Improved Properties of Post-Deposition Annealed Ga2O3/SiC and Ga2O3/Al2O3/SiC Back-Gate Transistors Fabricated by Radio Frequency Sputtering

Abstract

:1. Introduction

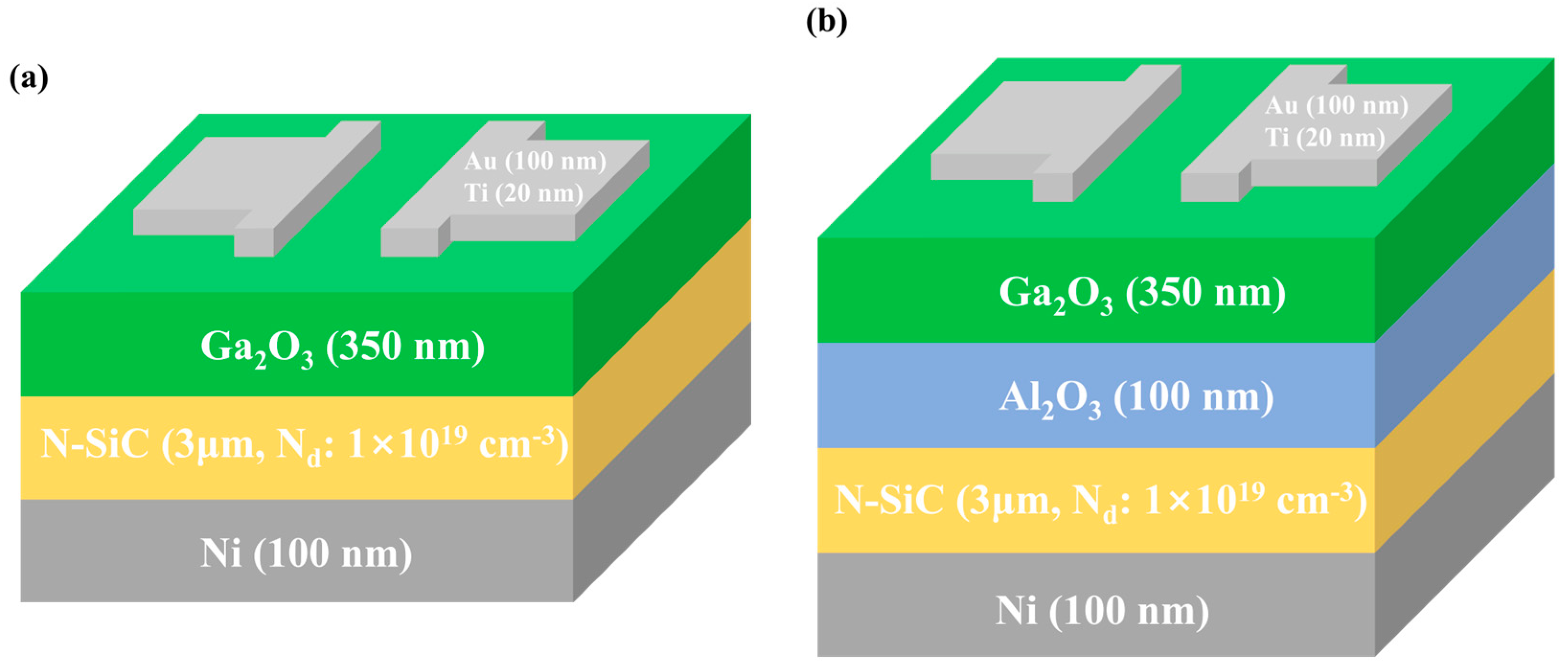

2. Experimental Details

3. Characterization and Instrumentation

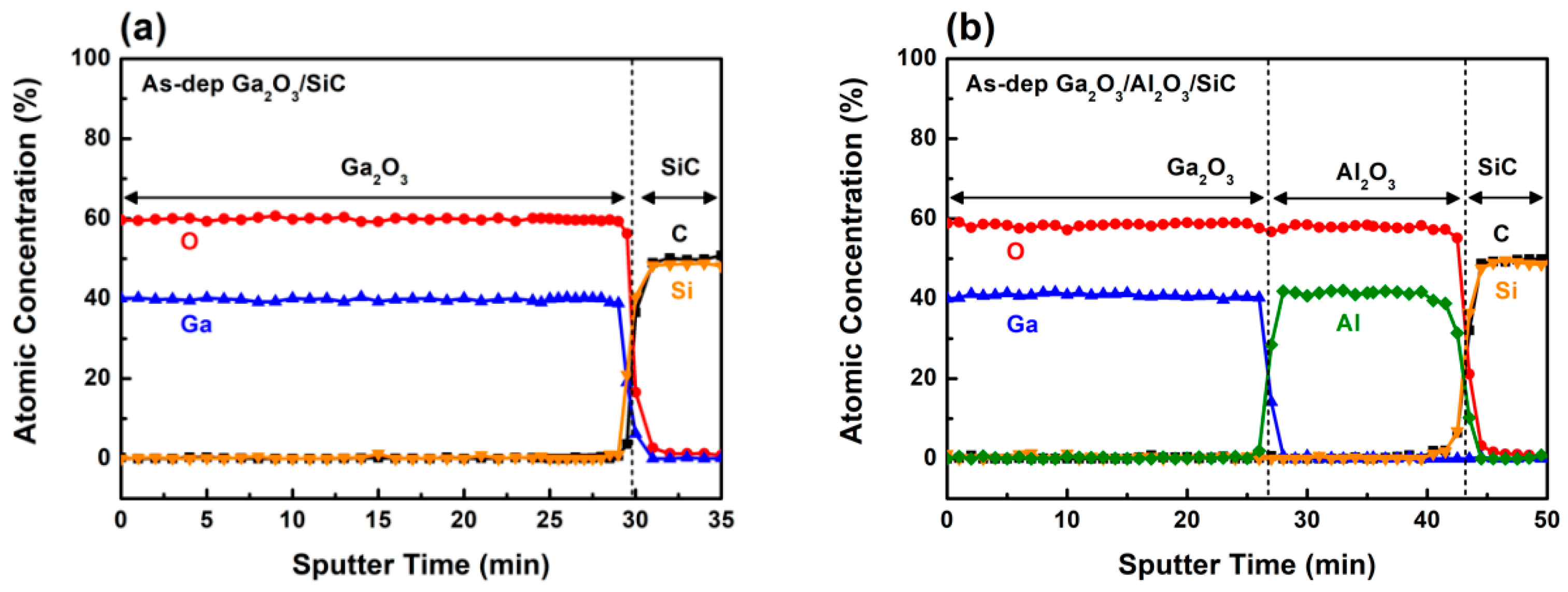

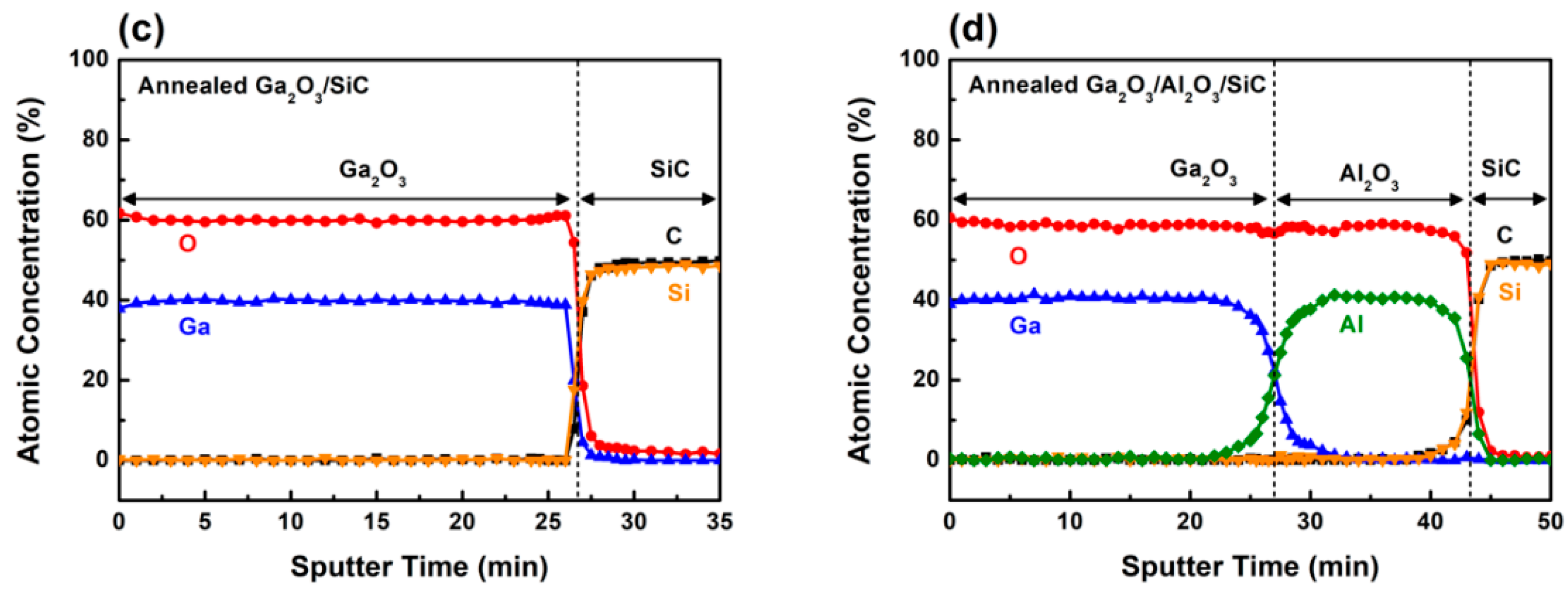

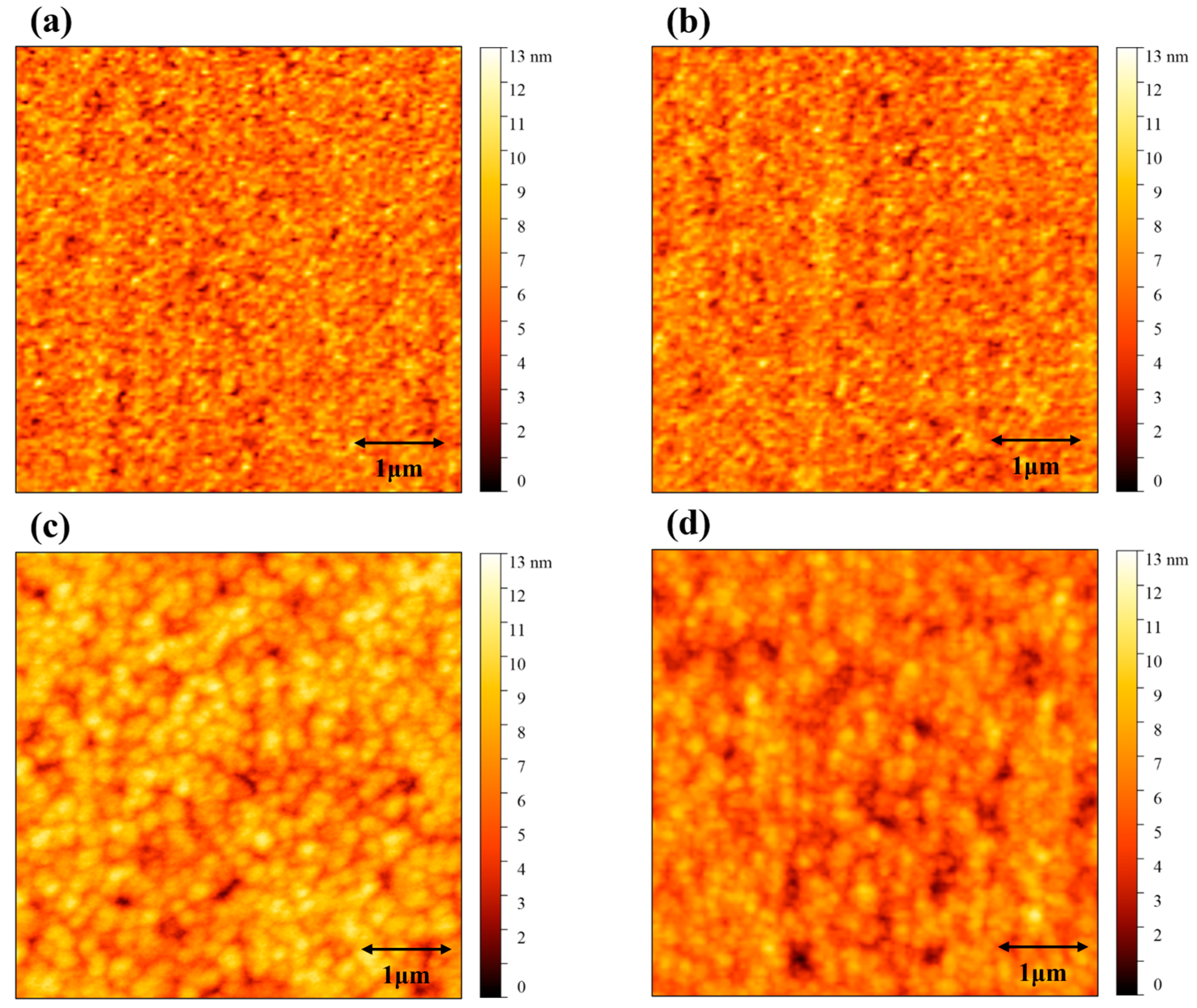

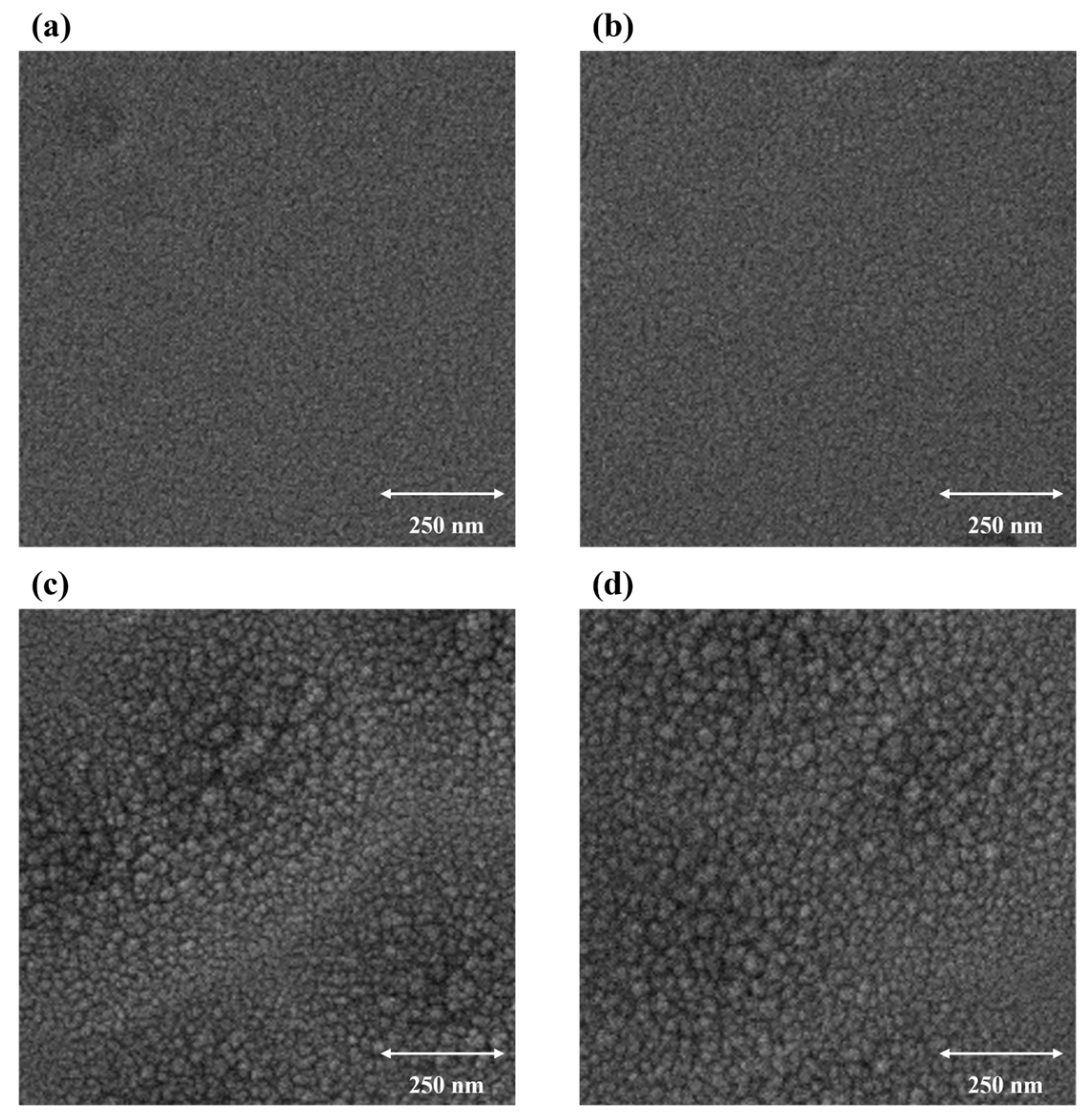

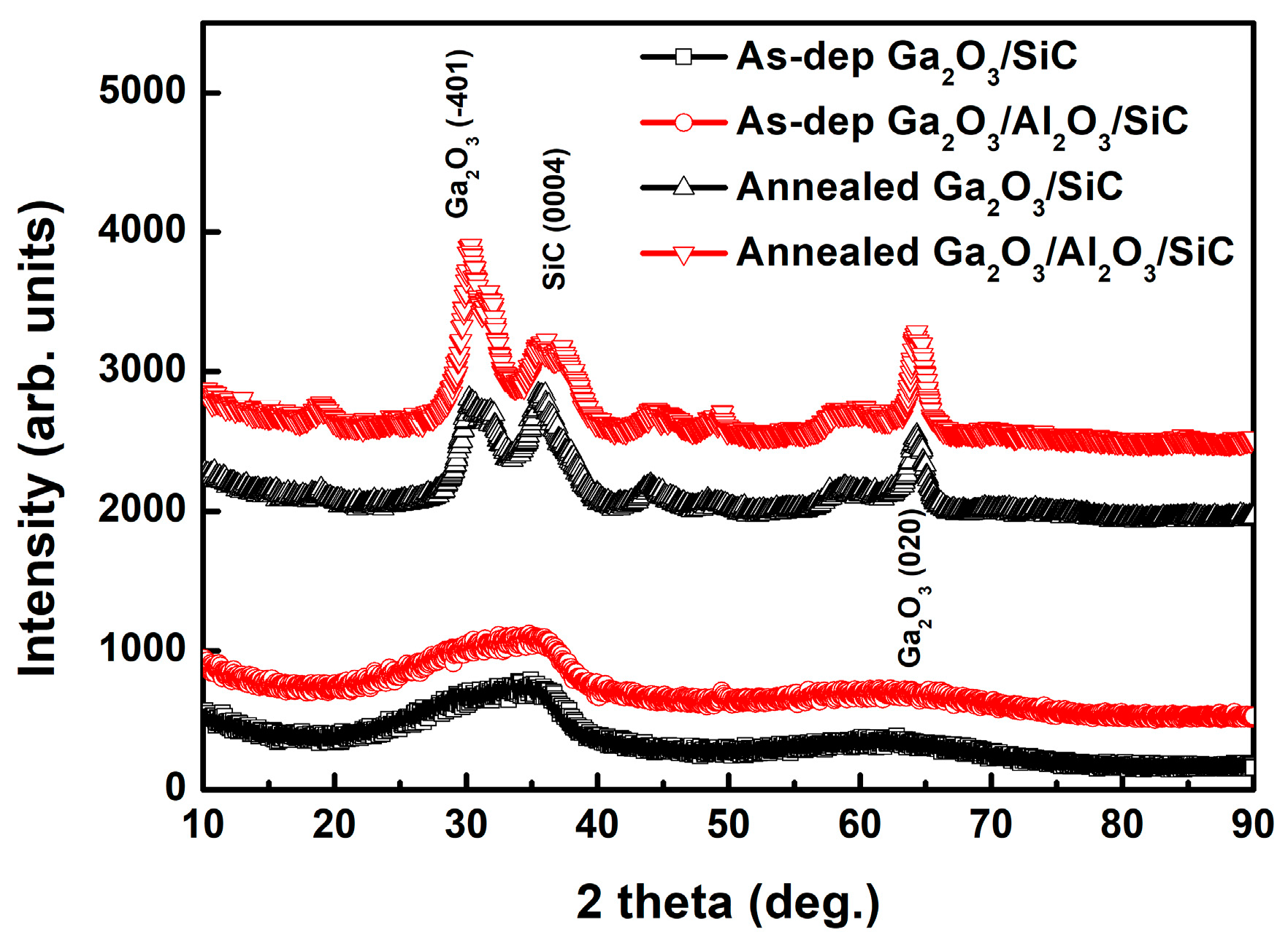

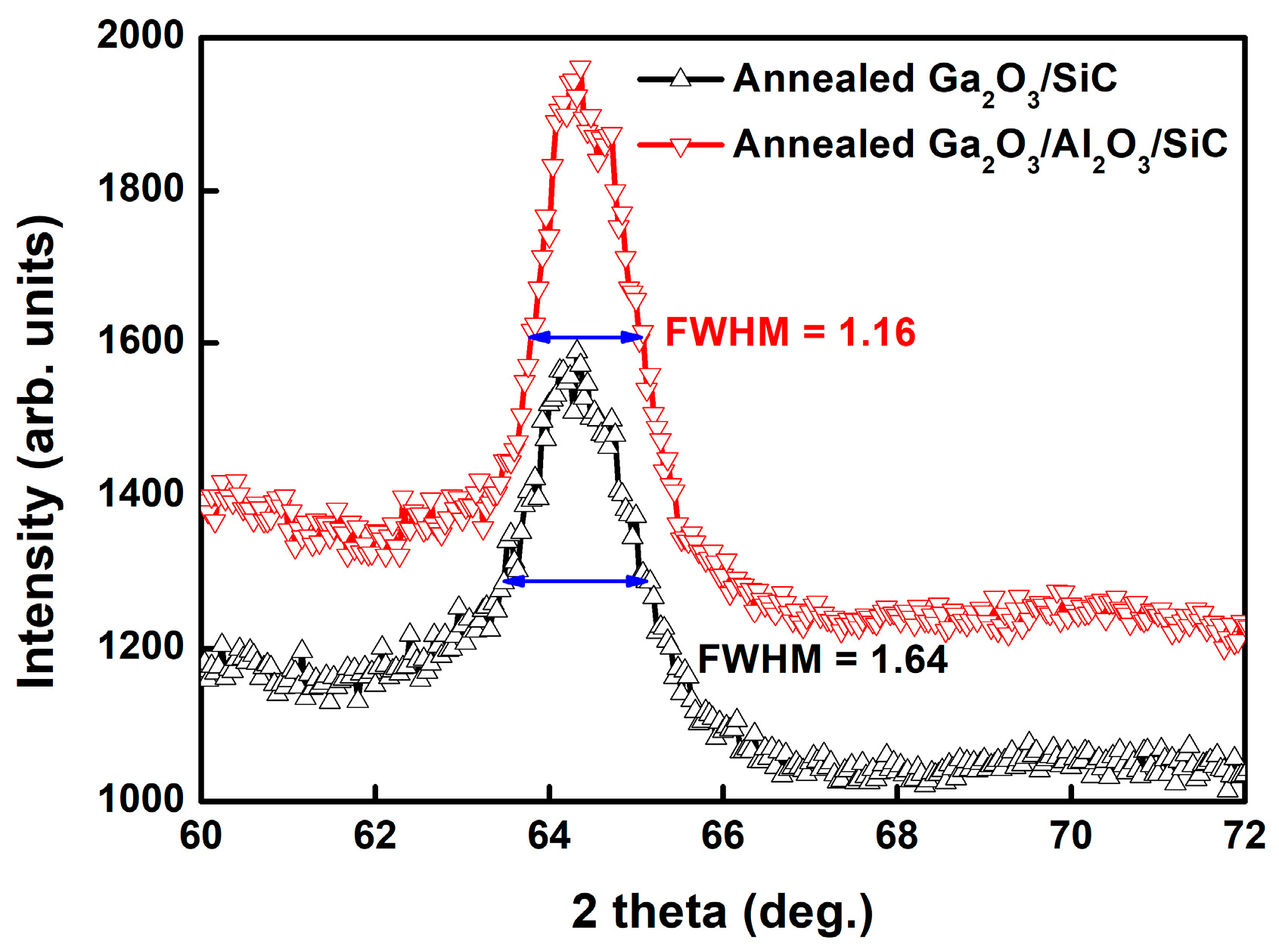

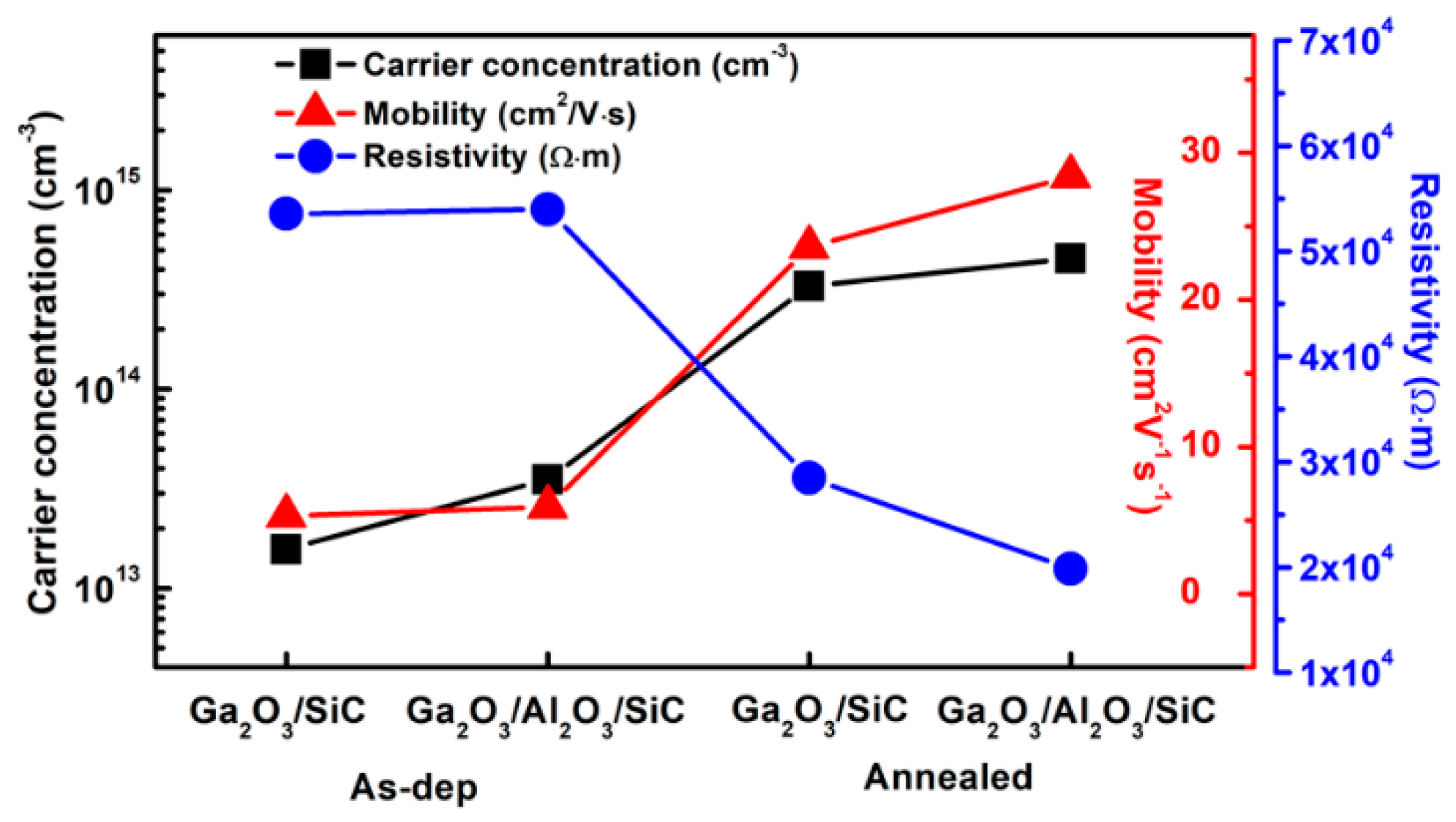

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oh, S.; Yang, G.; Kim, J. Electrical characteristics of vertical Ni/β-Ga2O3 Schottky barrier diodes at high temperatures. ECS J. Solid State Sci. Technol. 2016, 6, Q3022. [Google Scholar] [CrossRef]

- Byun, D.W.; Lee, Y.J.; Oh, J.M.; Schweitz, M.A.; Koo, S.M. Morphological and electrical properties of β-Ga2O3/4H-SiC heterojunction diodes. Electron. Mater. Lett. 2021, 17, 479–484. [Google Scholar] [CrossRef]

- Pérez-Tomás, A.; Jennings, M.R.; Davis, M.; Shah, V.; Grasby, T.; Covington, J.A.; Mawby, P.A. High doped MBE Si p–n and n–n heterojunction diodes on 4H-SiC. Microelectron. J. 2007, 38, 1233–1237. [Google Scholar] [CrossRef]

- Oshima, T.; Kaminaga, K.; Mukai, A.; Sasaki, K.; Masui, T.; Kuramata, A.; Yamakoshi, S.; Fujita, S.; Ohtomo, A. Formation of semi-insulating layers on semiconducting β-Ga2O3 single crystals by thermal oxidation. Jpn. J. Appl. Phys. 2013, 52, 051101. [Google Scholar] [CrossRef]

- Lee, H.J.; Shin, M.C.; Moon, S.Y.; Byun, D.W.; Kim, M.Y.; Lee, H.J.; Lee, G.H.; Jung, S.W.; Schweitz, M.A.; Park, J.; et al. Bandgap modulation and electrical characteristics of (AlxGa1−x)2O3/4H-SiC thin film heterostructures. Thin Solid Film. 2022, 754, 139276. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, W.; You, T.; Mu, F.; Hu, H.; Liu, Y.; Huang, H.; Suga, T.; Han, G.; Ou, X.; et al. β-Ga2O3 MOSFETs on the Si substrate fabricated by the ion-cutting process. Sci. China Phys. Mech. Astron. 2020, 63, 277311. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, J.; Qi, D.C.; Chen, L.; Zhang, K.H. Recent progress on the electronic structure, defect, and doping properties of Ga2O3. APL Mater. 2020, 8, 020906. [Google Scholar] [CrossRef]

- Lee, Y.J.; Schweitz, M.A.; Oh, J.M.; Koo, S.M. Influence of annealing atmosphere on the characteristics of Ga2O3/4H-SiC n-n heterojunction diodes. Materials 2020, 13, 434. [Google Scholar] [CrossRef]

- Bhuiyan, A.F.M.; Feng, Z.; Johnson, J.M.; Huang, H.L.; Sarker, J.; Zhu, M.; Karim, M.R.; Mazumder, B.; Hwang, J.; Zhao, H. Phase transformation in MOCVD growth of (AlxGa1−x)2O3 thin films. APL Mater. 2020, 8, 031104. [Google Scholar] [CrossRef]

- Vaca, D.; Yates, L.; Nepal, N.; Katzer, D.S.; Downey, B.P.; Wheeler, V.; Meyer, D.J.; Graham, S.; Kumar, S. Thermal conductivity of β-Ga2O3 thin films grown by molecular beam epitaxy. In Proceedings of the 2020 19th IEEE Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (ITherm), Orlando, FL, USA, 21–23 July 2020; pp. 1011–1016. [Google Scholar]

- Santia, M.D.; Tandon, N.; Albrecht, J.D. Lattice thermal conductivity in β-Ga2O3 from first principles. Appl. Phys. Lett. 2015, 107, 041907. [Google Scholar] [CrossRef]

- Cheng, Z.; Yates, L.; Shi, J.; Tadjer, M.J.; Hobart, K.D.; Graham, S. Thermal conductance across β-Ga2O3-diamond van der Waals heterogeneous interfaces. APL Mater. 2019, 7, 031118. [Google Scholar] [CrossRef]

- Bar-Cohen, A.; Albrecht, J.D.; Maurer, J.J. Near-junction thermal management for wide bandgap devices. In Proceedings of the 2011 IEEE Compound Semiconductor Integrated Circuit Symposium (CSICS), Waikoloa, HI, USA, 16–19 October 2011; pp. 1–5. [Google Scholar]

- Wang, T.; Wu, H.; Chen, C.; Liu, C. Growth, optical, and electrical properties of nonpolar m-plane ZnO on p-Si substrates with Al2O3 buffer layers. Appl. Phys. Lett. 2012, 100, 011901. [Google Scholar] [CrossRef]

- Qian, H.; Zhang, X.; Ma, Y.; Zhang, L.; Chen, T.; Wei, X.; Tang, W.; Zhou, X.; Feng, B.; Fan, Y.; et al. Quasi-vertical ε-Ga2O3 solar-blind photodetectors grown on p-Si substrates with Al2O3 buffer layer by metalorganic chemical vapor deposition. Vacuum 2022, 200, 111019. [Google Scholar] [CrossRef]

- Jian, Z.; Sayed, I.; Liu, W.; Mohanty, S.; Ahmadi, E. Characterization of MOCVD-grown AlSiO gate dielectric on β-Ga2O3 (001). Appl. Phys. Lett. 2021, 118, 172102. [Google Scholar] [CrossRef]

- Wang, T.; Li, W.; Ni, C.; Janotti, A. Band gap and band offset of Ga2O3 and (AlxGa1−x)2O3 alloys. Phys. Rev. Appl. 2018, 10, 011003. [Google Scholar] [CrossRef]

- Feng, Z.; Feng, Q.; Zhang, J.; Zhang, C.; Zhou, H.; Li, X.; Huang, L.; Xu, L.; Hu, Y.; Zhao, S.; et al. Band alignments of SiO2 and HfO2 dielectrics with (AlxGa1−x)2O3 film (0 ≤ x ≤ 0.53) grown on Ga2O3 buffer layer on sapphire. J. Alloys Compd. 2018, 745, 292–298. [Google Scholar] [CrossRef]

- Bhuiyan, A.F.M.; Feng, Z.; Johnson, J.M.; Huang, H.L.; Hwang, J.; Zhao, H. Band offsets of (100) β-(AlxGa1−x)2O3/β-Ga2O3 heterointerfaces grown via MOCVD. Appl. Phys. Lett. 2020, 117, 252105. [Google Scholar] [CrossRef]

- Singh, P.; Jha, R.K.; Singh, R.K.; Singh, B.R. Preparation and characterization of Al2O3 film deposited by RF sputtering and plasma enhanced atomic layer deposition. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2018, 36, 04G101. [Google Scholar] [CrossRef]

- Herrera, F.Á.; Hirano, Y.; Miura-Mattausch, M.; Iizuka, T.; Kikuchihara, H.; Mattausch, H.J.; Ito, A. Advanced short-channel-effect modeling with applicability to device optimization—Potentials and scaling. IEEE Trans. Electron Devices 2019, 66, 3726–3733. [Google Scholar] [CrossRef]

- Madadi, D.; Orouji, A.A. β-Ga2O3 double gate junctionless FET with an efficient volume depletion region. Phys. Lett. A 2021, 412, 127575. [Google Scholar] [CrossRef]

- Li, Z.; Wu, Y.; Feng, B.; Li, Y.; Liu, T.; Feng, J.; Chen, X.; Huang, R.; Xu, L.; Li, Z.; et al. Bandgap Tailoring of Monoclinic Single-Phase β-(AlxGa1−x)2O3 (0 ≤ x ≤ 0.65) Thin Film by Annealing β-Ga2O3/Al2O3 Heterojunction at High Temperatures. Phys. Status Solidi A 2021, 218, 2000785. [Google Scholar] [CrossRef]

- Liao, C.H.; Li, K.H.; Torres-Castanedo, C.G.; Zhang, G.; Li, X. Wide range tunable bandgap and composition β-phase (AlGa)2O3 thin film by thermal annealing. Appl. Phys. Lett. 2021, 118, 032103. [Google Scholar] [CrossRef]

- Nakagomi, S.; Sakai, T.; Kikuchi, K.; Kokubun, Y. β-Ga2O3/p-type 4H-SiC heterojunction diodes and applications to deep-UV photodiodes. Phys. Status Solidi A 2019, 216, 1700796. [Google Scholar] [CrossRef]

- Nepal, N.; Katzer, D.S.; Downey, B.P.; Wheeler, V.D.; Nyakiti, L.O.; Storm, D.F.; Hardy, M.T.; Freitas, J.A.; Jin, E.N.; Vaca, D.; et al. Heteroepitaxial growth of β-Ga2O3 films on SiC via molecular beam epitaxy. J. Vac. Sci. Technol. A Vac. Surf. Film. 2020, 38, 063406. [Google Scholar] [CrossRef]

- Singh, A.K.; Gupta, M.; Sathe, V.; Katharria, Y.S. Effect of annealing temperature on β-Ga2O3 thin films deposited by RF sputtering method. Superlattices Microstruct. 2021, 156, 106976. [Google Scholar] [CrossRef]

- Yu, J.; Nie, Z.; Dong, L.; Yuan, L.; Li, D.; Huang, Y.; Zhang, L.; Zhang, Y.; Jia, R. Influence of annealing temperature on structure and photoelectrical performance of β-Ga2O3/4H-SiC heterojunction photodetectors. J. Alloys Compd. 2019, 798, 458–466. [Google Scholar] [CrossRef]

- Anhar Uddin Bhuiyan, A.F.M.; Feng, Z.; Johnson, J.M.; Chen, Z.; Huang, H.L.; Hwang, J.; Zhao, H. MOCVD epitaxy of β-(AlxGa1−x)2O3 thin films on (010) Ga2O3 substrates and N-type doping. Appl. Phys. Lett. 2019, 115, 120602. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, H.C.; Liu, C.; Dong, J.W.; Chow, P. Annealing of Al2O3 thin films prepared by atomic layer deposition. J. Phys. D Appl. Phys. 2007, 40, 3707. [Google Scholar] [CrossRef]

- Kim, B.; Yang, D.; Sohn, W.; Lee, S.; Jang, T.; Yoon, E.; Park, Y.; Jang, H.W. Strain relaxation and dislocation annihilation in compositionally graded α-(AlxGa1−x)2O3 layer for high voltage α-Ga2O3 power devices. Acta Mater. 2021, 221, 117423. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, C.; Xu, Y.; Li, Z.; Chen, D.; Zhu, W.; Feng, Q.; Xu, S.; Zhang, J.; Hao, Y. Heteroepitaxial growth of β-Ga2O3 thin films on c-plane sapphire substrates with β-(AlxGa1−x)2O3 intermediate buffer layer by mist-CVD method. Mater. Today Commun. 2021, 29, 102766. [Google Scholar] [CrossRef]

- Bhuvana, K.P.; Elanchezhiyan, J.; Gopalakrishnan, N.; Balasubramanian, T. Influence of grain size on the properties of AlN doped ZnO thin film. Mater. Sci. Semicond. Process. 2011, 14, 84–88. [Google Scholar] [CrossRef]

- Assunção, V.; Fortunato, E.; Marques, A.; Gonçalves, A.; Ferreira, I.; Águas, H.; Martins, R. New challenges on gallium-doped zinc oxide films prepared by rf magnetron sputtering. Thin Solid Film. 2003, 442, 102–106. [Google Scholar] [CrossRef]

- Wang, D.; Ma, X.; Xiao, H.; Le, Y.; Ma, J. Ta-doped epitaxial β-Ga2O3 films deposited on SrTiO3 (100) substrates by MOCVD. Mater. Sci. Semicond. Process. 2021, 128, 105749. [Google Scholar] [CrossRef]

- Wang, S.; Hui, S.; Peng, K.; Bailey, T.P.; Zhou, X.; Tang, X.; Uher, C. Grain boundary scattering effects on mobilities in p-type polycrystalline SnSe. J. Mater. Chem. C 2017, 5, 10191–10200. [Google Scholar] [CrossRef]

- Oh, B.Y.; Jeong, M.C.; Ham, M.H.; Myoung, J.M. Effects of the channel thickness on the structural and electrical characteristics of room-temperature fabricated ZnO thin-film transistors. Semicond. Sci. Technol. 2007, 22, 608. [Google Scholar] [CrossRef]

- Makeswaran, N.; Battu, A.K.; Deemer, E.; Ramana, C.V. Crystal growth and structure–property optimization of thermally annealed nanocrystalline Ga2O3 films. Cryst. Growth Des. 2020, 20, 2893–2903. [Google Scholar] [CrossRef]

- Patel, S.L.; Chander, S.; Purohit, A.; Kannan, M.D.; Dhaka, M.S. Influence of NH4Cl treatment on physical properties of CdTe thin films for absorber layer applications. J. Phys. Chem. Solids 2018, 123, 216–222. [Google Scholar] [CrossRef]

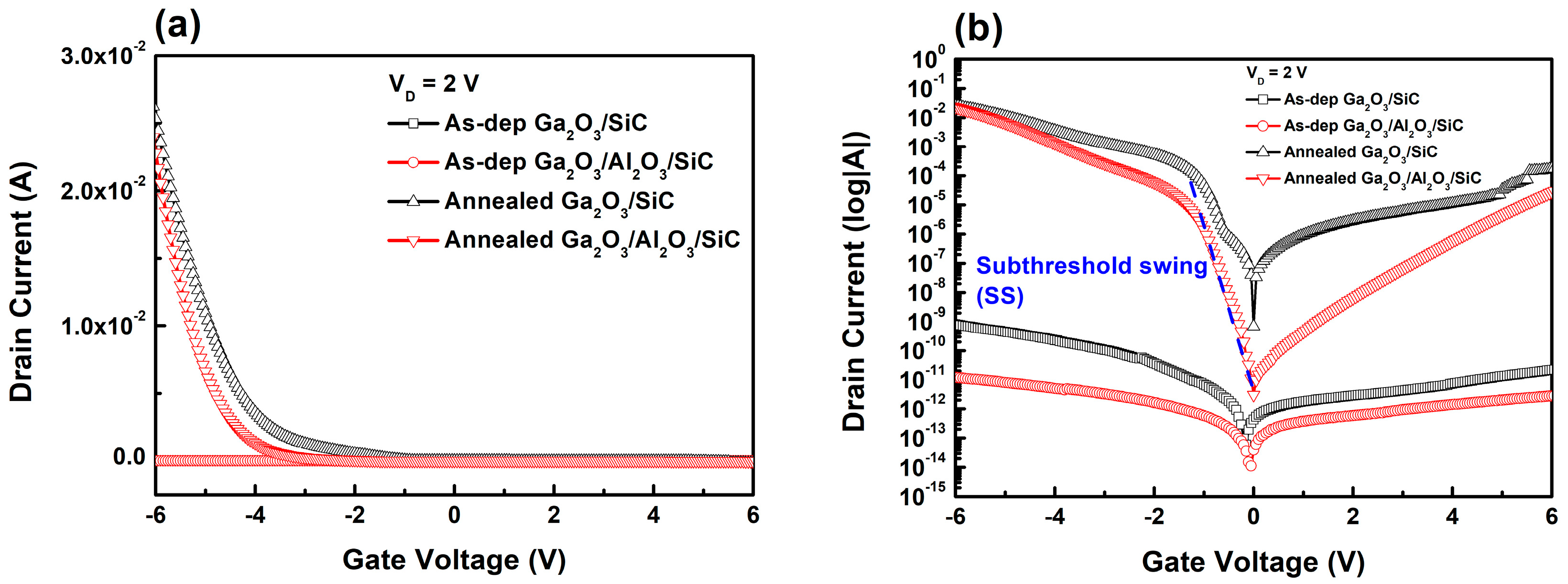

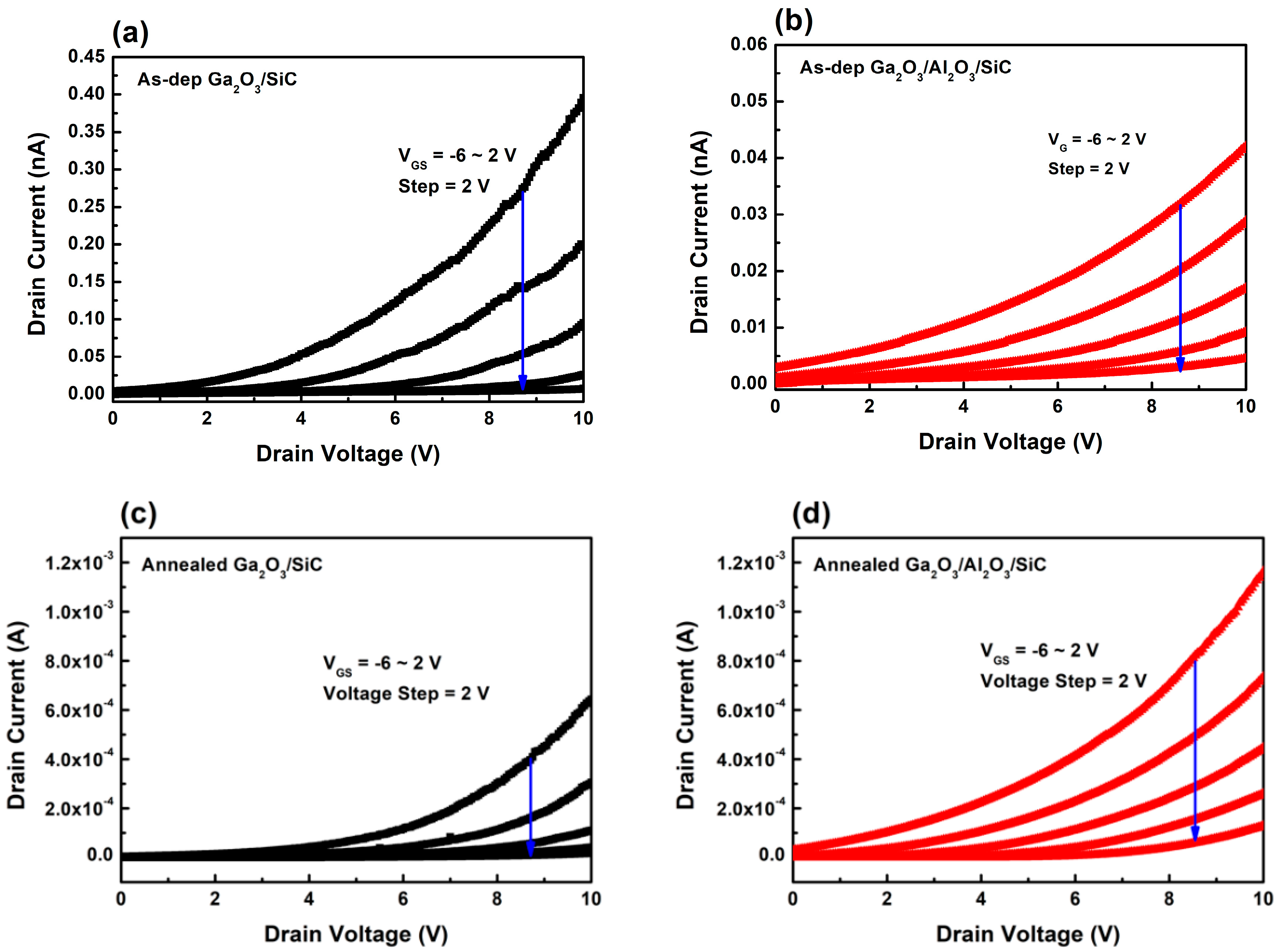

| As-Deposited | Annealed at 900 °C | |||

|---|---|---|---|---|

| Ga2O3/SiC | Ga2O3/Al2O3/SiC | Ga2O3/SiC | Ga2O3/Al2O3/SiC | |

| On current [A] (+6 V) | 8.03 × 10−10 | 1.19 × 10−11 | 2.53 × 10−2 | 2.27 × 10−2 |

| Off current [A] (−6 V) | −2.14 × 10−11 | −2.78 × 10−12 | −1.73 × 10−4 | −2.75 × 10−5 |

| On/off ratio | 3.74 × 10 | 4.29 | 1.46 × 102 | 8.27 × 102 |

| SS (mV·dec−1) | 233 | 234 | 182 | 154 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.-J.; Lee, G.-H.; Chung, S.-H.; Byun, D.-W.; Schweitz, M.A.; Chun, D.H.; Joo, N.Y.; Lim, M.; Erlbacher, T.; Koo, S.-M. Improved Properties of Post-Deposition Annealed Ga2O3/SiC and Ga2O3/Al2O3/SiC Back-Gate Transistors Fabricated by Radio Frequency Sputtering. Micro 2023, 3, 775-784. https://doi.org/10.3390/micro3040055

Lee H-J, Lee G-H, Chung S-H, Byun D-W, Schweitz MA, Chun DH, Joo NY, Lim M, Erlbacher T, Koo S-M. Improved Properties of Post-Deposition Annealed Ga2O3/SiC and Ga2O3/Al2O3/SiC Back-Gate Transistors Fabricated by Radio Frequency Sputtering. Micro. 2023; 3(4):775-784. https://doi.org/10.3390/micro3040055

Chicago/Turabian StyleLee, Hee-Jae, Geon-Hee Lee, Seung-Hwan Chung, Dong-Wook Byun, Michael A. Schweitz, Dae Hwan Chun, Nack Yong Joo, Minwho Lim, Tobias Erlbacher, and Sang-Mo Koo. 2023. "Improved Properties of Post-Deposition Annealed Ga2O3/SiC and Ga2O3/Al2O3/SiC Back-Gate Transistors Fabricated by Radio Frequency Sputtering" Micro 3, no. 4: 775-784. https://doi.org/10.3390/micro3040055

APA StyleLee, H.-J., Lee, G.-H., Chung, S.-H., Byun, D.-W., Schweitz, M. A., Chun, D. H., Joo, N. Y., Lim, M., Erlbacher, T., & Koo, S.-M. (2023). Improved Properties of Post-Deposition Annealed Ga2O3/SiC and Ga2O3/Al2O3/SiC Back-Gate Transistors Fabricated by Radio Frequency Sputtering. Micro, 3(4), 775-784. https://doi.org/10.3390/micro3040055