- 3.2Impact Factor

- 6.4CiteScore

- 16 daysTime to First Decision

From Surface Modification to Additive Manufacturing of Components by Solid-State Cold Spray Technology

This special issue belongs to the section “Manufacturing Processes and Systems“.

Special Issue Information

Dear Colleagues,

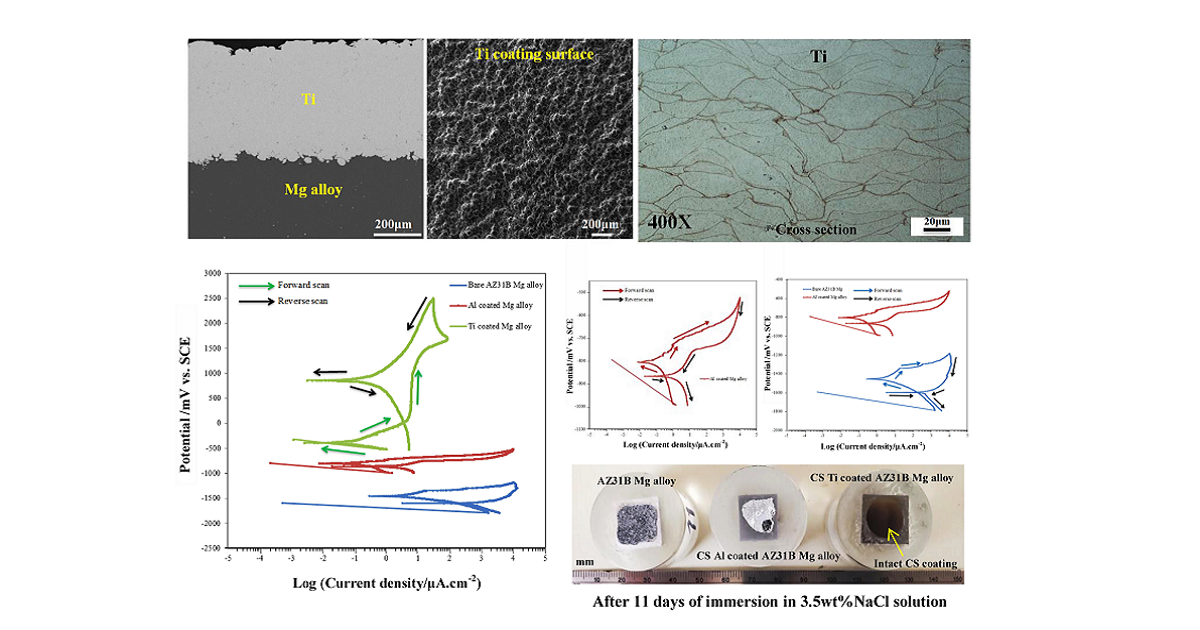

In additive manufacturing processes, sources such as electron beams or lasers with high energy are utilized for selectively melting down the powder bed, in which the resulted solidified metal can form the solid component. The most well known metal additive manufacturing methods include selective laser sintering, selective laser melting and electron beam melting. However, as high energy sources are used in these methods, disadvantages such as undesirable phase transformations, and residual stress caused by high processing temperatures, are inevitable. Likewise, most common additive manufacturing processes have been typically utilized to produce complicated Ti, Fe, or Ni-based alloy/super alloy components. Nonetheless, because of melting, these processes are not appropriate processes for producing the components made of non-ferrous alloys like Mg alloys, high-strength Cu, or Al-based alloys. Thus, another additive manufacturing technique is needed to produce the parts made of such non-ferrous materials. Cold spray is a newly developed technology that is able to produce the components via solid-state deposition of powder particles. Compared to traditional deposition processes which use high temperatures (such as prevalent additive manufacturing methods and traditional thermal spray processes), in the cold spray technique, the deposition process typically uses the kinetic energy of the powder particles, before impinging, in place of the thermal energy. The feedstock powder utilized in the CS process keeps its solid state throughout the whole deposition process. The deposition is attained via mechanical interlocking and local metallurgical bonding, which are formed by severe local plastic deformations at particle–substrate interfaces and also at the inter-particle boundaries. As mentioned, the relatively low temperature in the cold spray process averts the common defects occurring in the deposition processes that include high temperatures, like phase transformation, oxidation, residual thermal stress (tensile), grain growth, etc.

The abovementioned remarkable advantages make cold spray technology an effective method for producing coatings with a wide range of materials; they can comprise most metals and their alloys, nanostructured metals, and MMCs. In addition, there is no limitation in the growth of thickness in the cold spray coating process. Hence, besides the application of solid-state cold spray processes for the coating of surfaces and the repairing of structures, they can be employed in with faster build rates (minutes) compared to selective laser melting and electron beam melting processes.

The objective of this Special Issue is to present the latest experimental and theoretical developments in this field, through original research and short communication papers, and review articles from academia and industry around the world.

In particular, the topics of interest include, but are not limited to:

- 3D printed/additively manufactured coatings and repair of structurally critical components using cold spray technology.

- Cold spray additive manufacturing of high entropy alloys, Ti, Al, Fe, Ni based alloys and super alloys, refractory metals, etc.

- Improvement of corrosion, wear and high temperature oxidation resistances of additively manufactured cold sprayed components/deposits using post-cold spray treatments.

- Modification of mechanical properties of additively manufactured cold sprayed components using post-cold spray treatments.

- Application of additively manufactured cold sprayed components/deposits for biomedical applications.

- Hybrid additive manufacturing: the combination of cold spray processes and common additive manufacturing methods.

Dr. Mohammadreza Daroonparvar

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 250 words) can be sent to the Editorial Office for assessment.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- corrosion

- high temperature oxidation

- advanced manufacturing

- cold spray

- wear

- bio-medical application

- additively manufactured coatings

Benefits of Publishing in a Special Issue

- Ease of navigation: Grouping papers by topic helps scholars navigate broad scope journals more efficiently.

- Greater discoverability: Special Issues support the reach and impact of scientific research. Articles in Special Issues are more discoverable and cited more frequently.

- Expansion of research network: Special Issues facilitate connections among authors, fostering scientific collaborations.

- External promotion: Articles in Special Issues are often promoted through the journal's social media, increasing their visibility.

- Reprint: MDPI Books provides the opportunity to republish successful Special Issues in book format, both online and in print.