Dynamic and fast-changing designs for cutleries or flatware are one important nature of this production business. Globalized hospitality merchandise, the demanding nature of modern customers, throat-to-throat competition of manufacturing industries, and the modernization of the manufacturing processes are some of the major challenges for the cutlery (silverware) manufacturing industry. So far, traditional methods of moulding and shaping are considered to be the best to provide static designs and trademark patterns of the organisation. Preparing a designed mould for a fixed blueprint of cutlery and then producing it in bulk is the sole purpose of existing methods. However, with the invention of laser engraving and design systems, the entire business of cutlery production has revolutionized. Allowing for different designs for different cutleries to set without changing the whole production line was the aim of this study.

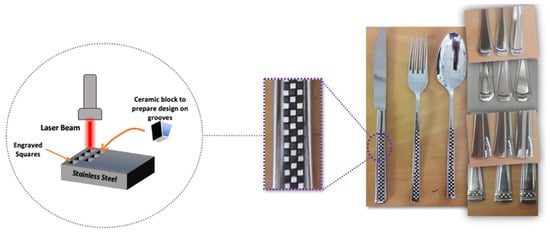

As shown in Figure 1, AISI-304 stainless steel, which is the general flatware material selected for laser engraving, was evaluated with three most vital input parameters (power, scanning speed and loops or number of passes) followed by the analysis of geometry, roughness, and volume removed/material removal (MR) as output variables. This study will provide insight into the know-how situation involving the processing of cutleries and introduction of different ceramic materials to the surface to define desired patterns. We produced different design patterns by laser and ingrained ceramic blocks on the silverware. This approach is much more flexible and adoptable for pattern changes. Besides that, there is no need to prepare a mould for each design. Belo Inox, Portugal supplied the silverware as per the collaborative project agreement.

Figure 1.

Laser engraved AISI-304 stainless steel flatware.

Author Contributions

Conceptualization, F.S.S.; methodology, V.R.; investigation, V.R., characterization, G.M.; optimization of the laser parameters, O.C. Everyone participated in the formal writing and review of the abstract. All authors have read and agreed to the published version of the manuscript.

Funding

The project is funded by “Cutlnov-Development of new aesthetics for cutlery by using new technologies” with the reference POCI-01-0247-FEDER-017828. The work is a joint venture of CMEMS-UMinho and Cutlnov.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).