Abstract

The reverse logistics of medical textiles has become a major concern in Morocco today, compelling authorities and professionals to develop a sustainable reverse logistics model. This study proposes a model for designing a sustainable closed-loop supply chain network in a fuzzy environment, using the medical textile life cycle as a case study. The model aims to generate economic gains, increase corporate social responsibility through job creation, and mitigate risks associated with the transportation of end-of-life products. In addition, the uncertainty of the model parameters is considered. The multi-objective model, formulated as a mixed-integer linear program, was solved using an exact approach, enabling strategic and tactical decision-making. Furthermore, the results demonstrate that accounting uncertainty can significantly impact strategic and tactical decisions in network design.

1. Introduction

The reverse logistics of health textiles (HTs), as a potential source of contamination, increasingly affects the quality of life of citizens [1]. Therefore, authorities and professionals are compelled to establish a sustainable reverse logistics model.

This paper aims to design a sustainable closed-loop supply chain network (SCLSCN) that integrates all stakeholders involved in the healthcare textile life_cycle, from manufacturing to product end-of-life. Indeed, the literature has proven the positive impact of sustainable logistics network design on the ecosystem of several sectors [2,3,4,5,6,7,8]. Nevertheless, the design of supply chain networks often faces challenges related to parameter uncertainty, a critical issue highlighted by M. B. and F. Goodarzian [9].

Several studies have focused on the design of the textile supply chain [10,11]. Hashim et al. [12] examined the critical supply chain risks associated with sustainable development goals in the Pakistani textile industry. However, this study provides a broad perspective on supply chain risks. Another study was conducted by Hu et al. [13], where they proposed a new sustainable model for managing the fashion supply chain, aiming to reduce waste. Nonetheless, the study did not address the specific risk posed by certain textiles after use. Taslimi et al. [14] introduced a periodic, load-dependent, capacitated vehicle routing problem to minimize risks in medical waste collection, but the study was limited to the operational level of the supply chain and did not consider environmental uncertainties.

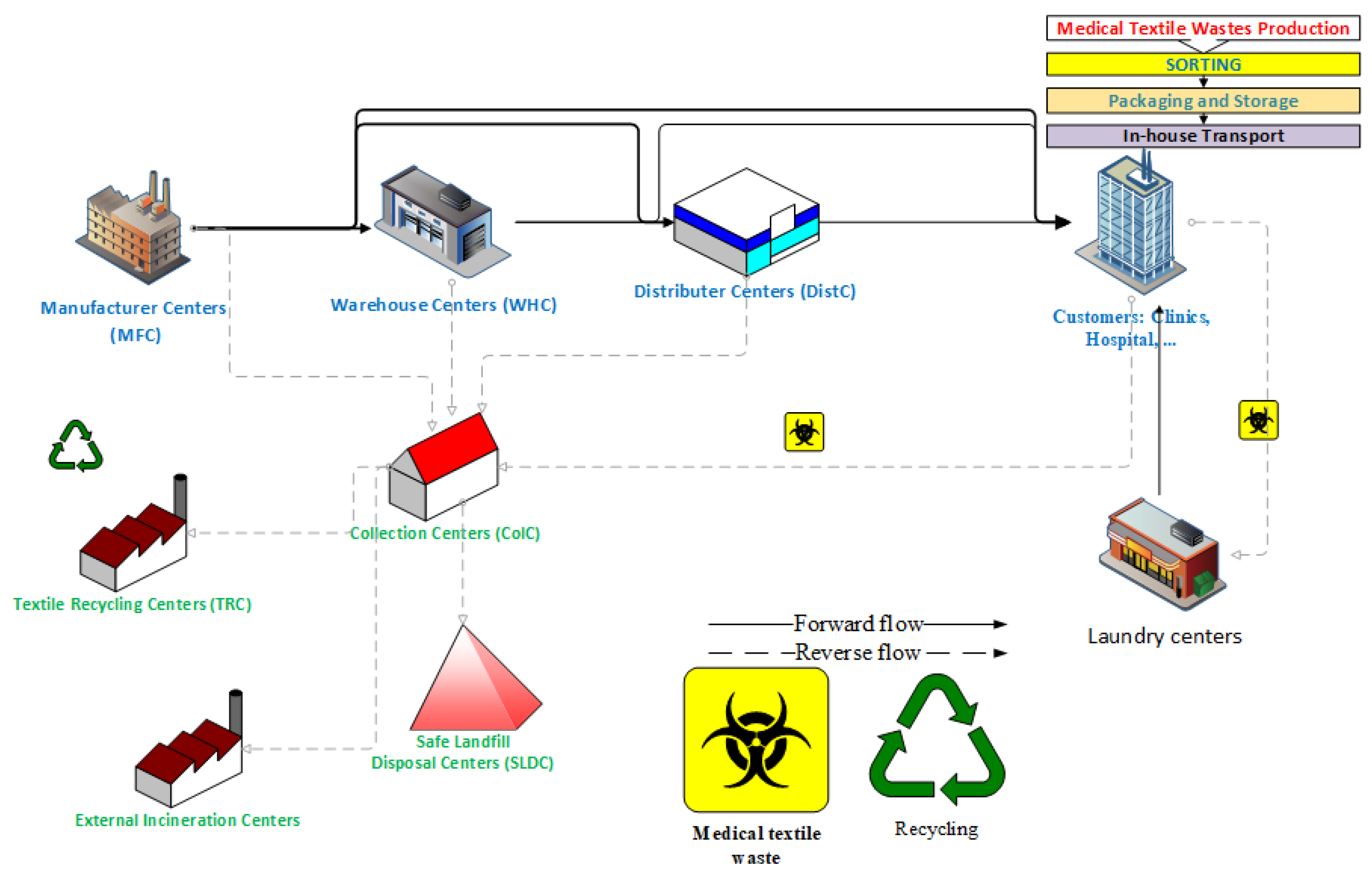

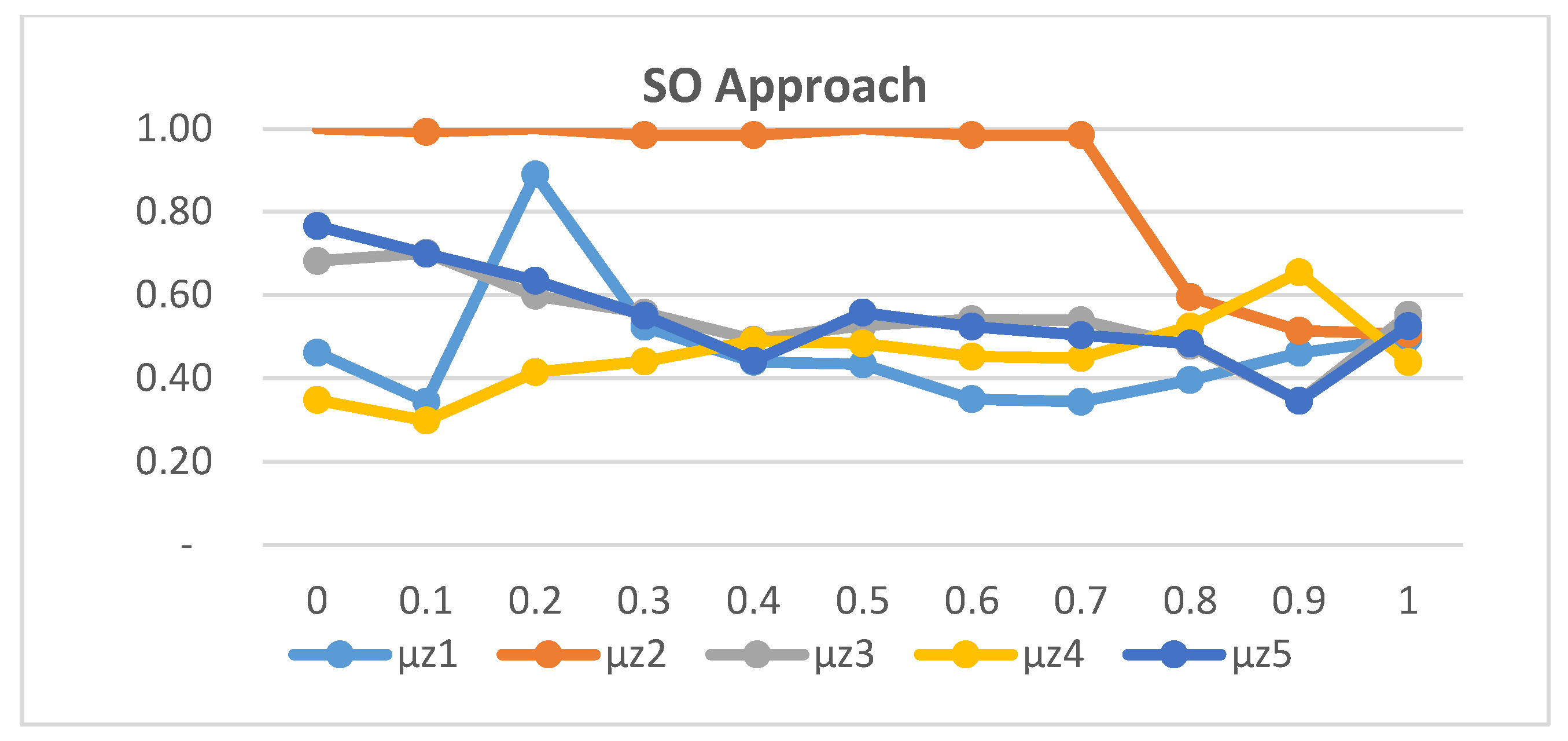

In our proposed network, shown in Figure 1, we adopt a semi-centralized collection for recyclable healthcare textiles, where the collection responsibilities are shared between the care units and the collection centers. This proposal aligns with previous studies that demonstrated the feasibility of semi-centralized collection of textiles and recyclables [15].

Figure 1.

The proposed SCLSCN scheme to manage end-of-life medical textiles.

None of the above studies addressed the specific case of sustainable design for the medical textile supply chain. Therefore, the main contributions of this paper, which distinguish it from related studies, are as follows:

- A sustainable closed loop supply chain network integrating inventory constraints and location allocation decisions.

- A novel environmental objective function to minimize the risk coming from the transport of used healthcare textiles (Hazmat items).

- A multi-objective model designed to maximize revenue and job creation and minimize transportation risks.

- A three-phase fuzzy mathematical programming approach to optimize the proposed model.

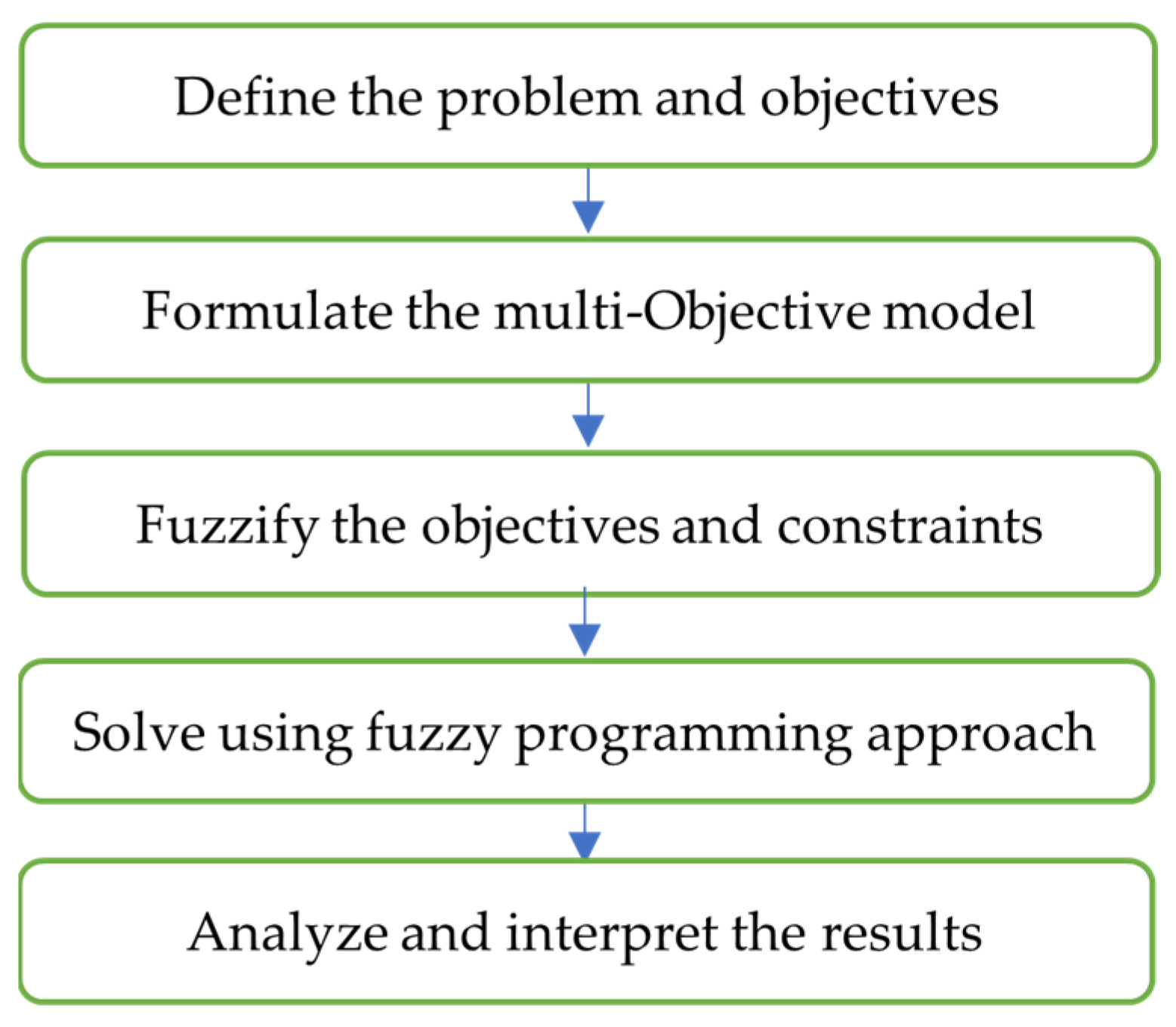

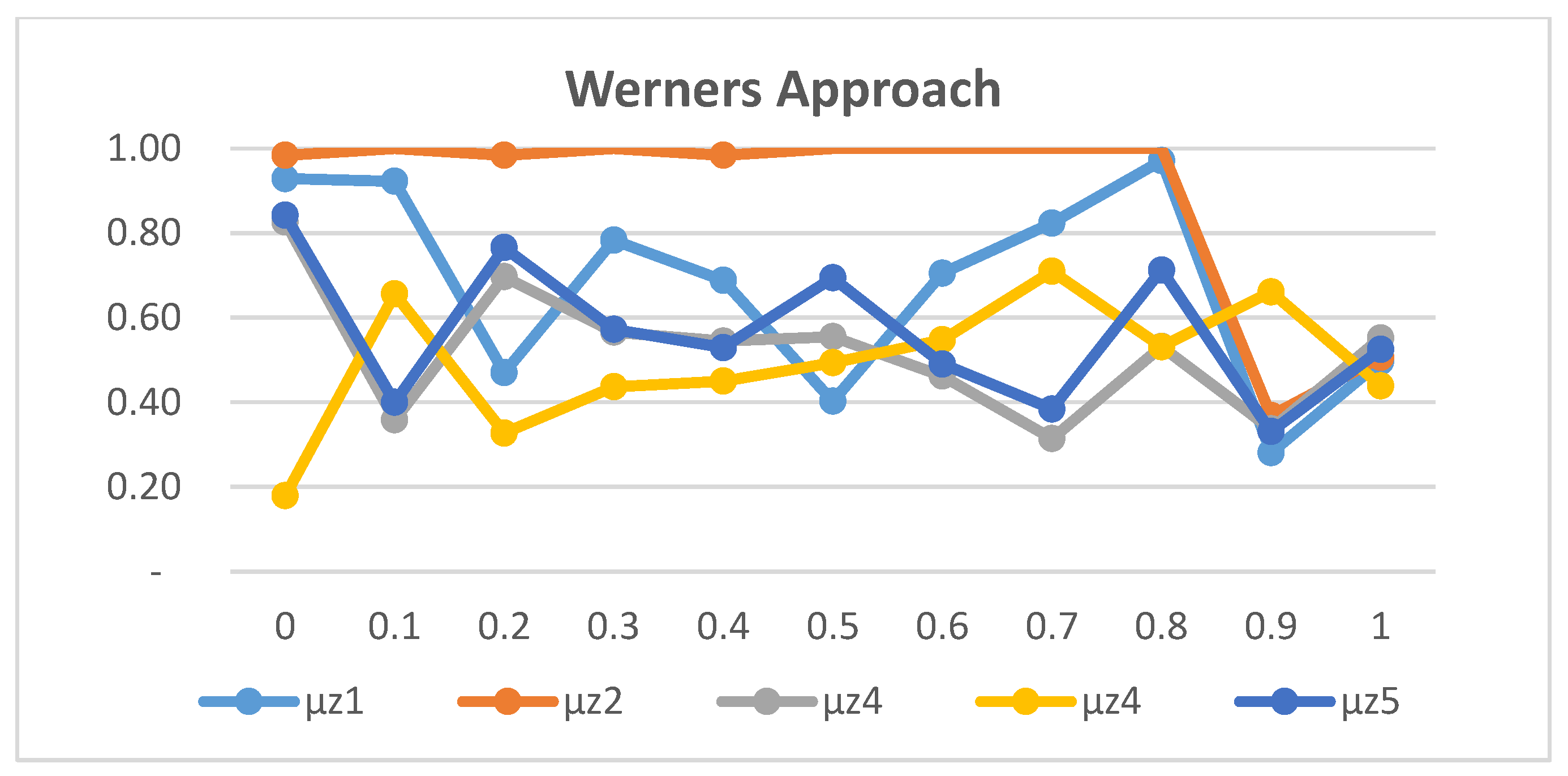

The basic methodology shown in Figure 2 seeks a trade-off between the main objectives related to the supply of end-of-life medical textiles. First, we will present our mathematical model. Then, we will solve the model using crisp numbers. Finally, we will provide conclusions and recommendations for future research.

Figure 2.

Flowchart of the methodology.

2. Material and Methods

2.1. Mathematical Formulation

We define the mathematical formulation of our multi-objective, mixed-integer linear programming (MOMILP) model, which aims to minimize costs, risks, and maximize job opportunities while accounting for the unique aspects of the proposed model. The mathematical formulation is based on the model presented by Ahlaqqach et al. in [5].

We consider three objective functions: profit, risk and job creation.

Profit (W1) is defined as the total sales minus total cost, including fixed opening center cost, job creation cost, purchased cost, return product from customer cost, facilities operating cost, non-used facility capacity cost, non-utilized collectors capacity cost, shortage cost, and transportation Cost.

The risk function (W2) accounts for contamination risks from accidents on routes used by vehicles transporting medical textiles.

where

- Rijpt: Contamination risk on road (i, j) for medical textiles p at time t;

- Lij: Binary variable equals ‘1’ if links is established between facilities ‘i’ and ‘j’;

- C: Set of customers indexed by ‘c’;

- L: Set of collector’s centers indexed by ‘l’;

- S: Set of Safe landfill disposal centers indexed by ‘s’;

- R: Set of textile Recycling centers indexed by ‘r’;

- E: Set of External incinerator centers indexed by ‘e’;

- N: Set of Laundry centers indexed by ‘e’.

The third objective aims to maximize job opportunities.

where

- Ja: Number of jobs create with center a, a∈A, with A represent all types of facility;

- Li: binary variable equals ‘1’ if location ‘i’ is open and ‘0’ otherwise.

Our multi-objective function is expressed as a scalar function:

where α, β, and δ are, respectively, the weight of profit, risk, and job creation objectives. Instead of using the absolutes values of W1, W2, and W3, respectively, we normalize them, so they become comparable. We use normalization in Bronfman et al. [1], where Yi and, Ui are the normalized objective function in case of minimization and maximization, respectively. Wimax, Wimin, and Wi represent the maximum possible, minimum possible, and actual value of each objective before normalization.

2.2. Fuzzifying the Model

We validate our model using Optimization Studio, Version IDE 22.1, IBM Corporation, Armonk, NY, USA. The results obtained are relevant, they respect all constraints, and the experiments enabled us to fine-tune the trade-off between the objectives of our model. However, the resolution of the first model supposes that all parameters are deterministic. In practice, we encounter fuzzy values associated with the risk and capacity parameters of each center, which are involved in both objective functions and constraints. Thus, the fuzzy, multi-objective, mixed-integer linear programming (FMOMILP) model with fuzzy risk may be formulated as follows:

where and represent the fuzzy set of the risk objective function values and the capacity of each center, respectively. The fuzzy parameters are expressed by a triangular distribution of parameters: the most probable, the most optimistic, and the most pessimistic value.

To solve this model, we used a three-phase fuzzy mathematical programming approach, transforming the model into a deterministic equivalent.

In the first two phases, we used the weighted average method proposed by Lai and Hwang [16] to convert the FMOMILP model into an equivalent auxiliary crisp MOMILP model. Several studies have sought to determine the best way to convert FMOMILP to MOMILP. In our study, we opted for the approach by Lai and Hwang [16], due to its suitability for our case [17]. This method provides more flexibility for decision-makers to achieve a fuzzy solution according to their preferences [18]. Therefore, the Positive Ideal Solutions (PIS) and Negative Ideal Solutions (NIS) of all crisp objective functions were calculated as follows:

Here, W2m, W2o, and W2p (the most probable, the most optimistic, and the most pessimistic value) are the three corner points that geometrically define the fuzzy objective W2. The related linear membership functions of these objective functions are given by:

In the third phase, we applied the fuzzy goal programming techniques from various approaches, including Zimmermann [19,20], Li, Zhang, and Li (LZL) [20], Werners [21], Selim and Ozkarahan (SO) [22], and the Torabi and Hassini (TH) approach [23], to solve the MOMILP model effectively.

3. Results and Discussion

The first set of experiments aimed to normalize our objective function using an exact approach. The results showed good performance for small instances.

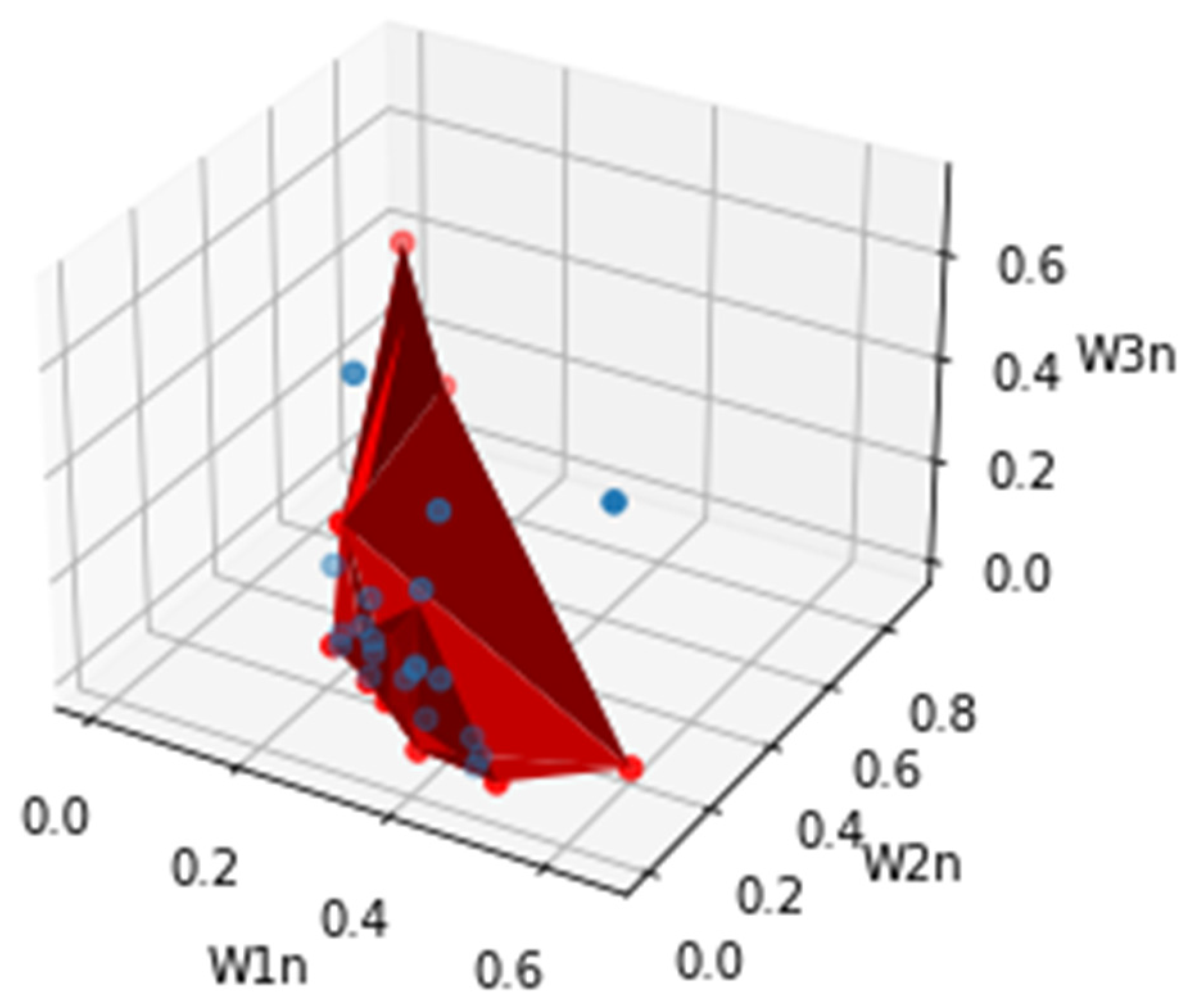

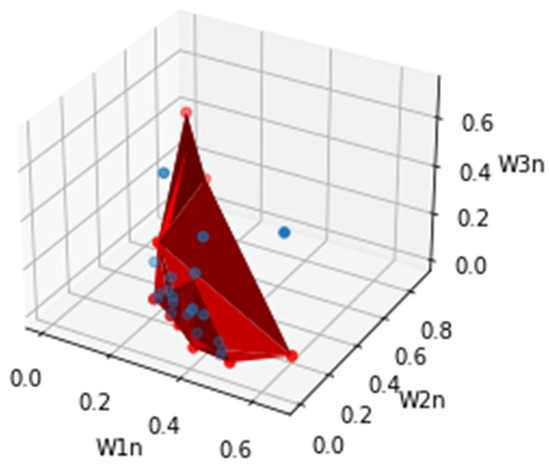

The second experiment allowed us to verify the feasibility of a trade-off between the studied objectives, highlighting the need for uncertainty integration in the design process. The three-dimensional Pareto front in Figure 3 provides a red region, which represents a trade-off among the three objectives. The blue points represent the dominated solutions, which will be avoided; certainly, they give preferential treatment to some objectives to the detriment of others.

Figure 3.

3D Pareto front of normalized objectives.

The third experiment highlighted the significant differences between deterministic models and those incorporating uncertainty, emphasizing the importance of integrating uncertainty into the design of sustainable closed-loop supply chain networks (SCLSCNs).

To address this challenge, a three-phase fuzzy mathematical programming was applied to solve our model and obtain optimum objectives. The results from this experiment, presented in Table 1, include the total satisfaction degree (TSD), membership function (MF), and objective function (OF) for each fuzzy goal programming approach tested. Based on these results, it can be concluded that the TH approach is the most appropriate method for the FMOMILP model of SCLSCN.

Table 1.

Satisfaction degree of objective functions.

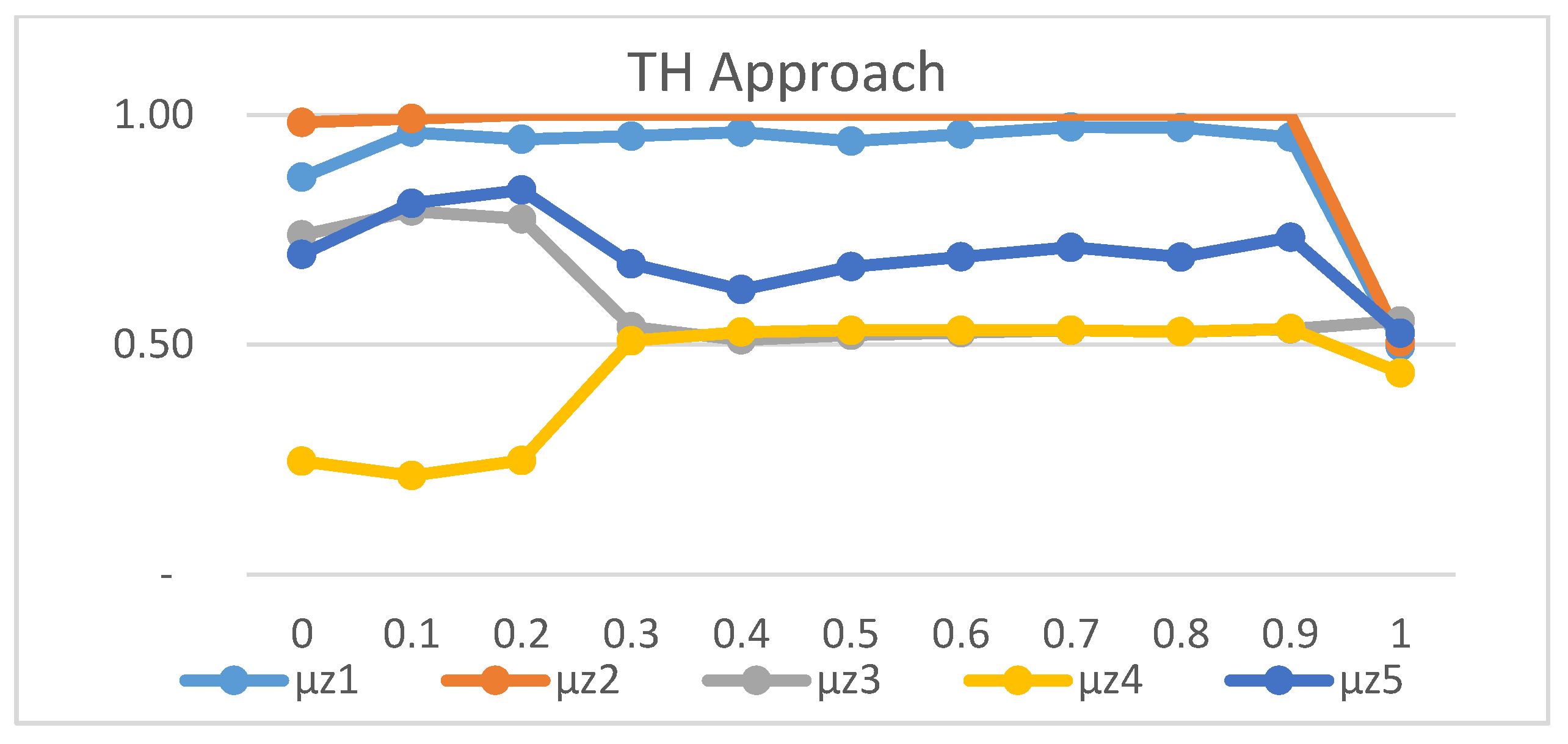

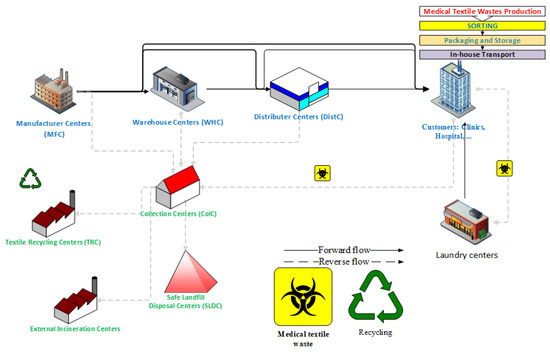

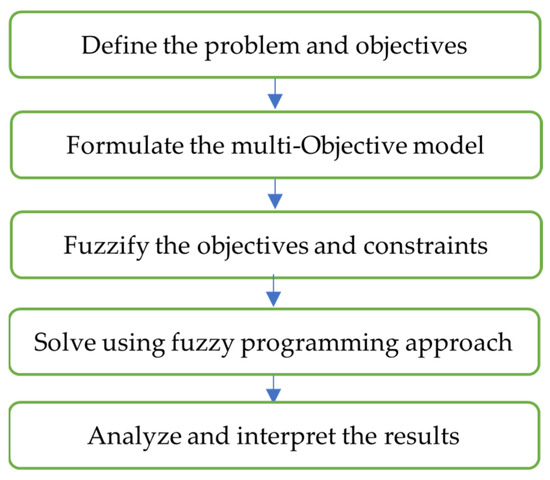

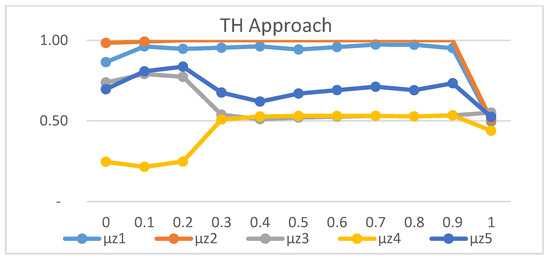

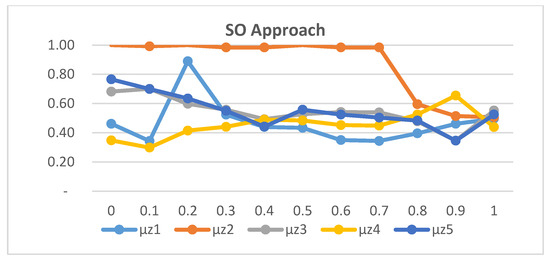

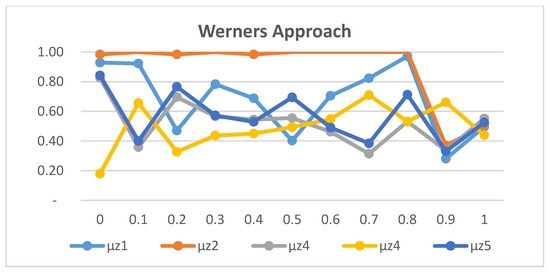

The second experiment, which focused on sensitivity analysis for the compensation coefficient γ demonstrated, as shown in Figure 4, Figure 5 and Figure 6, that the TH approach is relatively insensitive to changes in γ value. In contrast, the SO and Werners methods produced unbalanced solutions, while the TH approach maintained stable values for γ between 0.3 and 0.9.

Figure 4.

Sensibility analysis of γ value for the TH approach.

Figure 5.

Sensibility analysis of γ value for the SO approach.

Figure 6.

Sensibility analysis of γ value for the Werners approach.

The third experiment helped us to examine the impact of uncertainty on SCLSCND. We noticed that the SCLSCN proposed by the first experimentation (deterministic parameters) differed from the model that considered uncertainty. Since the external data (demand, capacity of public platforms) as well as the internal data (production capacity …) are often uncertain, accounting for these uncertainties is crucial for designing effective and robust logistic networks. This demonstrates the necessity of integrating uncertainty into the design process to ensure reliable decision-making.

4. Conclusions

To the best of our knowledge, this paper is one of the first to apply supply chain network design practices and tools to the reverse flows of medical textiles. It provides new insights into reverse logistics for used medical textile waste under uncertainty by proposing a multi-objective mathematical model with a three-phase fuzzy mathematical programming as an approach to cope with uncertainties.

This study developed a closed-loop supply chain network model to cope with conflicting sustainable development objectives. The hazardous nature of the healthcare textile has led us to integrate the risks associated with the transport of these materials. The social responsibility of the fabrics company is considered in sustainable closed-loop supply chain network designs with the integration of job opportunity created in the objective function. To encourage the company to adopt our approach, we have integrated the profit aspect to show the possibility of coexistence between these conflicting objectives. This model aims to generate economic gains, increase corporate social responsibility in terms of job creation, and reduce the risk associated with the transportation of used products. In addition, the uncertainty of the model parameters is considered. The multi-objective model expressed as a mixed-integer linear program was solved by an exact approach; this resolution allowed us to make strategic and tactical decisions. Furthermore, the result showed that considering uncertainty can significantly change the strategic and tactical decision making for the network design.

In this study, we focused on small instances to validate the model. Future work will concentrate on developing an efficient metaheuristic algorithm to address larger, more complex instances, enabling scalable and robust decision-making in real-world applications.

Author Contributions

Conceptualization, M.A. (Mustapha Ahlaqqach) and J.B.; methodology, M.A. (Mustapha Ahlaqqach); software, M.A. (Mustapha Ahlaqqach); validation, M.A. (Mustapha Ahlaqqach), A.T. and J.L.; formal analysis, M.A. (Mustapha Ahlaqqach); investigation, M.A. (Mustapha Ahlaqqach); resources, J.B.; data curation, M.A. (Mustapha Ahlaqqach); writing—original draft preparation, M.A. (Mustapha Ahlaqqach); writing—review and editing, A.T. and M.A. (Mariam Atwani); visualization, M.A. (Mustapha Ahlaqqach); supervision, J.B.; project administration, M.A. (Mustapha Ahlaqqach); funding acquisition, M.A.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data presented in this study are available on request from the corresponding author.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Ahlaqqach, M.; Benhra, J.; Mouatassim, S.; Lamrani, S. Hybridization of game theory and ridesharing to optimize reverse logistics of healthcare textiles. IOP Conf. Ser. Mater. Sci. Eng. 2020, 827, 012004. [Google Scholar] [CrossRef]

- Nasr, N.; Niaki, S.T.A.; Kashan, A.H.; Seifbarghy, M. An efficient solution method for an agri-fresh food supply chain: Hybridization of Lagrangian relaxation and genetic algorithm. Environ. Sci. Pollut. Res. 2021, 1–19. [Google Scholar] [CrossRef]

- Pahlevan, S.M.; Hosseini, S.M.S.; Goli, A. Sustainable supply chain network design using products’ life cycle in the aluminum industry. Environ. Sci. Pollut. Res. 2021, 1–25. [Google Scholar] [CrossRef] [PubMed]

- Goli, A.; Tirkolaee, E.B.; Weber, G.-W. A Perishable Product Sustainable Supply Chain Network Design Problem with Lead Time and Customer Satisfaction using a Hybrid Whale-Genetic Algorithm. In Logistics Operations and Management for Recycling and Reuse; Springer: Berlin/Heidelberg, Germany, 2020; pp. 99–124. [Google Scholar] [CrossRef]

- Ahlaqqach, M.; Benhra, J.; Mouatassim, S.; Lamrani, S. Closed loop location routing supply chain network design in the end of life pharmaceutical products. Supply Chain Forum 2020, 21, 79–92. [Google Scholar] [CrossRef]

- Goodarzian, F.; Hosseini-Nasab, H.; Fakhrzad, M.B. A Multi-objective Sustainable Medicine Supply Chain Network Design Using a Novel Hybrid Multi-objective Metaheuristic Algorithm. Int. J. Eng. 2020, 33, 1986–1995. [Google Scholar] [CrossRef]

- Momeni, M.A.; Jain, V.; Bagheri, M. A Multi-Objective Model for Designing a Sustainable Closed-Loop Supply Chain Logistics Network. Logistics 2024, 8, 29. [Google Scholar] [CrossRef]

- Douaioui, K.; Benmoussa, O.; Ahlaqqach, M. Optimizing Supply Chain Efficiency Using Innovative Goal Programming and Advanced Metaheuristic Techniques. Appl. Sci. 2024, 14, 7151. [Google Scholar] [CrossRef]

- Fakhrzad, M.B.; Goodarzian, F. A Fuzzy multi-objective programming approach to develop a green closed-loop supply chain network design problem under uncertainty: Modifications of imperialist competitive algorithm. RAIRO-Oper. Res. 2019, 53, 963–990. [Google Scholar] [CrossRef]

- Jäämaa, L.; Kaipia, R. The first mile problem in the circular economy supply chains—Collecting recyclable textiles from consumers. Waste Manag. 2022, 141, 173–182. [Google Scholar] [CrossRef] [PubMed]

- Hole, G.; Hole, A.S. Improving recycling of textiles based on lessons from policies for other recyclable materials: A minireview. Sustain. Prod. Consum. 2020, 23, 42–51. [Google Scholar] [CrossRef]

- Hashim, M.; Nazam, M.; Zia-ur-Rehman, M.; Abrar, M.; Baig, S.A.; Nazim, M.; Hussain, Z. Modeling Supply Chain Sustainability-Related Risks and Vulnerability: Insights from the Textile Sector of Pakistan. Autex Res. J. 2022, 22, 123–134. [Google Scholar] [CrossRef]

- Hu, Z.H.; Li, Q.; Chen, X.J.; Wang, Y.F. Sustainable Rent-Based Closed-Loop Supply Chain for Fashion Products. Sustainability 2014, 6, 7063–7088. [Google Scholar] [CrossRef]

- Taslimi, M.; Batta, R.; Kwon, C. Medical waste collection considering transportation and storage risk. Comput. Oper. Res. 2020, 120, 104966. [Google Scholar] [CrossRef]

- Jamaa, S.B.; Altman, Z.; Picard, J.-M.; Fourestié, B. Optimization of UMTS Radio Access Networks with Genetic Algorithms. In Metaheuristics for Hard Optimization; Springer: Berlin/Heidelberg, Germany, 2006; pp. 251–276. [Google Scholar] [CrossRef]

- Lai, Y.J.; Hwang, C.L. A new approach to some possibilistic linear programming problems. Fuzzy Sets Syst. 1992, 49, 121–133. [Google Scholar] [CrossRef]

- Pourjavad, E.; Mayorga, R.V. Multi-objective Fuzzy Programming of Closed-Loop Supply Chain Considering Sustainable Measures. Int. J. Fuzzy Syst. 2019, 21, 655–673. [Google Scholar] [CrossRef]

- Sanchis, R.; Díaz-Madroñero, M.; López-Jiménez, P.A.; Pérez-Sánchez, M. Solution Approaches for the Management of the Water Resources in Irrigation Water Systems with Fuzzy Costs. Water 2019, 11, 2432. [Google Scholar] [CrossRef]

- Zimmermann, H.-J. Methods and Applications of Fuzzy Mathematical Programming. In An Introduction to Fuzzy Logic Applications in Intelligent Systems; Springer: Boston, MA, USA, 1992; pp. 97–120. [Google Scholar] [CrossRef]

- Li, X.Q.; Zhang, B.; Li, H. Computing efficient solutions to fuzzy multiple objective linear programming problems. Fuzzy Sets Syst. 2006, 157, 1328–1332. [Google Scholar] [CrossRef]

- Werners, B.M. Aggregation Models in Mathematical Programming. In Mathematical Models for Decision Support; Springer: Boston, MA, USA, 1988; pp. 295–305. [Google Scholar] [CrossRef]

- Selim, H.; Ozkarahan, I. A supply chain distribution network design model: An interactive fuzzy goal programming-based solution approach. Int. J. Adv. Manuf. Technol. 2006, 36, 401–418. [Google Scholar] [CrossRef]

- Torabi, S.A.; Hassini, E. An interactive possibilistic programming approach for multiple objective supply chain master planning. Fuzzy Sets Syst. 2008, 159, 193–214. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).