Journal Description

Fuels

Fuels

is an international, peer-reviewed, open access journal on fuel science, published quarterly online by MDPI. The Institute of Energy and Fuel Processing Technology (ITPE) is affiliated to Fuels and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within ESCI (Web of Science), EBSCO, Ei Compendex, and other databases.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 22.8 days after submission; acceptance to publication is undertaken in 7.2 days (median values for papers published in this journal in the second half of 2025).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Journal Cluster of Energy and Fuels: Energies, Batteries, Hydrogen, Biomass, Electricity, Wind, Fuels, Gases, Solar, ESA and Methane.

Impact Factor:

2.8 (2024);

5-Year Impact Factor:

3.1 (2024)

Latest Articles

Derivation and Application of a New Type of Water Flooding Characteristic Curve

Fuels 2026, 7(1), 7; https://doi.org/10.3390/fuels7010007 - 20 Jan 2026

Abstract

►

Show Figures

The water flooding characteristic curve is a crucial tool in reservoir dynamic analysis, commonly employed to estimate water-driven geological reserves and recoverable reserves. However, due to approximations in theoretical derivations—such as equating average water saturation with outlet saturation or assuming that water cut

[...] Read more.

The water flooding characteristic curve is a crucial tool in reservoir dynamic analysis, commonly employed to estimate water-driven geological reserves and recoverable reserves. However, due to approximations in theoretical derivations—such as equating average water saturation with outlet saturation or assuming that water cut approaches unity—most conventional curves achieve high accuracy only during the high water-cut stage (>80%). This study eliminates systematic errors and enhances calculation accuracy by establishing an improved water flooding curve equation. Firstly, a theoretical analysis of the error in a WOR (water–oil ratio)-type water flooding characteristic curve is performed. The results demonstrate that as water cut increases, calculated dynamic geological and recoverable reserves gradually rise, approaching actual values only when the water cut exceeds 90%. Secondly, a new type of water flooding characteristic curve is derived by using the Buckley–Leverett water drive oil theory and the Welge equation to modify the saturation approximation. Comparative analysis via reservoir numerical simulation demonstrates that the proposed curve significantly enhances prediction accuracy across all water-cut stages above 50%, outperforming conventional curves. After the water cut reaches 50%, the calculation error of dynamic geological reserves is less than 10%, and the calculation error of recoverable reserves is less than 5%. Field application shows that the new water flooding characteristic curve maintains a stable linear shape under certain development conditions. After the adjustment of development conditions, it jumps to form a new stable straight-line segment, which is conducive to the rapid and accurate evaluation of the adjustment effect.

Full article

Open AccessArticle

Optimizing the Performance of Microbial Fuel Cells: Linking Laboratory Analysis and Multivariate Machine Learning Approach to Enhance Bioelectricity Generation from Wastewater

by

Mosammat Mustari Khanaum, Shafiqur Rahman and Md. Saidul Borhan

Fuels 2026, 7(1), 6; https://doi.org/10.3390/fuels7010006 - 20 Jan 2026

Abstract

►▼

Show Figures

Laboratory-based research on microbial fuel cells (MFCs) is often costly and limited to a small number of variables, making optimization challenging. However, machine learning (ML) offers a promising solution by enabling efficient multivariate principal component analysis (PCA) and multivariable optimization. These techniques can

[...] Read more.

Laboratory-based research on microbial fuel cells (MFCs) is often costly and limited to a small number of variables, making optimization challenging. However, machine learning (ML) offers a promising solution by enabling efficient multivariate principal component analysis (PCA) and multivariable optimization. These techniques can provide significant insights and optimization opportunities. The goal of this study is to propose an ML-based approach to explore the relationships between bioelectricity generation (in terms of voltage, power density (PD), current density (CD), and coulombic efficiency (CE)) and two key variables, chemical oxygen demand (COD) and pH, as well as to recommend their optimal combinations. Specifically, the objectives are to (1) integrate a laboratory-based MFC study with multivariate data analyses; (2) apply PCA to reduce data complexity by focusing on the principal components that account for the greatest variance, thus improving interpretability; and (3) identify the optimal combinations of COD and pH for maximizing bioelectricity generation. The PCA results demonstrated that COD positively influenced the generated voltage while having an inverse effect on CE. Additionally, both PD and CD increased with higher pH values. The optimal combination of COD and pH improved CD, PD, and CE; however, their optimal combination for generated voltage differed, with higher COD leading to higher voltage. The optimal predicted voltage, CD, PD, and CE of the study were 795.71 (mV), 1451.80 (mA/m2), 57.46 (mW/m2), and 4.85%, respectively. By integrating ML approaches, this study contributed to the optimization of bioelectricity generation from wastewater and offered valuable insights for researchers working in this field.

Full article

Figure 1

Open AccessArticle

Hydrogen Fuel in Aviation: Quantifying Risks for a Sustainable Future

by

Ozan Öztürk and Melih Yıldız

Fuels 2026, 7(1), 5; https://doi.org/10.3390/fuels7010005 - 19 Jan 2026

Abstract

The aviation industry, responsible for approximately 2.5–3.5% of global greenhouse gas emissions, faces increasing pressure to adopt sustainable energy solutions. Hydrogen, with its high gravimetric energy density and zero carbon emissions during use, has emerged as a promising alternative fuel to support aviation

[...] Read more.

The aviation industry, responsible for approximately 2.5–3.5% of global greenhouse gas emissions, faces increasing pressure to adopt sustainable energy solutions. Hydrogen, with its high gravimetric energy density and zero carbon emissions during use, has emerged as a promising alternative fuel to support aviation decarbonization. However, its large-scale implementation remains hindered by cryogenic storage requirements, safety risks, infrastructure adaptation, and economic constraints. This study aims to identify and evaluate the primary technical and operational risks associated with hydrogen utilization in aviation through a comprehensive Monte Carlo Simulation-based risk assessment. The analysis specifically focuses on four key domains—hydrogen leakage, cryogenic storage, explosion hazards, and infrastructure challenges—while excluding economic and lifecycle aspects to maintain a technical scope only. A 10,000-iteration simulation was conducted to quantify the probability and impact of each risk factor. Results indicate that hydrogen leakage and explosion hazards represent the most critical risks, with mean risk scores exceeding 20 on a 25-point scale, whereas investment costs and technical expertise were ranked as comparatively low-level risks. Based on these findings, strategic mitigation measures—including real-time leak detection systems, composite cryotank technologies, and standardized safety protocols—are proposed to enhance system reliability and support the safe integration of hydrogen-powered aviation. This study contributes to a data-driven understanding of hydrogen-related risks and provides a technological roadmap for advancing carbon-neutral air transport.

Full article

(This article belongs to the Special Issue Sustainable Jet Fuels from Bio-Based Resources)

►▼

Show Figures

Figure 1

Open AccessArticle

An Accessible Method for the Quantitative Determination of Succinimide Additives in Diesel Fuel

by

Marcella Frauscher, Bettina Ronai, Nicole Dörr and Alexandra Rögner

Fuels 2026, 7(1), 4; https://doi.org/10.3390/fuels7010004 - 19 Jan 2026

Abstract

►▼

Show Figures

Succinimide additives play an important role in combating engine deposits and are therefore commonly blended in fuels. As many of the methods currently used to quantify them in fuel rely on time-consuming techniques and the use of expensive laboratory equipment, a more practical

[...] Read more.

Succinimide additives play an important role in combating engine deposits and are therefore commonly blended in fuels. As many of the methods currently used to quantify them in fuel rely on time-consuming techniques and the use of expensive laboratory equipment, a more practical approach was explored. For this purpose, an existing method for aqueous samples involving a colour reaction with Rose Bengal dye and spectrophotometric detection in the UV/Vis range was modified for usage in the nonpolar fuel matrix and tested for applicability. The result was an accessible method for determining the succinimide additive content of diesel fuel—including biodiesel—that is easy to implement in the laboratory routine.

Full article

Figure 1

Open AccessArticle

A Multiscale CFD Model of Evaporating Hydrogen Menisci: Incorporating Subgrid Thin-Film Dynamics and In Situ Accommodation Coefficients

by

Ayaaz Yasin, Saaras Pakanati and Kishan Bellur

Fuels 2026, 7(1), 3; https://doi.org/10.3390/fuels7010003 - 12 Jan 2026

Abstract

►▼

Show Figures

Due to its high energy density, liquid Hydrogen is an essential fuel for both terrestrial energy systems and space propulsion. However, uncontrolled evaporation poses a challenge for cryogenic storage and transport technologies. Accurate modeling of evaporation remains difficult due to the multiscale menisci

[...] Read more.

Due to its high energy density, liquid Hydrogen is an essential fuel for both terrestrial energy systems and space propulsion. However, uncontrolled evaporation poses a challenge for cryogenic storage and transport technologies. Accurate modeling of evaporation remains difficult due to the multiscale menisci formed by the wetting liquid phase. Thin liquid films form near the walls of containers, ranging from millimeters to nanometers in thickness. Heat conduction through the solid walls enables high evaporation rates in this region. Discrepancies in the reported values of the accommodation coefficients (necessary inputs to models) further complicate evaporation calculations. In this study, we present a novel multiscale model for CFD simulations of evaporating Hydrogen menisci. Film profiles below 10

Figure 1

Open AccessFeature PaperArticle

Characterization, Kinetic Studies, and Thermodynamic Analysis of Pili (Canarium ovatum Engl.) Nutshell for Assessing Its Biofuel Potential and Bioenergy Applications

by

Kaye Papa, Jeffrey Lavarias, Melba Denson, Danila Paragas, Mari Rowena Tanquilut and Arly Morico

Fuels 2026, 7(1), 2; https://doi.org/10.3390/fuels7010002 - 23 Dec 2025

Abstract

Pili nutshell (PS), an abundant agro-industrial byproduct in the Bicol Region, Philippines, demonstrates substantial potential as a solid biofuel and bioenergy feedstock. Proximate and ultimate analyses revealed high volatile matter (72.00 ± 0.20 wt%), low ash content (4.33 ± 0.76 wt%), and a

[...] Read more.

Pili nutshell (PS), an abundant agro-industrial byproduct in the Bicol Region, Philippines, demonstrates substantial potential as a solid biofuel and bioenergy feedstock. Proximate and ultimate analyses revealed high volatile matter (72.00 ± 0.20 wt%), low ash content (4.33 ± 0.76 wt%), and a higher heating value of 20.60 MJ/kg, indicating strong suitability as a solid fuel for thermochemical conversion and biofuel production. Thermogravimetric analysis (TGA) was conducted from 30 °C to 900 °C at heating rates of 10, 15, and 20 °C/min under nitrogen to examine its thermal decomposition behavior. The process followed three stages: initial moisture loss, active devolatilization, and lignin-rich char formation. The resulting kinetic and thermodynamic parameters are directly relevant for designing fast pyrolysis processes aimed at liquid biofuel production and optimizing downstream fuel utilization of the derived bio-oil and char. Kinetic analysis using the Coats–Redfern method identified third-order reaction (CR03) and diffusion-controlled (DM6) models as best-fitting, with activation energies ranging from 64.03–96.21 kJ/mol (CR03) and 66.98–104.72 kJ/mol (DM6). Corresponding thermodynamic parameters—ΔH (58.67–90.95 kJ/mol), ΔG (201.51–231.46 kJ/mol), and ΔS (−174.57 to −255.08 kJ/mol·K)—indicated an endothermic, non-spontaneous, entropy-reducing reaction pathway. Model-free methods confirmed a highly reactive zone at α = 0.3–0.6, with consistent Ea values (~130–190 kJ/mol). These findings affirm the viability of PS for fast pyrolysis, offering data-driven insights for optimizing advanced fuel and bioenergy systems in line with circular economy objectives.

Full article

(This article belongs to the Special Issue Biofuels and Bioenergy: New Advances and Challenges)

►▼

Show Figures

Figure 1

Open AccessArticle

Novel Precise Plugging and Thickening Technology for Secondary Grouting and Enhanced Methane Gas Extraction at the Bottom of Failed Drillholes

by

Sijiang Wu, Xiao Luo, Wei Li, Peng Ren, Dongyu Wang, Baobin Gao and Alhaji Safiwu

Fuels 2026, 7(1), 1; https://doi.org/10.3390/fuels7010001 - 19 Dec 2025

Abstract

►▼

Show Figures

Methane gas (CH4) leakage and gas extraction efficiency in drillholes present persistent challenges in coal mine gas management. To address these issues, a novel gas leakage detection device and a precision secondary grouting and thickening system were developed and field-tested at

[...] Read more.

Methane gas (CH4) leakage and gas extraction efficiency in drillholes present persistent challenges in coal mine gas management. To address these issues, a novel gas leakage detection device and a precision secondary grouting and thickening system were developed and field-tested at the Li YaZhuang Coal Mine, China. The system enables accurate identification of leakage zones and provides adjustable sealing length and depth, withstanding grouting pressures up to 2.0 MPa to achieve the full-section sealing of drillholes. Field application on 23 drillholes demonstrated a significant improvement in gas extraction performance. The average methane concentration and pure gas flow rate increased by more than 2-fold (2.61 and 3.05, respectively) compared with the pregrouting values, indicating substantial increases in gas extraction stability and duration. This study validates the effectiveness and practicality of the proposed secondary grouting technology for restoring failed drillholes, mitigating gas leakage, and improving methane recovery. The results provide a technical reference for advancing gas control strategies in high-gas coal seams.

Full article

Figure 1

Open AccessArticle

Mechanistic Evaluation of Surfactant-Enhanced Oil Mobility in Tight Conglomerate Reservoirs: A Case Study of Mahu Oilfield, NW China

by

Jing Zhang, Sai Zhang, Yueli Feng, Jianxin Liu, Hao Bai, Ziliang Li, Erdong Yao and Fujian Zhou

Fuels 2025, 6(4), 93; https://doi.org/10.3390/fuels6040093 - 12 Dec 2025

Abstract

►▼

Show Figures

To address the challenges of strong heterogeneity and poor crude oil mobility in tight conglomerate reservoirs of the Mahu Oilfield, this study systematically evaluated the effects of different surfactants on wettability alteration, spontaneous imbibition, and relative permeability through high-temperature/high-pressure spontaneous imbibition experiments, online

[...] Read more.

To address the challenges of strong heterogeneity and poor crude oil mobility in tight conglomerate reservoirs of the Mahu Oilfield, this study systematically evaluated the effects of different surfactants on wettability alteration, spontaneous imbibition, and relative permeability through high-temperature/high-pressure spontaneous imbibition experiments, online Nuclear Magnetic Resonance (NMR) monitoring, and relative permeability measurements. Core samples from the Jinlong and Madong areas (porosity: 5.98–17.55%; permeability: 0.005–0.148 mD) were characterized alongside X-Ray Diffraction (XRD) data (clay mineral content: 22–35.7%) to compare the performance of anionic, cationic, nonionic, and biosurfactants. The results indicated that the nonionic surfactant AEO-2 (Fatty Alcohol Polyoxyethylene Ether) (0.2% concentration) at 80 °C exhibited optimal performance, achieving the following results: 1. a reduction in wettability contact angles by 80–90° (transitioning from oil-wet to water-wet); 2. a decrease in interfacial tension to 0.64 mN/m; 3. an imbibition recovery rate of 40.14%—5 to 10 percentage points higher than conventional fracturing fluids. NMR data revealed that nanopores (<50 nm) contributed 75.36% of the total recovery, serving as the primary channels for oil mobilization. Relative permeability tests confirmed that AEO-2 reduced residual oil saturation by 6.21–6.38%, significantly improving fluid flow in highly heterogeneous reservoirs. Mechanistic analysis highlighted that the synergy between wettability reversal and interfacial tension reduction was the key driver of recovery enhancement. This study provides a theoretical foundation and practical solutions for the efficient development of tight conglomerate reservoirs.

Full article

Figure 1

Open AccessArticle

Evaluating Techno-Economic Feasibility of Green Hydrogen Production Integrated with a Wave Energy Converter Device

by

Sagar Kansara, Kourosh Rezanejad, Mohammad Jahanbakht and Diogo M. F. Santos

Fuels 2025, 6(4), 92; https://doi.org/10.3390/fuels6040092 - 4 Dec 2025

Abstract

The urgent need to address climate change has driven the exploration of sustainable energy solutions, with wave energy and green hydrogen emerging as prominent alternatives to traditional fossil fuels. This study examines the potential synergy between wave energy and hydrogen production, with a

[...] Read more.

The urgent need to address climate change has driven the exploration of sustainable energy solutions, with wave energy and green hydrogen emerging as prominent alternatives to traditional fossil fuels. This study examines the potential synergy between wave energy and hydrogen production, with a focus on the economic viability of integrating these technologies. Through a detailed analysis of the levelised cost of electricity (LCOE) and the levelised cost of hydrogen (LCOH), this paper examines how coastal regions in Portugal and across Western Europe can harness wave energy to produce green hydrogen, a crucial component in the global energy transition. The techno-economic assessment accounts for capital and operational costs, energy efficiency, and lifetime performance to determine how design and location affect economic feasibility. Preliminary analysis indicates that regions with significant wave power potential present opportunities for competitive LCOE values, with some coastal areas achieving LCOE figures as low as 0.10 €/kWh. Additionally, the LCOH analysis reveals that among various storage methods, compressed gas hydrogen at 350 bar stands out as the most cost-effective option. This research highlights the transformative potential of wave energy-driven hydrogen production as a crucial solution for decarbonising the maritime sector. Future technological advancements and cost efficiencies are poised to overcome current economic barriers and accelerate the transition to a sustainable, low-carbon energy landscape.

Full article

(This article belongs to the Topic Hydrogen Energy Technologies, 3rd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Numerical Simulation Data Versus PIV Measurement Data for a Hydrogen-Fueled Afterburner System

by

Andreea Cristina Mangra, Florin Gabriel Florean and Cristian Carlanescu

Fuels 2025, 6(4), 91; https://doi.org/10.3390/fuels6040091 - 4 Dec 2025

Abstract

►▼

Show Figures

The global concern regarding the reduction of carbon emissions has led to the development of hydrogen as a clean, carbon-free fuel for combustion systems. The present work combines Particle Image Velocimetry flow field measurements and Reynolds-Averaged Navier–Stokes numerical simulations to investigate the reactive

[...] Read more.

The global concern regarding the reduction of carbon emissions has led to the development of hydrogen as a clean, carbon-free fuel for combustion systems. The present work combines Particle Image Velocimetry flow field measurements and Reynolds-Averaged Navier–Stokes numerical simulations to investigate the reactive flow downstream of a newly developed flame holder as part of a hydrogen-fueled afterburner system. The obtained numerical results are in reasonable agreement, for a RANS simulation, with the PIV measured data. According to the results presented in this article, it can be seen that ignition occurs, the flame is attached to the flame holder, and vortices develop downstream of the flame holder. These vortices facilitate the mixing of hydrogen with the flue gas coming from the gas generator. The recirculation zone generated by the flame holder in the flow measures approximately 100 mm, with the peak negative velocity reaching around 10 m/s. Downstream of the recirculation zone, the far-field free stream velocity on the centerline reaches 20 m/s. Outside the recirculation region, in the radial direction, the free stream is accelerated to an experimentally measured value of approximately 40 m/s, at 20 mm downstream from the flame holder, and 35 m/s at 100 mm downstream of the flame holder. The information gathered thus far will aid further investigation of the presented hydrogen-fueled afterburner system.

Full article

Figure 1

Open AccessReview

Ricinus communis as a Sustainable Alternative for Biodiesel Production: A Review

by

Miriam Martínez-González, Miguel Angel Ramos-López, Ana L. Villagómez-Aranda, José Alberto Rodríguez-Morales, Juan Campos-Guillén, Karla Elizabeth Mariscal-Ureta, Aldo Amaro-Reyes, Juan Antonio Valencia-Hernández, Diana Saenz de la O and Carlos Eduardo Zavala-Gómez

Fuels 2025, 6(4), 90; https://doi.org/10.3390/fuels6040090 - 2 Dec 2025

Abstract

The current rise in global energy demand and environmental degradation has highlighted the need to use renewable energy as an alternative to fossil fuels. Ricinus communis L. (castor bean oil) has emerged as a promising source for biofuels production due to high oil

[...] Read more.

The current rise in global energy demand and environmental degradation has highlighted the need to use renewable energy as an alternative to fossil fuels. Ricinus communis L. (castor bean oil) has emerged as a promising source for biofuels production due to high oil content (45–55%), ability to grow on marginal soils, and resistance to adverse conditions. This review analyzes 93 relevant studies from 2019 to 2025, selected by the PRISMA method (Preferred Reporting Items for Systematic reviews and Meta-Analyses) from databases such as Google Scholar and Web of Science. There were identified that agronomic techniques such as optimized plant spacing, balanced fertilization, and elicitation can significantly increase productivity. Among the production methods used, heterogeneous catalysis (96.8%) and enzymatic processes (90%) stand up for their sustainability and efficiency. However, the main limitation remains the high viscosity of castor biodiesel (14–18 mm2/s at 40 °C), which exceeds international quality standards. Even so, castor biodiesel offers excellent lubricity (reduces injection wear by 20%), has standard oxidative stability, and has a relatively low cetane number (38–42), which poses challenges for ignition quality. Improvement strategies such as blending, enzymatic modification, and additive incorporation have shown potential to mitigate these limitations. The review also addresses environmental benefits, regulatory challenges, and market opportunities where the castor biodiesel offers competitive advantages. Enhancing research and innovation, supported by targeted public policies and technical standards, is essential to overcome current barriers and enable the commercial adoption of castor biodiesel as part of a more sustainable and diversified energy future.

Full article

(This article belongs to the Special Issue Biomass Conversion to Biofuels: 2nd Edition)

►▼

Show Figures

Figure 1

Open AccessArticle

Influence of CA-Modified Hβ on Methane-Assisted Hydroconversion of Polycyclic Aromatics to Monocyclic Aromatics

by

Zhibing Shen, Ruiyuan Tang, Shengrong Liang, Juntao Zhang, Leyuan Li and Shangli Zhang

Fuels 2025, 6(4), 89; https://doi.org/10.3390/fuels6040089 - 26 Nov 2025

Abstract

►▼

Show Figures

The conversion of polycyclic aromatic hydrocarbons (PAHs) to monocyclic aromatic hydrocarbons holds significant importance in the petrochemical and coal chemical industries, as it enables the production of high-value-added chemicals. In this study, we investigated the methane-assisted hydroconversion of PAHs to monocyclic aromatic hydrocarbons

[...] Read more.

The conversion of polycyclic aromatic hydrocarbons (PAHs) to monocyclic aromatic hydrocarbons holds significant importance in the petrochemical and coal chemical industries, as it enables the production of high-value-added chemicals. In this study, we investigated the methane-assisted hydroconversion of PAHs to monocyclic aromatic hydrocarbons with methyl side chains over Zn-based catalysts from Hβ zeolites treated with citric acid (CA) at different concentrations. The CA-modified Hβ catalysts were characterized using X-ray diffraction (XRD), N2 adsorption–desorption, pyridine–Fourier transform infrared spectroscopy (Py-FTIR), and ammonia temperature-programmed desorption (NH3-TPD). The results show that low CA concentrations facilitate the removal of amorphous aluminum from the zeolite framework, thereby increasing the specific surface area, pore volume, and pore diameter of the Zn/Hβ catalyst, as well as improving its Lewis/Brønsted (L/B) acid ratio. In contrast, excessive CA treatment causes the undesirable removal of framework aluminum and leads to structural collapse in the mesoporous regions formed at the interfaces between certain crystal aggregates. This, in turn, has a negative impact on the catalyst’s specific surface area, pore volume, pore size distribution, total acidity, and L/B ratio. Experimental data further indicate that the optimal Zn/Hβ catalyst, prepared using Hβ treated with 0.08 M CA, achieves a naphthalene conversion rate of up to 99% and a benzene–toluene–xylene (BTX) selectivity of 60% in the liquid product over a 10 h reaction period. These findings confirm that CA treatment not only enhances the catalytic activity of Zn/Hβ but also significantly improves its operational stability. This work provides new insights into the rational design of catalysts for the efficient conversion of PAHs to monocyclic aromatic hydrocarbons and the utilization of methane resources.

Full article

Figure 1

Open AccessArticle

A Global Review of Blue and Green Hydrogen Fuel Production Technologies, Trends and Future Outlook to 2050

by

Muhammad Ammar, Babatunde Oyeleke Oyewale, Ahmed Elseragy, Ibrahim M. Albayati and Aliyu M. Aliyu

Fuels 2025, 6(4), 88; https://doi.org/10.3390/fuels6040088 - 26 Nov 2025

Abstract

►▼

Show Figures

Hydrogen is emerging as a key energy carrier in the transition to a low-carbon economy. This study reviews blue and green hydrogen, analysing their production technologies, environmental impacts, economic viability and global deployment trends. Blue hydrogen, derived from natural gas, coal or biomass

[...] Read more.

Hydrogen is emerging as a key energy carrier in the transition to a low-carbon economy. This study reviews blue and green hydrogen, analysing their production technologies, environmental impacts, economic viability and global deployment trends. Blue hydrogen, derived from natural gas, coal or biomass with carbon capture, utilisation and storage, offers a transitional pathway by reducing emissions relative to unabated fossil routes, but its benefits depend on high CO2 capture efficiencies and strict methane leakage control. Green hydrogen, produced via renewable-powered electrolysis and advanced thermochemical, photochemical and photoelectrochemical methods, represents the most sustainable long-term solution, though it is currently limited by cost and scale. This comparative assessment shows that green hydrogen’s production emissions, in the range of 0.67 kgCO-eq/kgH to 1.74 kgCO2-eq/kgH2, are substantially lower than those of blue hydrogen, in the range of 1.21 kgCO2-eq/kgH2 to 4.56 kgCO2-eq/kgH2, reinforcing its alignment with climate neutrality goals. Global production remains below 1% from low-emission sources, yet momentum is growing, with renewable-rich regions investing in large-scale electrolysers. A long short-term memory forecast suggests that blue hydrogen will dominate in the short term, but green hydrogen will surpass it around 2042. Together, both pathways are essential, blue hydrogen as a bridging option and green hydrogen as the foundation of a sustainable hydrogen economy.

Full article

Figure 1

Open AccessArticle

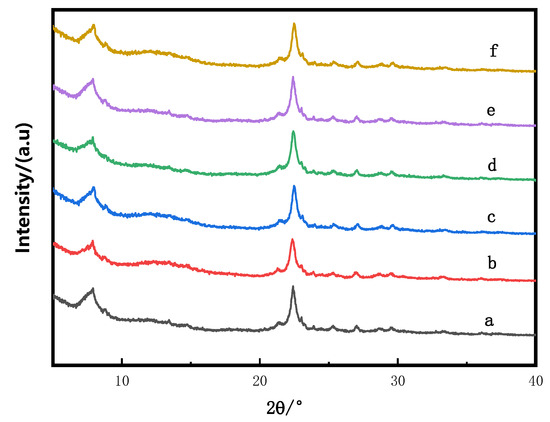

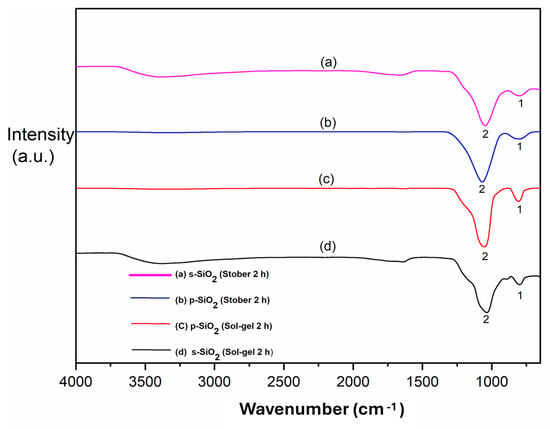

Effects of Calcination Time and Sulfonation on Silica Particles Synthesised Using the Stober and Sol–Gel Methods for Fuel Cell Applications

by

Livhuwani Modau, Charles Muzenda, Tebogo Mashola, Touhami Mokrani, Rudzani Sigwadi and Fulufhelo Nemavhola

Fuels 2025, 6(4), 87; https://doi.org/10.3390/fuels6040087 - 25 Nov 2025

Abstract

►▼

Show Figures

SiO2 is a versatile inorganic substance with a wide spectrum of applications in areas such as fuel cells. In this study, pristine (p-SiO2) and sulfonated silica (s-SiO2) particles were synthesised using the sol–gel and Stober methods. Furthermore, this

[...] Read more.

SiO2 is a versatile inorganic substance with a wide spectrum of applications in areas such as fuel cells. In this study, pristine (p-SiO2) and sulfonated silica (s-SiO2) particles were synthesised using the sol–gel and Stober methods. Furthermore, this study investigated the impact of calcination time and surface changes on the morphology, and hence functionality, of silica particles synthesised as potential fuel cell membrane additives. Tetraethyl orthosilicate (TEOS) was used as a silica precursor dissolved in water, with sulfuric acid serving as the sulfonation agent. Parametric data on particle morphology, such as particle size, porosity, total surface area, and agglomeration, were measured and evaluated using BET, Fourier-transform infrared (FTIR), X-ray diffraction (XRD), and scanning electron microscopy (SEM). The amorphous nature of silica particles was confirmed by XRD analysis. The BET outcome data acquired for the synthesised silica particles were a surface area ranging from 271 to 487 m2/g, a pore diameter of 12.10–21.02 nm, and a total pore volume of 0.76–1.58 cm3/g. These data give crucial characteristics for designing appropriate silica nanofillers for hybrid fuel cell membranes. As a result, the data gathered can be used to make future decisions about silica synthesis methods for various specific applications, such as fuel cell applications.

Full article

Figure 1

Open AccessReview

Harnessing Mechanical Force for Greenhouse Gas Conversion: A Mini-Review on Mechanochemistry in the Dry Reforming of Methane

by

Abdulwahab Saad, Kehinde Temitope Alao, Idris Temitope Bello, Fawziyah Oyefunke Olarinoye and Abdulhammed K. Hamzat

Fuels 2025, 6(4), 86; https://doi.org/10.3390/fuels6040086 - 21 Nov 2025

Abstract

►▼

Show Figures

Dry reforming of methane (DRM) is a promising method for turning two major greenhouse gases, CO2 and CH4, into syngas (H2 + CO). This syngas has the right H2/CO ratio for making valuable chemicals and liquid fuels.

[...] Read more.

Dry reforming of methane (DRM) is a promising method for turning two major greenhouse gases, CO2 and CH4, into syngas (H2 + CO). This syngas has the right H2/CO ratio for making valuable chemicals and liquid fuels. However, there are significant challenges that make it tough to implement commercially. One big issue is that the process requires a lot of energy because it is highly endothermic, needing temperatures over 700 °C. This high heat can quickly deactivate the catalyst due to carbon build-up (coking) and the thermal sintering of metal nanoparticles. Researchers increasingly recognize mechanochemistry—a non-thermal, solid-state technique employing mechanical force to drive chemical transformations—as a sustainable, solvent-free strategy to address these DRM challenges. This mini-review critically assesses the dual role of mechanochemistry in advancing DRM. First, we examine its established role in creating advanced catalysts at lower temperatures. Here, mechanochemical methods help produce well-dispersed nanoparticles, enhance strong interactions between metal and support, and develop bimetallic alloys that resist coke formation and show great stability. Second, we delve into the exciting possibility of using mechanochemistry to directly engage in the DRM reaction at near-ambient temperatures, which marks a major shift from traditional thermocatalysis. Lastly, we discuss the key challenges ahead, like scalability and understanding the mechanisms involved, while also outlining future directions for research to fully harness mechanochemistry for converting greenhouse gases sustainably.

Full article

Figure 1

Open AccessArticle

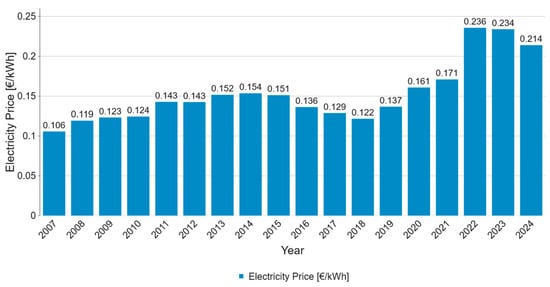

Multi-Objective Optimization of Grid Mix Scenarios for Green Hydrogen Production in Germany: Balancing Environmental Impact and Energy Costs

by

Shreyas Mysore Guruprasad, Yajing Chen, Ann-Katrin Müller, Gabriel Sultan and Agnetha Flore

Fuels 2025, 6(4), 85; https://doi.org/10.3390/fuels6040085 - 21 Nov 2025

Abstract

As global decarbonization accelerates, the environmental and economic viability of hydrogen production largely depends on the evolving electricity supply mix. This study focused on alkaline water electrolysis (AWE) to identify the key factors affecting the competitiveness of green hydrogen. In this study, the

[...] Read more.

As global decarbonization accelerates, the environmental and economic viability of hydrogen production largely depends on the evolving electricity supply mix. This study focused on alkaline water electrolysis (AWE) to identify the key factors affecting the competitiveness of green hydrogen. In this study, the temporal dynamics of grid transformation in Germany and the EU over a 20-year period (2025–2045) were addressed by developing a multi-objective optimization framework that integrates environmental impact analysis with machine-learning surrogate models to evaluate trade-offs between the carbon footprint and energy cost per kilogram of hydrogen. Grid-mix scenarios were generated via constrained Latin Hypercube Sampling under policy constraints, including coal phase-out and ≥80% renewables, screened for Pareto optimality, and clustered into distinct archetypes. The results indicated that cost-effective, low-carbon hydrogen production can be achieved through balanced portfolios that emphasize hydropower, biomass, and solar energy. Scenarios that minimize energy costs alone tend to breach environmental targets, whereas ultra-low-emission paths incur steep energy cost penalties. A representative scenario for 2034 (GWP = 24.57 kg CO2-eq/kg H2; Energy Cost = 9.47 €/kg H2) demonstrated a realistic synergy between policy constraints, cost, and environmental impact.

Full article

(This article belongs to the Special Issue Sustainability Assessment of Renewable Fuels Production)

►▼

Show Figures

Figure 1

Open AccessReview

Integrated Techno-Economic and Environmental Assessment of U-Shaped (Horseshoe) Well Technology for Enhanced Recovery in Unconventional Shale and Tight Reservoirs

by

Habib Ouadi, Olusegun Stanley Tomomewo, Yahia Zakaria Benkhira, Gizem Yildirim, Aimen Laalam and Abderrahmane Mellak

Fuels 2025, 6(4), 84; https://doi.org/10.3390/fuels6040084 - 18 Nov 2025

Abstract

►▼

Show Figures

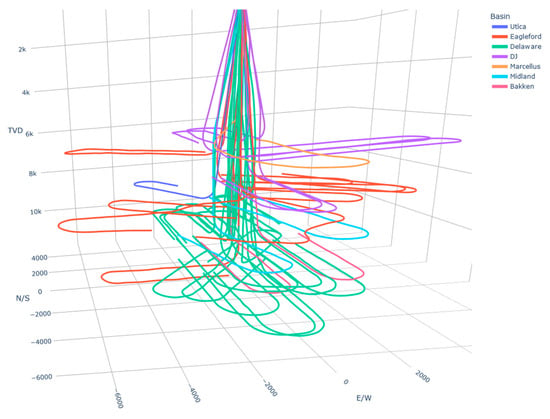

The development of unconventional resources continues to be propelled by innovations that enhance economic efficiency and maximize reservoir contact within operational constraints. Among the most recent of these is the U-shaped, or “horseshoe,” well design, which connects two parallel horizontal laterals with a

[...] Read more.

The development of unconventional resources continues to be propelled by innovations that enhance economic efficiency and maximize reservoir contact within operational constraints. Among the most recent of these is the U-shaped, or “horseshoe,” well design, which connects two parallel horizontal laterals with a 180° turn, effectively doubling the reservoir exposure from a single wellhead. This paper provides a comprehensive literature review of the current state of knowledge on U-shaped well technology. It surveys the operational drivers for their adoption, the critical drilling, and completion technologies that have enabled its successful implementation and discusses key design considerations for a successful operation. Field data from major North American shale basins, including the Permian, Eagle Ford, Bakken, and Haynesville, demonstrate substantial economic benefits, such as capital cost savings of approximately 20–25% compared to traditional methods. Lifecycle assessments indicate notable environmental advantages, including a 29.3% reduction in carbon emissions, a 15.8% reduction in water use, and a 50% decrease in land disturbance. Despite these clear benefits, gaps remain regarding long-term performance validation, stimulation of curved sections, and fracture modeling accuracy. Addressing these gaps is essential to fully realize the potential of U-shaped wells as a sustainable and economically attractive approach in the evolving landscape of unconventional energy development.

Full article

Figure 1

Open AccessArticle

Non-Supported Heteroatom Modification Molybdenum-Based Catalyst for Synthesis Low-Carbon Alcohols from Coal-Based Syngas

by

Peixuan Sun, Ruiyuan Tang, Lixia He, Zhibing Shen, Lingying Wang, Yuanyu Tian and Juntao Zhang

Fuels 2025, 6(4), 83; https://doi.org/10.3390/fuels6040083 - 7 Nov 2025

Abstract

Amid growing concerns over fossil fuel depletion and environmental degradation, developing alternative energy sources is imperative. While MoS2-based catalysts are known for their syngas conversion activity, their selectivity toward alcohols remains limited. This study addresses this gap by developing Cu-promoted MoS

[...] Read more.

Amid growing concerns over fossil fuel depletion and environmental degradation, developing alternative energy sources is imperative. While MoS2-based catalysts are known for their syngas conversion activity, their selectivity toward alcohols remains limited. This study addresses this gap by developing Cu-promoted MoS2 catalysts to enhance alcohol synthesis. The results indicated that the introduction of copper significantly modulates the catalytic performance of MoS2. We demonstrate that incorporating Cu significantly modulates the catalytic properties of MoS2. The optimized catalyst with 9 wt% Cu loading exhibited a CO conversion of 17.9% and a markedly improved total alcohol selectivity of 46.4%, with a space-time yield of 67.6 mg·g−1·h−1. Although Cu addition slightly reduced CO conversion, it markedly improved alcohol selectivity by facilitating active site dispersion, suppressing Fischer-Tropsch side reactions, and stabilizing heteroatomic active phases. Finally, a catalytic mechanism for the synthesis of low-carbon alcohols from syngas on MoS2-based catalysts was proposed based on the catalyst analysis and reaction results.

Full article

(This article belongs to the Special Issue Sustainability Assessment of Renewable Fuels Production)

►▼

Show Figures

Figure 1

Open AccessArticle

Changes in the Operating Conditions of Distribution Gas Networks as a Function of Altitude Conditions and the Proportion of Hydrogen in Transported Natural Gas

by

Krzysztof Kogut, Piotr Narloch, Katarzyna Kapusta and Ewa Zięba

Fuels 2025, 6(4), 82; https://doi.org/10.3390/fuels6040082 - 6 Nov 2025

Abstract

►▼

Show Figures

The article presents a comparison between the pressure conditions of a real low-pressure gas network and the results of hydraulic calculations obtained using various simulation programs and empirical equations. The calculations were performed using specialized gas network analysis software: STANET (ver 10.0.26), SimNet

[...] Read more.

The article presents a comparison between the pressure conditions of a real low-pressure gas network and the results of hydraulic calculations obtained using various simulation programs and empirical equations. The calculations were performed using specialized gas network analysis software: STANET (ver 10.0.26), SimNet SSGas 7, and SONET. Additionally, the simulation results were compared with calculations based on the empirical Darcy–Weisbach and Renouard equations. In the first part of the analysis, two calculation models were compared. In one model, the geodetic elevation of individual network nodes was included (elevation-aware model), while in the second, calculations were performed without considering node elevation (flat model). For low-pressure gas networks, accounting for elevation is critical due to the presence of the pressure recovery phenomenon, which does not occur in medium- and high-pressure networks. Furthermore, considering the growing need to increase the share of renewable energy, the study also examined the network’s operating conditions when using natural gas–hydrogen mixtures. The following hydrogen concentrations were considered: 2.5%, 5.0%, 10.0%, 20.0%, and 50.0%. The results confirm the importance of incorporating elevation data in the modeling of low-pressure gas networks. This is supported by the small differences between calculated results and actual pressure measurements taken from the operating network. Moreover, increasing the hydrogen content in the mixture intensifies the pressure recovery effect. The hydraulic results obtained using different computational tools were consistent and showed only minor discrepancies.

Full article

Figure 1

Open AccessArticle

Polyvinyl Alcohol-Based Binder Systems for Biomass and Charcoal Briquettes

by

Nataliya Korol and Viktor Yankovych

Fuels 2025, 6(4), 81; https://doi.org/10.3390/fuels6040081 - 21 Oct 2025

Abstract

►▼

Show Figures

Biomass briquettes are increasingly used as renewable solid fuels, yet their durability under humid storage remains a key limitation. This study evaluated the mechanical performance and water resistance of briquettes made from fine (0–1 mm) and coarse (0–3 mm) charcoal fractions using molasses

[...] Read more.

Biomass briquettes are increasingly used as renewable solid fuels, yet their durability under humid storage remains a key limitation. This study evaluated the mechanical performance and water resistance of briquettes made from fine (0–1 mm) and coarse (0–3 mm) charcoal fractions using molasses as a primary binder, polyvinyl alcohol (PVA, 3–7%) as a synthetic binder, and liquid soap (1–9%) as a surfactant additive. Compressive strength was measured in the dry state, after four days of water immersion, and after re-drying, while water absorption was monitored over immersion times from 15 min to 4 days. Fine-fraction briquettes showed higher strength and lower water uptake than coarse fractions, with optimal PVA contents of 6–7% providing maximum dry and post-drying strength. Moderate soap addition (2–3%) improved binder dispersion and early wet strength, whereas higher levels (>5%) reduced durability. Water absorption kinetics indicated that particle size controlled early swelling, while binder composition influenced the rate but not the final saturation. The best performance in humid storage was achieved by 0–1 mm + 4% PVA and 0–1 mm + 5% PVA + 3% soap formulations. These results support the formulation of eco-friendly binder systems that balance strength, moisture resistance, and cost for large-scale biomass briquette production.

Full article

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Catalysts, Energies, Fuels, Hydrogen, Nanoenergy Advances

Hydrogen Energy Technologies, 3rd Edition

Topic Editors: Bahman Shabani, Mahesh SuryawanshiDeadline: 1 November 2026

Topic in

Energies, Geosciences, Applied Sciences, Mining, Fuels, Fractal Fract

Basin Analysis and Modelling, 2nd Edition

Topic Editors: Jingshou Liu, Wenlong Ding, Lei Gong, Ang LiDeadline: 1 December 2026

Special Issues

Special Issue in

Fuels

Current Initiatives on Carbon Dioxide Utilization (CDU) for Fuel Production

Guest Editors: Athanasios Tiliakos, Adriana MarinoiuDeadline: 15 February 2026

Special Issue in

Fuels

Advances in Propulsion and Energy Systems: Fuel Injection and Combustion Systems

Guest Editors: Steven Begg, Nwabueze EmekwuruDeadline: 31 March 2026

Special Issue in

Fuels

Biofuels and Bioenergy: New Advances and Challenges

Guest Editor: Nikolaos KokkinosDeadline: 30 April 2026

Special Issue in

Fuels

Sustainability Assessment of Renewable Fuels Production

Guest Editors: Stella Bezergianni, Loukia P. ChrysikouDeadline: 31 May 2026