Abstract

This study investigates the effects of Ti addition on the microstructures, melting temperature ranges, thermal expansion behavior, high-temperature creep and oxidation resistances of an equimolar CoNiFeCr alloy of a foundry origin. The addition of 1.5 wt.% Ti does not really change the single-phase state of the reference quaternary alloy but induces a significant decrease in the melting start and melting end temperatures. The thermal expansion coefficient is slightly lowered. The creep resistance at 1100 °C is significantly enhanced. The oxidation at 1200 °C is controlled by species diffusion through a continuous chromia layer. The parabolic constant is higher than for the quaternary alloy, due to external and internal Ti oxidation. The presence of a thin layer of titanium oxide covering the chromia scale is suspected to limit chromia volatilization and the scale spallation at cooling. Globally, Ti demonstrated the beneficial influence of the high-temperature properties of the alloy.

1. Introduction

Many industrial or transportation applications require structural materials that are able to resist heat, mechanical stresses, and chemical aggression. Two major examples are the glass-forming tools and the components working in the hottest parts of combustible turbines. Among the first metallic materials to answer these needs are highly alloyed steels and superalloys [1,2]. More recently, the multi-principal elements alloys (MPEAs), high-entropy alloys (HEAs), and medium-entropy alloys (MEAs) have been discovered; these represent a third family candidate for these applications. Notably, based on comparisons with superalloys, many of these XEAs may now be considered as superalloy versions, containing lowered quantities of Co and Ni critical elements (and Cr, if present, favoring chromia-forming behavior [3,4]). In the case of the Cantor’s alloy, Fe and Mn are present in rather high proportions, and as a result, the cobalt and nickel content are significantly reduced. In order to reinforce, at high temperature, the oxidation-resistant Mn-free version of Cantor’s alloy (equimolar CoNiFeCr), with preservation of its FCC single-phase state, solid solution strengthening can be considered. Tungsten, molybdenum, tantalum, and rhenium are traditionally used for this purpose. Unfortunately, they induce an increase in volume mass if present in significant quantities in the alloys. Titanium, which is much lighter, is worthy of consideration.

This element is already present in many superalloys, for various reasons. For instance, it allows the formation of MC carbides and it can take part in the formation of the gamma prime precipitates; both of these functions are useful for alloy strengthening. In some conditions, it can positively influence creep resistance [5] and it has a non-neutral impact on hot oxidation behavior [6,7,8]. It was seen that, in the case of the cobalt-based and nickel-based alloys, the presence of Ti enhances the mechanical resistance at high temperature (notably against creep) and plays a double role in oxidation by oxidizing both externally (with possible development of an outer titanium oxide scale) and internally (affecting internal oxides in the subsurface). In commercial superalloys containing titanium, the Ti content is generally rated between 0.5 and 5 wt.% [9], regardless of the superalloys’ metallurgy, which may be cast (e.g., Mar-M 200), wrought (e.g., Inconel 718), O.D.S. (e.g., MA6000), or single-crystalline (e.g., CMSX6).

In the present study, we wish to explore the ways in which introducing Ti into an equimolar CoNiFeCr alloy affects the microstructure of the alloy and its high-temperature thermal, mechanical, and chemical properties. We aimed to achieve 2 wt.% Ti content. This choice, in the middle of the [0.5–5] interval, was inspired by the improvements in creep and hot oxidation behaviors previously observed for Ni–Cr–C alloys due to the addition of Ti with this content [10].

2. Materials and Methods

First, a compact ovoid ingot weighing 40 g (similar to an egg, with a height and a maximal diameter both equal to about 20 mm) was created via casting in an inert atmosphere. The metal mixture—prepared from high-purity (>99.9%) cobalt, nickel, iron, chromium, and titanium (flakes, balls, and rods; Alfa Aesar)—was placed in the copper crucible of an induction furnace surrounded by a copper coil. Crucible and coil were continuously cooled via fresh water circulation. A silica tube was placed between the crucible and the coil, and it was closed. The initial laboratory air was replaced by an inert atmosphere made of pure argon at about 300 millibars. An alternative current was generated in the coil to induce Foucault’s currents, which heated the metals via the Joule effect until they reached a liquid state. The operating parameters were a frequency ≅ 100 kHz, voltage from 0 to 5 kV, and intensity of several A. After ten minutes spent at the maximal power, the liquid was considered wholly chemically homogenized and the progressive decrease in voltage resulted in liquid-state cooling, solidification, and solid-state cooling.

The obtained ingot was cut using a metallographic precision saw. A part was embedded (in a cold resin mixture) for chemical and microstructure control. Other samples were prepared in order to explore the following properties of the alloys at high temperature:

- A small parallelepiped (about 2 mm × 2 mm × 7 mm) was used to specify the temperatures at the start and end of fusion and solidification by differential thermal analysis (DTA).

- A small square-based prism (about 5 mm × 5 mm × 2 mm) was used to specify the thermal dimensional behavior by thermo-dilatometry analysis (TDA).

- A square-based prism (about 10 mm × 10 mm × 3 mm) was used to determine the mass gain kinetic during hot oxidation by thermo-gravimetry analysis (TGA).

- A long parallelepiped (about 15 mm × 2 mm × 1.5 mm) was used to perform a flexural creep test of the central three points (3PFC).

All the obtained samples were taken from the core of the ingot about 5 mm below the shrinkage defects zone. It must be noted here that all the faces of these samples were examined with the naked eye, and based on these observations, it was suggested that the alloy was homogeneous.

The embedded sample used for chemical and microstructure control was subjected to X-ray diffraction (XRD) using a Bruker D8 Advance diffractometer (the wavelength of the used radiation was 0.154 nanometers). The diffraction results were analyzed using the DIFFRAC.EVA V5.0 software. After grinding (SiC papers from #240 to #1200) and polishing (textile disk enriched with 1 µm alumina particles), the same sample was placed in the chamber of a scanning electron microscope (SEM; model: JSM 6010LA from JEOL, Tokyo, Japan), in which its microstructure was observed in backscattered mode (BSE) at various magnifications for an acceleration voltage rated at 20 kV. The chemical composition was measured by energy-dispersive spectrometry (EDS) of the SEM (several × 250 full-frame acquisitions followed by the calculation of the average contents and their standard deviation values). Elemental maps were also acquired.

The DTA run was performed using a TG-ATD 92-16.18 machine (SETARAM, Caluire, France), with a 20 K min−1 heating rate from ambient temperature to 1000 °C; a 5 K min−1 heating rate up to 1450 °C; a −5 K min−1 cooling rate down to a temperature of 1000 °C; and, finally, a −20 K min−1 cooling rate. The TDA run was performed using a SETARAM dilatometer (model: Ligne 96 TMA) with a 10 K min−1 heating rate from ambient temperature to 1200 °C and a −10 K min−1 cooling rate to return to ambient temperature.

The 3PFC run was performed using a TMA 92-16.18 dilatometer (SETARAM, Caluire, France) modified to allow bending creep tests. Taking into account the distance between the two (sample/alumina rod support) contacts, and the accurately measured width and thickness of the parallelepiped, the central load was calculated in order to produce a tensile stress equal to 10 MPa in the central bottom location in the surface of the sample. This stress is rather low; this was a deliberate choice which was made to eliminate any risk of the alumina rod pressing on the middle of the top surface of the parallelepiped sample during the bending creep test. Heating was performed at 20 K min−1, the isothermal creep at 1100 °C followed during a 200 h period (or less in cases of previous alloy failure), and cooling was performed at a cooling rate of −20 K min−1 until room temperature was reached.

The TGA run was performed, under circulation of synthetic air (dry 80%N2–20%O2, about 1.5 L h−1), using a TG 92-16.18 thermo-balance (SETARAM, Caluire, France), with a 20 K min−1 heating rate from ambient temperature to 1200 °C, a 50 h isothermal stage and a −5 K min−1 cooling rate to return to room temperature.

3. Results

3.1. Characteristics of the Obtained Alloy

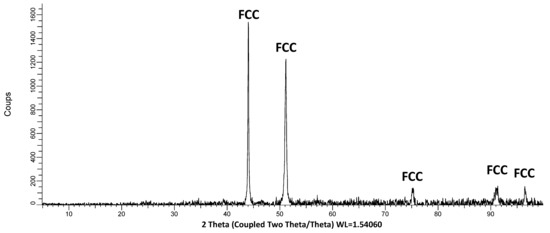

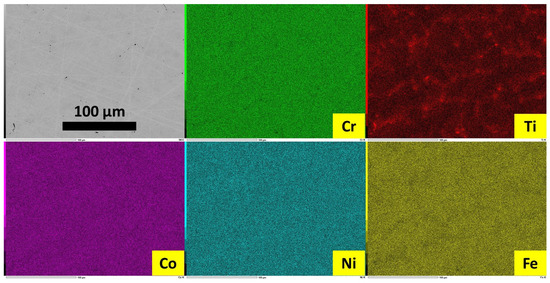

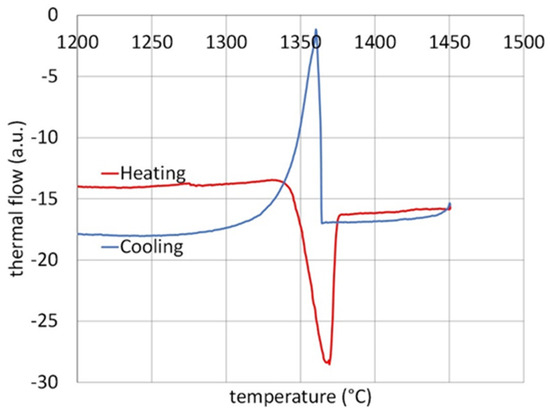

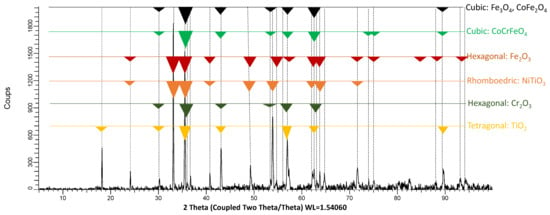

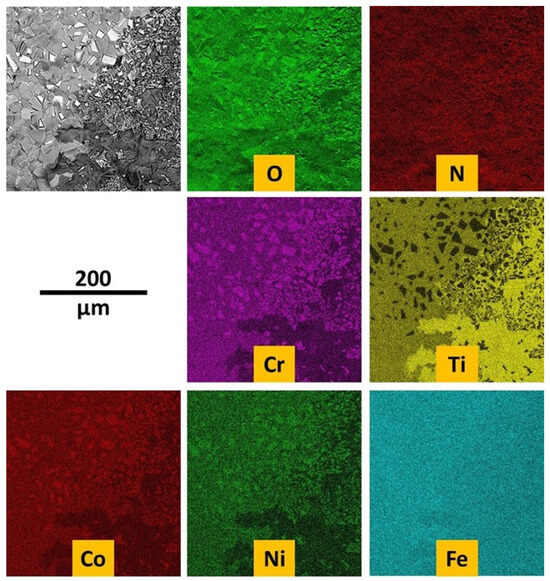

The EDS control of the chemical composition of the obtained ingot shows that the targeted weight contents in Co, Ni, Fe and Cr are well respected (Table 1). Their atomic contents are very close to one another. In contrast, the obtained content for titanium is lower than was desired (1.5 wt.% against 2 wt.%). A quarter of the titanium quantity introduced initially was seemingly lost via the formation of oxides or nitrides with O and N present as traces in the pure argon in the whole fusion chamber (which had a volume of several liters). Ti oxides and nitrides were present all around the ingot after it was cooled down to room temperature at the end of the experiment; they were mixed in with the thin chromia scale covering the external surface of the ingot. The microstructure appears as single-phased during SEM/BSE imaging, which was confirmed by XRD (Figure 1). However elemental EDS mapping allowed us to observe that Ti was segregated in the grain boundaries (Figure 2). The DTA run (Figure 3) led to a heating curve with only one endothermic peak and, similarly, cooling with a single exothermic peak (which started abruptly because of a delayed nucleation). Re-melting started at about 1280 °C and cooling finished at about 1250 °C (Table 2). The alloy was expected to remain solid at temperatures up to 1250 °C at least, and this allowed us to choose temperatures equal to a maximum of 1200 °C for the other tests. The characteristic temperatures are listed in Table 2. They are compared with a Ti-free CoNiFeCr alloy analyzed in the same conditions which was studied in parallel with the same apparatus, and whose solidus and liquidus temperatures are about 150 °C higher [11].

Table 1.

Chemical composition of the obtained alloy (average and standard deviation values from five ×250 full-frame EDS analyses).

Figure 1.

The diffractogram acquired on the as-cast studied alloy (FCC peaks correspond to the matrix the crystalline network of which is Face Centered Cubic).

Figure 2.

EDS elemental mapping acquired on the as-cast alloy.

Figure 3.

Enlargement of the zones of interest of the DTA curve.

Table 2.

Characteristic temperatures resulting from DTA.

3.2. Thermal and Mechanical Behavior

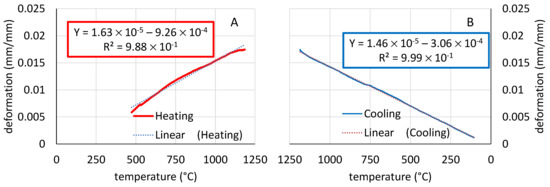

The used apparatus usually induces some irregularities in the low-temperature part of the heating phase (when the alumina apparatus is not at thermal equilibrium) and the corresponding part of the heating curve is removed in Figure 4A). The average thermal expansion coefficient is about 16 × 10−6 K−1. The cooling curve is much more regular. It is, moreover, rather straight, and the thermal contraction coefficient is about 15 × 10−6 K−1 (Figure 4B). The values are gathered in Table 3. They are slightly lower than those for the Ti–free equimolar CoNiFeCr alloy previously evocated [11].

Figure 4.

Dimensional deformation during heating (A) and during cooling (B) observed during the thermo-dilatometry test.

Table 3.

Coefficients of thermal expansion and of thermal contraction.

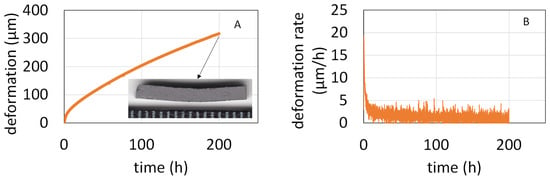

The downward displacement of the central point during the flexural isothermal creep test is plotted versus time in Figure 5A. The deformation was rather fast (reaching a maximum of 20 µm h−1) during the first few hours of the isothermal creep phase. It slowed down to reach only about 2 µm h−1 (Figure 5B). When it was decided to interrupt the test after 200 h (to allow other users to benefit from the apparatus), the deformation was very slow and the total deformation was only 325 µm. These results are shown in Table 4. The Ti-free equimolar CoNiFeCr alloy deformed much more rapidly (by almost 700 µm after 140 h), with a particularly high deformation rate during the first 50 h of the test and, thereafter, a creep rate which was double that of the present Ti-containing alloy [12].

Figure 5.

Displacement of the upper central point (A, including a photo of the sample at the end of test) and its displacement rate (B) versus time during the flexural creep test at 1100 °C for 10 MPa.

Table 4.

Creep deformation data.

3.3. Oxidation Behavior at High Temperature: Kinetic

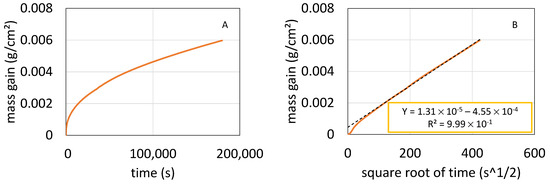

The mass gain curve obtained at 1200 °C with the thermo-balance is plotted versus time in Figure 6A and versus the square root of time (Figure 6B). Obviously, after a mass gain mixing a linear part and a parabolic one during the three first hours of the isothermal stage (better seen in the beginning of the curve plotted versus the square root of time), the mass gain regime became purely parabolic. This is confirmed by the straight line in Figure 6B. This shows that a continuous oxide scale isolated the alloy from the oxidizing atmosphere, leading to kinetics that obeyed Wagner’s law. The slope of the straight line allows us to estimate the parabolic constant: Kp ≅ 86 × 10−12 g2 cm−4 s−1. This is more than three times higher than that of the Ti-free equimolar CoNiFeCr alloy [13].

Figure 6.

Oxidation in synthetic air at 1200 °C: mass gain curve plotted versus time (A) and versus the square root of time (B).

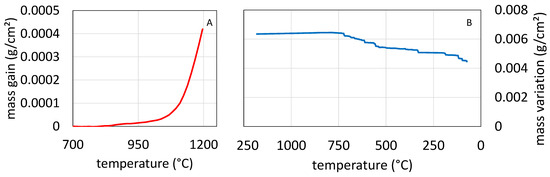

In fact, oxidation and, thus, mass gain started not at the beginning of the isothermal stage, but during the heating. The graph presented in Figure 7A, which was plotted after having corrected the mass gain from the air buoyancy variations due to heating (Archimedes’ pressure), shows that the mass gain began to be detectable at about 810 °C for the +20 K min−1 heating rate (100 °C lower than for the CoNiFeCr alloy [13]). After the end of the isothermal stage, the mass gain continued for a while before slowing down (this was the high-temperature part of cooling) and then almost stopping. Cooling induced more and more intense compression stress in the external oxide scale because of the alloy contraction at 15 × 10−6 K−1 (Figure 4B) against about half this value for the oxide. This ultimately resulted in scale breaking and oxide parts losses, visualized in Figure 7B by the irregular decrease in mass under about 710 °C (30 °C below the CoNiFeCr alloy, the oxide scale of which spalled off much more [13]). All quantitative results are presented in Table 5.

Figure 7.

Mass gain during the heating (A) and mass loss during the post-isothermal cooling (B).

Table 5.

Characteristic data for the three steps of the hot oxidation test.

3.4. Oxidation Behavior at High Temperature: Oxidation Products

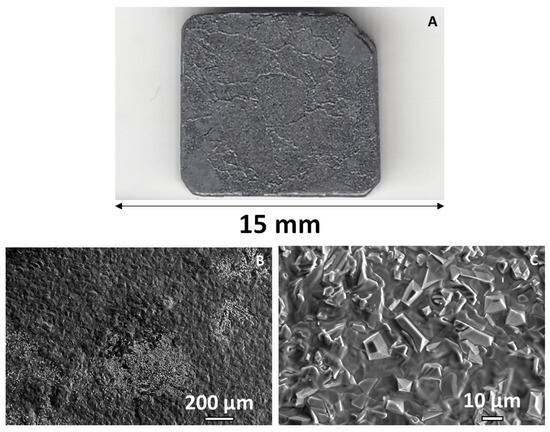

The scale spallation described above was rather limited, as suggested by the rather low mass loss per surface unit area (less than 2 mg cm−2) and by the photograph of the oxide sample (Figure 8A), which also shows two SEM micrographs taken in secondary electron mode (SE) to better depict the outermost morphology (Figure 8B,C). XRD was performed on the oxidized surface. A diffractogram is shown in Figure 9. It is hard to attribute the peaks to particular oxides with certitude, since the same peaks can correspond to different oxides (e.g., Fe3O4, CoFe2O4, CoCrFeO4). Fe2O3 can be excluded and the other oxides which appear to be present are compounds involving titanium (NiTiO3 and TiO2).

Figure 8.

General aspect of the oxidized sample (A) and SEM/SE micrographs taken on the outermost side of the oxide scale at two different magnifications (B,C).

Figure 9.

Diffractogram acquired on the oxidized sample.

EDS elemental maps were also performed on the outermost side of the oxide scale (Figure 10). It seems that the relevant area is composed of mainly chromia (top left part) and of an oxide of both Fe and Ti.

Figure 10.

EDS elemental mapping on the outermost side of the external scale.

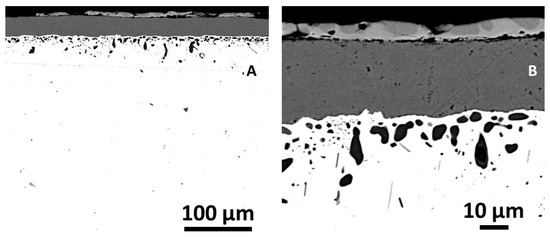

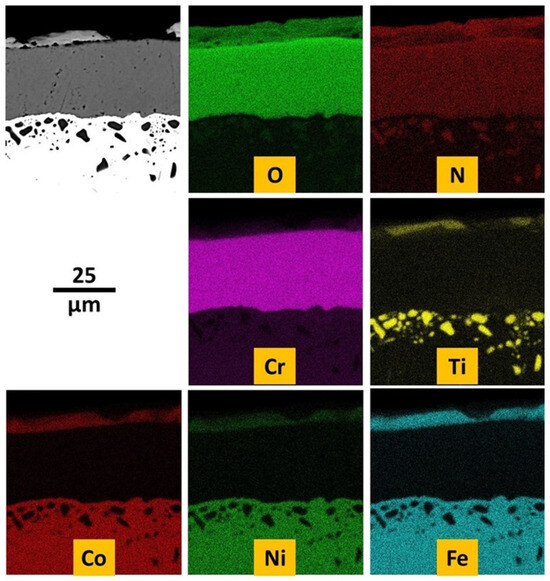

After cross-sectional preparation, one can better distinguish the oxidation product with the SEM in BSE (Figure 11). Over the alloy, there is a continuous oxide scale made of an outermost thin scale containing two types of areas with two different gray levels, and a thick oxide beneath. Internal oxidation also occurred, as evidenced by the presence of black oxides dispersed at a 50 µm depth under the scale/alloy interface. EDS elemental mapping shows qualitatively that the thick oxide scale is chromia and the thin outermost oxide is composed of titanium oxide and a mixed oxide containing Ti, Fe, and seemingly also Cr, Co, and Ni (Figure 12). This was confirmed quantitatively by EDS spot analyses. The internal particles are not oxides, in fact, but titanium nitrides.

Figure 11.

General (A) and detailed (B) SEM/BSE micrographs taken on the external oxide scale and on the subsurface affected by oxidation.

Figure 12.

EDS elemental mapping evidencing the elements involved in oxidation (and nitridation) externally and internally.

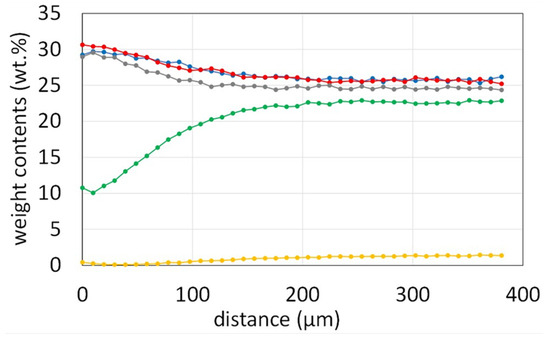

According to the concentration profiles acquired on the subsurface perpendicular to the oxide scale/alloy interface (Figure 13), one can see that chromium and titanium both diffused in the direction of the oxidation front.

Figure 13.

EDS concentration profiles performed on the subsurface perpendicularly to the scale/alloy interface.

4. Discussion

Thus, adding Ti to the equimolar-based alloy did not change the FCC single-phase state of the equimolar quaternary CoNiFeCr alloy, even if some rare and very small black precipitates rich in Ti were seen with the SEM in BSE imaging mode. We must take into account that about a quarter of the titanium quantity initially introduced was lost during elaboration, despite the inert atmosphere. However, the refractoriness of the alloy was significantly decreased by the presence of the 1.5 wt.% Ti, resulting in a possible decrease in maximal service temperature for mechanical reasons (creep). In fact, as previously observed, for instance, for FeNi-based [14] and Ni-based [15,16] superalloys, the addition of Ti seemed to improve the creep resistance of the CoNiFeCr alloy. It seems that Ti is rather efficient at solid solution strengthening. Unfortunately, the presence of Ti seems to accelerate oxidation. This was previously observed in a polycrystalline Ni-based superalloy [17] and was found again here by comparison with the quaternary CoNiFeCr alloy (Ti: Kp was three times higher). Another comparison with the quaternary alloy showed that when Ti is present, the alloy becomes more reactive at heating and mass gain starts at a lower temperature.

The post mortem examination of the oxidized sample allowed us to observe previously witnessed phenomena, such as a thin layer of Ti-rich oxide (rutile TiO2 [10,18]). It was also reported previously that Ti diffused through the chromia scale to feed the growth of this outer thin Ti oxide [19,20]. This could also be observed in our experiments via the gradient in the Ti content in the subsurface.

It was observed here that the thin Ti-rich outer oxide scale was composed of a dark (seemingly TiO2) part and a pale one, gathering all elements and more in contact with the thick chromia layer beneath. It is possible that, at the particularly high temperature of the oxidation test carried out here (1200 °C), TiO2 partially reacted with chromia to create this intermediate pale oxide separating the dark titanium oxide and the dark chromia.

It was previously suspected that this outer scale of titanium-rich oxide, which seemingly continuously recovered the outer side of chromia, protected the chromia from re-oxidizing into volatile CrO3 [10]. This seems to be effectively the case when one considers the linearity of the isothermal mass gain when plotted versus the square root of time. In addition, such a limitation or suppression of the volatilization of chromia at such a high temperature, at which chromia volatilization should be intensive, may induce an accelerated mass gain without accelerating damage to the alloy. In addition to this possible protection against volatilization, the thin outermost continuous scale prevents too-intensive scale spallation when the temperature decreases, as was noted here based on a comparison with the Ti-free quaternary alloy.

5. Conclusions

The high-temperature performances of the refractory equimolar CoNiFeCr alloy are globally enhanced by a moderate addition of titanium. Despite the decrease in refractoriness, special focus must be dedicated to the high-temperature mechanical and chemical behaviors of the Ti-doped version studied in this paper. This still single-phase alloy presents properties which are consistently improved by the presence of Ti, even in small quantities. This appears as a new basis upon which better-performing versions can be developed by introducing particles of a second phase for further strengthening. Before that, other Ti contents need to be tested to identify the optimum one. In the field of the understanding of phenomena, it could be interesting to investigate the successive steps of the oxidation progression to obtain a better understanding of when the internal and external oxidation of titanium starts and what is the possible competition with chromia, and what are the kinetics of thickening of the titanium oxide scale and of the growth of the internal oxides in relation to the progression of Ti diffusion, for instance. This can be explored by means of post mortem analysis of samples oxidized for several durations of exposure, and if available, oxidizing the samples at high temperature in an X-ray diffractometer that is able to analyze the surfaces in situ.

Author Contributions

Conceptualization, P.B.; methodology, P.B. and L.A.; software, P.B. and L.A.; validation, P.B., S.H., L.A. and C.R.; formal analysis, P.B. and S.H.; investigation, P.B. and S.H.; resources, L.A.; data curation, P.B.; writing—original draft preparation, P.B.; writing—review and editing, P.B.; visualization, P.B.; supervision, P.B.; project administration, P.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Bradley, E.F. Superalloys: A Technical Guide; ASM International: Materials Park, OH, USA, 1988. [Google Scholar]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide; ASM International: Materials Park, OH, USA, 2002. [Google Scholar] [CrossRef]

- Kofstad, P. High temperature corrosion. In Electrochemistry and Corrosion Science; Springer: Boston, MA, USA, 2004. [Google Scholar] [CrossRef]

- Young, D.J. High Temperature Oxidation and Corrosion of Metals; Elsevier: Amsterdam, The Netherlands, 2008. [Google Scholar] [CrossRef]

- Fukui, Y.; Sasaki, R.; Hataya, F.; Kashimura, T. Effect of titanium, niobium and zirconium on creep rupture strength and ductility of cobalt base superalloys. Metall. Trans. A 1981, 12, 1033–1039. [Google Scholar] [CrossRef]

- Wagner, G.P.; Simkovich, G. The oxidation of cobalt-chromium-titanium alloys at 1000 °C. Oxid. Met. 1986, 26, 139–155. [Google Scholar] [CrossRef]

- Taylor, M.; Ding, R.; Mignanelli, P.; Hardy, M. Oxidation behaviour of a developmental nickel-based alloy and the role of minor elements. Corros. Sci. 2022, 196, 110002. [Google Scholar] [CrossRef]

- Nguyen, T.D.; Zhang, J.; Young, D.J. Effects of Si, Al and Ti on corrosion of Ni-20Cr and Ni-30Cr alloys in Ar-20CO2 at 700 °C. Corros. Sci. 2018, 130, 161–176. [Google Scholar] [CrossRef]

- Available online: https://www.phase-trans.msm.cam.ac.uk/2003/Superalloys/compositions.gif (accessed on 13 November 2025).

- Berthod, P.; Kretz, E.; Allègre, F.; Ritouet, M.; Schweitzer, T.; Aranda, L. Oxidation and creep properties at 1200 °C of cast quaternary Ni-Cr-C-Ti alloys. Mater. Sci. Eng. A 2017, 699, 145–155. [Google Scholar] [CrossRef]

- Chevalme, R.; Hammi, S.; El Hadad, Y.; Amrouche, L.; Aranda, L.; Berthod, P. Refractoriness, thermal expansion behavior and microstructure stability at elevated temperature of an equimolar cast quaternary CoNiFeCr alloy and of two slightly modified versions. HAL 2025, 04937298. Available online: https://hal.science/hal-04937298v1 (accessed on 30 August 2025).

- El Hadad, Y.; Amrouche, L.; Chevalme, R.; Hammi, S.; Aranda, L.; Berthod, P. As-cast microstructure, room temperature hardness and high temperature creep deformation of an equimolar quaternary CoNiFeCr alloy and of two slightly modified versions. HAL 2025, 04937299. Available online: https://hal.science/hal-04937299v1 (accessed on 30 August 2025).

- Hammi, S.; El Hadad, Y.; Amrouche, L.; Chevalme, R.; Aranda, L.; Berthod, P. Influence of the presence of Ti or Ta on the oxidation behavior at 1200 °C of cast MPEAs derived from an equimolar CoNiFeCr basis. In Proceedings of the TMS 2025 154th Annual Meeting & Exhibition Supplemental Proceedings, Las Vegas, NV, USA, 23–27 March 2025. [Google Scholar]

- Baik, S.I.; Wang, S.Y.; Liaw, P.K.; Dunand, D.C. Increasing the creep resistance of Fe-Ni-Al-Cr superalloys via Ti additions by optimizing the B2/L21 ratio in composite nanoprecipitates. Acta Mater. 2018, 157, 142–154. [Google Scholar] [CrossRef]

- Lemos, G.; Fredel, M.C.; Pyczak, F.; Tetzlaff, U. Creep resistance improvement of a polycrystalline Ni-based superalloy via TiC particles reinforcement. Mater. Sci. Eng. A 2022, 854, 143821. [Google Scholar] [CrossRef]

- Choi, B.G.; Kim, I.S.; Hong, H.U.; Do, J.; Jung, J.E.; Chang, Y. Effect of Ti content on creep properties of Ni-base single crystal superalloys. Met. Mater. Int. 2017, 23, 877–883. [Google Scholar] [CrossRef]

- Lapington, M.T.; Crudden, D.J.; Reed, R.C.; Moody, M.P.; Bagot, P.A.J. Characterization of oxidation mechanisms in a family of polycrystalline chromia-forming nickel-base superalloys. Acta Mater. 2021, 206, 116626. [Google Scholar] [CrossRef]

- Cruchley, S.; Evans, H.E.; Taylor, M.P.; Hardy, M.C.; Stekovic, S. Chromia layer growth on a Ni-based superalloy: Sub-parabolic kinetics and the role of titanium. Corros. Sci. 2013, 75, 58–66. [Google Scholar] [CrossRef]

- Chen, J.H.; Rogers, P.M.; Little, J.A. Oxidation behavior of several chromia-forming commercial nickel-base superalloys. Oxid. Met. 1997, 47, 381–410. [Google Scholar] [CrossRef]

- Nowak, W.J.; Wierzba, B.; Sieniawski, J. Effect of Ti and Ta on oxidation kinetic of chromia forming Ni-base superalloys in Ar-O2-based atmosphere. High Temp. Mater. Process. 2018, 37, 801–806. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).