Abstract

Background/Objectives: Toolmark analysis on cartridge cases offers critical insights in forensic ballistics, as the impressions left on cartridge cases by firearm components—such as the firing pin, breech face, and annulus—carry distinctive patterns and act as unique identifiers that can be used for firearm linkage. This study aims to develop a systematic and interpretable feature extraction pipeline for these regions to support future automation and comparison studies in forensic cartridge case analysis. Methods: A dataset of 20 high-resolution cartridge case images was prepared, and each region of interest (firing pin impression, breech face, and annulus) was manually annotated using the LabelMe tool. ImageJ and Python-based scripts were employed for feature extraction, capturing geometric descriptors (area, perimeter, circularity, and eccentricity) and texture-based features (Local Binary Patterns and Haralick statistics). In total, 61 quantitative features were derived from the annotated regions. Similarity between cartridge cases was evaluated using Euclidean distance metrics after normalization. Results: The extracted and calibrated region-wise geometric and texture features demonstrated distinct variation patterns across firing pin, breech face, and annulus regions. Pairwise similarity analysis revealed measurable intra-class differences, indicating the discriminative potential of the extracted features even within cartridges likely fired from the same firearm. Conclusions: This study provides a foundational, region-wise quantitative framework for analysing cartridge case impressions. The extracted dataset and similarity outcomes establish a baseline for subsequent research on firearm identification and model-based classification in forensic ballistics.

1. Introduction

In forensic science, firearm identification is a crucial component of crime scene investigations [1]. When a firearm is discharged, it leaves behind a wealth of microscopic evidence on the fired cartridge case. Among these, the impressions left by the firing pin, breech face, and annulus are particularly valuable, as they are influenced by the mechanical structure and condition of the firearm. These impressions contain unique striation patterns and surface characteristics that can be analysed to link a cartridge to a specific weapon [2].

In India, firearm-related fatalities remain a significant concern. According to [3], there were 26,550 firearm-related deaths in 2016, equivalent to a rate of 3.20 per 10,000 people. In a tertiary-care autopsy series from North India (2016–2017) [4], firearm deaths comprised 13 of 1639 medico-legal autopsies, with a marked male predominance (~92%); suicide was the most frequent manner (~62%), followed by homicide (~31%), and accidental cases (~8%), with incidents more common in rural settings and during early morning hours. These figures underscore both the lethality of firearm events and the operational burden on forensic services. Given the complexity and labour-intensive nature of traditional firearm identification and the growing workload of ballistic experts, there is a critical need to move toward automated and semi-automated approaches [1,5,6,7]. This study contributes to this goal by offering a region-wise, interpretable feature extraction pipeline that supports future automation efforts.

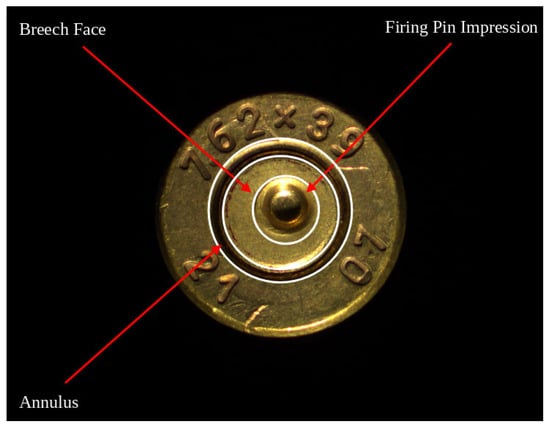

1.1. Anatomy of the Base of a Cartridge Case

The figure below (Figure 1) shows the anatomy of the base of a fired cartridge case, recovered from crime scene. The base of a cartridge case is technically known as the head stamp. It contains several concentric circles and markings impressed by the manufacturer, such as alphabets, numbers, typical symbols, geometrical patterns, etc. By reading these impressions, it is possible to extract information such as name of manufacturer, country of origin, year of manufacture, bore and caliber, etc. [8].

Figure 1.

Base of a fired cartridge case illustrating the three key regions used for analysis: firing pin impression, breech face, and annulus.

An unfired cartridge typically consists of three primary components: the cartridge case, the bullet, and a propellant charge or explosive. The cartridge case, usually metallic, is sealed at its base and contains the explosive material between the base and the projectile. The bullet is positioned at the open end (mouth) of the case. Once the cartridge is loaded into a firearm’s chamber, the act of firing causes the firing pin to strike the primer located at the base of the cartridge. This impact forms a concave indentation, known as the firing pin impression [2,8]. This mechanical strike triggers a chemical reaction, igniting the propellant and generating high-pressure gases. The high pressure exerted by the gases propel the bullet through the firearm’s barrel and simultaneously push the cartridge case backward. As a result, the base of the cartridge case comes into forceful contact with the firearm’s breech face, leaving behind a distinctive breech face impression. The area of the base where this mark occurs is referred to as the breech face region. After discharge, the empty cartridge case is typically ejected from the chamber, either manually or automatically, lands on the ground, making it retrievable for forensic examination [9].

As illustrated in Figure 1, the base of a fired cartridge case contains multiple regions of forensic interest. The firing pin impression is a concave indentation created when the firing pin strikes the primer. Surrounding this is the breech face region, which bears mechanical marks resulting from contact with the breech surface of the firearm. Encircling both is the annulus, a narrow ring-shaped zone that may exhibit subtle flowback deformations or stress patterns due to the pressure generated during firing. While often overlooked in earlier studies, the annulus provides valuable Supplementary Information for firearm identification, especially when analysed alongside the breech face and firing pin marks.

Traditionally, firearm examiners have relied on visual inspection using optical microscopes to compare cartridge marks. However, this process can be subjective and labour-intensive. With the advancement of digital imaging and computer vision techniques, there is growing interest in automating the analysis of ballistic evidence through objective, quantifiable methods [10].

This study aims to explore an alternative path to firearm classification by focusing solely on feature extraction and statistical analysis. Using a small dataset of 20 cartridge images, we manually annotated the firing pin mark, breech face, and annulus regions. From these regions, we extracted both geometric and texture-based features including area, perimeter, roundness, eccentricity, local binary patterns (LBP), and Haralick features derived from the grey-level co-occurrence matrix (GLCM).

Rather than building a classification model; which is limited by the small dataset size and the fact that all cartridges are presumed to come from two firearms of same make; we focus on region-wise feature analysis, detailed visualizations and pairwise similarity assessment. This approach allows us to understand the variation in physical characteristics across samples and to create a structured dataset that may serve as a basis for future classification tasks involving larger and more diverse samples.

By documenting this feature extraction and analysis process, this work contributes to the growing field of automated ballistic evidence processing and demonstrates the feasibility of such analysis even in small-scale studies.

1.2. Contributions of the Study

This study explores region-wise feature extraction from fired cartridge case images to aid in forensic analysis of firearm toolmarks. The primary contributions of this research are as follows:

- Region-wise manual annotation and segmentation: Three key regions, firing pin impression, breech face, and annulus, were manually annotated using LabelMe. This region-specific segmentation enables localized feature extraction and detailed analysis.

- Feature extraction combining geometric and texture descriptors: A comprehensive set of geometric (area, perimeter, circularity, roundness, solidity, eccentricity) and texture-based (local binary pattern and Haralick features) metrics were extracted from each region using ImageJ and Python-based tools.

- Pixel-to-millimetre calibration for quantitative analysis: Calibration was performed using ImageJ to convert pixel values into real-world metric units (mm2), enhancing the accuracy and interpretability of geometric measurements.

- Creation of a benchmark dataset: A dataset of 20 high-resolution cartridge case images with region-level annotations and extracted features was created. This serves as a foundational resource for similarity analysis and future classification-based research.

- Visualization-based exploratory analysis: Boxplots and histograms were generated for selected features across all three regions. These visualizations provide insight into inter and intra-region variations, facilitating pattern recognition in toolmark characteristics.

- Similarity analysis using Euclidean distance: A 20 × 20 distance matrix was computed using normalized features and Euclidean distance. The resulting heatmap offers a visual and quantitative means to assess similarity between cartridge samples.

2. Related Work

A number of prior studies have addressed the challenge of feature extraction from ballistic cartridge case images, with varying emphasis on firing pin, breech face, and occasionally annulus impressions. This section reviews recent and relevant research related to the feature extraction and similarity analysis of cartridge case impressions, focusing on the three main regions: firing pin, breech face, and annulus impressions.

Alsop et al. [11] used micro-computed tomography (micro-CT) to characterize three-dimensional surface morphology of cartridge cases, enabling precise volumetric and shape-based analyses. While this approach achieved high structural accuracy, it required sophisticated imaging equipment. Also, this study did not include any region-specific 2D feature extraction.

Guyll et al. [12] focused on the empirical validation of forensic cartridge-case comparisons by assessing examiner performance and statistical reliability using both optical and 3D data. Their work established the forensic credibility of comparison practices but did not address algorithmic or texture-based computational analysis.

Riva et al. [13] proposed a likelihood ratio-based technique for interpreting impressed marks on cartridge cases, introducing a quantitative model for similarity estimation between firearm toolmarks. However, their study primarily targeted overall mark comparison and lacked fine-grained region-level segmentation or analysis of distinct zones such as the firing pin, breech face, and annulus.

Tai and Eddy [14] conducted a study that applies statistical record linkage principles to match cartridge cases using 3D topographic data, focusing on breech face impressions. It demonstrates scalable matching over a large dataset and emphasizes statistical rigor. However, this method does not include analysis of firing pin or annulus impressions and is limited to 3D data without comparing region-specific texture descriptors or similarity measures.

Kara and Karatatar [1] compared multiple image similarity metrics, including SSIM, RMSE, and PSNR, on 3D cartridge case images. The analysis involves firing pin, breech face, and ejector mark impressions. However, this method does not perform independent analysis or feature extraction from each region and does not include annulus impressions in its evaluation.

Basu et al. [2] developed an open-access feature-based likelihood ratio system using 3D cartridge case images across multiple regions, including the firing pin and breech face, to validate feature-extraction methods on a large dataset of 300 firearms (10 case samples each). Their findings support the use of multiregional features and robust statistical modelling in firearm source attribution. While this study explored large-scale probabilistic modelling using 3D features and thousands of samples, our work takes a complementary approach by focusing on interpretable, region-wise analysis using 2D images and accessible tools. This makes it suitable for small-scale or early-stage forensic investigations where only basic imaging and analysis tools are available.

Bouthillier et al. [6] applied U-Net models for segmenting breech face and firing pin regions in high-resolution cartridge case images. They achieved high accuracy in locating these regions. The work focuses solely on region segmentation and does not perform feature extraction or similarity analysis. Annulus impressions were not considered.

Patten et al. [15] used contrastive neural networks for similarity scoring between cartridge cases, showing improved performance over traditional methods on large datasets. They offer a deep learning approach to source identification. While powerful, the method lacks region-specific interpretability and does not analyse or compare firing pin, breech face, and annulus impressions individually.

As summarized in Table 1, previous studies have explored various approaches to cartridge case toolmark identification.

Table 1.

Comprehensive summary of existing work on toolmark identification of cartridge cases.

3. Methodology

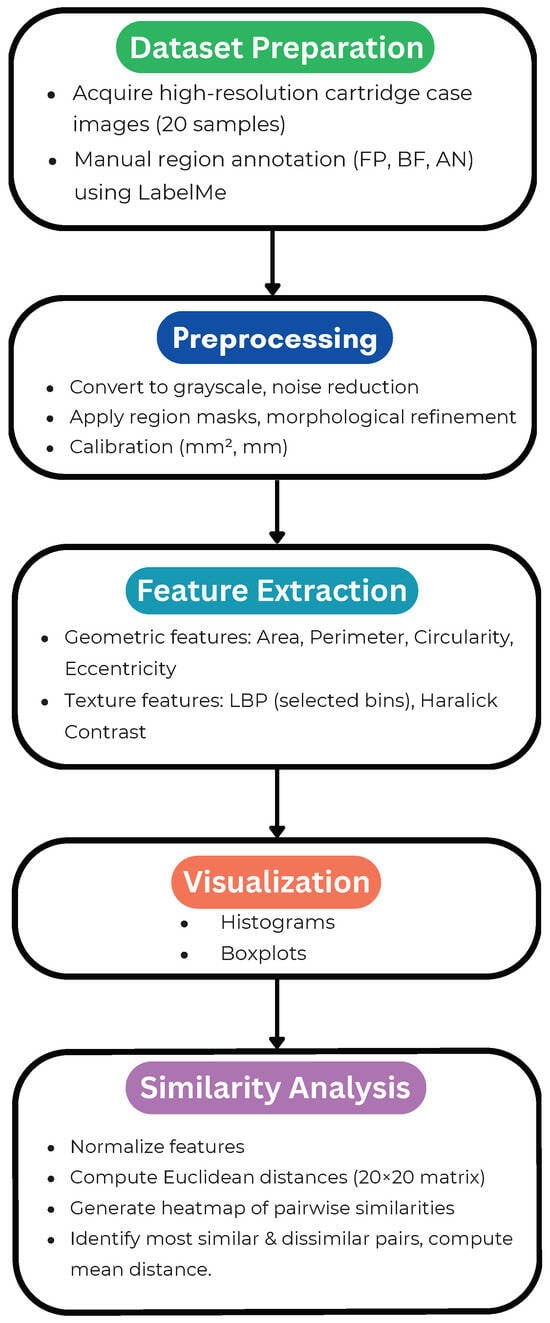

This section outlines the methodology adopted to achieve the objectives of the study. The overall workflow of the proposed system is illustrated in Figure 2.

Figure 2.

Overall system workflow of the methodology.

3.1. Dataset Description

The dataset used in this study comprises high-resolution digital images of 20 fired cartridge cases of 7.62 mm caliber rifle collected from the Ballistics Division of Central Forensic Science Laboratory (CFSL), Directorate of Forensic Science Services, Ministry of Home Affairs, Government of India, Guwahati, Assam. These images were captured using a Comparison Microscope (Make: Leica FSM with DMC 4500 Camera and computer system, Leica Microsystems, Wetzlar, Germany).

To capture detailed impressions of the cartridge base, including the firing pin mark, breech face, and annulus, a Stemi 508 doc stereo microscope was used, equipped with a Zeiss Axiocam ERc 5s digital CMOS camera. The image acquisition process was carried out at the Central Forensic Science Laboratory (CFSL) itself. Microscopic imaging was conducted using 50× magnification with optimized single source coherent lighting via angle-poised gooseneck light to ensure even and clear illumination of the surface characteristics of firing pin and breech face marks. Images were captured using Carl Zeiss ZEN software (version 3.7, Carl Zeiss Microscopy GmbH, Jena, Germany) on a connected PC with a 64-bit operating system and 4 GB RAM. The final images were stored in JPEG format at a resolution of 2560 × 1920 pixels, preserving fine details necessary for feature extraction.

The imaging setup used for capturing the base of the cartridge cases is shown in Figure 3.

Figure 3.

Imaging setup used for capturing images of the base of cartridge cases.

The dataset comprises 20 fired cartridge cases of 7.62 mm calibre rifles obtained from the Ballistics Division of the Central Forensic Science Laboratory (CFSL), Guwahati, India. All 20 cartridge cases made available to the authors were included in this study without any additional selection criteria. The objective was to conduct region-wise analysis across all accessible samples to establish a foundational feature-extraction and similarity-computation framework for forensic ballistic images.

Owing to the sensitive nature of forensic evidence and ongoing case confidentiality, the raw images cannot be publicly released. Nevertheless, all analytical steps, preprocessing parameters, and feature-extraction procedures have been described in detail to ensure methodological transparency and reproducibility.

Unlike studies focused on deep learning or classification, this research does not rely on a large dataset. Instead, it emphasizes region-wise manual annotation and feature-level analysis from a limited number of carefully acquired and calibrated cartridge case images. Each image underwent manual annotation to isolate key regions (firing pin, breech face, annulus), forming the basis for detailed geometric and texture-based feature extraction.

3.2. Annotation Process

Accurate region-wise annotation is critical in ballistic image analysis because it determines the quality and reliability of all subsequent feature-extraction and comparison steps [16]. Following recommendations from recent ballistic-imaging studies, our pipeline comprised: (i) region definition, (ii) tool selection and implementation, and (iii) mask generation.

Region definition: Three regions of forensic interest were annotated in each cartridge case image—the firing pin impression (FP), the breech face (BF) region, and the annulus (AN). The FP appears centrally as a circular, oval, or occasionally rectangular indentation produced by the firing pin. The BF region corresponds to the surrounding case-head surface that contacts the firearm’s breech face and often exhibits fine striations and toolmarks [6,11,13]. The annulus is the narrow ring immediately after the BF; it can show subtle flowback or stress patterns after discharge.

Tool selection and implementation: We used LabelMe, an open-source graphical annotation tool, to delineate regions with polygon labels [17,18]. Polygonal annotation enables precise tracing of irregular boundaries typical of forensic impression regions. LabelMe exports annotations in JSON format, which integrates cleanly with downstream computer-vision workflows.

Mask generation: For each annotated image, the LabelMe JSON was batch-converted to a pixel-wise label mask using labelme_json_to_dataset. This produced a binary/instance mask in PNG (with background = 0 and unique integer labels for FP, BF, and AN), along with ancillary files (e.g., info.yaml). These masks were used as inputs for region-specific feature extraction.

The three regions of forensic interest—firing pin (FP), breech face (BF), and annulus (AN)—were selected because they collectively capture the most characteristic toolmarks produced during the firing process. The FP impression encodes the unique geometry of the firing pin tip; the BF area reflects pressure-induced and striated marks from the breech surface; and the AN region records peripheral deformation and flowback caused by chamber pressure. These regions are the most consistently observed across cartridge cases and have been shown in prior forensic studies to contain complementary discriminative information for firearm identification [2,6].

To address potential inter-operator variability, all annotations were conducted by a single trained operator following a uniform annotation protocol, including fixed zoom levels, consistent boundary definitions, and identical labelling conventions across all 20 samples. This procedure minimized subjective inconsistencies between samples. However, we acknowledge that manual delineation can still introduce operator bias. Future work will include inter-annotator reliability assessment (e.g., using Dice or IoU scores) and the development of semi-automated deep learning-based segmentation models to further enhance reproducibility and objectivity.

3.3. Feature Extraction

Feature extraction is the process of converting the annotated image regions into quantitative descriptors suitable for comparison and analysis [2]. In this study, features were extracted for three regions of interest—the firing pin impression (FP), breech face region (BF), and annulus (AN)—to characterize their geometry and texture [2,14]. We extracted two types of features: geometric features (area, perimeter, circularity, roundness, solidity and eccentricity) and texture-based features (LBP histograms with 10 bins from bin 0 to bin 9 and haralick features such as ASM, contrast, correlation and homogeneity) [19].

Geometric features: For each region (FP, BF, AN), geometric features were computed. These features include area, perimeter, circularity, roundness, solidity, and eccentricity and are used to describe the shape and structure of the marked regions. Circularity is computed using the following formula:

roundness is computed using the following formula:

and eccentricity is used to measure how much the shape deviates from a perfect circle [16,20].

Texture features: For texture analysis, we extracted Haralick features from the grey-level co-occurrence matrix (GLCM). We extracted angular second moment (ASM/energy), contrast, correlation, and homogeneity as Haralick descriptors [19].

Additionally, local binary patterns (LBP) were computed to capture micro-textural patterns. We applied the uniform LBP operator with 8 sampling points and a radius of 1. We formed the LBP histogram and retained bins 0–9 for analysis/visualization, with bin 0 representing completely uniform micro-textures [21].

All extracted features such as geometric descriptors (area, perimeter, circularity, roundness, solidity and eccentricity), Haralick ASM, contrast, correlation, homogeneity and LBP bin 0 to LBP bin 9 were computed separately for each of the three regions (FP, BF, and AN) across 20 cartridge case images.

Software used: The entire feature extraction process was carried out using ImageJ and Python. Python libraries included OpenCV and scikit-image for image processing and measurement. Prior to measurement, pixel size was calibrated to millimetres using ImageJ’s Set Scale tool based on known dimensions, so that area and length metrics are reported in physical units [22].

3.4. Preprocessing

Prior to feature extraction, each cartridge case image underwent a structured preprocessing workflow to ensure consistency, enhance clarity, and accurately isolate the regions of interest (ROIs).

Greyscale conversion and denoising: high-resolution images were first converted to greyscale to reduce computational complexity and focus on intensity-based texture and shape features [23]. A gentle Gaussian blur () was applied to suppress background noise while preserving edge structure [24].

Region annotation and mask generation: For localized analysis, three key regions FP, BF, and AN, were manually delineated in LabelMe [17,18]. The resulting JSON annotations were batch-converted to pixel-wise label masks (PNG) using labelme_json_to_dataset. Morphological operations (erosion/dilation) were then applied, as needed, to refine boundaries and remove small artifacts or holes in the masks.

Calibration and contrast normalization: Before any geometric measurements, pixel size was calibrated to millimetres using ImageJ’s Set Scale tool based on known dimensions of the cartridge head, ensuring that area and length metrics are reported in physical units. To enhance texture visibility where appropriate, selective histogram equalization (e.g., per-ROI, avoiding over-enhancement) was applied to improve contrast in texture-rich zones [25].

Resizing: To preserve calibrated scale, ROIs used for geometric measurements were not resized. When down/up-sampling was required for texture computations or visualization, original-resolution ROIs were retained in parallel for all calibrated geometric measurements.

The final pre-processed ROIs (greyscale) and their masks were used to compute geometric features (e.g., area, perimeter, circularity) and texture features (e.g., local binary patterns and Haralick descriptors).

Post-feature normalization: After feature extraction, a separate normalization step was performed using scikit-learn’s MinMaxScaler to scale all feature values to [0,1] prior to computing pairwise Euclidean distances for similarity analysis. This prevents features with larger numeric ranges from dominating the distance computation.

4. Results and Analysis

This section presents quantitative and qualitative results: boxplots and histograms of key features, a pairwise distance heatmap, and similarity statistics.

4.1. Feature Summary

This section provides a comprehensive summary of geometric and texture-based features extracted from the firing pin, breech face, and annulus regions of the 20 cartridge case images analysed in this study. The extracted geometric features include area (mm2), perimeter (mm), circularity, and eccentricity, highlighting differences in size and shape regularity across these regions. Texture-based features include local binary pattern (LBP) histograms and Haralick texture features such as angular second moment (ASM/Energy), contrast, correlation, and homogeneity, derived from the grey-level co-occurrence matrix (GLCM).

The geometric features extracted from the firing pin are summarized in Table 2.

Table 2.

Geometric features extracted from the firing pin (FP).

The geometric features extracted from the breech face are summarized in Table 3.

Table 3.

Geometric features extracted breech face (BF).

The geometric features extracted from the annulus region are summarized in Table 4.

Table 4.

Geometric features extracted from annulus (AN).

The geometric feature analysis revealed that firing pin regions demonstrated high circularity and low eccentricity, indicating predominantly round and regular shapes, whereas breech face regions exhibited significant variability in both circularity and eccentricity, reflective of irregular shapes due to unique surface characteristics. Annulus regions displayed moderate geometric variability.

The texture-based features extracted from the firing pin region are summarized in Table 5. The texture-based features extracted from the breech face region are summarized in Table 6. The texture-based features extracted from the annulus region are summarized in Table 7.

Table 5.

Texture-based features extracted from firing pin (FP).

Table 6.

Texture-based features extracted from breech face (BF).

Table 7.

Texture-based features extracted from annulus (AN).

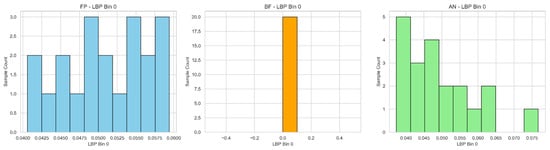

Texture analysis further differentiated the regions. The firing pin exhibited low Haralick contrast and high uniformity in LBP features, suggesting smoother textures with minimal surface variations. Conversely, breech face regions showed high Haralick contrast and low LBP uniformity, indicative of complex textures with significant variations. Annulus regions demonstrated intermediate texture complexity, consistent with moderate textural variations.

Collectively, these extracted features distinctly characterize each cartridge region, providing essential quantitative metrics for subsequent forensic identification and similarity analysis, thus reinforcing the utility of the feature extraction methodology implemented in this study.

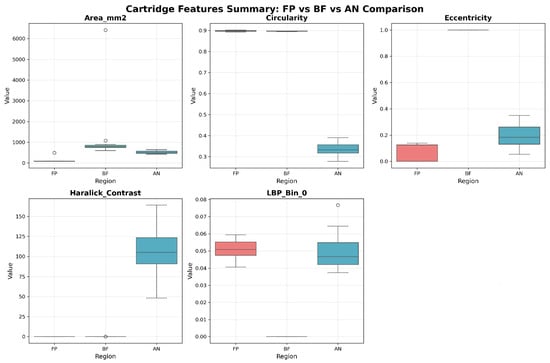

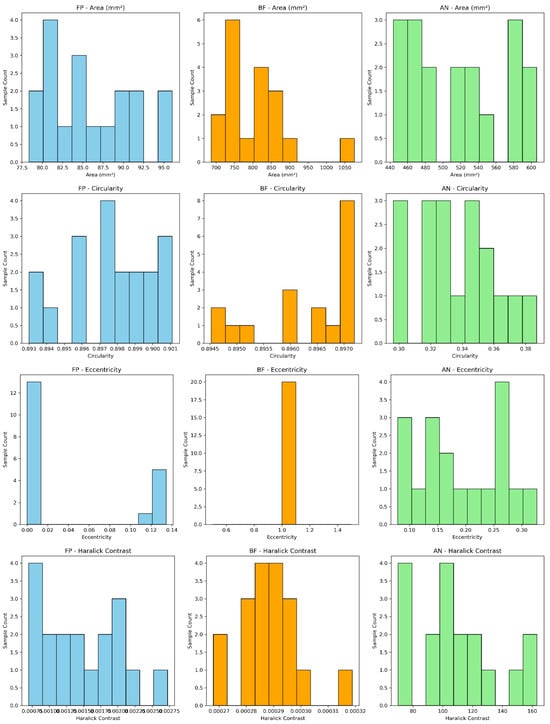

4.2. Visualization

To better understand the distribution and variability of features extracted from the firing pin, breech face, and annulus regions, two visualization techniques were employed. These include boxplots and histograms, each offering intuitive insights into the geometric and texture-based characteristics of the cartridge case impressions.

Boxplots were generated for key geometric features such as area, circularity, and eccentricity, as well as for selected texture descriptors like Haralick contrast and LBP bin frequencies. These boxplots reveal region-specific variability:

- Firing pin regions exhibited low variance in area and high circularity, indicating consistent and round impressions.

- Breech face regions showed wider interquartile ranges for circularity and eccentricity, reflecting diverse and irregular surface patterns.

- Annulus regions displayed intermediate variability, with more consistent eccentricity than the breech face, but less regular than the firing pin.

Figure 4 shows the boxplots of geometric and texture-based features.

Figure 4.

Boxplots of geometric and texture-based features.

Histograms were used to show the distribution of values for each feature across all 20 samples. For example, histograms of Haralick contrast revealed that the breech face marks had a right-skewed distribution, indicating higher texture complexity, whereas firing pin marks were concentrated in lower contrast bins. LBP histograms further highlighted the uniform textural properties of firing pin regions, with bin 0 dominating most samples, in contrast to the more dispersed distributions observed in breech face and annulus areas.

Figure 5 shows the histograms of geometric and texture-based features.

Figure 5.

Histograms of geometric and texture-based features.

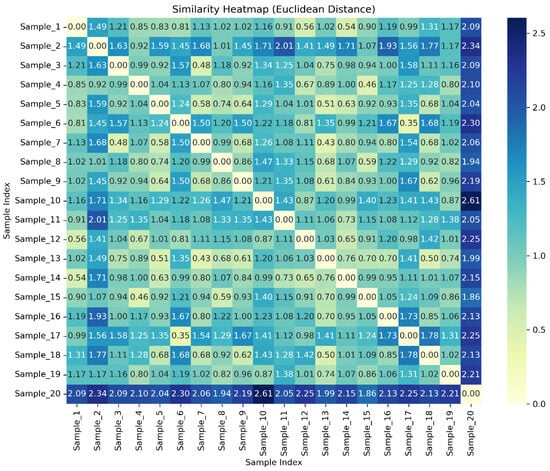

4.3. Similarity Analysis

To quantitatively analyse the similarity and dissimilarity among segmented cartridge case images, Euclidean distance measurements were calculated between every pair of samples. After segmentation into three distinct areas (firing pin (FP), breech face (BF), and annulus (AN)) feature extraction was performed, yielding numerical feature vectors for each of the 20 cartridge case images.

The Euclidean distance between each pair of cartridge case samples (i) and (j) was computed using the following formula:

where () and () represent feature values of samples (i) and (j), respectively, and (n) is the number of extracted features.

This resulted in a 20 × 20 symmetric distance matrix, with diagonal elements naturally being zero, as they represent the distance of a sample to itself. To summarize overall similarity, the mean distance for each sample was computed, providing insight into the average similarity of each cartridge image relative to all others.

The complete 20 × 20 Euclidean distance matrix is provided in the Supplementary Materials (Table S1) for reference.

Further analysis was conducted to explicitly identify the most similar and dissimilar pairs among the samples. For this, diagonal elements were excluded by setting them to infinity to avoid self-comparisons. The smallest distance identified represented the most similar pair of cartridge samples, suggesting high forensic relevance, potentially indicating matches or cartridges fired from identical or similar firearms. Conversely, the largest distance identified highlighted the most dissimilar cartridge pair, indicating clear differences possibly due to varied firearm or ammunition characteristics.

The Euclidean distance analysis, visualized through a similarity heatmap, provided clear insights into the relationships among the 20 segmented cartridge case images. Notably, samples exhibited varying degrees of similarity, with Sample_6 and Sample_17 displaying the highest similarity (lowest Euclidean distance ≈ 0.35), suggesting a strong likelihood of originating from similar firearms or manufacturing conditions. Conversely, Sample_20 consistently showed significant dissimilarity from all other samples, highlighting distinct differences potentially arising from unique firearm characteristics or different ammunition batches. This heatmap visualization effectively underscores the discriminative power of the segmentation and feature extraction approach, offering valuable quantitative evidence for forensic firearm analysis and cartridge case identification.

Figure 6 shows the heatmap of the Euclidean distance matrix, illustrating the similarity relationships among the cartridge case images.

Figure 6.

Heatmap of Euclidian distance matrix.

The above quantitative approaches facilitate robust forensic interpretations, clearly distinguishing between samples based on measurable feature differences, enhancing the reliability and interpretability of forensic firearm analysis.

To find the most similar and most dissimilar samples precisely, all pairwise distances in the matrix are compared. The smallest non-zero value is considered as the most similar pair, and the largest value for the most dissimilar pair, excluding self-comparisons along the diagonal. The diagonal elements are excluded from consideration because the distances of each sample with itself is zero. The most similar sample pairs, based on the computed Euclidean distances (lowest distance), are summarized in Table 8.

Table 8.

Most similar pairs based on computed Euclidian distances (lowest distance).

Mean of distances for each sample have been computed to determine how generally similar or dissimilar a sample is from all others. The table below (Table 9) summarizes the mean distances of each sample.

Table 9.

Mean distance of each sample.

The following interpretations can be obtained from Table 9.

- Low mean distance: Indicates similarity, suggesting the sample is more similar to others on average. Sample_13 had the lowest mean distance (~0.94), suggesting it generally resembles most other samples closely.

- High mean distance: Indicates more dissimilarity, suggesting the sample is distinctly different from most others. Sample_20 had the highest mean distance (~2.15), indicating significant difference from others.

4.4. Limitations

While the analysis presented in this study provides meaningful insights into the geometric and texture-based characteristics of firing pin, breech face, and annulus impressions, it is limited by the small number of available samples. The dataset comprised only 20 cartridge case images, as provided by the Ballistics Division, which were the complete set of cases available at the time of study. The authors did not perform any selection or exclusion; all available images were included in the analysis to ensure objectivity and completeness.

Despite this limitation, the results demonstrate the feasibility of the proposed feature extraction and similarity analysis methodology for ballistic image examination. Future research should aim to extend this work using larger and more diverse datasets, including cases from multiple firearms, and to explore integration with machine learning or 3D imaging techniques for enhanced forensic identification accuracy.

5. Discussion

The detailed feature extraction and analysis presented in this study identified region-specific patterns that offer valuable insights into the forensic comparison of ballistic cartridge case impressions. With a dataset comprising 20 annotated cartridge images segmented into firing pin (FP), breech face (BF), and annulus (AN) regions, the extracted features provided a multidimensional representation of both geometric and texture-based characteristics.

The firing pin region consistently demonstrated high circularity, solidity, and roundness, along with low eccentricity and Haralick contrast values. These findings reinforce the notion that firing pin impressions are generally uniform in shape and smooth in texture, making them reliable markers for firearm identification. LBP histograms for this region further confirmed dominant bin 0 values, indicating a prevalence of uniform texture patterns across samples.

In contrast, the breech face region exhibited greater variability across all feature categories. Circularity and eccentricity values showed significant spread, suggesting irregular shapes likely caused by unique toolmarks and surface wear patterns. Texture features such as Haralick contrast were higher on average, and LBP distributions were more dispersed, reflecting the complex and textured nature of breech face impressions. This variability, while introducing challenges in similarity matching, also indicates a potentially rich source of discriminative information.

The annulus region displayed intermediate characteristics. While not as consistent as the firing pin nor as variable as the breech face, it exhibited moderate roundness and texture complexity. LBP and Haralick features positioned it between the other two regions, indicating that annulus impressions can contribute supplemental forensic information, particularly when combined with features from FP and BF regions.

Similarity analysis using Euclidean distance highlighted that Sample_6 and Sample_17 were the most similar, with the smallest inter-sample distance, suggesting strong alignment in all three regions. On the other hand, Sample_20 was the most dissimilar, standing out with higher distances from all other samples. The accompanying heatmap visually reinforced these findings, providing a clear matrix-based representation of inter-sample relationships.

Overall, the extracted features effectively capture the intra-class variability among cartridge case impressions. The consistency of firing pin features, the complexity of breech face textures, and the supplementary nature of annulus characteristics collectively demonstrate the viability of handcrafted feature-based approaches in forensic firearm analysis. Although limited by the small sample size and lack of ground-truth firearm identity labels, this study establishes a foundational methodology for future classification efforts involving larger and more diverse datasets.

While this study employed two-dimensional geometric and texture-based features, the proposed framework aligns closely with recent advances in three-dimensional ballistic imaging. Modern 3D systems provide detailed surface topography that enhances mark visualization and comparison accuracy. However, these systems also require specialized instrumentation and higher computational resources. The 2D methodology presented here offers a lightweight and accessible alternative that can serve as a complementary or preliminary step for rapid screening before 3D analysis. In future work, the extracted 2D descriptors could be adapted as input features or validation references within hybrid 2D-3D forensic workflows.

6. Conclusions

This study has presented a structured and interpretable approach for analysing ballistic cartridge case impressions by focusing on region-wise feature extraction from the firing pin, breech face, and annulus regions. A dataset of 20 high-resolution cartridge images was manually segmented, and both geometric and texture-based features were extracted using ImageJ and Python-based tools.

The analysis revealed that firing pin regions are characterized by high regularity and uniform texture, making them reliable for comparison. Breech face impressions displayed greater variability and complexity, which offers a richer set of discriminative features. The annulus region, although less consistent, provided Supplementary Information that enhanced the overall interpretability of the dataset.

Similarity assessment is conducted using Euclidean distance and visual heatmaps confirmed meaningful relationships between samples, with some impressions showing high similarity while others stood out as distinct. These findings validate the effectiveness of the handcrafted feature extraction process in capturing forensic-relevant details.

Although this study does not employ machine learning classification due to dataset size limitations, it successfully lays the groundwork for future research. The structured dataset and insights presented here can support the development of automated ballistic identification systems, especially when scaled to larger and more diverse sample sets.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/forensicsci5040062/s1, Table S1: 20 × 20 symmetric distance matrix using Euclidean distance.

Author Contributions

Conceptualization, S.B., R.S., R.B.G., C.J.K., B.C., L.D. and M.J.S.; methodology, S.B., B.C. and L.D.; software, S.B., C.J.K., B.C. and L.D.; validation, S.B. and M.J.S.; formal analysis, S.B., R.S., R.B.G. and C.J.K.; investigation, M.J.S.; resources, R.S. and M.J.S.; data curation, S.B., R.S., B.C. and L.D.; writing—original draft preparation, S.B., B.C., L.D. and M.J.S.; writing—review and editing, M.J.S.; visualization, S.B., R.S., R.B.G. and C.J.K.; supervision, M.J.S.; project administration, S.B. and M.J.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research and the APC were funded by Biomedical Sensors & Systems Lab, University of Memphis, Memphis, TN 38152, USA.

Institutional Review Board Statement

Ethical review and approval were waived for this study, as it did not involve human participants, animals, or any sensitive personal data. The research utilized only digital images of cartridge cases that were provided by the Ballistics Division of Central Forensic Science Laboratory (CFSL), Guwahati, Assam, for academic and analytical purposes only. No physical evidence or cartridge cases were handled or removed from the laboratory, in full compliance with legal and institutional regulations.

Informed Consent Statement

Not applicable.

Data Availability Statement

Due to the sensitivity of ballistic evidence and the fact that the cartridge images originate from ongoing case investigations, the original images cannot be publicly shared. However, the extracted feature datasets and derived analytical results are available from the corresponding author upon reasonable request.

Acknowledgments

The authors gratefully acknowledge the Ballistics Division of Central Forensic Science Laboratory (CFSL), Guwahati, Assam, for providing access to high-resolution cartridge case images used in this research. The images were made available solely for academic analysis and interpretation, without any handling or transfer of physical evidence. The authors also thank the supporting laboratory staff and institutional authorities for their guidance and technical assistance throughout this study.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Kara, I.; Karatatar, A. Classification of fired cartridge cases using 3D image capture and a comparison of database correlation method performance. J. Forensic Sci. 2022, 67, 1998–2008. [Google Scholar] [CrossRef] [PubMed]

- Basu, N.; Bolton-King, R.S.; Morrison, G.S. Forensic comparison of fired cartridge cases: Feature-extraction methods for feature-based calculation of likelihood ratios. Forensic Sci. Int. Synerg. 2022, 5, 100272. [Google Scholar] [CrossRef] [PubMed]

- Naghavi, M.; Marczak, L.B.; Kutz, M.; Shackelford, K.A.; Arora, M.; Miller-Petrie, M.; Aichour, M.T.E.; Akseer, N.; Al-Raddadi, R.M.; Alam, K.; et al. Global mortality from firearms, 1990–2016. JAMA 2018, 320, 792–814. [Google Scholar] [CrossRef] [PubMed]

- Mehta, N.; Aggarwal, A.D.; Girdhar, P. Profile of firearm-related deaths at a tertiary care hospital in North India—A two-year retrospective study. J. Contemp. Clin. Pract. 2025, 11, 578–584. [Google Scholar]

- Pisantanaroj, P.; Tanpisuth, P.; Sinchavanwat, P.; Phasuk, S.; Phienphanich, P.; Jangtawee, P.; Tantibundhit, C. Automated firearm classification from bullet markings using deep learning. IEEE Access 2020, 8, 78236–78251. [Google Scholar] [CrossRef]

- Le Bouthillier, M.E.; Hrynkiw, L.; Beauchamp, A.; Duong, L.; Ratté, S. Automated detection of regions of interest in cartridge case images using deep learning. J. Forensic Sci. 2023, 68, 1958–1971. [Google Scholar] [CrossRef]

- Guo, B.E.; Shen, Y.; Zhou, Z.F.; Liu, X.; Wei, Y.X.; Yang, L. Advanced deep learning for automatic classification of fired bullets from standard-issue firearms. Sci. Justice 2025, 65, 101335. [Google Scholar] [CrossRef]

- Mookiah, M.R.K.; Puch-Solis, R.; Farhan, S.; Ajala, B.; Nic Daeid, N. Automated segmentation of the breech and firing pin faces of fired cartridge case images. Forensic Sci. Int. 2025, 375, 112554. [Google Scholar] [CrossRef]

- Sharma, B.K. Firing pin micro-printing for identification of firearm. Indian J. Forensic Med. Pathol. 2023, 16, 1. [Google Scholar] [CrossRef]

- Rukhman, I.; Marzia, A. Advancements and applications in gunshot identification and forensic ballistics. Forensic Insights Health Sci. Bull. 2025, 3, 12–16. [Google Scholar] [CrossRef]

- Alsop, K.; Norman, D.; Remy, G.; Wilson, P.; Williams, M.A. Quantitative characterisation of ballistic cartridge cases from micro-CT. Forensic Sci. Int. 2021, 326, 110913. [Google Scholar] [CrossRef] [PubMed]

- Guyll, M.; Madon, S.; Yang, Y.; Burd, K.A.; Wells, G. Validity of forensic cartridge-case comparisons. Proc. Natl. Acad. Sci. USA 2023, 120, e2210428120. [Google Scholar] [CrossRef] [PubMed]

- Riva, F.; Mattijssen, E.J.; Hermsen, R.; Pieper, P.; Kerkhoff, W.; Champod, C. Comparison and interpretation of impressed marks left by a firearm on cartridge cases—Towards an operational implementation of a likelihood ratio-based technique. Forensic Sci. Int. 2020, 313, 110363. [Google Scholar] [CrossRef] [PubMed]

- Tai, X.H.; Eddy, W.F. Automatically matching topographical measurements of cartridge cases using a record linkage framework. arXiv 2020, arXiv:2003.00060. [Google Scholar] [CrossRef]

- Patten, C.; Saunders, C.; Puthawala, M. Deep learning for forensic identification of source. arXiv 2025, arXiv:2503.20994. [Google Scholar] [CrossRef]

- Gadelmawla, E.; Khalifa, W.M.; Elewa, I.M. Measurement and inspection of roundness using computer vision. MEJ-Mansoura Eng. J. 2020, 33, 20–32. [Google Scholar] [CrossRef]

- Severinski, K.; Cvija, T. Medical data annotation and JSON to dataset conversion using LabelMe and Python. Ri-STEM 2021, 27. [Google Scholar]

- Russell, B.C.; Torralba, A.; Murphy, K.P.; Freeman, W.T. LabelMe: A database and web-based tool for image annotation. Int. J. Comput. Vis. 2008, 77, 157–173. [Google Scholar] [CrossRef]

- Oprisan, A.; Oprisan, S.A. Bounds for Haralick features in synthetic images with sinusoidal gradients. Front. Signal Process. 2023, 3, 1271769. [Google Scholar] [CrossRef]

- Jiang, B.; Du, X.; Bian, S.; Wu, L. Roundness error evaluation in image domain based on an improved bee colony algorithm. Mech. Sci. 2022, 13, 577–584. [Google Scholar] [CrossRef]

- Sedaghatjoo, Z.; Hosseinzadeh, H.; Bigham, B.S. Local binary pattern (LBP) optimization for feature extraction. arXiv 2024, arXiv:2407.18665. [Google Scholar] [CrossRef]

- Schroeder, A.B.; Dobson, E.T.; Rueden, C.T.; Tomancak, P.; Jug, F.; Eliceiri, K.W. The ImageJ ecosystem: Open-source software for image visualization, processing, and analysis. Protein Sci. 2021, 30, 234–249. [Google Scholar] [CrossRef]

- Wang, J.; Lee, S. Data augmentation methods applying grayscale images for convolutional neural networks in machine vision. Appl. Sci. 2021, 11, 6721. [Google Scholar] [CrossRef]

- Li, P.; Wang, H.; Yu, M.; Li, Y. Overview of image smoothing algorithms. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2021; Volume 1883, p. 012024. [Google Scholar] [CrossRef]

- MathWorks. Adjust Image Contrast Using Histogram Equalization. 2021. Available online: https://www.mathworks.com/help/images/histogram-equalization.html (accessed on 15 July 2025).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).