1. Introduction

In forensics, scientists widely adopt silicone elastomers as artificial skins to avoid ethical concerns arising from human cranial impact injury-related experiments [

1]. Although silicone elastomer and human skin constitutive responses are comparable [

2], it is still challenging to fabricate an ideal silicone skin simulant, such as replicating the fibre structure in a biological skin. The integration of additives into the silicone elastomer can enhance its mechanical behaviour and other desired functional properties. Nonetheless, the primary interest of most silicone-based composite studies was to maximise the functional properties rather than directly mimic the biological structure and mechanical behaviours of the human skin.

Short polyethylene (PE) fibres possess comparable elastic modulus, diameter, and length to the collagen fibres in the human skin [

3] and can also enhance the mechanical properties of the skin simulant. A silicone-based composite composed of short PE fibres can emulate better structural replication of the human skin than silicone elastomers. Besides the fibres, bioactive glass (BG), a composition of 45% weight of silica, is a particle that is believed to increase the stiffness of the silicone rubber and have biointegrative properties [

4]. Nonetheless, the tensile characterisation of both composites is yet to be comprehensively determined. The present study investigates the influences of short PE fibres and bioglass particles with two different filler concentrations (1% and 3%) on the tensile properties of the silicone based composites via experiments. The tensile properties of the composite skin simulants are compared with those of human skin to develop suitable skin simulant candidates for forensics and biomedical applications.

2. Materials and Methods

In the present study, silicone-based composite skin simulants were integrated with bioactive glass particles and short PE fibres. For a platinum silicone matrix, Ecoflex® (Smooth-On, Inc., Macungie, PA, USA) soft silicone with a shore 00 scale hardness of 10 was mixed with Mold Star® (Smooth-On, Inc., Macungie, PA, USA) platinum silicone with a shore A hardness of 30 in 8:92 composition by weight, respectively.

Short high-density PE fibres, Short StuffTM E380F (Minifibers, Inc., Johnson City, TN, USA), with an average diameter of 15 μm and a length of 0.5 mm, were selected as the fibre reinforcement. The selected fibre length cannot exceed the thickness of a tensile sample, which is 2.5 mm, to be entirely positioned in the through-thickness direction. Bioactive glass particles (45% SiO2, 24.5% CaO, 24.5% Na2O, and 6% P2O5), GL160 (Mo-Sci LLC, Rolla, MO, USA), with a diameter of 53 µm, were also selected as a reinforcement with the advantages of biointegration and tensile stiffness enhancement.

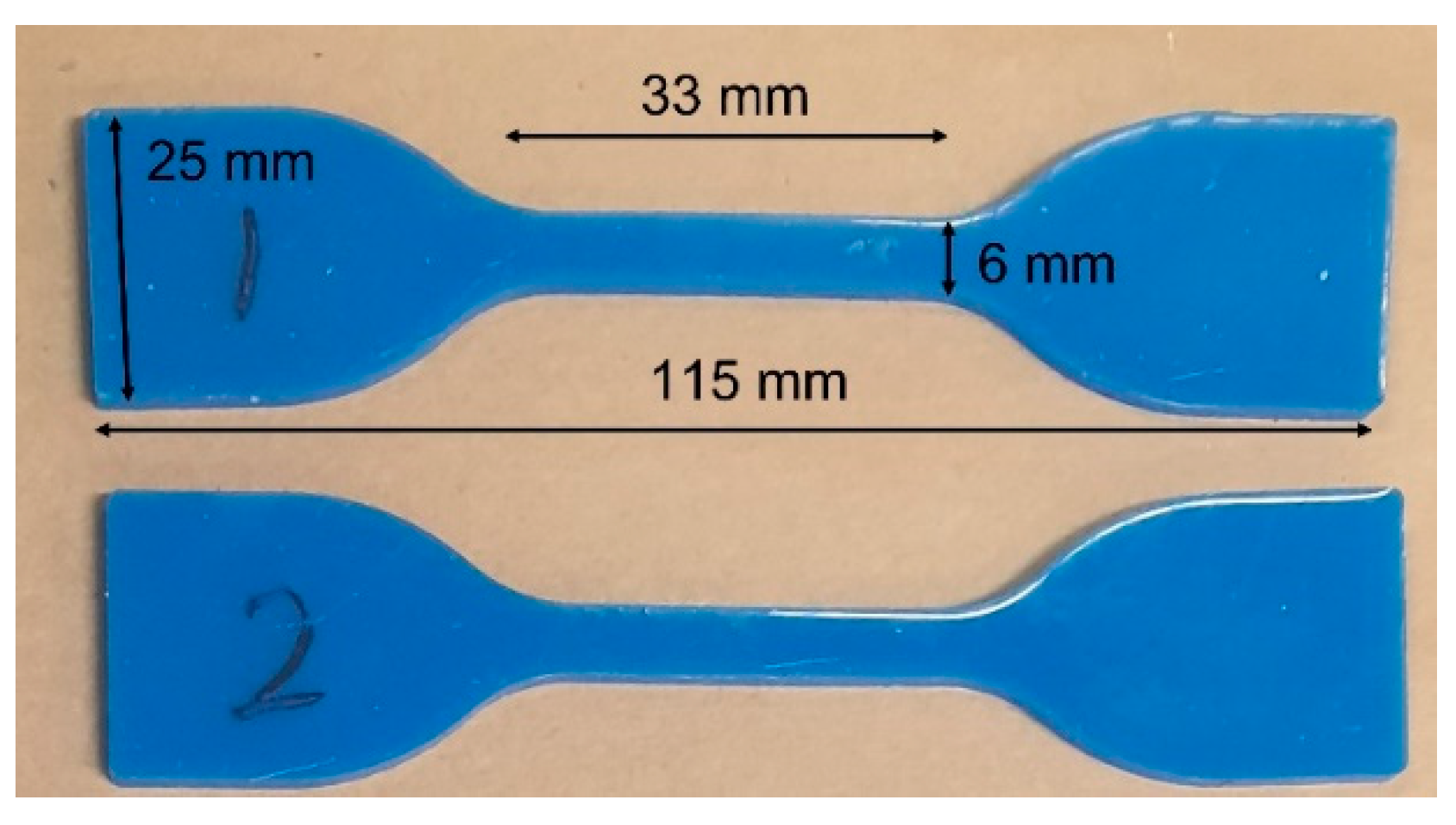

Initially, the platinum silicone and soft silicone were mixed manually in the selected ratio for five minutes. Short PE fibres and bioglass particles were added and mixed randomly with the silicone in a centrifugal mixer at 2000 rpm for five minutes. Subsequently, the composites were vacuum degassed until the residual air was expelled. The skin simulants were then processed using compression moulding and cured for six hours at room temperature. The filler weight concentrations were 1% and 3% of the total weight of composite material. The geometry of the composite specimens is based on the ASTM D412 type-C standard, as shown in

Figure 1.

A uniaxial tensile test was conducted according to the ASTM D412 standard with five samples in each composite category by Instron 5569 machine at a strain rate of 0.012 s−1. Additionally, high friction grips were inserted to prevent the slipping of the soft specimens. The specimens were tested to failure, where the tensile strength and the failure strain were extracted. The stretch ratio (λ) was introduced by converting from the displacement and strain of the sample. Subsequently, the elastic modulus of the composites was determined by the slope of the stress-strain plot at the stretch ratio beyond 1.6.

The tensile properties of the composite skin simulants were compared to the human skin and the related skin simulants in the literature. This was intended to reflect the degree of proximity of the tensile properties between the skin simulants and the human biological skins for different applications.

3. Results

Three important tensile properties of platinum silicone and composite skin simulants, tensile strength, failure strain, and elastic modulus, are outlined in

Table 1. The composites reinforced with short PE fibres exhibit 9% and 11% tensile strength reductions at 1% and 3% of fibre weight fractions, respectively. Similarly, the silicone composites reinforced with bioglass particles show that their tensile strength decreases as the particle concentration increases.

The addition of inclusions in the present study contributes to the deterioration of failure strain for every sample with significant differences from the platinum silicone. Compared between the two types of inclusions, the silicone composite reinforced with short PE fibres suffers a greater failure strain decline than that of the composite with bioglass particles. While the failure strain reduction pattern of the composites with bioglass particles is linear, the failure strain of the composites reinforced with short PE fibres falls substantially at a 1% fibre weight concentration. This reduction rate starts to decrease as the fibre weight fraction grows. At 3% PE fibre concentration, the composite with PE fibres demonstrates a failure strain drop of 41% from the pure platinum silicone to the failure strain of 182%.

The elastic moduli of the composites reinforced with both reinforcement types enhance with the additive concentration. The greatest moduli enhancements of the composites with PE fibres and bioglass particles are 14% and 5% (13.9 and 12.8 MPa), respectively, from the platinum silicone at a 3% reinforcement composition. Importantly, the short PE fibres contribute to a greater elastic modulus of a composite than bioactive glass particles for all filler concentrations. Moreover, linear moduli increment relationships can be nearly observed in the composites integrated with bioglass particles.

4. Discussion

Fibre property and interfacial bonding are important factors in determining the load-carrying capability of a composite. During tensile loading, the load transfer from the silicone matrix to the fibres occurred through the interfaces between them. With the presence of the fibres, the silicone-based composite reinforced with short PE fibres demonstrated an increase in tensile stiffness. It also maintained the tensile strength within 10% of the platinum silicone despite the substantial reduction of the failure strain. Furthermore, the importance of interfacial bonding was considered by procuring short PE fibres with a high surface area of 8 m

2/gm. The surface area of the fibres is greater than textiles fibres with a similar diameter [

5].

Matrix or fibre failure was found to be the primary cause of the failure of the composites in the present study. The crack propagated from the edge of a specimen that possessed the highest stress until the material failed. The tear marks with a rough surface were observed. Nonetheless, the failure mode of the short fibre reinforced composite is very complex [

6].

Bioactive glass particles also restrained the movement of the silicone matrix leading to a failure strain reduction of the composites. Debonding of a particle creates a cavity that induces an extra stress raiser. Therefore, the tensile strength of a composite is dominated by the weakest path of a material [

7]. With the integration of particles, the particles prevent material crack growth that supports the strengthening of tensile properties. Contrarily, they generate stress concentrations that cause a negative contribution [

7]. The reduction of the tensile strength of the composites reinforced with bioactive glass particles also conforms to the literature [

8,

9], which reported the inverse relationship between the tensile strength of a composite and the particle concentration.

From the experimental results, since the short polyethylene fibres manifested significant tensile stiffness strengthening, the composite skin simulant reinforced with PE fibres improved the elastic modulus and reduced the failure strain more effectively than the composite integrated with bioactive glass particles.

Typical tensile strength in skin simulant materials is between 2 to 7 MPa [

10]. The reduction of the tensile strength of a silicone-based composite reinforced with particles can also be noticed in Haider et al. [

11]. In this study, the decline rate of the silicone-based composite integrated with 5% bioactive glass particles is similar to the tensile strength reduction rate of the silicone film reinforced with 5% Schott bioactive glass particles, as reported in Cohrs et al. [

4]. Moreover, the composite skin simulants demonstrate an identical tensile strength reduction relationship to the silicone-based composites reinforced with polyester powder [

11].

Tensile mechanical properties of the human skins in literature and the composite skin simulants are presented in

Table 2. The human skin properties in the literature were selected from an in-vitro study, which involves a process of removing the skin from a body for external tensile testing. Human skin has a wide range of tensile strength and elastic modulus varied with the location. The human scalp possesses inferior tensile properties to the human skin in the abdomen. Therefore, the human scalp region is the primary interest in this tensile characterisation for cranial injury and medical applications.

Silicone elastomers often possess prolonged failure strain due to their ductility, more than 500%. Their failure strains are significantly greater than those of the human skins, ranging between 37% to 207% [

12,

13,

14]. Due to the low ductility of fibres, the integration of fibres could reduce the failure strain of silicone. Accordingly, the results exhibited a 28% and 41% reduction in failure strain for the composites with 1% and 3% concentrations of short polyethylene fibres. Nonetheless, the composite material remained moderate failure strain excess compared to the human skin. Similarly, bioglass particles also contributed to a decline in failure strain of a material at a lower rate than that caused by the short PE fibres. Initially, tensile strength and elastic modulus of the platinum silicone were in the lower region of both these properties of the human scalps. With the reinforcement integration, the composites could also provide tensile strength well within the human scalp range. Moreover, the simulant material enhanced its elastic modulus and reduced the failure strain to better replicate the tensile properties of the human scalp, which leads to a more suitable human synthetic skin.

5. Conclusions

Short high-density polyethylene fibres and bioactive glass particles were selected as the reinforcements for silicone elastomer to fabricate biocompatible composite skin simulants that possess similar fibre structures and tensile properties to the human scalp. Based on the characterisation of the tensile properties, the results demonstrated that short polyethylene fibre and bioactive glass additives enhanced the elastic moduli of the silicone matrix by approximately 5% and 2%, respectively, per each percentage of reinforcement integration. All composite skin simulants exhibited a slight decrease in tensile strength and a considerable reduction in failure strain.

Author Contributions

Conceptualisation, A.C. and R.D.; methodology, A.C.; formal analysis, A.C.; investigation, A.C.; resources, A.C.; data curation, A.C.; writing—original draft preparation, A.C.; writing—review and editing, A.C., R.D. and S.A.; visualisation, A.C.; supervision, R.D. and S.A. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank RMIT University for its administrative and technical support.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Taylor, S.C.; Kranioti, E.F. Cranial trauma in handgun executions: Experimental data using polyurethane proxies. Forensic Sci. Int. 2018, 282, 157–167. [Google Scholar] [CrossRef] [PubMed]

- Meunier, L.; Chagnon, G.; Favier, D.; Orgéas, L.; Vacher, P. Mechanical experimental characterisation and numerical modelling of an unfilled silicone rubber. Polym. Test. 2008, 27, 765–777. [Google Scholar] [CrossRef]

- Wenger, M.P.; Bozec, L.; Horton, M.A.; Mesquida, P. Mechanical Properties of Collagen Fibrils. Biophys. J. 2007, 93, 1255–1263. [Google Scholar] [CrossRef] [PubMed]

- Cohrs, N.H.; Schulz-Schönhagen, K.; Jenny, F.; Mohn, D.; Stark, W.J. Bioactive glass containing silicone composites for left ventricular assist device drivelines: Role of Bioglass 45S5® particle size on mechanical properties and cytocompatibility. J. Mater. Sci. 2017, 52, 9023–9038. [Google Scholar] [CrossRef]

- Ko, F.K.; Yang, H. Functional nanofibre: Enabling material for the next generations smart textiles. J. Fiber Bioeng. Inform. 2008, 1, 81–92. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Materials Science and Engineering: An Introduction; Wiley: New York, NY, USA, 2018. [Google Scholar]

- Fu, S.-Y.; Feng, X.-Q.; Lauke, B.; Mai, Y.-W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate–polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Ziraki, S.; Zebarjad, S.M.; Hadianfard, M.J. A study on the tensile properties of silicone rubber/polypropylene fibers/silica hybrid nanocomposites. J. Mech. Behav. Biomed. Mater. 2016, 57, 289–296. [Google Scholar] [CrossRef] [PubMed]

- Cohrs, N.H.; Schulz-Schönhagen, K.; Mohn, D.; Wolint, P.; Bürgisser, G.M.; Stark, W.J.; Buschmann, J. Modification of silicone elastomers with Bioglass 45S5® increases in ovo tissue biointegration. J. Biomed. Mater. Res. B Appl. Biomater. 2019, 107, 1180–1188. [Google Scholar] [CrossRef] [PubMed]

- Mitra, A.; Choudhary, S.; Garg, H. Maxillofacial prosthetic materials-an inclination towards silicones. J. Clin. Diagn. Res. JCDR 2014, 8, ZE08. [Google Scholar] [CrossRef] [PubMed]

- Haider, Y.M.; Abdullah, Z.S.; Jani, G.H.; Mokhtar, N. Evaluation of Some Mechanical Properties of a Maxillofacial Silicon Elastomer Reinforced with Polyester Powder. Int. J. Dent. 2019, 2019, 2948457. [Google Scholar] [CrossRef]

- Holzmann, H.; Korting, G.W.; Kobelt, D.; Vogel, H.G. Prüfung der mechanischen Eigenschaften von menschlicher Haut in Abhängigkeit von Alter und Geschlecht. Arch. Klin. Exp. Derm. 1971, 239, 355–367. [Google Scholar] [CrossRef] [PubMed]

- Jansen, L.; Rottier, P. Some Mechanical Properties of Human Abdominal Skin Measured on Excised Strips. Dermatology 1958, 117, 65–83. [Google Scholar] [CrossRef]

- Annaidh, A.N.; Bruyère-Garnier, K.; Destrade, M.; Gilchrist, M.D.; Otténio, M. Characterization of the anisotropic mechanical properties of excised human skin. J. Mech. Behav. Biomed. Mater. 2012, 5, 139–148. [Google Scholar] [CrossRef] [Green Version]

| Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).