Abstract

The goal of this work was to study the effects of cyclic close die forging on the microstructure and mechanical properties of Ti–5Al–3Mo–1.5V alloy, which was produced in Vietnam. The factors considered include the deformation temperature (Td), at 850 °C, 900 °C, and 950 °C, and the number of cycles performed while forging in closed die (n)— 3, 6, and 9 times. The responses measured were average grain diameter (dtb) and tensile stress (σb). The results indicate that the smallest average grain size of 1 μm could be obtained at Td = 900 °C, n = 9 times and the tensile stresses were enhanced. The experimental results we obtained also suggest that the microstructure of Ti–5Al–3Mo–1.5V alloy is accordant for superplastic deformation. The superplastic forming of this alloy can show maximum elongation of 1000% or more.

1. Introduction

Titanium alloy is a structural material with many outstanding properties: high strength, small density, good ductility, high melting point, and outstanding corrosion resistance. Therefore, titanium alloy is increasingly used in many different technical industries, especially in the aviation, automotive, and defense industries [1]. However, at room temperature, the durability of titanium alloy is very high, making it difficult to cut, so it is usually deformed at high heat in the range of 600–1050 °C [2].

In order to improve the applicability of titanium alloys in practice, it is necessary to study the methods of improving mechanical properties and technology, and especially the deformation ability of materials. One of the measures to improve deformation capacity is the need to prepare the workpiece with fine grain and deformation under reasonable conditions of strain temperature and rate. Meanwhile, the titanium alloy is deformed in the superplastic state [3,4].

Superplasticity is the ability of plastic deformation to a large extent of a metal or alloy under certain conditions of the microstructure, temperature, and strain rate under the impact of small stress, and it is dependent on the strain rate [5]. For uniaxial tension tests, the elongation to fracture above 200% is usually indicative of superplasticity, although some materials can achieve extension up to 1000%. This shows that such values are greater by one or two orders of magnitude compared to those of conventional metallic materials. The superplastic state is characterized by three basic signs: a very large degree of plastic deformation, which can reach hundreds or even thousands of percent without destroying the material; the stress needed to deform the material in the superplastic state is very small compared to the plastic deformation in the normal state; the yield stress is very sensitive to changes in the strain rate, which means that metal tendency can harden by the strain rate [6,7].

In order to appear structurally superplastic, three conditions must be ensured: the microstructure of the material, the deformation temperature, and the strain rate. Metals and alloys have a fine and stable microstructure (usually between 5 and 15 µm) and the particle size is almost unchanged during deformation. The temperature range of deformation to superplastic deformation is quite wide, usually ranging from 0.5 to 0.9 Tnc (Tnc—the melting point of the material in degrees Kelvin). The deformation temperature must ensure no change during deformation and uniformity throughout the workpiece. The strain rate must be small enough for diffusion to occur and must be large enough at high temperatures to ensure that the particles do not grow during machining. Normally, the strain rate of superplastic deformation usually ranges from 10−4 to 10−2 s−1 [5,6,7].

The method that can be used to give the material a fine grain structure is severe plastic deformation (SPD). Severe plastic deformation (SPD) is a group of metalworking techniques involving very large strains typically involving a complex stress state or high shear, resulting in a high defect density and equiaxed ultrafine grain (UFG) size (d < 500 nm) or nanocrystalline (NC) structure (d < 100 nm) [8,9].

In the methods of SPD, the cyclic closed die forging (CCDF) method is the method that can allow for obtaining materials with very fine microorganisms, even nano-organization for industrial alloy grades. It can be carried out over a wide temperature range (20–950 °C) by using specialized mold structures and heaters and allows for the deformation of workpieces with large sizes and volumes compared to some other methods, such as [9,10] high-pressure twisting, pressing through a broken channel, and so forth. Moreover, the requirements for the equipment, tools, and molds for the deformation are quite simple, easy to fabricate, and at the same time, highly capable of industrial applications.

The technology parameters of the CCDF method affecting the structure and mechanical properties of the titanium alloy include the deformation temperature and the number of deformation times. In the present work, the influence of CCDF was carried out in the temperature range between 800 and 900 °C and the number of deformation times on the structure and properties of Ti–5Al–3Mo–1.5V titanium alloy were studied.

2. Experimental Procedure

2.1. Materials

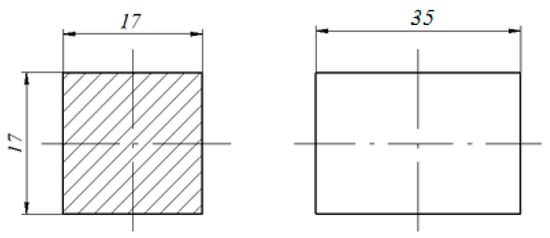

The material used in this study was an σ/β titanium Ti–5Al–3Mo–1.5V alloy. The Ti–5Al–3Mo–1.5V titanium alloy was produced in Vietnam. The test specimens were in the casting state. The rectangular specimens with a width of 17 mm, a length of 17 mm, and a height of 25 mm were used for the experiment (Figure 1). The chemical composition of the analyzed Ti–5Al–3Mo–1.5V alloy is shown in Table 1.

Figure 1.

The specimen used in the experiment.

Table 1.

Chemical composition of the analyzed Ti–5Al–3Mo–1.5V alloy (wt %).

2.2. The Experimental Method

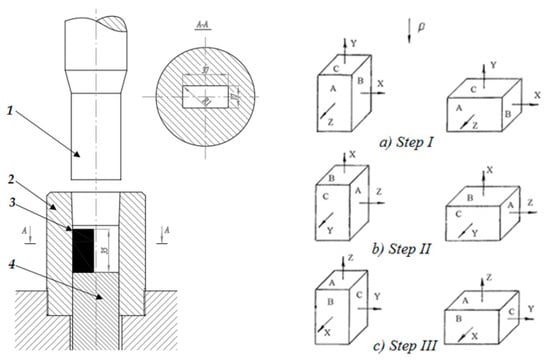

The CCDF process was performed in steps and cycles in a closed die. The deformation cycle consists of three steps, I, II, and III. The forging dies and the order of steps per cycle are shown in Figure 2. The initial workpiece’s faces were marked as A, B, and C, which correspond to the coordinate axes of X, Y, and Z.

Figure 2.

The forging dies and the steps of the CCDF process. (1) Punch; (2) Die; (3) Workpiece; (4) Ejector.

In Step I (Figure 2a), when the punch is pressed down, the height of the workpiece in the Y direction is reduced, the size of the workpiece is stretched in the X direction, and the size of the workpiece in the Z direction does not change due to restriction by the die.

In Step II (Figure 2b), the workpiece is removed from the mold after Step I, placing the workpiece in the mold so that the direction of the pressure coincides with the X direction (rotating the workpiece by 90°). After deformation, the workpiece size along the X-axis decreases with the pressing stroke, the workpiece size in the Z-axis is increased, and the workpiece size in the Y-axis remains constant.

After the end of Step II, the workpiece is removed and rotated 90°, and Step III of the cycle pressing is performed (Figure 2c). In this step, the workpiece is reduced in size along the Z-axis, the dimension increases along the Y-axis, and the dimension along the X-axis remains constant.

By deforming over a number of cycles (1–3 cycles), the workpiece is deformed relatively evenly along the axis, which helps improve the microstructure and mechanical properties of the material; specifically, the fine stable grain size will be obtained and the plastic deformation ability will increase.

2.3. Experimental Conditions and Equipment

There were 9 experimental specimens deformed by the cyclic closed die forging with the deformation temperature and the number of deformation times shown in Table 2. The cyclic closed die forging process was performed by a 100-ton hydraulic press (YH32–100T). The strain rate of the workpiece depends on the pressing speed of the experimental equipment, which was about 1 mm/s.

Table 2.

The experimental parameters.

The containers with the specimens were heated to the deformation temperature (850, 900, and 950 °C) in a Nabertherm chamber furnace LH120/13, and the specimens were then placed into the working chamber of a forging die (Figure 3). The delay before beginning the extrusion was 20–30 s. The heating process for the die was done on a furnace capable of heating up to 800 °C, with a set temperature of ±3 °C.

Figure 3.

Scheme of the CCDF set-up and tools: (a) experiment die; (b) punch and die.

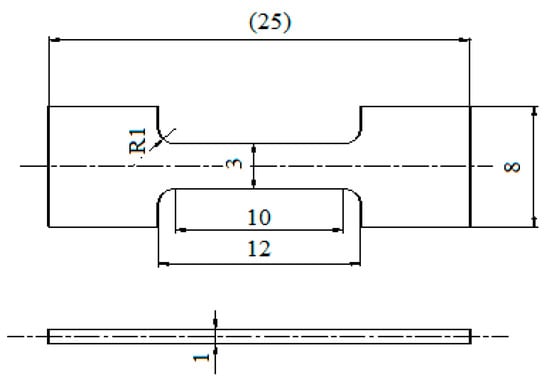

The microstructure of the deformed samples was examined using a Nova-NanoSEM-450 scanning electron microscope (SEM) and optical microscopy. A tensile test was performed on compression puller TT-HW2-1000. The tensile properties of the material deformed at deformation temperature were determined by a tensile test at room temperature. The tensile samples for the tensile test are presented in Figure 4.

Figure 4.

The specimen for the tensile test.

The microstructure, texture, and mechanical properties were determined on the central portion of the deformed samples, where steady deformation occurred. The average grain size was determined according to the Standard Test Methods for Determining Average Grain Size (ASTM E 112) [11] or [12] micrographic determination of the apparent grain size (ISO 643: 2019).

3. Results and Discussion

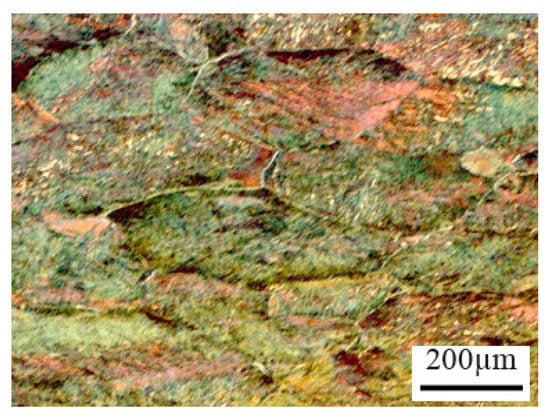

The microscopic image in Figure 5 shows an average grain size of about 300 µm. The mechanical properties of the initial test specimens are shown in Table 3.

Figure 5.

Microscopic image of Ti–5Al–3Mo–1.5V alloy of initial test specimens (×100).

Table 3.

Mechanical properties of Ti–5Al–3Mo–1.5V alloy.

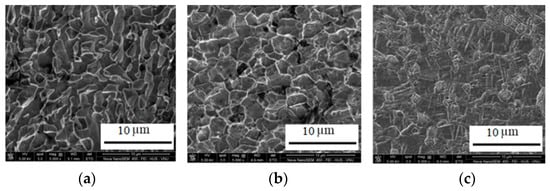

Figure 6 shows the microstructure of some experimental specimens after CCDF with different strain temperatures and numbers of deformation times. Small grain growth was noticed after the severe plastic deformation tests. Using the Snyder–Graff method [13], we could determine the average grain diameter on the microscopic images of the experimental specimens after the CCDF process (Table 4).

Figure 6.

The microstructure of some experimental specimens after CCDF (×5000): (a) No.3; (b) No.5; (c) No.9.

Table 4.

The average grain size of the experimental specimens.

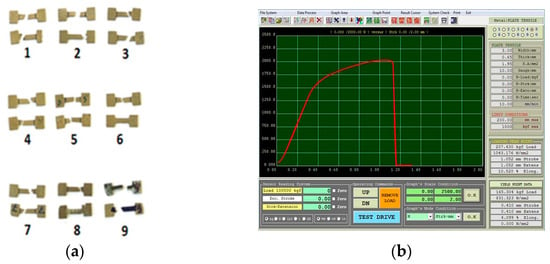

The tensile test specimens were also numbered 1 to 9, corresponding to the test conditions in Table 2. The tensile stress of the experimental specimens with different strain temperatures and numbers of deformation times are given in Figure 7 and Table 5. The tensile test resulted in a noticeable enhancement of the mechanical characteristics compared to the initial alloy.

Figure 7.

The tensile results: (a) specimens after tensile tests; (b) tensile test chart after 9 deformation times at 950 °C.

Table 5.

Mechanical properties of Ti–5Al–3Mo–1.5V alloy after CCDF.

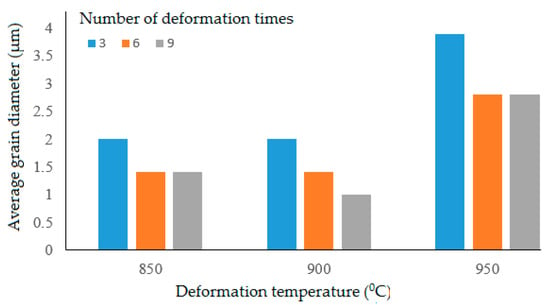

From the experimental results, it was found that after the CCDF process, Ti–5Al–3Mo–1.5V titanium alloy had a significantly improved microstructure. The average grain size decreased significantly (Figure 8). However, it was found that at the pressing temperature of 950 °C, the microscopic structure of the specimens was different because the specimens were deformed at temperatures above the Ac3 region (phase transition temperature), so the microstructure obtained was phase α’ (mactenxite), the oversaturated hexagonal α phase of molybdenum and vanadium [2]. At a deformation temperature over 900 °C, the average grain size increased with increasing temperature; the smallest average grain size was obtained in the temperature range of 870–900 °C.

Figure 8.

The average grain size of experimental specimens.

The specimens after deformation by CCDF also significantly improved the mechanical properties. After one cycle (three deformation times) to three cycles (nine deformation times) of CCDF, the ultimate tensile stress increased from 11 to 43%, compared to the initial specimens (Table 5).

4. Conclusions

The main conclusions from the research results of the current work can be drawn as follows.

The CCDF of Ti–5Al–3Mo–1.5V titanium alloy at a deformation temperature of 850–950 °C and the number of deformation times from 3 to 9 times resulted in considerable refinement of the microstructure. After one cycle of the CCDF process (three steps), the average grain size obtained approximately 3–4 µm, and after three cycles, the average grain size obtained was about 1–2 µm.

As a result of CCDF at 900 °C and 9 times of deformation, the alloy exhibited a very small average grain size whilst maintaining good mechanical properties. The average grain diameter and ultimate tensile stress of the alloy were 1 µm and 1295 MPa, respectively.

The Ti–5Al–3Mo–1.5V alloy microstructure was obtained after the CCDF processes, which met the superplastic forming conditions, in order to improve the plastic deformation ability of this alloy. The superplastic forming problems can be considered in future work.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Ermachenko, A.G.; Lutfullin, R.Y.; Mulyukov, R.R. Technologies of Processing Titanium Alloys and their applications in Industry. Rev. Adv. Mater. Sci. 2011, 29, 68–82. [Google Scholar]

- Motyka, M.; Kubiak, K.; Sieniawski, J.; Ziaja, W. Hot Plasticity of Alpha Beta Alloys; Department of Materials Science, Rzeszow University of Technology Poland: Rzeszów, Poland, 2002. [Google Scholar]

- Stolyarov, V.V. Mechanical and Functional Properties of Titanium Alloys Processed by Severe Plastic Deformation. Mater. Sci. Forum 2011, 137–148. [Google Scholar] [CrossRef]

- Authors Group of ASM Handbook Committee. Metals Handbook Volume 14–Forming and Forging; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

- Giuliano, G. Superplastic Forming of Advanced Metallic Material; Woodhead Publishing Limited: Cambridge, UK, 2011. [Google Scholar]

- Nieh, T.G.; Wadsworh, J.; Sherby, O.D. Superplasticity in Metals and Ceramics; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Sieniawski, J.; Motyka, M. Superplasticity in Titanium alloys. J. Achiev. Mater. Manuf. Eng. 2007, 24, 123–130. [Google Scholar]

- Valiev, R.Z.; Islamgaliev, R.K.; Alexandrov, I.V. Bulk Nanostructured Materials from Severe Plastic Deformation. Progress Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Sheik, H.M.; Sanjeev, S.; Brijesh, K. A Review of Severe Plastic Deformation. Int. Refereed J. Eng. Sci. 2017, 6, 66–85. [Google Scholar]

- Metayer, J.; Bing, Y.E.; Wei, G.; Wang, Q.-D.; Zhou, H.; Mollet, F. Microstructure and mechanical properties of Mg–Si alloys processed by cyclic closed-die forging. Trans. Nonferrous Metals Soc. China 2014, 24, 66–75. [Google Scholar] [CrossRef]

- ASTM E 112. Standard Test Methods for Determining Average Grain Size; ASTM: West Conshohocken, PA, USA, 1967. [Google Scholar]

- ISO 14250. Steel—Metallographic Characterization of Duplex Grain Size and Distributions; ISO: London, UK, 2007. [Google Scholar]

- Snyder, R.W.; Graff, H.F. Study of grain size in hardened high-speed steel. Metal Progress 1938, 33, 377–380. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).