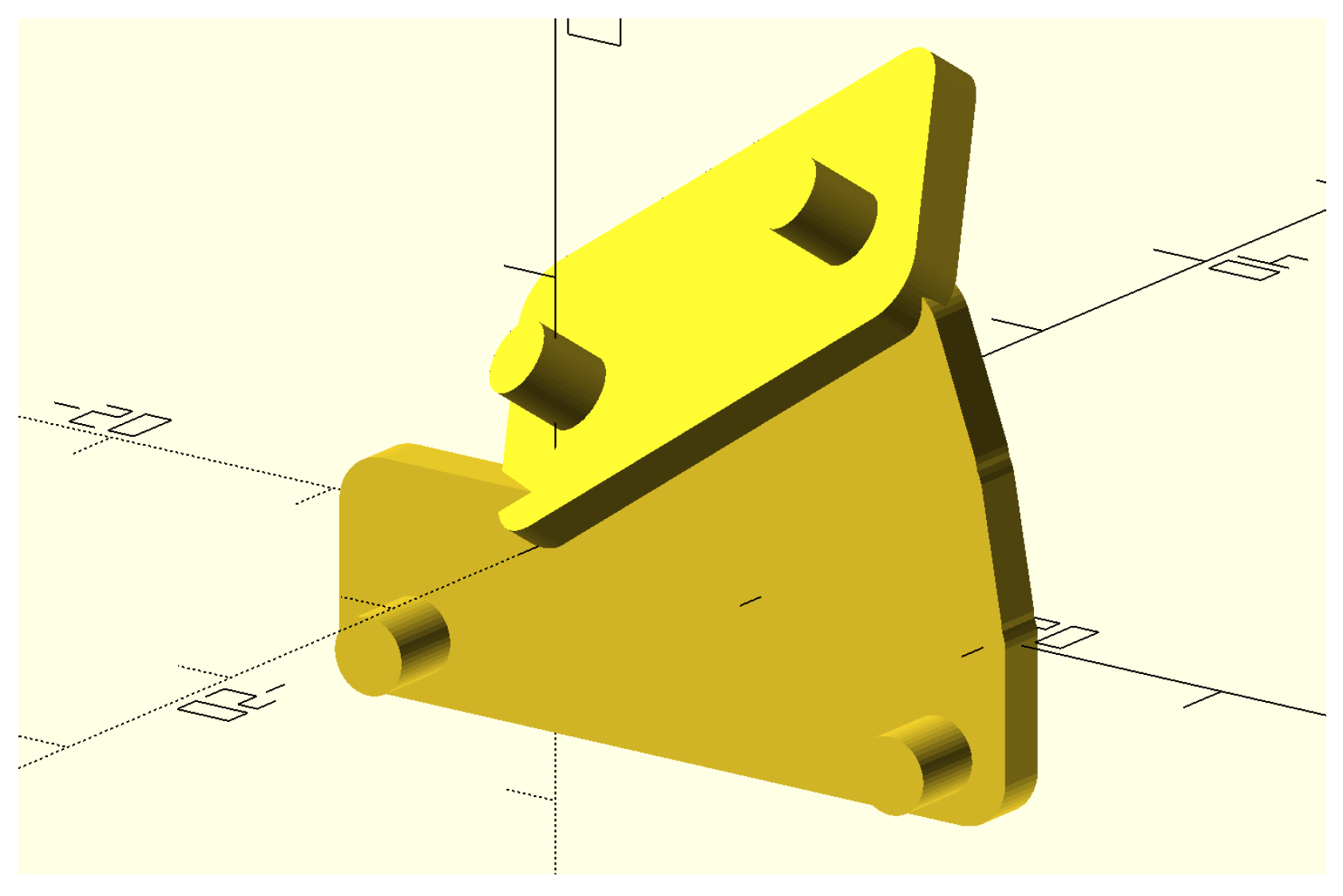

2. The Vertical Bench Setup

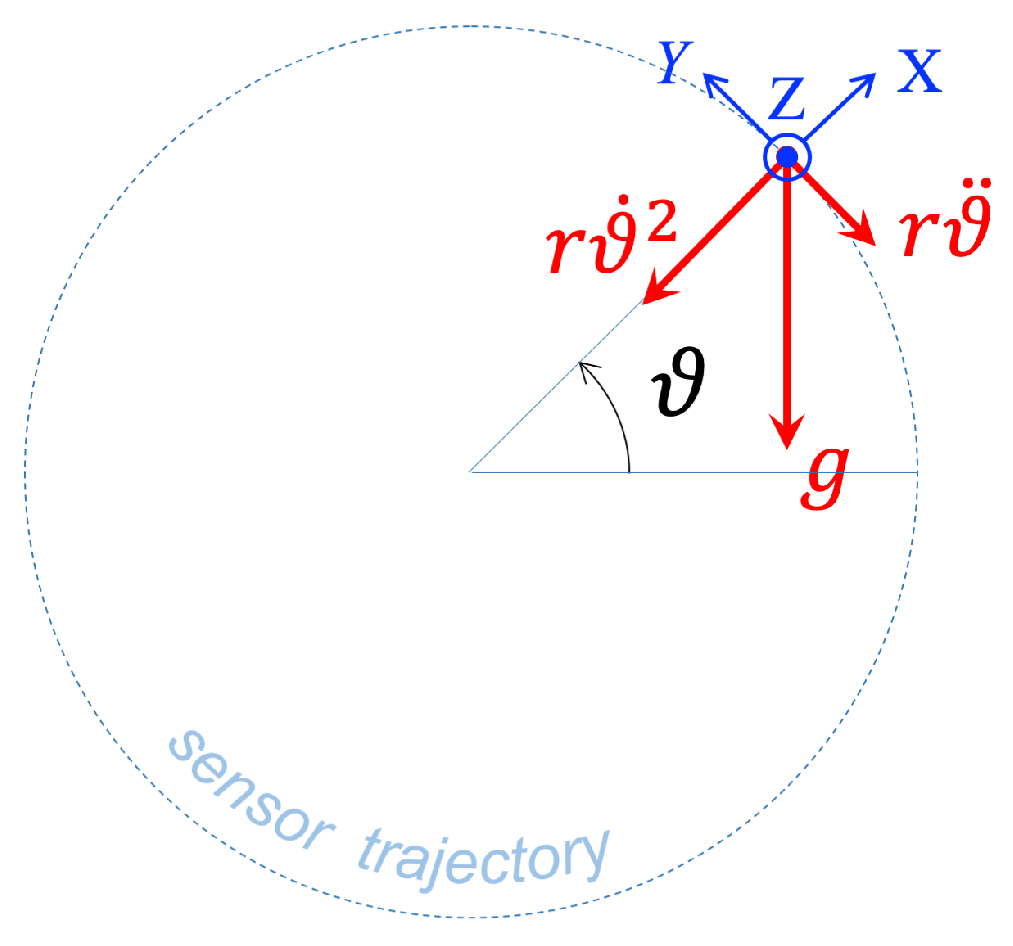

2.1. Basic Acceleration Model

- Gravity g, directed downwards;

- Centripetal acceleration , directed toward the center of rotation;

- Angular (tangential) acceleration , tangent to the circular trajectory.

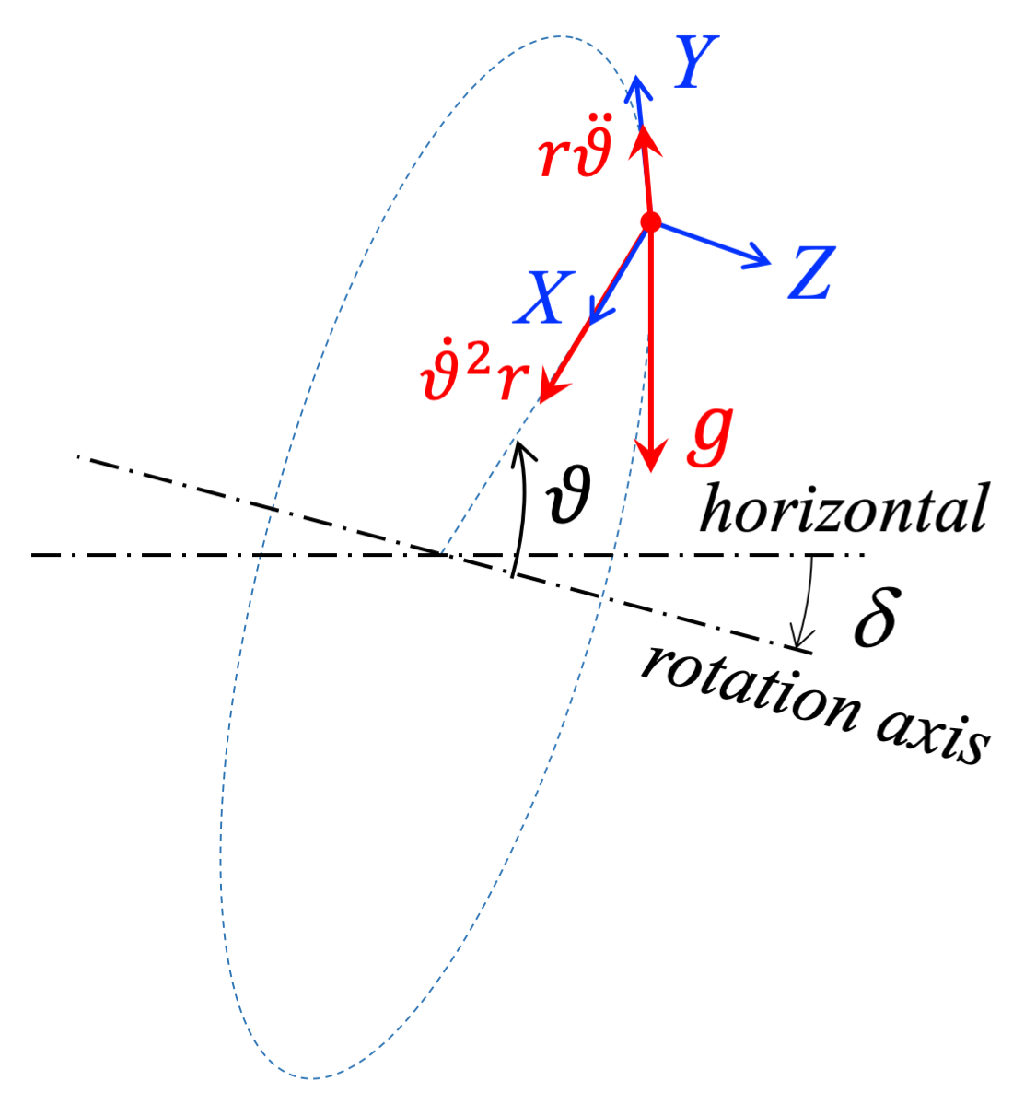

2.2. Verticality Assumption

- is definitely negligible in and , as its effect would only become observable beyond the sixth decimal place, which is well below the sensitivity of any MEMS accelerometer. Consequently, .

3. The Dynamic Calibration Model

3.1. Modeling the Rotation Speed

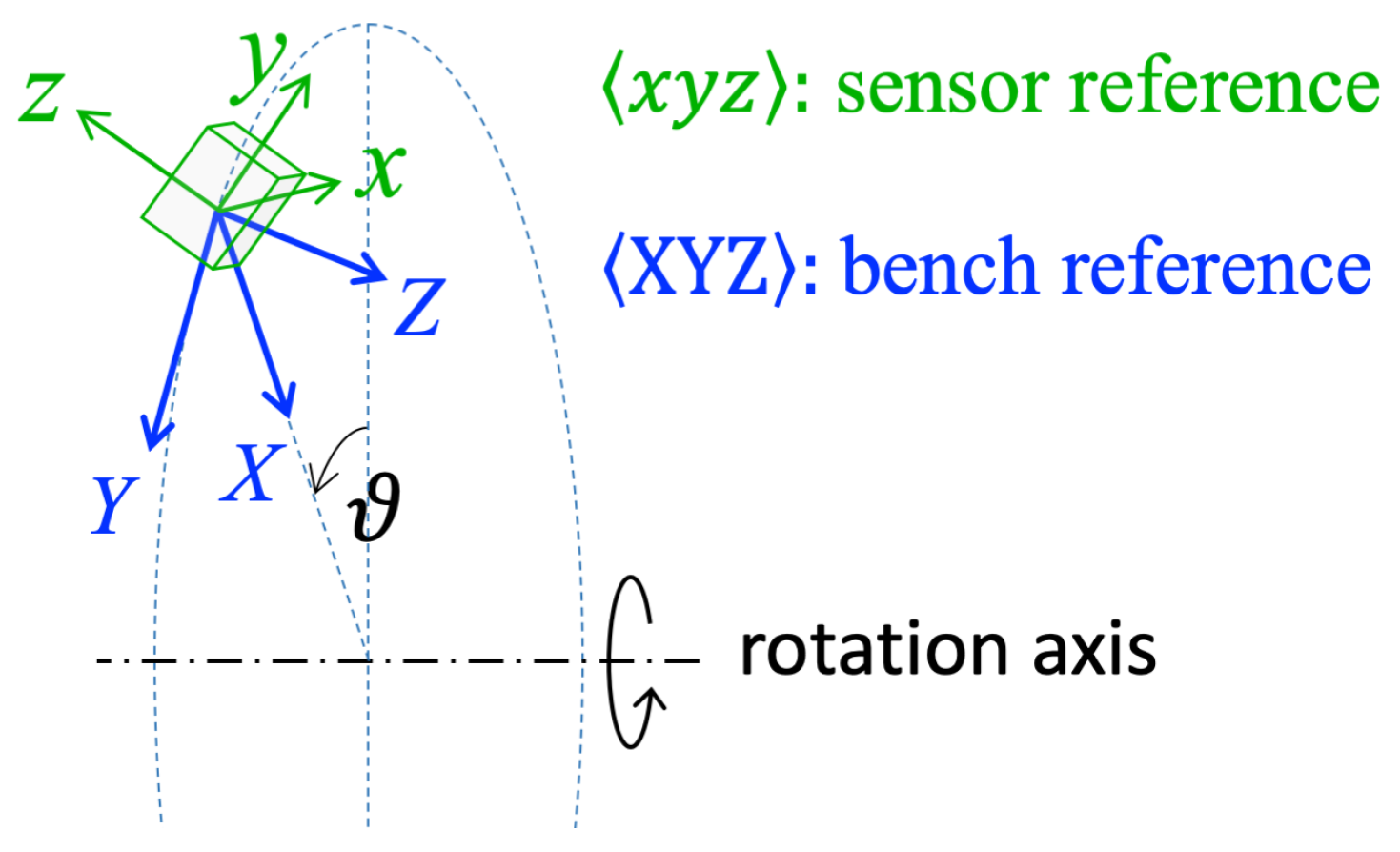

3.2. Sensor Orientation

A ‘Good’ Sensor Orientation

3.3. The Accelerometer Model

- is the output acceleration, as generated by the sensor under test.

- is the sensed acceleration, that is, the actual acceleration applied along the sensing axes .

- and are the accelerometer offset and gain.

3.4. The Calibration Problem

Problem Determinability

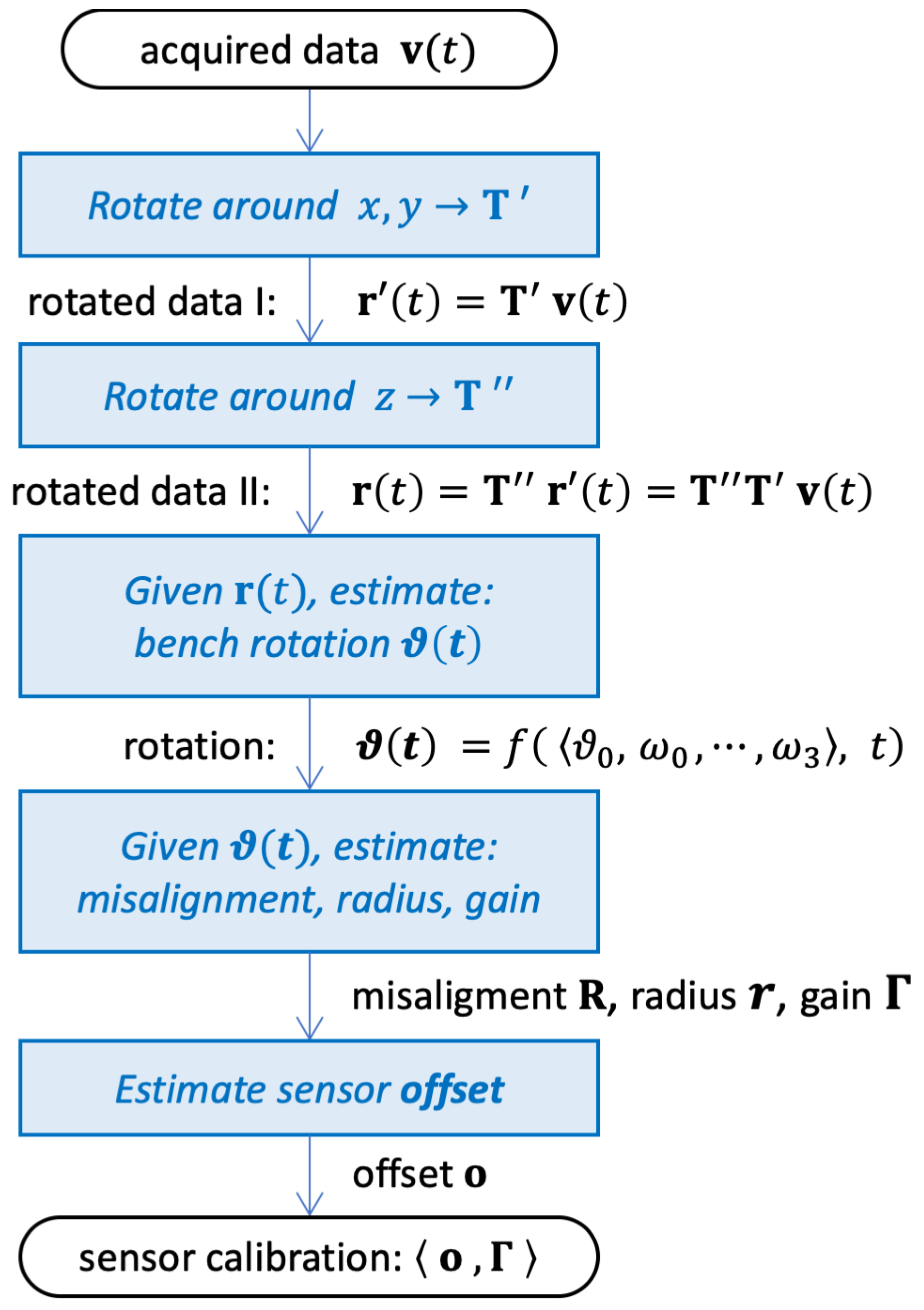

4. The Calibration Algorithm

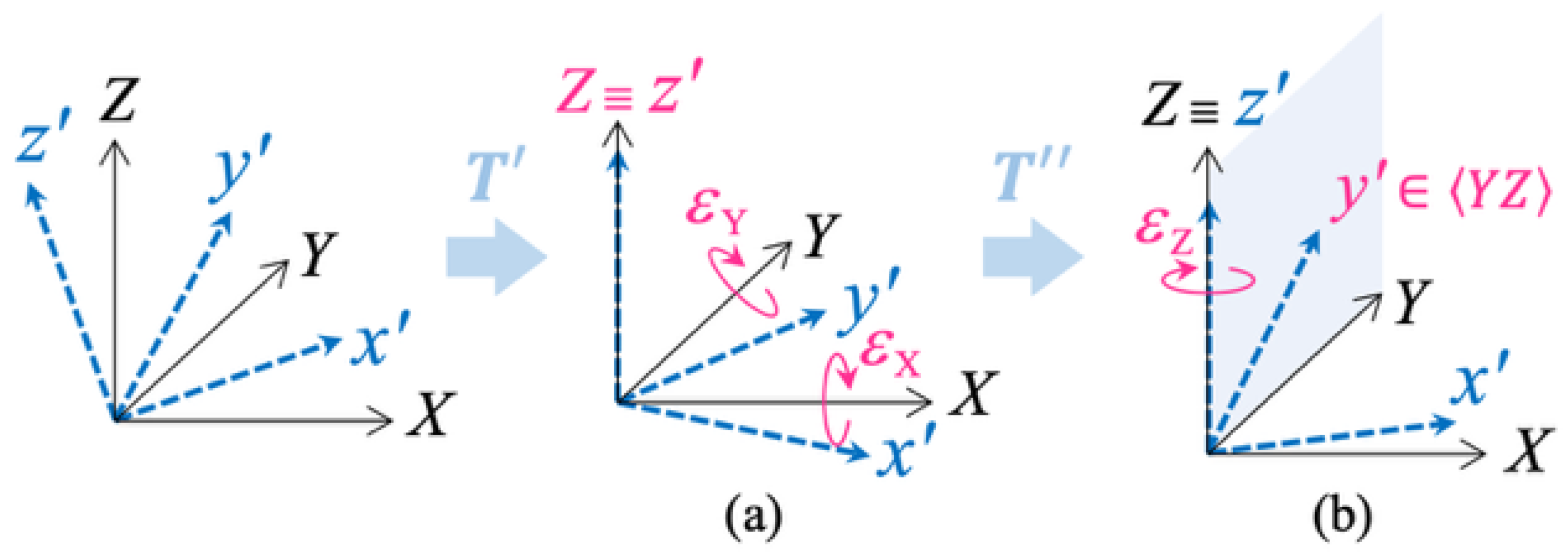

4.1. Partial Alignment

- Apply first a rotation around X and Y that aligns to Z, thus making and .

- Apply then a rotation around that brings the axis into the plane, thus making .

Estimation of and

4.2. Estimation of the Angular Velocity

4.3. Estimating Misalignment, Gain, and Radius

4.4. Estimation of the Offset

5. Results

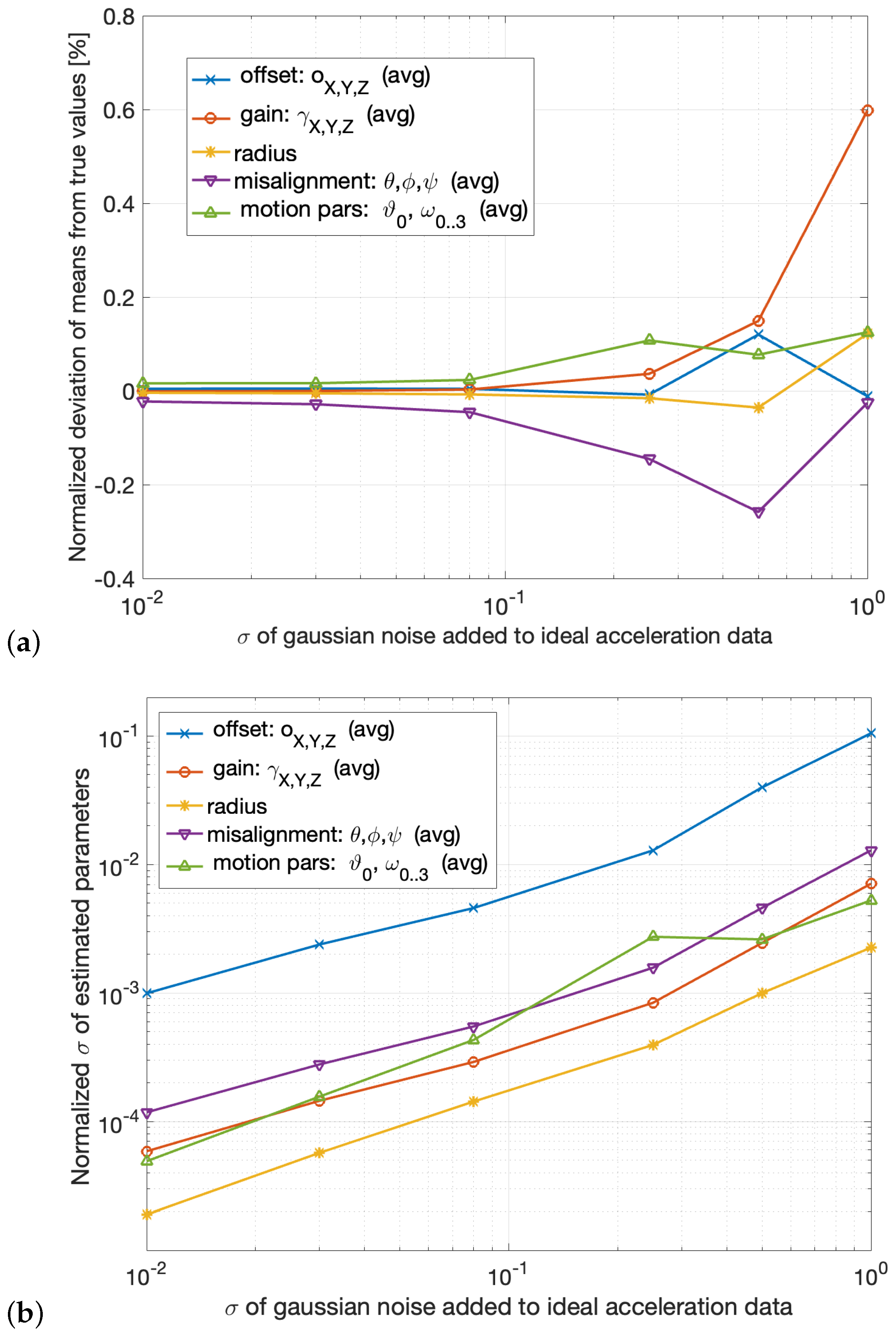

5.1. Measuring Accuracy and Precision with Synthetic Data

- Sensor offset (mean of x, y, and z components);

- Sensor gain (mean of x, y, and z components);

- Rotation radius;

- Misalignment (mean of the three Euler angles);

- Motion parameters (mean of the five components).

- The standard deviation of all parameters increases roughly proportionally to the data noise across the entire range, without signs of divergence. This behavior indicates that the estimation method remains robust even under noise levels well above those commonly encountered in MEMS accelerometers.

- The estimation of the rotation radius r exhibits the lowest standard deviation, supporting the validity of the choice to estimate the radius through calibration in the proposed setup.

- The precision in the estimation of the sensor’s gain is one order of magnitude higher than that of the sensor’s offset across the entire noise range.

5.2. Performance Assessment on a Real Sensor

5.3. Precision Assessment

Evaluation of the Noise Sources

- The sensor noise, including all the noise sources originated by the sensor itself.

- The bench noise, including the noise sources due to all mechanical non-idealities (such as friction irregularities and clearances in the ball bearings, vibration of the supports, etc.) that give rise to undesired and unpredictable deviations from the ideal acceleration defined by the dynamical model (1).

- The proposed method is capable of achieving accurate parameter estimation even under relatively noisy conditions.

- Nonetheless, improving the mechanical quality of the setup—while maintaining its low-cost nature—could further reduce the bench noise and thereby enhance significantly the calibration accuracy.

6. Conclusions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zihajehzadeh, S.; Loh, D.; Lee, T.J.; Hoskinson, R.; Park, E.J. A cascaded Kalman filter-based GPS/MEMS-IMU integration for sports applications. Measurement 2015, 73, 200–210. [Google Scholar] [CrossRef]

- Frosio, I.; Pedersini, F.; Borghese, N.A. Autocalibration of MEMS Accelerometers. IEEE Trans. Instrum. Meas. 2009, 58, 2034–2041. [Google Scholar] [CrossRef]

- Ang, W.T.; Khosla, P.K.; Riviere, C.N. Nonlinear Regression Model of aLow-g MEMS Accelerometer. IEEE Sens. J. 2007, 7, 81–88. [Google Scholar] [CrossRef]

- Frosio, I.; Pedersini, F.; Borghese, N.A. Autocalibration of Triaxial MEMS Accelerometers With Automatic Sensor Model Selection. IEEE Sens. J. 2012, 12, 2100–2108. [Google Scholar] [CrossRef]

- Tan, C.W.; Park, S. Design of accelerometer-based inertial navigation systems. IEEE Trans. Instrum. Meas. 2005, 54, 2520–2530. [Google Scholar] [CrossRef]

- Zhang, M.; Yan, S.; Deng, Z.; Chen, P.; Li, Z.; Fan, J.; Liu, H.; Liu, J.; Tu, L. Cross-Coupling Coefficient Estimation of a Nano-g Accelerometer by Continuous Rotation Modulation on a Tilted Rate Table. IEEE Trans. Instrum. Meas. 2021, 70, 1–12. [Google Scholar] [CrossRef]

- García, J.A.; Lara, E.; Aguilar, L. A Low-Cost Calibration Method for Low-Cost MEMS Accelerometers Based on 3D Printing. Sensors 2020, 20, 6454. [Google Scholar] [CrossRef] [PubMed]

- Särkkä, O.; Nieminen, T.; Suuriniemi, S.; Kettunen, L. A Multi-Position Calibration Method for Consumer-Grade Accelerometers, Gyroscopes, and Magnetometers to Field Conditions. IEEE Sens. J. 2017, 17, 3470–3481. [Google Scholar] [CrossRef]

- Won, S.h.P.; Golnaraghi, F. A Triaxial Accelerometer Calibration Method Using a Mathematical Model. IEEE Trans. Instrum. Meas. 2010, 59, 2144–2153. [Google Scholar] [CrossRef]

- Glueck, M.; Oshinubi, D.; Schopp, P.; Manoli, Y. Real-Time Autocalibration of MEMS Accelerometers. IEEE Trans. Instrum. Meas. 2014, 63, 96–105. [Google Scholar] [CrossRef]

- Lee, D.; Lee, S.; Park, S.; Ko, S. Test and error parameter estimation for MEMS—based low cost IMU calibration. Int. J. Precis. Eng. Manuf. 2011, 12, 597–603. [Google Scholar] [CrossRef]

- Asadi, A.A.; Homaeinezhad, M.R.; Arefnezhad, S.; Safaeifar, A.; Zoghi, M. Designing a 2-DOF passive mechanism for dynamical calibration of MEMS-based motion sensors. In Proceedings of the 2014 Second RSI/ISM International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 15–17 October 2014; pp. 256–261. [Google Scholar] [CrossRef]

- Zhang, R.; Hoflinger, F.; Reind, L.M. Calibration of an IMU Using 3-D Rotation Platform. IEEE Sens. J. 2014, 14, 1778–1787. [Google Scholar] [CrossRef]

- Emel’yantsev, G.I.; Blazhnov, B.A.; Dranitsyna, E.V.; Stepanov, A.P. Calibration of a precision SINS IMU and construction of IMU-bound orthogonal frame. Gyroscopy Navig. 2016, 7, 205–213. [Google Scholar] [CrossRef]

- Vyalkov, A.V.; Vyalkova, T.P. Calibration of IMU MEMS Sensors with the Use of a Manual Calibration Test Rig. Gyroscopy Navig. 2023, 14, 113–128. [Google Scholar] [CrossRef]

- Pedersini, F. Dynamic Calibration of Triaxial Accelerometers With Simple Setup. IEEE Sens. J. 2022, 22, 9665–9674. [Google Scholar] [CrossRef]

- ADXL317 Data Sheet. 2019. Available online: https://www.analog.com/media/en/technical-documentation/data-sheets/ADXL317.pdf (accessed on 17 June 2025).

- MPU-9250 Product Specification, 2016. PS-MPU-9250A-01, Rev. 1.1. Available online: https://invensense.tdk.com/download-pdf/mpu-9250-datasheet (accessed on 17 June 2025).

- Penrose, R. On best approximate solutions of linear matrix equations. Math. Proc. Camb. Philos. Soc. 1956, 52, 17–19. [Google Scholar] [CrossRef]

- Lagarias, J.C.; Reeds, J.A.; Wright, M.H.; Wright, P.E. Convergence Properties of the Nelder–Mead Simplex Method in Low Dimensions. Siam J. Optim. 1998, 9, 112–147. [Google Scholar] [CrossRef]

- Pavese, F. Replicated observations in metrology and testing: Modelling repeated and non-repeated measurements. Accredit. Qual. Assur. 2007, 12, 525–534. [Google Scholar] [CrossRef]

- ESP32 WROOM 32UE Datasheet. Version 1.2. 2021. Available online: https://www.espressif.com/en/support/documents/technical-documents (accessed on 17 June 2025).

| Parameter | Mean | Std. Deviation | |

|---|---|---|---|

| Radius [mm] | r | ||

| Misalignment | |||

| Gain | |||

| Offset [m/s2] | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pedersini, F. Simple Calibration of Three-Axis Accelerometers with Freely Rotating Vertical Bench. Sensors 2025, 25, 3998. https://doi.org/10.3390/s25133998

Pedersini F. Simple Calibration of Three-Axis Accelerometers with Freely Rotating Vertical Bench. Sensors. 2025; 25(13):3998. https://doi.org/10.3390/s25133998

Chicago/Turabian StylePedersini, Federico. 2025. "Simple Calibration of Three-Axis Accelerometers with Freely Rotating Vertical Bench" Sensors 25, no. 13: 3998. https://doi.org/10.3390/s25133998

APA StylePedersini, F. (2025). Simple Calibration of Three-Axis Accelerometers with Freely Rotating Vertical Bench. Sensors, 25(13), 3998. https://doi.org/10.3390/s25133998