Biomass Pyrolysis Characterization and Energy Utilization

A special issue of Processes (ISSN 2227-9717). This special issue belongs to the section "Energy Systems".

Deadline for manuscript submissions: 25 July 2026 | Viewed by 1817

Special Issue Editors

Interests: polymer science; pyrolysis mechanisms; physical chemistry; algorithm development; kinetic modeling; machine learning applications; topology; catastrophe theory; rheology

Interests: organic synthesis; physical chemistry; thermal-induced reactions; chemical reactivity; organic chemistry; density functional theory; algorithm development; topology

Special Issue Information

Dear Colleagues,

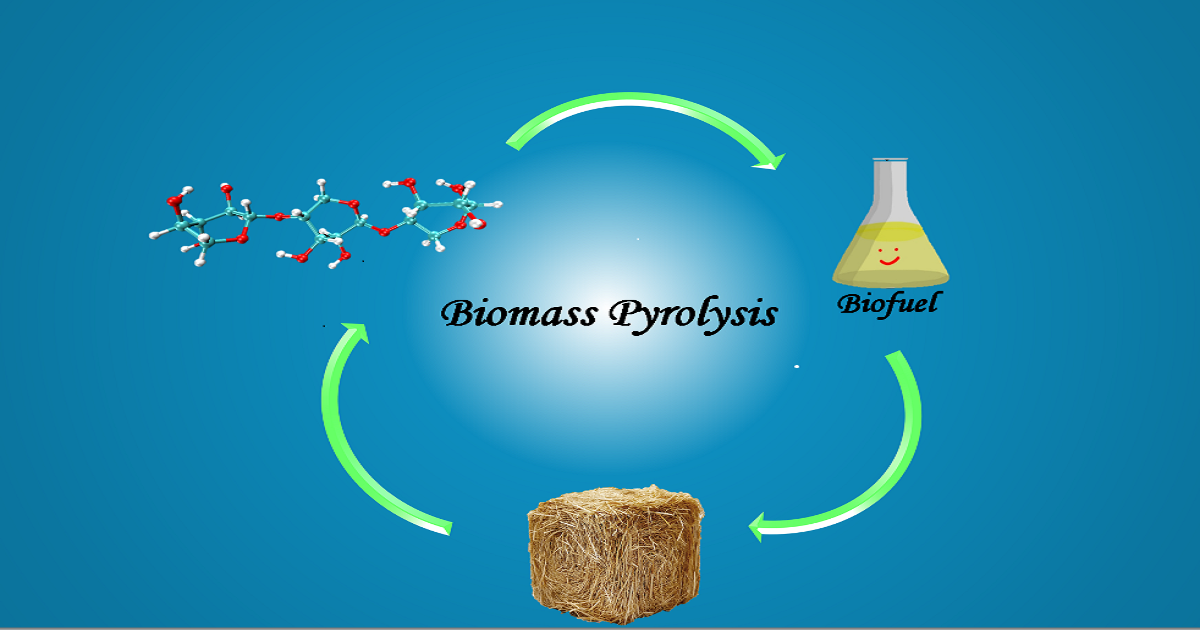

Biomass pyrolysis is a rapidly advancing field attracting growing attention from both academia and industry because this thermal process converts organic residues into valuable chemicals and fuels. This highlights the potential of biomass as an abundant and renewable source of carbon and hydrogen; it is estimated to provide up to 147 exajoules by 2030, which is equivalent to approximately 36% of current global energy consumption.

Despite the significant progress made, the commercial deployment of sustainable bioproducts, such as advanced biofuels, remains limited. Key challenges include multi-scale complexities, the absence of unified kinetic models, limitations in experimental tools for product detection and identification, and a fundamental lack of understanding regarding catalytic effects and interactions among the primary biomass components (cellulose, hemicellulose, and lignin).

This Special Issue aims to consolidate recent breakthroughs in biomass pyrolysis and energy utilization, advancing the current state-of-the-art by compiling pioneering theoretical insights and engineering applications. We warmly invite original research articles and reviews that explore advances across a wide range of disciplines, including but not limited to the following topics:

- Quantum and molecular mechanics approaches.

- Thermogravimetric analysis and pyrolysis kinetics.

- Mass spectrometry and product characterization.

- Machine learning frameworks for reaction prediction and modeling.

Through this initiative, we seek to foster interdisciplinary collaboration and accelerate innovation in the development of sustainable, bio-based energy solutions.

Dr. Leandro Ayarde-Henríquez

Prof. Dr. Eduardo Chamorro

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- biomaterials

- polymer science

- clean energy production

- pyrolysis mechanisms

- low-carbon technologies

- circular bio-economies

- physical chemistry

- algorithm development

- kinetic modeling

- machine learning applications

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.

Further information on MDPI's Special Issue policies can be found here.