Abstract

The rapid evolution of Industry 4.0 technologies has resulted in a scenario in which collaborative networks are essential to overcome the challenges related to their implementation. However, the frameworks to guide such collaborations remain underexplored. This study addresses this gap by proposing Business Rules and Goals Models to operationalize Industry 4.0 solutions through enterprise collaboration. Using the For Enterprise Modeling (4EM) method, the research integrates qualitative insights from expert opinions, including interviews with 12 professionals (academics, industry professionals, and consultants) from Brazilian manufacturing sectors. The Goals Model identifies five main objectives—competitiveness, efficiency, flexibility, interoperability, and real-time collaboration—while the Business Rules Model outlines 18 actionable recommendations, such as investing in digital infrastructure, upskilling employees, and standardizing information technology systems. The results reveal that cultural resistance, limited resources, and knowledge gaps are critical barriers, while interoperability and stakeholder integration emerge as enablers of digital transformation. The study concludes that successfully adopting Industry 4.0 requires technological investments, organizational alignment, structured governance, and collaborative ecosystems. These models provide a practical roadmap for companies navigating the complexities of Industry 4.0, emphasizing adaptability and cross-functional synergy. The research contributes to the literature on collaborative networks by connecting theoretical frameworks with actionable enterprise-level strategies.

1. Introduction

The fusion of current manufacturing technologies with next-generation information technologies is driving a paradigm shift in manufacturing known as the fourth industrial revolution []. Industry 4.0 represents the beginning of the Fourth Industrial Revolution, reflects the prevailing trend of automation technologies in the manufacturing sector [], and enables digital transformation and value creation processes []. The essence of Industry 4.0 is the use of Information and Communication Technology (ICT) to connect business departments, factories, group companies, and external companies related to manufacturing and support, such as customers, raw material suppliers, logistics companies, and energy suppliers []. Industry 4.0 should be integration and assimilation of concepts such as Cyber–physical Systems (CPSs), Internet of Services (IoS), Internet of Things (IoT), intelligent manufacturing, Artificial Intelligence (AI), mobile computing, data mining, Additive Manufacturing (AM), cybersecurity, intelligent robots, Digital Twins (DTs), Cloud Computing (CC), Machine Learning (ML), Augmented Reality (AR), blockchain, industrial wireless networks, big data, sustainable manufacturing, autoconfiguration and self-optimization of production processes, product customization, among others [,,,,]. These technologies enhance operational efficiency, increase productivity, minimize downtime, and enable a potential profit surge []. By equipping production with actuators, autonomous systems, and sensors, Industry 4.0 will help make factories more intelligent, flexible, and dynamic []. Industry 4.0 can help companies adequately meet the increasing volatility of markets, the growing demands and complexity of products and services, and the reduction in innovation cycles [].

After the introduction of Industry 4.0, manual labor will be replaced by high-performance machines with programmable logic controllers or robotics with an accuracy of 99.9996% []. McKinsey predicts that by 2025, between 65 and 90% of factories in developed countries will adopt the Industrial Internet of Things (IIoT), while in factories located in developing countries, this percentage will be between 50 and 70% []. This adoption could add USD 11.1 trillion to the global economy [].

Researchers should explore management aspects and best practices to support companies implementing Industry 4.0 projects []. In addition, several aspects must be discussed to implement Industry 4.0-related solutions and technologies [] successfully. Collaboration between suppliers and consumers of Industry 4.0 technologies is one of the most important requirements for the consolidation of the paradigm, as it promotes the configuration of shared resources, social interaction, commercial collaboration, and general production management in order to carry out product lifecycle tasks efficiently and flexibly []. Collaboration with other companies such as customers, suppliers, information systems developers and suppliers, and systems consultants to adapt to Industry 4.0 is also effective for companies to acquire appropriate knowledge and understanding [].

There are four key success factors in Industry 4.0: collaboration, innovation, integration, and interoperability []. Collaboration is at the heart of many Industry 4.0 challenges [], which should be emphasized most when implementing solutions related to Industry 4.0 [,]. It is essential to understand the mechanisms by which organizations establish collaborative structures to access external knowledge, information, and technologies, thereby integrating digital practices that enhance their competitive advantage []. Industry 4.0 can be seen from the perspective of collaborative networks, as it connects manufacturing systems, products, and value chains, among other parties, and it is necessary to understand the interactions between companies to achieve the effectiveness, agility, and resilience of future industrial systems []. A collaboration network must be modeled and analyzed to reveal meaningful engineered information for optimal production decisions in an innovative shop floor [].

In a complex system such as a collaborative network, enterprise modeling is essential to understand, manage, simulate, or predict network behavior [] and provide adapted and structured solutions for companies []. Industry 4.0 needs advanced modeling methods [], and techniques of enterprise modeling and associated visual languages are essential and helpful in supporting the development of intelligent enterprises [], helping to understand their operations, analyze their running, and design new systems from several points of view []. Often, the developed model is considered an object used for negotiating interfaces between business partners, especially in the case of networked and collaborative enterprises []. This observation highlights the need for a deeper understanding of how modeling methods, such as For Enterprise Modeling (4EM), facilitate alignment among organizations with diverse goals, constraints, and responsibilities. While the literature acknowledges the relevance of collaboration and modeling in Industry 4.0 contexts, it often lacks concrete examples of how enterprise models can be used to structure and optimize real-world collaborative arrangements, particularly in distributed manufacturing settings. Therefore, it becomes essential to explore enterprise modeling not only as a descriptive tool but as a strategic mechanism for promoting shared understanding, aligning objectives, and supporting decision-making in inter-organizational environments. This is particularly relevant for networked and collaborative enterprises, where the developed model helps mediate understanding and expectations across organizational boundaries. However, despite the recognized importance of collaboration and modeling in Industry 4.0, few studies have focused on how enterprise modeling techniques can be used to design, support, and optimize collaboration in distributed manufacturing settings.

There is a gap in the literature regarding structured approaches to modeling inter-organizational collaboration, specifically those oriented toward distributed manufacturing under Industry 4.0 principles. Moreover, existing works often focus on technological implementation, with limited emphasis on aligning goals, rules, and constraints among collaborative partners. To address this gap, this article proposes an enterprise modeling approach to represent the collaborative process among companies participating in collaborative networks for distributed manufacturing. The 4EM method was adopted to support this representation, with a particular emphasis on the Goals Model and Business Rules Model. This multi-view modeling approach aims to make explicit the goals to be pursued collaboratively, the constraints to be considered, and the opportunities enabled by successful operationalization within Industry 4.0 environments.

2. Theoretical Background

This section presents a theoretical framework for the topics of Industry 4.0 and collaborative networks and discusses the intersection between these two areas.

2.1. Industry 4.0

The concept of digital transformation predates the formalization of Industry 4.0. It corresponds to the continuous integration of digital technologies in organizations to improve processes, business models, and customer experiences []. Digital transformation has its origins in the 1970s and 1980s with the development of Manufacturing Resources Planning (MRP) and Enterprise Resources Planning (ERP) systems, which enabled the automation and integration of various functions and the basis for organizational digitalization []. In the 1990s, the internet and e-commerce expanded digital transformation, influencing operational efficiency, the creation of new business models, and customer interaction channels [].

As two concurrently emerging topics, enterprise architecture and digital transformation affect each other, as a successful implementation of enterprise architecture creates a strong input for digital transformation []. The main enterprise architecture frameworks developed are the Zachman Framework (ZFEA), Department of Defense Architecture Framework (DoDAF), Federal Enterprise Architecture Framework (FEAF), The Open Group Architectural Framework (TOGAF), and NIST Enterprise Architecture Model [,]. In parallel to their development, digital business ecosystems emerged, highlighting the importance of collaborative and interconnected networks for business competitiveness []. The emerging digital economy was also one of the bases for digital transformation, addressing topics such as disintermediation, value networks, and the transformation of organizational structures [].

Digital transformation provided the fundamental technological and organizational principles that paved the way for more specialized concepts, such as Industry 4.0 []. Based on the fundamental principles and technological advances established by digital transformation, the Industry 4.0 concept represents a more specialized and structured approach to integrating emerging technologies in industrial manufacturing contexts. Industry 4.0 is one of the approaches to intelligent manufacturing characterized by adaptability, efficient use of resources, ergonomics, and integration of customers and suppliers [,]. The term Industry 4.0 was first introduced in 2011 when a set of recommendations was submitted to the German government by the Working Group on Industry 4.0 []. Officially, this initiative was presented in Germany in 2012 during the Hannover Fair []. As a trend in German and worldwide industry, Industry 4.0 will significantly shorten the new product development lifecycle and provide a solution to the increasing market demand requirements [].

According to Prause [], Industry 4.0 aims to create horizontal integration through value networks that include secure, cooperative, and open business models. Such business models must integrate all stakeholders of international supply chains (customers, employees, shareholders, creditors, top management, and public authorities) and consider the needs of small and medium-sized enterprises [].

Consolidation of Industry 4.0 aims to ensure the localization of high-tech manufacturing, work, and well-being for people in a specific region to generate a competitive advantage. This organizational strategy covers companies’ design, manufacturing, operation, and service dimensions and includes the operational, strategic, and environmental levels [].

Shamim et al. [] state that challenges for Industry 4.0 include mass customization, flexibility in production processes, lean production, efficiency and effectiveness in Supply Chain Management (SCM), product management, customer response time, instantaneous receipt of information about customers’ needs and desires, intelligent work environment, and appropriate combination of products and services.

Industry 4.0 leads to many beneficial results that can efficiently and cost-effectively address global challenges related to customized production. Benefits of Industry 4.0 include compatibility, decentralization, real-time responsiveness and monitoring, modularity, service orientation, efficiency, traceability, security, sustainability, flexibility, productivity, energy and resources efficiency, transparency, integration promotion, profitability, and a user-friendly interface [,]. The global Industry 4.0 market is expected to increase from USD 101.69 billion in 2020 to USD 377.30 billion in 2029 [,].

To support the collaborative and distributed manufacturing environments envisioned by Industry 4.0, a set of enabling technologies and solutions is required. These technologies and solutions provide the foundation for connectivity, automation, data analysis, and integration across organizational boundaries. The selection of technologies and solutions presented in the following subsection is grounded in the literature and reflects those most relevant to developing collaboration processes in smart manufacturing contexts.

2.1.1. Main Technologies and Solutions of Industry 4.0

Within the scope of Industry 4.0, Frank et al. [] divide the related technologies into six main objectives: vertical integration, virtualization, automation, traceability, flexibility, and energy management. In vertical integration, there are sensors, actuators, and Programmable Logic Controllers (PLCs); Supervisory Control and Data Acquisition (SCADA); Manufacturing Execution Systems (MESs); ERP; and Machine-To-Machine (M2M). Virtualization includes virtual commissioning, process simulation, and AI for predictive maintenance and production planning. In automation, there are M2M communication, robots (e.g., industrial robots, autonomous guided vehicles, or similar), and automatic identification of non-conformities in production. In traceability, the identification and traceability of raw materials and products can be mentioned. In terms of flexibility, 3D printing and flexible and autonomous lines are used. Finally, in energy management, there is a monitoring system and an energy efficiency improvement system.

The identification in the literature points to the main Industry 4.0 technologies and solutions being CPSs, big data, the IoT, ML, AM, collaborative robots, AR, blockchain, CC, cybersecurity, and DTs. A brief description of each of these concepts is presented in the following paragraphs.

CPSs are considered the core technology of Industry 4.0 [], as it integrates the physical and digital worlds, constituting an intelligent mechanical environment resulting from the fusion of physical dimensions, computation, and networking []. CPSs represent an innovative era of manufacturing systems, enabling the convergence of various organizational layers—from production to logistics—across supply chains and distribution networks []. Implementing CPSs in production systems provides a coherent and real-time representation of products, production assets, and system operations while considering changing processes []. CPSs profoundly impact the entire manufacturing value chain, impacting both upstream and downstream activities, including interactions with suppliers and end customers []. Through real-time data sharing, CPSs enhance supply chains visibility, responsiveness, and transparency, empowering firms to adapt swiftly to demand fluctuations, streamline logistics operations, and optimize inventory levels []. Moreover, the global market for CPSs is projected to reach approximately USD 137.566 billion by 2028 [].

Due to their magnitude, variety, and velocity, big data processes and analyzes massive volumes of data, which exceed the limitations of usual data management and processing systems []. Big data plays an essential role in enhancing competitiveness by enabling the identification and analysis of critical manufacturing challenges, such as process deviations, quality inconsistencies, and inefficiencies in energy consumption []. Fundamentally, big data encompasses collecting, storing, analyzing, and visualizing data originating from diverse sources such as business transactions, sensors, social media, and mobile devices []. Adopting big data technologies allows organizations to go beyond merely collecting and storing extensive datasets, enabling them to extract valuable insights to support data-driven decision-making []. Insights derived from big data can enhance product quality, greater process efficiency, and improved service offered []. Projections indicate that the value of big data applications in the manufacturing sector is expected to surpass USD 4.5 billion by 2025 [] and the global big data market is expected to experience a revenue increase, reaching approximately USD 655.53 billion by 2029 [].

Within the context of Industry 4.0, AM has transformed both product development and production processes across various sectors []. AM refers to a production technique in which components are fabricated by sequentially adding material layer-by-layer, based on a three-dimensional (3D) computer model []. Unlike traditional subtractive manufacturing techniques, AM stands out for its capacity to reduce material waste while producing intricately shaped and multi-material components, being widely applied in rapid prototyping, as it enables low-volume and customized production by facilitating agile responses to changes in customer requirements []. It has been projected that global AM-associated revenues will reach approximately USD 23 billion by 2027 [].

Collaborative robotics is becoming one of the enabling technologies of modern manufacturing industries []. Due to their low cost and high operational flexibility, collaborative robots have become common in tasks that require direct interaction []. Industry 4.0 envisions a factory of the future empowered by intelligent information systems, increased automation, and adaptable and collaborative robots, also known as cobots []. Cobots represent a new generation of robotic systems designed for industrial use, being distinguished by their ability to operate without physical barriers and work safely alongside humans []. The global market for cobots is anticipated to reach USD 10.14 billion by 2025 [].

Among the core enabling technologies of Industry 4.0, AR stands out as an auspicious tool for enhancing the flow of information from the digital environment to the physical workspace of smart operators in a seamless and non-intrusive []. AR constitutes an innovative component of Industry 4.0 strategies, enabling more effective interaction between human operators and advanced technological systems []. AR integrates the digital world with the real world, offering users an immersive and real-time experience []. Integrating manual and automated processes presents a promising approach to addressing the challenges of Industry 4.0. AR-based virtual assistants deliver immersive experiences that improve operators’ understanding of complex activities through AR simulations, which create safe and risk-free environments []. The global market for AR and Virtual Reality (VR) is projected to reach from USD 97.9 billion [] to USD 814.7 billion by 2025 [].

Blockchain-based solutions have been receiving increasing attention within the scope of Industry 4.0 []. Blockchain enhances various aspects of industrial systems, including data security, anonymity, privacy, traceability, integrity, accountability, robustness, reliability, transparency, and authentication, contributing to long-term sustainability and improved operational efficiency across the company []. Within supply chains, blockchain can be employed to register production changes in a single shared ledger, providing complete data visibility, and allowing stakeholders to track a product’s status and place in real time, as all transactions are securely time-stamped and accessible []. Blockchain is frequently identified as a potential enabler for efficient contracting in production environments involving multiple and diverse partners, and it supports the decentralized management of demand response []. According to a 2017 forecast by Gartner, the total business value generated by blockchain technologies is expected to surpass USD 176 billion by 2025 and exceed USD 3.1 trillion by 2030 [,].

CC represents a fundamental component of the smart factory of Industry 4.0 []. CC is a paradigm that enables on-demand access to computing resources—such as processing power, networking, and storage—on a real-time basis, with minimal interaction with the service provider []. CC is a set of technologies that enable organizations’ IT infrastructure resources as a service via the Internet, offering organizations advantages such as cost reduction, scalability, flexibility, faster service speed, and easy accessibility []. Cloud-based manufacturing equipment, through machine-to-machine (M2M) communication and human–machine interfaces, is capable of recognizing, analyzing, and interpreting the intentions of objects, users, and systems and within its operational environment, which enables a level of self-awareness in which the equipment can understand its status, context, and available courses of action []. The global CC market is projected to reach approximately USD 1143 billion by 2028 [].

Cybersecurity is one of the primary challenges faced by companies adopting the Industry 4.0 paradigm [,]. Cybersecurity encompasses the set of measures adopted by individuals and organizations to mitigate cyber threats, safeguard hardware and digital services against theft or damage, and prevent unauthorized access to sensitive data []. In the context of Industry 4.0, cybersecurity plays a vital role in avoiding the loss of organizational competitiveness []. A core objective of cybersecurity investment is to securing assets from compromise across key dimensions, including confidentiality, integrity, control, availability, authenticity, and utility [,]. The global cybersecurity market was worth USD 162.5 billion in 2021 [] and its size is expected to reach between USD 281.7 billion and USD 400 billion by 2027 [,].

Growing attention is being given to the integration and alignment between physical manufacturing systems and their cyber counterparts []. In general, a DT is a one-to-one virtual replica of a “technical asset” such as a machine, component, sensor, actuator, production unit, plant, and part of the environment [,,,], and it consists of 3D models grouped into assemblies with the possibility of remote monitoring and data synchronization with a real system and offline simulation []. The DT paves the way for cyber–physical integration [], being one of the major pillars for smart manufacturing, as it allows us to analyze the past and predict the future [,]. Through the cyber–physical closed loop, a DT can optimize the whole manufacturing process []. Key technologies, such as the IoT, CC, AI, and data analytics, are fundamental for the development of DTs []. A DT comprises three fundamental components: the physical structures operating in the physical world, the virtual models in the digital world, and the connected data that interconnect and synchronize the two worlds []. As a DT comprises three components, its data sources differ from big data []. The data of big data originates from physical structures, information systems, and the Internet-based sources, which are all generated by operations in the physical world, while the data in a DT is derived not only from the physical world but also from the virtual models []. The global DT market was valued at approximately USD 3.1 billion in 2020 and is projected to grow significantly, reaching around USD 29.1 billion by 2025, USD 48.2 billion by 2026, and USD 195.4 billion by 2030 [,,,].

The IoT allows physical devices to communicate, exchange data, and collaborate in decision-making, effectively enhancing their ability to perceive, process, and act []. The IoT has many advanced features, such as intelligent processing, reliable transmission, and complete perception [], and it is through it that M2M communication is carried out []. The International Data Corporation (IDC) has forecast that there will be an estimated 41.6 billion connected IoT devices, generating 79.4 zettabytes (ZBs) in 2025 [,]. The global forecast for the IIoT in terms of market size is projected from USD 110.6 billion to USD 950 billion by the year 2025 [,]. It is estimated that by 2029, more than 15 billion IoT devices will be attached to the enterprise infrastructure or in terms of mobility [,].

ML refers to a branch of AI that enables computers to learn patterns to make decisions or predictions from data without being explicitly programmed []. ML is a field of AI focused on developing algorithms that learn directly from their input data []. ML algorithms are mainly divided into four categories: supervised learning, unsupervised learning, semi-supervised learning, and reinforcement learning []. ML is essential to Industry 4.0 success because it improves cyber resilience by quickly detecting anomalies and modifying defenses []. The application of ML in manufacturing aims to optimize production at multiple levels, including the process, product, machine, and system levels []. The global market size of ML is expected to reach USD 152.24 billion in 2028 and USD 225.91 billion dollars by 2030 [,].

2.1.2. Design Principles of Industry 4.0

According to Lee et al. [] and Lu [], six design principles are identified in Industry 4.0: interoperability, virtualization, decentralization, real-time capability, service orientation, and modularity. These design principles support companies in the identification of potential Industry 4.0 pilots, which can then be implemented [].

Interoperability can be viewed as the ability of the cyber–physical–human system, such as smart products, smart factories, human resources, and others, to connect and communicate with each other and operate together []. In Industry 4.0, interoperability synthesizes software components, application solutions, business processes, and the commercial context of every diversified, heterogeneous, and autonomous procedure []. The interoperability of Industry 4.0 requires specific principles to ensure the complete accuracy and efficiency of the process. Accessibility, availability in multiple languages, security, privacy, subsidiarity, use of open standards, free software, and multilateral solutions are appropriate for Industry 4.0 to be interoperable [].

In Industry 4.0, virtualization implies a CPS is able to monitor physical processes and sensor data is linked to virtual plant models and simulation models []. Through virtualization, a virtual copy of the physical world is created for an employee to be notified in cases of failure and for information related to the next steps of work or security measures implemented to be provided [].

Within Industry 4.0, decentralization is a common characteristic and can be implemented through decentralized production control []. The growing demand for individual products hampers the centralized control of systems []. In order to make decisions, all elements must have access to relevant information, which implies that the elements in a decentralized production control must communicate with each other naturally, as in a social network [,].

Real-time capability is of great importance in intelligent manufacturing, as it is highly desirable that operators and managers can access line performance in real-time and be notified of any potential problems []. In Industry 4.0 with large data capacity, better production control performance is desirable due to the amount of real-time information that must be adopted to increase the quality of decision-making [].

Service orientation makes business services, CPSs, and employees available through the IoS and can be used by other participants, offering them internally and beyond the company’s boundaries []. In addition to technical changes, service orientation enables the acquisition of new business models based on pay-per-use or signatures and flexible and upgradeable processes for introducing customized services [].

According to Belkadi et al. [], modularity represents the decomposition of a system into independent parts (modules) that can be treated as logical units. Modular systems can adapt flexibly to changing requirements by replacing or expanding individual modules and can be easily adjusted in case of seasonal fluctuations or changes in product characteristics []. Like scalability, convertibility, integrability, and diagnostic, modularity is one of the essential components for Cyber–physical Production Systems (CPPSs) to be adaptive and responsive to changing product requirements [,].

2.1.3. Critical Success Factors for Industry 4.0 Consolidation

Critical success factors refer to the key organizational actions required to ensure success and maintain competitiveness, thereby supporting change processes within a company []. Identifying these factors is essential for prioritizing strategic resources, particularly in contexts with limited resources such as those involved in the development of smart manufacturing [].

Critical success factors are important to overcome challenges related to Industry 4.0 consolidation []. These factors are fundamental elements identified in the literature as essential for the effective adoption of digital transformation initiatives in various domains of Industry 4.0 [].

Analyzing the literature, it was observed that critical success factors for Industry 4.0 consolidation can be divided into technological, organizational, environment, and strategic dimensions. Table 1 presents the main critical success factors for Industry 4.0 consolidation, dividing it into four dimensions. Regarding the technological dimension, success factors can guide decisions on which Industry 4.0 technologies should be prioritized for investment []. Regarding the organizational dimension, companies should develop effective change management strategies to overcome resistance and ensure successful adoption, as well as invest in training and development programs to equip employees with the necessary skills []. The environmental dimension reflects the surrounding factors []. The strategic dimension is essential for the successful implementation of Industry 4.0, and in relation to strategies, companies should prioritize the identified factors in their strategic planning processes, allocate resources accordingly, and develop strategies to mitigate the risks associated [].

Table 1.

Critical success factors for Industry 4.0 consolidation.

2.2. Collaborative Networks

A collaborative network comprises diverse business structures (e.g., organizations and individuals) that are greatly independent, geographically distributed, and dissimilar in terms of their operating environment, social capital, culture, and goals but that collaborate to reach common or compatible goals more effectively, thus collectively generating value and whose interactivities are aided by computer networks []. Collaborative networks are formed by participants who work together in an atmosphere of mutual trust and knowledge exchange, aiming to reach a common goal [], and are based on the reciprocal commitment of participants to solving everyday problems. This collaboration requires mutual trust (requiring effort, time, and dedication) and the transparent sharing of resources, information, and responsibilities to collectively plan and execute coordinated activities to achieve common goals []. Within a collaborative network, partners collectively pursue business opportunities in a specific domain that would be unattainable or economically unfeasible if undertaken individually [].

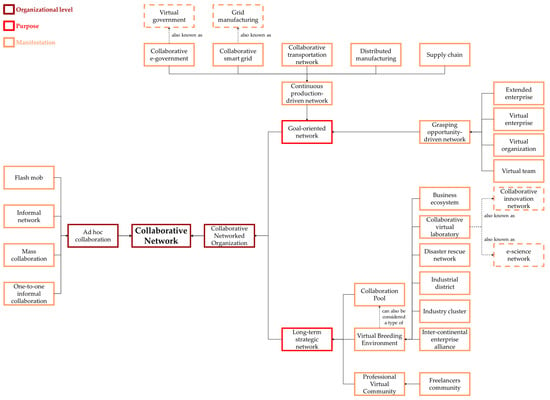

Figure 1 shows a partial taxonomy of collaborative networks, based on the conceptual frameworks proposed in the literature [,,,,,,,,,,,,,,,,,,,]. In Figure 1, we distinguish collaborative networks by organizational level, purpose, and manifestation [], and we have adapted and expanded this framework to include additional forms of ad hoc collaboration, as discussed in the recent literature. However, the evolution of ICTs, coupled with deeper insights into collaboration mechanisms and supporting frameworks, has led to the advent of various new forms of collaborative networks [,].

Figure 1.

Partial taxonomy of collaborative networks based on organizational level, purpose, and manifestation [,,,,,,,,,,,,,,,,,,,].

A Collaborative Networked Organization (CNO) refers to a business-oriented network characterized by well-defined organizational elements, including a structured composition, clearly assigned roles, and established governance rules []. A CNO evolves through distinct stages over its lifecycle, with each phase defined by specific partial goals to be achieved and the corresponding processes to be executed [].

Ad hoc collaboration refers to a spontaneous and unstructured network typically arising in a crisis []. Various ad hoc collaboration processes can emerge within virtual communities that are not necessarily business-oriented—e.g., in a natural catastrophe, individuals or organizations may voluntarily come together, contributing efforts to support a shared goal and improve the overall situation. However, such collaborations typically lack formal planning or organizational structures to coordinate their activities [,].

Goal-oriented networks are characterized by intense interaction among their participants, with the aim of reaching a common goal []. These networks can be driven either by continuous production/service provision activities or by the aim of grasping a single (collaboration) opportunity [].

Continuous production-driven networks remain stable for an extended period with well-defined roles for their participants []. Supply chains represent a solid long-term network of enterprises, each having assigned specific functions within the production value chain, encompassing all stages—including initial product design, raw materials procurement, manufacturing, shipping, distribution, warehousing, and delivery of final products to customers []. A smart grid can be specified as overlaying a gathered communications and control system onto the existing power delivery infrastructure ensuring provision of correct information to the appropriate entity []. Thanks to intelligent technologies and information and communication technology, collaborative smart grids empower their clients with reliable, sustainable, economical, safe, and efficient energy []. Collaborative e-government refers to the association of governmental organizations—such as city halls, tax offices, cadaster offices, and civil infrastructures departments—that integrate their services through interconnected computer networks, offering unified services to citizens through a common front end []. Collaborative transportation networks involve a diverse range of actors, including banks, gas stations, logistics operators, parking management entities, and road management entities to provide integrated transportation services []. In distributed manufacturing, production control is carried out locally and concurrently across shop-floor systems, enabling these systems to respond more rapidly, operate in an event-driven manner, and continuously revise production plans and schedules []. Distributed manufacturing represents systems in which various plants, suppliers, and transportation networks collaborate to optimize overall operations [].

Grasping opportunity-driven networks are dynamically formed collaborative structures established to seize specific business opportunities that arise within a specified time frame []. Extended Enterprises (EEs), Virtual Enterprises (VEs), Virtual Organizations (VOs), and Virtual Teams (VTs) are examples of such networks, and consist of groups of autonomous organizations or individuals who share resources and skills in a coordinated manner to respond effectively to emerging business opportunities []. A VE refers to a transitory alliance of enterprises that collaborate by sharing core competencies, resources, and skills to more effectively act in response to business opportunities, with their cooperation supported through computer networks []. A VO is a concept akin to that of a VE, consisting of a group of legally independent organizations that collaborate by sharing resources and skills to reach a common mission or goal but are not restricted to alliances among for-profit enterprises []. An EE refers to a concept generally applied to an organization in which a leading or most prominent enterprise ‘‘extends” its operational boundaries to encompass all or part of its supplier network []. A VT is a transitory group of professionals who collaborate to achieve a communal goal—such as executing a consultancy job or carrying out a collective project—using computer networks as their interaction environment [].

Long-term strategic networks are crucial alliances established to serve as basis or breeding environments for goal-oriented networks, and their purpose is to create favorable circumstances and provide aid for the dynamic formation of goal-oriented networks whenever a business possibility emerges []. These networks consist of Collaboration Pools (CPools), Professional Virtual Communities (PVCs), and Virtual Breeding Environments or Virtual Organization Breeding Environments (VBEs).

PVCs are networks formed by individual professionals who collaborate on a long-term basis, enabling them to quickly respond to business opportunities by dynamically creating temporary VTs [].

VBE refers to an alliance of organizations and supporting institutions dedicated to a long-term cooperation accord, adhering to common operational principles and infrastructures, with the primary goal of enhancing their readiness to quickly form temporary alliances for collaboration in potential VOs [,]. Industry clusters are geographically concentrated groups of interrelated industries, connected through the flow of goods and services. These conduct regional wealth creation, mainly by exporting goods and services []. An industrial district represents a concept quite similar to an industry cluster. It can be focused on one sector or cover several sectors in a given region, encompassing other institutions besides enterprises, such as local development agencies and academic and research institutions []. Business ecosystems are organizations that have resources and act together cooperatively or competitively to form a unique independent system, and platform-based ecosystems, such as Apple or Google, start-up ecosystems, such as Canvas, and mobility ecosystems, such as Uber, are examples of these networks []. An inter-continental enterprise alliance represents a special case of VBE, encompassing sub-networks of enterprises across different continents []. Disaster rescue networks represent a strategic alliance of governmental/nongovernmental organizations specialized in rescue operations in case of disasters []. Collaborative virtual laboratories aim to provide remote access for students at all levels of laboratories. A project by the Ministry of Education of India is a good example. In it, students of various disciplines of science and engineering access laboratories to perform the experiments remotely [].

A PVC is a breeding environment focused on human professionals, not organizations, and aims to facilitate the creation of dynamic VTs when a collaboration opportunity arises. It can also be seen as a social network with a business purpose []. The European Society of Concurrent Enterprising Network is an example of a PVC, and represents a nonprofit organization that unites researchers, academics, and industry professionals to exchange ideas, insights, practices, views, and the State-of-the-Art research and developments in the area of concurrent enterprising [].

CPool, introduced in the SYNERGY project [], refers to both formal and informal groupings of potential collaborators and their supporting institutions []. These entities operate under a foundational long-term cooperation agreement, share common operating principles and infrastructure, and aim to enhance their preparedness for the rapid formation of temporary alliances for collaborating in potential VOs []. A CPool is similar to a VBE but encompasses a broader range of groups of potentially collaborating organizations. A VBE can be considered a specific and formally structured type of CPool [].

2.3. Collaborative Networks in the Context of Industry 4.0

Collaborative networks can be considered a significant enabler for digital transformation [,,,,,]. They can play an important role in the digital transformation processes due to the growing interconnectivity between organizations, people, and physical systems, supported by recent developments in information and communication technologies []. Digital transformation requires a networking perspective, encouraging partnerships with suppliers, customers, and other stakeholders [].

Managers can use collaborative networks to build long-term relationships and strategic alliances, enhancing supply chain resilience []. Internally, within industries, collaboration occurs among many departments, including manufacturing, market research, product design, production planning, and service design []. External collaboration implies engaging with suppliers and customers in co-design and co-innovation activities, as well as leveraging social networks to gain better insights into market trends []. By using collaborative networks through horizontal integration in the Industry 4.0 context, companies can achieve higher levels of market responsiveness [], increase resilience, and implement a circular economy []. At the horizontal integration level, the goal is to establish closer relationships among all stakeholders in the value chain, which involves networking suppliers, manufacturers, distributors, service providers, product recycling entities, and even customers []. At this level, the leading Industry 4.0 technologies for collaboration are CC, IoT, mobile computing, and cybersecurity [].

When Industry 4.0 key technologies (CPSs, CC, the IoT, and big data) collaborate, they create an intelligent production collaborative network that enhances companies’ efficiency, productivity, and competitiveness []. IoT and cloud technologies are key drivers of value chain performance in the Industry 4.0. They enable the connection of stakeholders and significantly enhance the value chain by provisioning horizontal integration within the supply chain []. With the aid of embedded systems, this collaborative network can reach high levels of traceability for value chain components and processes. This collaborative network is driven by cloud and CPS technologies, with support from big data, the Industrial Internet, VR, and AR. When CC and CPSs are interconnected, they serve as key drivers for market awareness. CPSs enable rapid reactions from the production line through machine interoperability, while a cloud-based environment offers potential service innovation opportunities for customers. The Industrial Internet can help create flexibility and fast changes in manufacturing, while big data can provide valuable information when firms face turbulent market environments. Technologies such as VR and AR can improve production simulation and material handling, helping firms’ internal processes during turbulent markets [].

To enable information gathering in distributed manufacturing through sensor-based environments and dynamic sharing of heterogeneous resources via cloud-based systems, a range of Industrial Internet platforms has been proposed to support collaboration among ubiquitous enterprises in the move toward smart manufacturing []. Progress in the Industrial Internet and collaborative e-work has enabled cyber–physical collaboration among geographically scattered organizations, evolving from simple file exchanges to direct access to computers, databases, machines, and software [].

This section has explored the foundational concepts of Industry 4.0, detailing its core technologies and solutions and highlighting the critical role of collaborative networks in enabling distributed manufacturing. Section 2.1 introduces Industry 4.0, its main technologies and solutions (Section 2.1.1), design principles (Section 2.1.2), and critical success factors (Section 2.1.3) necessary for its consolidation. Section 2.2 then addresses the broader concept of collaborative networks, while Section 2.3 focuses on the particularities of collaborative networks within the Industry 4.0 context.

The literature underscores the complexity and interconnectedness of technological, organizational, and collaborative dimensions necessary for successful Industry 4.0 implementation. However, a notable gap remains in modeling the dynamic interactions and governance mechanisms within collaborative networks, especially under the distributed manufacturing paradigm. Addressing this gap requires a structured, multi-view enterprise modeling approach that captures goals, business rules, and constraints to design and manage Industry 4.0 collaborations effectively. The following section presents the methodological framework employed in this study to develop such models and provide actionable insights for capturing and representing the complex goals, rules, and interactions among networked enterprises in Industry 4.0 environments.

3. Materials and Methods

This research was developed through expert judgment and the 4EM enterprise modeling method. It is a qualitative approach to research, providing greater proximity between researchers and the problems studied. It is also exploratory, providing correlations between the objects of study to collaborate with future research.

Liao et al. [] state that within the scope of Industry 4.0, one solution to acquire knowledge from the perspective of collaboration is through the study of questions related to “who” is working in Industry 4.0, “when”, and “where”. Thus, using the qualitative approach and business modeling is justified to represent aspects of the collaboration process between companies for operationalizing solutions and technologies related to Industry 4.0, as both are suitable for answering questions of this nature [].

3.1. Enterprise Modeling

Enterprise modeling is the process of creating models—visionary representations—that can be used by individuals or machines to aid analysis, control, reasoning, (re)design, understanding, and even learning about numerous aspects of an enterprise []. Enterprise modeling can be defined as the practice of externalizing knowledge through models that represent the structure, functionality, behavior, organization, management, operations, and maintenance of an enterprise or its network, along with the relationships it maintains with its environment []. In a simplified way, an enterprise model represents the critical components of a business, such as organizational areas, processes, and human resources, depicting current state of the enterprise and its parts in a structured format to facilitate understanding and analysis of the organization [].

Enterprise modeling is a method used to represent and understand a business’s behavior and structure, analyze business processes, and, in many cases, facilitate business process reengineering []. Initially focused on production management and later addressing all company functions, research in enterprise modeling has been developed since 1980, within the scope of the need to integrate business functions []. Enterprise modeling helps understand the systemic implications/risks in making timely decisions, optimizing enterprises for expected outcomes, creating alignment between strategies, operation, and information systems implementation, and providing a foundation for continuous improvement [].

Enterprise models have continuously been used to capitalize knowledge explicitly and structure it [,]. Research in enterprise modeling has resulted in the development of various modeling techniques that offer visual representations to enhance understanding and communication about business architecture []. The method’s success in different fields depends on its explanatory and representative capabilities []. When choosing a modeling technique, process experts should always consider who will read and use such models [].

The main methods for enterprise modeling are: ArchiMate, Architecture of Integrated Information Systems (ARIS), Business Process Modeling Notation (BPMN), Computer Integrated Manufacturing Open System Architecture (CIMOSA), Generalized Enterprise Reference Architecture and Methodology (GERAM), Graphs with Results and Actions Inter-related (GRAI), Integration DEFinition (IDEF), Organizational Requirements Definition of Information Technology Systems (ORDIT), Purdue Enterprise Reference Architecture (PERA), Structured Analysis and Design Technique (SADT), Unified Modelling Language (UML), and 4EM.

Table 2 compares the main enterprise modeling methods, aiming to determine whether or not each method meets the analyzed requirements, which are considered important for enterprise modeling.

Table 2.

Comparison between the main enterprise modeling methods [,,,,,,].

We used the 4EM method since it fully meets various requisites that other methods do not ponder, and considers the aspects emphasized by Berio and Vernadat [] for enterprise modeling. In previous research, such a method has been employed and demonstrated efficient in guiding an implementation process of ERP systems from the perspective of innovation networks []. It identified in the Six Sigma program changes necessary to enable the implementation of a self-organizing network []. It contributed to establishing a methodical common understanding between automakers and suppliers to support collaborative management practices []. Moreover, it has demonstrated suitable for formalizing Sensing, Smart, and Sustainable (S^3) enterprises [], and socio-technical systems comprising blockchain-enabled organizations [].

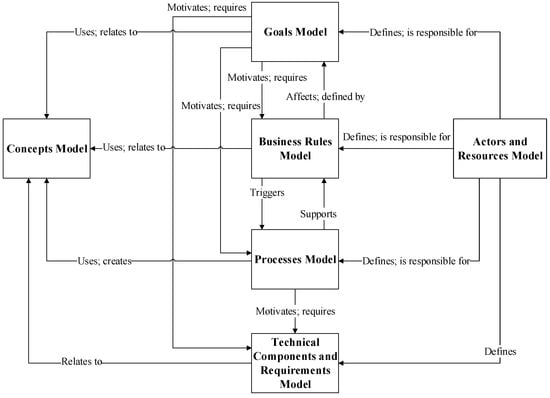

The 4EM method offers multiple perspectives within a unified modeling language, with modeling constructs to connect them []. The 4EM method comprises six submodels: the Goals Model, Business Rules Model, Processes Model, Actors and Resources Model, Technical Requirements and Components Model, and Concepts Model []. The Goals Model outlines the business strategy, emphasizing the goals and difficulties that need to be overcome for achieving its purposes. The Business Rules Model establishes the rules that govern the organization, defining and constraining the actions that can be taken to meet the several goals. The Processes Model specifies the organizational activities and the interactions between processes, including how its manage information and materials. The Actors and Resources Model clarifies who is responsible for a specific process, resource, or task. The Components and Technical Requirements Model highlights the ability for improvement in IT business processes and identifies possible configurations and features of future information systems. The Concepts Model defines attributes, entities, and relationships within the organization.

The structure of the 4EM method is illustrated in Figure 2.

Figure 2.

Structure of the 4EM method. Reproduced from Sousa et al. [], Gestão & Produção, licensed under CC BY 4.0.

3.2. Expert Judgment

According to Makridakis et al. [], expert judgment is based on human judgment and the intuition of business experts to create future scenarios. For developing expert judgments, it is essential to follow structured approaches. These procedures include collecting opinions from several experts, designing unbiased questions, and enabling group discussions to overcome misunderstandings, language barriers, or ambiguity []. Expert judgments are particularly valuable for problem elements that are difficult to quantify []. Following Kusumastuti et al. [], our research was based on information collected from in-depth interviews, where their opinions and statements were clustered and deduced. At the same time, the results were discussed and confirmed through a focus group discussion, including professors from three other universities.

Experts are individuals who possess interpretative, process, and technical knowledge about their fields of expertise, and they have systematically organized knowledge in circumscribed experiences that result from their actions or obligations of a certain operable status in an organization []. The literature does not establish a definitive number of experts for such studies []. In this research, we selected 12 experts in the field of Industry 4.0, ensuring diversity by including professionals from various domains to avoid a homogeneous expert panel. Convenience sampling was employed to select the interviewees, as they were readily accessible to participate in our research []. Table 3 presents the composition of the expert panel, which included 12 professionals with diverse backgrounds from academia and industry, ensuring a heterogeneous and multidisciplinary perspective on Industry 4.0 implementation.

Table 3.

Expert panel.

The study in organizations of such diverse sectors is justified because, according to Kamble et al. [], studies on the successful implementation of Industry 4.0 in different industry environments are needed to improve understanding of these factors. The Brazilian context was examined because it is particularly interesting for open innovation research, as its companies are remarkably close to collaboration in comparison with other countries [], and Brazil is a country that faces heightened challenges in digitization []. Moreover, Brazil needs to be aware of the challenges and bottlenecks and face them so that Industry 4.0 becomes effective [,,,].

Semi-structured interviews were conducted using an interview script to collect information from the experts. Interviews were chosen as the research method for this study because they allow for an in-depth exploration of the subject matter []. The script on topics related to enterprise modeling of the collaboration process between companies to operationalize technologies and solutions related to Industry 4.0 was developed and provided to the professionals interviewed before the conversation. In interviews open questions were used because they enable an in-depth exploration of topics and elicit more detailed and comprehensive responses []. Each interview was recorded, and the recording was transcribed to provide an accurate interpretation of what was said.

To analyze the interview data, we employed a thematic analysis approach, a widely used method in qualitative research for identifying, analyzing, and reporting patterns (themes) within data []. This approach enabled us to code the transcribed content, cluster similar ideas, and extract key themes related to collaboration processes and the operationalization of Industry 4.0 technologies. The thematic analysis followed six structured steps:

- Familiarization with the data;

- Generation of initial codes;

- Searching for themes;

- Reviewing themes;

- Defining and naming themes;

- Producing the final report.

The themes emerging from individual interviews were triangulated during the focus group discussion, ensuring robustness and validating the interpretation of findings. The data collected through semi-structured interviews played a central role in informing the development of both the Goals Model and the Business Rules Model. Experts’ responses were analyzed thematically to identify common goals, operational constraints, and strategic priorities related to collaboration in Industry 4.0 contexts. These insights were then translated into structured modeling elements using the 4EM method. Specifically, recurring goals mentioned by different interviewees were categorized and refined into the main ones presented in the Goals Model. At the same time, procedural insights and rules described by participants were formalized as business rules in the corresponding model. This direct translation from qualitative data to modeling artifacts ensured that the models were grounded in empirical evidence and reflected the perspectives of professionals actively engaged in Industry 4.0 implementation.

4. Results

This article presents the Goals Model and the Business Rules Model of collaboration between companies to operationalize Industry 4.0 technologies and solutions in collaborative networks for distributed manufacturing. Goals modeling was used as the main starting point in the enterprise design process []. We presented the Goals Model because together, the enterprise business processes and the goals are the focus of 4EM, and this method provides the language constructs to capture and describe enterprise situations to make sense of situations, which could be relevant to identify problems or indeed to improve or change the current situation []. We also presented the Business Rules Model because it has a wide interface with the Goals Model.

It is important to emphasize that adapting to the Industry 4.0 paradigm is quite complex, and thus, the experiences obtained during the project vary significantly between organizations. Thus, in this research, the 4EM submodels Processes Model, Actors and Resources Model, Technical Components and Requirements Model, and Concepts Models were not presented because, according to the professionals interviewed, the information needed for their development varies greatly between organizations and presenting such a generic model is not useful for the literature and business practice.

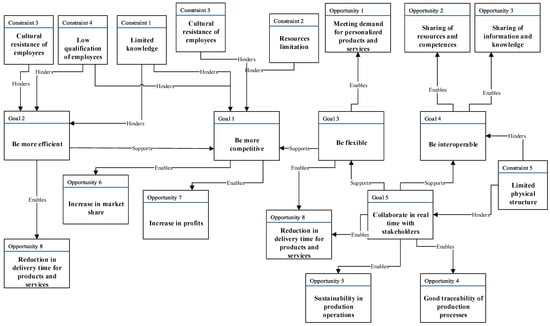

4.1. Goals Model

Figure 3 presents the Goals Model of the collaboration process between companies to operationalize Industry 4.0 technologies and solutions in collaborative networks. The main objective sought by a company that aims to adapt to this paradigm is to be more competitive (Goal 1) due to the great competition and technological development imposed by the market. Achieving this objective enables increased market share (Opportunity 6) and profits (Opportunity 7). Technologies and solutions of Industry 4.0 can potentially increase business competitiveness in the age of digital transformation by making processes, products, and services of companies more competitive [,]. By connecting the physical world with the digital world, the IoT enables real-time monitoring and control across the entire supply chain, supporting enhanced operational efficiency, costs reduction, better risk management, and higher levels of customer satisfaction [,]. Big data is crucial for organizations to improve performance, being one of the top three investment priorities among all digital technologies, due to its potential to enhance revenue and customer value—by up to 15% and 23% in initial implementation phases, and reaching gains of 45% and 41%, during the maturity stage []. ML has significantly transformed predictive analytics—particularly in pricing forecasts—by effectively identifying complex data patterns, supporting real-time predictions, and enabling informed decisions in uncertain environments [,,]. In contrast to traditional production systems, CPSs enable more flexible manufacturing processes to enhance efficiency and productivity, providing substantial real-time benefits in terms of cost reduction and optimized resources utilization []. AM is recognized as a game-changer in production processes by replacing traditional manufacturing by providing design flexibility, customization, reduced material waste, transport requirements, shortened lead time, and tooling requirements [,,]. Collaborative robots, also called cobots, combine the repetitive performance of robots with people’s skills and abilities, improving operational flexibility and work conditions for operators [,]. AR allows better tracking and analysis of consumer interactions, which can help improve future marketing strategies and develop personalized products []. Through the transparency and traceability of blockchain, companies can gain a better understanding of the environmental impact at different stages of the supply chain, trace the origin and flow of products, handle bottlenecks, protect data privacy, foster trust among supply chain stakeholders, enhance collaboration efficiency between supply chain partners, and promote the sustainability of the supply chain [,,]. CC has entirely transformed how businesses deal with their data and processes, enabling rapid innovation, utilizing adaptive resources, and improving scalability and responsiveness while providing financial gain [,].

Figure 3.

Goals Model.

For a company to be more competitive (Goal 1), it is necessary to discuss and face some restrictions that prevent it, such as limited knowledge of the digital transformation necessary for the company to achieve the Industry 4.0 philosophy (Constraint 1), limited resources (Constraint 2) of the company, cultural resistance of employees (Constraint 3), and low qualification of employees (Constraint 4). Cultural factors may represent a roadblock to digital transformation, which makes digitalization not just a technical issue but also a cultural one []. Liboni et al. [] state that the issue of organizational culture is a problem in Brazil, and companies must spend time and effort to educate and train employees. The necessity of change will only be accepted by employees if the requirements and a clear strategy can be presented []. Employees must understand that in the medium and long term, digital transformation brings benefits such as reduced downtime in processes, eliminating damage and downtime in machines and equipment, and reducing accidents, among others [].

Achieving the goal of being more efficient (Goal 2) enables the company to reduce the delivery time of products and services (Opportunity 8); however, to achieve this, it is necessary to face the cultural resistance of employees (Constraint 3) and low qualification of employees (Constraint 4). Dealing with employee resistance is a challenge for organizations, as employees may be frightened of losing their jobs with increasing digitization and do not have the appropriate skills to handle new technologies []. For implementing Industry 4.0, sufficient competencies must be developed to ensure sufficiently skilled personnel; among those competencies, IT-related skills, interdisciplinary thinking, and acting will be in demand in the future. Training, advanced training, and new training programs are required to prepare employees [].

Achieving the goal of being more flexible (Goal 3) enables meeting the demand for personalized products and services (Opportunity 1) and reducing the delivery time of products and services (Opportunity 8). The key distinction between customization and personalization is data entry and who makes the change; in personalization, the company proactively adapts the product based on data reflecting customer preferences, while customization involves the customer actively selecting from predefined options offered by the company to suit their specific requirements []. However, product customization companies can obtain greater operational efficiency, higher productivity, better management of assets and industrial processes, and greater efficiency and productivity in the supply chain []. Mass personalization can contribute to identifying trends by comparing the type of products generated with augmented digital engineering tools [].

For being interoperable (Goal 4), the company must be willing to make investments to improve its limited physical structure (Constraint 5). According to Herrero et al. [], transitioning toward Industry 4.0 requires significant investment in devices and mechanisms, enabling interconnectivity between people, machines, and processes. However, many companies often think the return on investment is uncertain while adopting Industry 4.0 technologies []. Being interoperable (Goal 4) enables the sharing of resources and skills (Opportunity 2) and the sharing of information and knowledge (Opportunity 3). To implement an infrastructure that enables interoperability among networked enterprises, it is essential for business partners to formally define their workflow structures and model the sequences of processes, tasks, actions, and the exchange of messages across different applications []. When knowledge integration between partners is limited, potential operational synergies may be compromised, and an improved interoperability of knowledge at the organizational level can mitigate both of these problems, promoting improved decision-making and more substantial partner synergies [].

Achieving the goal of collaborating in real-time with stakeholders (Goal 5) enables good traceability of production processes (Opportunity 4), sustainability in production operations (Opportunity 5), and reduction in the delivery time of products and services (Opportunity 8). The collaborative approach in organizations based on digitization enables seamless communication among supply chain stakeholders, optimizes costs, and facilitates a resilient and agile supply chain capable of steering the complexities of the modern business environment []. The collaboration of the entire ecosystem, such as the logistics service provider, supplier, and the user, is needed to recognize the critical operations of the concerned firm and then look for sources and capabilities to keep them operational []. Inter-organizational collaborations among internal supply chain members and external supply chain actors benefit the focal enterprise’s overall environmental performance and the management regarding its impact on the environment []. CC and related services facilitate the evolution of physical production into connected, real-time systems within manufacturing environments, allowing the collaborative use of manufacturing resources and capabilities among various stakeholders to support business operations and physical production []. However, a company also needs blockchain to build stable and trustworthy connections with all stakeholders—especially final consumers—as due to its distributed, decentralized, and collaborative structure, blockchain allows equal participation and transparent interactions among all actors [].

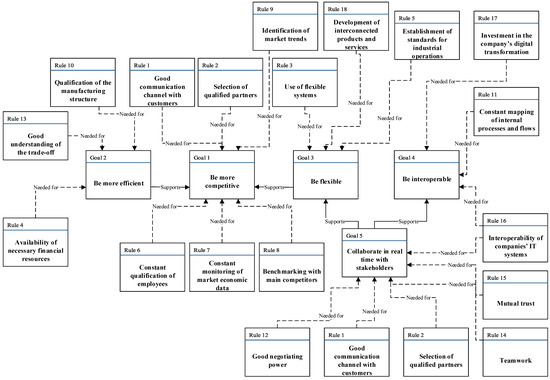

4.2. Business Rules Model

Figure 4 presents the Business Rules Model. For being more competitive (Goal 1), aiming at the joint development of products and services, the company must have a good communication channel with customers (Rule 1), selection of qualified partners (Rule 2), identification of market trends (Rule 9), constant qualification of employees (Rule 6), constant monitoring of economic market data (Rule 7), and benchmarking with competitors (Rule 8). The current market trends are increasingly driven by the demand for mass customization, requiring production systems to simultaneously ensure high levels of flexibility and productivity []. In the context of digital transformation, building an effective communication channel between customer needs and production capacity is essential to enable customized services, particularly in scenarios involving low-volume and high-variety production []. Technological advances concerned with Industry 4.0 provide real-time interaction and information exchange between designers and users, improving product development effectiveness and marketing aspects []. In these communication channels, blockchain allows the customers to monitor their product’s source, delivery, and vendor, irrespective of their purchasing channel [].

Figure 4.

Business Rules Model.

For being more efficient (Goal 2), the company needs the availability of the necessary financial resources (Rule 4), qualification of its manufacturing structure (Rule 10), and good knowledge of the trade-off (Rule 13). The continuous deployment of intelligent services relies on the integration of technologies such as Computer Numeric Control (CNC), industrial robots, smart sensors, advanced tagging systems, intelligent agents, smartphones, video cameras, and appliances with multi-sensor advice or smart objects to enhance situational consciousness and optimize business operations within digital environments [].

For being flexible (Goal 3), the use of flexible systems is necessary (Rule 3), likewise the establishment of standards for industrial operations (Rule 5), and the development of interconnected products and services (Rule 18). Interconnected products and services allow the company to improve its performance in the market constantly by receiving constant customer feedback. Flexible systems should concentrate on core activities, be adaptative to emerging scenarios, use strategic flexibility to be proactive and reactive to change, recognize innovation as a key driver for maintaining competitiveness in the goods and services market, and be market-flexible to fulfill customers’ demands [,,]. In a flexible system, machines and computers collaborate, collect, and exchange information to optimize production efficiency and reinforce a factory’s competitive advantage in the marketplace []. Examples of flexible systems are artificial intelligence, big data, machine learning, and multi-purpose robots that do not require task-specific programming [,].

For being interoperable (Goal 4), constant mapping of internal processes and flows is necessary (Rule 11), interoperability of companies’ IT systems (Rule 16), and investment in the company’s digital transformation (Rule 18). The experts interviewed in this research state that implementing and operationalizing technologies and solutions related to Industry 4.0 require specialized employees, State-of-the-Art computers and machines, and a change in the company’s organizational culture. Process mapping is commonly employed as a key initial step when optimizing existing manufacturing processes, as it helps to visualize complex systems, identify workflow, reduce or eliminate unnecessary steps, inefficiencies, and bottlenecks, and finally introduce new technologies or solutions to streamline the manufacturing process chain []. Digital technologies in the context of prediction and real-time monitoring can support traditional process mapping techniques []. Data from the ERP and MES can be captured by Radio Frequency Identification (RFID) and examined through algorithms and simulations, focusing on factors such as throughput time, machine availability, failures, cycle time, bottlenecks, and other relevant metrics []. DTs can enhance traditional mapping analysis by highlighting cause-and-effect relationships through ML algorithms []. In intelligent manufacturing, algorithms that can effectively identify the root causes of defects and identify necessary maintenance activities to reduce unpremeditated downtime are essential [].

For collaborating in real-time with stakeholders (Goal 5), the company must have a good communication channel with customers (Rule 1), a selection of qualified partners (Rule 2), good negotiating power (Rule 12), teamwork (Rule 14), mutual trust (Rule 15), and interoperability of companies’ IT systems (Rule 16). For Wu et al. [], innovative manufacturing companies established in collaborative environments must have ICT systems that instantly collect and analyze information generated in machines and industrial processes. Mutual trust is important because data security issues in collaborative networks are a serious limitation, as companies can resist exchanging data [].

5. Discussion

The 4EM method was chosen for modeling companies’ goals and rules for the collaboration process between companies to operationalize technologies and related solutions of Industry 4.0 because it provides a systematic way of analyzing and documenting a company’s components, which is useful for understanding projects. The absence of a standardized implementation approach is one of the significant difficulties in shifting toward digital transformation [].

The Goals Model presented facilitated the understanding of strategies, detailing the goals sought by an organization and opportunities arising from the operationalization of the solutions and technologies, as well as visualizing the restrictions that prevent the achievement of goals. Therefore, the Goals Model presented may become a reference for guiding future acquisitions. The cultural resistance of employees may represent the main obstacle to the acquisition and adequate use of solutions and technologies since, as Industry 4.0 implies profound changes in the work environment, many employees avoid their inclusion in the digital transformation. Many issues lead to such resistance, such as fear of losing one’s job, fear of robot accidents, fear of machine-driven decision-making, discomfort caused by the virtualization of the factory floor, etc.

In addition to being closely related to the desired goals, the Business Rules Model guidelines also signaled the primary considerations to be made when carrying out activities in the collaborative network. According to the professionals interviewed, along with investment in organizational change management and employee training, clearly defining the goals sought by the company acquiring Industry 4.0 solutions and technologies is essential for the success of digital transformation. Employees must understand that in the medium and long term, the implementation of solutions and technologies and changes to the company’s structure brings benefits such as reduced downtime in processes, elimination of damage and downtime in machines and equipment, and reduction in accidents, among others.

The contributions of the Goals Model and Business Rules Model to enterprise practice can be significant, as enterprise models serve as a means of representing organizational knowledge and can act both as a source of information for knowledge management and as a foundation for organizational learning []—one of the core pillars of Industry 4.0. Efficient knowledge management is essential for leveraging data and effectively utilizing Industry 4.0 technologies [].

This research contributes to the theoretical advancement of Industry 4.0 implementation by providing a structured modeling approach for inter-organizational collaboration in distributed manufacturing settings. The use of the 4EM method, particularly through the Goals and Business Rules Models, offers a multi-perspective framework that can be replicated in future academic studies to investigate alignment between strategic objectives and operational constraints in Industry 4.0 environments. Furthermore, this study addresses a literature gap by linking enterprise modeling techniques to collaborative networks, moving beyond traditional technology-centered perspectives to emphasize organizational and managerial alignment.

6. Practical Implications

This study presents a Goals Model and a Business Rules Model that highlight the essential requirements for the successful implementation of Industry 4.0 in collaborative networks. The proposed models serve as a roadmap for decision-makers seeking to implement Industry 4.0 solutions collaboratively. The Goals Model can guide firms in identifying and aligning their strategic goals with technological initiatives, while the Business Rules Model highlights critical organizational practices necessary for success. Below are expanded and actionable recommendations for managers and policymakers to effectively navigate digital transformation.

6.1. Managerial Implications

Managers can utilize the Goals Model to assess an organization’s readiness for Industry 4.0 and identify key constraints to address, such as limited resources, cultural resistance, or low employee qualifications. The Business Rules Model provides a practical foundation for defining operational priorities, such as communication with customers, technology investments, partner selection, and team collaboration. Together, these models enable a structured and strategic approach to digital transformation. By implementing the outlined managerial practices in alignment with these models, organizations can increase competitiveness, streamline operations, and foster collaborative innovation.

6.1.1. Enhancing Competitiveness

Customer-centric co-development involves establishing digital platforms, such as IoT-enabled feedback systems and blockchain technologies for traceability, to engage customers actively in the product design process. This approach ensures that the resulting products and services are more closely aligned with market needs and expectations, thereby enhancing personalization, responsiveness, and customer satisfaction.

Use of the Goals Model can guide strategic partner selection to assess the interoperability and digital maturity of potential collaborators. By applying this model, organizations can identify and prioritize partners with complementary capabilities such as cloud-based data sharing systems, thereby fostering more effective, integrated, and secure collaborative relationships.

6.1.2. Increasing Operational Efficiency

Targeted investments should focus on allocating resources to automation technologies, such as cobots and AI-driven predictive maintenance systems, as well as to real-time monitoring tools like DTs. These technologies play a critical role in reducing production downtime, improving operational visibility, and increasing overall efficiency in Industry 4.0 environments, directly contributing to Goal 2.

Employee upskilling is also essential and involves implementing continuous training programs in key areas such as the IoT, data analytics, and cybersecurity. These initiatives help to bridge existing skill gaps and reduce cultural resistance to digital transformation, ensuring that the workforce is better prepared to adopt and manage emerging technologies.

6.1.3. Enabling Flexibility

Companies should adopt modular production systems to enable greater responsiveness to customized orders. This adoption involves the implementation of reconfigurable manufacturing lines and the use of AM, which allows for more flexible and efficient adaptation to varying customer demands in dynamic market environments.