A Comparison Between Passive-Controlled Natural Ventilation vs. Mechanical Ventilation with Heat Recovery

Abstract

1. Introduction

2. Background

- Improved envelope performance (insulation, airtightness, high-efficiency glazing)

- Mechanical ventilation with heat recovery and high-efficiency components

- Replacement of technical systems to minimize operational energy use

- Life cycle environmental impacts and embodied energy in materials

- The potential of advanced natural ventilation systems as low-energy, low-impact alternatives

3. Methods

- Energy performance (heating consumption)

- Carbon footprint (life cycle stages A1–A3, B4, C3, C4, and D)

- Capital cost investments (payback period)

- Indoor environmental quality (IEQ) (CO2, air temperatures, and relative air humidity, %RH)

3.1. Case Study Setup

3.1.1. Natural Ventilation System Strategy, N-Tech

3.1.2. Mechanical Ventilation System Strategy, M-Tech

3.1.3. Daylight Strategy for N-Tech—Two-Layered High-Transmittance Glazing

3.1.4. Daylight Strategy for M-Tech—Three-Layered Low Transmittance Glazing

4. Results

4.1. Energy Consumption and Indoor Environment

4.2. Life Cycle Analysis, GWP Comparison

- N-Tech: 6.9 (+/− 0.36) t. CO2 eqv

- M-Tech: 49.7 (+/− 0.79) t. CO2 eqv

- N-Tech: 2.55 (+/− 0.59) CO2 eqv per m2/year

- M-Tech: 4.42 (+/− 0.96) CO2 eqv per m2/year

4.3. Capital Cost, Payback Period Comparison

5. Discussion

6. Limitations of the Study

7. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Use of Artificial Intelligence

Acknowledgments

Conflicts of Interest

Abbreviations

| IEQ | Indoor environmental quality |

| GWP | Global warming potential |

| PBT | Payback time |

| PV | Photovoltaics |

| GHGPBT | Green house gas protocol payback time |

| CAV | Constant air ventilation |

| VAV | Variable air ventilation |

| U-value | Thermal transmittance (W/m2 K) |

| SHGC | Solar heat gain coefficient (%) |

| PBP | Payback period |

| PPD | Percentage of people dissatisfied |

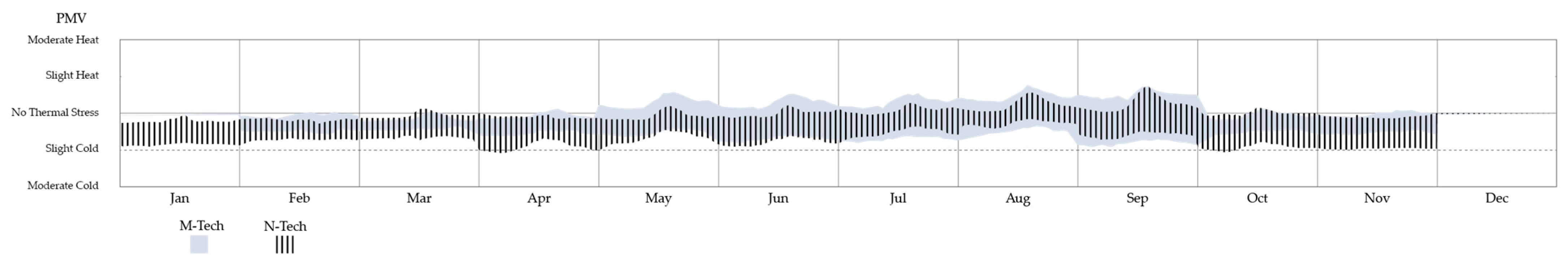

| PMV | Predicted mean vote |

| LCA | Life cycle analysis |

| LCI | Life cycle inventory |

Appendix A

| Building/Tech | ID | Key Numbers |

|---|---|---|

| A/N-Tech | A1 | PPD: 12.7 Neutral: 47.8% Slight Heat Stress: 1.4% Slight Cold Stress: 50.8% CO2 PPM (2σ,avg, −2σ): 541, 798, 1522 |

| A/N-Tech | A2 | PPD: 22.2 Neutral s: 25.6% Slight Heat Stress: 3.1% Slight Cold Stress: 71.4% CO2 PPM (2σ,avg, −2σ): 449, 710, 1169 |

| A/N-Tech | A3 | PPD: 10.4 Neutral: 61.6% Slight Heat Stress: 0.6% Slight Cold Stress: 37.7% CO2 PPM (2σ,avg, −2σ): 449, 777, 1351 |

| A/N-Tech | A4 | PPD: 13.4 Neutral: 43.9% Slight Heat Stress: 1.5% Slight Cold Stress: 54.6% CO2 PPM (2σ,avg, −2σ): 473, 993, 1787 |

| B/M-Tech | B1 | PPD: 12.8 Neutral: 51.7% Slight Heat Stress: 0% Slight Cold Stress: 48.3% CO2 PPM (2σ,avg, −2σ): 462, 656, 880 |

| B/M-Tech | B2 | PPD: 12.9 Neutral: 35.9% Slight Heat Stress: 1.8% Slight Cold Stress: 62.2% CO2 PPM (2σ,avg, −2σ): 554, 807, 1067 |

| B/M-Tech | B3 | PPD: 8.7 Neutral: 76.1% Slight Heat Stress: 12.1% Slight Cold Stress: 11.8% CO2 PPM (2σ,avg, −2σ): 538, 741, 943 |

| B/M-Tech | B4 | PPD: 7.3 Neutral: 91.8% Slight Heat Stress: 2% Slight Cold Stress: 6.2% CO2 PPM (2σ,avg, −2σ): 485, 632, 779 |

| A/N-Tech | Average, A1–A3 | Avg PPD: 14.7 Avg Neutral: 44.7% Avg Slight Heat Stress: 1.7% Avg Slight Cold Stress: 53.6% CO2 PPM (2σ,avg, −2σ): 478, 820, 1457 |

| B/M-Tech | Average, B1–B4 | Avg PPD: 10.4 Avg Neutral: 63.9% Avg Slight Heat Stress: 4.0% Avg Slight Cold Stress: 18.1% CO2 PPM (2σ,avg, −2σ): 510, 732, 917 |

References

- European Commission. Comprehensive Study of Building Energy Renovation Activities and the Uptake of Nearly Zero-Energy Buildings in the EU; European Commission: Brussels, Belgium, 2019.

- European Commission. Renovation Wave. 2025. Available online: https://energy.ec.europa.eu/topics/energy-efficiency/energy-efficient-buildings/renovation-wave_en (accessed on 15 April 2025).

- European Parliament and Council. Directive (EU) 2024/1275 of 24 April 2024 on the Energy Performance of Buildings (Recast) (Text with EEA Relevance). 2024. Available online: https://eur-lex.europa.eu/eli/dir/2024/1275/oj/eng (accessed on 15 April 2025).

- Volf, C. Light, Air and Natural Surroundings—Different Hospital Typologies. In Proceedings of the ARCH 17: 3rd International Conference on Architecture, Research, Care and Health, Copenhagen, Denmark, 26–28 April 2017; Aalborg University’s Research Portal: Aalborg, Denmark, 2017; pp. 203–226. [Google Scholar]

- Zimmermann, R.K.; Andersen, C.M.E.; Kanafani, K.; Birgisdottir, H. SBI 2020:04—Klimapåvirkning fra 60 Bygninger—Muligheder for Udformning af Referenceværdier til LCA for Bygninger; Statens Byggeforskningsinstitut: Hørsholm, Denmark, 2020. [Google Scholar]

- Bygningsreglementet. BR18, §298. 2020. Available online: https://www.bygningsreglementet.dk/Tekniske-bestemmelser/11/Krav/297_298#:~:text=Klimap%C3%A5virkningen%20skal%20opg%C3%B8res%20i%20kg%20CO2-%C3%A6kvivalenter%20pr.%20m2,-%20Vurdering%20af%20bygningers%20milj%C3%B8m%C3%A6ssige%20kvalitet%20-%20Beregningsmetode (accessed on 15 April 2025).

- Schnieders, J.; Hermelink, A. CEPHEUS results: Measurements and occupants’ satisfaction provide evidence for Passive Houses being an option for sustainable building. Energy Policy 2006, 34, 151–171. [Google Scholar] [CrossRef]

- Chung, K.C.; Hsu, S.P. Effect of ventilation pattern on room air and contaminant distribution. Build. Environ. 2001, 36, 989–998. [Google Scholar] [CrossRef]

- Novoselac, A.; Srebric, J. Comparison of air exchange efficiency and contaminant removal effectiveness as IAQ indices. ASHRAE Trans. 2003, 109, 339–349. [Google Scholar]

- Wolkoff, P.; Kjærgaard, S.K. The dichotomy of relative humidity on indoor air quality. Environ. Int. 2007, 33, 850–857. [Google Scholar] [CrossRef] [PubMed]

- Byggeindustrien. Innlegg: VVS—Den Skjulte Klimakjempen—Hvorfor vi må Kutte Utslippene Fra VVS Raskt. Available online: https://www.bygg.no/innlegg-vvs-den-skjulte-klimakjempen-hvorfor-vi-ma-kutte-utslippene-fra-vvs-raskt/2330913 (accessed on 15 April 2025).

- European Parlement and Council. Commission Regulation (EU) 2024/1781 of 13 June 2024, Establishing a Framework for Setting Ecodesign Requirements for Sustainable Products and Repealing Directive 2009/125/EC (Ecodesign for Sustainable Products Regulation). Official Journal of the European Union, L 202. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:32024R1781 (accessed on 15 April 2025).

- Volf, C.; Petersen, P.M.; Thorseth, A.; Vestergaard, S.; Martiny, K. Daylight quality: High-transmittance glass versus low transmittance glass—Effects on daylight quality, health, comfort and energy consumption. Ann. Med. 2024, 56, 2297273. Available online: https://www.tandfonline.com (accessed on 15 April 2025). [CrossRef] [PubMed]

- Angelopoulos, C.; Cook, M.; Iddon, C.; Porritt, S. Evaluation of Thermal Comfort in Naturally Ventilated School Classrooms During the Heating Season Using CFD; Loughborough University: Loughborough, UK, 2017; Available online: https://publications.ibpsa.org/conference/paper/?id=bs2017_128 (accessed on 5 September 2023).

- Gil-Baez, M.; Barrios-Padura, Á.; Molina-Huelva, M.; Chacartegui, R. Natural ventilation systems to enhance sustainability in buildings: A review towards zero energy buildings in schools. E3S Web Conf. 2017, 22, 00053. [Google Scholar] [CrossRef]

- European Union. Commission Regulation (EU) No 1253/2014. 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32014R1253 (accessed on 15 April 2025).

- Bygningsreglementet. BR18, §443, Paragraph 2. 2020. Available online: https://www.bygningsreglementet.dk/tekniske-bestemmelser/22/vejledninger/version-2-generel_vejledning/kap-1_5/ (accessed on 15 April 2025).

- Bygningsreglementet. BR18, §443, Subsection 3. 2020. Available online: https://www.bygningsreglementet.dk/Tekniske-bestemmelser/22/Krav/443_446 (accessed on 15 April 2025).

- Huang, H.; Wan Mohd Nazi, W.I.B.; Yu, Y.; Wang, Y. Energy performance of a high-rise residential building retrofitted to passive building standard—A case study. Appl. Therm. Eng. 2020, 181, 115902. [Google Scholar] [CrossRef]

- AlFaris, F.; Juaidi, A.; Manzano-Agugliaro, F. Energy retrofit strategies for housing sector in the arid climate. Energy Build. 2016, 131, 158–171. [Google Scholar] [CrossRef]

- Hu, X.; Xiang, Y.; Zhang, H.; Lin, Q.; Wang, W.; Wang, H. Active–passive combined energy-efficient retrofit of rural residence with non-benchmarked construction: A case study in Shandong province, China. Energy Rep. 2021, 7, 1360–1373. [Google Scholar] [CrossRef]

- Amoah, B.O.K.; Nguyen, V.T.; Najafi, H. A multi-facet retrofit approach to improve energy efficiency of existing class of single-family residential buildings in hot-humid climate zones. Energies 2020, 13, 1178. [Google Scholar] [CrossRef]

- Ji, Y.; Li, G.; Su, F.; Chen, Y.; Zhang, R. Retrofit analysis of city-scale residential buildings in the hot summer and cold winter climate zone. Energies 2023, 16, 6152. [Google Scholar] [CrossRef]

- Han, T.; Liu, P.; Niu, C.; Li, Q. Evaluation of energy-saving retrofit projects of existing rural residential envelope structures from the perspective of rural residents: The Chinese case. Environ. Dev. Sustain. 2023, 25, 8419–8446. [Google Scholar] [CrossRef]

- Kadrić, D.; Aganovic, A.; Martinović, S.; Delalić, N.; Delalić-Gurda, B. Cost-related analysis of implementing energy-efficient retrofit measures in the residential building sector of a middle-income country—A case study of Bosnia and Herzegovina. Energy Build. 2022, 257, 111765. [Google Scholar] [CrossRef]

- Huang, Y.; Niu, J.-L.; Chung, T.-M. Energy and carbon emission payback analysis for energy-efficient retrofitting in buildings—Overhang shading option. Energy Build. 2012, 44, 94–103. [Google Scholar] [CrossRef]

- Malode, S.; Prakash, R.; Mohanta, J.C. Sustainability assessment of rooftop solar photovoltaic systems: A case study. Environ. Impact Assess. Rev. 2024, 108, 107609. [Google Scholar] [CrossRef]

- Rehman, O.A.; Palomba, V.; Frazzica, A.; Cabeza, L.F. Analysis of a heat pump-based energy system exploiting a low GWP refrigerant in different European climates. E3S Web Conf. 2023, 414, 03012. [Google Scholar] [CrossRef]

- Gigasari, A.R.; Cárcel-Carrasco, J.; Iglesias, L.M.P.; Amani, N. Evaluating carbon payback time by optimizing insulation materials for different orientations: A cradle-to-gate life cycle assessment. Energy Environ. 2025, 36, 1290–1308. [Google Scholar] [CrossRef]

- Tremeac, B.; Meunier, F. Life cycle analysis of 4.5 MW and 250 W wind turbines. Renew. Sustain. Energy Rev. 2009, 13, 2104–2110. [Google Scholar] [CrossRef]

- ISO 14040:2006; 2006 Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerlan, 2006. Available online: https://www.iso.org/standard/37456.html (accessed on 15 April 2025).

- EN 15978:2011; Sustainability of Construction Works. Assessment of Environmental Performance of Buildings. Calculation Method. CEN: Brussels, Belgium, 2011. Available online: https://webshop.ds.dk/standard/M240512/ds-en-15978-2012 (accessed on 15 April 2025).

- Southall, R.G. An assessment of the potential of supply-side ventilation demand control to regulate natural ventilation flow patterns and reduce domestic space heating consumption. Energy Build. 2018, 168, 201–214. [Google Scholar] [CrossRef]

- Zhang, W.; Wu, W.; Yan, B.; Malkawi, A. Applying machine learning for building natural ventilation control. In Proceedings of the 16th Conference of the International Society of Indoor Air Quality and Climate: Indoor Air, Seoul, Republic of Korea, 20–24 July 2020. [Google Scholar]

- Hamada, A.A.; Hong, S.; Mumovic, D.; Raslan, R. Towards healthy and energy-efficient buildings in the context of Egypt: Modelling demand-controlled ventilation to improve the indoor air quality in a generic office space in Cairo. J. Phys. Conf. Ser. 2023, 2600, 102017. [Google Scholar] [CrossRef]

- Scheuring, L.; Weller, B. Energy-efficient controlled natural ventilation in nonresidential buildings—Experimental investigation of opening durations. Bauphysik 2021, 43, 113–124. [Google Scholar] [CrossRef]

- METRO THERM, ECO 360 R ventilationsanlæg. Available online: https://www.genvex.com/produkter/ventilationsanlaeg/eco-360-r-ventilationsanlaeg (accessed on 15 April 2025).

- Leapcraft. Wireless Sensor from Leapcraft. Available online: https://www.leapcraft.com (accessed on 15 April 2025).

- NOTECH. Fuldskala Afprøvning og Dokumentation af NOTECH-Systemet i en Skoleklasse, og i Lab på TI. Available online: https://realdania.dk/publikationer/faglige-publikationer/notech (accessed on 15 April 2025).

- Bygningsreglementet. BR18 General Requirements for Mechanical Systems. 2020. Available online: https://www.bygningsreglementet.dk/tekniske-bestemmelser/22/krav/421_429/#78c2af6e-fe56-4728-8249-a612cc4289d3 (accessed on 15 April 2025).

- Ökobau.dat: 8.2.01 Building Service Engineering/Air Conditioning and Ventilation/Ventilation System UUID: 690f1fb5-b209-4530-8b5e-2ca5acfe30d2. Available online: https://oekobaudat.de/OEKOBAU.DAT/datasetdetail/process.xhtml?uuid=690f1fb5-b209-4530-8b5e-2ca5acfe30d2&version=20.24.070&stock=OBD_2024_I&lang=en (accessed on 15 April 2025).

- Ökobau.dat: 8.2.03 Building Service Engineering/Air Conditioning and Ventilation/Accessory UUID: 40edb030-3b81-47f6-a24f-acd8b2be0d20. Available online: https://oekobaudat.de/OEKOBAU.DAT/datasetdetail/process.xhtml?uuid=40edb030-3b81-47f6-a24f-acd8b2be0d20&version=20.24.070&stock=OBD_2024_I&lang=en (accessed on 15 April 2025).

- Søuld/Eelgrass. Available online: https://www.sould.dk/performance (accessed on 15 April 2025).

- Ökobau.dat: 7.1.05 Components for Windows and Curtain Walls/Frames/Profiles/Aluminium UUID: d0e0f205-2f4d-4c7f-b63a-23a9abd6e60a. Available online: https://oekobaudat.de/OEKOBAU.DAT/datasetdetail/process.xhtml?uuid=d0e0f205-2f4d-4c7f-b63a-23a9abd6e60a&version=20.24.070&stock=OBD_2024_I&lang=en (accessed on 15 April 2025).

- Ökobau.dat: 7.2.01 Components for Windows and Curtain Walls/Infill/Transparent Infill. Available online: https://oekobaudat.de/OEKOBAU.DAT/datasetdetail/process.xhtml?uuid=ba58d8b9-945b-4428-b4e0-aecda8b3df18&version=20.24.070&stock=OBD_2024_I&lang=en (accessed on 15 April 2025).

- Danish Energy Agency. Available online: https://ens.dk/analyser-og-statistik/noegletal-om-energiforbrug-og-forsyning (accessed on 15 April 2025).

- Danish Law on Environmental Impact of Buildings. Available online: https://www.retsinformation.dk/eli/lta/2021/2580 (accessed on 15 April 2025).

- Borodinecs, A.; Zemitis, J.; Palcikovskis, A. HVAC System Control Solutions Based on Modern IT Technologies: A Review Article. Energies 2022, 15, 6726. [Google Scholar] [CrossRef]

- Sara, A. Sharbaf, Patricia Schneider-Marin, Cost-benefit analysis of sustainable upgrades in existing buildings: A critical review. Energy Build. 2025, 328, 115142. [Google Scholar] [CrossRef]

| Article | Country | Year | Type of Renovation | Pay-Back Period (Years) |

|---|---|---|---|---|

| [19] | China | 2020 | insulation, windows, ventilation system, airtightness | 18 |

| [20] | Saudi Arabia | 2016 | windows, shading | 4 |

| [21] | China | 2021 | insulation, windows, HVAC, PV | 11 |

| [22] | Canada | 2020 | insulation, windows, HVAC | 11–13 |

| [23] | China | 2023 | insulation, windows, HVAC, controls | 4–19 |

| [24] | China | 2023 | insulation, windows, heating system | 21–25 |

| [25] | Bosnia and Herzegovina | 2022 | insulation, windows, HVAC | 20 |

| [26] | Hong Kong | 2012 | windows, shading | 46 |

| Apartment | Ventilation Strategy | Gross Area | Window Properties | Window-Floor Ratio |

|---|---|---|---|---|

| 63/A1 | N-Tech (NOTECH) 2-layered glazing | 88 m2 | 7.8 m2/1.12 W/m2 K/0.77 | 8.9% |

| 65/A2 | N-Tech (NOTECH) 2-layered glazing | 87 m2 | 11.5 m2/1.12 W/m2 K/0.77 | 13.2% |

| 73/A3 | N-Tech (NOTECH) 2-layered glazing | 56 m2 | 5.7 m2/1.12 W/m2 K/0.77 | 10.2% |

| 75/A4 | N-Tech (NOTECH) 2-layered glazing | 57 m2 | 5.7 m2/0.8 W/m2 K/0.53 | 10.0% |

| 77/B1 | M-Tech (Genvex Eco 360 R [37]) 3-layered glazing | 79 m2 | 10.4 m2/0.8 W/m2 K/0.53 | 13.2% |

| 81/B2 | M-Tech (Genvex Eco 360 R [37]) 3-layered glazing | 88 m2 | 9.7 m2/0.8 W/m2 K/0.53 | 11.0% |

| 87/B3 | M-Tech (Genvex Eco 360 R [37]) 3-layered glazing | 86 m2 | 12.0 m2/0.8 W/m2 K/0.53 | 14.0% |

| 93/B4 | M-Tech (Genvex Eco 360 R [37]) 3-layered glazing | 57 m2 | 6.3 m2/0.8 W/m2 K/0.53 | 11.1% |

| Ventilation Strategy | Ventilation Setpoint 1 Ventilation (l-s m2) Summer Period (1 May–31 October) | Ventilation Setpoint 2 Ventilation (l-s m2) Winter Period (1 November–30 April) |

|---|---|---|

| N-Tech | 0.65 * | 0.3 |

| M-Tech | 0.3 | 0.3 |

| System Parameters | M-Tech | N-Tech |

|---|---|---|

| Ventilation technology | Genvex Eco 360 R Power Supply: 1 × 230 V + N + PE, 10 A, 50 Hz Fan Speed: 3740 rpm Power Consumption (max per motor): 90 W | WindowMaster NOTECH Eelgrass Window frame, alu |

| Heat recovery rate (%) | 83–85% | 0% |

| Effect (Watt) | 100–180 W | 0 W |

| Noise (min/max db(A)) | Supply Air, Lw 74.8 db Extract Air, Lw 63.5 db Outdoor Air, Lw 62.2 db Exhaust Air, Lw 73.8 db Cabinet, Lp 44.7 db | 0 db |

| Unit weight | 43 kg | 4 kg |

| GWP (50-year) M-Tech: Unit/12 m ducts N-Tech: NT1/NT2 and NT3 MTech 1, NTech 2, Pr. unit | A1–A3, 1193.8/239.1 C2, 4.0/0.9 C3, 0.4/0.0 C4, 0.9/0.0 D, −507.8/−96.3 A–C, 1199 +/− 60 | A1–A3, 124.0/138.4 C2, 0.0/0.0 C3, 0.0/0.0 C4, 11.5/17.3 D, −76.0/−86.4 A–C 156 +/− 8 |

| Window technology | 3-layered windows (shgc: 0.53), Uw: 0.8 | 2-layered high-transmittance, low-iron glazing (shgc: 0.77), Uw: 1.1 |

| 2-layered glazing 3 pr. m2 3-layered glazing 4 pr. m2 | A1–A3, 59.8 C2, 0.1 C3, 3.0 C4, 0.5 D, −0.9 Total A–C 63 +/− 3 | A1–A3, 38.3 C2, 0.1 C3, 1.5 C4, 0.4 D, −0.5 Total A–C 40 +/− 2 |

| Upfront installation cost for ventilation system Euro pr. m2 (gfa) | −62.6 | −25.3 |

| Upfront installation cost for windows Euro pr. m2 (gfa) | 67 | 65 |

| N-Tech | Average, IEQ | Avg PPD: 14.7 Avg PMV Neutral state: 44.7% Avg PMV Slight Heat Stress: 1.7% Avg PMV Slight Cold Stress: 53.6% CO2 PPM (2σ,avg, −2σ): 478, 820, 1457 |

| M-Tech | Average, IEQ | Avg PPD: 10.4 Avg PMV Neutral: 63.9% Avg PMV Slight Heat Stress: 4.0% Avg PMV Slight Cold Stress: 18.1% CO2 PPM (2σ,avg, −2σ): 510, 732, 917 |

| System Performance | M-Tech | N-Tech |

|---|---|---|

| Ventilation System Operation | Mechanical ventilation with possible over-ventilation and limited user control; operates at consistent flow rates regardless of actual demand. M-Tech ensures air quality, but can lead to heat loss if overactive. | Demand-controlled natural ventilation that adjusts flow based on indoor conditions, minimizing unnecessary air exchange. N-Tech may sacrifice air quality during low ventilation periods, but conserves thermal energy more effectively. |

| Solar Gains and Window Design | Lower SHGC reduces solar gain, preventing overheating but increasing reliance on active heating. Low U-value (0.8) reduces heat loss. M-Tech retains heat better but misses out on beneficial solar gains. | Higher SHGC glazing increases passive solar heating but also potentially allows more heat loss due to a higher U-value (1.12). N-Tech benefits from solar heat in winter but may risk higher energy loss. |

| Thermostatic Control Uncertainty | Manual thermostats used by occupants; no data on actual setpoints or whether full heating capacity was reached. Without data on user settings, it is unclear how much heating demand is driven by system design versus user behavior. It is difficult to isolate technical performance from occupant influence. | Same condition—thermostats controlled manually, with no monitoring of settings or system outputs. |

| Control Logic and System Responsiveness | Fast-reacting control system maintains stable temperatures but may overcompensate, leading to short-cycle heating and inefficiencies. M-Tech offers high comfort consistency but at an energy cost. | Passive system with slower response to temperature changes, allowing for greater fluctuation before intervention. N-Tech allows broader thermal variation but may better align with energy conservation goals. |

| Parameter | M-Tech | N-Tech | Comment |

|---|---|---|---|

| Net Present Value (NPV) | −133.6 EUR/m2 | −70.0 EUR/m2 | NPV [50 y] (M-Tech is nearly twice as expensive) |

| Annuity | −5.3 EUR/m2 | −2.8 EUR/m2 | |

| Operational Costs excl. energy cost | (filter and part replacement, servicing) −42 EUR/m2 | (filter replacement, servicing) −2.2 EUR/m2 | N-Tech’s lack of operational costs is a key advantage. |

| Maintenance and replacement of key components | (regular servicing and few large) parts −29.5 EUR/m2 | (no major replacements until 25 y) −48.3 EUR/m2 | Long replacement cycles expected for N-Tech |

| Upfront investment | (installation, materials, consulting) −62.6 EUR/m2 | (installation, materials, consulting) −25.3 EUR/m2 | Potential for N-Tech costs to drop over time with scaling. |

| Cost, installation, replacements, maintenance, annually | −5.3 EUR/m2 | −2.8 EUR/m2 | N-Tech has significantly lower annual cost. |

| Energy cost, Heating, annually | −9.0 EUR/m2 | −8.4 EUR/m2 | (based on 2025 avg. DK prices) [46] |

| Energy cost, Electricity, annually | −4.5 EUR/m2 | 0 EUR/m2 | (based on 2025 avg. DK prices) [46] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Volf, C.; Negendahl, K. A Comparison Between Passive-Controlled Natural Ventilation vs. Mechanical Ventilation with Heat Recovery. Air 2025, 3, 31. https://doi.org/10.3390/air3040031

Volf C, Negendahl K. A Comparison Between Passive-Controlled Natural Ventilation vs. Mechanical Ventilation with Heat Recovery. Air. 2025; 3(4):31. https://doi.org/10.3390/air3040031

Chicago/Turabian StyleVolf, Carlo, and Kristoffer Negendahl. 2025. "A Comparison Between Passive-Controlled Natural Ventilation vs. Mechanical Ventilation with Heat Recovery" Air 3, no. 4: 31. https://doi.org/10.3390/air3040031

APA StyleVolf, C., & Negendahl, K. (2025). A Comparison Between Passive-Controlled Natural Ventilation vs. Mechanical Ventilation with Heat Recovery. Air, 3(4), 31. https://doi.org/10.3390/air3040031