Abstract

As a regional product, Koryciński cheese is one of the most important cheeses in the Podlasie region of Poland. In this study, the influence of technological processes, such as ripening, on shaping the organoleptic characteristics of cheese was determined. Korycin-type cheeses are produced from cow’s milk according to traditional technology. The ripening process lasted 466 h at 5 °C, 10 °C, and 15 °C. The aging temperature had a decisive influence on the number of esters and organic acids formed, which were analyzed by gas chromatography–mass spectrometry (GC/MS). The organoleptic properties of the cheeses were also related to the ripening temperature.

1. Introduction

Koryciński cheese (ser Koryciński) is an original Polish traditional cheese produced in the Podlasie district in the Korycin municipality. Since 2005, its name has been protected by the State List of Traditional Product. In 2012, it was registered by the European Commission, receiving a certificate of Protected Geographical Indication (PGI). Its production is limited exclusively to the areas of the three Podlasie province municipalities located in the Sokółka district: Korycin, Suchowola, and Janów [1]. The community of Koryciński cheese producers continues to grow, and, in 2011, united over 30 members [2]. For the production of Koryciński cheese, unpasteurized cow’s milk, rennet, and a denaturation temperature of 33–36 °C are used. The ripening of Koryciński cheese depends on the individual production conditions and lasts 2–6 weeks at room temperature, which leads to particular variations in the sensory characteristics of the final product. This unique product is the reason for the popularity of the Korycin region [3,4].

Koryciński cheese is a semi-hard cheese with a distinctive creamy texture. Many biological and chemical processes occur during cheese ripening, especially lipolysis, proteolysis, and acidification [5]. Lipolysis and proteolysis processes are usually autocatalytic, while microbial activity is responsible for acidification [6,7]. The microbial composition of raw milk consists of lactic acid bacteria (LAB), Brevibacterium linens, yeasts and molds, Staphylococcus aureus and other Micrococcaceae, Pseudomonas, coliforms, Escherichia coli, enterococci, Clostridium perfringens, and spores of anaerobic lactate-fermenting bacteria. Pseudomonas, Lactococci, and Micrococcaceae were the most numerous groups [8,9,10].

The volatile composition of semi-hard cheeses is one of the most substantial sensory attributes aside from taste. The most common compounds of semi-hard cheeses are esters—Ethyl hexanoate, Ethyl propanoate, and Ethyl octanoate; ketones—Acetone, Octadien –2–One, and aldehydes—Hexanal, Heptanal, Octanal, and Nonanal [11,12,13].

Currently, the profile of volatile compounds in regional cheeses is studied using headspace-solid phase microextraction (HS–SPME) techniques [14,15,16]. However, in recent years, modifications in the form of vacuum-assisted HS–SPME (Vac–HS–SPME) have also been used in the study of semi-hard cheeses, giving excellent results in the determination of short-chain volatile compounds, as noted by Sýkor et al. [17]. Solid-phase microextraction (SPME) is a classical research technique and still forms the basis for the analysis of volatile compounds [18,19]. The current trend is to determine the influence of microorganisms on the development of the sensory and aromatic properties of cheese [20,21]. The most commonly used technological modifications are fungi of the genus Aspergillus [22,23], Enterococcus faecium [24], or Monascus [6,25,26].

The aim of this article is to compare the volatile composition with sensory data during the ripening of Koryciński cheeses under different temperature conditions.

2. Results and Discussion

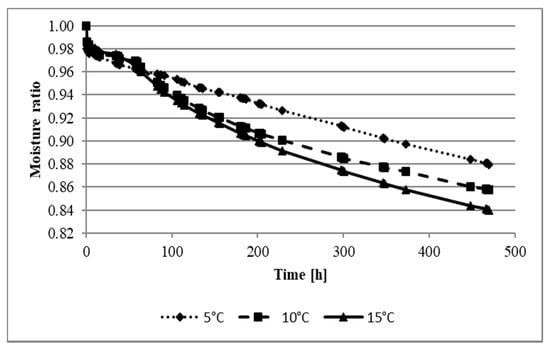

Figure 1 shows the moisture ratio (MR) dependence on the maturation time of the analyzed cheese. The moisture ratio decreases with the maturation time in all the samples studied. This process is dynamic for up to 60 h. The cheese’s humidity depended on the ripening temperature—the highest MR (0.88) was recorded for 5 °C and the lowest MR (0.84) for 15 °C. Koryciński cheese, which belongs to the semi-hard cheese group, releases a large amount of water during maturation. Tulyaganovich et al. [27] indicate that this is a typical feature of this type of cheese. Other researchers also observed a decrease in moisture content during the cheese’s maturation process [28,29]. The cheese’s ripening temperature is an essential parameter affecting the physicochemical properties of cheese, such as moisture, due to the properties of the casein complex and its ability to hold water [30,31,32]. Researchers analyzing the cheese’s maturation processes point out the crucial role of the temperature and humidity in shaping the quality of the final product [33,34]. As indicated by Łepecka et al. [35], in the production of semi-hard cheese, apart from external conditions such as the ripening temperature, specific species of bacteria from unpasteurized milk may be of critical importance in physicochemical properties, including moisture retention.

Figure 1.

Changes in the moisture ratio of Korycin cheese during ripening at different temperatures.

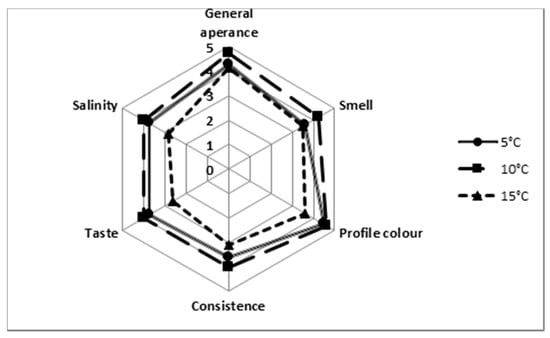

Figure 2 shows the sensory evaluation of Korycin cheeses matured under different conditions. In each test subject during criterion assessment, the cheese maturing at 10 °C has an advantage over the rest. A ripening temperature lowered by 5 °C has a less favorable effect on the aroma or external factors such as the appearance or consistency of the cheese. Cheeses ripened at the highest temperature (15 °C) scored the lowest on the organoleptic evaluation. Other researchers who observed the cheese’s ripening at different temperatures found that it plays a substantial role in profiling the evaluation of the final product [32,36,37]. Walsh et al. [32] indicate that cheddar maturation at 10 °C has a positive effect on its sensory characteristics, such as smell (mainly buttery, fatty, and pleasant). Many researchers point out the ripening time of the cheese has a significant influence on the course of lipolysis [38,39,40].

Figure 2.

Sensory evaluation scores of Koryciński cheese ripened in various conditions.

The aromatic profile (Table 1) of the studied cheeses consisted of 38 chemical compounds, the amount of which strongly depended on the conditions of the maturation process. There were 11 compounds from the group of hydrocarbons; 9 esters; 5 aldehydes; 5 organic acids; 2 alcohols; 2 lactones; 1 ketone; and 1 monoterpene.

Table 1.

Volatile content in analyzed cheese [µg/kg]. The content of chemical compounds in the aroma is marked with the same letters (a, b, c) when they do not differ statistically significantly. Statistically homogeneous groups at α = 0.05 marked with the same letters.

No trend was observed in the hydrocarbon group to determine the effect of the temperature on the overall behavior of the entire group. Nevertheless, individual compounds underwent significant changes depending on the temperature of the cheese ripening. The greatest contribution in this group was n-dodecane, whose content in the aromatic profile decreased with the increasing temperature (16.35 µg/kg for 5 °C and 4.37 µg/kg for 15 °C). Similarly, in the studies of Bertuzzi et al. [41] and Atik et al. [42], the studied cheeses showed no significant effect compared to the other compounds.

In the ester group, a significant effect of the temperature on the behavior of all the compounds representing this group was observed. With the increasing cheese ripening temperature, a significant reduction was observed in all the esters. The most important compounds were the hexanoic acid ethyl ester and the acetanoic acid ethyl ester. A similar decrease in the ester content was reported when Regginito cheese was analyzed [43]. A study by Di Donato et al. [14] similarly confirmed a decrease in the ester content, including the key hexanoic acid ethyl ester.

Another group, whose share in the aromatic profile of the studied cheeses is relatively small, consists of aldehydes. The sum of the aldehydes ranges from 4–10 µg/kg, and their share is not statistically significantly dependent on the temperature of the cheese’s maturation process. A study by Ceruti et al. [43] reported similar aldehyde levels. Furthermore, the time or method of ripening did not significantly affect the aldehyde content in the aromatic profile of the cheeses. A study by Van Leuven et al. [44] also confirmed that the aldehyde group was quantitatively an insignificant part of the aromatic profile of the ripened cheeses.

The organic acids are the most important group giving aroma to the cheeses studied. A significant influence of the temperature on the formation of the organic acids’ content was observed—with an increase in the temperature of the ripened cheeses, an increase in the content of the organic acids in the volatile fraction was observed. The main aromatic compounds identified were hexanoic acid (26.23–108.24 µg/kg) and acetanoic acid (43.91–103.54 µg/kg). Many researchers confirm the fact that the amount of octanoid acid also increases with the number of days until the 25th week of cheese maturation [45,46,47].

The long-chain alcohols n–pentadecanol, and 1 decanol–2hexyl, had no significant effect on shaping the volatile compound profiles of the studied cheeses. Due to the chain length, the low volatility of these compounds is to be expected. Additionally, a study by Amárita et al. [48] confirmed the absence of long-chain alcohols in the cheese aromatics detected by the SPME-GC/MS technique [48].

In the group of lactones, the content of the volatile profile of 4–hexanolide was significantly dependent on the ripening temperature. An increase in the temperature resulted in a decrease in the 4–hexanolide content in the aromatic profile of cheeses. Lactones with few carbons in the ring are frequently detected compounds in the aromatic profiles of various ripened cheeses [44]. Researchers confirm that the influence of ripening on labeled lactone compounds can be significant [49,50].

3. Materials and Methods

3.1. Cheesemaking

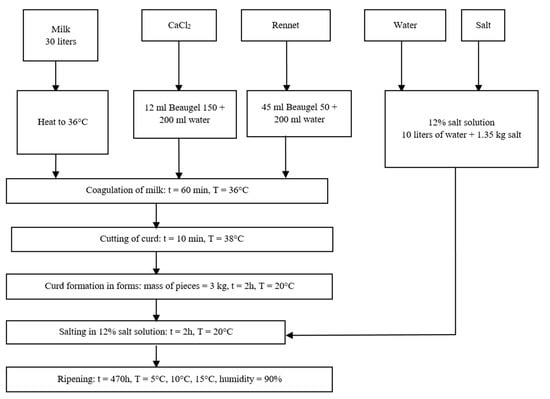

We made Koryciński cheeses from cow’s milk from a local dairy farm. We used whole milk containing 4.19% fat, 3.5% protein, and 4.7% carbohydrates. Figure 3 shows the technological process and production conditions. Beaugel 50 and Beaugel 150 (0.58 g CaCl2/mL) rennet by Ets Coquard Co. (Villefranche-sur-Saône, France), were used to denaturate the milk. After processing, all 3 kg cheese pieces were left to drain at room temperature for approximately 5 h. Ripening was carried out in KK350 TOP + POLEKO ripening cabinets ensuring stable conditions of 5 °C, 10 °C, and 15 °C at 90% humidity.

Figure 3.

Technological procedures and process conditions in the production of laboratory-scale Koryciński cheese.

3.2. Moisture Content Analysis

We controlled the cheese mass during the ripening process with the WPT2 Radwag laboratory balance. Drying the product in a convection dryer and measuring the dry matter allowed us to determine the moisture content. The moisture ratio MR was calculated according to Equation (1), where M (t) is the actual moisture content, M0 is the initial moisture content, and Me is the equilibrium moisture content. The value of the equilibrium moisture content Me is usually very low, and Equation (1) is often simplified to the form of Equation (2) without significantly changing the value of MR [51,52].

3.3. GC/MS Analysis

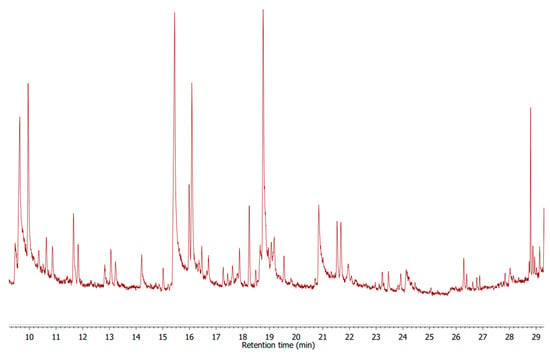

Solid-phase microextraction (SPME) was used to isolate and concentrate the volatile flavor compounds [53]. A representative cheese sample (4.2 g) was transferred to a 20 mL septum-capped vial with 0.123 µg of 2–undecanone as an internal standard. During isolation, samples were placed in an 80 °C water bath with stirring. Each sample was equilibrated and absorbed on the SPME fiber (2 cm–50/30 μm divinylbenzene/carboxen/polydimethylsiloxane; Supelco, Inc., Bellefonte, PA, USA) for 45 min. A Clarus 680 gas chromatograph coupled to a Perkin Elmer mass spectrometry detector (GC/MS) SQ 8S by Perkin Elmer, with a column ELITE-5MS (Crossbond 5% diphenyl and 95% dimethylpolysiloxane) 30 m × 0.25 mm ID × 0.25 μm film was used. Scanning was performed from 50 to 350 m/z in electronic impact (EI) at 70 eV, mode at 5 scan s−1. Analyses were performed using helium as the carrier gas at a flow rate of 1.0 mL min−1 in a split ratio of 1:10 and the following program: (a) 45 °C for 2 min; (b) rate of 5.0 °C min−1 for 45–160 °C; and (c) rate of 15 °C min−1 for 160–280 °C. The injector was maintained at 250 °C in each case. Three different analytical methods were employed to perform most of the compound identification: (1) retention indices (KI), (2) GC/MS retention times (authentic chemicals), and (3) mass spectra, with similarity indexes > 90%-authentic chemicals and NIST11 spectral library collection [54]. All aroma standards used for identification and quantification were food grade [55]. Figure 4 shows an example chromatogram of the analysis of aromas of the tested cheeses.

Figure 4.

Typical chromatogram of an analysis of the volatile components of cheese by GC/MS.

3.4. Sensory Analysis

Eight trained testers performed the sensory analysis; each tester was given a whole cheese and a smooth-bladed knife. First, the external appearance features were evaluated. Second, consistency, odor, taste, and salt content were evaluated using a five-point scoring scale (5—liked very much, 1—disliked) [56,57].

3.5. Statistical Analysis

Tukey’s test, with the significance level of α = 0,05, was used to measure the ripening effects in the cheeses. In the analysis of volatility, a one-way analysis (ANOVA) was performed to detect significant differences in the concentrations of analytes as a function of the main factors studied (ripening temperature). The data were processed with Statistica (version 10) by StatSoft [58].

Author Contributions

Conceptualization, J.K. and M.C.; methodology, J.K.-K.; software, M.K. (Martyna Krzyszkowska) and Z.B.; validation, M.K. (Mariusz Kasprzak) and J.K.; formal analysis, M.C.; investigation, J.K. and J.K.-K.; resources, M.K. (Martyna Krzyszkowska); data curation, Z.B.; writing—original draft preparation, J.K.; writing—review and editing, J.K.; visualization, J.K.; supervision, M.K. (Mariusz Kasprzak); project administration, M.K. (Mariusz Kasprzak); funding acquisition, M.K. (Mariusz Kasprzak), All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data are available at the research unit of the Institute of Dietetics and Dietotherapy, Faculty of Biological Sciences-University of Zielona Góra, Kalsk 67, 66–100 Kalsk. Or made available upon direct request: j.kliks@wzs.uz.zgora.pl.

Conflicts of Interest

The authors declare no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

Sample Availability

Samples of compounds, including samples of biological materials, are stored in the testing facility.

References

- Schlegel-Zawadzka, M.; Prusak, A.; Sikora, T. Food and Nutritional Globalization vs. Trends of Protection of Traditional Food Products in Poland. In Proceedings of the 57th EOQ Congress Quality Renaissance—Co-Creating a Viable Future, Tallinn, Estonia, 17–20 June 2013. [Google Scholar]

- Gąsiorek, P.; Kaus, I.; Pruszyńska, B. Przetwórstwo rolno-spożywcze w województwie podlaskim. In Analiza Kierunków Rozwoju i Aktualna Sytuacja w Rolnictwie Województwa Podlaskiego; ZNSGGW: Białystok, Poland, 2011; p. 93. [Google Scholar]

- Makała, H. Atrakcyjność Dziedzictwa Kulinarnego Podlasia. Zeszyty Naukowe. Tur. I Rekreac. 2014, 2, 81–90. [Google Scholar]

- Zrobek, J. Innovations in the Agricultural Sector. In Innovations and Knowledge Commercialization; Center for Technology Transfer UŁ: Łódź, Poland, 2015; p. 123. [Google Scholar]

- Bansal, V.; Veena, N. Understanding the role of pH in cheese manufacturing: General aspects of cheese quality and safety. J. Food Sci. Technol. 2022, 1–11. [Google Scholar] [CrossRef]

- Weng, S.; Ai, L.; Wang, G.; Wang, S.; Zhu, H.; Xiong, Z.; Zhang, H.; Xia, Y. Study on flavor characteristics of soft cheese fermented by Monascus. Food Ferment. Technol. 2019, 55, 43–58. [Google Scholar]

- Xia, Y.; Yuan, R.; Weng, S.; Wang, G.; Xiong, Z.; Zhang, H.; Song, X.; Liu, W.; Ai, L. Proteolysis, lipolysis, texture and sensory properties of cheese ripened by Monascus fumeus. Food Res. Int. 2020, 137, 109657. [Google Scholar] [CrossRef]

- Centeno, J.; Menéndez, S.; Rodriguez-Otero, J. Main microbial flora present as natural starters in Cebreiro raw cow’s-milk cheese (Northwest Spain). Int. J. Food Microbiol. 1996, 33, 307–313. [Google Scholar] [CrossRef]

- Kamilari, E.; Tsaltas, D.; Stanton, C.; Ross, R.P. Metataxonomic Mapping of the Microbial Diversity of Irish and Eastern Mediterranean Cheeses. Foods 2022, 11, 2483. [Google Scholar] [CrossRef]

- Quigley, L.; O’Sullivan, O.; Beresford, T.P.; Ross, R.P.; Fitzgerald, G.F.; Cotter, P.D. Molecular approaches to analysing the microbial composition of raw milk and raw milk cheese. Int. J. Food Microbiol. 2011, 150, 81–94. [Google Scholar] [CrossRef]

- Delgado, F.J.; González-Crespo, J.; Cava, R.; García-Parra, J.; Ramírez, R. Characterisation by spme–gc–ms of the volatile profile of a Spanish soft cheese PDO Torta del Casar during ripening. Food Chem. 2010, 118, 182–189. [Google Scholar] [CrossRef]

- Lee-Rangel, H.A.; Mendoza-Martinez, G.D.; Diaz de León-Martínez, L.; Relling, A.E.; Vazquez-Valladolid, A.; Palacios-Martínez, M.; Hernández-García, P.A.; Chay-Canul, A.J.; Flores-Ramirez, R.; Roque-Jiménez, J.A. Application of an electronic nose and HS-SPME/GC-MS to determine volatile organic compounds in fresh mexican cheese. Foods 2022, 11, 1887. [Google Scholar] [CrossRef]

- Tekin, A.; Hayaloglu, A.A. Understanding the mechanism of ripening biochemistry and flavour development in brine ripened cheeses. Int. Dairy J. 2022, 137, 105508. [Google Scholar] [CrossRef]

- Di Donato, F.; Biancolillo, A.; Mazzulli, D.; Rossi, L.; D’Archivio, A.A. hs-spme/gc–ms volatile fraction determination and chemometrics for the discrimination of typical Italian Pecorino cheeses. Microchem. J. 2021, 165, 106133. [Google Scholar] [CrossRef]

- Iranmanesh, M.; Ezzatpanah, H.; Akbari-Adergani, B.; Karimi Torshizi, M.A. SPME/GC-MS characterization of volatile compounds of Iranian traditional dried Kashk. Int. J. Food Prop. 2018, 21, 1067–1079. [Google Scholar] [CrossRef]

- Martín, I.; Rodríguez, A.; García, C.; Córdoba, J.J. Evolution of Volatile Compounds during Ripening and Final Sensory Changes of Traditional Raw Ewe’s Milk Cheese “Torta del Casar” Maturated with Selected Protective Lactic Acid Bacteria. Foods 2022, 11, 2658. [Google Scholar] [CrossRef] [PubMed]

- Sýkora, M.; Vítová, E.; Jeleń, H. Application of vacuum solid-phase microextraction for the analysis of semi-hard cheese volatiles. Eur. Food Res. Technol. 2020, 246, 573–580. [Google Scholar] [CrossRef]

- Cozzolino, R.; Martignetti, A.; De Giulio, B.; Malorni, L.; Addeo, F.; Picariello, G. SPME GC-MS monitoring of volatile organic compounds to assess typicity of Pecorino di Carmasciano ewe-milk cheese. Int. J. Dairy Technol. 2021, 74, 383–392. [Google Scholar] [CrossRef]

- Demirci, S.; Öztürk, H.İ.; Atik, D.S.; Koçak, C.; Demirci, T.; Akın, N. Volatile profile evolution and sensory evaluation of traditional skinbag Tulum cheeses manufactured in Karaman mountainous region of Turkey during ripening. Eur. Food Res. Technol. 2021, 247, 2097–2108. [Google Scholar] [CrossRef]

- Cardinali, F.; Foligni, R.; Ferrocino, I.; Harasym, J.; Orkusz, A.; Milanović, V.; Franciosa, I.; Garofalo, C.; Mannozzi, C.; Mozzon, M.; et al. Microbiological, morpho-textural, and volatile characterization of Portuguese Queijo de Nisa PDO cheese. Food Res. Int. 2022, 162, 112011. [Google Scholar] [CrossRef]

- Jiao, J.; Zheng, Z.; Liu, Z.; You, C. Study of the compositional, microbiological, biochemical, and volatile profile of red-veined cheese, an internal monascus-ripened variety. Front. Nutr. 2021, 8, 649611. [Google Scholar] [CrossRef]

- Jin, Y.; Li, D.; Ai, M.; Tang, Q.; Huang, J.; Ding, X.; Wu, C.; Zhou, R. Correlation between volatile profiles and microbial communities: A metabonomic approach to study Jiang-flavor liquor Daqu. Food Res. Int. 2019, 121, 422–432. [Google Scholar] [CrossRef]

- Tomita, S.; Nomura, M.; Arakawa, Y.; Miura, T.; Hayashida, S.; Hagi, T.; Kobayashi, M.; Suzuki, S.; Yamashita, H.; Sato, K.; et al. Volatile and soluble metabolite profiles in surface-ripened cheeses with Aspergillus oryzae and Aspergillus sojae. Food Res. Int. 2022, 158, 111535. [Google Scholar] [CrossRef]

- Yerlikaya, O.; Akbulut, N. Potential use of probiotic Enterococcus faecium and Enterococcus durans strains in Izmir Tulum cheese as adjunct culture. J. Food Sci. Technol. 2019, 56, 2175–2185. [Google Scholar] [CrossRef]

- Wu, S.; Yu, H.; Liu, Z.; You, C. Influence of Monascus purpureus BD-M-4 on the physicochemical properties, proteolysis and volatile compounds of surface mould-ripened cheese. Food Sci. Biotechnol. 2019, 28, 129–138. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, T.; Zhang, Y.; Song, B.; Pang, X.; Lv, J. Effects of Monascus on Proteolysis, Lipolysis, and Volatile Compounds of Camembert-Type Cheese during Ripening. Foods 2022, 11, 1662. [Google Scholar] [CrossRef]

- Tulyaganovich, K.Z.; Boboniyozovich, R.K.; Abdurasul o’g’li, A.A.; Saydvaliyevich, P.O.R.; Sanjar o’g’li, M.S.; Komiljon o’g’li, M.D. Technological factors affecting the storage of the quality of semi-hard cheeses. Galaxy Int. Interdiscip. Res. J. 2022, 10, 355–358. [Google Scholar]

- Khosrowshahi, A.; Madadlou, A.; Zadeh Mousavi, M.E.; Emam-Djomeh, Z. Monitoring the chemical and textural changes during ripening of Iranian White cheese made with different concentrations of starter. J. Dairy Sci. 2006, 89, 3318–3325. [Google Scholar] [CrossRef]

- Pinheiro, J.S.; Sudré, B.G.S.S.; Alexandre, A.C.S.; Campolina, G.A.; Correia, E.F.; Sobrinho, P.D.S.C. Influence of the starter cultures and ripening on the physicochemical and sensory characteristics of Serro artisanal cheese. Int. J. Gastron. Food Sci. 2021, 24, 100331. [Google Scholar] [CrossRef]

- D’Incecco, P.; Limbo, S.; Hogenboom, J.; Rosi, V.; Gobbi, S.; Pellegrino, L. Impact of extending hard-cheese ripening: A multiparameter characterization of Parmigiano reggiano cheese ripened up to 50 months. Foods 2020, 9, 268. [Google Scholar] [CrossRef] [PubMed]

- Rezaei, A.; Alirezalu, K.; Damirchi, S.A.; Hesari, J.; Papademas, P.; Domínguez, R.; Lorenzo, J.M.; Yaghoubi, M. Effect of pasteurization and ripening temperature on chemical and sensory characteristics of traditional motal cheese. Fermentation 2020, 6, 95. [Google Scholar] [CrossRef]

- Walsh, E.A.; Diako, C.; Smith, D.M.; Ross, C.F. Influence of storage time and elevated ripening temperature on the chemical and sensory properties of white Cheddar cheese. J. Food Sci. 2020, 85, 268–278. [Google Scholar] [CrossRef] [PubMed]

- Manzo, N.; Santini, A.; Pizzolongo, F.; Aiello, A.; Marrazzo, A.; Meca, G.; Durazzo, A.; Lucarini, M.; Romano, R. Influence of ripening on chemical characteristics of a traditional Italian cheese: Provolone del Monaco. Sustainability 2019, 11, 2520. [Google Scholar] [CrossRef]

- Mureşan, C.C.; Marc, R.A.; Anamaria Semeniuc, C.; Ancuţa Socaci, S.; Fărcaş, A.; Fracisc, D.; Pop, C.R.; Rotar, A.; Dodan, A.; Mureşan, V.; et al. Changes in physicochemical and microbiological properties, fatty acid and volatile compound profiles of Apuseni cheese during ripening. Foods 2021, 10, 258. [Google Scholar] [CrossRef]

- Łepecka, A.; Okoń, A.; Szymański, P.; Zielińska, D.; Kajak-Siemaszko, K.; Jaworska, D.; Neffe-Skocinska, K.; Sionek, B.; Trząskowska, M.; Kołożyn-Krajewska, D.; et al. The Use of Unique, Environmental Lactic Acid Bacteria Strains in the Traditional Production of Organic Cheeses from Unpasteurized Cow’s Milk. Molecules 2022, 27, 1097. [Google Scholar] [CrossRef]

- O’Mahony, J.A.; Sheehan, E.M.; Delahunty, C.M.; McSweeney, P.L. Lipolysis and sensory characteristics of Cheddar cheeses ripened using different temperature-time treatments. Le Lait 2006, 86, 59–72. [Google Scholar] [CrossRef]

- Sihufe, G.A.; Zorrilla, S.E.; Sabbag, N.G.; Costa, S.C.; Rubiolo, A.C. The influence of ripening temperature on the sensory characteristics of Reggianito Argentino cheese. J. Sens. Stud. 2010, 25, 94–107. [Google Scholar] [CrossRef]

- Esmaeilzadeh, P.; Ehsani, M.R.; Mizani, M.; Givianrad, M.H. Characterization of a traditional ripened cheese, Kurdish Kope: Lipolysis, lactate metabolism, the release profile of volatile compounds, and correlations with sensory characteristics. J. Food Sci. 2021, 86, 3303–3321. [Google Scholar] [CrossRef]

- Serrapica, F.; Masucci, F.; Di Francia, A.; Napolitano, F.; Braghieri, A.; Esposito, G.; Romano, R. Seasonal variation of chemical composition, fatty acid profile, and sensory properties of a mountain pecorino cheese. Foods 2020, 9, 1091. [Google Scholar] [CrossRef]

- Setyawardani, T.; Sulistyowati, M.; Widayaka, K.; Rahardjo, A.H.D. The Physicochemical and Sensory Qualities of Goat Cheese with Indigenous Probiotic Starter at Different Temperatures and Storage Durations. Anim. Prod. 2018, 19, 197–205. [Google Scholar] [CrossRef]

- Bertuzzi, A.S.; McSweeney, P.L.; Rea, M.C.; Kilcawley, K.N. Detection of volatile compounds of cheese and their contribution to the flavor profile of surface-ripened cheese. Compr. Rev. Food Sci. Food Saf. 2018, 17, 371–390. [Google Scholar] [CrossRef] [PubMed]

- Atik, D.S.; Akın, N.; Akal, H.C.; Koçak, C. The determination of volatile profile during the ripening period of traditional Tulum cheese from Turkey, produced in Anamur in the Central Taurus region and ripened in goatskin. Int. Dairy J. 2021, 117, 104991. [Google Scholar] [CrossRef]

- Ceruti, R.J.; Zorrilla, S.E.; Sihufe, G.A. Volatile profile evolution of Reggianito cheese during ripening under different temperature–time combinations. Eur. Food Res. Technol. 2016, 242, 1369–1378. [Google Scholar] [CrossRef]

- Van Leuven, I.; Van Caelenberg, T.; Dirinck, P. Aroma characterisation of Gouda-type cheeses. Int. Dairy J. 2008, 18, 790–800. [Google Scholar] [CrossRef]

- Van Mastrigt, O.; Abee, T.; Lillevang, S.K.; Smid, E.J. Quantitative physiology and aroma formation of a dairy Lactococcus lactis at near-zero growth rates. Food Microbiol. 2018, 73, 216–226. [Google Scholar] [CrossRef]

- Wang, J.; Yang, Z.J.; Xu, L.Y.; Wang, B.; Zhang, J.H.; Li, B.Z.; Cao, Y.; Tan, L. Key aroma compounds identified in Cheddar cheese with different ripening times by aroma extract dilution analysis, odor activity value, aroma recombination, and omission. J. Dairy Sci. 2021, 104, 1576–1590. [Google Scholar] [CrossRef]

- Yavuz, M.; Kasavi, C.; Öner, E.T. Developments in effective use of volatile organic compound analysis to assess flavour formation during cheese ripening. J. Dairy Res. 2021, 88, 461–467. [Google Scholar] [CrossRef] [PubMed]

- Amárita, F.; De La Plaza, M.; De Palencia, P.F.; Requena, T.; Peláez, C. Cooperation between wild lactococcal strains for cheese aroma formation. Food Chem. 2006, 94, 240–246. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Z.; Yu, H.; Lou, X.; Huang, J.; Yuan, H.; Wang, B.; Xu, Z.; Tian, H. Characterization of Six Lactones in Cheddar Cheese and Their Sensory Interactions Studied by Odor Activity Values and Feller’s Additive Model. J. Agric. Food Chem. 2021, 70, 301–308. [Google Scholar] [CrossRef] [PubMed]

- Ianni, A.; Bennato, F.; Martino, C.; Grotta, L.; Martino, G. Volatile flavor compounds in cheese as affected by ruminant diet. Molecules 2020, 25, 461. [Google Scholar] [CrossRef]

- Izadi, Z.; Mohebbi, M.; Shahidi, F.; Varidi, M.; Salahi, M.R. Cheese powder production and characterization: A foam-mat drying approach. Food Bioprod. Process. 2020, 123, 225–237. [Google Scholar] [CrossRef]

- Özbek, B.; Dadali, G. Thin-layer drying characteristics and modelling of mint leaves undergoing microwave treatment. J. Food Eng. 2007, 83, 541–549. [Google Scholar] [CrossRef]

- Boylston, T.D.; Wang, H.; Reitmeier, C.A.; Glatz, B.A. Effects of processing treatment and sorbate addition on the flavor characteristics of apple cider. J. Agric. Food Chem. 2003, 51, 1924–1931. [Google Scholar] [CrossRef]

- NIST (National Institute of Standards and Technology). 2012. Available online: http://webbook.nist.gov/chemistry/name-ser.html (accessed on 12 January 2012).

- SAFC (Sigma-Aldrich Flavors & Fragances). 2011. Available online: http://www.sigmaaldrich.com/safcglobal/en-us/home.html (accessed on 17 March 2011).

- Barukčić, I.; Ščetar, M.; Marasović, I.; Lisak Jakopović, K.; Božanić, R. Evaluation of quality parameters and shelf life of fresh cheese packed under modified atmosphere. J. Food Sci. Technol. 2020, 57, 2722–2731. [Google Scholar] [CrossRef] [PubMed]

- Delahunty, C.; Drake, M. Sensory character of cheese and its evaluation. Cheese Chem. Phys. Microbiol. 2004, 1, 455–487. [Google Scholar]

- Ropars, J.; Didiot, E.; de la Vega, R.C.R.; Bennetot, B.; Coton, M.; Poirier, E.; Giraud, T. Domestication of the emblematic white cheese-making fungus Penicillium camemberti and its diversification into two varieties. Curr. Biol. 2020, 30, 4441–4453. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).