The present work describes experimental studies related to the characterization of CuSbS2 directly synthesized after 2 h of mechanochemical synthesis (MCS) at 340 rpm, starting from mixtures of elemental powders. X-ray diffraction (XRD) and UV-VIS-NIR spectroscopy were carried out to analyze the crystal structure, degree of crystallinity, crystallite size and optical properties of the mechanochemically synthesized CuSbS2 powders. Rietveld refinement was carried out using Diffrac. TOPAS (Bruker AXS). Thermal stability of the synthesized materials was evaluated by the vacuum thermal heat treatment of the mechanochemically synthesized CuSbS2 powders at 350 °C for 24 h. Furthermore, the CuSbS2 powders were also analyzed by field-emission scanning electron microscopy (FE-SEM), laser diffraction, and differential thermal analysis.

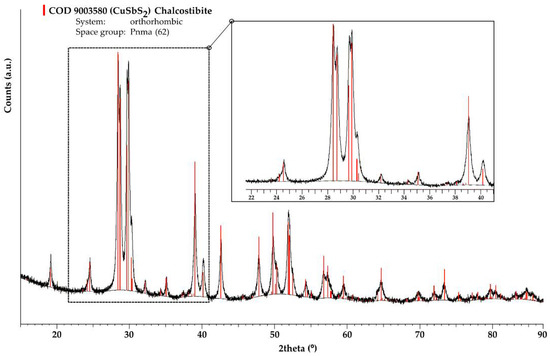

As the Figure 1 shows, all XRD peaks were assigned to the orthorhombic chalcostibite phase with the space group Pnma (COD database file 9003580). This result is significant and demonstrates the direct synthesis of CuSbS2 powders at room temperature after a short-duration MCS process. The absence of any phase transformation with heat treatment at 350 °C/24 h revealed the strong structural stability of the produced phase. The optical bandgap was determined to be around 1.41 eV, in good agreement with the values reported in the literature. This suggests that mechanochemically synthesized CuSbS2 compounds can be considered suitable to be used as absorber materials of thin-film solar cells. Additionally, the obtained results also indicate that the MCS process is a viable and promising route for the preparation of materials for photovoltaic applications.

Figure 1.

Typical XRD pattern of the CuSbS2 powders produced directly by mechanochemical synthesis.

Author Contributions

Conceptualization, J.B.C. and F.N.; investigation, L.E., I.F., J.M. and T.P.S.; writing—original draft preparation, J.B.C. and F.N.; writing—review and editing, L.E., I.F., J.M., T.P.S., J.B.C. and F.N.; project administration, F.N.; funding acquisition, F.N. All authors have read and agreed to the published version of the manuscript.

Funding

This work is funded by national funds through the FCT–Fundação para a Ciência e a Tecnologia, I.P., under the project PTDC/EAM-PEC/29905/2017 (LocalEnergy project, http://localenergy.lneg.pt, accessed on 2 June 2022).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The “Direção Geral de Energia e Geologia” participates as an “External Advisor” in LocalEnergy project.

Conflicts of Interest

The authors declare no conflict of interest.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).