Abstract

This study investigates the photocatalytic degradation of organic compounds on TiO2-coated concrete paving cubes, with a focus on their potential for environmental remediation in urban settings. The TiO2 P25 coating significantly enhanced the photocatalytic activity of the concrete surface, enabling effective degradation of model pollutants such as methylene blue. Various application methods were evaluated, including surface coating with and without impregnation, and bulk incorporation of TiO2 into the concrete matrix. Surface properties were assessed using contact angle measurements and absorption tests. Among all tested variants, the surface-coated and impregnated sample (SURF-IMP) showed the highest photocatalytic efficiency, achieving over 67% pollutant degradation. This variant also demonstrated the lowest water absorption and the highest contact angle, confirming improved surface hydrophobicity. In contrast, the bulk-modified sample (MIX) exhibited weaker performance due to limited surface accessibility of TiO2 particles. These findings highlight the importance of the application method in optimizing the performance of TiO2-functionalized concrete. The developed system offers a practical approach to integrating photocatalytic properties into paving materials for applications such as air purification, surface decontamination, and sustainable urban infrastructure.

1. Introduction

The increasing levels of air pollution and environmental degradation in urban areas pose serious challenges to sustainable development, human health, and the longevity of civil infrastructure [1,2,3]. Urban surfaces such as pavements, façades, and concrete structures tend to accumulate particulate matter, organic pollutants, and microorganisms, resulting not only in aesthetic deterioration but also in accelerated chemical and physical degradation [2,4,5]. Addressing these challenges requires innovative multifunctional materials that combine structural performance with environmental self-cleaning and pollutant degradation capabilities [6,7,8].

In this context, photocatalytic materials—particularly titanium dioxide (TiO2)—have emerged as promising candidates due to their stability, non-toxicity, abundance, and strong oxidative potential under light irradiation [1,9,10,11]. When exposed to ultraviolet (UV) or visible light, TiO2 generates reactive oxygen species (ROS) capable of decomposing a wide range of organic and inorganic contaminants, including volatile organic compounds (VOCs), nitrogen oxides (NOx), and hydrocarbons [4,10,11,12,13]. This photocatalytic mechanism has been successfully applied in environmental cleanup, air purification, and wastewater treatment processes [7,14,15,16,17]. In addition, TiO2-based materials have shown potential in energy-related applications, such as hydrogen production from organic feedstocks, highlighting their versatility in pollutant degradation and resource transformation [18]. Recent advancements in heterogeneous photocatalysis have significantly improved the design and efficiency of TiO2-based materials. Modifications such as metal and non-metal doping (e.g., nitrogen, sulfur, carbon), surface sensitization, and hybrid composite formation have extended TiO2 activity into the visible light spectrum, which is crucial for real-world applications where UV radiation is limited [9,14,19,20,21]. Moreover, innovative deposition techniques such as sol–gel processing, spray and dip coating, plasma treatment, and nanostructured film formation have enhanced TiO2 adhesion, dispersion, and long-term durability on construction surfaces [22,23,24,25]. These developments have positioned TiO2 as a cornerstone material in the emerging field of photocatalytic construction composites, where functionality extends beyond mechanical strength to include environmental remediation and sustainability [12,26,27,28,29].

Concrete, as the most widely used construction material worldwide, provides an ideal substrate for TiO2 integration due to its abundance, surface exposure, and structural versatility [19,23,30]. However, its inherently porous microstructure promotes the accumulation of dust, smog particles, and organic pollutants, leading to discoloration, surface weakening, and reduced service life [24,31,32]. The incorporation of TiO2 into concrete—either as a surface coating or a bulk additive—offers a viable solution to mitigate these effects. Upon illumination, TiO2 promotes photocatalytic degradation of pollutants, thus reducing maintenance needs, improving hydrophilicity and self-cleaning properties, and extending the lifespan of concrete elements [2,7,12,33]. Furthermore, TiO2-based coatings have been shown to improve the depolluting efficiency of urban infrastructure by reducing atmospheric concentrations of NOx, CO, and VOCs in both indoor and outdoor environments [13,18,34,35,36].

Recent studies have expanded the functionality of TiO2-modified construction materials. Nitrogen-doped TiO2 composites have shown improved visible-light activity, enabling efficient photocatalytic performance even in shaded or low-light urban environments [10,14]. Hybrid systems such as TiO2/SiO2, Cu–TiO2/SiO2, and black TiO2 have been developed to enhance light absorption, charge carrier separation, and overall photocatalytic stability [24,25]. Investigations by Khannyra et al. [17] demonstrated that appropriately engineered TiO2 coatings retain high self-cleaning efficiency and mechanical integrity even after long-term exposure to environmental stressors. Moreover, research by Kalinowski et al. [33] and Jenim et al. [12] highlighted the potential of nano-TiO2-modified cementitious composites to achieve carbon-negative performance through simultaneous air purification and CO2 reduction. These findings emphasize the dual environmental and structural benefits of TiO2 integration in cementitious materials.

In addition to environmental reactivity, TiO2 incorporation improves mechanical behavior and durability of cementitious composites. Studies indicate that optimal nano-TiO2 dosages (1–6 wt.%) increase compressive and flexural strength, refine pore structure, and enhance resistance to freeze–thaw cycles and abrasion [34,35,36]. When combined with recycled aggregates such as reclaimed asphalt pavement, CRT glass, or industrial by-products, TiO2 improves interfacial bonding while preserving photocatalytic activity, contributing to more sustainable composite design [29,30,32]. Recent research highlights the development of TiO2 enhanced building materials for environmental purification [37] and demonstrates the effectiveness of hydrophilic polymer dispersions that improve TiO2 dispersion uniformity, resulting in enhanced surface activation and NOx degradation [38], while comparative analyses of spray- and dip-coated layers underscore the importance of the deposition method for long-term self-cleaning performance [39]. Additional advances include immobilization strategies for TiO2 on reusable substrates and reactor systems that enhance photocatalytic efficiency and enable catalyst recovery [40], as well as progress in visible-light-activated TiO2 materials relevant to pollutant degradation in alkaline environments typical of cementitious systems [41]. Based on these developments, the present study investigates TiO2-coated concrete paving units intended for environmental remediation and long-term durability in urban conditions. The experimental program encompasses photocatalytic degradation of organic contaminants and NOx [6,10,14], surface self-cleaning ability [17,24], and changes in surface wettability associated with TiO2 coating and dispersion mechanisms [38,39]. Measurements of water and oil absorption, contact angles, and photodegradation efficiency are conducted under natural and artificial illumination, while UV exposure, moisture cycling, and abrasion tests follow methodologies used in durability studies of photocatalytic building materials [12,19,25]. These analyses provide a comprehensive understanding of the potential of TiO2-modified concrete to enhance air quality, surface functionality, and material lifespan within urban infrastructure, contributing to the development of sustainable, multifunctional construction materials.

2. Materials and Methods

2.1. Materials and Chemicals

All reagents used in this study were of analytical grade and applied without further purification. Deionized water was employed for all solution preparations. Concrete paving blocks were fabricated using ordinary Portland cement (CEM I 42.5R), industrial sand (0–2 mm), and gravel (2–8 mm), following standard construction practice to ensure reproducibility and mechanical stability. The detailed composition of the concrete mixture is presented in Table 1.

Table 1.

Composition of the concrete mixture.

Concrete cubes with dimensions of 5 × 5 × 5 cm3 were cast in steel molds and cured under controlled laboratory conditions (18 ± 2 °C, relative humidity > 90%) for 14 days. The impregnation agent (Feda, Warsaw, Poland) was primarily composed of Tetrahydro-1,3,4,6-tetrakis(hydroxymethyl)imidazo[4,5-d]imidazole-2,5(1H,3H)-dione, stabilized with a mixture of 5-chloro-2-methyl-4-isothiazolin-3-one and 2-methyl-4-isothiazolin-3-one (3:1). Titanium dioxide (TiO2, anatase phase, <100 nm, Sigma-Aldrich, Saint Louis, MO, USA) was used as the photocatalyst.

The impregnation system was designed to utilize the four hydroxymethyl (–CH2OH) groups in Feda compound, which form hydrogen bonds with hydroxyl groups on the TiO2 surface. These interactions enhance the adhesion of nanoparticles to the concrete matrix and limit their potential leaching under aqueous conditions.

2.2. Preparation of TiO2-Coated Concrete Cubes

The preparation of TiO2-coated concrete cubes followed a multi-step procedure to ensure uniform coating and reproducible photocatalytic performance. Initially, dry components—cement, sand, and gravel—were thoroughly mixed until a homogeneous composition was achieved. Deionized water was then gradually added while mixing to reach a workable consistency. The fresh mixture was poured into molds (5 × 5 × 5 cm3), compacted to remove air voids, and leveled to achieve surface uniformity. After casting, the molds were placed in a curing chamber maintained at 18 ± 2 °C and relative humidity above 90% for 14 days, ensuring proper hydration and strength development.

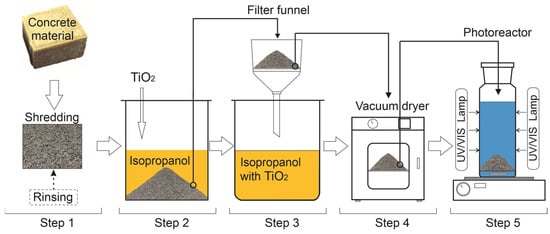

Following the curing process, the TiO2/Feda coating was applied via immersion. TiO2 nanoparticles were dispersed in deionized water containing 2 wt.% of Feda agent and magnetically stirred for 1 h to ensure complete homogenization. The coating process is schematically illustrated in Figure 1.

Figure 1.

Schematic illustration of concrete cube preparation and TiO2 impregnation/coating process. Concrete cubes were cast, cured, and then impregnated and coated with TiO2 for uniform surface coverage.

The cured concrete cubes were immersed in this dispersion for 10 min, drained, and dried at 60 °C for 2 h. This procedure was repeated up to three times to obtain multilayer coverage, providing enhanced surface uniformity and photocatalytic performance. After coating, the samples were stored under ambient conditions for 24 h before testing. The parameters applied during the coating process are summarized in Table 2.

Table 2.

TiO2 coating parameters.

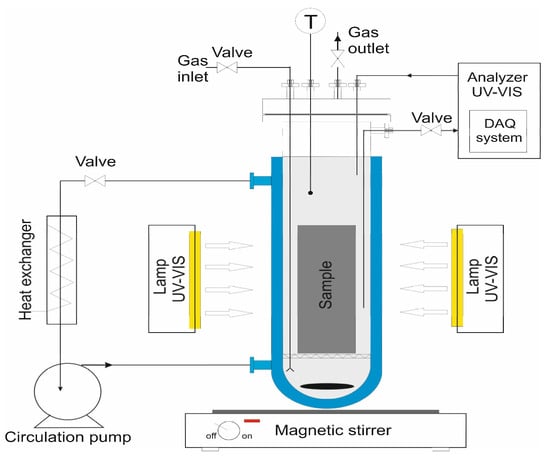

2.3. Analysis of Water Absorption and Wettability

The water absorption behavior of the cementitious samples was analyzed using a gravimetric method based on indirect contact. Prior to testing, all concrete cubes (both TiO2/Feda-coated and uncoated reference samples) were dried in a laboratory oven at 105 °C for 3 h to remove physically adsorbed moisture. Each cube was subsequently placed on a polyethylene (PE) foam pad saturated with deionized water, ensuring uniform water delivery to the sample surface (Figure 2). The mass of each sample was recorded at regular intervals using a standard analytical balance (accuracy ±0.1 mg). This setup is distinct from a contact angle measurement, which assesses surface wettability rather than absorption kinetics.

Figure 2.

Experimental setup for gravimetric analysis of water absorption using PE foam contact method.

The wetting rate Nw was calculated according to Equation (1):

where:

- Nw—wetting rate [g/(m2·h)];

- Δm = mt − m0—difference in the mass of the sample at time t(mt) and the initial mass (m0) [g];

- A—surface area of the sample in contact with the sponge, through which absorption occurs [m2];

- Δt—time interval during which absorption is measured [h].

Contact angle measurements were carried out using a Goniometer OCA 25 (DataPhysics Instruments, Filderstadt, Germany) to determine surface wettability (10 μL water droplets). Microscopic observations were performed using a Bresser Researcher Bino Binocular Microscope 40×–1000× (Bresser, Rhede, Germany) to examine surface morphology and coating uniformity. The oven drying parameters were 105 °C for 3 h.

This experimental setup allows reproducible evaluation of water absorption kinetics and wettability of both TiO2/Feda-coated and uncoated concrete samples, providing the basis for subsequent quantitative analysis in the Results and Discussion section.

2.4. Mechanical Properties of TiO2-Modified Concrete Cubes

The mechanical properties of the concrete cubes were evaluated using compressive strength testing. Concrete specimens with dimensions of 50 × 50 × 40 mm were prepared and classified into four groups:

- REF—reference concrete cube without TiO2;

- SURF-noIMP—concrete cube with TiO2 (P25) applied on the surface, without impregnation;

- SURF-IMP—concrete cube with TiO2 (P25) applied on the surface with impregnation;

- MIX—concrete cube with TiO2 (P25) distributed throughout the concrete mass (0.5 wt.%).

All samples were cured for 28 days under humid conditions. Prior to testing, the specimens were dried to constant mass. Compressive strength measurements were conducted using a MEGA 100 universal testing machine (ViaTeco, Warszawa, Poland). For each sample type, three replicates (n = 3) were tested, and the mean values with standard deviations (SD) were reported.

2.5. Photocatalytic Activity Tests

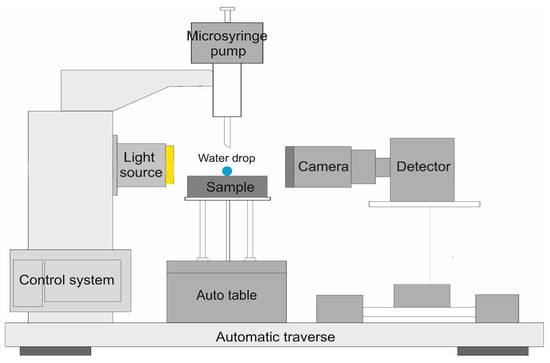

The photocatalytic performance of TiO2-coated concrete cubes was evaluated using methylene blue (MB) as a model organic pollutant. Each concrete cube was uniformly coated with a 10 mg/L aqueous solution of MB and allowed to rest in the dark for 1 h to reach adsorption–desorption equilibrium. Subsequently, the samples were irradiated under a Xe-arc lamp (4 × 75 W, spectral range 320–780 nm, light intensity 55 W/m2 at a distance of 20 cm) for 4 h. The experimental setup for the photocatalytic tests is presented in Figure 3.

Figure 3.

Schematic diagram of the photocatalytic reactor (75 W × 4 Xe-arc; Shredded paving stone with TiO2 and methylene blue dye addition).

The concentration of residual methylene blue (MB) was measured spectrophotometrically at 664 nm, the wavelength of maximum absorbance of the dye. All measurements were performed in triplicate (n = 3) to ensure reproducibility. The main experimental parameters for the photocatalytic degradation tests, including TiO2 loading, sample geometry, irradiation conditions, and solution volume, are summarized in Table 3. The photocatalytic degradation process was monitored by recording changes in MB absorbance at regular time intervals throughout the irradiation period.

Table 3.

Photocatalytic degradation test parameters.

3. Results and Discussion

3.1. Effect of Surface TiO2 Loading (ppm) on the Preparation of Concrete Cubes

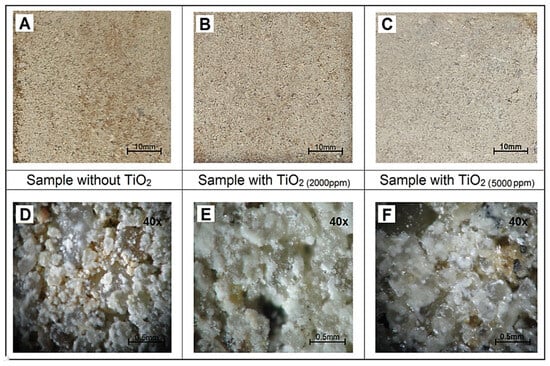

Preliminary optimization tests were conducted to evaluate the influence of TiO2 concentration and its mode of application on the physicochemical properties of concrete paving cubes. TiO2 suspensions in isopropanol were prepared at varying concentrations and applied either onto the surface or incorporated within the bulk material. Among the tested concentrations, 5000 ppm exhibited the most stable dispersion, homogeneous deposition, and reproducible photocatalytic performance under laboratory conditions [11,33].

As illustrated in Figure 4, the uncoated reference sample (REF) presented a heterogeneous concrete surface with open pores and a rough morphology, which facilitates water ingress but provides limited chemical activity. At 2000 ppm TiO2, partial surface coverage was observed, indicating initial photocatalyst adhesion, although the distribution remained non-uniform. Increasing the loading to 5000 ppm produced a darker and smoother surface, suggesting the formation of a continuous TiO2 layer that enhances light absorption and active-site availability, in line with observations by Khannyra et al. [17] and Luna et al. [25]. Therefore, subsequent experiments were performed using 5000 ppm TiO2 as the optimized surface concentration.

Figure 4.

Paving stones without and with the addition of TiO2: (A–C) Surface images showing differences in appearance between the reference sample and the sample with TiO2; (D–F) Microscopic views (40×) illustrating changes in surface texture resulting from the addition of TiO2.

3.2. Wettability and Water Absorption Behavior

The influence of TiO2 surface modification on the wettability and water absorption behavior of concrete paving cubes was evaluated. Contact angle (CA) measurements revealed a significant alteration in surface energy due to the presence of TiO2 coatings (Figure 5, Table 4). The unmodified reference concrete (REF) exhibited complete wetting (CA ≈ 0° for both water and oil), confirming its inherently hydrophilic and oleophilic character.

Figure 5.

Image of a distilled water droplet placed on the SURF-IMP concrete surface during static contact angle measurement (droplet volume: 10 µL, temp.: 23 ± 1 °C, RH (relative humidity): 50 ± 5%, measurement time after droplet deposition: 5 s).

Table 4.

Wettability Analysis of Cubic Concrete Samples Using the Contact Angle Method.

Among the TiO2-modified samples, SURF-noIMP (TiO2 deposited on the surface without impregnation) displayed moderate water (77.1°) and oil (31.7°) contact angles, indicating partial resistance to liquid spreading. The MIX variant, where TiO2 nanoparticles were incorporated into the bulk concrete, showed lower contact angles (67.2° for water; 19.4° for oil), reflecting limited availability of active TiO2 at the surface. In contrast, the SURF-IMP sample, subjected to surface impregnation, exhibited the highest hydrophobic and oleophobic response (water CA = 86.5°, oil CA = 37.1°), highlighting the effect of the impregnation process in densifying the near-surface layer and promoting chemical anchoring of TiO2 nanoparticles. This is consistent with prior studies reporting enhanced surface performance through impregnation strategies [24,38].

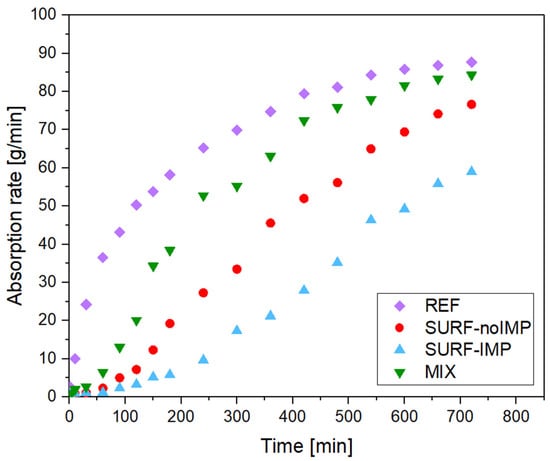

The water absorption kinetics, evaluated via gravimetric analysis using saturated PE foam pads, further supported these observations. Reference samples (R) absorbed water rapidly (Nw = 80 g/m2·h), whereas TiO2-coated specimens showed significantly reduced water uptake (Table 5). The SURF-IMP sample demonstrated the lowest wetting rate (Nw = 32 g/m2·h), indicating that the combination of TiO2 deposition and surface impregnation effectively reduces capillary absorption, improving the durability and functional performance of concrete surfaces.

Table 5.

Example results of water absorption.

These results collectively demonstrate that TiO2 coatings reduce water uptake and modify surface energy, with the impregnation method yielding the most pronounced effects. The observed trends are in agreement with previous reports indicating that surface-exposed TiO2 enhances hydrophobicity and self-cleaning potential, while bulk-embedded particles contribute less to surface functionalization [8,17,24,38].

Microscopic observations using a Bresser Researcher Bino Binocular Microscope (Bresser, Germany) revealed uniform coverage in the SURF-IMP samples, whereas MIX and SURF-noIMP surfaces exhibited partial or non-uniform TiO2 distribution. Future work will employ SEM/EDS analysis to investigate nanoparticle distribution, adhesion, and interactions within the cementitious matrix at the micro- and nanoscale.

The correlation between surface chemistry and water absorption is shown in Figure 6. After 720 min of immersion, the REF sample exhibited the highest absorption rate (87.69%), while the SURF-IMP specimen showed the lowest (58.96%). The reduced absorption of SURF-IMP can be attributed to the filling and nucleation effects of TiO2, which refine the pore network and strengthen the interfacial transition zone (ITZ) through enhanced C–S–H formation [35,36]. This dual mechanism limits water ingress and supports the development of durable, photocatalytically active surfaces suitable for long-term urban exposure.

Figure 6.

Water absorption rate of concrete cubes prepared using different TiO2 application methods: SURF-noIMP (TiO2 applied on the surface without impregnation), SURF-IMP (TiO2 applied on the surface with impregnation), MIX (TiO2 distributed throughout the entire concrete mass), and REF (reference sample without TiO2).

3.3. Compressive Strength of Concrete Cubes

The prepared concrete cubes containing TiO2 exhibited enhanced technical properties, including higher compressive strength and lower water absorption, while maintaining favorable mechanical performance. The compressive strength results of the different concrete samples after 28 days of curing under moist conditions are summarized in Table 6.

Table 6.

Compressive strength of concrete cubes (mean ± SD, n = 3).

Analysis of the data presented in Table 6 shows that the SURF-noIMP and SURF-IMP samples, containing approximately 5.9 g TiO2/m2 on the surface and within surface pores, exhibited no significant change in compressive strength compared with the reference sample (REF), with mean values of 42.1 MPa. The surface impregnation effectively minimized TiO2 leaching from the concrete surface, while maintaining the mechanical integrity of the material.

In contrast, the MIX samples, with TiO2 homogeneously distributed throughout the concrete matrix, showed an increase in compressive strength relative to REF. Incorporation of 5.0 g TiO2 per kg of concrete (0.5 wt.%) led to an increase in compressive strength from 41.6 to 44.3 MPa, corresponding to an improvement of approximately 6.5%. This enhancement is attributed to the micro-filling effect of the nanoparticles. The addition of 0.5 wt.% nano-TiO2 promotes cement hydration through a nucleation effect, resulting in a denser microstructure and reduced porosity compared with concrete samples without TiO2.

3.4. Photocatalytic Degradation of Pollutants

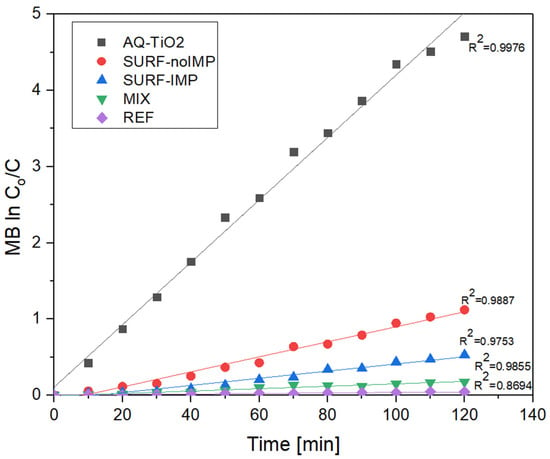

The photocatalytic degradation efficiency of methylene blue (MB) was evaluated over 120 min under simulated solar irradiation (Figure 7). The quantitative results, including initial and final molar concentrations and calculated degradation degrees with standard deviations, are summarized in Table 6. These data confirm that TiO2-modified surfaces exhibit markedly improved pollutant removal compared with the uncoated reference sample.

Figure 7.

Photocatalytic degradation of methylene blue (MB) on concrete samples over 120 min: AQ-TiO2 (aqueous TiO2 suspension), SURF-noIMP (TiO2 on surface without impregnation), SURF-IMP (TiO2 on surface with impregnation), MIX (TiO2 distributed throughout concrete mass), and REF (reference without TiO2).

The reference sample (REF) showed minimal degradation (4.11%), confirming the absence of any photocatalytic contribution from the unmodified concrete. In contrast, all TiO2-coated samples exhibited significant degradation, proportional to the degree of TiO2 surface exposure. The SURF-noIMP sample achieved a degradation rate of 41.11%, reflecting the inherent photocatalytic activity of surface-deposited TiO2. The MIX sample, with TiO2 uniformly distributed throughout the concrete matrix, displayed only 15.99% degradation, as the majority of nanoparticles remained embedded within the cement paste and were shielded from light and reactants. This behavior is consistent with previous studies showing that only exposed TiO2 surfaces contribute to photochemical reactions [13,20,31].

The SURF-IMP configuration exhibited the highest photocatalytic efficiency (67.41%), highlighting the synergistic effect of the impregnation process. The functional impregnation medium, containing hydroxymethyl-rich imidazolidinone derivatives, likely promoted TiO2 particle retention through hydrogen bonding and covalent Si–O–Ti linkages, preventing photocatalyst leaching and sustaining long-term reactivity [25,33,38]. The improved surface uniformity and compactness enhance light absorption and active-site availability, directly contributing to the increased degradation kinetics of methylene blue.

The photocatalytic performance of concrete cubes with different TiO2 surface treatments was evaluated based on the degradation of methylene blue. Table 7 presents the initial and final molar concentrations of the pollutant along with the degree of degradation for each sample. The SURF-IMP configuration demonstrated the highest photocatalytic efficiency (67.41%), followed by SURF-noIMP (41.11%) and MIX (15.99%), while the uncoated reference (REF) exhibited negligible degradation (4.11%). The low variability between replicates (SD ≤ 3.5%) confirms the reproducibility of the measurements.

Table 7.

Initial and final molar concentrations of pollutant and degree of degradation (SD) on concrete cubes with and without TiO2 coating.

The superior efficiency of the SURF-IMP samples is attributed to the functional impregnation, which enhances TiO2 retention and maintains an active surface layer through hydrogen bonding and covalent Si–O–Ti interactions [38]. In contrast, TiO2 dispersed within the bulk (MIX) shows lower surface availability, resulting in reduced photocatalytic activity [33]. The effectiveness of surface-localized TiO2 in promoting pollutant degradation and self-cleaning performance is consistent with previous studies on cementitious materials [9,24]. Overall, the results indicate that optimized surface loading and stable retention of TiO2 significantly enhance the photocatalytic performance of concrete paving blocks, in line with general principles of heterogeneous photocatalysis [3].

4. Conclusions

The results of this study demonstrate that the method use for TiO2 incorporation exerts a decisive influence on both the photocatalytic efficiency and surface performance of concrete paving blocks. Among all tested configurations, the surface application of TiO2 combined with a functional impregnation treatment proved to be the most effective modification strategy. This system achieved the highest pollutant degradation efficiency—over sixteen times greater than that of the unmodified reference sample—confirming the pronounced photocatalytic activity of the treated surface.

In addition to superior photocatalytic performance, the impregnated TiO2 coating significantly reduced water absorption and increased the contact angle values, indicating enhanced hydrophobicity and improved resistance to environmental factors such as moisture ingress and surface fouling. These characteristics are essential for extending the service life, self-cleaning capability, and long-term durability of concrete elements exposed to outdoor conditions. Conversely, the incorporation of TiO2 nanoparticles within the bulk of the concrete matrix yielded markedly lower photocatalytic activity. This is primarily attributed to the partial encapsulation of TiO2 particles within the cementitious microstructure, which limits their accessibility to ultraviolet radiation and atmospheric pollutants. Consequently, the spatial distribution and stabilization of TiO2 on the concrete surface are key determinants of its functional effectiveness.

Overall, the application of TiO2 through surface coating combined with impregnation presents a practical and scalable approach for producing multifunctional, photocatalytically active concrete materials. Such surfaces not only enhance the environmental performance of urban infrastructure—by contributing to air purification and self-cleaning effects—but also improve durability and reduce maintenance demands. Therefore, this technology represents a promising pathway toward the development of sustainable and intelligent construction materials for next-generation urban environments.

Author Contributions

Conceptualization, K.B. and A.L.; methodology, K.B. and A.L.; validation, K.B. and A.L.; formal analysis, K.B. and A.L.; investigation, K.B. and A.L.; resources, K.B. and A.L.; data curation, K.B. and A.L.; writing—original draft preparation, K.B. and A.L.; writing—review and editing, K.B. and A.L.; visualization, K.B. and A.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding authors.

Acknowledgments

In the preparation of this manuscript, we used generative artificial intelligence (GenAI) tools solely for language editing of selected sections of the text. The final content, analysis, and interpretations were fully developed and verified by the authors. All use of GenAI tools is transparent and complies with the journal’s policies on AI-assisted writing.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| AQ-TiO2 | aqueous solution containing TiO2 (P25) |

| SURF-noIMP | concrete cube with TiO2 (P25) on the surface, no impregnation |

| SURF-IMP | concrete cube with TiO2 (P25) on the surface, with impregnation |

| MIX | concrete cube with TiO2 (P25) distributed throughout the entire concrete mass |

| REF | reference concrete cube without TiO2 |

| Xe-arc | xenon lamp |

References

- Ohtani, B.; Pal, B.; Ikeda, S. Photocatalytic organic syntheses: Selective cyclization of amino acids in aqueous suspensions. Catal. Surv. Asia 2003, 7, 165–176. [Google Scholar] [CrossRef]

- Żenkiewicz, M. Adhezja i Modyfikowanie Warstwy Wierzchniej Tworzyw Wielkocząsteczkowych; WNT: Warszawa, Poland, 2000. [Google Scholar]

- Ibhadon, A.; Fitzpatrick, P. Heterogeneous photocatalysis: Recent advances and applications. Catalysts 2013, 3, 189–218. [Google Scholar] [CrossRef]

- Fujishima, A.; Zhang, X.; Tryk, D.A. Heterogeneous photocatalysis: From water photolysis to applications in environmental cleanup. Int. J. Hydrogen Energy 2007, 32, 2664–2672. [Google Scholar] [CrossRef]

- Wang, H.; Li, X.; Zhao, X.; Li, C.; Song, X.; Zhang, P.; Huo, P.; Li, X. A review on heterogeneous photocatalysis for environmental remediation: From semiconductors to modification strategies. Chin. J. Catal. 2022, 43, 178–214. [Google Scholar] [CrossRef]

- Chen, D.; Cheng, Y.; Zhou, N.; Chen, P.; Wang, Y.; Li, K.; Huo, S.; Cheng, P.; Peng, P.; Zhang, R.; et al. Photocatalytic degradation of organic pollutants using TiO2-based photocatalysts: A review. J. Clean. Prod. 2020, 268, 121725. [Google Scholar] [CrossRef]

- Ren, G.; Han, H.; Wang, Y.; Liu, S.; Zhao, J.; Meng, X.; Li, Z. Recent Advances of Photocatalytic Application in Water Treatment: A Review. Nanomaterials 2021, 11, 1804. [Google Scholar] [CrossRef]

- Gopalan, A.-I.; Lee, J.-C.; Saianand, G.; Lee, K.-P.; Sonar, P.; Dharmarajan, R.; Hou, Y.-L.; Ann, K.-Y.; Kannan, V.; Kim, W.-J. Recent Progress in the Abatement of Hazardous Pollutants Using Photocatalytic TiO2-Based Building Materials. Nanomaterials 2020, 10, 1854. [Google Scholar] [CrossRef] [PubMed]

- Kotzias, D.; Binas, V.; Kiriakidis, G. Smart Surfaces: Photocatalytic Degradation of Priority Pollutants on TiO2-Based Coatings in Indoor and Outdoor Environments—Principles and Mechanisms. Materials 2022, 15, 402. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, Q.; Shan, R.; Zhang, F.; Muhammad, Y.; Huang, K. Photocatalytic Degradation of Vehicular Exhaust by Nitrogen-Doped Titanium Dioxide Modified Pavement Material. Transp. Res. Part D 2021, 91, 102690. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.; Dong, X.; Xi, X.; Dong, P. Recent Advances in TiO2-Based Photocatalytic Concrete: Synthesis Strategies, Structure Characteristics, Multifunctional Applications, and CFD Simulation. Chem. Eng. J. 2024, 496, 154186. [Google Scholar] [CrossRef]

- Jenim, J.; Dharshini, M.P.; Ajin, M.L.; Moses, J.J.; Retnam, K.P.; Arunachalam, K.P.; Avudaiappan, S.; Munoz, R.F.A. A Comprehensive Review of Titanium Dioxide Nanoparticles in Cementitious Composites. Heliyon 2024, 10, e39238. [Google Scholar] [CrossRef]

- McIntyre, H.M.; Hart, M.L. Immobilization of TiO2 Nanoparticles in Cement for Improved Photocatalytic Reactivity and Treatment of Organic Pollutants. Catalysts 2021, 11, 938. [Google Scholar] [CrossRef]

- Dong, P.; Wang, C.; Tan, J.; Wang, Y.; Xi, X.; Zhang, J. Solar-Driven Photocatalytic Removal of NO over a Concrete Paving Eco-Block Containing Black TiO2. J. Mater. Chem. A 2023, 11, 25429. [Google Scholar] [CrossRef]

- Caputo, P.; Porto, M.; Angelico, R.; Loise, V.; Calandra, P.; Rossi, C.O. Bitumen and Asphalt Concrete Modified by Nanometer-Sized Particles: Basic Concepts, the State of the Art and Future Perspectives of the Nanoscale Approach. Adv. Colloid Interface Sci. 2020, 285, 102283. [Google Scholar] [CrossRef]

- Aboelkheir, M.G.; Thomas, S.; de Souza, F.G.; Toledo Filho, R.D.; Celestino, R.; Thode Filho, S.; de Carvalho, F.V.; Maranhão, F.d.S.; Pereira, E.D.; da Costa, V.C.; et al. Influence of UV-modified GTR on the properties of interlocking concrete paving units. J. Mol. Struct. 2021, 1234, 130110. [Google Scholar] [CrossRef]

- Khannyra, S.; Luna, M.; Almoraima Gil, M.L.; Addou, M.; Mosquera, M.J. Self-Cleaning Durability Assessment of TiO2/SiO2 Photocatalysts Coated Concrete: Effect of Indoor and Outdoor Conditions on the Photocatalytic Activity. Build. Environ. 2022, 211, 108743. [Google Scholar] [CrossRef]

- Gunerhan, A.; Altuntas, O.; Açıkkalp, E. A Comprehensive Analysis of the Production of H2 and Value-Added Chemicals from the Electrolysis of Biomass and Derived Feedstocks. Biomass Bioenergy 2025, 192, 107510. [Google Scholar] [CrossRef]

- Carmona-Quiroga, P.M.; Martínez-Ramírez, S.; Viles, H.A. Efficiency and Durability of a Self-Cleaning Coating on Concrete and Stones Under Both Natural and Artificial Ageing Trials. Appl. Surf. Sci. 2018, 433, 312–320. [Google Scholar] [CrossRef]

- Quagliarini, E.; Bondioli, F.; Goffredo, G.B.; Cordoni, C. Self-Cleaning and De-Polluting Stone Surfaces: TiO2 Nanoparticles for Limestone. Constr. Build. Mater. 2012, 37, 51–57. [Google Scholar] [CrossRef]

- Sadeghnejad, M.; Shafabakhsh, G. Use of Nano SiO2 and Nano TiO2 to Improve the Mechanical Behaviour of Stone Mastic Asphalt Mixtures. Constr. Build. Mater. 2017, 157, 965–974. [Google Scholar] [CrossRef]

- Jamshidi, A.; Kurumisawa, K.; White, G.; Nishizawa, T.; Igarashi, T.; Nawa, T.; Mao, J. State-of-the-Art of Interlocking Concrete Block Pavement Technology in Japan as a Post-Modern Pavement. Constr. Build. Mater. 2019, 200, 713–755. [Google Scholar] [CrossRef]

- Custódio, P.; Lied, E.B.; da Silva, A.V.; Frare, L.M.; Stival Bittencourt, P.R.; de Oliveira Basso, R.L.; Tavares, F.O.; Honório, J.F.; Trevisan, A.P. TiO2 Coated Fiber Cement Composites: Effect of the Load of TiO2 Particles on Photocatalytic Degradation of H2S. Constr. Build. Mater. 2020, 262, 120379. [Google Scholar] [CrossRef]

- Khannyra, S.; Mosquera, M.J.; Addou, M.; Gil, M.L.A. Cu-TiO2/SiO2 Photocatalysts for Concrete-Based Building Materials: Self-Cleaning and Air De-Pollution Performance. Constr. Build. Mater. 2021, 313, 125419. [Google Scholar] [CrossRef]

- Luna, M.; Delgado, J.J.; Romero, I.; Montini, T.; Almoraima Gil, M.L.; Martínez-López, J.; Fornasiero, P.; Mosquera, M.J. Photocatalytic TiO2 Nanosheets-SiO2 Coatings on Concrete and Limestone: An Enhancement of De-Polluting and Self-Cleaning Properties by Nanoparticle Design. Constr. Build. Mater. 2022, 338, 127349. [Google Scholar] [CrossRef]

- Guan, X.; Wang, J.; Xiao, F. Sponge City Strategy and Application of Pavement Materials in Sponge City. J. Clean. Prod. 2021, 303, 127022. [Google Scholar] [CrossRef]

- Toro, C.; Jobson, B.T.; Haselbach, L.; Shen, S.; Chung, S.H. Photoactive Roadways: Determination of CO, NO, and VOC Uptake Coefficients and Photolabile Side Product Yields on TiO2 Treated Asphalt and Concrete. Atmos. Environ. 2016, 139, 37–45. [Google Scholar] [CrossRef]

- Somorjai, G.A.; Li, Y. Introduction to Surface Chemistry and Catalysis, 2nd ed.; Wiley: Hoboken, NJ, USA, 2010; ISBN 978-0-470-45702-5. [Google Scholar]

- Yang, Z.; Xu, Y.; Cai, X.; Wu, J.; Wang, J. Studying properties of pervious concrete containing recycled aggregate loaded with TiO2/LDHs and its liquid pollutant purification. Constr. Build. Mater. 2023, 406, 133398. [Google Scholar] [CrossRef]

- Netinger Grubeša, I.; Barišić, I.; Habuda-Stanić, M.; Grdić, D. Effect of CRT glass and TiO2 as a replacement for fine aggregate and cement on properties of pervious concrete paving flags. Constr. Build. Mater. 2023, 397, 132426. [Google Scholar] [CrossRef]

- Mishra, S.; Dhada, I.; Haldar, P.; Zende, P. Evaluation of photocatalytic efficiency of TiO2 applied over cement plaster for mitigating urban air pollutant: TVOC. Build. Environ. 2025, 267, 112223. [Google Scholar] [CrossRef]

- Al Ja’fari, M.S.; Al-Adaileh, M.M.; Al-Adayleh, A.K.; Al-Kheetan, M.J.; Jweihan, Y.S.; Albayati, A.H.; Rabi, M.; Alrwashdeh, S.S.; Al-Noaimat, Y.A.; Ghaffar, S.H. Titanium Dioxide for Improved Performance of Reclaimed Asphalt Pavement Aggregates in Concrete. Sustainability 2025, 17, 9034. [Google Scholar] [CrossRef]

- Kalinowski, M.; Chilmon, K.; Jackiewicz-Rek, W. Carbon-Negative Nano-TiO2-Modified Photocatalytic Cementitious Composites: Removal of Airborne Pollutants (NOx and O3) and Its Impact on CO2 Footprint. Coatings 2024, 14, 1607. [Google Scholar] [CrossRef]

- Ashwini, R.M.; Sambhana, K.D.; Manjunatha, M. Enhancing Concrete Performance and Sustainability with Nano TiO2: Engineering, Microstructural, and Life Cycle Evaluation. Iran. J. Sci. Technol. Trans. Civ. Eng. 2025. [Google Scholar] [CrossRef]

- Florean, C.T.; Vermesan, H.; Thalmaier, G.; Neamtu, B.V.; Gabor, T.; Campian, C.; Hegyi, A.; Csapai, A. The Influence of TiO2 Nanoparticles on the Physico–Mechanical and Structural Characteristics of Cementitious Materials. Coatings 2024, 14, 218. [Google Scholar] [CrossRef]

- Abdullah, G.M.S.; Chohan, I.M.; Ali, M.; Bheel, N.; Ahmad, M.; Najeh, T.; Gamil, Y.; Almujibah, H.R. Effect of titanium dioxide as nanomaterials on mechanical and durability properties of rubberised concrete by applying RSM modelling and optimizations. Front. Mater. 2024, 11, 135709. [Google Scholar] [CrossRef]

- Tang, S.; Mu, B.; Li, Y.; Tian, J.; Li, Y.; Cao, Y.; Bahnemann, D.W.; Pan, J. Advances in TiO2-enhanced photocatalytic building materials: Applications in cement and asphalt for environmental purification. Low-Carbon Mater. Green Constr. 2024, 2, 26. [Google Scholar] [CrossRef]

- Kim, J.S.; Song, K.; Kim, J.; Kang, H.J.; Yu, D.; Kim, H.G.; Kim, Y.S. A Study on Maximizing the Performance of a Concrete-Based TiO2 Photocatalyst Using Hydrophilic Polymer Dispersion. Catalysts 2025, 15, 935. [Google Scholar] [CrossRef]

- Lessa, F.P.; Lima Jr, O.; Margalho, É.; Pinheiro, C. Application of nano-TiO2 and micro-ZnO on cementitious surfaces for self-cleaning façades by spray coating and dip coating: A comparative study. J. Build. Pathol. Rehabil. 2025, 10, 16. [Google Scholar] [CrossRef]

- Cob-Cantú, J.R.; López-Velázquez, K.; Ronderos-Lara, J.G.; Hoil-Canul, E.R.; Castillo-Quevedo, C.; Maldonado-López, L.A.; Cabellos-Quiroz, J.L. TiO2 nanoparticles immobilized on mortar spheres as a strategy for efficient photocatalyst reuse: New UV reactor design for dye removal. Front. Chem. 2025, 13, 1581274. [Google Scholar] [CrossRef]

- Chauke, N.M.; Ngqalakwezi, A.; Raphulu, M. Transformative advancements in visible-light-activated titanium dioxide for industrial wastewater remediation. Int. J. Environ. Sci. Technol. 2025, 22, 8521–8552. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).