Abstract

Bio-based phenolic resins were developed with phenol substitution levels of 20% and 40% with crude extracts obtained from spent coffee grounds. The experimental resins were characterized in terms of their physical, chemical and bonding properties and exhibited the typical property levels of Phenol-Formaldehyde-type resins. Plywood panels were produced bonded with the novel experimental resins, exhibiting satisfactory performance, comparable to the reference panels in terms of both shear strength and wood failure, based on the requirements of the European standards. The results demonstrate the potential of using biomass-derived compounds as substitutes for petrochemical phenol in the production of wood adhesives, thereby increasing the bio-based content of the wood panel composites produced with them and improving their sustainability.

1. Introduction

Currently, formaldehyde-based adhesives, including phenolic, urea–formaldehyde, and melamine–formaldehyde adhesives, are mainly used in plywood, with phenolic resins being promoted for their excellent bonding strength and water resistance [1,2,3]. Phenolic resins are produced via the condensation reaction of phenol and formaldehyde, toxic compounds that raise health and environmental issues. Phenol is a non-renewable petroleum resource, and can be harmful to health, affecting the eyes, skin, and respiratory system, etc. [4,5].

Bio-based adhesives have advantages compared to oil-based adhesives with regard to human and environmental toxicity. Moreover, issues such as biodegradability, lower toxicity, low carbon footprint and sustainability are very important. A series of bio-adhesives, including starch adhesive [6], tannin adhesive [7], and protein-based adhesive [8], have been examined as adhesives and more specifically for plywood applications. Among them, vegetable proteins emerge as raw material for the preparation of biomass-derived adhesives due to their numerous functional groups such as amino groups, carboxylic acid groups, and hydroxyl groups that can form hydrogen bonding with wood components and among themselves [8]. Moreover, protein-based adhesives are mainly based on renewable resources, they are biodegradable, non-toxic and thus they reduce the environmental impact [9,10]. However, due to the presence of the large number of hydrophilic groups in the protein the water resistance of the protein adhesives is poor [11]. Averina et al. studied the adhesive properties of potato and corn proteins using glyoxal as a crosslinking agent [12]. In another recent study [13], an eco-friendly wood adhesive derived from soybean protein and epoxidized cardanol, was studied for wood composite applications. The cardanol-based epoxy acted as a cross-linking agent for reacting with hydrophilic groups in soybean protein while sodium hydroxide unfolded the globular soybean protein and exposed its hydrophilic groups inside to outside, and reacted with cardanol-based epoxy, which improved the cross-linking density, flatness, thermal stability of the cured adhesive, providing better mechanical properties for final wood-based composites [13]. Li et al. [14] prepared an environmentally friendly phenolic resin using waste plant protein, which achieved a significant wet shear strength. However, due to the high cost of soy protein, finding cost-effective alternatives remains a challenge. Yang et al. [15] explored modifying phenolic resin with soybean powder to create a copolymer resin. The modified resin demonstrated good water resistance, making it suitable for outdoor applications. Previous research studies indicated that plywood made with phenolic resins modified by soybean protein isolate exhibited good mechanical properties [16].

In this study, modified phenol-formaldehyde-type resins were prepared with a substantial substitution of phenol by crude extracts derived from spent coffee grounds. The phenol-formaldehyde (PF) reaction mechanism can be described in two stages: electrophilic addition of formaldehyde to the activated ortho and para positions of phenol to form hydroxymethyl phenols, followed by step-growth polymerization through the reaction of hydroxymethyl groups to form methylene and ether bridges, leading to a cross-linked network [17]. When protein is introduced into phenol–formaldehyde systems substituting partially phenol, its amino groups (–NH2) react with formaldehyde to form N-methylol derivatives. These intermediates can either self-condense or react with methylolated phenols, creating nitrogen-containing methylene bridges [14]. The experimental resins were successfully utilized in the production of plywood panels at pilot scale and evaluated in accordance with EU standards and requirements.

2. Materials and Methods

2.1. Extraction of Crude Extracts from Spent Coffee Grounds

For the substitution of phenol, crude extracts were obtained from oil-free spent coffee grounds. The extraction of coffee oil from spent coffee grounds was carried out following the biorefinery development method presented by Giannakis et al. [18]. Briefly, coffee oil was extracted using ethyl acetate as a solvent through ultrasound-assisted extraction in an ultrasonic water bath, with an initial solid-to-liquid ratio of 1:10 (w/v). Three consecutive extractions were performed for 20 min each, after which the liquid fraction was separated from the solids by filtration and subsequently evaporated. The resulting oil-free solids were subjected to ultrasound-assisted extraction with ethanol (70% and 96%, v/v) at a solid-to-liquid ratio of 1:10 (w/v) for three consecutive 20 min cycles. The resulting crude extract was separated by filtration, subsequently evaporated, characterized in terms of protein and total phenolic content, and finally employed as a partial substitute for phenol in plywood resin formulation.

2.2. Analytical Methods

The protein content was determined by the Kjeldahl method and a Nitrogen-Protein Factor of 6.25. The total phenolic content was determined by the Folin–Ciocalteu colorimetric method, using caffeic acid as the standard [19].

2.3. Materials for Resins Synthesis and Plywood Production

PanReac (Barcelona, Spain) supplied 37% w/w formaldehyde and 90% phenol, while Elton Group S.A. (Thessaloniki, Greece) provided industrial-grade sodium hydroxide (50% w/w). Three experimental crude extract samples from spent coffee grounds were supplied by the Department of Food Science and Human Nutrition at the Agricultural University of Athens (AUA) (Crude extract 1, 2 and 3). As a reference, soy protein isolate was obtained from MyProtein.gr (Athens, Greece) and wheat flour (all-purpose flour) from St. George Mills (Volos, Greece) for the preparation of the glue mixture in plywood panel production.

Experimental phenol–formaldehyde resins with commercial protein and crude extract samples, along with standard phenol–formaldehyde resins, were synthesized at the laboratory of CHIMAR HELLAS SA. The resulting resins were used for plywood panel production in the pilot facilities of CHIMAR HELLAS SA.

2.4. Synthesis of Reference and Bio-Based Resins

The crude extract samples obtained from spent coffee grounds at AUA were subsequently sent to CHIMAR, where drawing on the company’s proprietary expertise and by fine-tuning the resin synthesis parameters, they were used to substitute phenol—a petrochemical feedstock—in the formulation of a phenol–formaldehyde (PF) adhesive resin based on a standard industrial formulation currently used in the sector.

Three crude extracts were produced at AUA by ethanol extraction: one using 70% ethanol (Crude extract 1) and two samples using 96% ethanol (Crude extracts 2 and 3). Phenol was substituted by crude extract 1 at levels of 20% (PP1-20%) and 40% (PP1-40%) for the production of bio-based resins. With crude extract 2, some difficulties were observed, as during the final synthesis step of the resin with 20% phenol replacement, the viscosity increased excessively, terminating the synthesis process. Crude extract 3 was also used for phenol substitution 40% yielding bio-based resin (PP3-40%). A commercial soy protein sample was used to substitute 20% of phenol in the synthesis of the PPC-20% resin, serving as a reference for the experimental crude extract samples. The formulations studied were as follows:

- Reference PF resin

- PPC-20% resin with 20% phenol substitution by commercial Soy Protein

- PP1-20% resin with 20% phenol substitution by Crude extract sample 1

- PP1-40% resin with 40% phenol substitution by Crude extract sample 1

- PP2-20% resin with 20% phenol substitution by Crude extract sample 2

- PP3-40% resin with 40% phenol substitution by Crude extract sample 3

The resin synthesis followed the resole-type process [17], consisting of a phenolation stage followed by condensation. Formaldehyde was added to phenol in the presence of sodium hydroxide, which acted as a basic catalyst to initiate phenolation. The subsequent condensation reaction was conducted at elevated temperatures. Once the target viscosity was achieved, the resin was cooled to room temperature and stored at 5 °C, in accordance with standard recommendations for this resin type. The final formaldehyde-to-phenol (F:P) molar ratio ranged between 2.0 and 2.2, while the solid content was between 40% and 48%. In the case of the experimental resins, the crude extract sample was introduced simultaneously with phenol, with all other formulation parameters remaining constant. All resins were supplied in liquid form.

2.5. Characterization of Resin Properties

Standard laboratory analysis methods were used to determine the properties of the resins produced. The solid content, pH value, viscosity, gelation time, alkalinity and free formaldehyde of all resins were analyzed. The solid content was determined by drying 2 g of resin at 120 °C for 2 h. A digital GLP21 pH-meter from CRISON was used to measure the pH value of the resins, with a single Hamilton glass electrode attached. Viscosity was measured using a Brookfield rotational viscometer at 25 °C, with a small sample adapter (SC4-45Y), which requires a sample chamber SC4-13R and a spindle SC4-18. Gelation time was determined by measuring the time required for gelation in boiling water. To determine alkalinity, the resin sample were titrated with HCl acid, to calculate the remaining NaOH in the resin. The free formaldehyde content of the resin was measured with dissolution of the resin sample in methanol and titration with HCl, followed by hydroxylamine hydrochloride addition and titration with NaOH.

2.6. Plywood Production

The produced resins were evaluated in plywood panels manufactured at CHIMAR pilot plant. The panel production process was conducted in accordance with typical industrial manufacturing practices. The mechanical strength and water resistance of the produced plywood panels were evaluated according to the prevailing European standards (EN 314-1:2004 [20] and EN 314-2:1993 [21]). Additionally, the formaldehyde emission potential was assessed by measuring the Formaldehyde release using the Gas Analysis Method (ISO 12460-3:2023) [22].

For the plywood manufacturing process, a glue mixture composed of resin, wheat flour, and water was prepared and applied to birch wood veneers (50 × 50 cm × 1.5 mm) using a spatula and roller. The glued veneers were then stacked and subjected to a pre-pressing step. Subsequently, they were hot-pressed in a hydraulic press under an elevated temperature of 130–150 °C, at a sufficient duration of 4–6 min to ensure complete resin curing. The obtained plywood panels were allowed to cool, and they were then trimmed and underwent evaluation of their properties. Each adhesive formulation was tested in duplicate panel sets.

3. Results

3.1. Composition of Crude Extracts from Spent Coffee Grounds

In this study, coffee oil was first separated from spent coffee grounds, and the remaining solids were subsequently subjected to extraction using aqueous ethanol solutions at 70% and 96% (v/v). The resulting extracts were employed as partial substitutes for petrochemical raw materials in the synthesis of phenol–formaldehyde resins. The SCGs crude extracts exhibited a dark-brown appearance and a viscous liquid consistency after solvent extraction. The protein and total phenolic contents of crude extracts obtained using 70% aqueous ethanol and 96% ethanol were determined and are presented in Table 1. The extract obtained with 96% ethanol exhibited a significantly higher protein content (14.4% ± 0.3%) compared to the 70% aqueous ethanol extract (5.5% ± 0.2%). In contrast, the total phenolic content, determined as caffeic acid equivalents (CAE), was slightly higher in the 96% ethanol extract (89.9 ± 0.2 mg CAE/g extract) than in the 70% aqueous ethanol extract (87.0 ± 0.9 mg CAE/g extract), although no significant differences were observed.

Table 1.

Protein and total phenolics content of crude extracts from different concentrations of ethanol solutions.

3.2. PF and Protein-Based Resins Synthesis and Evaluation

In this study, three crude extracts from spent coffee grounds obtained through ethanol extraction were evaluated: one extracted with 70% ethanol (Crude extract 1) and two with 96% ethanol (Crude extract 2 and Crude extract 3). These were employed by CHIMAR to synthesize PF resins, replacing either 20% (PP1-20%), or 40% (PP1-40%) of the phenol. When Crude extract 2 (96% ethanol extract) was used to substitute 20% of the phenol the resin’s viscosity rose sharply during polymerization, terminating the synthesis. Crude extract 3, again extracted with 96% ethanol to maximize protein yield, was also used to substitute 40% of phenol and, unlike the earlier 96% extract (Crude extract 2), it allowed completion of synthesis without excessive viscosity, yielding a final viscosity comparable to the reference. A standard PF resin (0% substitution) and a resin with 20% phenol substituted by commercial Soy Protein (PPC-20%) were prepared as references for the experimental protein-based resins. The physicochemical properties of the experimental and the reference resins are summarized in Table 2 below.

Table 2.

Physicochemical properties of the synthesized resins.

These data indicate that the experimental resins exhibit slower curing (longer gel times) compared to conventional phenol–formaldehyde resin, due to fewer activated phenolic rings, which slow resin condensation. Replacing phenol with protein eliminates reactive aromatic sites and introduces proteins that compete for formaldehyde through the formation of N-methylol adducts. The resulting molecules are larger due to the high molecular weight of proteins, are structurally bulkier, leaving some formaldehyde unreacted and leading to higher free-formaldehyde levels in the experimental resins. Regarding final viscosity, PP1-40% is significantly higher, as the high degree of phenol substitution introduces a greater load of macromolecular species (proteins and co-extracted phenolic compounds). The remaining properties of the reference and experimental resins do not exhibit any significant differences.

3.3. Plywood Production and Evaluation

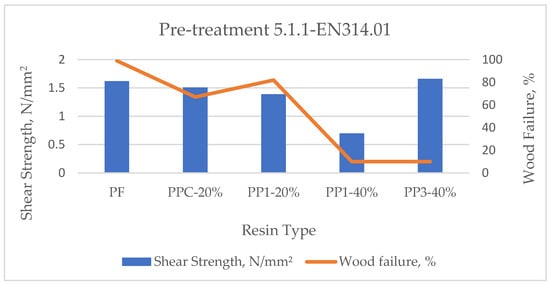

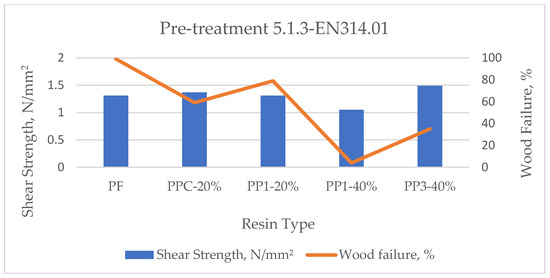

The results from the testing of the plywood panels, that had been produced using the standard PF resin and the PPC-20% resin with the commercial soy protein as reference, along with experimental resins in which 20% and 40% of phenol were replaced with the Crude extract 1 sample, and 40% of phenol in the final experimental resin was replaced with the Crude extract 3 sample, are presented below in Table 3 and Figure 1 and Figure 2.

Table 3.

Plywood panels properties using standard Phenol-Formaldehyde resin and bio-based resins with commercial protein and experimental Crude extract samples.

Figure 1.

Shear strength and wood failure of plywood panels bonded with reference and experimental resins after pre-treatment 5.1.1.

Figure 2.

Shear strength and wood failure of plywood panels bonded with reference and experimental resins after pre-treatment 5.1.3.

When comparing the experimental sample Crude extract 1 with commercial Soy Protein, the results indicate that the boards produced with the PP1-20% resin exhibit properties comparable to those of the boards with the PPC-20% resin under both pre-treatment conditions. Relative to the reference PF resin, the experimental resin PP1-20% demonstrated slightly lower strength after pre-treatment 5.1.1, while shear strength was equivalent for PP1-20% and the reference resin following pre-treatment 5.1.3. In both cases, wood failure was marginally lower for the resins with 20% phenol substitution.

When the phenol substitution with the Crude extract 1 sample was increased to 40%, the shear strength decreased significantly in both tests, while the wood failure was nearly zero. The panels produced with the experimental resin PP3-40% (Crude extract 3) exhibited higher shear strength in both tests compared to those made with the PF and the PPC-20% reference resins, although wood failure was significantly reduced. The sharp decrease in wood failure and bond quality at higher substitution levels (40%) can be attributed to a reduced cross-linking density resulting from fewer reactive phenolic sites. In addition, the higher protein and macromolecular content of the crude extract may slow condensation kinetics and limit the accessibility of reaction sites due to the bulk of the protein molecules. Similar effects have also been reported in soy- and lignin-modified PF systems at high substitution levels [10,17]. Nevertheless, the PP3-40% boards, with 40% phenol replaced by Crude extract 3, met the EN 314-2:1993 standard [21], as their shear strength exceeded 1 N/mm2.

4. Discussion

The performance of bio-based plywood adhesives should ultimately be assessed against established international standards, such as EN 314-2:1993, which specify shear strength thresholds for exterior-grade panels without wood-failure requirements once the minimum strength criterion of 1 N/mm2 is satisfied. Under EN 314-1 pre-treatments, PP1-20% performed comparably to PF (especially under cyclic conditioning), PP1-40% showed reduced strength due to limited reactivity, while PP3-40% achieved the highest shear strengths (>1 N/mm2), confirming compliance with EN 314-2:1993 despite lower wood failure.

Protein-modified phenolic resins with lower wood-failure values may still comply with standard requirements, as observed in soy-based PF systems [15,16]. Among various bio-based approaches—such as lignin substitution [2,4], tannin adhesives [7], and soy protein formulations [8,9,10]—spent coffee grounds represent a low-cost and abundant residue feedstock that enables panel production without compromising performance.

5. Conclusions

This study demonstrates that incorporating crude extract from spent coffee grounds into phenolic adhesive resin systems can help reduce the use of petrochemical phenol in composite wood panels made from them, without compromising the performance of the produced plywood type panels. Such bio-based adhesives produced from renewable sources, extracted from spent coffee grounds, lower the fossil material content and CO2 footprint, enhancing the environmental sustainability of wood-based panel production and promoting material circularity. It should also be noted that while moderate substitution levels (e.g., 20%) maintained comparable performance to conventional PF resins, higher levels (e.g., 40%) revealed clear limitations in bond quality and wood failure, highlighting the need for further optimization before large-scale application. Future work should focus on comprehensive physicochemical and thermal characterization of SCG crude extracts to better understand their behavior and interactions in phenolic resin systems, as well as on the thermal analysis of protein-based resins, since thermal stability and curing behavior are crucial determinants of resin performance. Such studies could provide valuable insights into optimizing substitution levels, curing conditions, and long-term performance of bio-based phenol–formaldehyde adhesives.

Author Contributions

Conceptualization, D.M., K.K., E.A., N.G., K.F. and E.S.; methodology, D.M. and K.K.; validation, D.M., K.K. and E.A.; formal analysis/investigation/data curation, D.M. and K.K.; resources, E.A.; writing—original draft preparation, D.M., K.K. and E.S.; writing—review and editing, D.M., K.K., E.A., E.S. and A.K.; project administration/funding acquisition, E.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research has been co-financed by the European Regional Development Fund (ERDF) of the European Union and Greek national funds through the Operational Program Competitiveness, Entrepreneurship and Innovation (EPAnEK 2014–2020), under the Action “RESEARCH–CREATE–INNOVATE” Β’ CALL (project code: T2EDK-00189, project title: Production of sustainable biofuels and value-added products from municipal organic solid wastes of catering services—Brew2Bio), as well as by private funds.

Data Availability Statement

The original contributions presented in this study are included in the article. Further inquiries can be directed to the corresponding author.

Conflicts of Interest

Authors Dimitrios Moutousidis, Konstantina Karidiand Eleftheria Athanassiadou were employed by the company CHIMAR HELLAS SA. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest. The funders ERDF and EPAnEK provided no guidance or input in this work and manuscript.

Abbreviations

The following abbreviations are used in this manuscript:

| EU | European Union |

| EN | European Norm |

| AUA | Agricultural University of Athens |

| SCG | Spent coffee grounds |

| CAE | Caffeic acid equivalents |

| FAN | Free alpha-amino nitrogen |

| DCW | Dry cell weight |

| FAMEs | Fatty Acid Methyl Esters |

| HPLC | High performance liquid chromatography |

| FID | Flame ionization detector |

| RI | Refractive Index |

| PF | Phenol formaldehyde resin |

| PP1-20% | Bio-based resin with 20% phenol substituted by Crude extract sample 1 |

| PPC-20% | Bio-based resin with 20% phenol substituted by commercial Soy Protein |

| PP1-40% | Bio-based resin with 40% phenol substituted by Crude extract sample 1 |

| PP3-40% | Bio-based resin with 40% phenol substituted by Crude extract sample 3 |

References

- Sarika, P.R.; Nancarrow, P.; Khansaheb, A.; Ibrahim, T. Bio-Based Alternatives to Phenol and Formaldehyde for the Production of Resins. Polymers 2020, 12, 2237. [Google Scholar] [CrossRef] [PubMed]

- Liu, Q.; Xu, Y.; Kong, F.; Ren, H.; Zhai, H. Synthesis of Phenolic Resins by Substituting Phenol with Modified Spruce Kraft Lignin. Wood Sci. Technol. 2022, 56, 1527–1549. [Google Scholar] [CrossRef]

- Sandomierski, M.; Buchwald, T.; Strzemiecka, B.; Voelkel, A. Carbon Black Modified with 4-Hydroxymethylbenzenediazonium Salt as Filler for Phenol-Formaldehyde Resins and Abrasive Tools. J. Appl. Polym. Sci. 2020, 137, 48160. [Google Scholar] [CrossRef]

- Gong, X.; Meng, Y.; Lu, J.; Tao, Y.; Cheng, Y.; Wang, H. A Review on Lignin-Based Phenolic Resin Adhesive. Macromol. Chem. Phys. 2022, 223, 2100434. [Google Scholar] [CrossRef]

- Chen, S.; Shi, S.Q.; Zhou, W.; Li, J. Developments in Bio-Based Soy Protein Adhesives: A Review. Macromol. Mater. Eng. 2022, 307, 2200009. [Google Scholar] [CrossRef]

- Qiao, Z.; Gu, J.; Lv, S.; Cao, J.; Tan, H.; Zhang, Y. Preparation and Properties of Normal Temperature Cured Starch-Based Wood Adhesive. BioResources 2016, 11, 4839–4849. [Google Scholar] [CrossRef]

- Faris, A.H.; Ibrahim, M.N.M.; Rahim, A.A. Preparation and Characterization of Green Adhesives Using Modified Tannin and Hyperbranched Poly(amine-ester). Int. J. Adhes. Adhes. 2016, 71, 39–47. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Xie, W.; Tang, Y.; Yang, F.; Gong, C.; Wang, C.; Li, X.; Li, C. Preparation and Characterization of Soybean Protein Adhesives Modified with an Environmentally Friendly Tannin-Based Resin. Polymers 2023, 15, 2289. [Google Scholar] [CrossRef] [PubMed]

- Frihart, C.R.; Birkeland, M.J. Soy Properties and Soy Wood Adhesives. ACS Symp. Ser. 2014, 1178, 167–180. [Google Scholar] [CrossRef]

- Hemmilä, V.; Adamopoulos, S.; Karlsson, O.; Kumar, A. Green Binders for Wood Adhesives: A Review. Rev. Adhes. Adhes. 2017, 5, 325–370. [Google Scholar] [CrossRef]

- Wu, Z.; Xi, X.; Lei, H.; Du, G. Soy-Based Adhesive Cross-Linked by Phenol–Formaldehyde–Glutaraldehyde. Polymers 2017, 9, 169. [Google Scholar] [CrossRef] [PubMed]

- Averina, E.; Konnerth, J.; van Herwijnen, H.W.G. Protein Adhesives: Investigation of Factors Affecting Wet Strength of Alkaline Treated Proteins Crosslinked with Glyoxal. Polymers 2022, 14, 4351. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.; Zhang, E.; Tu, Y.; Ye, M.; Chen, N. An Eco-Friendly Wood Adhesive Consisting of Soybean Protein and Cardanol-Based Epoxy for Wood Based Composites. Polymers 2022, 14, 2831. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Wang, S.; Zhang, X.; Wu, H.; Wang, Y.; Zhou, N.; Zhao, Z.; Wang, C.; Zhang, X.; Wang, X.; et al. Synthesis and Characterization of an Environmentally Friendly Phenol–Formaldehyde Resin Modified with Waste Plant Protein. Polymers 2023, 15, 2975. [Google Scholar] [CrossRef] [PubMed]

- Yang, I.; Kuo, M.; Myers, D.J. Bond Quality of Soy-Based Phenolic Adhesives in Southern Pine Plywood. J. Am. Oil Chem. Soc. 2006, 83, 231–237. [Google Scholar] [CrossRef]

- Lorenz, L.; Frihart, C.R.; Wescott, J.M. Chromatographic Analysis of the Reaction of Soy Flour with Formaldehyde and Phenol for Wood Adhesives. J. Am. Oil Chem. Soc. 2007, 84, 769–776. [Google Scholar] [CrossRef]

- Pilato, L. (Ed.) Phenolic Resins: A Century of Progress, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 140–143. [Google Scholar] [CrossRef]

- Giannakis, N.; Carmona-Cabello, M.; Makri, A.; Leiva-Candia, D.; Filippi, K.; Argeiti, C.; Pateraki, C.; Dorado, M.P.; Koutinas, A.; Stylianou, E. Spent Coffee Grounds and Orange Peel Residues Based Biorefinery for Microbial Oil and Biodiesel Conversion Estimation. Renew. Energy 2020, 145, 1230–1241. [Google Scholar] [CrossRef]

- Faustino, H.; Gil, N.; Baptista, C.; Duarte, A.P. Antioxidant Activity of Lignin Phenolic Compounds Extracted from Kraft and Sulphite Black Liquors. Molecules 2010, 15, 9308–9322. [Google Scholar] [CrossRef] [PubMed]

- EN 314-1:2004; Plywood—Bonding Quality—Part 1: Test Methods. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- EN 314-2:1993; Plywood—Bonding Quality—Part 2: Requirements. European Committee for Standardization (CEN): Brussels, Belgium, 1993.

- ISO 12460-3:2023; Wood-Based Panels—Determination of Formaldehyde Release—Part 3: Gas Analysis Method. International Organization for Standardization (ISO): Switzerland, Geneva, 2023.

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).