High Entropy Alloys as Filler Metals for Joining

Abstract

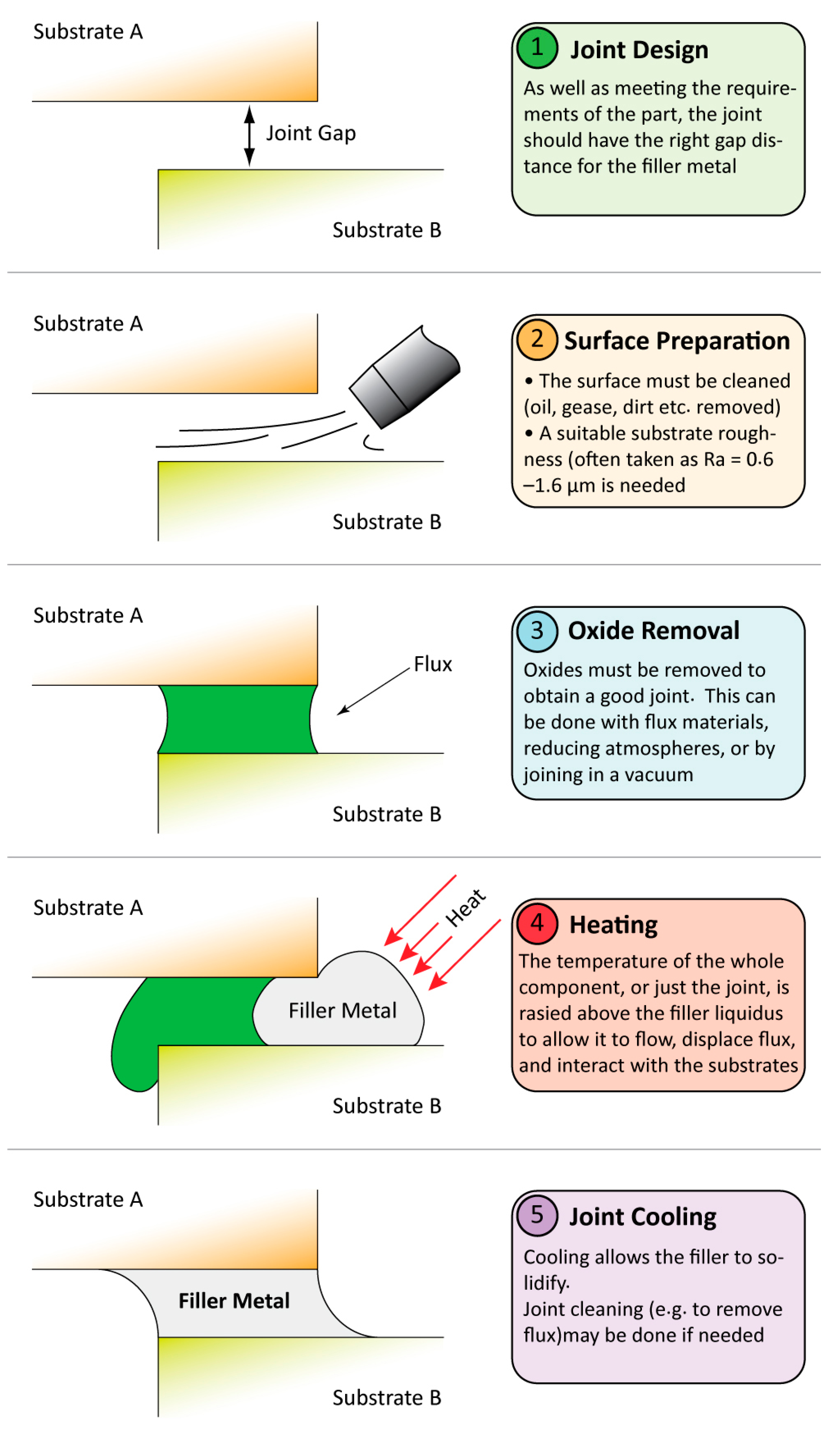

1. Introduction

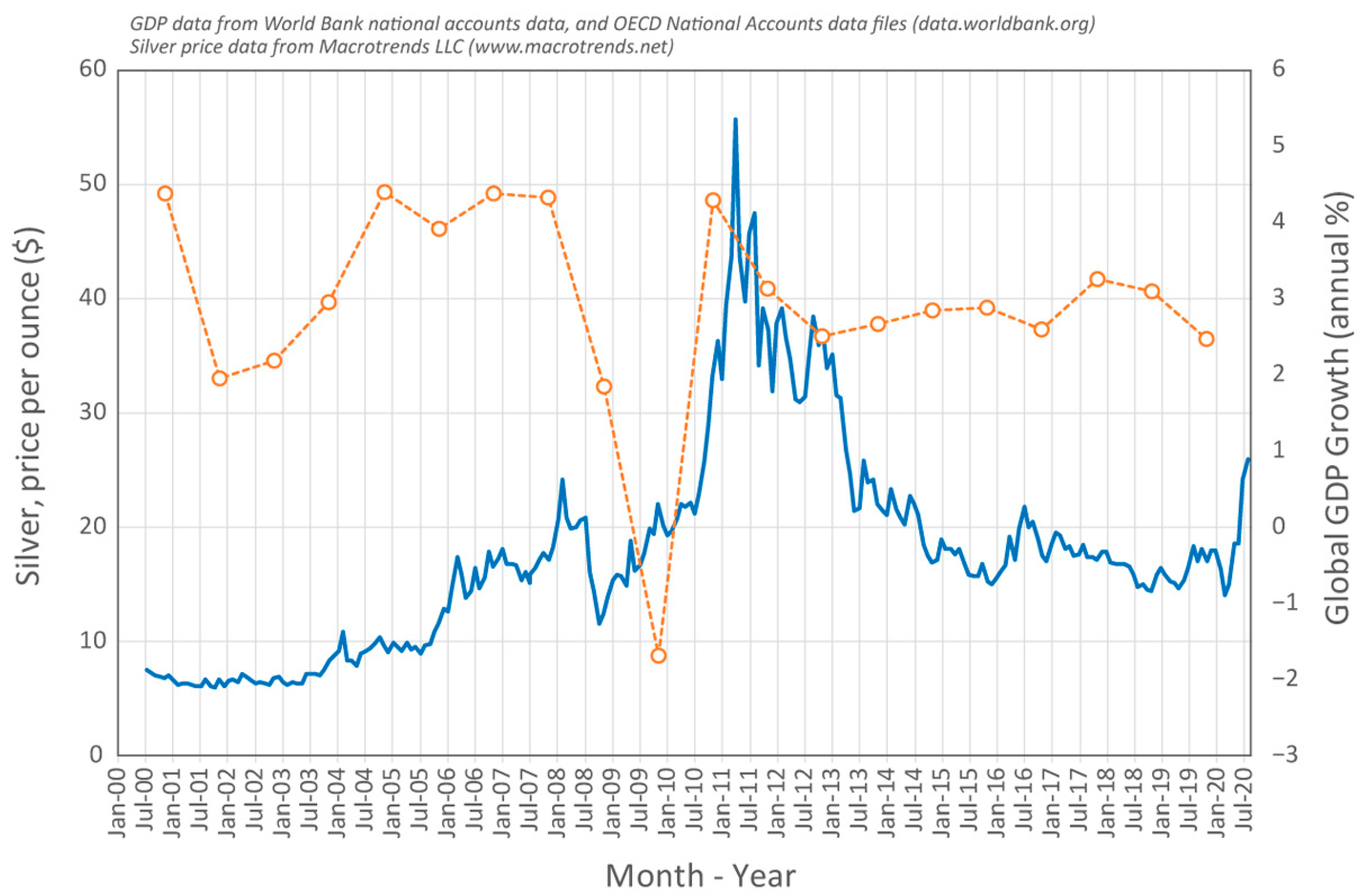

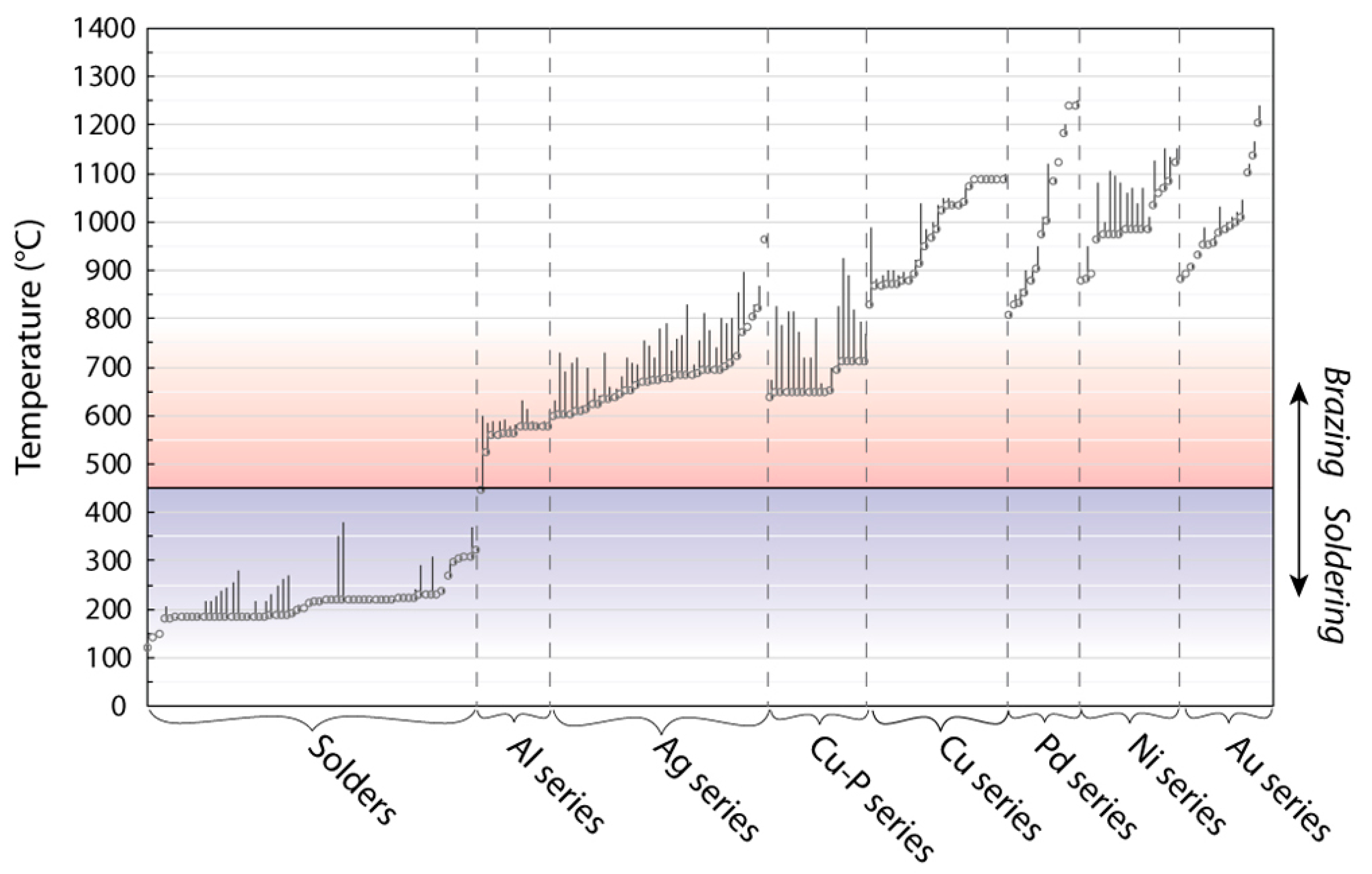

1.1. Existing Filler Metals

1.1.1. Solders

1.1.2. Brazing Filler Metals

2. Development of HEAs as Filler Metals

2.1. Application of Reported HEAs as Fillers

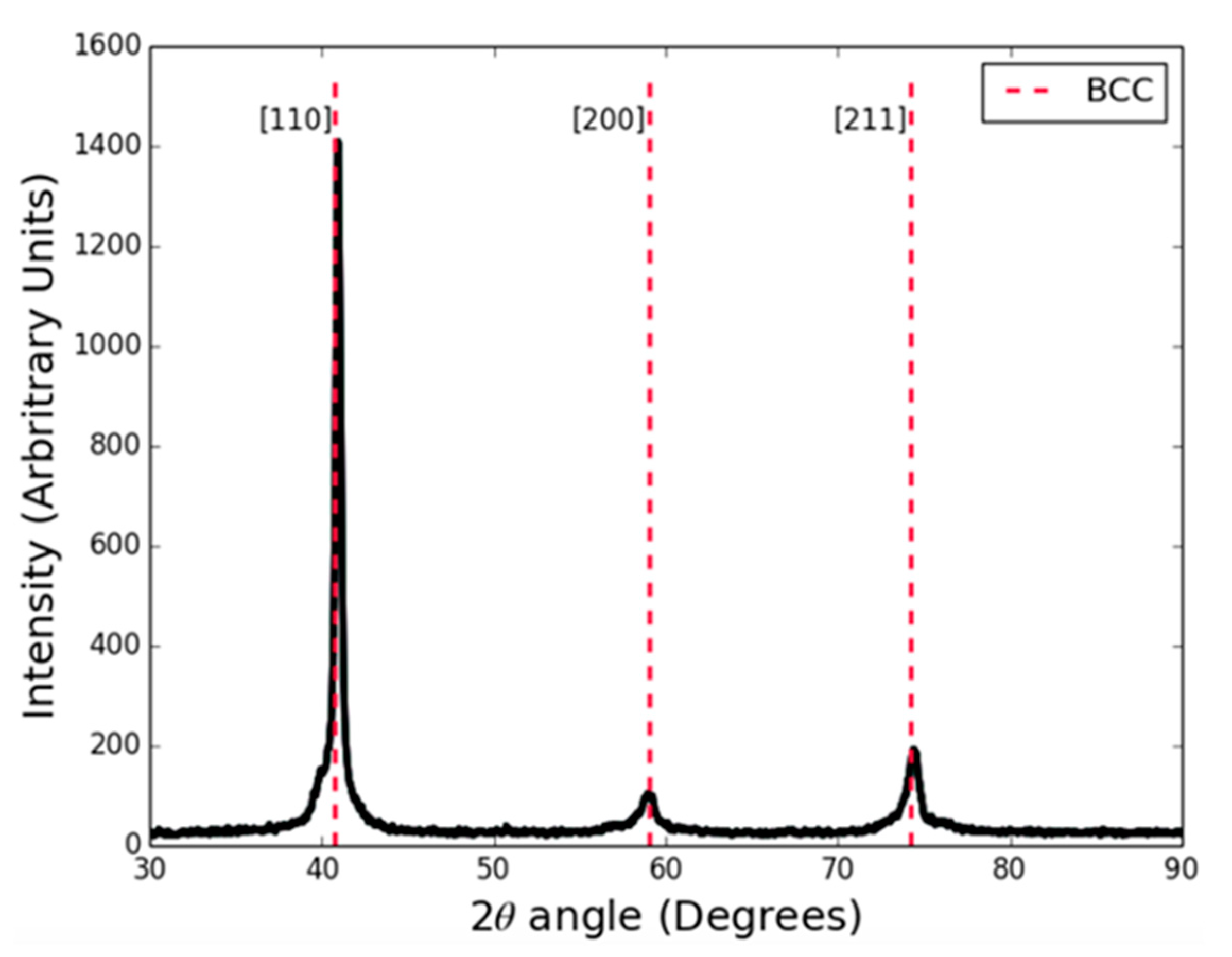

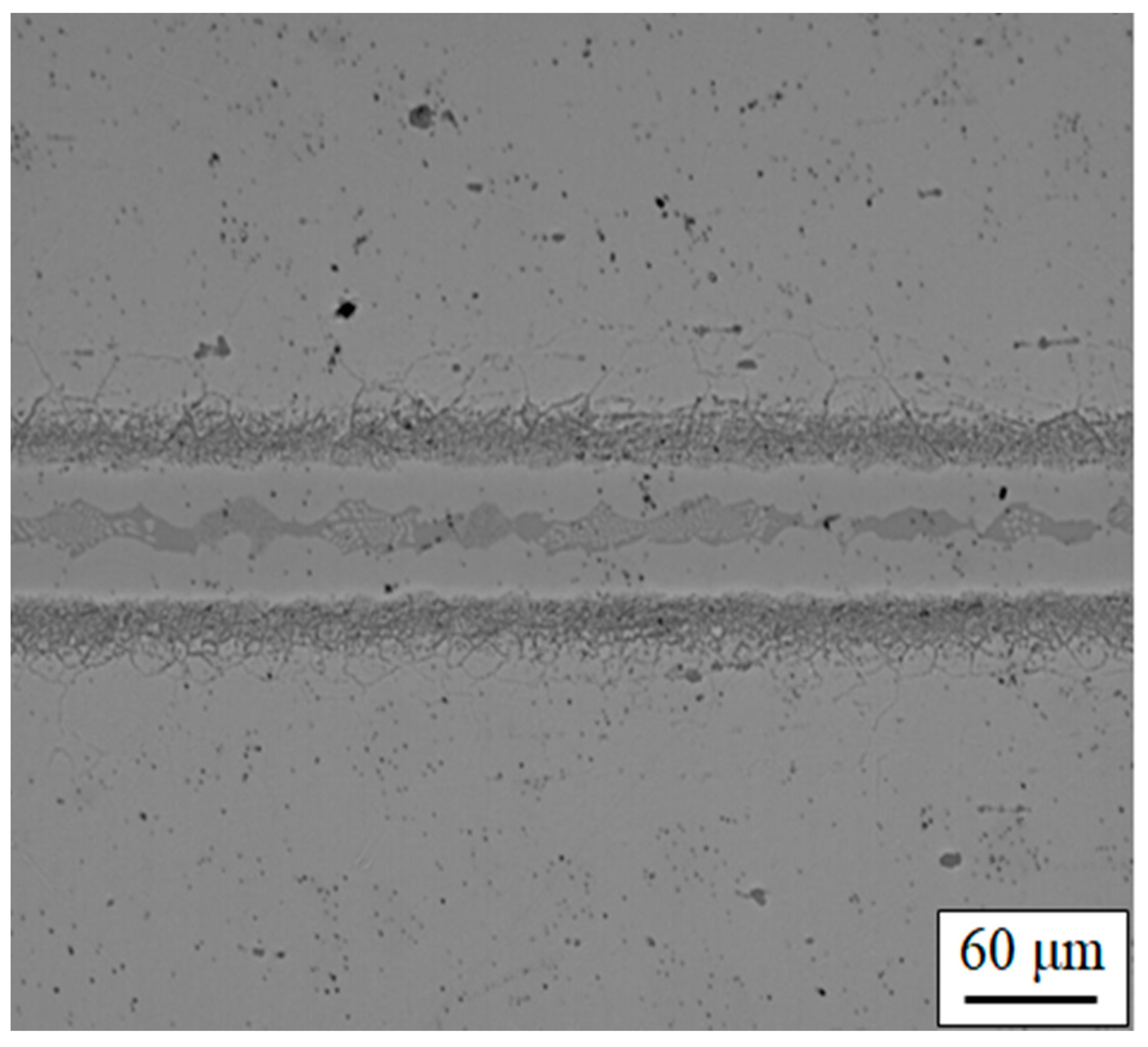

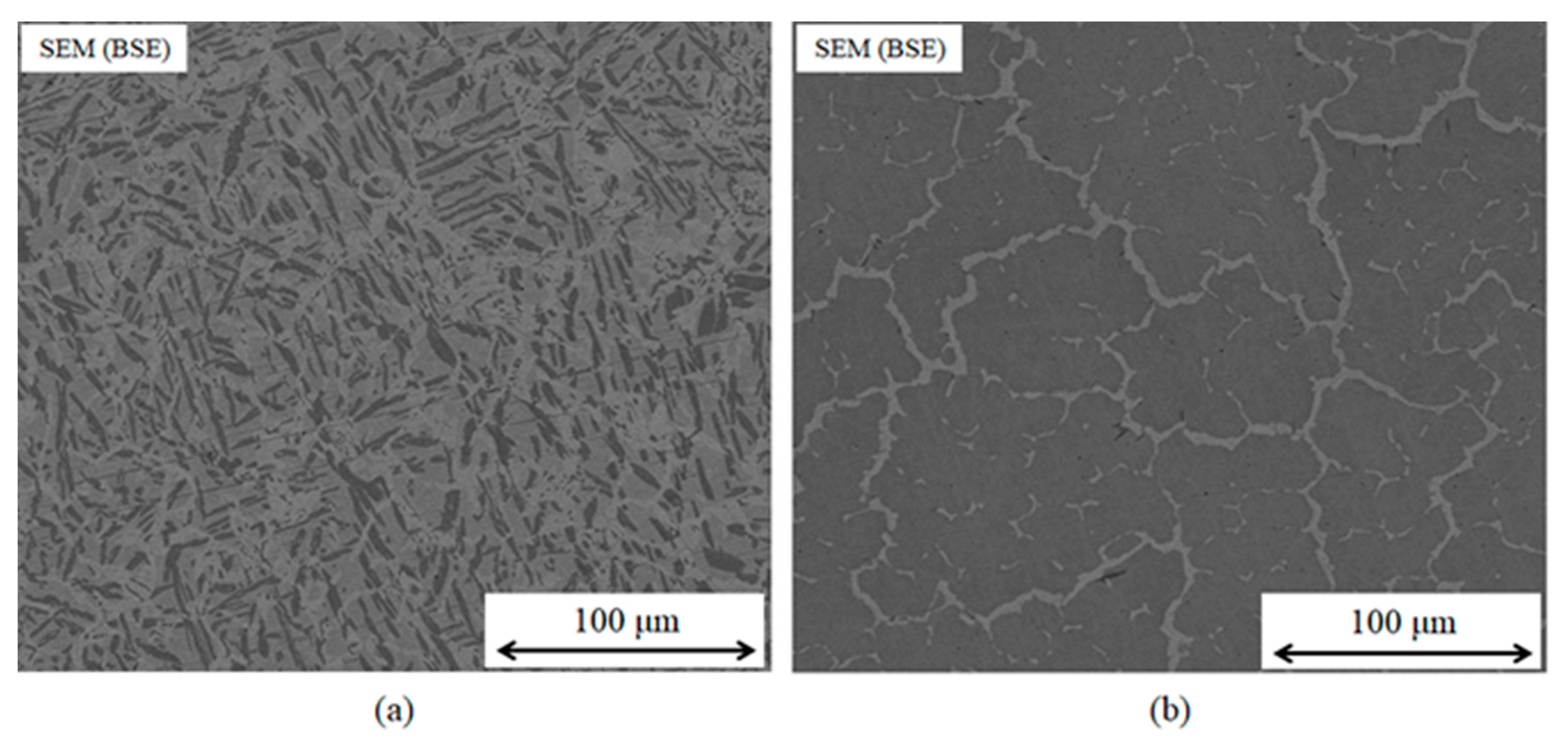

2.2. Development of New HEA Compositions as Fillers

3. Reducing Reliance on Undesirable Elements

4. Widening Service Temperature

4.1. Increasing Service Temperature, Avoiding Brittle Phases

4.2. Intermediate Temperature Fillers

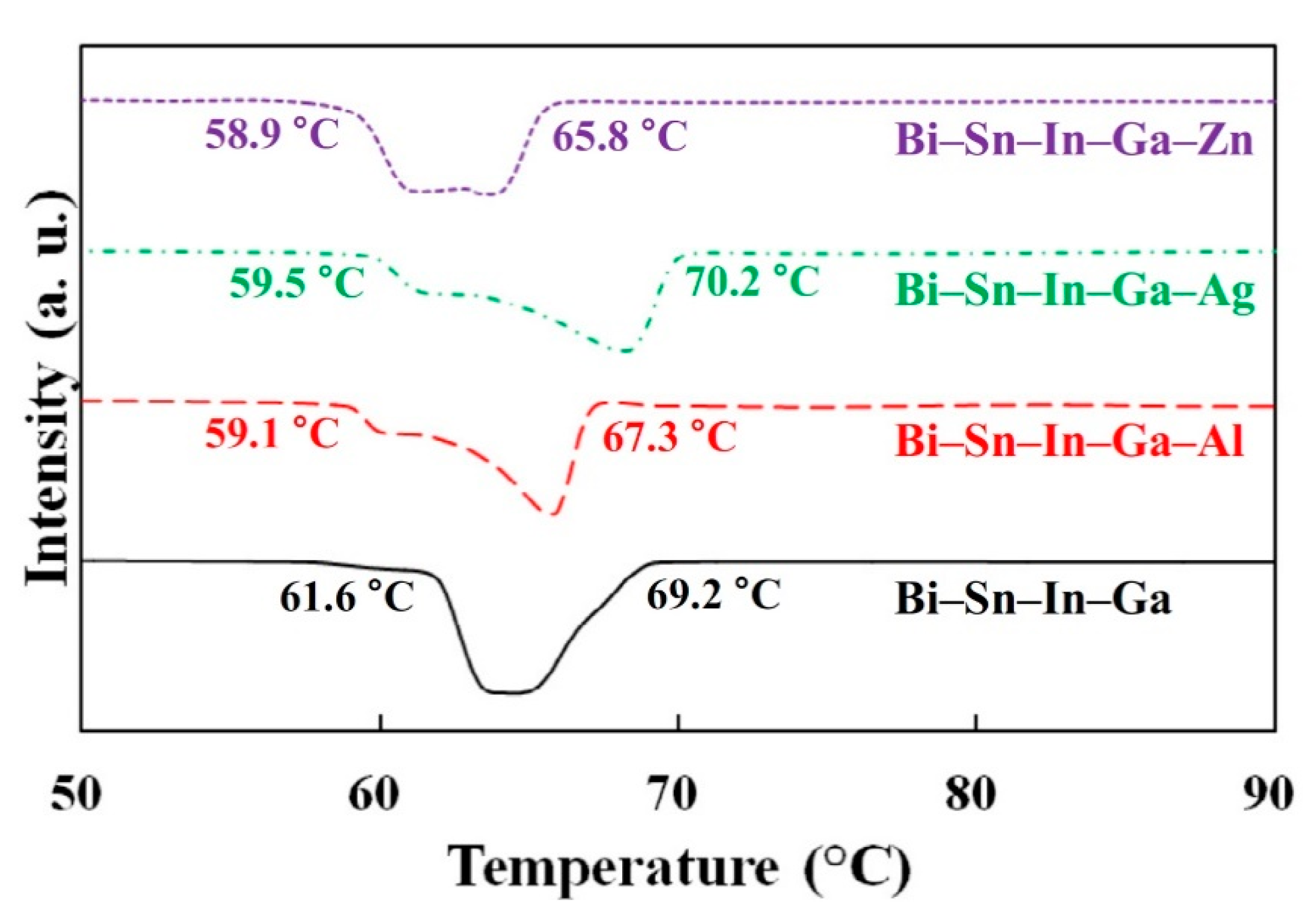

4.2.1. Higher Temperature Solders

4.2.2. Reduced Temperature Brazing Filler Metals

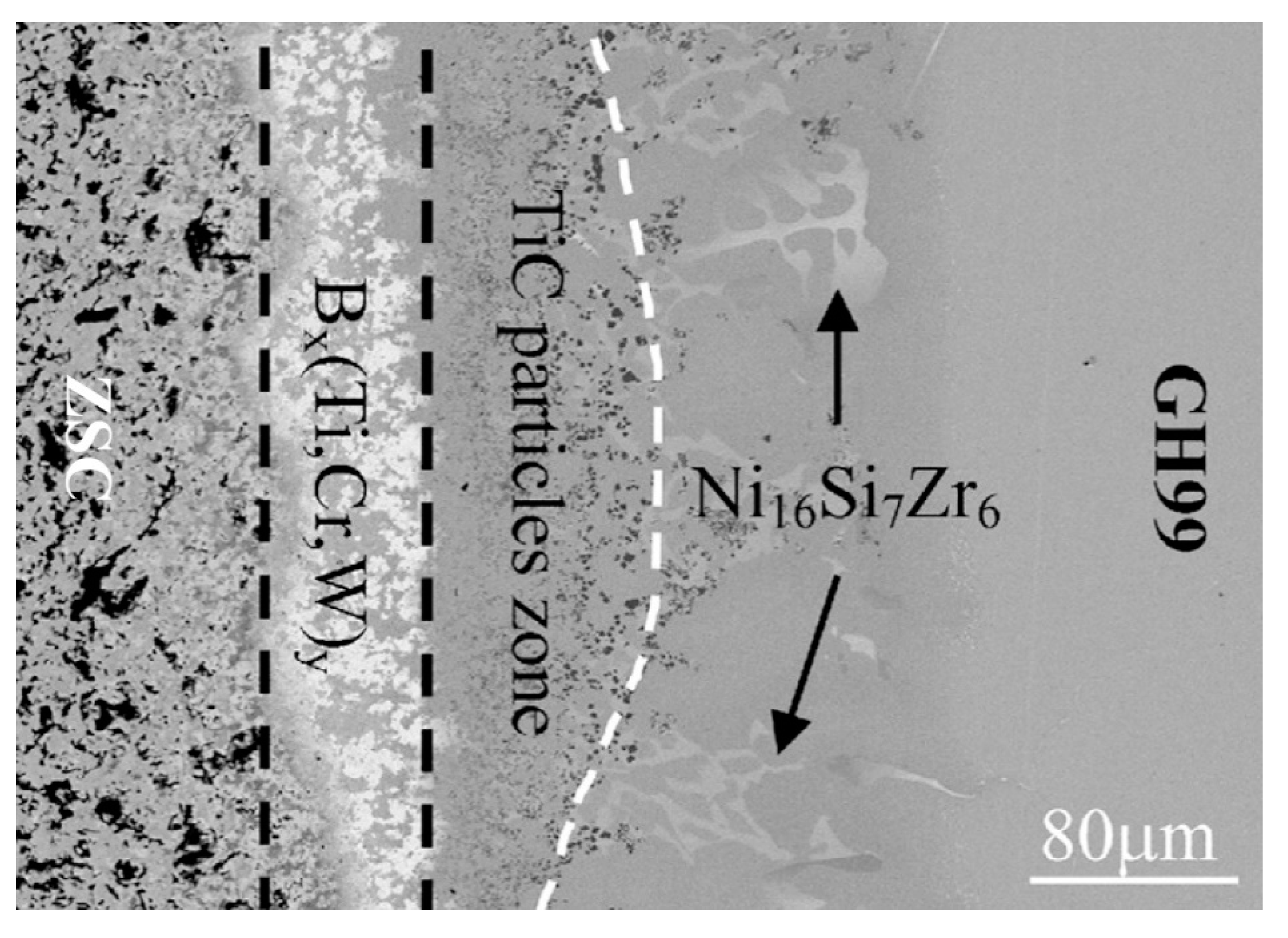

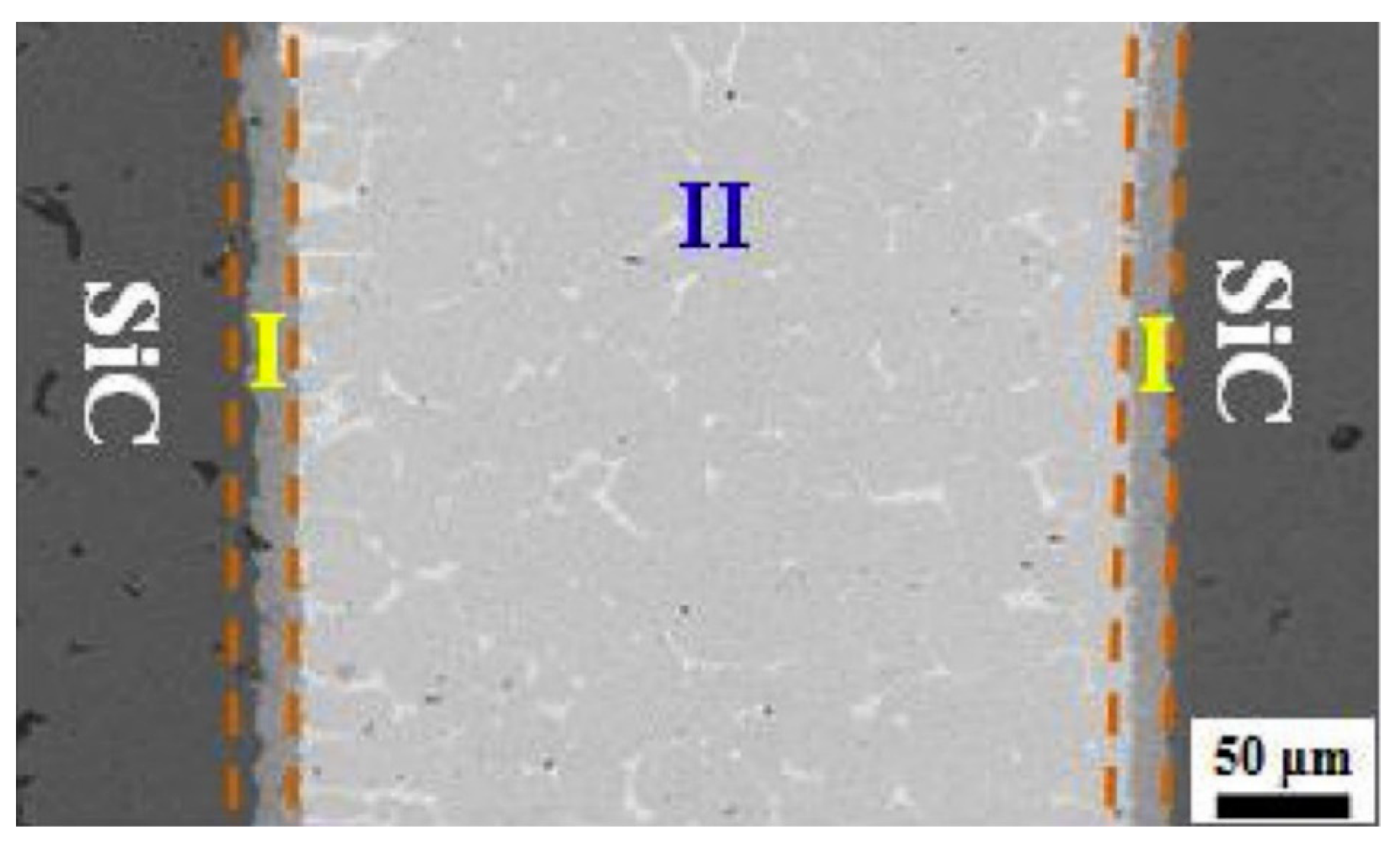

5. Fillers for Extreme Environments

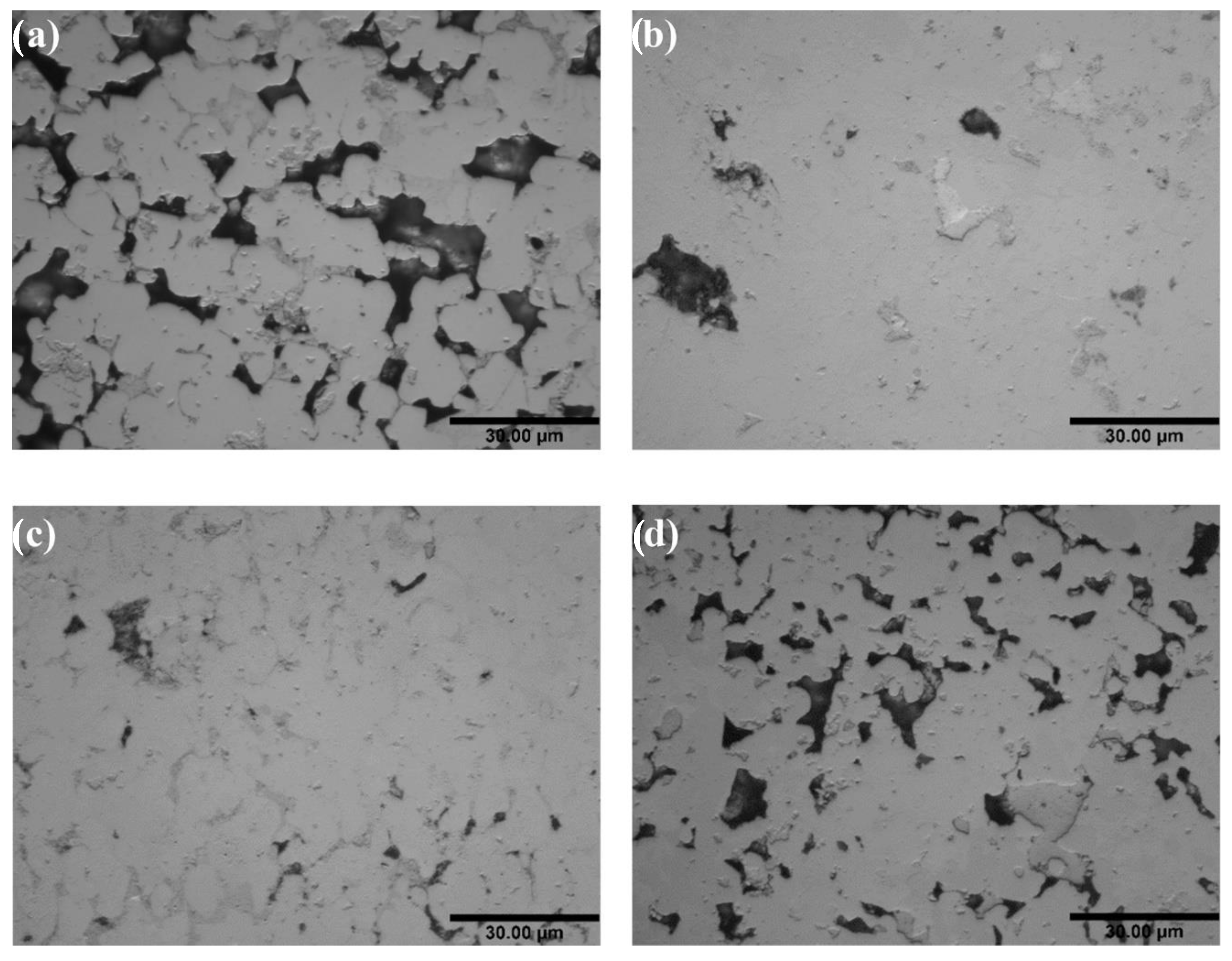

6. Improved Service Reliability of Solders

7. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lin, C.; Shiue, R.-K.; Wu, S.-K.; Huang, H.-L. Infrared Brazing of CoCrFeMnNi Equiatomic High Entropy Alloy Using Nickel-Based Braze Alloys. Entropy 2019, 21, 283. [Google Scholar] [CrossRef] [PubMed]

- Way, M.; Willingham, J.; Goodall, R. Brazing filler metals. Int. Mater. Rev. 2020, 65, 257–285. [Google Scholar] [CrossRef]

- Zhou, Q.; Bieler, T.R.; Nicholas, J. Transient porous nickel interlayers for improved silver-based Solid Oxide Fuel Cell brazes. Acta Mater. 2018, 148, 156–162. [Google Scholar] [CrossRef]

- Galindo-Nava, E.; Jing, Y.; Jiang, J. Predicting the hardness and solute distribution during brazing of Ti-6Al-4V with TiZrCuNi filler metals. Mater. Sci. Eng. A 2018, 712, 122–126. [Google Scholar] [CrossRef]

- Герваш, A.; Giniyatulin, R.; Guryeva, T.; Glazunov, D.; Kuznetsov, V.; Mazul, I.; Ogursky, P.; Piskarev, P.; Safronov, V.; Eaton, R.; et al. The development of technology of Be/CuCrZr joining using induction brazing. Fusion Eng. Des. 2019, 146, 2292–2296. [Google Scholar] [CrossRef]

- He, Z.; Sun, L.; Li, C.; Si, X.; Zhang, C.; Qi, J.; Feng, J.; Cao, J. Wetting and brazing of Cf/C composite with Si–Zr eutectic alloy: The formation of nano-and coarse-SiC reaction layers. Carbon 2020, 167, 92–103. [Google Scholar] [CrossRef]

- Heo, H.; Kim, G.; Kim, D.Y.; Moon, C.; Kim, K.C.; Jung, K.; Kang, C.-Y. Microstructure and mechanical properties of Ni foam/stainless steel joint brazed using Ni-based alloy. Mater. Sci. Eng. A 2019, 740, 63–70. [Google Scholar] [CrossRef]

- Luo, Y.; Jiang, W.; Zhang, W.; Zhang, Y.; Woo, W.; Tu, S. Notch effect on creep damage for Hastelloy C276-BNi2 brazing joint. Mater. Des. 2015, 84, 212–222. [Google Scholar] [CrossRef]

- Munez, C.; Garrido, M.; Rams, J.; Ureña, A. Experimental study of W–Eurofer laser brazing for divertor application. J. Nucl. Mater. 2011, 418, 239–248. [Google Scholar] [CrossRef]

- Gu, T.; Tong, V.S.; Gourlay, C.M.; Ben Britton, T. In-situ study of creep in Sn-3Ag-0.5Cu solder. Acta Mater. 2020, 196, 31–43. [Google Scholar] [CrossRef]

- Fernie, J.A.; Drew, R.A.L.; Knowles, K.M. Joining of engineering ceramics. Int. Mater. Rev. 2009, 54, 283–331. [Google Scholar] [CrossRef]

- ISO. 9453-2014 Soft Solder Alloys—Chemical Compositions and Forms; ISO: Geneva, Switzerland, 2014; p. SO 9453:2014. [Google Scholar]

- ISO. 17672-2016 Brazing—Filler Metals; ISO: Geneva, Switzerland, 2016; p. ISO 17672:12016. [Google Scholar]

- Olson, D.L. ASM Handbook Volume 6: Welding, Brazing and Soldering; ASM International: Cleveland, OH, USA, 1993; p. 2603. [Google Scholar]

- Roberts, P. Industrial Brazing Practice; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Zhang, J.; Gu, J.; Li, L.; Huan, Y.; Wei, B. Bonding of Alumina and Metal Using Bulk Metallic Glass Forming Alloy. Int. J. Mod. Phys. B 2009, 23, 1306–1312. [Google Scholar] [CrossRef]

- Sun, R.; Zhu, Y.; Guo, W.; Peng, P.; Li, L.; Zhang, Y.; Fu, J.; Li, F.; Zhang, L. Microstructural evolution and thermal stress relaxation of Al2O3/1Cr18Ni9Ti brazed joints with nickel foam. Vacuum 2018, 148, 18–26. [Google Scholar] [CrossRef]

- He, H.; Huang, S.; Xiao, Y.; Goodall, R. Diffusion reaction-induced microstructure and strength evolution of Cu joints bonded with Sn-based solder containing Ni-foam. Mater. Lett. 2020, 281, 128642. [Google Scholar] [CrossRef]

- He, H.; Huang, S.; Ye, Y.; Xiao, Y.; Zhang, Z.; Li, M.; Goodall, R. Microstructure and mechanical properties of Cu joints soldered with a Sn-based composite solder, reinforced by metal foam. J. Alloy. Compd. 2020, 845, 156240. [Google Scholar] [CrossRef]

- Yeh, J.W. Alloy Design Strategies and Future Trends in High-Entropy Alloys. JOM 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Cantor, B. Multicomponent and high entropy alloys. Entropy 2014, 16, 4749–4768. [Google Scholar] [CrossRef]

- Miracle, D.B.; Miller, J.D.; Senkov, O.; Woodward, C.; Uchic, M.D.; Tiley, J. Exploration and Development of High Entropy Alloys for Structural Applications. Entropy 2014, 16, 494–525. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Barron, P.; Carruthers, A.; Fellowes, J.; Jones, N.; Dawson, H.; Pickering, E. Towards V-based high-entropy alloys for nuclear fusion applications. Scr. Mater. 2020, 176, 12–16. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy Design and Properties Optimization of High-Entropy Alloys. JOM 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Zhu, J.; Fu, H.; Zhang, H.; Wang, A.; Li, H.; Hu, Z. Microstructure and compressive properties of multiprincipal component AlCoCrFeNiCx alloys. J. Alloy. Compd. 2011, 509, 3476–3480. [Google Scholar] [CrossRef]

- Pickering, E.; Jones, N.G. High-entropy alloys: A critical assessment of their founding principles and future prospects. Int. Mater. Rev. 2016, 61, 183–202. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Correlation between microstructure, mechanical properties, and brazing temperature of steel to titanium joint. J. Alloy. Compd. 2009, 487, 639–645. [Google Scholar] [CrossRef]

- Sun, Z.; Ma, Y.; Zhang, B.; Zhang, L. Controlling interfacial reactions of Ti3SiC2/Ti2AlNb brazed joints by transferring graphene layers. Mater. Sci. Eng. A 2020, 771, 138624. [Google Scholar] [CrossRef]

- Kotadia, H.R.; Howes, P.D.; Mannan, S.H. A review: On the development of low melting temperature Pb-free solders. Microelectron. Reliab. 2014, 54, 1253–1273. [Google Scholar] [CrossRef]

- Ma, H.; Suhling, J.C. A review of mechanical properties of lead-free solders for electronic packaging. J. Mater. Sci. 2009, 44, 1141–1158. [Google Scholar] [CrossRef]

- Laurila, T.; Vuorinen, V.; Paulasto-Kröckel, M. Impurity and alloying effects on interfacial reaction layers in Pb-free soldering. Mater. Sci. Eng. R Rep. 2010, 68, 1–38. [Google Scholar] [CrossRef]

- Pu, L.; He, Q.; Yang, Y.; Zhao, X.; Hou, Z.; Tu, K.N.; Liu, Y. The Microstructure and Mechanical Property of the High Entropy Alloy as a low Temperature Solder. In Proceedings of the 2019 IEEE 69th Electronic Components and Technology Conference (ECTC), Las Vegas, NV, USA, 28–31 May 2019; pp. 1716–1721. [Google Scholar]

- Kim, S.H.; Nam, Y.; Lee, H.; Back, S.; Park, M.-s.; Jang, G.J.; Choi, J.-P.; Aranas, C., Jr. Microstructural transformation and thermo-mechanical improvement of quinary Bi–Sn–In–Ga–Zn solder bumps on a flexible PET substrate. Mater. Sci. Eng. B 2017, 224, 93–102. [Google Scholar] [CrossRef]

- Yang, J.; Xue, S.; Xue, P.; Lv, Z.; Long, W.; Zhang, G.; Zhang, Q.; He, P. Development of Zn–15Al–xZr filler metals for Brazing 6061 aluminum alloy to stainless steel. Mater. Sci. Eng. A 2016, 651, 425–434. [Google Scholar] [CrossRef]

- Bridges, D.; Zhang, S.; Lang, S.; Gao, M.; Yu, Z.; Feng, Z.; Hu, A. Laser brazing of a nickel-based superalloy using a Ni-Mn-Fe-Co-Cu high entropy alloy filler metal. Mater. Lett. 2018, 215, 11–14. [Google Scholar] [CrossRef]

- Tillmann, W.; Ulitzka, T.; Wojarski, L.; Manka, M.; Wagstyl, D. Development of high entropy alloys for brazing applications. Weld. World 2020, 64, 201–208. [Google Scholar] [CrossRef]

- Tillmann, W.; Wojarski, L.; Stangier, D.; Manka, M.; Timmer, C. Application of the eutectic high entropy alloy Nb0.73CoCrFeNi2.1 for high temperature joints. Weld. World 2020, 64, 1597–1604. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; He, R.; Tan, C.; Huttula, M.; Cao, W. A novel high entropy CoFeCrNiCu alloy filler to braze SiC ceramics. J. Eur. Ceram. Soc. 2020, 40, 3391–3398. [Google Scholar] [CrossRef]

- Wang, G.; Yang, Y.; Wang, M.; He, R.; Tan, C.; Cao, W.; Xu, H. Brazing ZrB2-SiC ceramics to Nb with a novel CoFeNiCrCu high entropy alloy. J. Eur. Ceram. Soc. 2021, 41, 54–61. [Google Scholar] [CrossRef]

- Gao, M. Development of New High Entropy Alloys for Brazing of Ni-Base Superalloys. Ph.D. Thesis, Colorado School of Mines, Arthur Lakes Library, Golden, CO, USA, 2017. [Google Scholar]

- Gao, M.; Schneiderman, B.; Gilbert, S.M.; Yu, Z. Microstructural Evolution and Mechanical Properties of Nickel-Base Superalloy Brazed Joints Using a MPCA Filler. Met. Mater. Trans. A 2019, 50, 5117–5127. [Google Scholar] [CrossRef]

- Snell, R. The Development of Novel Silver Brazing Alloys. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2018. [Google Scholar]

- Way, M.; Luo, D.; Tuley, R.; Goodall, R. A new High Entropy Alloy brazing filler metal design for joining skutterudite thermoelectrics to copper. J. Alloy. Compd. 2020, 157750. [Google Scholar] [CrossRef]

- Hardwick, L.; Rodgers, P.; Pickering, E. Development of novel nickel-based brazing alloys, utilising alternative melting point depressants and high entropy alloy concepts. In Proceedings of the 12th International Conference on Brazing, High Temperature Brazing and Diffusion Bonding, Aachen, Germany, 21–23 May 2019; pp. 7–17. [Google Scholar]

- Sharma, A. High-Entropy Alloys for Micro- and Nanojoining Applications. In Engineering Steels and High Entropy-Alloys; IntechOpen: London, UK, 2020. [Google Scholar]

- Cao, J.; Zhang, L.; Wang, H.; Wu, L.; Feng, J. Effect of Silver Content on Microstructure and Properties of Brass/steel Induction Brazing Joint Using Ag-Cu-Zn-Sn Filler Metal. J. Mater. Sci. Technol. 2011, 27, 377–381. [Google Scholar] [CrossRef]

- Pineau, A.; Antolovich, S.D. High temperature fatigue of nickel-base superalloy—A review with special emphasis on deformation modes and oxidation. Eng. Fail. Anal. 2009, 16, 2668–2697. [Google Scholar] [CrossRef]

- Elrefaey, A. High-temperature brazing in aerospace engineering. Weld. Join. Aerosp. Mater. 2012, 329–362. [Google Scholar] [CrossRef]

- Lee, I.-K.; Sheu, H.-H.; Hsu, H.-Y. The effects of graphene content on the mechanical properties and thermal conductivity of Inconel 718 superalloy brazed using BNi-2/graphene composite filler metal. Results Phys. 2020, 16, 102828. [Google Scholar] [CrossRef]

- Steelant, J. Hypersonic Technology Developments with EU Co-Funded Projects; European Space Research and Technology Centre Noordwijk: Noordwijk, the Netherlands, 2010. [Google Scholar]

- Knoche, R.; Koch, D.; Tushtev, K.; Horvath, J.; Grathwohl, G.; Schmidt, S.; Beyer, S. Interlaminar properties of 2D and 3D C/C composites obtained via rapid-CVI for propulsion systems. In Proceedings of the 5th European Workshop on Thermal Protection Systems and Hot Structures, Noordwijk, The Netherlands, 17–19 May 2006. [Google Scholar]

- Lu, C.-L.; Lu, S.-Y.; Yeh, J.-W.; Hsu, W.-K. Thermal expansion and enhanced heat transfer in high-entropy alloys. J. Appl. Crystallogr. 2013, 46, 736–739. [Google Scholar] [CrossRef]

- Tillmann, W.; Wojarski, L.; Manka, M.; Timmer, C. Eutectic high entropy alloys–A novel class of materials for brazing applications. In Proceedings of the International Brazing & Soldering Conference, New Orleans, LA, USA, 15–18 April 2018; pp. 142–148. [Google Scholar]

- Wang, Q.; Lu, Y.; Yu, Q.; Zhang, Z. The Exceptional Strong Face-centered Cubic Phase and Semi-coherent Phase Boundary in a Eutectic Dual-phase High Entropy Alloy AlCoCrFeNi. Sci. Rep. 2018, 8, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Rao, J.C.; Diao, H.Y.; Ocelík, V.; Vainchtein, D.; Zhang, C.; Kuo, C.C.; Tang, Z.; Guo, W.; Poplawsky, J.D.; Zhou, Y.; et al. Secondary phases in AlxCoCrFeNi high-entropy alloys: An in-situ TEM heating study and thermodynamic appraisal. Acta Mater. 2017, 131, 206–220. [Google Scholar] [CrossRef]

- Hardwick, L.; Pickering, P.R.E.; Goodall, R. Development of a novel Ni-based Multi-Principal Element Alloy filler metal, using an alternative melting point depressant. Metall. Mater. Trans. A 2021. Under Review. [Google Scholar]

- Wang, F.; Chen, H.; Huang, Y.; Liu, L.; Zhang, Z. Recent progress on the development of Sn–Bi based low-temperature Pb-free solders. J. Mater. Sci. Mater. Electron. 2019, 30, 3222–3243. [Google Scholar] [CrossRef]

- Amalu, E.H.; Ekere, N.N. Damage of lead-free solder joints in flip chip assemblies subjected to high-temperature thermal cycling. Comput. Mater. Sci. 2012, 65, 470–484. [Google Scholar] [CrossRef]

- Gayle, F.W.; Becka, G.; Syed, A.; Badgett, J.; Whitten, G.; Pan, T.-Y.; Grusd, A.; Bauer, B.; Lathrop, R.; Slattery, J.; et al. High temperature lead-free solder for microelectronics. JOM 2001, 53, 17–21. [Google Scholar] [CrossRef]

- Zeng, G.; McDonald, S.; Nogita, K. Development of high-temperature solders: Review. Microelectron. Reliab. 2012, 52, 1306–1322. [Google Scholar] [CrossRef]

- Fei, X.; Qiu, X.-m.; Li, Y.-d. Effects of Sn element on microstructure and properties of Zn–Cu–Bi–Sn high-temperature solder. Trans. Nonferrous Met. Soc. China 2015, 25, 879–884. [Google Scholar]

- Li, Y.; Wong, C.-P. Recent advances of conductive adhesives as a lead-free alternative in electronic packaging: Materials, processing, reliability and applications. Mater. Sci. Eng. R Rep. 2006, 51, 1–35. [Google Scholar] [CrossRef]

- Liu, J.; Lu, D.; Andersson, C.; Li, C.; Wang, X.; Yuan, W. Properties of Two New Medium Temperature Solders; Soldering & Surface Mount Technology: London, UK, 2009. [Google Scholar]

- Prach, M.; Koleňák, R. Soldering of Copper with High-temperature Zn-based Solders. Procedia Eng. 2015, 100, 1370–1375. [Google Scholar] [CrossRef]

- Koleňak, R.; Martinkovic, M.; Koleňakova, M. Shear Strength and Dsc Analysis of High-Temperature Solders. Arch. Met. Mater. 2013, 58, 529–533. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, D.; Cheng, F.; Wang, Y. Development of ZrF4-containing CsF–AlF3 flux for brazing 5052 aluminium alloy with Zn–Al filler metal. Mater. Des. 2016, 90, 610–617. [Google Scholar] [CrossRef]

- Xing, F.; Qiu, X. Thermal properties, electrochemical behavior, and microstructure of Zn-5Sn-2Cu-1.5 Bi-xRE high-temperature solder. J. Mater. Eng. Perform. 2015, 24, 1679–1686. [Google Scholar] [CrossRef]

- Liu, L.; Tan, J.; Liu, X. Reactive brazing of Al alloy to Mg alloy using zinc-based brazing alloy. Mater. Lett. 2007, 61, 2373–2377. [Google Scholar] [CrossRef]

- Huang, H.-Z.; Lu, D.; Shuai, G.-W.; Wei, X.-Q. Effects of Phosphorus Addition on the Corrosion Resistance of Sn–0.7Cu Lead-Free Solder Alloy. Trans. Indian Inst. Met. 2016, 69, 1537–1543. [Google Scholar] [CrossRef]

- Watanabe, T.; Komatsu, S.; Oohara, K. Development of flux and filler metal for brazing magnesium alloy AZ31B. Weld. J. 2005, 84, 37–40. [Google Scholar]

- Ma, L.; Qiao, P.; Long, W.; He, D.; Li, X. Interface characteristics and mechanical properties of the induction brazed joint of magnesium alloy AZ31B with an Al-based filler metal. Mater. Des. 2012, 37, 465–469. [Google Scholar] [CrossRef]

- Chang, S.; Tsao, L.; Lei, Y.a.; Mao, S.; Huang, C. Brazing of 6061 aluminum alloy/Ti–6Al–4V using Al–Si–Cu–Ge filler metals. J. Mater. Proc. Technol. 2012, 212, 8–14. [Google Scholar] [CrossRef]

- Dai, W.; Xue, S.; Lou, J.; Wang, S. Development of Al–Si–Zn–Sr filler metals for brazing 6061 aluminum alloy. Mater. Design 2012, 42, 395–402. [Google Scholar] [CrossRef]

- Srinivas, V.; Singh, A.K.; Reddy, M. Vacuum brazing of dissimilar tubular component of AA2219 and AISI 304 by a low melting Al-18Ag-20Cu-5Si-0.2 Zn braze alloy. J. Mater. Proc. Technol. 2018, 252, 1–12. [Google Scholar]

- Tsao, L.; Weng, W.; Cheng, M.; Tsao, C.; Chuang, T. Brazeability of a 3003 Aluminum alloy with Al-Si-Cu-based filler metals. J. Mater. Eng. Perform. 2002, 11, 360–364. [Google Scholar] [CrossRef]

- Shen, Z.-G.; Tian, L.-L.; Liu, X. Automotive exhaust thermoelectric generators: Current status, challenges and future prospects. Energy Convers. Manag. 2019, 195, 1138–1173. [Google Scholar] [CrossRef]

- Chen, S.-W.; Chu, A.H.; Wong, D.S.-H. Interfacial reactions at the joints of CoSb 3 -based thermoelectric devices. J. Alloy. Compd. 2017, 699, 448–454. [Google Scholar] [CrossRef]

- Sui, F.; Long, W.; Liu, S.; Zhang, G.; Bao, L.; Li, H.; Chen, Y. Effect of calcium on the microstructure and mechanical properties of brazed joint using Ag–Cu–Zn brazing filler metal. Mater. Des. 2013, 46, 605–608. [Google Scholar] [CrossRef]

- He, R.; Schierning, G.; Nielsch, K. Thermoelectric devices: A review of devices, architectures, and contact optimization. Adv. Mater. Technol. 2018, 3, 1700256. [Google Scholar] [CrossRef]

- Shi, L.; Huang, X.; Gu, M.; Chen, L. Interfacial structure and stability in Ni/SKD/Ti/Ni skutterudite thermoelements. Surf. Coatings Technol. 2016, 285, 312–317. [Google Scholar] [CrossRef]

- Wu, F.; He, Q.; Hu, D.; Gao, F.; Song, H.; Jia, J.; Hu, X. Thermal Decomposition of Thermoelectric Material CoSb3: A Thermogravimetry Kinetic Analysis. J. Electron. Mater. 2013, 42, 2574–2581. [Google Scholar] [CrossRef]

- Braunovic, M.; Aleksandrov, N. Intermetallic compounds at aluminum-to-copper and copper-to-tin electrical interfaces. In Proceedings of the Thirty-Eighth IEEE Holm Conference on Electrical Contacts, Philadelphia, PA, USA,, 18–21 October 1992; pp. 25–34. [Google Scholar]

- Okamoto, H. Ag-Sb (Silver-Antimony). J. Phase Equilib. Diffus. 2007, 28, 403. [Google Scholar] [CrossRef]

- Singh, P.; Khirwadkar, S.; Patel, N.; Mokaria, P.; Bhope, K.; Belsare, S.; Menon, V.; Deepu, K.; Mehta, M.; Tripathi, S.; et al. Development of tungsten armored high heat flux plasma facing components for ITER like divertor application. Fusion Eng. Des. 2019, 146, 2273–2276. [Google Scholar] [CrossRef]

- Odegard, B.; Kalin, B. A review of the joining techniques for plasma facing components in fusion reactors. J. Nucl. Mater. 1996, 233, 44–50. [Google Scholar] [CrossRef]

- Barabash, V.; Akiba, M.; Cardella, A.; Mazul, I.; Odegard Jr, B.; Plöchl, L.; Tivey, R.; Vieider, G. Armor and heat sink materials joining technologies development for ITER plasma facing components. J. Nucl. Mater. 2000, 283, 1248–1252. [Google Scholar] [CrossRef]

- Lorenzetto, P.; Andrade, J.; Banetta, S.; Cicero, T.; Dellopoulos, G.; Durocher, A.; Escourbiac, F.; Felip, M.; Ferrand, L.; Gavila, P.; et al. EU contribution to the procurement of blanket first wall and divertor components for ITER. Fusion Eng. Des. 2018, 136, 975–982. [Google Scholar] [CrossRef]

- Mazul, I.; Belyakov, V.; Герваш, А.; Giniyatulin, R.; Guryeva, T.; Kuznetsov, V.; Makhankov, A.; Okunev, A.; Sevryukov, O. Technological challenges at ITER plasma facing components production in Russia. Fusion Eng. Des. 2016, 109, 1028–1034. [Google Scholar] [CrossRef]

- De Prado, J.; Sánchez, M.; Wirtz, M.; Pintsuk, G.; Du, J.; Linke, J.; Ureña, A. Impact of thermal fatigue on W–W brazed joints for divertor components. J. Mater. Proc. Technol. 2018, 252, 211–216. [Google Scholar] [CrossRef]

- Knaster, J.; Moeslang, A.; Muroga, T. Materials research for fusion. Nat. Phys. 2016, 12, 424–434. [Google Scholar] [CrossRef]

- Kalin, B.; Suchkov, A.; Fedotov, V.; Sevryukov, O.; Ivannikov, A.; Gervash, A. Brazing of Be with CuCrZr-bronze using copper-based filler metal STEMET. Nucl. Mater. Energy 2016, 9, 388–393. [Google Scholar] [CrossRef]

- Franconi, E.; Ceccotti, G.; Magnoli, L. Development of beryllium bonds for plasma-facing components. J. Nucl. Mater. 1992, 191, 493–498. [Google Scholar] [CrossRef]

- Hosemann, P.; Frazer, D.; Fratoni, M.; Bolind, A.; Ashby, M. Materials selection for nuclear applications: Challenges and opportunities. Scr. Mater. 2018, 143, 181–187. [Google Scholar] [CrossRef]

- El-Atwani, O.; Li, N.; Li, M.; Devaraj, A.; Baldwin, J.K.S.; Schneider, M.M.; Sobieraj, D.; Wróbel, J.S.; Nguyen-Manh, D.; Maloy, S.A.; et al. Outstanding radiation resistance of tungsten-based high-entropy alloys. Sci. Adv. 2019, 5, eaav2002. [Google Scholar] [CrossRef]

- Anderson, I.E.; Cook, B.A.; Harringa, J.L.; Terpstra, R.L. Sn-Ag-Cu solders and solder joints: Alloy development, microstructure, and properties. JOM 2002, 54, 26–29. [Google Scholar] [CrossRef]

- Sayyadi, R.; Naffakh-Moosavy, H. The Role of Intermetallic Compounds in Controlling the Microstructural, Physical and Mechanical Properties of Cu-[Sn-Ag-Cu-Bi]-Cu Solder Joints. Sci. Rep. 2019, 9, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Leong, Y.M.; Haseeb, A.S.M.A. Soldering Characteristics and Mechanical Properties of Sn-1.0Ag-0.5Cu Solder with Minor Aluminum Addition. Materials 2016, 9, 522. [Google Scholar] [CrossRef] [PubMed]

- Tu, K.; Zeng, K. Tin–lead (SnPb) solder reaction in flip chip technology. Mater. Sci. Eng. R Rep. 2001, 34, 1–58. [Google Scholar] [CrossRef]

- Nogita, K.; Read, J.; Nishimura, T.; Sweatman, K.; Suenaga, S.; Dahle, A.K. Microstructure control in Sn–0.7 mass% Cu alloys. Mater. Trans. 2005, 46, 2419–2425. [Google Scholar] [CrossRef]

- Wang, F.; Ma, X.; Qian, Y. Improvement of microstructure and interface structure of eutectic Sn–0.7 Cu solder with small amount of Zn addition. Scr. Mater. 2005, 53, 699–702. [Google Scholar] [CrossRef]

- Kanlayasiri, K.; Kongchayasukawat, R. Property alterations of Sn-0.6 Cu-0.05 Ni-Ge lead-free solder by Ag, Bi, in and Sb addition. Trans. Nonferrous Met. Soc. China 2018, 28, 1166–1175. [Google Scholar] [CrossRef]

- Shen, J.; Pu, Y.; Yin, H.; Luo, D.; Chen, J. Effects of minor Cu and Zn additions on the thermal, microstructure and tensile properties of Sn–Bi-based solder alloys. J. Alloys Compd. 2014, 614, 63–70. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, Q.; Wang, L.; Zeng, X.; Li, M.; Wang, Z.; Zhang, X.; Zhu, X. Ultrasonic soldering of Cu alloy using Ni-foam/Sn composite interlayer. Ultrason. Sonochem. 2018, 45, 223–230. [Google Scholar] [CrossRef]

- Zhang, Q.K.; Long, W.M.; Yu, X.Q.; Pei, Y.; Qiao, P. Effects of Ga addition on microstructure and properties of Sn–Ag–Cu/Cu solder joints. J. Alloys Compd. 2015, 622, 973–978. [Google Scholar] [CrossRef]

- El-Daly, A.; Hammad, A.; Al-Ganainy, G.; Ragab, M. Influence of Zn addition on the microstructure, melt properties and creep behavior of low Ag-content Sn–Ag–Cu lead-free solders. Mater. Sci. Eng. A 2014, 608, 130–138. [Google Scholar] [CrossRef]

- El-Daly, A.; El-Hosainy, H.; Elmosalami, T.; Desoky, W. Microstructural modifications and properties of low-Ag-content Sn–Ag–Cu solder joints induced by Zn alloying. J. Alloys Compd. 2015, 653, 402–410. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, F.; Li, X. Effect of Ni, Bi concentration on the microstructure and shear behavior of low-Ag SAC–Bi–Ni/Cu solder joints. J. Mater. Sci. Mater. Electron. 2014, 25, 2627–2633. [Google Scholar] [CrossRef]

- Ren, G.; Collins, M.N.; Punch, J.; Dalton, E.; Coyle, R. Pb-free solder—Micsrostructural, material reliability, and failure relationships. In Handbook of Materials Failure Analysis; Elsevier: Amsterdam, The Netherlands, 2020; pp. 107–151. [Google Scholar]

- Kim, J.; Yu, J.; Kim, S.-H. Effects of sulfide-forming element additions on the Kirkendall void formation and drop impact reliability of Cu/Sn–3.5 Ag solder joints. Acta Mater. 2009, 57, 5001–5012. [Google Scholar] [CrossRef]

- Kim, S.; Yu, J. Effects of Ag on the Kirkendall void formation of Sn–xAg/Cu solder joints. J. Appl. Phys. 2010, 108, 083532. [Google Scholar] [CrossRef]

- Gao, F.; Nishikawa, H.; Takemoto, T. Additive effect of Kirkendall void formation in Sn-3.5 Ag solder joints on common substrates. J. Electron. Mater. 2008, 37, 45–50. [Google Scholar] [CrossRef]

- Wang, Y.-W.; Lin, Y.; Kao, C.R. Kirkendall voids formation in the reaction between Ni-doped SnAg lead-free solders and different Cu substrates. Microelectron. Reliab. 2009, 49, 248–252. [Google Scholar] [CrossRef]

- Cho, M.G.; Kang, S.K.; Shih, D.-Y.; Lee, H.M. Effects of minor additions of Zn on interfacial reactions of Sn-Ag-Cu and Sn-Cu solders with various Cu substrates during thermal aging. J. Electron. Mater. 2007, 36, 1501–1509. [Google Scholar] [CrossRef]

- Chason, E.; Jadhav, N.; Pei, F.; Buchovecky, E.; Bower, A. Growth of whiskers from Sn surfaces: Driving forces and growth mechanisms. Prog. Surf. Sci. 2013, 88, 103–131. [Google Scholar] [CrossRef]

- Xue, P.; Xue, S.-B.; Shen, Y.-F.; Zhu, H. Inhibiting the growth of Sn whisker in Sn-9Zn lead-free solder by Nd and Ga. J. Mater. Sci. Mater. Electron. 2014, 25, 2671–2675. [Google Scholar] [CrossRef]

- Gain, A.K.; Zhang, L. Microstructure, thermal analysis and damping properties of Ag and Ni nano-particles doped Sn–8Zn–3Bi solder on OSP–Cu substrate. J. Alloys Compd. 2014, 617, 779–786. [Google Scholar] [CrossRef]

- Chen, W.; Xue, S.; Wang, H. Wetting properties and interfacial microstructures of Sn–Zn–xGa solders on Cu substrate. Mater. Design 2010, 31, 2196–2200. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, B.; Yan, K.; Wang, M.; Kabra, S.; Chiu, Y.-L.; Dye, D.; Lee, P.D.; Liu, Y.; Cai, B. Probing deformation mechanisms of a FeCoCrNi high-entropy alloy at 293 and 77 K using in situ neutron diffraction. Acta Mater. 2018, 154, 79–89. [Google Scholar] [CrossRef]

- Chen, C.; Qian, S.; Liu, R.; Wang, S.; Liao, B.; Zhong, Z.; Cao, L.; Coenen, J.W.; Wu, Y. The microstructure and tensile properties of W/Ti multilayer composites prepared by spark plasma sintering. J. Alloys Compd. 2019, 780, 116–130. [Google Scholar] [CrossRef]

- She, Z.; Li, R.; Guo, W.; Xue, H.; Zhang, X. A density functional theory study on the interfacial bonding properties of SiO2 ceramic and Ag (Ti) filler metal. J. Asian Ceram. Soc. 2020, 8, 1–8. [Google Scholar] [CrossRef]

- Zhang, J.; Xu, Q.; Hu, Y.; Mao, C.; Zhou, X.; Lu, X.; Zhang, M.; Tong, Y.; Tang, K.; Peng, P. Interfacial bonding mechanism and adhesive transfer of brazed diamond with Ni-based filler alloy: First-principles and experimental perspective. Carbon 2019, 153, 104–115. [Google Scholar] [CrossRef]

| Fillers | Melting Range (°C) | Substrate(s) | Target Application | Ref. |

|---|---|---|---|---|

| Zn-4Al | 381–409 | Cu | Electronics | [65] |

| 381–412 | Cu, Ni, Ag | Electronics | [66] | |

| Zn-2Cu-1.5Bi-7Sn | 387–393 | Cu | Electronics | [62] |

| Zn-15Al | 388–447 | 5052 Al | Not specific | [67] |

| Zn-5Sn-2Cu-1.5Bi-0.1RE | 390–395 | Functional materials | [68] | |

| Zn-2Cu-1.5Bi-3Sn | 391–400 | Cu | Electronics | [62] |

| Zn-1.5Al-2.0Re | 400–410 | AZ31B/Al6061 | Not specific | [69] |

| Au-10.6Ag-10.5Ge | 401–441 | Al-SiC composite | Electronics | [64] |

| Au-13.8Ag-10.5Ge | 410–450 | Al-SiC composite | Electronics | [64] |

| Ag-13.3Cu-42.4Sb | 423–429 | Al-SiC composite | Electronics | [64] |

| Mg-28.7Al | 438–460 | AZ31B | Not specific | [70] |

| Zn-15Al-0.3Zr | 445 (liquidus) | 6061 Al/304SS | Automotive/aerospace | [35] |

| Mg-65.1In-6.4Zn-0.7Al | 449 (liquidus) | AZ31 | Not specific | [71] |

| Al-38.7Mg-9.2Zn | 451–469 | AZ31B | Not specific | [72] |

| Zn–22Al | 451–488 | 5052 Al | Not specific | [67] |

| Mg-64.6In-1.2Zn-0.8Al | 471 (liquidus) | AZ31 | Not specific | [71] |

| Al-8.4Si-20Cu-10Ge-0.1Re | 479–514 | Al/Ti-6Al-4V | Aerospace/chemical | [73] |

| Ag-33.5Cu-20.5Sb | 483–488 | Al-SiC composite | Electronics | [64] |

| Al-8.4Si-20Cu-10Ge | 489–513 | Al/Ti-6Al-4V | Aerospace/chemical | [73] |

| Al–6.5Si–42Zn–0.12Sr | 493–520 | 6061 Al | Automotive; electrical connections | [74] |

| Al-18Ag-20Cu-5Si-0.2Zn | 494–515 | AA2219/AISI 304 | Not specific | [75] |

| Al-7Si-20Cu-2Sn-1Mg | 501–522 | 3003 Al | Heat exchangers | [76] |

| Al-9.6Si-20Cu | 523–535 | Al/Ti-6Al-4V | Aerospace/chemical | [73] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, D.; Xiao, Y.; Hardwick, L.; Snell, R.; Way, M.; Sanuy Morell, X.; Livera, F.; Ludford, N.; Panwisawas, C.; Dong, H.; et al. High Entropy Alloys as Filler Metals for Joining. Entropy 2021, 23, 78. https://doi.org/10.3390/e23010078

Luo D, Xiao Y, Hardwick L, Snell R, Way M, Sanuy Morell X, Livera F, Ludford N, Panwisawas C, Dong H, et al. High Entropy Alloys as Filler Metals for Joining. Entropy. 2021; 23(1):78. https://doi.org/10.3390/e23010078

Chicago/Turabian StyleLuo, Dan, Yong Xiao, Liam Hardwick, Robert Snell, Matthew Way, Xavier Sanuy Morell, Frances Livera, Nicholas Ludford, Chinnapat Panwisawas, Hongbiao Dong, and et al. 2021. "High Entropy Alloys as Filler Metals for Joining" Entropy 23, no. 1: 78. https://doi.org/10.3390/e23010078

APA StyleLuo, D., Xiao, Y., Hardwick, L., Snell, R., Way, M., Sanuy Morell, X., Livera, F., Ludford, N., Panwisawas, C., Dong, H., & Goodall, R. (2021). High Entropy Alloys as Filler Metals for Joining. Entropy, 23(1), 78. https://doi.org/10.3390/e23010078