Ultrasoft, Adhesive and Millimeter Scale Epidermis Electronic Sensor for Real-Time Enduringly Monitoring Skin Strain

Abstract

1. Introduction

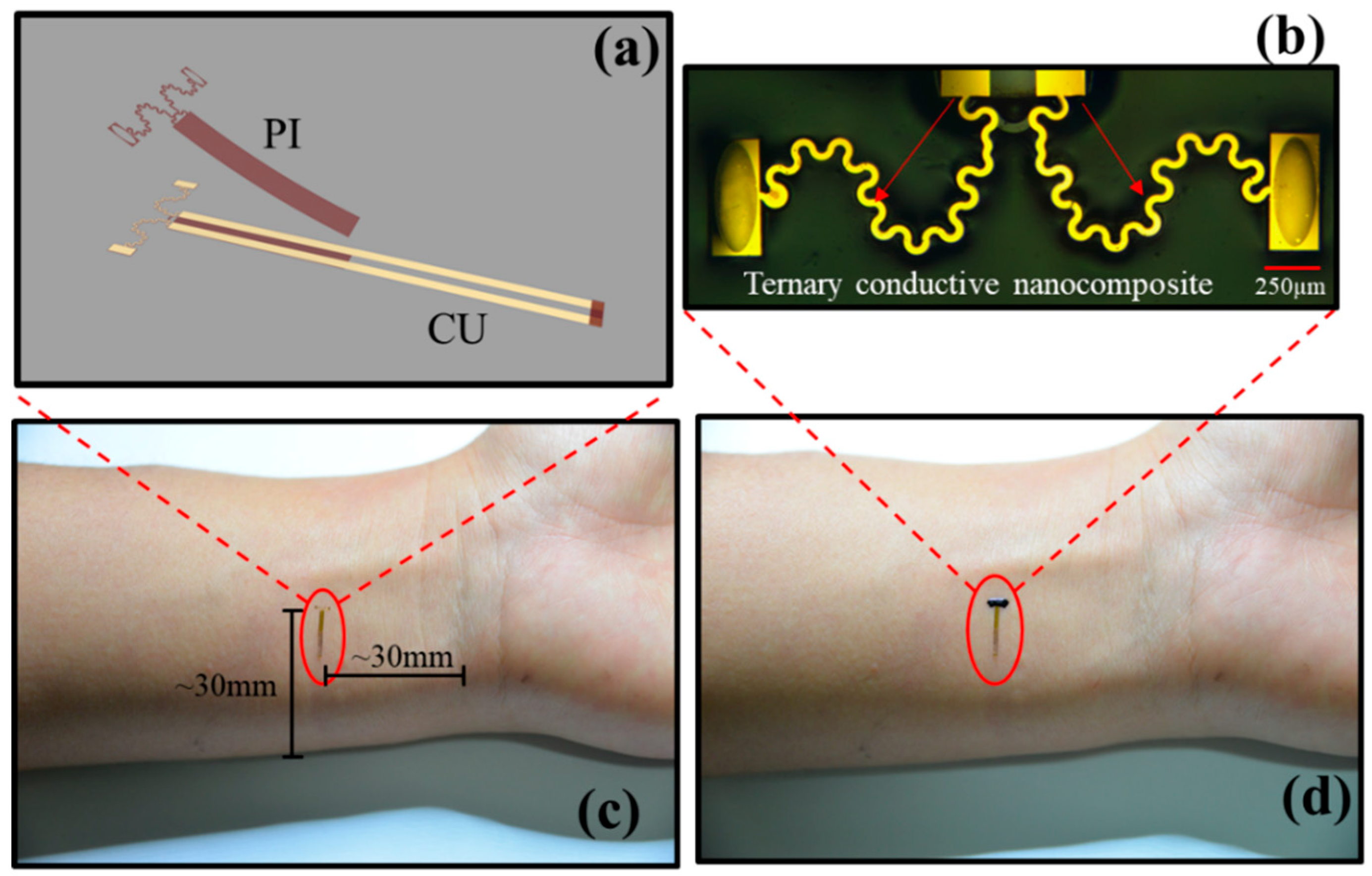

2. Design and Fabrication of the EES for Skin Strain Measurement

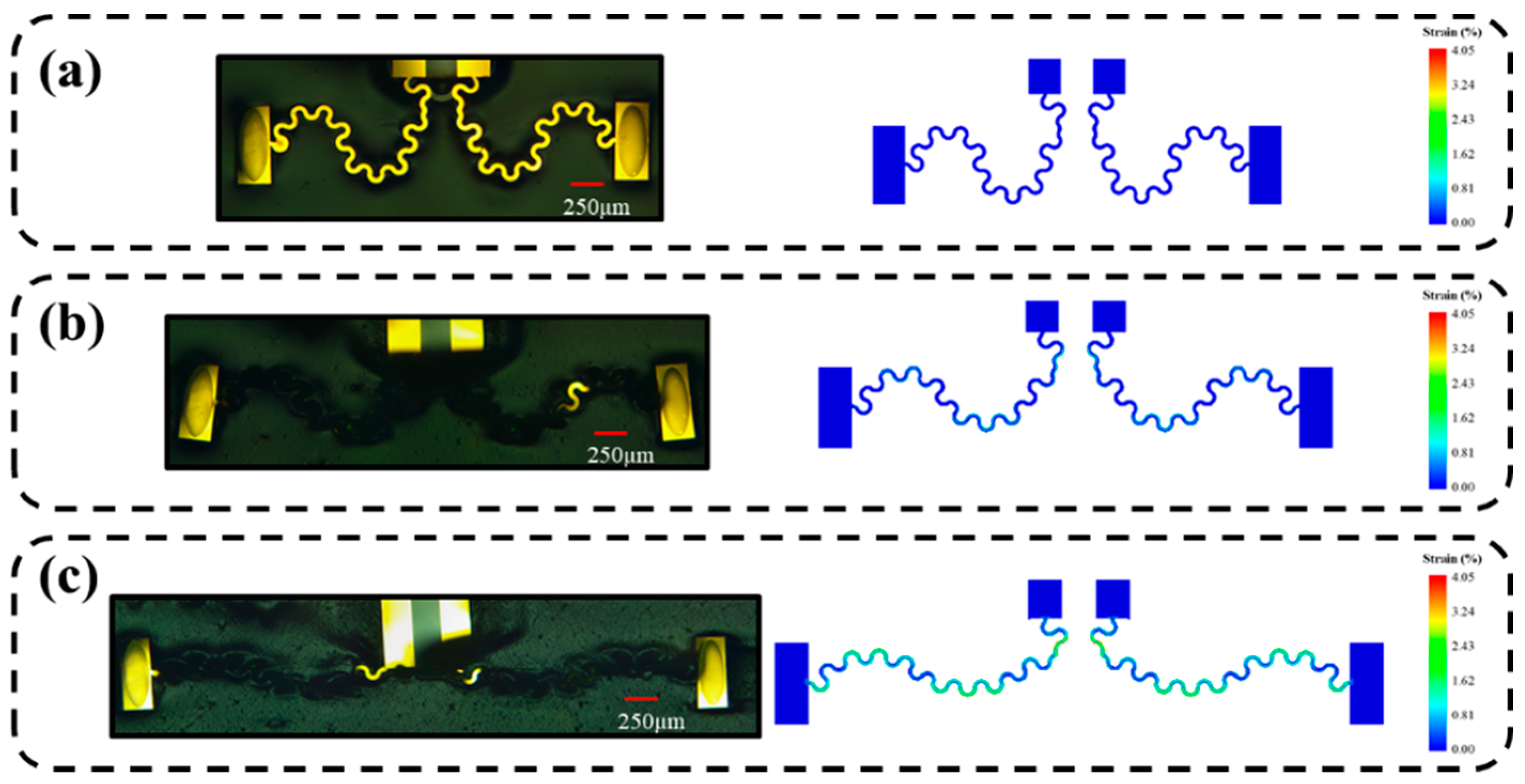

2.1. Design

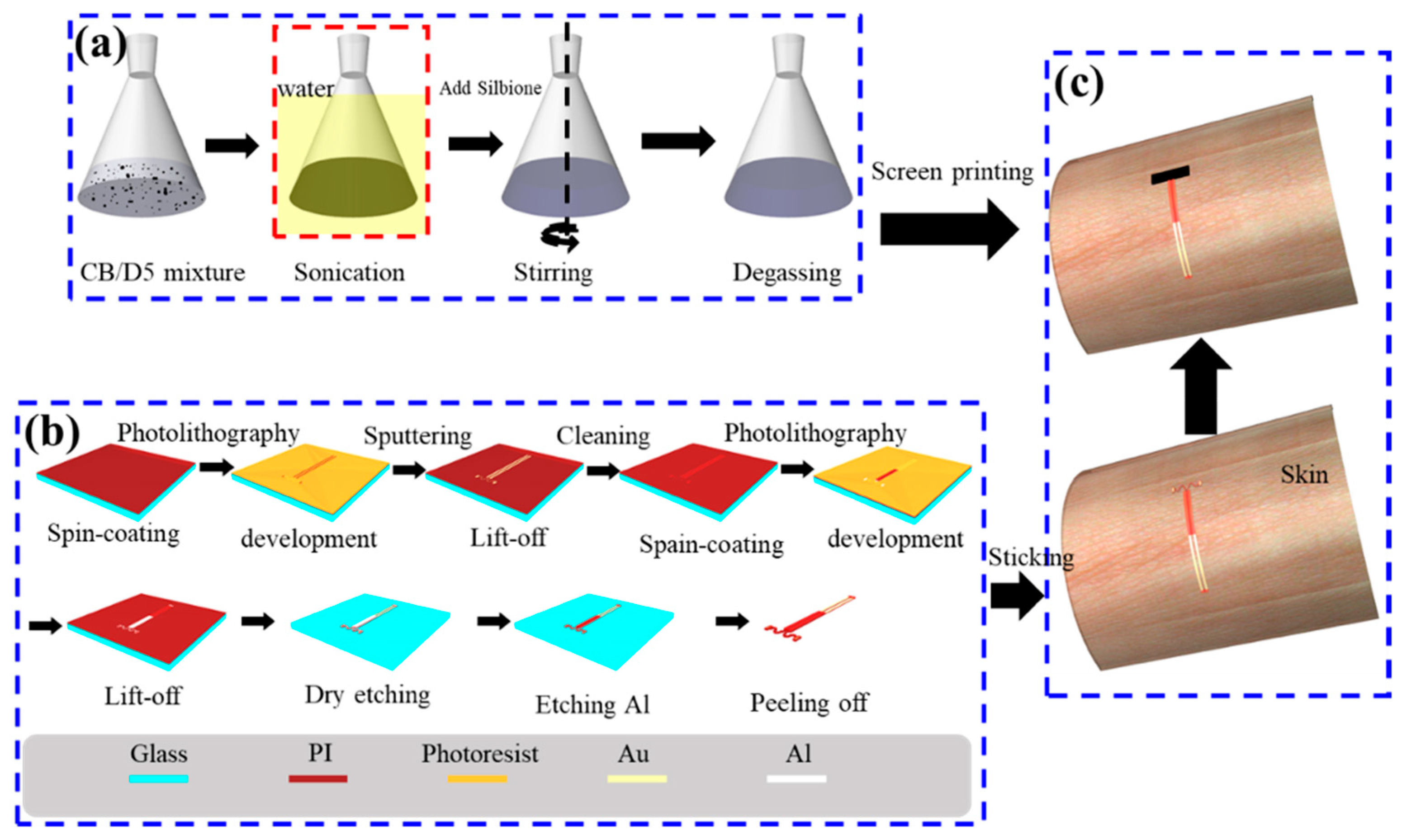

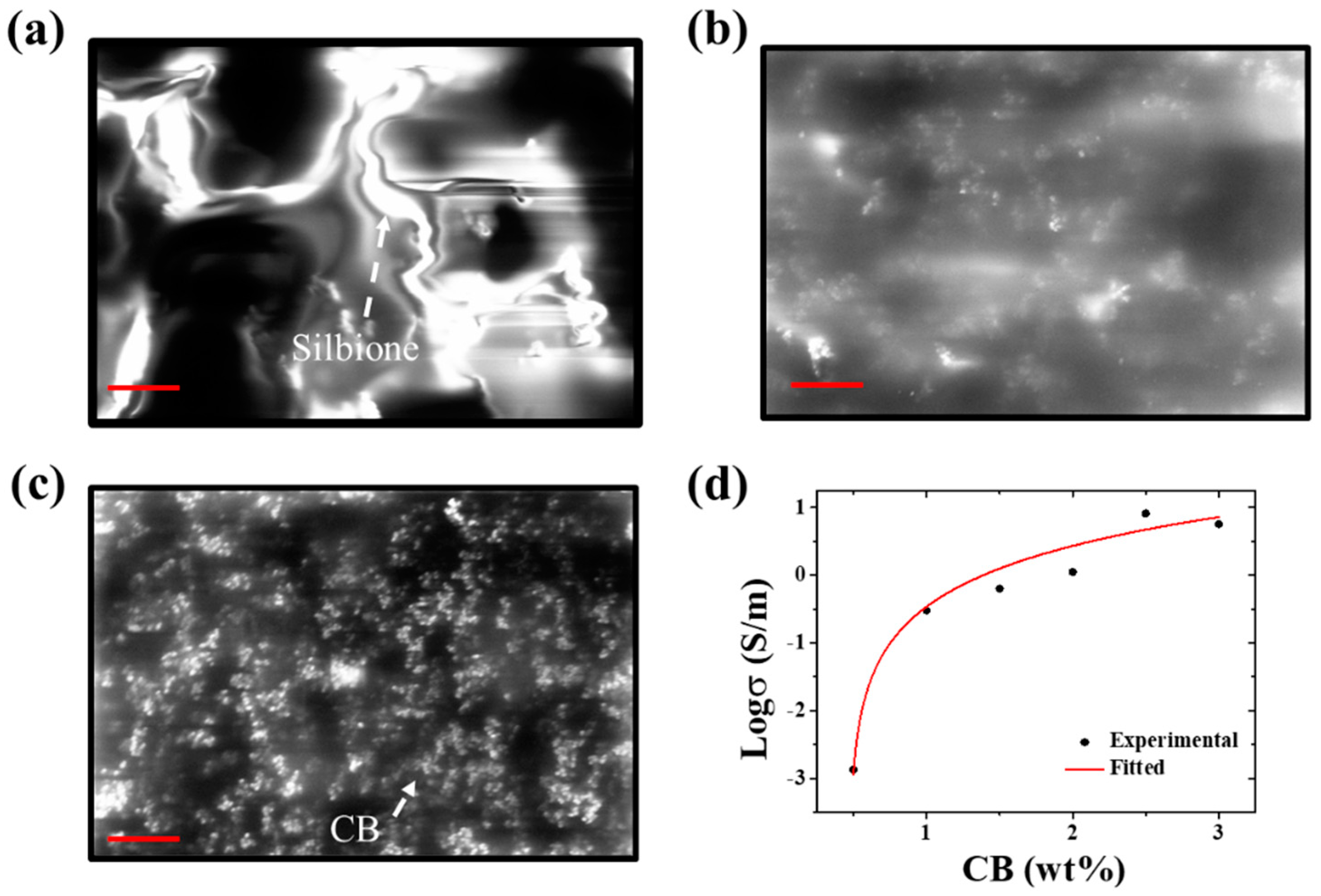

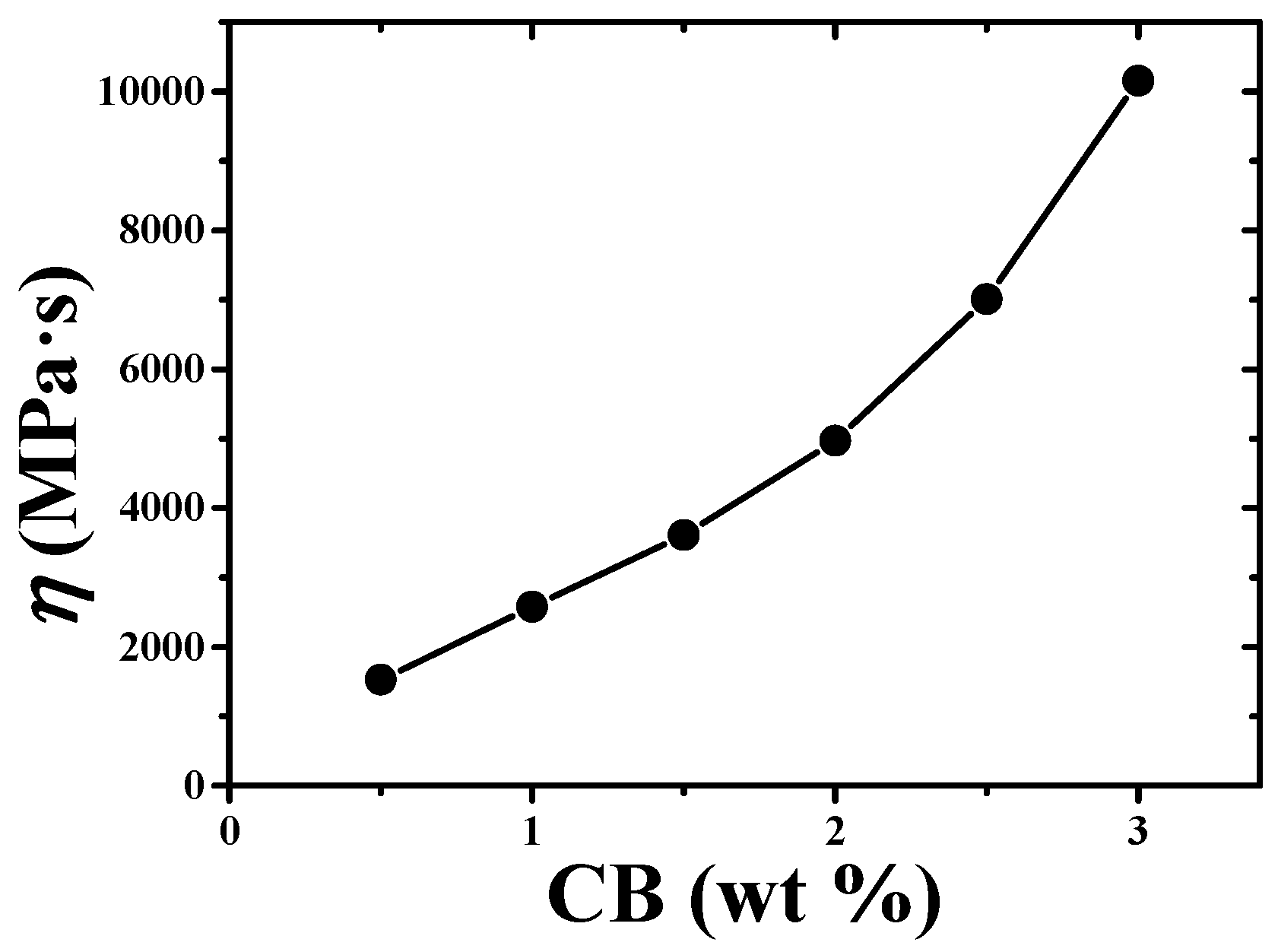

2.2. Material

2.3. Fabrication Process

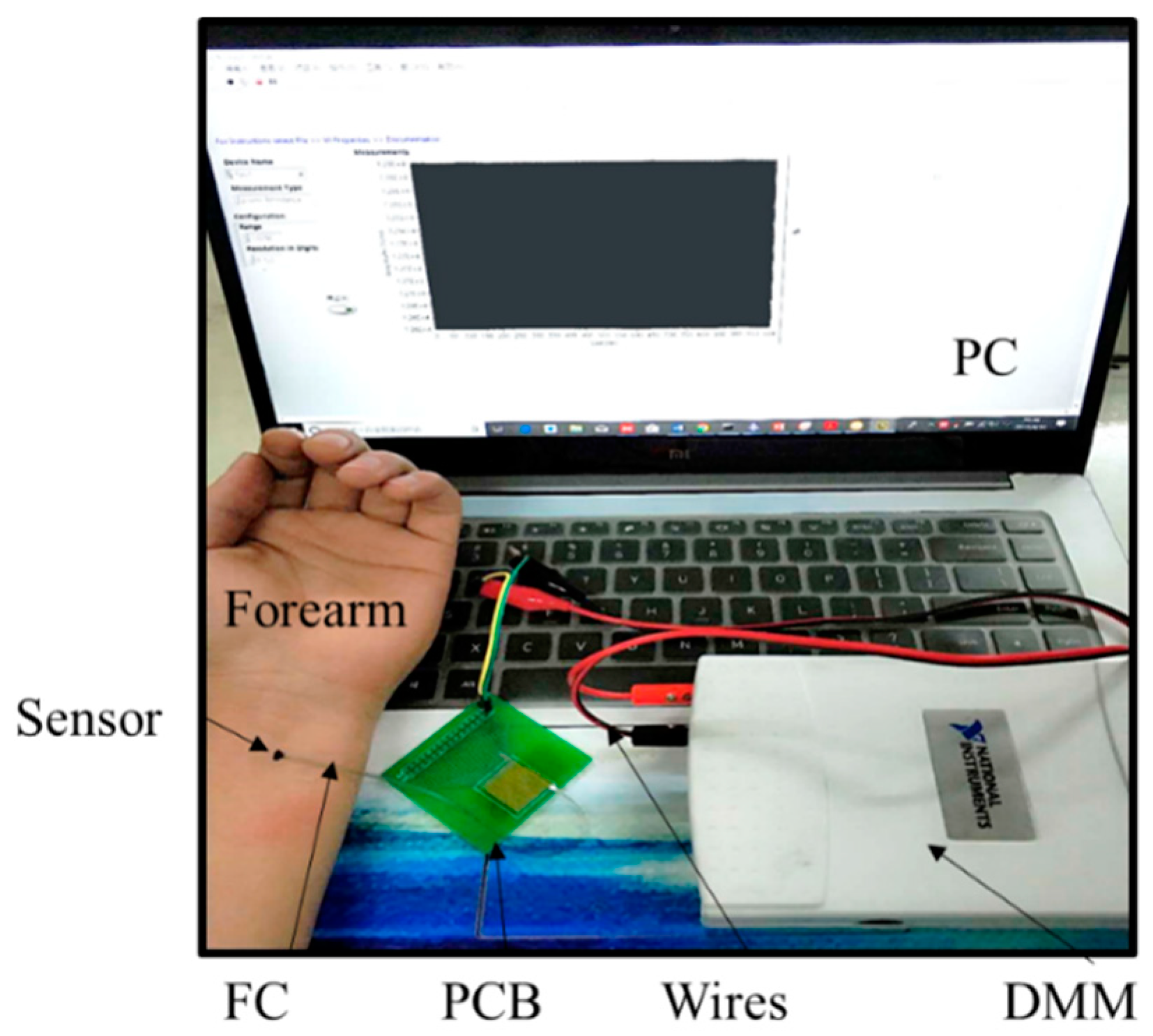

3. Experimental Setup

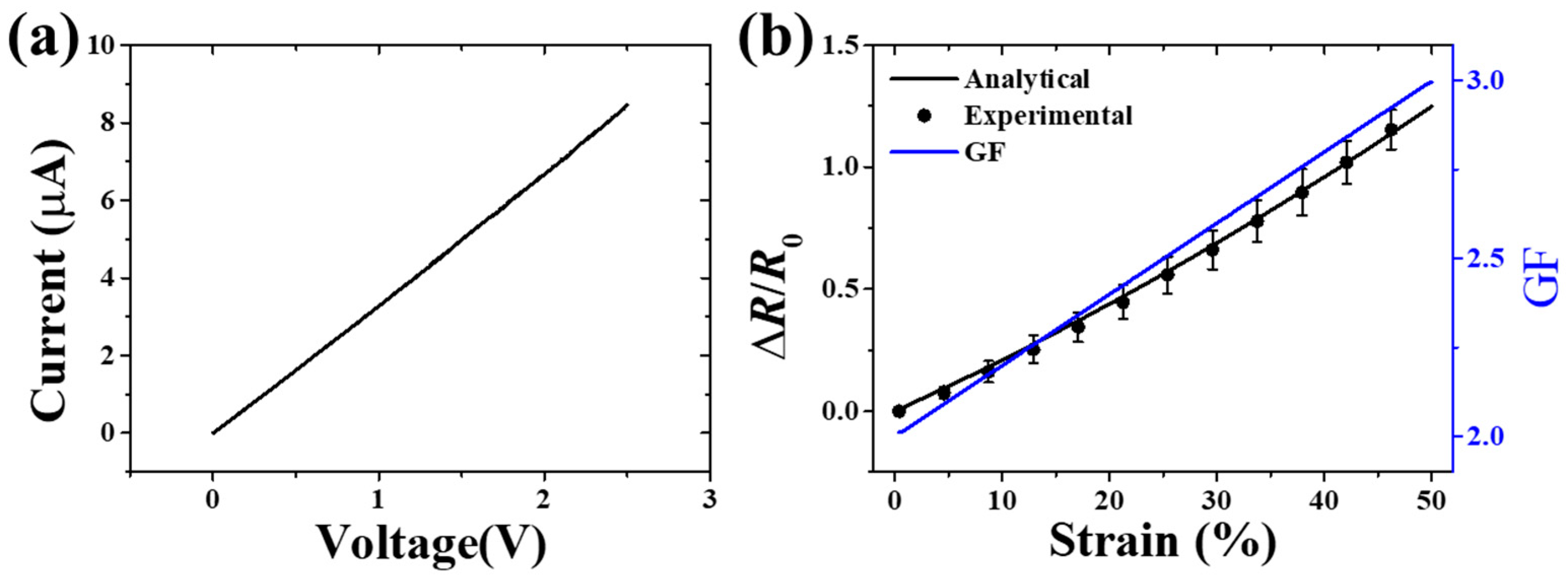

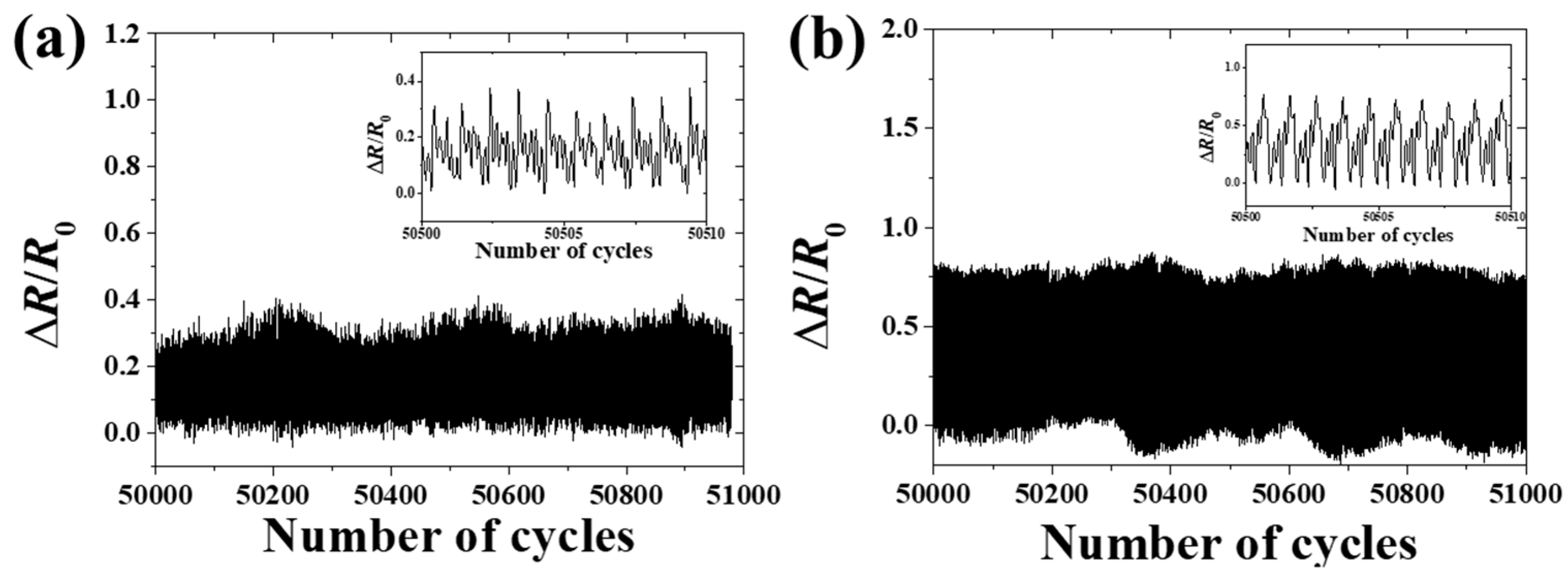

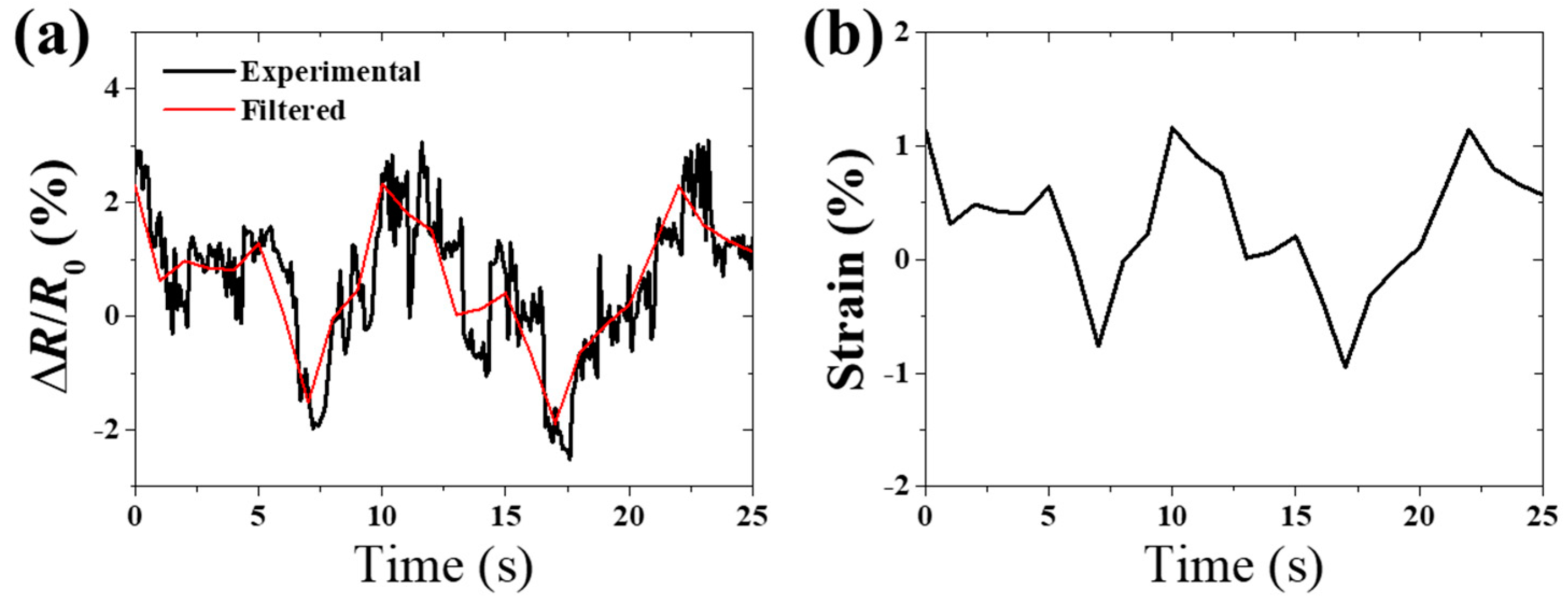

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Kim, D.H.; Lu, N.S.; Ma, R.; Kim, Y.S.; Kim, R.H.; Wang, S.D.; Wu, J.; Won, S.M.; Tao, H.; lslam, A.; et al. Epidermal electronics. Science 2011, 333, 838–843. [Google Scholar] [CrossRef] [PubMed]

- Bandodkar, A.J.; Jeerapan, I.; Wang, J. Wearable chemical sensors: Present challenges and future prospects. ACS Sens. 2016, 1, 464–482. [Google Scholar] [CrossRef]

- Bandodkar, A.J.; Jia, W.; Wang, J. Tattoo-based wearable electrochemical devices: A review. Electroanalysis 2015, 27, 562–572. [Google Scholar] [CrossRef]

- Trung, T.Q.; Lee, N.E. Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoring and personal healthcare. Adv. Mater. 2016, 28, 4338–4372. [Google Scholar] [CrossRef] [PubMed]

- Qiao, Y.C.; Wang, Y.F.; Tian, H.; Li, M.R.; Jian, J.M.; Wei, Y.H.; Tian, Y.; Wang, D.Y.; Pang, Y.; Geng, X.S.; et al. Multilayer graphene epidermal electronic skin. ACS Nano 2018, 12, 8839–8846. [Google Scholar] [CrossRef] [PubMed]

- Madhvapathy, S.R.; Ma, Y.J.; Patel, M.; Krishnan, S.; Wei, C.; Li, Y.J.; Xu, S.; Feng, X.; Huang, Y.G.; Rogers, J.A. Epidermal electronic systems for measuring the thermal properties of human skin at depths of up to several millimeters. Adv. Funct. Mat. 2018, 28, e1802083. [Google Scholar] [CrossRef]

- Gao, W.; Emaminejad, S.; Nyein, H.Y.Y.; Challa, S.; Chen, K.; Peck, A.; Fahad, H.M.; Ota, H.; Shiraki, H.; Kiriya, D.; et al. Fully integrated wearable sensor arrays for multiplexed in situ perspiration analysis. Nature 2016, 529, 509–514. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Choi, T.K.; Lee, Y.B.; Cho, H.R.; Ghaffari, R.; Wang, L.; Choi, H.J.; Chung, T.D.; Lu, N.S.; Hyeon, T.; et al. A graphene-based electrochemical device with thermoresponsive microneedles for diabetes monitoring and therapy. Nat. Nanotechnol. 2016, 11, 566–572. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Lu, S.; Zhang, S.; Li, Y.; Qu, Z.; Chen, Y.; Lu, B.; Wang, X.; Feng, X. Skin-like biosensor system via electrochemical channels for noninvasive blood glucose monitoring. Sci. Adv. 2017, 3, e1701629. [Google Scholar] [CrossRef] [PubMed]

- Li, H.C.; Xu, Y.; Li, X.M.; Chen, Y.; Jiang, Y.; Zhang, C.X.; Lu, B.W.; Wang, J.; Ma, Y.J.; Chen, Y.H.; et al. Epidermal inorganic optoelectronics for blood oxygen measurement. Adv. Healthc. Mater. 2017, 6, 1601013. [Google Scholar] [CrossRef] [PubMed]

- Webb, R.C.; Bonifas, A.P.; Behnaz, A.; Zhang, Y.H.; Yu, K.J.; Cheng, H.Y.; Shi, M.X.; Bian, Z.G.; Liu, Z.J.; Kim, Y.S.; et al. Ultrathin conformal devices of precise and continuous thermal characterization of human skin. Nat. Mater. 2013, 12, 938–944. [Google Scholar] [CrossRef]

- Lee, J.W.; Xu, R.X.; Lee, S.; Jang, K.I.; Yang, Y.C.; Banks, A.; Yu, K.J.; Kim, J.; Xu, D.; Ma, S.Y.; et al. Soft, thin skin-mounted power management systems and their use in wireless thermography. Proc. Natl. Acad. Sci. USA 2016, 113, 6131–6136. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.H.; Webb, R.C.; Luo, H.Y.; Xue, Y.G.; Kurniawan, J.; Cho, N.H.; Krishnan, S.; Li, Y.H.; Huang, Y.G.; Rogers, J.A. Theoretical and experimental studies of epidermal heat flux sensors for measurements of core body temperature. Adv. Healthc. Mater. 2016, 5, 119–127. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Liu, Z.; Zhang, T. Flexible sensing electronics for wearable/attachable health monitoring. Small 2017, 13, 1602790. [Google Scholar] [CrossRef]

- Wang, X.; Gu, Y.; Xiong, Z.; Cui, Z.; Zhang, T. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater. 2014, 26, 1336–1342. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly stretchable and sensitive strain sensor based on silver nanowire-elastomer nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Muth, J.T.; Vogt, D.M.; Truby, R.L.; Menguc, Y.; Kolesky, D.B.; Wood, R.J.; Lewis, J.A. Embedded 3D printing of strain sensors within highly stretchable elastomers. Adv. Mater. 2014, 26, 6307–6312. [Google Scholar] [CrossRef] [PubMed]

- Guder, F.; Ainla, A.; Redston, J.; Mosadegh, B.; Glavan, A.; Martin, T.J.; Whitesides, G.M. Paper-based electrical respiration sensor. Angew. Chem. Int. Ed. 2016, 55, 5727–5732. [Google Scholar] [CrossRef]

- Thap, T.; Yoon, K.H.; Lee, J. Graphite based electrode for ECG monitoring: Evaluation under freshwater and saltwater conditions. Sensors 2016, 16, 542. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, L.; Yang, T.; Li, X.; Zang, X.; Zhu, M.; Wang, K.; Wu, D.; Zhu, H. Wearable and highly sensitive graphene strain sensors for human motion monitoring. Adv. Funct. Mater. 2014, 24, 4666–4670. [Google Scholar] [CrossRef]

- Su, M.; Li, F.; Chen, S.; Huang, Z.; Qin, M.; Li, W.; Zhang, X.; Song, Y. Nanoparticle based curve arrays for multirecognition flexible electronics. Adv. Mater. 2016, 28, 1369–1374. [Google Scholar] [CrossRef] [PubMed]

- Nassar, J.M.; Mishra, K.; Lau, K.; Aguirre-Pablo, A.A.; Hussain, M.M. Recyclable nonfunctionalized paper-based ultralow-cost wearable health monitoring system. Adv. Mater. Technol. 2017, 2, 1600228. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.B.; Xie, Y.Q. Flexible, Stretchable sensors for wearable health monitoring: Sensing mechanisms, materials, fabrication strategies and features. Sensors 2018, 28, 645. [Google Scholar] [CrossRef]

- Li, Y.J.; Ma, Y.J.; Wei, C.; Luan, H.W.; Xu, S.; Han, M.D.; Zhao, H.B.; Liang, C.M.; Yang, Q.S.; Yang, Y.Y.; et al. Thin, millimeter scale fingernail sensors for thermal characterization of nail bed tissue. Adv. Funct. Mater. 2018, 28, 1801380. [Google Scholar] [CrossRef]

- Khang, D.Y.; Jiang, H.; Huang, Y.; Rogers, J.A. A stretchable form of single-crystal silicon for high-Performance electronics on rubber substrates. Science 2006, 311, 208–212. [Google Scholar] [CrossRef]

- Su, Y.; Wang, S.; Huang, Y.; Luan, H.; Dong, W.; Fan, J.A.; Yang, Q.; Rogers, J.A.; Huang, Y. Elasticity of fractal inspired interconnects. Small 2015, 11, 367–373. [Google Scholar] [CrossRef]

- Xiao, J.; Carlson, A.; Liu, Z.J.; Huang, Y.; Jiang, H.; Rogers, J.A. Stretchable and compressible thin films of stiff materials on compliant wavy substrates. Appl. Phys. Lett. 2008, 93, 013109. [Google Scholar] [CrossRef]

- Wang, S.; Song, J.; Kim, D.-H.; Huang, Y.; Rogers, J.A. Local versus global buckling of thin films on elastomeric substrates. Appl. Phys. Lett. 2008, 93, 023126. [Google Scholar] [CrossRef]

- Wang, L.F.; Gao, G.R.; Zhou, Y.; Xu, T.; Chen, J.; Wang, R.; Zhang, R.; Fu, J. Tough, adhesive, self-healable, and transparent ionically conductive zwitterionic nanocomposite hydrogels as skin strain sensors. ACS Appl. Mater. Inter. 2019, 11, 3506–3515. [Google Scholar] [CrossRef]

- Lai, J.L.; Zhou, H.W.; Wang, M.C.; Chen, Y.K.; Jin, Z.Y.; Li, S.L.; Yang, J.J.; Jin, X.L.; Liu, H.B.; Zhao, W.F. Recyclable, stretchable and conductive double network hydrogels towards flexible strain sensors. J. Mater. Chem. C 2018, 6, 13316–13324. [Google Scholar] [CrossRef]

- Ge, G.; Zhang, Y.Z.; Shao, J.J.; Wang, W.J.; Si, W.L.; Huang, W.; Dong, X.C. Stretchable, transparent, and self-patterned hydrogel-based pressure sensor for human motions detection. Adv. Funct. Mater. 2018, 28, 1802576. [Google Scholar] [CrossRef]

- Huang, Y.; Ding, Y.; Bian, J.; Su, Y.; Zhou, J.; Duan, Y.; Yin, Z. Hyper-stretchable self-powered sensors based on electrohydrodynamically printed, self-similar piezoelectric nano/microfibers. Nano Energy 2017, 40, 432–439. [Google Scholar] [CrossRef]

- Ryu, S.; Lee, P.; Chou, J.B.; Xu, R.; Zhao, R.; Hart, A.J.; Kim, S.-G. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 2015, 9, 5929–5936. [Google Scholar] [CrossRef]

- Sanli, A.; Benchirouf, A.; Müller, C.; Kanoun, O. Piezoresistive performance characterization of strain sensitive multi-walled carbon nanotube-epoxy nanocomposites. Sens. Actuators A Phys. 2017, 254, 61–68. [Google Scholar] [CrossRef]

- Kong, J.-H.; Jang, N.-S.; Kim, S.-H.; Kim, J.-M. Simple and rapid micropatterning of conductive carbon composites and its application to elastic strain sensors. Carbon 2014, 77, 199–207. [Google Scholar] [CrossRef]

- Eswaraiah, V.; Balasubramaniam, K.; Ramaprabhu, S. Functionalized graphene reinforced thermoplastic nanocomposites as strain sensors in structural health monitoring. J. Mater. Chem. 2011, 21, 12626. [Google Scholar] [CrossRef]

- Tadakaluru, S.; Thongsuwan, W.; Singjai, P. Stretchable and flexible high-strain sensors made using carbon nanotubes and graphite films on natural rubber. Sensors 2014, 14, 868–876. [Google Scholar] [CrossRef]

- Alamusi; Hu, N.; Fukunaga, H.; Atobe, S.; Liu, Y.; Li, J. Piezoresistive strain sensors made from carbon nanotubes based polymer nanocomposites. Sensors 2011, 11, 10691–10723. [Google Scholar] [CrossRef] [PubMed]

- Yin, F.; Ye, D.; Zhu, C.; Qiu, L.; Huang, Y.A. Stretchable, highly durable ternary nanocomposite strain sensor for structural health monitoring of flexible aircraft. Sensors 2017, 17, 2677. [Google Scholar] [CrossRef]

- Buganza-Tepole, A.; Steinberg, J.P.; Kuhl, E.; Gosain, A.K. Application of finite element modeling to optimize flap design with tissue expansion. Plast. Reconstr. Surg. 2014, 134, 785–792. [Google Scholar] [CrossRef]

- Ryu, S.Y.; Xiao, J.L.; Park, W.I.; Son, K.S.; Huang, Y.Y.; Paik, U.; Rogers, J.A. Lateral buckling mechanics in silicon nanowires on elastomeric substrates. Nano Lett. 2009, 9, 3214–3219. [Google Scholar] [CrossRef] [PubMed]

- Agache, P.G.; Monneur, C.; Lévèque, J.L.; Derigal, J. Mechanical properties and Young’s modulus of human skin in vivo. Arch. Dermatol. Res. 1980, 269, 221–232. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.J.; Pharr, M.; Wang, L.; Kim, J.; Liu, Y.H.; Xue, Y.G.; Ning, R.; Wang, X.F.; Chung, H.U.; Feng, X.; et al. Soft elastomers with ionic liquid-filled cavities as strain isolating substrates for wearable electronics. Small 2017, 13, 1602954. [Google Scholar] [CrossRef] [PubMed]

- Cai, M.; Du, Y.; Nie, S.; Wang, C.; Song, J. Soft elastomers with programmable stiffness as strain-isolating substrates for stretchable electronics. ACS Appl. Mater. Inter. 2019. [Google Scholar] [CrossRef] [PubMed]

- Xu, F.; Wen, T.; Seffen, K.; Lu, T. Modeling of skin thermal pain: A preliminary study. Appl. Math. Comput. 2008, 205, 37–46. [Google Scholar] [CrossRef]

- Duan, L.Y.; Fu, S.R.; Deng, H.; Zhang, Q.; Wang, K.; Chen, F.; Fu, Q. The resistivity-strain behavior of conductive polymer composites: Stability and sensitivity. J. Mater. Chem. A 2014, 2, 17085–17098. [Google Scholar] [CrossRef]

- Gabriel, S.; Lau, R.W.; Gabriel, C. The dielectric properties of biological tissues: III. Parametric models for the dielectric spectrum of tissues. Phys. Med. Biol. 1996, 41, 2271–2293. [Google Scholar] [CrossRef]

- The Engineering ToolBox. Available online: https://www.engineeringtoolbox.com/ (accessed on 23 May 2019).

- Lacour, S.P.; Chan, D.; Wagner, S.; Li, T.; Suo, Z.G. Mechanisms of reversible stretchability of thin metal films on elastomeric substrates. Appl. Phys. Lett. 2006, 88, 204103. [Google Scholar] [CrossRef]

- Oskouyi, A.B.; Sundararaj, U.; Mertiny, P. Current-voltage characteristics of nanoplatelet-based conductive nanocomposites. Nanoscale Res. Lett. 2014, 9, 368. [Google Scholar] [CrossRef]

- Paredes-Madrid, L.; Matute, A.; Bareno, J.O.; Vargas, C.A.P.; Velasquez, E.I.G. Underlying physics of conductive polymer composites and force sensing Resistors (FSRs). A study on creep response and dynamic loading. Materials 2017, 10, 1334. [Google Scholar] [CrossRef] [PubMed]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, J.; Li, Y.; Xing, Y. Ultrasoft, Adhesive and Millimeter Scale Epidermis Electronic Sensor for Real-Time Enduringly Monitoring Skin Strain. Sensors 2019, 19, 2442. https://doi.org/10.3390/s19112442

Zhang J, Li Y, Xing Y. Ultrasoft, Adhesive and Millimeter Scale Epidermis Electronic Sensor for Real-Time Enduringly Monitoring Skin Strain. Sensors. 2019; 19(11):2442. https://doi.org/10.3390/s19112442

Chicago/Turabian StyleZhang, Jianpeng, Yuhang Li, and Yufeng Xing. 2019. "Ultrasoft, Adhesive and Millimeter Scale Epidermis Electronic Sensor for Real-Time Enduringly Monitoring Skin Strain" Sensors 19, no. 11: 2442. https://doi.org/10.3390/s19112442

APA StyleZhang, J., Li, Y., & Xing, Y. (2019). Ultrasoft, Adhesive and Millimeter Scale Epidermis Electronic Sensor for Real-Time Enduringly Monitoring Skin Strain. Sensors, 19(11), 2442. https://doi.org/10.3390/s19112442