Abstract

Pulque is an ethnic and traditional fermented beverage produced and consumed in Mexico; it is obtained from certain varieties of Agave, and its final alcohol content is around 4% to 7%. It is rich in protein and its carbohydrate content brings it a characteristic flavor; also, some probiotic bacteria are present in pulque. On the other hand, foams are a colloid system where the air bubble phase is dispersed in a continuous liquid phase. The foaming of liquids has been recognized as a method that shortens processes such as drying and preserves quality attributes. The present work studied the drainage kinetics of different pulque foams prepared with egg white in order to obtain a product suitable for further drying. Different egg white and pulque concentrations, as well as mixing times, were evaluated. The drainage volume was recorded and foam density was determined among different experiments. It was found that the lowest volume was drained when mixing for 20 min, and the lowest foam density was obtained when egg white and pulque were mixed in a 2:1 ratio. The drainage kinetics of the foam determines important information for its further use in a new product with pulque.

1. Introduction

Food foams are colloids and can be considered as biphasic systems, where air is dispersed in a continuous liquid. Structurally, when the volume fraction of air is high, bubbles are distorted in the form of polyhedra separated by thin liquid films. Three adjacent films intersect in a channel called the Plateau border, and the continuous phase is interconnected through a network of Plateau borders [1]. Common food foams are obtained by decreasing the superficial tension established between the air and the liquid, as well as through the employment of tensoactive agents like proteins.

Egg white is one of the most widely employed proteins in foam preparation because of its versatility in producing different foods. Food foam preparation involves the incorporation of a foaming agent into a liquid with high energy mixing. Different foods have been processed by foaming using egg white like figs [2], carrots [3], pineapple [4], and blueberries [5], among others.

Pulque is an ethnic and traditional beverage produced and consumed in some Mexican areas; it is a milky white, viscous, and slightly acidic beverage whit an alcoholic content around 4–7%, it is produced by the spontaneous fermentation of a sugar-rich extract obtained from some Agave plants (A. atrovirens, A. americana, A. salmiana, and A. mapisaga). Due to its nature and rapid fermentation, pulque can only be drunk in a short period of time or a bad flavor can be expected because of the excess of post-fermentation biochemical products [6].

Pulque has a unique flavor, which can be sour or slightly sweet; when liquid egg white (LEW) is employed as a foaming agent, the resulting foam can have an airy texture along with pulque’s bouquet. LEW will produce a more stable foam, while the pulque adds new flavors; therefore, a new flavor experience can be achieved, leading to culinary innovation. In addition, pulque is rich in nutrients, such as probiotics, vitamins, and amino acids.

Since pulque contains probiotics and vitamins and LEW is a good source of protein, the combination of the two ingredients can confer functional and health benefits on the final product. From another point of view, pulque is an ethnic and traditional beverage, and when combined with liquid egg white, an interesting connection between indigenous and modern ingredients can be highlighted.

The objective of this work was to study the effect of using egg white as a foaming agent at different concentrations and mixing times on the stability of pulque foams which can be employed in further works.

2. Materials and Methods

2.1. Materials

Pulque was purchased in a local pulqueria located in Acultzingo, Veracruz, Mexico, and transported in a stainless steel container at 6 °C to the laboratory; liquid egg white protein was obtained from a local supermarket.

2.2. Foam Preparation

Liquid egg white (LEW) as a foaming agent was mixed with pulque using a kitchen-type mixer (KitchenAid Mixer) at maximum speed. The design of the experiment consisted of pulque (P) and LEW mixed at concentrations of 1:1, 1:2, and 2:1 (v/v), respectively; the mixing times evaluated were 2, 5, 10, 15, and 20 min.

2.3. Drainage Kinetics

Each pulque foam (500 mL) was placed in a Buchner funnel and the liquid, drained by gravity, was collected in a graduated cylinder. The volume of liquid drained V (mL) was measured as a function of time (t) during 120 min. The maximum volume of liquid drained Vmax (final or equilibrium value) was estimated by letting the foam drain over-night and measuring the volume of liquid drained after 24 h [1,2].

Equation (1) was employed for data adjustment as reported by [1]

where k and n are the drainage constant and the apparent kinetic order of the drainage process, respectively.

V(t) = Vmax tn /(k + tn)

2.4. Foam Density

Foam density (FD) was measured in terms of the mass–volume ratio [7]. Each pulque foam was poured into a standard measuring cylinder without trapping and avoiding the breakage of the foam structure, and then the weight and volume were recorded. The density of pulque foams was calculated using Equation (2), where m represents the mass of the pulque foam in grams and V1 stands for the volume of that foam in cm3.

FD (g/cm3) = m/V1

2.5. Data Modeling and Analysis

Drainage curves and data analysis were performed by employing CuveExpertBasic V2.2.3. The results represent the mean value of three replicates and their standard deviation.

3. Results and Discussion

Foams are important in certain foods such as mousse, milk, and others, as well as being a way to increase the surface area of liquid products. Therefore, a better understanding of their stability has been a key factor in the food industry.

To obtain a foam, high-pressure homogenization or whipping is necessary; however, the system tends to be unstable due to the relaxation of the interfaces. Foam stability is related to foam density and the velocity of the liquid drained when the foam loses its structure. Foam drainage is the first step of foam instability and is the result of the drainage of the liquid through the thin films between the air bubbles. The second step is when bubble coalescence is observed due to the merging of two or more small bubbles, resulting in a phase separation.

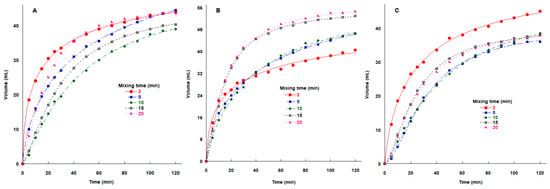

Figure 1A–C show the experimental data fitted to Equation (1) for the different foams prepared. It can be observed that, at the beginning of the process, the drainage velocity is fast and then it starts to decrease until it reaches a pseudo-equilibrium, which represents the maximum liquid volume that can be drained.

Figure 1.

Fitted drainage volume curves of pulque foam prepared with a ratio 1:1 (A), 1:2 (B), and 2:1 (C) LEW:P at different mixing times.

In an ideal case, the pulque bubbles have a dodecahedral shape and they are separated by thin films where a radial pressure gradient in the film from its center to the outer periphery exists, which induces the liquid drainage from the thin film to the Plateau border. Also, gravity influences the drainage on the interconnected network of Plateau borders and, as a result, the foam could be drier at the top [8].

As expected, drainage decreases at higher LEW concentrations (Figure 1) and this could be related to protein denaturalization and adsorption in the liquid–air interface. A similar behavior was reported in foams prepared with apple juice and egg white protein [1].

According to Narsimhan and Xiang [8], globular proteins, like those contained in LEW, provide higher foam stability because of their capacity to form cohesive, elastic, and viscous films. It has also been observed that the formation of a multilayer of globular proteins increases when higher protein concentrations are employed, providing good stability to the foams.

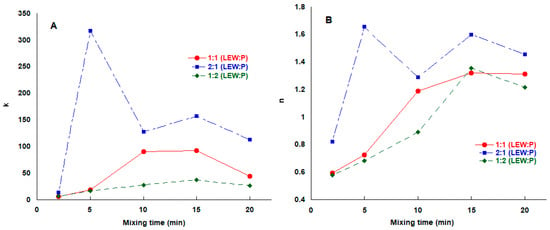

As can be seen in Figure 2A,B, at a mixing time of 5 min, the highest “k” value was observed in a pulque foam prepared in a 2:1 ratio; that value indicates that when preparing the foam under those conditions, less volume will be drained at a higher speed when compared with the other treatments. In Figure 2B, as the LEW concentration increases, the drainage curves have a more pronounced sigmoidal shape and the “n” values rise (n ≈ 1.6). This could be related to a higher amount protein rich in globular proteins, which are responsible for foam formation. The maximum “n” value was observed when LEW and pulque were mixed in a 2:1 ratio during 5 min, indicating a more sigmoidal shape of the curve during the first few minutes of the process.

Figure 2.

Values of k (A) and n (B) obtained for pulque foams prepared with different LEW:P ratios at different mixing times.

Raharitsifa et al. [1] studied the effect of 0.5% egg white protein on apple juice foams and reported values of n and k of 0.546 and 206, respectively. They argued that when n values were close to unity, the rate of drainage was initially rapid and then slowed down at longer mixing times.

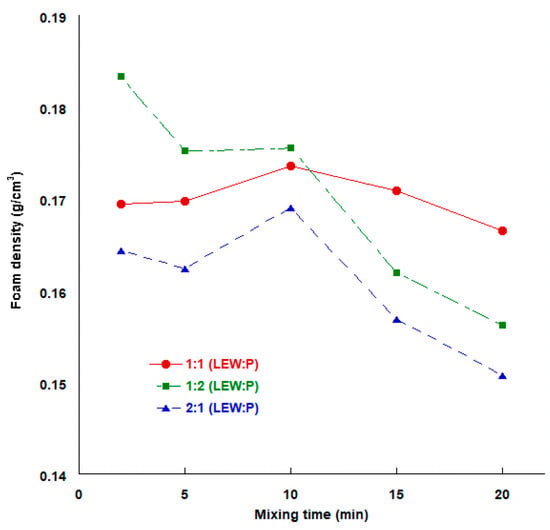

The changes in foam density at different LEW:P ratios and mixing times are shown in Figure 3. When the LEW concentration and mixing time increased, the foams were less dense; this can could be due to greater air incorporation. At 10 min of mixing, all treatments showed a slight foam density increase; one possible explanation is that a small amount of liquid is released from the foam but it is reincorporated immediately due to the continuous mixing process, so that as the mixing process continues, foam density decreases again. Ng and Sulaiman [9] observed a similar behavior in beetroot foams; they reported that an increase in the concentration of the foaming agent caused a decrease in the foam density of the beetroot samples, which could be due to an expansion in foam volume. In another study, Arshdeep et al. [10] reported that foam density depends strictly on the foaming agent. They found that soy protein isolate produced foams with higher density than pea protein isolate; according to them, the lower density values could be due to the lower dispensability of soy protein in the food material, resulting in a smaller air–liquid interface.

Figure 3.

Pulque foam densities prepared with different LEW:P ratios at different mixing times.

The study of foam density and the concentration of the foaming agent is relevant since it impacts further use. For example, in the foam-mat drying of peach puree, Arshdeep et al. [10] reported that the drying time was inversely affected by the concentration of the foaming agents employed; with an increase in foaming agent concentration, a significant decrease in drying time was observed.

Shaari et al. [4] studied the foam-mat drying of pineapple using different egg albumin concentrations. Their results showed that a higher foaming material concentration led to a lower foam density, a higher retention of phenolic compounds, and lower drying times; therefore, a lower degradation of important biomolecules by heat was observed.

In general terms, a low foam density can help to remove water faster from the samples during drying as it provides a large surface area; therefore, pulque foams prepared with a 2:1 LEW/pulque ratio can be easily dried.

In Figure 3, a high foam density can also be observed at a low concentration of LEW, which can be caused by the restriction of movement of the egg protein from the aqueous phase towards the liquid–air interface. Foam densities around 0.2–0.6 g/cm3 have been found in foamed materials and vary according to the foaming agent and mixing time [4,9].

In this work, when compared with the other treatments, in the 2:1 (LEW:P) foam formed using a mixing time of 20 min, a low volume of liquid drained was observed (38 mL) and the lowest foam density was obtained (0.152 g/cm3), so an optimal foam structure can be produced for further processing.

4. Conclusions

In general terms, pulque foams were stable, showing a characteristic structure. The stability of the foam increased with higher concentrations of foaming agents, while liquid egg white drainage decreased as its concentration increased. This was noticeable in the foams prepared with a 2:1 ratio (LEW/pulque) and mixed for 20 min.

Higher concentrations and longer mixing times of liquid egg white resulted in less dense pulque foams, which is desirable for further processing.

By studying the behavior of pulque foam stability, additional processing technologies for new product development can be assessed while also highlighting local gastronomic raw materials.

Author Contributions

Conceptualization, C.A.O.-S. and N.G.-C.; methodology, E.H.-A.; validation, A.F.-L.; formal analysis, U.R.M.-C.; investigation, A.F.-L.; resources, A.F.-L.; data curation, N.G.-C. and C.A.O.-S.; writing—original draft preparation, C.A.O.-S.; writing—review and editing, C.A.O.-S. and N.G.-C.; visualization, U.R.M.-C.; supervision, A.F.-L. and E.H.-A.; project administration, C.A.O.-S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data is available upon reasonable request.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Raharitsifa, N.; Genovese, D.B.; Ratti, C. Characterization of Apple Juice Foams for Foam-mat Drying Prepared with Egg White Protein and Methylcellulose. J. Food Sci. 2006, 71, E142–E151. [Google Scholar] [CrossRef]

- Varhan, E.; Elmas, F.; Koç, M. Foam mat drying of fig fruit: Optimization of foam composition and physicochemical properties of fig powder. J. Food Process. Eng. 2019, 42, e13022. [Google Scholar] [CrossRef]

- Fardiyah, Q.; Rumhayati, B.; Khotimah, Y.H. The Effect of Temperature and Concentration of Foaming Agent to the β-Carotene Content in Product Derived from Carrots. IOP Conf. Ser. Mater. Sci. Eng. 2018, 299, 012008. [Google Scholar] [CrossRef]

- Shaari, N.A.; Sulaiman, R.; Rahman, R.A.; Bakar, J. Production of pineapple fruit (Ananas comosus) powder using foam mat drying: Effect of whipping time and egg albumen concentration. J. Food Process. Preserv. 2018, 42, e13467. [Google Scholar] [CrossRef]

- Darniadi, S.; Ifie, I.; Ho, P.; Murray, B.S. Evaluation of total monomeric anthocyanin, total phenolic content and individual anthocyanins of foam-mat freeze-dried and spray-dried blueberry powder. J. Food Meas. Charact. 2019, 13, 1599–1606. [Google Scholar] [CrossRef]

- Escalante, A.; Soto, D.R.L.; Gutiérrez, J.E.V.; Giles-Gómez, M.; Bolívar, F.; López-Munguía, A. Pulque, a Traditional Mexican Alcoholic Fermented Beverage: Historical, Microbiological, and Technical Aspects. Front. Microbiol. 2016, 7, 1026. [Google Scholar] [CrossRef]

- Li, T.S.; Sulaiman, R.; Rukayadi, Y.; Ramli, S. Effect of gum Arabic concentrations on foam properties, drying kinetics and physicochemical properties of foam mat drying of cantaloupe. Food Hydrocoll. 2021, 116, 106492. [Google Scholar] [CrossRef]

- Narsimhan, G.; Xiang, N. Role of Proteins on Formation, Drainage, and Stability of Liquid Food Foams. Annu. Rev. Food Sci. Technol. 2018, 9, 45–63. [Google Scholar] [CrossRef] [PubMed]

- Ng, M.L.; Sulaiman, R. Development of beetroot (Beta vulgaris) powder using foam mat drying. LWT 2018, 88, 80–86. [Google Scholar] [CrossRef]

- Brar, A.S.; Kaur, P.; Kaur, G.; Subramanian, J.; Kumar, D.; Singh, A. Optimization of Process Parameters for Foam-Mat Drying of Peaches. Int. J. Fruit Sci. 2020, 20, S1495–S1518. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).