Abstract

Lime-based repair mortars, plasters, and renders are widely utilized in the conservation of traditional buildings. Historically, considerable emphasis has been placed on ensuring that new repair mortars are aesthetically compatible with existing historic materials. However, comparatively less focus has been placed on ensuring hygric compatibility, which is critical to maintaining the moisture equilibrium of traditional masonry walls and preventing moisture accumulation caused by repair interventions. The FabTrads project examined the hygrothermal properties of newly fabricated quicklime mortars, prepared with binder-to-aggregate ratios of 1:2 and 1:4, alongside a range of historic lime-based mortars, plasters, and renders, sourced from buildings across Ireland. This paper presents a comparative analysis of their hygric behaviour. Experimental results indicate that the capillary absorption of the fabricated mortars correlates well with their historic counterparts. Both fabricated mortars exhibited vapour diffusion resistance factors within the range of the historic samples, albeit towards the higher end. Hygrothermal simulations of vapour and liquid water transport revealed that the moisture behaviour of the fabricated mortars is largely within the range of performance of their historic counterparts. Relative humidity was slightly elevated for the fabricated mortars in the models concerning vapour transfer. Notwithstanding this, the findings provide a reassuring indication that the hygric performance of fabricated quicklime mortars is comparable with that of traditional lime-based materials, supporting their appropriate use in conservation practices without adversely affecting the moisture dynamics of the building fabric.

1. Introduction

The conservation of historic buildings requires a careful balance between preserving historic character and original materials and meeting contemporary building performance expectations of low operational energy use and indoor thermal comfort. As traditional buildings are increasingly subject to adaptive reuse and thermal upgrading, such interventions must be undertaken with sensitivity to ensure that the architectural integrity and historic significance of the building fabric are not compromised.

Before the widespread adoption of industrial cement production in the 19th century, the majority of masonry structures across Europe and beyond were constructed using lime-based materials. Lime remained in widespread use well into the mid-20th century, and its revival in the late 20th century continues today, driven both by its suitability in conservation practice and its appeal as a more sustainable alternative to Portland cement. Traditionally, lime was employed in a range of building applications, including mortars for bedding and pointing masonry units, internal plasters, and external renders. These materials played a critical role in defining the physical and hygric performance of building envelopes, with Banfill (2021) estimating that the bedding and jointing mortar may account for up to 40% of the volume of the wall [1]. In contrast to modern cementitious materials, lime mortars are distinguished by their high capillary absorption and vapour permeability, properties that enable the movement of liquid water and water vapour through the building fabric [2]. This moisture managing ability within solid wall constructions helps to prevent the accumulation of damp and promotes natural drying, which is particularly important in buildings lacking damp-proof courses and other modern moisture control systems.

In recognition of these properties, the repair of historic buildings demands a “like-for-like” material strategy, where the repair materials should closely match the physical and chemical behaviour of the original fabric. The use of incompatible materials, especially impermeable cement mortars, renders, and plasters, has been shown to disrupt moisture dynamics, trapping water within walls and accelerating decay of the adjacent masonry [2]. Significant research and conservation practice have focused on replicating the composition of historic mortars, using microscopy and chemical analysis to provide detail on the type of binder, aggregates, grading curves, and recognition of characteristic inclusions such as lime lumps, fuel ash, shell fragments, or brick dust [3,4,5]. However, there has been less emphasis on establishing the compatibility of the hygric performance of modern replicas. In practice, efforts to simulate traditional formulations often stop at compositional analysis, with assumptions made that the correct ingredients and mixing methods will result in equivalent in-service behaviour. However, this overlooks the complex interactions between the material microstructure and environmental performance, particularly regarding hygrothermal properties, which are less frequently tested in the field. Researchers have investigated various properties related directly or indirectly to hygric behaviour—for example, porosity [6,7,8] and capillary absorption [9] for historic and repair mortars. However, the full range of hygric properties, including sorption capacity, permeability, and capillary absorption, is rarely analysed comprehensively for historic mortars, which is essential for forming an accurate understanding.

Quicklime mortars, also referred to as “hot-mixed” mortars, have gained popularity due to their historical authenticity and their potential to replicate the qualities of the original mortars more faithfully than pre-hydrated lime putty-based alternatives [10,11]. Quicklime mortars are prepared by mixing unslaked lime (calcium oxide) with aggregates and water, often directly on site. This initiates an exothermic slaking reaction that produces calcium hydroxide, while binding to the aggregate particles. This method of preparation, widely used historically, is thought to result in mortars with improved workability with less water added, resulting in a positive influence on the mechanical and water-related performance of the mortars [12].

Since the complete set of hygrothermal properties of historic lime-based mortars, plasters, and renders has rarely been comprehensively measured [1], a thorough comparison between these properties and those of newly fabricated restoration mortars has yet to be fully conducted. The FabTrads Project was initiated to explore the hygrothermal performance of traditional building materials. For this, the hygrothermal properties of a range of historic mortars, renders, and plasters were measured, along with two newly fabricated quicklime mortars as used in the conservation industry in Ireland today. This paper investigates and compares the hygric performance of these newly fabricated restoration mortars compared with their historic counterparts tested within the same study. The historic mortars are investigated in more detail in another paper by the authors [13].

This paper presents and compares key hygrothermal properties, sorption capacity, vapour diffusion resistance, and capillary absorption, selected for their critical role in hygrothermal modelling. While other material characteristics such as compressive strength, flexural resistance, setting times, and shrinkage behaviour are important for structural integrity and aesthetics, they are beyond the scope of this study. The primary focus here is to evaluate whether modern fabricated quicklime mortars provide functional equivalence to their historic counterparts in terms of moisture behaviour, thereby ensuring that the long-term moisture dynamics of repaired walls remain unchanged and can mitigate the risk of moisture accumulation and subsequent decay in historic structures.

2. Materials and Methodology

2.1. Materials

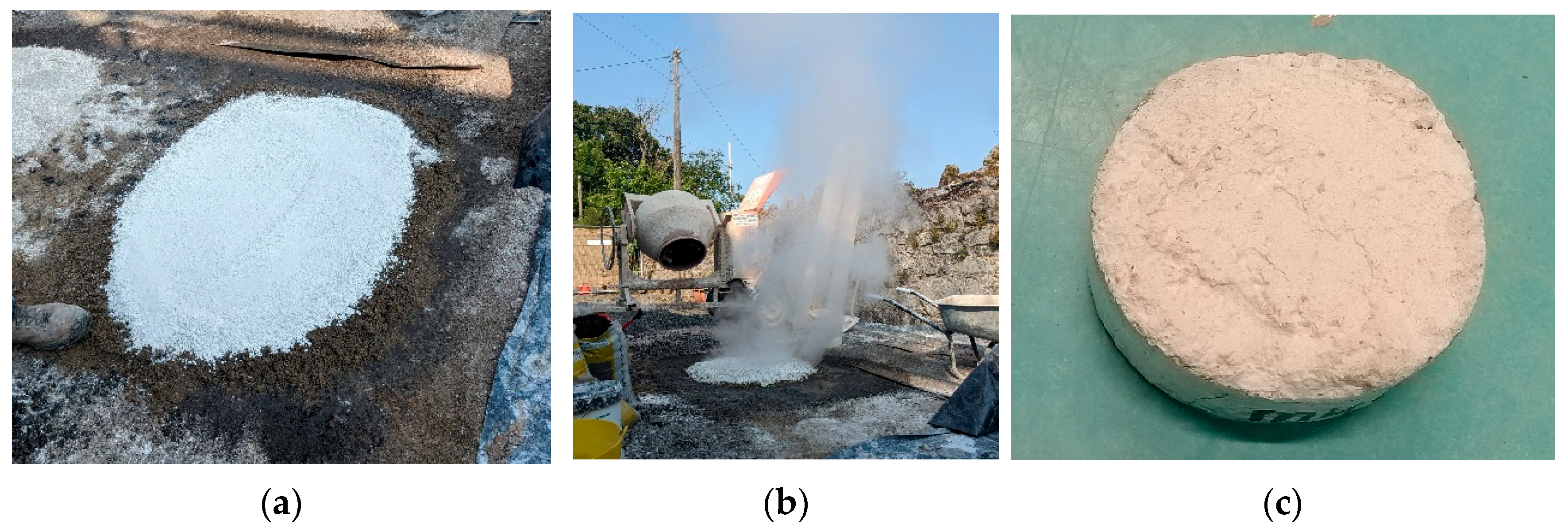

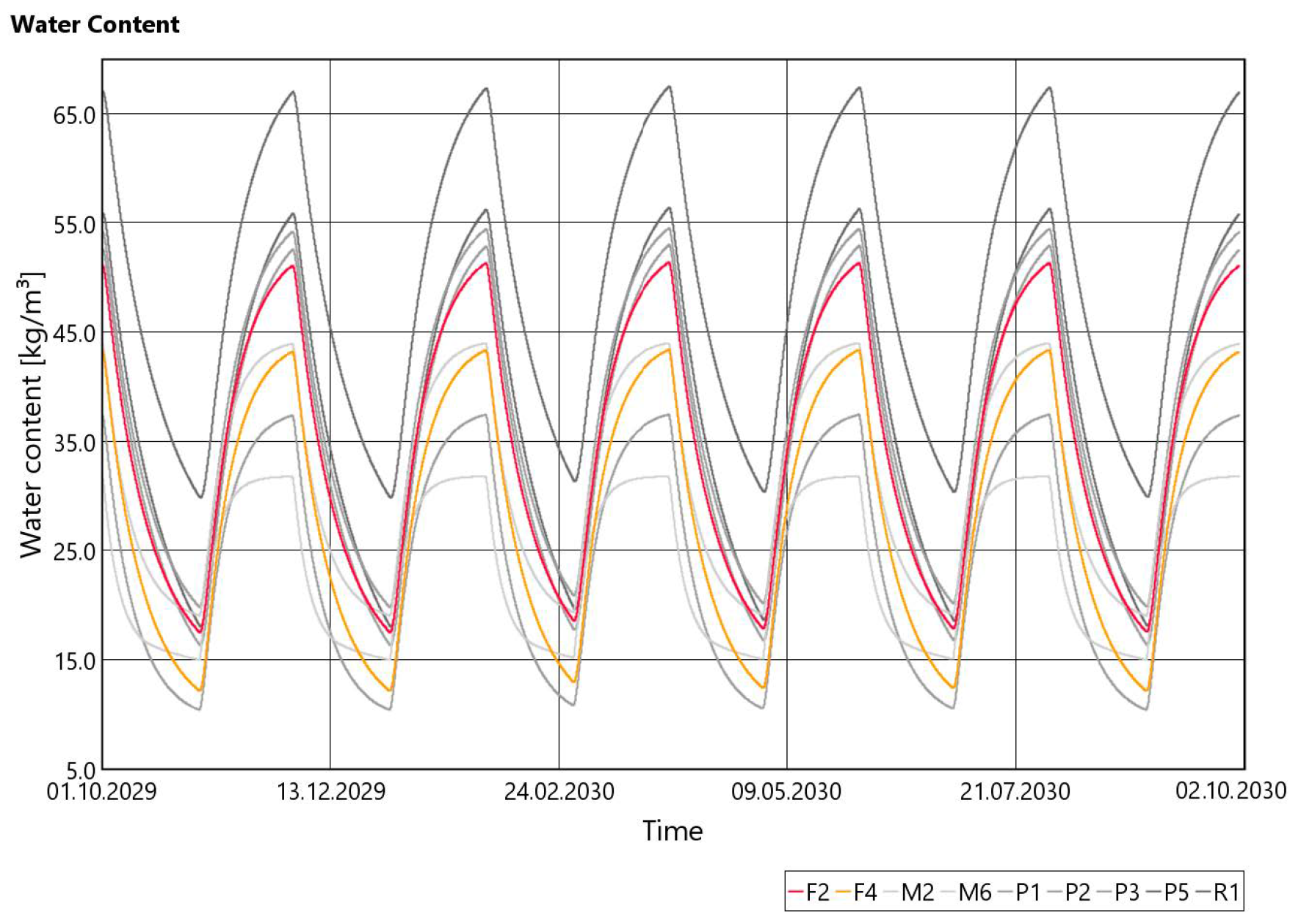

Two replica fabricated mortars were made on site at a historic building currently undergoing conservation works. The formulation was based on the guidance of expert lime craftsman Damien Condon (Co. Tipperary, Ireland) and reflects methods routinely employed in traditional conservation practice, as shown in Figure 1. Two binder-to-aggregate ratios (by volume of the unslaked lime) were prepared: 1:2 and 1:4. While a 1:3 ratio is more commonly used in practice, the inclusion of 1:4 aimed to explore the influence of binder content on the hygrothermal behaviour of the mortar. It is important to note that as quicklime (CaO) slakes to calcium hydroxide (Ca(OH)2), it approximately doubles in volume. As a result, the effective binder-to-aggregate ratios shift to approximately 1:1 and 1:2 by volume, respectively. The mortars were produced using a traditional hot-mix method, involving a layer slaking technique of alternative layers of quicklime and damp Wexford beach pebble sand aggregate, with watering of each layer. A small amount (10% by volume) of wood ash was added as a pozzolanic component. This inclusion reflects the likely presence of such impurities in historic mortars, where limestone was burned in fuel-rich kilns with the fuel ash acting as a pozzolan and contributing to mortar hydraulicity. After slaking, the mixture was transferred to a mechanical mixer, where additional water was added to achieve a workable consistency. The mortar was placed in cylindrical moulds (~100 mm diameter and a thickness of 50 mm–120 mm) and cured in the laboratory for 3 months prior to commencement of testing. It is likely that full carbonation was not achieved during this time frame. Banfill (2021) observes that carbonation typically increases the density of lime mortar, with hot-mix mortar showing increases of over 5%; however, in some cases, the difference is not significant [1]. These samples are referred to as the fabricated samples (F2 and F4 for 1:2 and 1:4 binder: aggregate ratios, respectively).

Figure 1.

Preparation of quicklime samples: (a) layers of quicklime and sand aggregate, (b) release of steam during exothermic reaction, and (c) cylindrical samples.

Seven lime-based mortars, plasters, and renders were sourced from historic buildings (constructed before 1900) in Ireland that were undergoing renovation, as shown in Figure 2 and listed in Table 1. Some samples were manually extracted from the building using hand tools, while others were collected from construction waste. The samples were irregularly shaped and often friable, making it difficult to cut them into uniform pieces. These samples are referred to as the historic samples with mortar (M) from between masonry units; plaster (P) from the internal side of the wall, and render (R) from the external side of the wall.

Figure 2.

Plaster on a rubble stone wall during removal (a). Removal of sections of lath and plaster (b).

Table 1.

List of fabricated and historic plaster samples.

2.2. Laboratory Testing

The fabricated samples followed the established testing methodology, which was also adopted for a range of traditional bricks and stones used in masonry construction in Ireland [13] as set out in Table 2. The samples were stored in the laboratory (RH 40–60%) prior to testing. Six fabricated samples were tested for each test.

Table 2.

Overview of testing methodology.

Adaptations were made to accommodate the irregular shapes of the historic samples. These adaptations are indicated in the table with an asterisk (*). The historic samples exhibited irregular cross-sectional areas and variable thicknesses, which inevitably introduced some measurement uncertainties. However, this approach remains valuable, as it is the only viable method for assessing actual historic materials, given that cutting or reshaping these friable samples is not feasible without causing damage or altering their hygric properties. A minimum of four historic samples were tested for each test, with up to six samples included where suitable material was available.

2.3. Hygrothermal Modelling

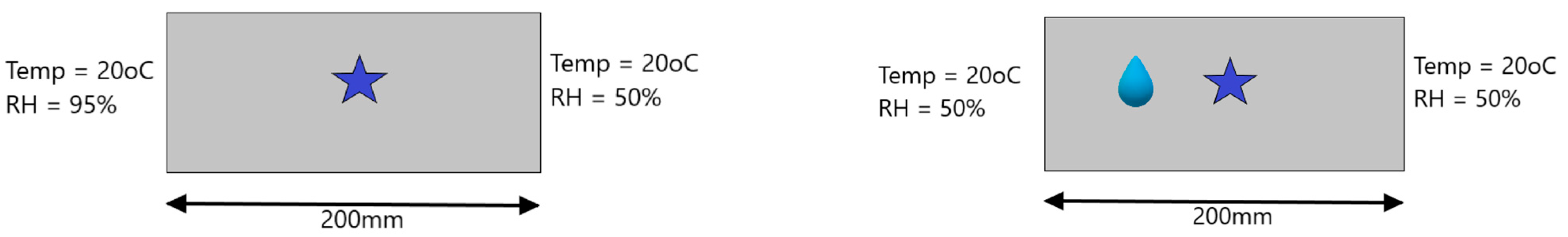

Two hygrothermal simulations were carried out using WUFI Pro 7 (Fraunhofer IBP, Stuttgart—Vaihingen, Germany) to investigate water vapour and liquid water transfer in the mortars, as shown in Figure 3. The simulations were undertaken in steady-state climates on both sides of a hypothetical “wall” of solid mortar. The simulations do not fully represent real-life conditions, as they examine moisture behaviour solely within the mortar, without accounting for the complexities of the masonry. The simulations were run with the fabricated mortars (F2 and F4) and all tested historic lime-based mortars, plasters, and renders. The material properties measured during experimental testing (Section 3.1 and Table 3) were used to create material files.

Figure 3.

Simulations 1 and 2, showing a solid piece of mortar; the star indicates the location of the results (RH or moisture content) output in Figures 8–11. Note: The star is the location of measurement and the droplet is the location of added moisture source.

Table 3.

Overview of the hygrothermal properties of materials used in the simulations.

Simulation 1 focuses on vapour transfer, with water vapour moving from a high relative humidity (RH) environment (95%) on the left-hand side (LHS) to a lower RH environment (50%) on the right-hand side (RHS). The results for water content and RH are investigated at the centre of the sample, marked at 100 mm with a star in Figure 3. Simulation 2 examines liquid water transfer under conditions of a constant RH on both sides. Liquid water is introduced at 50 mm from the external side (left-hand side) by way of a user-defined constant monthly moisture load of 10,000 g/m2, applied intermittently for one month at a time in alternating months, to simulate wetting and drying cycles in the WUFI model. This is a high moisture load and was selected to investigated moisture conditions that would result in a high RH (~75–95%) in the material, which is a RH value commonly seen in buildings at risk of material decay.

3. Results

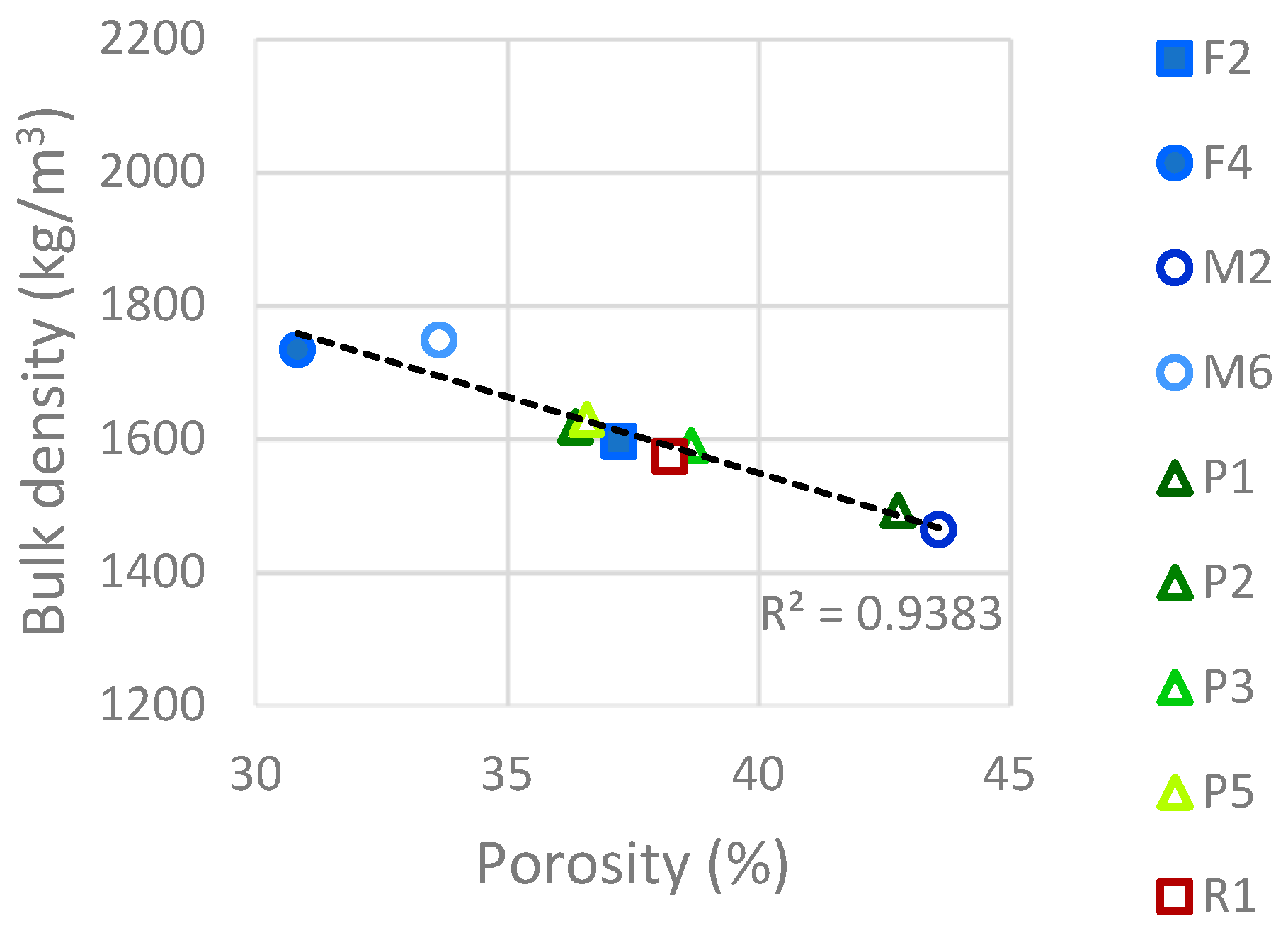

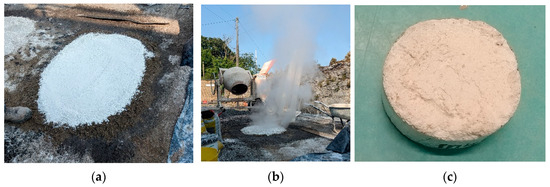

3.1. Bulk Density and Open Porosity

The relationship between open porosity and bulk density for the samples (Figure 4) follows an expected linear pattern due to employing the shared measurement method (R2 = 0.94). The fabricated mortars (F2, F4) are closely aligned to the linear relationship between increasing porosity and decreasing bulk density. F2 (1:2 binder/aggregate ratio) is positioned in the mid-range of the samples tested, while F4 (1:4 binder/aggregate ratio) has lower porosity. This contradicts the findings of Margalha et al. 2011, who found that compositions with a lower binder content produce mortars with greater open porosity [12]. This highlights the likely impact of other variables on binder performance, such as aggregate grading, water content, etc.

Figure 4.

Relationship between bulk density and open porosity.

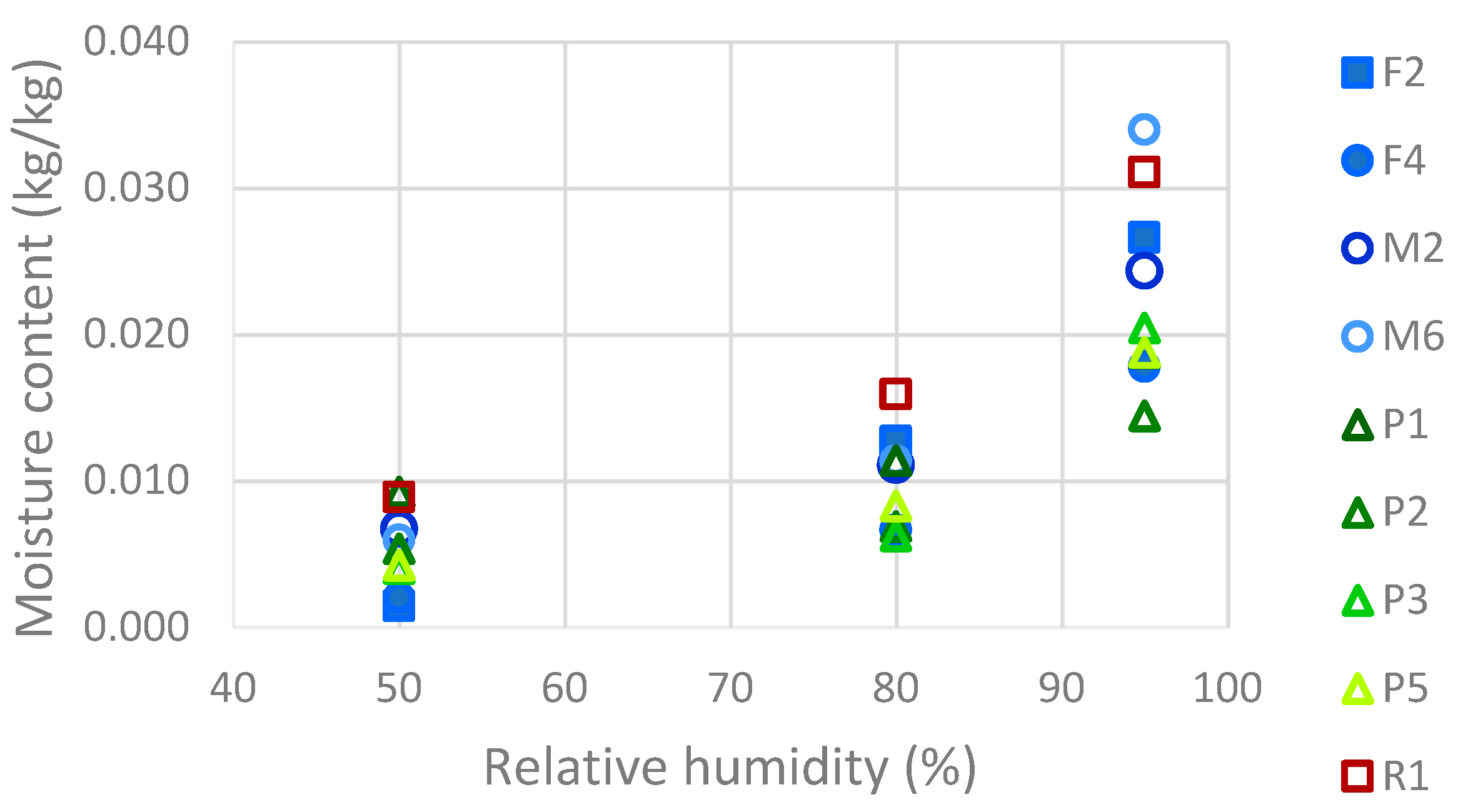

3.2. Sorption Capacity

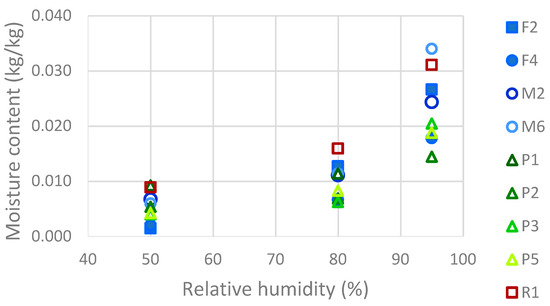

Moisture adsorption was assessed at three relative humidity (RH) levels, namely 50%, 80%, and 95%, as shown in Figure 5. As observed in similar studies involving bricks and stones, no direct correlation was found between open porosity and overall moisture uptake [20,21]. This supports the understanding that moisture adsorption capacity is strongly influenced by pore size distribution, with open porosity having a lesser effect.

Figure 5.

Water content at different relative humidities—50%, 80%, and 95%.

The fabricated mortars (F2 and F4) demonstrate moisture contents that fall within the observed range for the other historic materials at both 80% and 95% RH. However, at 50% RH, both F2 and F4 exhibit slightly lower moisture content than their historic counterparts. Such behaviour might indicate a lower tendency to adsorb moisture in low-RH environments, though it is not established if this is a fundamental material characteristic or confined to this sample set, and is possibly due to the incomplete carbonation of the samples at the time of testing. Since relative humidities of 50% do not pose a hygric risk, the values at 80% and 95% RH are of greater relevance.

3.3. Capillary Absorption

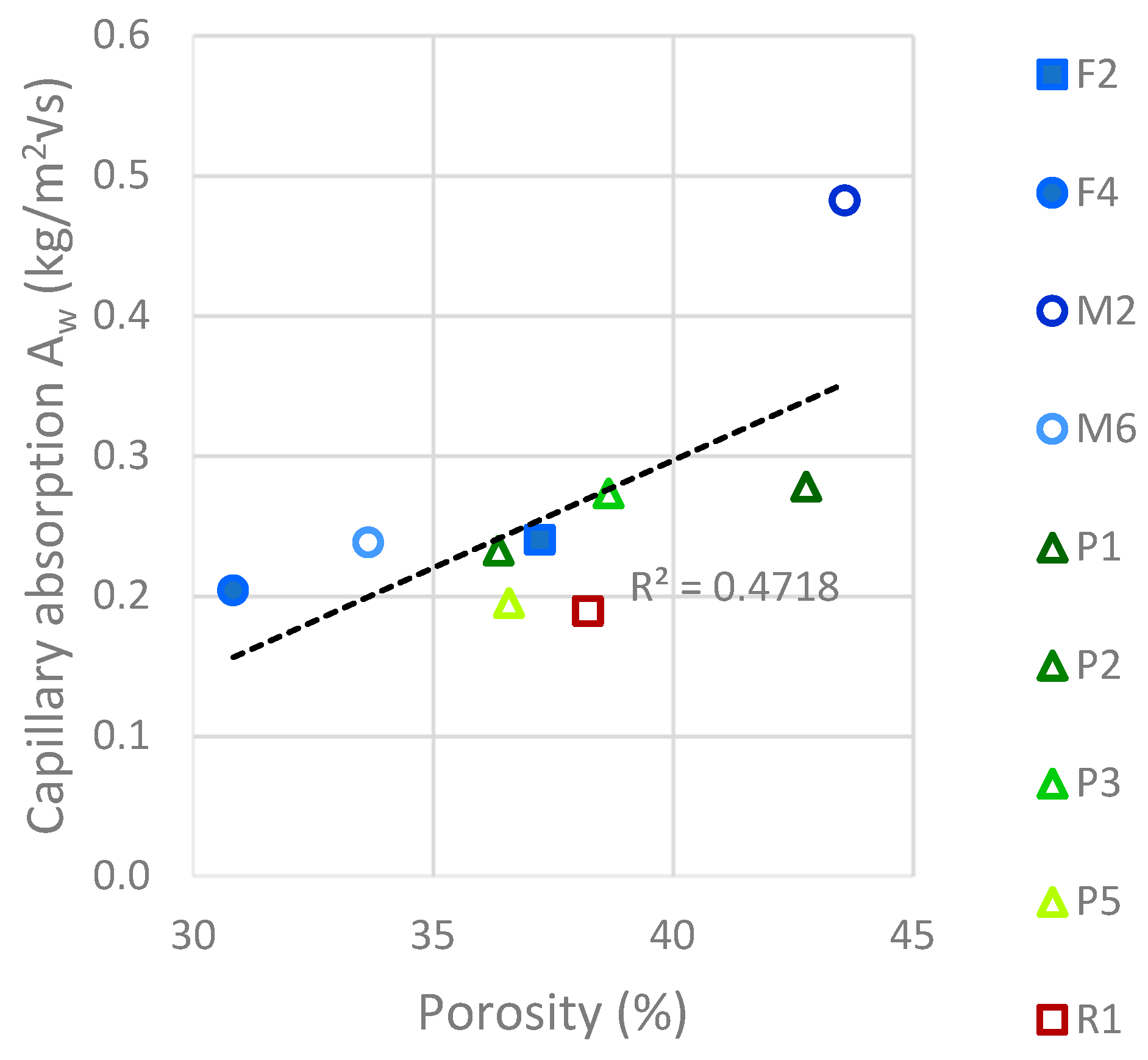

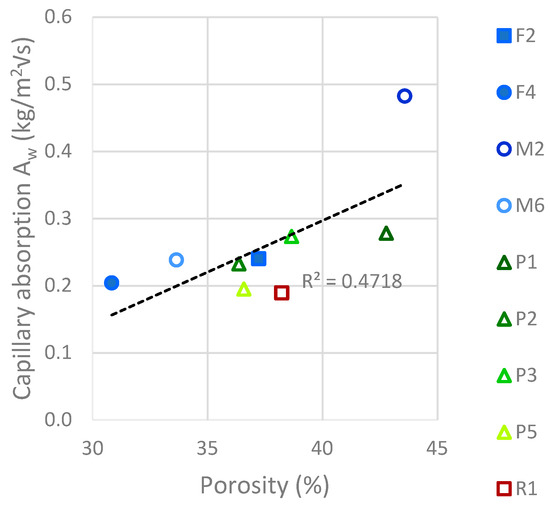

Capillary absorption was evaluated by plotting the water absorption coefficient (Aw) against total porosity (%) for all material samples, as shown in Figure 6. A weak correlation was observed (R2 = 0.47), indicating that while porosity influences capillary uptake, it does not fully explain the variability, again highlighting the importance of pore structure and connectivity.

Figure 6.

Relationship between open porosity and capillary absorption.

The fabricated mortar F2 lies near the centre of the distribution, closely aligned with the trend line, suggesting typical capillary behaviour relative to its porosity. F4 has only a slightly lower capillary absorption despite its lower porosity. Similarly, Arrizzi and Cultrone (2014) found that mortars with the highest lime content absorbed the highest amount of water by capillarity [22]. M2 exhibits high capillary absorption, attributed to its high porosity, which likely results from poor compaction within a rubble stone wall, unlike the denser mortar joints in a brick wall or the more consolidated nature of plaster or render.

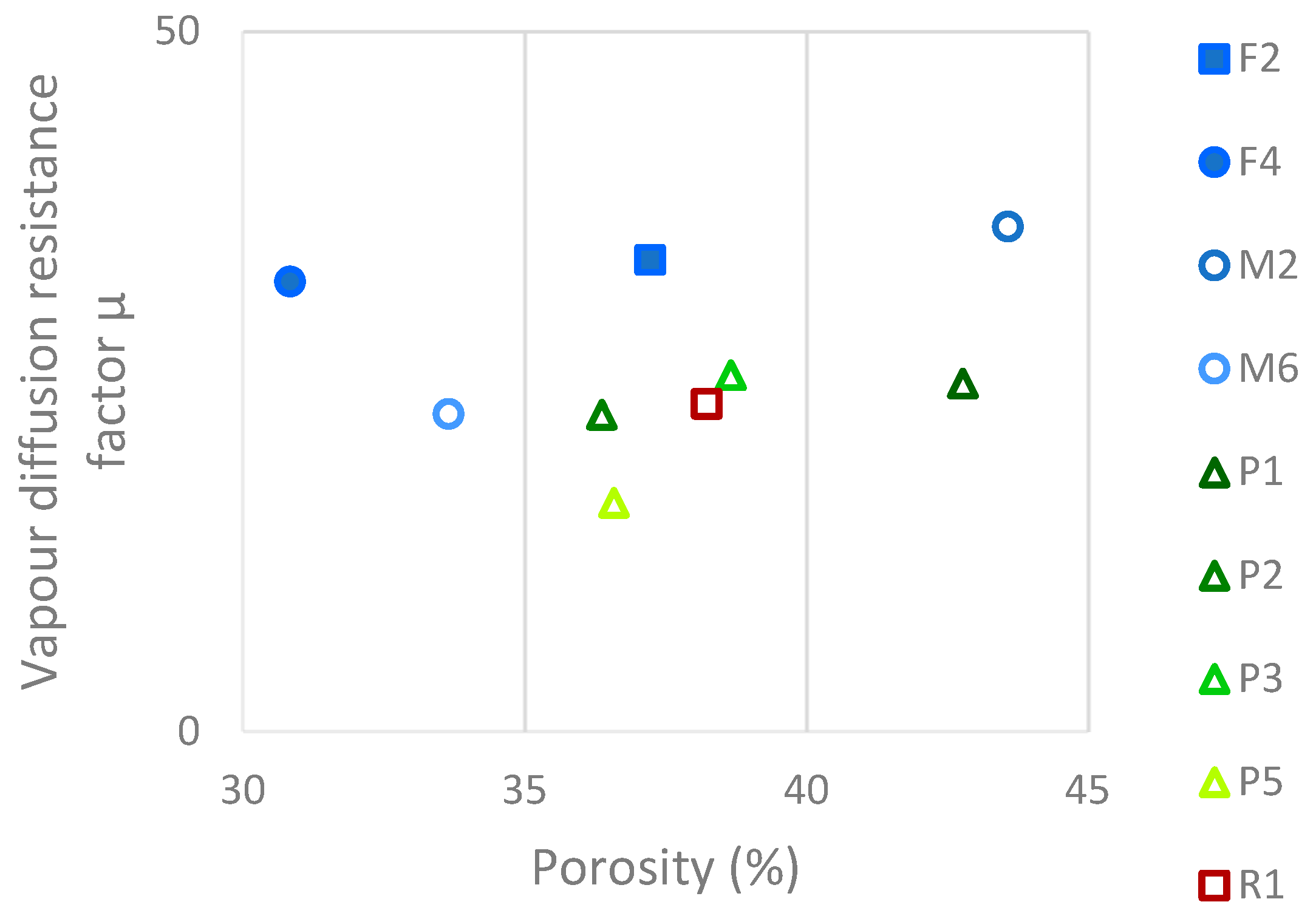

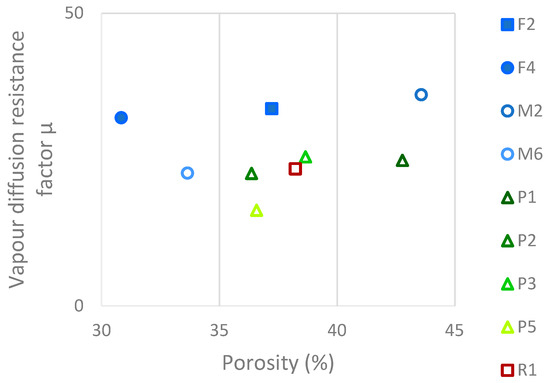

3.4. Vapour Diffusion Resistance

Vapour diffusion resistance (μ) was plotted against total porosity (%) for all material samples as shown in Figure 7. No relationship was observed between open porosity and vapour diffusion resistance, while analyses of brick and stone materials have shown an increase in vapour permeability at higher open porosity [20,21]. The lack of correlation observed here aligns with Arrizzi and Cultrone (2014), who also found that vapour diffusion in their mortar samples was not influenced by porosity or aggregate content [22]. The fabricated mortars (F2 and F4) exhibited vapour diffusion resistance values toward the higher end of the range compared with their historic counterparts, with only M2 showing higher values. Increased vapour diffusion resistance is undesirable for lime-based materials, as it indicates a restriction in vapour movement through the material. However, the results are relatively closely grouped, suggesting that the slightly elevated vapour resistance of the fabricated mortars are unlikely to significantly affect moisture content in wall constructions. Additionally, differences in measurement methods, using thicker and fully intact fabricated mortars compared with irregular historic samples, may have contributed to the variation in the values observed.

Figure 7.

Relationship between open porosity and vapour resistance.

4. Discussion and Hygrothermal Modelling

The experimental results highlight the individual characteristics of the fabricated plasters compared with historic materials and are set out in Table 3. However, they do not fully reflect the complex interactions among hygrothermal processes. Unlike standalone tests, which isolate characteristics such as vapour permeability, capillary absorption, and sorption capacity, hygrothermal simulations can capture the dynamic and interdependent nature of moisture storage and transfer processes within building materials.

To investigate these complex interactions, two distinct and abstract one-dimensional simulation models of a pure lime-based material were developed using WUFI Pro 7, as described in Section 2.3, to separately investigate the impact of a relative humidity gradient and intermittent water inputs While an almost limitless range of configurations is theoretically possible, encompassing variations in sample thickness, moisture inputs, and measurement locations, the parameters selected for this study were chosen for their simplicity and for producing elevated relative humidity levels, which pose particular risks for traditional buildings. Together, these simulations offer a more integrated understanding of mortar’s performance, particularly in relation to moisture dynamics within the building envelope. The historic lime-based materials are not separated according to function (mortar, plaster, and render), which has been investigated in another paper by the authors [13].

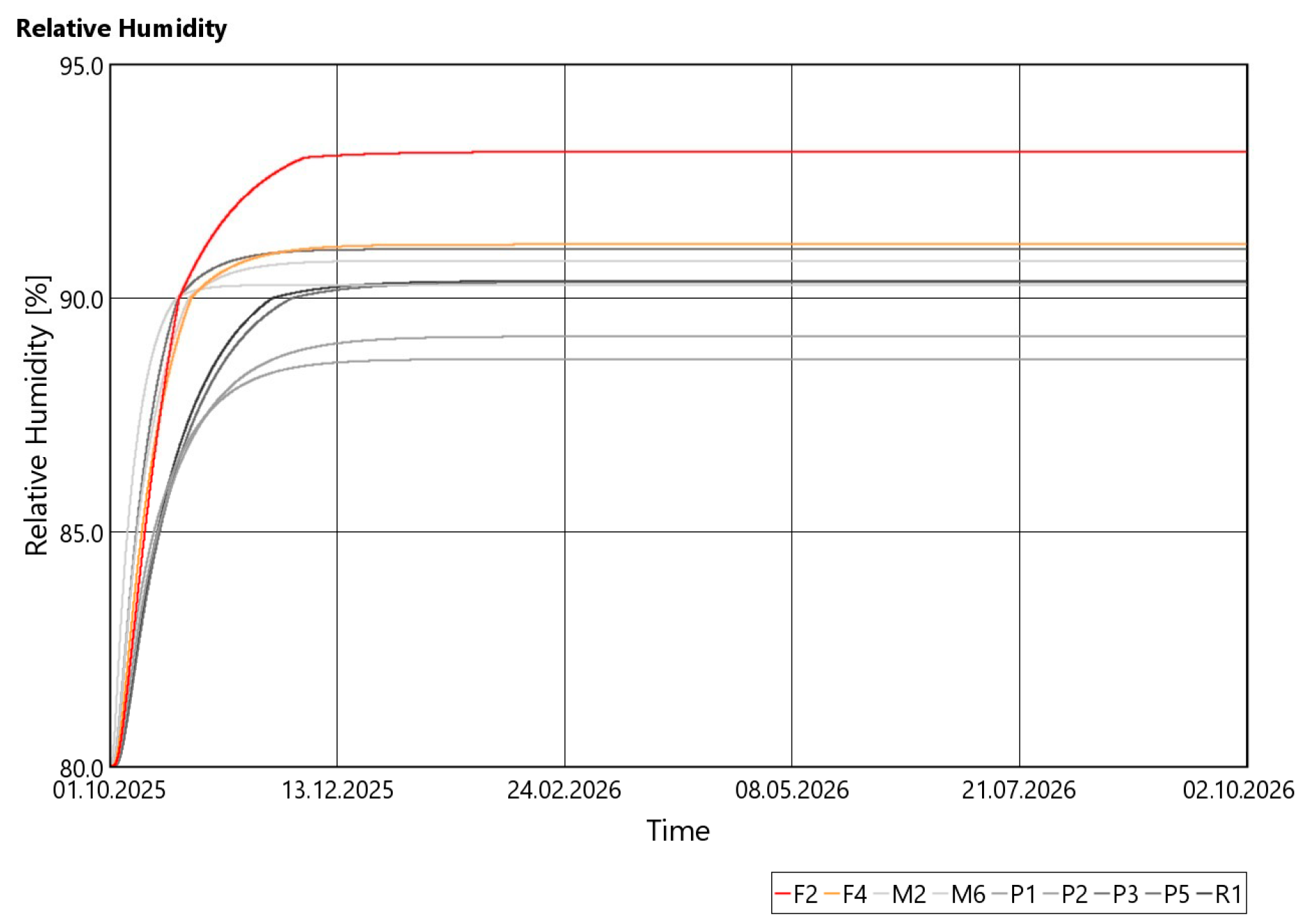

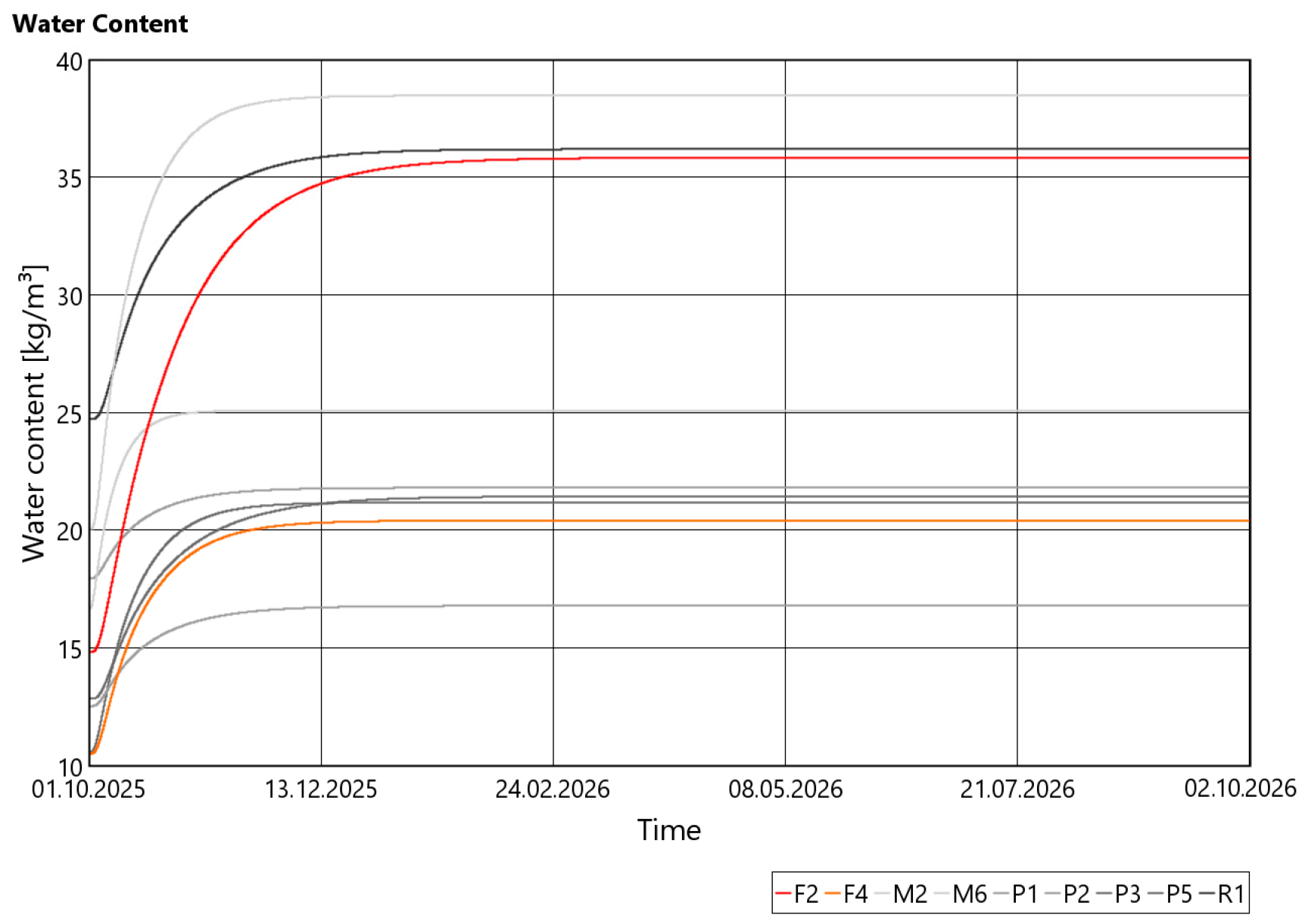

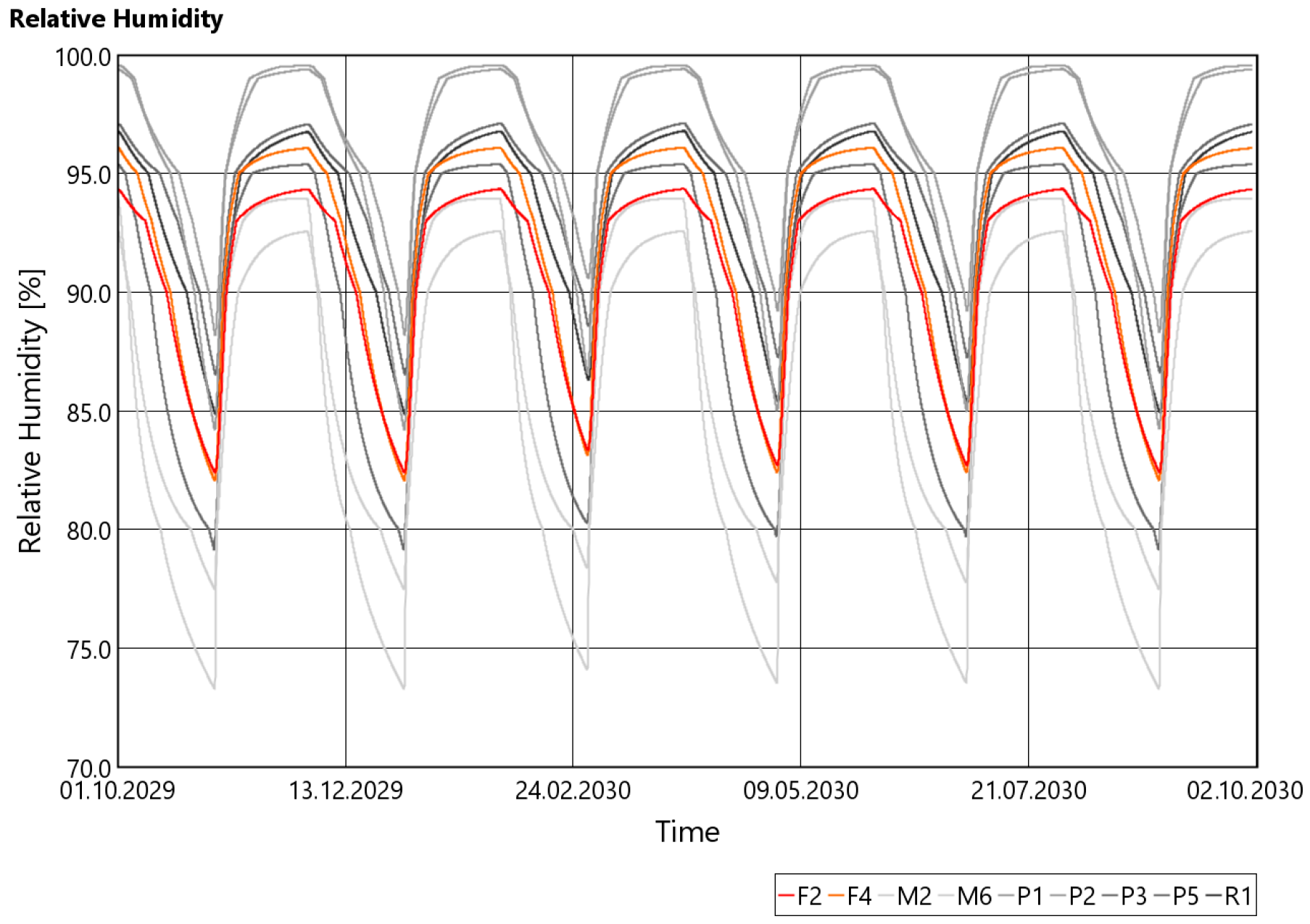

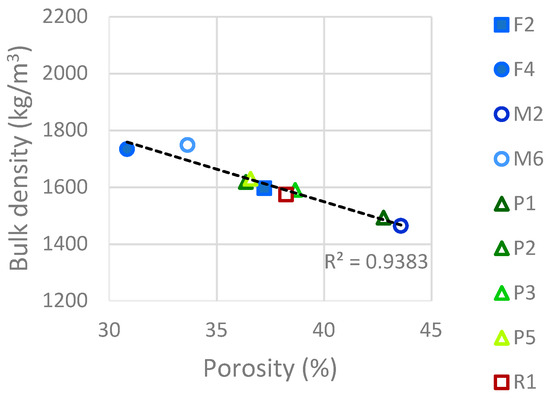

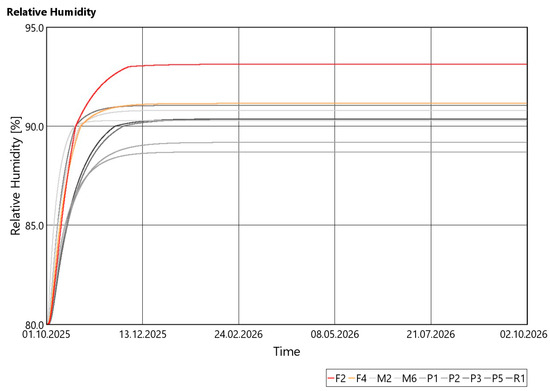

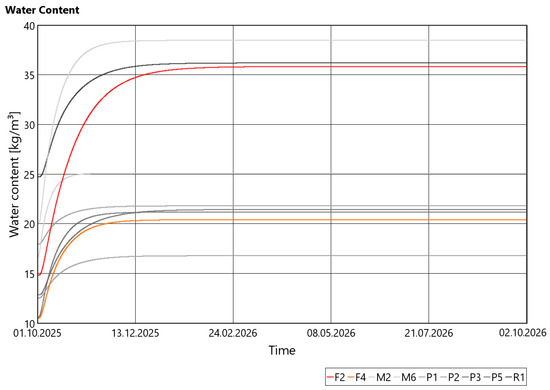

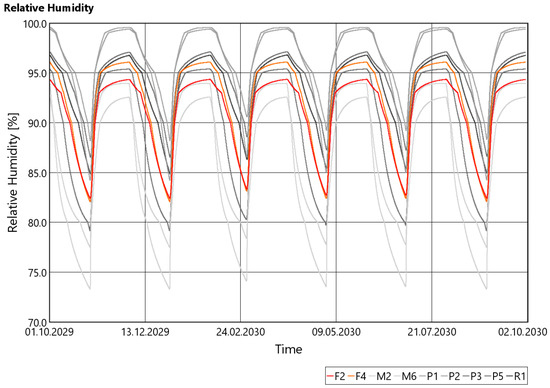

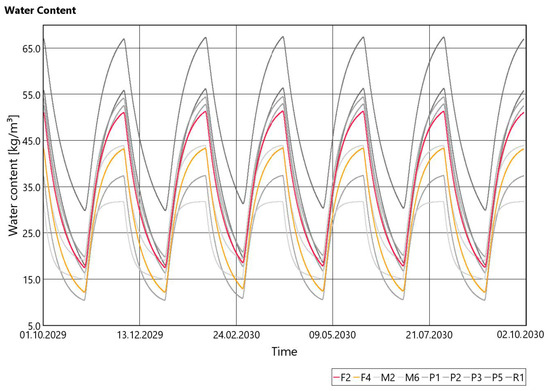

The simulations show RH and moisture content during vapour transfer from high to low RH environment (Simulation 1, Figure 8 and Figure 9) and due to intermittent introduction of liquid water (Simulation 2, Figure 10 and Figure 11). The graphs display relative humidity (RH) and moisture content at the location indicated in Figure 3 and demonstrate that the fabricated mortars (represented by red and orange lines) generally fall within the range exhibited by their historic counterparts (depicted in grey). This alignment suggests comparable hygric behaviour across both groups of materials. The only notable deviation occurs in RH for Simulation 1, where the values for mortar F2 slightly exceeds the historic range (Figure 8), likely due to the higher vapour resistance observed experimentally. This is notable but is likely to be of lesser significance in real-life wall assemblies, where both vapour and liquid water transfer mechanisms occur simultaneously.

Figure 8.

Simulation 1—RH, with fabricated mortar highlighted (F2, red; F4, orange) and historic mortars, plasters, and renders in grey, collectively illustrating the performance spectrum of the historic dataset.

Figure 9.

Simulation 1—water content, with fabricated mortar highlighted (F2, red; F4, orange) and historic mortars, plasters, and renders in grey, collectively illustrating the performance spectrum of the historic dataset.

Figure 10.

Simulation 2—RH, with fabricated mortars highlighted (F2, red; F4, orange) and historic mortars, plasters, and renders in grey, collectively illustrating the performance spectrum of the historic dataset.

Figure 11.

Simulation 2—Water content, with fabricated mortars highlighted (F2, red; F4, orange) and historic mortars, plasters, and renders in grey, collectively illustrating the performance spectrum of the historic dataset.

The behaviour of F4 largely falls within the mid-range of the historic mortars. In fact, F4’s performance aligns more closely with the historic samples than F2, despite F2 having experimentally measured porostiy and capillary absorption more closely resembling those of the historic materials. This illustrates the complex interplay of moisture storage and trasfer mechanisms, and highlights issues with comparisons of individual parameters in isolation.

In conservation, it is crucial that repair materials are hygrically compatible with historic fabric to prevent moisture-related damage. The simulation results indicate that the fabricated mortars exhibit moisture content and relative humidity levels comparable with those of historic mortars, based on the specific modelling inputs used. This supports the idea that the fabricated mortars are suitable for conservation applications, as their hygrothermal behaviour aligns with the traditional materials. As a result, they can help preserve the original moisture dynamics within walls, reducing risks such as trapped moisture and material decay. In practice, it is essential that any proposed fabricated mortar closely replicates the specific hygric behaviour of the existing historic materials in a given building.

These findings support the importance of a performance-based approach to conservation. Compositional and manufacturing replication of historic mortars can never be fully captured, and therefore, functional compatibility, including in the hygric properties, is crucial to collectively define material performance. This approach validates selecting repair mortars based on measurable performance in addition to historic binder ratios or aggregate compositions, framing material selection in terms of actual moisture dynamics and durability outcomes. It is essential that hygrothermal testing of actual historic lime-based mortars, plasters, and renders continues, both to expand the available dataset and to deepen our understanding of their moisture-related behaviour. Such testing allows for more accurate characterization of historic materials’ performance, informs the development of compatible repair mortars, and supports a performance-based approach to conservation. Increasing the body of empirical data will also help account for variability in historic construction practices and provide a more robust foundation for designing interventions that minimize the risk of moisture-related deterioration. Overall, this research demonstrates that aligning repair mortars with historic hygric performance, rather than purely compositional fidelity, offers a robust and flexible strategy for heritage conservation.

5. Conclusions

The hygric performance of repair lime mortars is critical to ensuring compatibility with existing historic masonry. Other important properties, such as mechanical behaviour, shrinkage, and durability, also play an important role but were not considered in this research. Laboratory investigations revealed that the fabricated quicklime mortar F2 falls within the mid-range of density and porosity observed in historic mortars, while F4 exhibits lower porosity and correspondingly higher density. Both fabricated mortars demonstrated mid-range capillary absorption, despite the lower porosity of F4. Adsorption and vapour permeability did not correlate to open porosity, and both fabricated mortars showed low adsorption at 50% RH but aligned more closely with historic mortars at higher relative humidity levels (80% and 95%). Vapour diffusion resistance for both F2 and F4 was at the higher end of the historic range.

Hygrothermal modelling of vapour and liquid water transfer provides a more holistic understanding of moisture dynamics. In two modelled scenarios, fabricated mortars displayed moisture behaviour comparable with that of historic mortars, with the exception of F2 having slightly elevated RH in the vapour transfer model (Simulation 1). While this modelling does not aim to represent the complexity of real-world moisture conditions in walls, it supports the conclusion that the fabricated mortars are likely to perform in a similar range to historic materials, thereby minimizing the risk of moisture-related deterioration.

This paper emphasizes the importance of mortar and render matching, not only in terms of aesthetic and compositional compatibility but also with regard to hygric performance. Ensuring that the repair materials align with the moisture transport characteristics of historic substrates is critical to preserving the long-term durability and performance of heritage structures.

Author Contributions

Conceptualization, R.W. and A.H.; methodology, R.W. and A.H.; formal analysis, R.W. and A.H.; investigation, R.W. and A.H.; resources, C.E.P. and O.K.; writing—original draft preparation, R.W.; writing—review and editing, R.W. and A.H.; supervision, O.K.; project administration, O.K.; funding acquisition, C.E.P. and O.K. All authors have read and agreed to the published version of the manuscript.

Funding

This research, conducted as part of the FabTrads project, is supported by the Sustainable Energy Authority of Ireland under Grant Agreement 21/RDD/729.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

During the preparation of this work the authors used ChatGPT-4 in order to improve readability of the text. After using this tool/service, the authors reviewed and edited the content as needed and take full responsibility for the content of the publication.

Acknowledgments

The work in the laboratory was facilitated by Damian Condron (sample preparation) and technical staff at the Civil Engineering Laboratory, University College Dublin, namely John Ryan, Maria Judge, and David Morgan. Thanks to Ciaran McNally and Civil Engineering at UCD for the long-term use of space and facilities.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Banfill, P.F.G. Hygrothermal Simulation of Building Performance: Data for Scottish Masonry Materials. Mater. Struct. 2021, 54, 167. [Google Scholar] [CrossRef]

- Torney, C.; Snow, J. Lime Mortars in Traditional Buildings: Short Guide 6; Technical Report; Historic Environment: Edinburgh, Scotland, 2014; Available online: https://www.researchgate.net/publication/264563855 (accessed on 27 August 2025).

- Pavía, S.; Bolton, J. Stone, Brick and Mortar: Historical Use, Decay and Conservation of Building Materials in Ireland; Wordwell: Bray, Co.: Wicklow, Ireland, 1999; ISBN 9781869857325. [Google Scholar]

- Hughes, J.J.; Cuthbert, S.J. The Petrography and Microstructure of Medieval Lime Mortars from the West of Scotland: Implications for the Formulation of Repair and Replacement Mortars. Mater. Struct. 2000, 33, 594–600. [Google Scholar] [CrossRef]

- Bartz, W.; Rogóż, J.; Rogal, R.; Cupa, A.; Szroeder, P. Characterization of Historical Lime Plasters by Combined Non-Destructive and Destructive Tests: The Case of the Sgraffito in Bożnów (SW Poland). Constr. Build. Mater. 2012, 30, 439–446. [Google Scholar] [CrossRef]

- Groot, C.J.W.P.; Ashall, G.J.; Hughes, J.J.; Bartos, P.J.M. Characterisation of Old Mortars with Respect to Their Repair: A State of the Art. In Characterisation of Old Mortars with Respect to Their Repair; RILEM Publications SARL: Bagneux, France, 2007; Chapter 1; pp. 1–8. [Google Scholar]

- Schueremans, L.; Cizer, Ö.; Janssens, E.; Serré, G.; Van Balen, K. Characterization of Repair Mortars for the Assessment of Their Compatibility in Restoration Projects: Research and Practice. Constr. Build. Mater. 2011, 25, 4338–4350. [Google Scholar] [CrossRef]

- Kurugöl, S.; Güleç, A. Physico-Chemical, Petrographic, and Mechanical Characteristics of Lime Mortars in Historic Yoros Castle (Turkey). Int. J. Archit. Herit. 2011, 6, 322–341. [Google Scholar] [CrossRef]

- Misiewicz, J.; Kwiatkowska, L.; Ballai, G. Investigation of Mortars from Historical Monuments of North-East Poland and Assessment of Compatibility between Historic and Restoration Mortars. Constr. Build. Mater. 2025, 474, 141075. [Google Scholar] [CrossRef]

- Copsey, N. Historic Literature Review of Traditional Lime Mortars: Excerpts from Historic Texts 160 BC—1955; Historic Environment: Edinburgh, Scotland, 2019. [Google Scholar]

- Pavía, S.; Veiga, R.; Hughes, J.; Pesce, G.; Valek, J.; Alvarez, J.I.; Faria, P.; Padovnik, A. RILEM TC 277-LHS Report: How Hot Are Hot-Lime-Mixed Mortars? A Review. Mater. Struct. 2023, 56, 87. [Google Scholar] [CrossRef]

- Margalha, M.G.L.B.; Veiga, M.D.R.; Santos Silva, A.; de Brito, J. Traditional Methods of Mortar Preparation: The Hot Lime Mix Method. Cem. Concr. Compos. 2011, 33, 796–804. [Google Scholar] [CrossRef]

- Walker, R.; Hofheinz, A.; Engel Purcell, C.; Kinnane, O. The Hygrothermal Properties and Behaviour of Historic Mortars, Plasters and Renders. Constr. Build. Mater. 2025, in press. [Google Scholar]

- EN1936:2006; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. iTeh, Inc.: Newark, DE, USA, 2006.

- ISO 12570:2000; Hygrothermal Performance of Building Materials and Products—Determination of Moisture Content by Drying at Elevated Temperature. ISO: Geneva, Switzerland, 2000.

- ISO 12571:2021; Hygrothermal Performance of Building Materials and Products—Determination of Hygroscopic Sorption Properties. ISO: Geneva, Switzerland, 2021.

- EN 13755:2008; Natural Stone Test Methods—Determination of Water Absorption at Atmospheric Pressure. iTeh, Inc.: Newark, DE, USA, 2008.

- ISO 15148:2002; Hygrothermal Performance of Building Materials and Products—Determination of Water Absorption Coefficient by Partial Immersion. ISO: Geneva, Switzerland, 2002.

- ISO 12572:2016; Hygrothermal Performance of Building Materials and Products—Determination of Water Vapour Transmission Properties—Cup Method. ISO: Geneva, Switzerland, 2016.

- Hofheinz, A.; Walker, R.; Engel Purcell, C.; Kinnane, O. The Hygrothermal Properties of Historic Bricks: Case Study of Traditional Brick Construction Material in Ireland. Build. Environ. 2025, 270, 112491. [Google Scholar] [CrossRef]

- Hofheinz, A.; Walker, R.; Engel Purcell, C.; Kinnane, O. The Hygrothermal Properties of Stone Used in Traditional Construction: A Western European Case Study. Build. Environ. 2025, 276, 112855. [Google Scholar] [CrossRef]

- Arrizzi, A.; Cultrone, G. The Water Transfer Properties and Drying Shrinkage of Aerial Lime-Based Mortars: An Assessment of Their Quality as Repair Rendering Materials. Environ. Earth Sci. 2014, 71, 1699–1710. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).