1. Introduction

Strain gauge force transducers are not new in the realm of engineering, as strain gauges are especially useful and prominent tools in structural analysis. This methodology implements the use of strain gauges on a small-scale laboratory experiment with the ability to expand as needed into larger structures. A transducer is an instrument that converts one form of energy into another [

1].

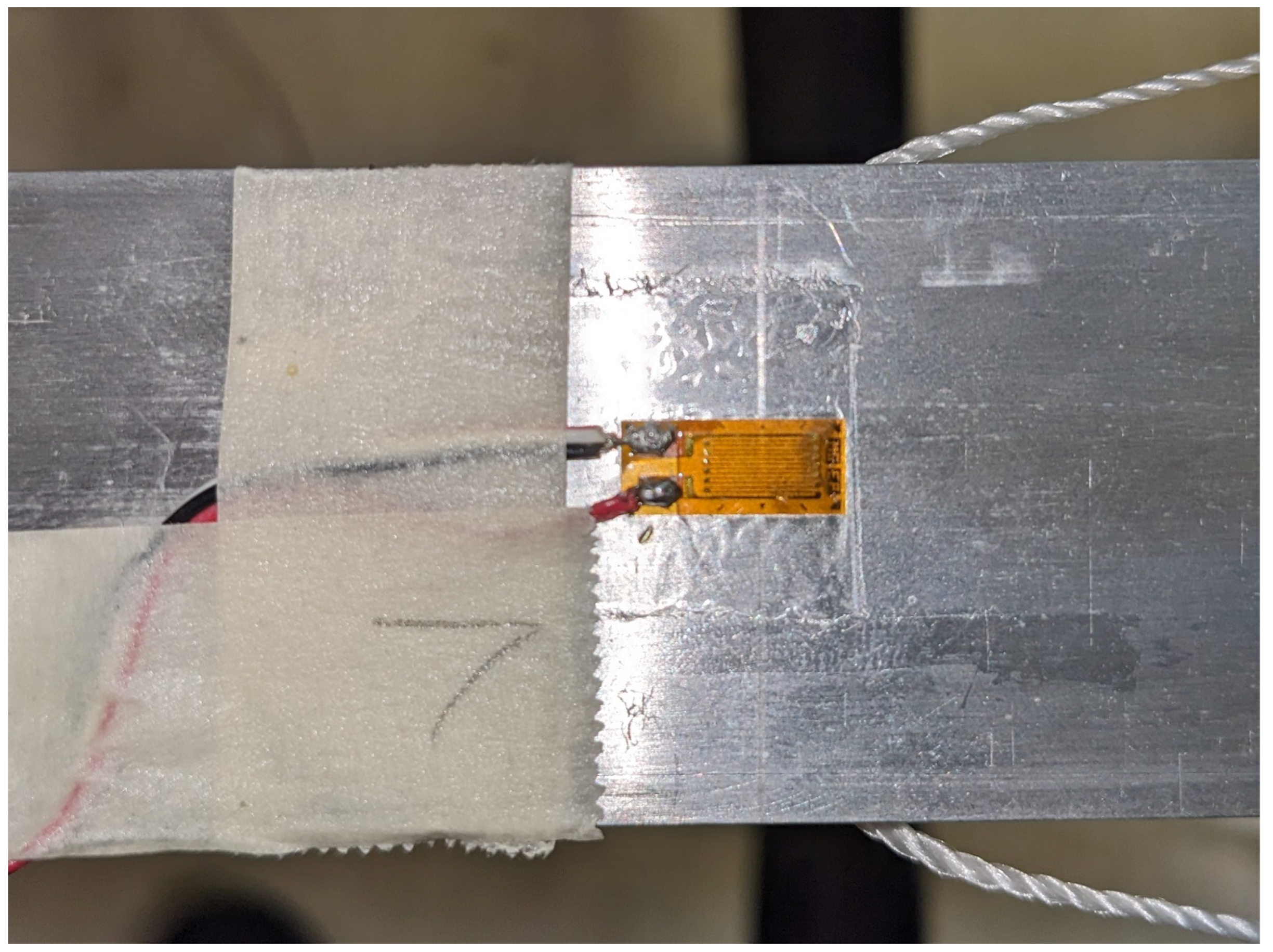

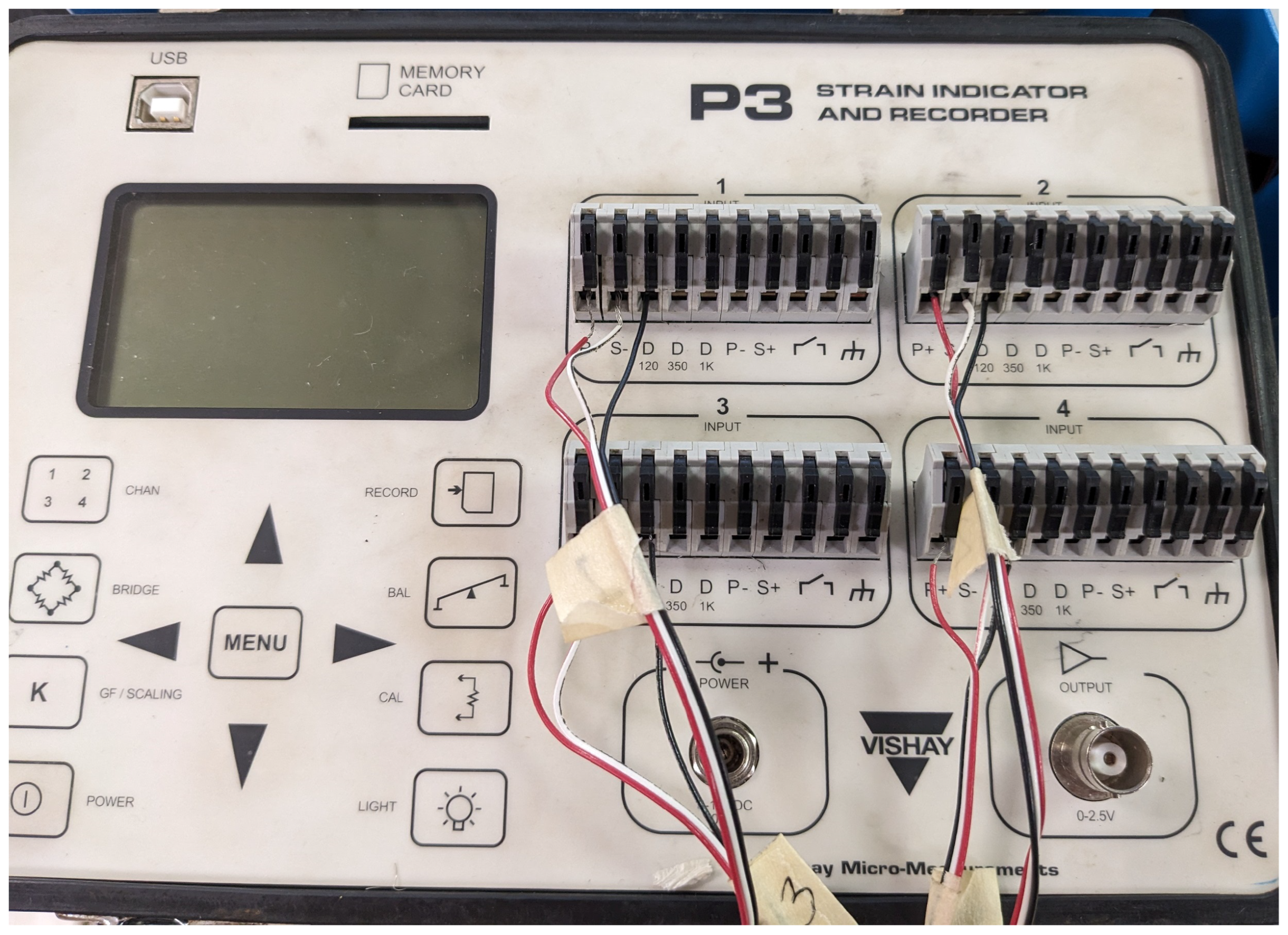

Regarding the context of the laboratory experiment, the mechanical energy of the applied forces are converted into an electrical signal via the use of a Wheatstone bridge circuit that is integrated in a Vishay P3 recorder [

2]. Strain gauges are constructed on a thin, flexible material with high-gauge wire. These gauges operate such that the resistance of the wire changes under an applied load. The Wheatstone bridge that is used is able to measure very fine changes in the resistance of the wire. Essentially, the circuit is made up of four resistors wired in a diamond pattern, with three of those resistors being highly precise values and the other being the strain gauge in the system to complete the circuit. By assessing the change of resistance of the strain gauge, the strain value is the response to an applied load.Load identification and the determination of forces and/or loads on a structure from measured responses are critical in monitoring structural health. The process as a whole is challenging due to the uncertainty of measurements and the complexity of loads.

As these tools are very effective, they have increasingly become a topic of research for load determination. An alternative method of force determination to strain gauges are Fiber Bragg Grating (FBG) sensors and fiber optics, which are prominently used in structural analysis. One study shows that researchers were able to create a method to identify the load of a moving car on a bridge through the use of long-gauge fiber optic strain responses [

3]. Similarly, another study shows that the use of an FBG sensor is able to measure longitudinal strains when a beam is subjected to multiple loads [

4]. An additional study looked at using an FGB sensor to measure the force and position of a weight that was attached to a surgical forceps [

5]. The practicality of FBG sensors continues as these are also used in measuring dynamic strain in cantilever beams, which can yield strains in linear and nonlinear systems [

6]. Ultimately, the decision was made to focus on strain gauges. Strain gauges display remarkable accuracy in the detection of minor changes of resistance which as a result can precisely quantify any applied loads. The methodology found in this study reduces the number of necessary strain gauges and promises a more cost-effective approach which results in a practical application of identifying loads.

Innovative techniques using nonlinear strain gauges are frequently being studied, such as one that highlights a triaxial force transducer and the calibration method [

7]. Although rigidly mounted, the strain gauges are still able to observe dynamic forces such as those caused by acceleration and vibration, thus making this method highly desirable in load testing for aircraft and automobiles [

7]. As the testing highlighted in this study is static, nonlinear strain gauges are not necessary. Furthermore, the strain present is only in one direction, thus making a triaxial strain gauge excessive.

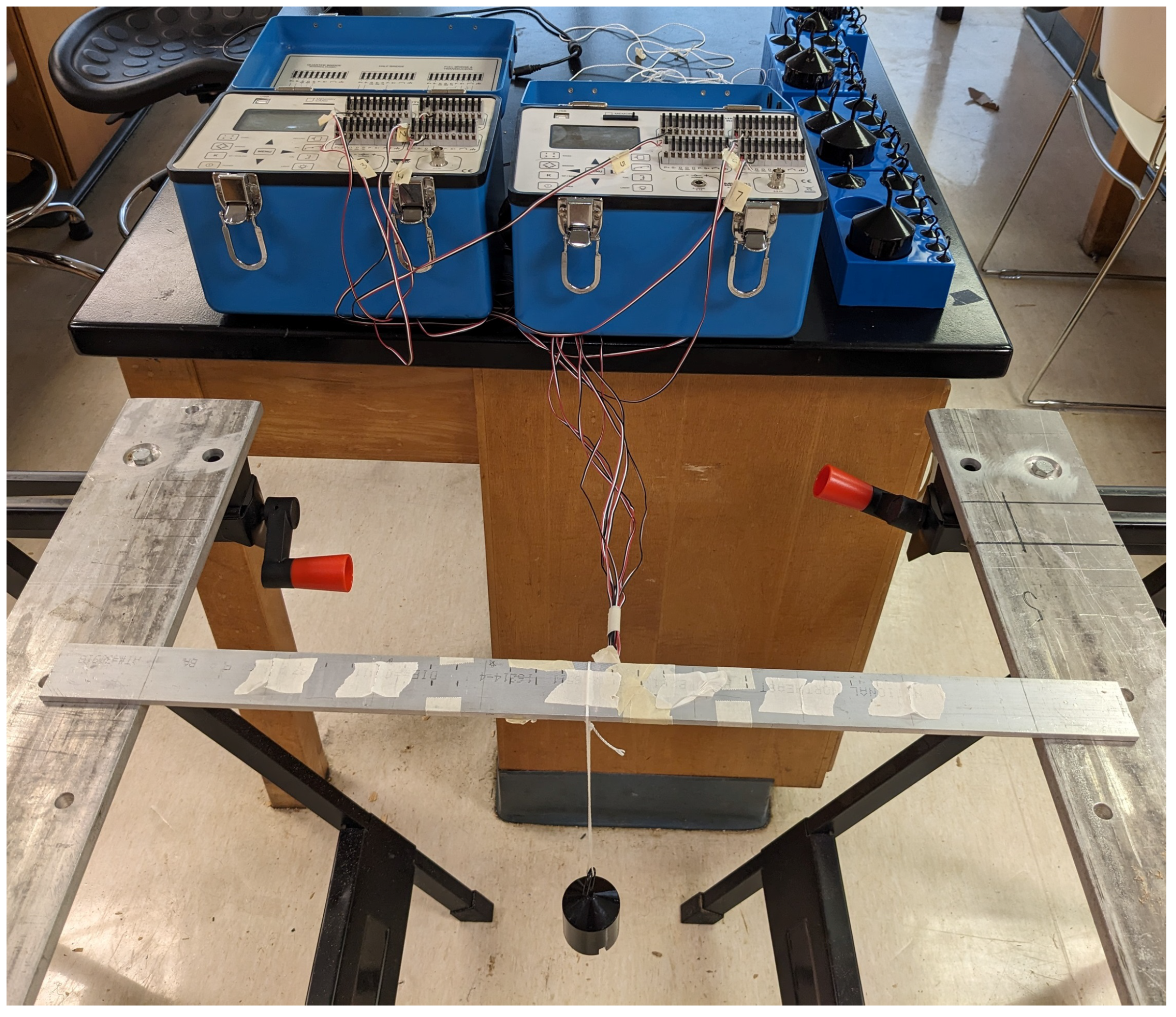

Previously, a strain gauge force transducer was created to determine both the magnitudes and locations of several applied forces at the same time [

8]. To do so, four strain gauges are required for the initial force and two more are necessary for each additional applied force. The methodology focused on in this study aimed to reduce the number of necessary strain gauges for determining the load magnitude by eliminating the unknown locations. The benefit of knowing the location where the force is applied is such that only one strain gauge is needed per force.

2. Theory

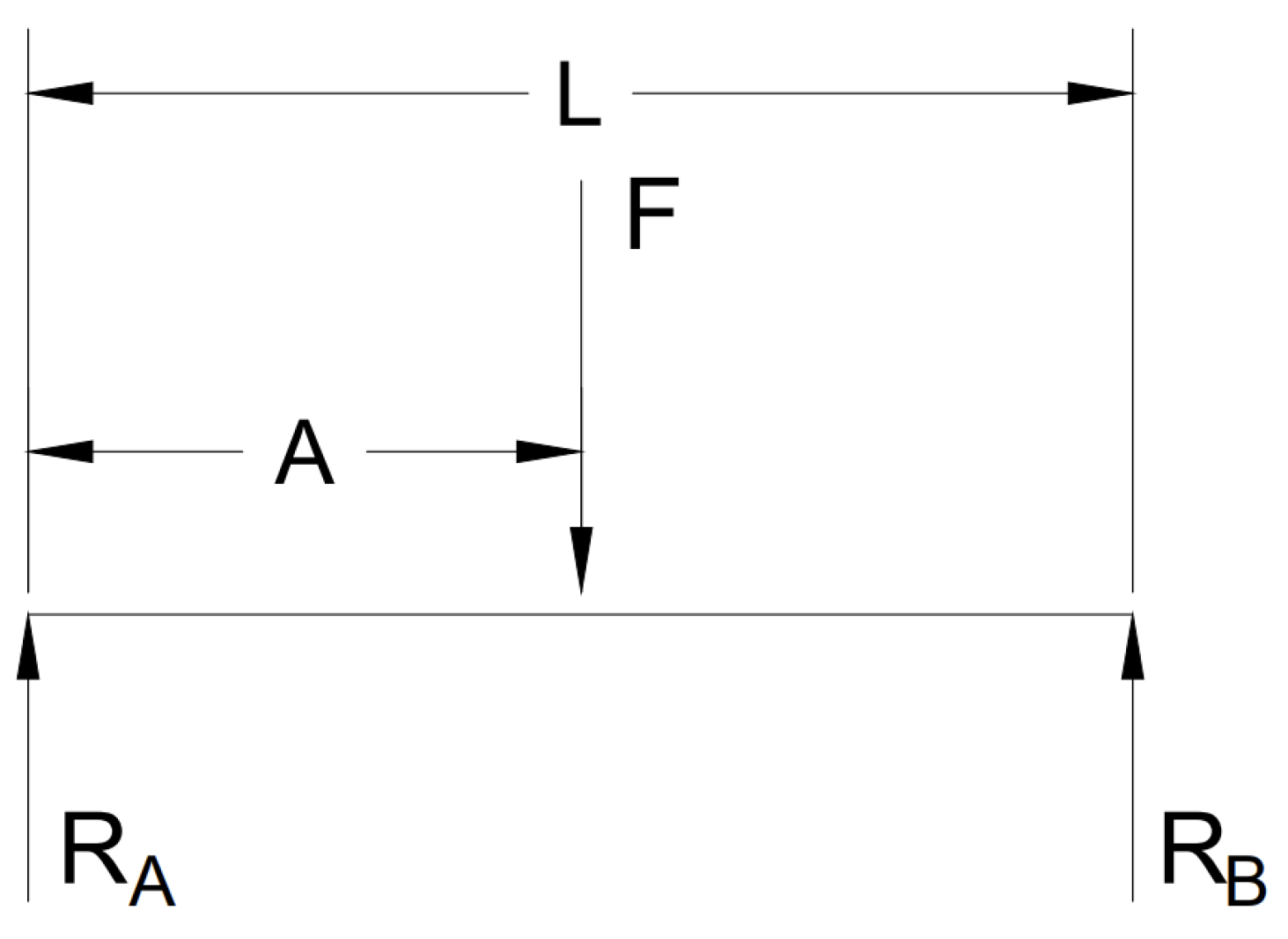

Consider a simply supported beam with a given length

L subjected to a force

F (see

Appendix A) at a location

A, and that has two reaction forces at each end,

and

, as shown in

Figure 1. The beam is assumed to be in static equilibrium. Therefore, it is expected that the maximum moment,

is to occur at the point of the applied force

A, as shown in

Figure 2. To recreate this graph, a piece-wise function composed of two equations is used: one representing the increasing moment before the point of the applied force and the other representing the decreasing moment after the point of the applied force [

9].

The applied force

F can be determined if the moment at the location of the force

A is known, from Equation (

1). However, it is not possible to directly measure the moment, so the relationship between bending stress and moment must be utilized. This relationship is represented in Equation (

2), where

denotes bending stress,

y is the distance from the neutral axis of the beam to where the stress is calculated, and

I is the area moment of inertia [

10].

Bending stress itself cannot be directly measured, but it can be accurately calculated using the well-established relationship between stress and strain. This relationship is represented in Equation (

3), where

E denotes Young’s modulus, a material property that quantifies the stiffness of a solid, and

symbolizes the strain, a dimensionless measure of the deformation experienced by the material. By utilizing this fundamental relationship, it is possible to infer the bending stress from the measured strain values [

10].

Strain, being a physical quantity, can be measured using strain gauges. By combining Equations (

2) and (

3), a relationship can be established between the bending moment and strain resulting in Equation (

4).

A calibration factor,

, is used to account for different geometric and material properties. In this experiment, one

was used since a beam that was homogeneous with a constant cross-section was utilized. However, if the beam has variable width or thickness, or is non-homogeneous,

must be calculated separately for each strain gauge. The experimental

can be determined with the use of a known force value and a tool such as Excel Solver. The theoretical

can be represented by Equation (

5). Equation (

4) was subsequently rewritten to include

and is represented by Equation (

6).

By using the relationship established between moment and strain, the magnitude of a force can be calculated using Equations (

1) and (

6). In situations where multiple forces are present, as shown in

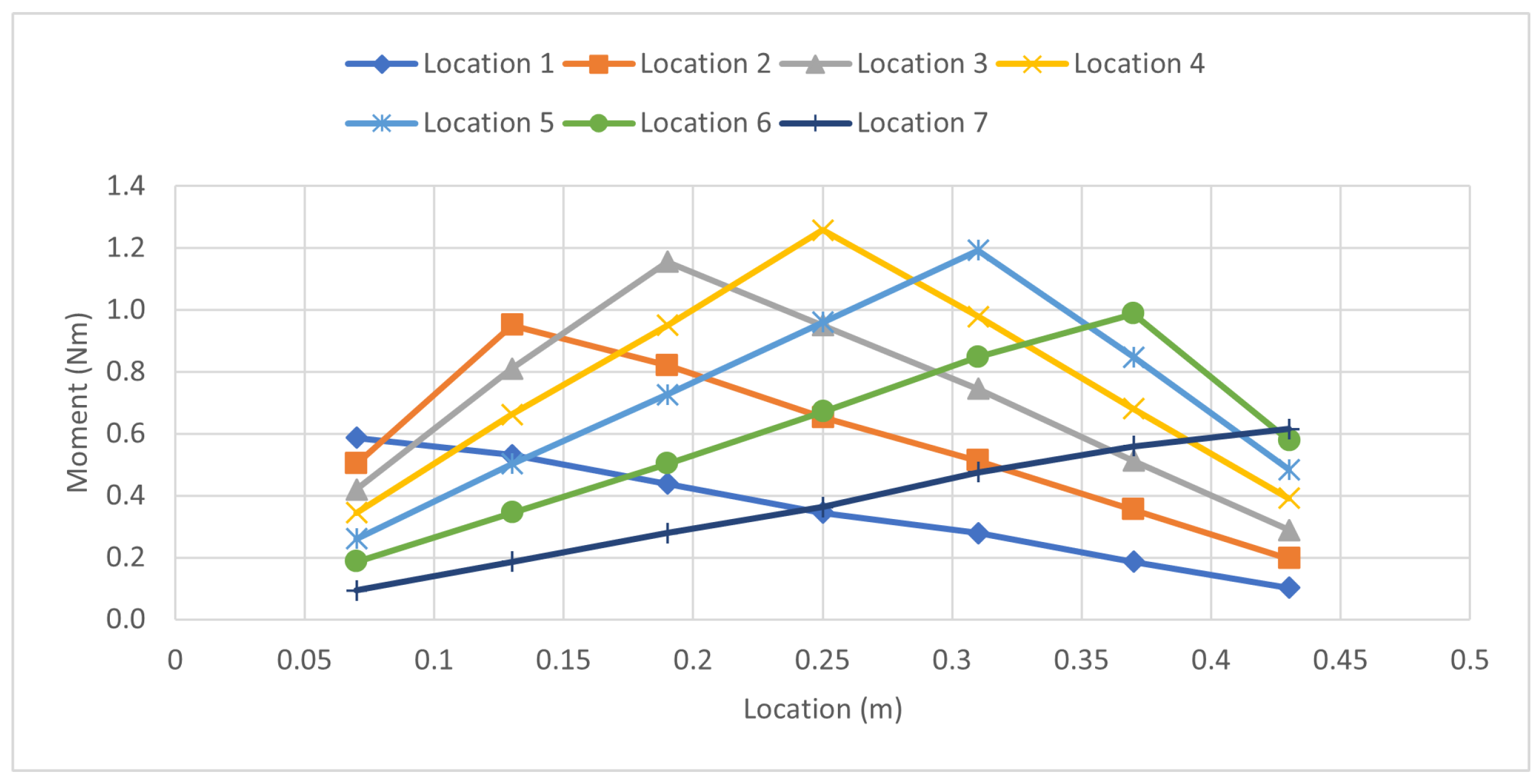

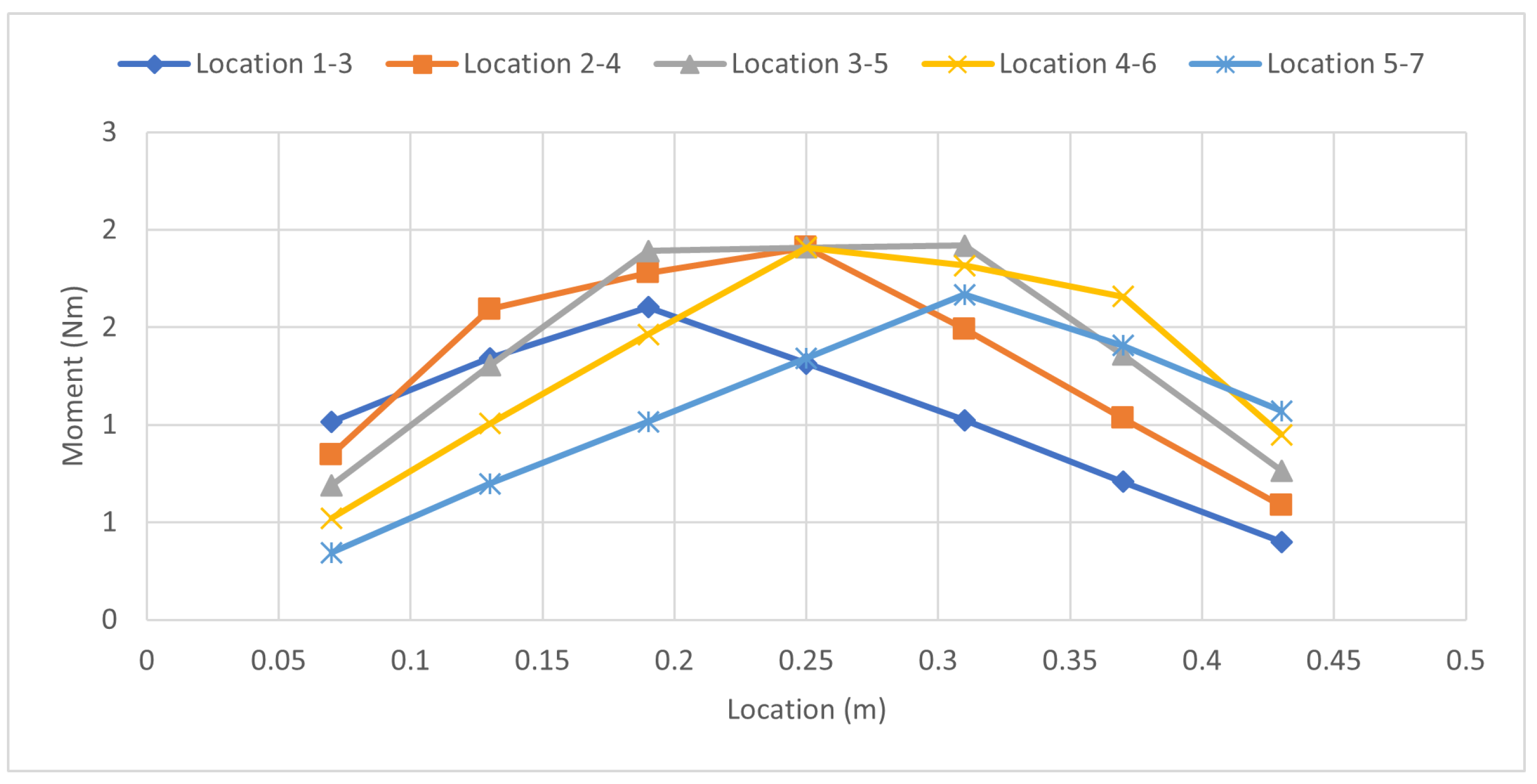

Figure 3, it is necessary to introduce multiple strain gauges, with one strain gauge placed at each force location. If superposition is used, which states that the total effect of multiple forces on a system is equal to the sum of the effects of each individual force, Equation (

1) can be turned into a summation of all strain gauges to cover all the forces [

11]. This is represented in Equation (

7), where

m represents the location at which the moment is calculated,

N represents the total number of forces, and

n is the dummy index.

and

represent the location of the forces. Lastly, the

represents the force magnitude for various locations.

In the experiment being conducted, seven force locations were utilized. If Equation (

7) is to be written in its full matrix form to encompass all seven forces, it would result in Equation (

8).

Equation (

8) can be written in a condensed form, represented by Equation (

9), where [M] is the column vector representing the bending moment at each location, [F] is the column vector representing the magnitude of the applied force at each location, and [L] is the geometric matrix.

As matrix [L] is symmetric, it can be inverted to calculate the forces at each of the locations as represented in Equation (

10). Additionally, Equation (

6) can be used to replace the moment matrix with the strain gauge values from the experiment and multiplied by the calibration factor, as represented in Equation (

11). This establishes the final relationship between the strain gauge readings and the forces.

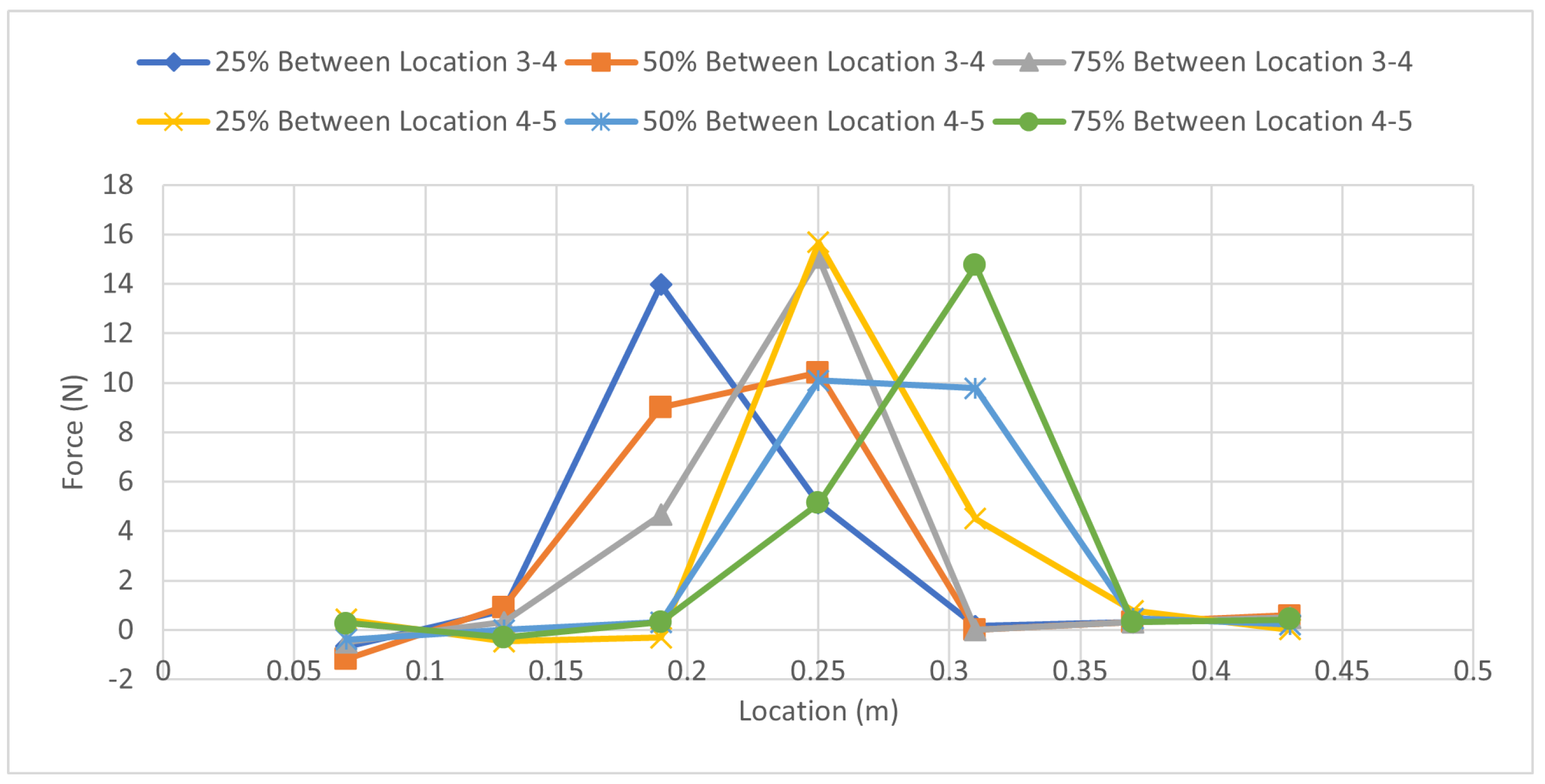

If the position of a force between two strain gauges is known, the force will be distributed to the two nearby strain gauges as shown in

Figure 4. Force

is the actual force being applied; however, the strain gauges will see that the force is distributed among the two strain gauges nearby as

and

.

represents the position of the force referenced from the left adjacent strain gauge and

ℓ refers to the spacing between such adjacent strain gauges. In Equations (

12) and (

13), the forces at the adjacent strain gauges can be calculated by knowing such values.

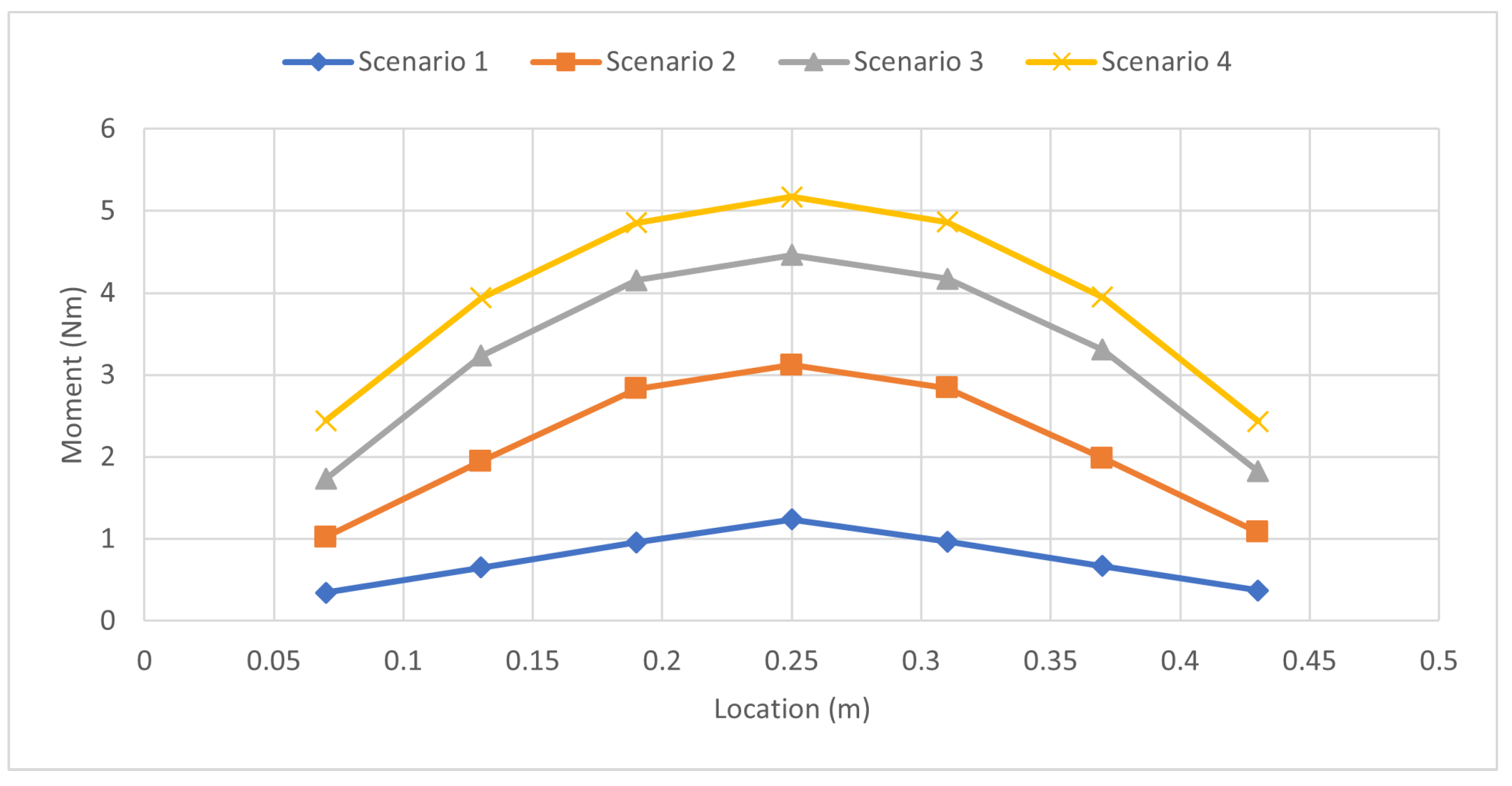

4. Conclusions

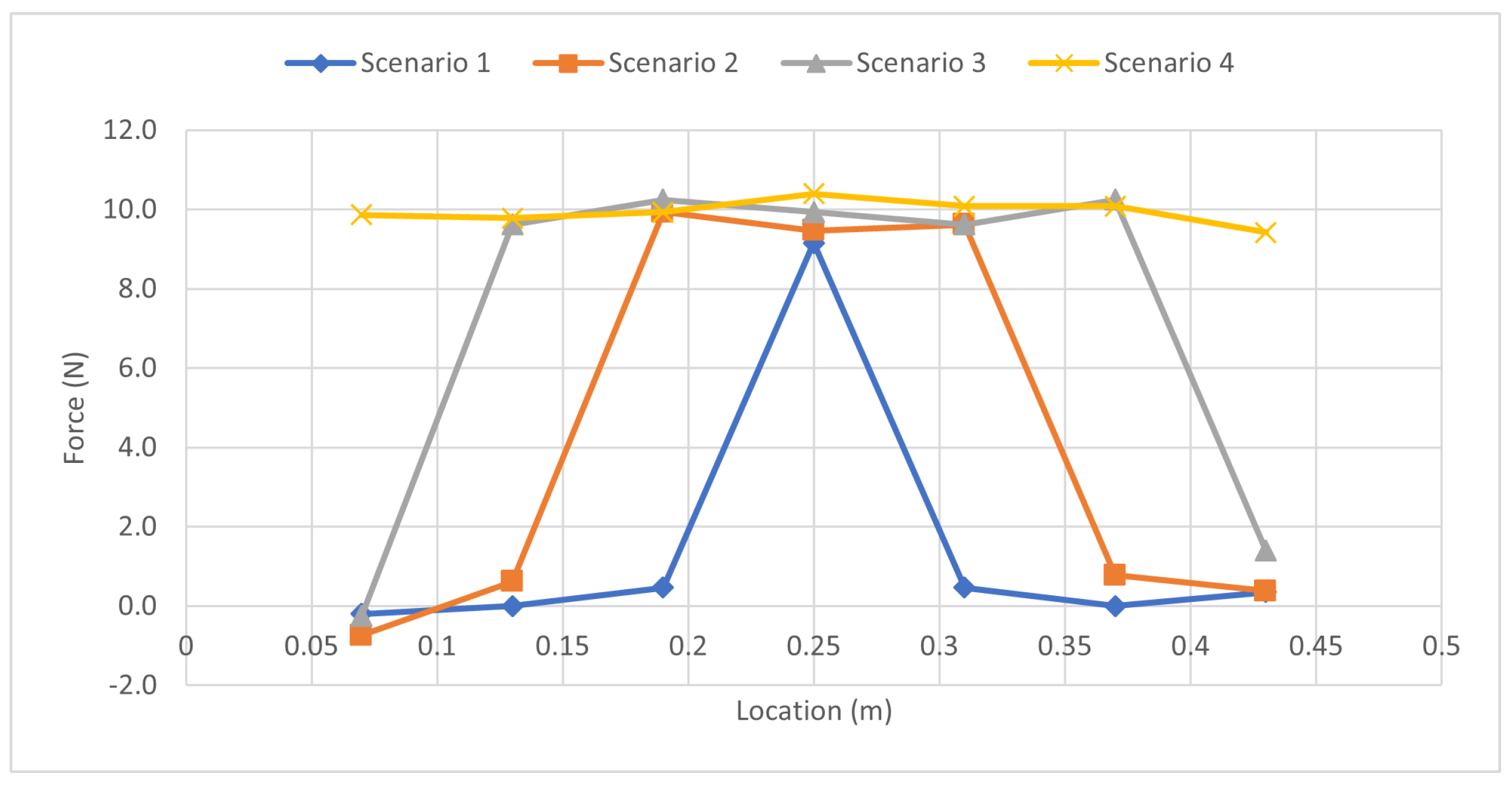

This new methodology of force determination using a uniaxial strain gauge at each force location yielded results such that the process can be deemed accurate for simply supported, uniform beams. Additionally, this methodology identifies the magnitudes of loads at given locations while successfully calculating zero force loads elsewhere on the beam. The major benefit of this methodology is the minimization of the number of strain gauges required to determine force magnitudes on a beam. A reduction in strain gauges minimizes the number of channels required, thus further lowering the overall cost per test.

Before the experimental data were collected, the goal was to have the error fall within 5%. The overall force errors for cases where the loads were in line with the strain gauge locations peaked at 4.9%. The majority of errors for these data sets could be attributed to slight discrepancies in strain gauge placements and load location, as well as small imperfections in the thickness of the beam. Additionally, movement could have occurred resulting in the designated resting areas possibly shifting.

The data from the load being applied between strain gauges yielded an error of 6.6%. This is slightly higher than the goal, but causes for errors are most likely attributed to the inaccurate placement of the loads between strain gauges. Overall, the methodology and theory both have the ability to be modified for various load applications to suit any need while maintaining accuracy.