Abstract

The global energy crisis, driven by factors such as increased demand, limited fossil fuel resources, and growing environmental concerns created an urgent need for energy-efficient solutions across all sectors. Among these, refrigeration systems, which are used extensively in both domestic and commercial settings, are responsible for a sizeable amount of global energy consumption. Finding ways to reduce energy used in the refrigeration could play a crucial role in mitigating the energy crisis. Phase Change Materials (PCMs) have emerged as a promising technology to enhance the energy efficiency of refrigeration systems. By storing and releasing energy in the form of latent heat, PCMs optimize energy conversion rate of the processes, reduce power consumption, and lower the overall environmental impact. The present research focus Calcium Chloride Hexahydrate (CCH) as the PCM which acts as an intermediary between the heat sources to achieve optimal effectiveness. To improve system performance and optimize PCM quantity, two novel system configurations were assessed in the mass proportions of 1 kg and 2 kg of PCM with water. The incorporation of PCZ enhanced the overall heat energy utilisation, recovery of waste heat, and greater system output. And actual COP of the refrigeration system was meet out with the domestic refrigerator in ranges of 1.0759 to 1.1537. The above two novel system were proved that a vital role in removal of waste latent heat into lateral use in the ranges of 110.8 kJ (min.) into 226.8 kJ (max.). Finally proposed system was avoided global warming temperature raise because of uses of waste heat into lateral uses in the refrigeration systems.

1. Introduction

The condenser in a refrigerator releases heat as it operates, typically dissipating the heat into the surrounding environment. This process occurs when the refrigerant changes from a gas to a liquid, releasing heat in the process. When a material changes phases, usually from a solid to a liquid or a liquid to a gas, PCM absorbs and stores thermal energy. This change happens at a specific temperature, and during this process, the PCM absorbs a large amount of heat without significant changes in temperature (latent heat). In this concept, the heat released by the refrigerator’s condenser is directed into the PCM. The PCM will absorb this heat and store it while transitioning from solid to liquid (or liquid to gas, depending on the specific material). As the PCM absorbs heat, its temperature remains relatively constant during the phase change, providing a buffer that prevents the surrounding environment from heating up too much. When the refrigerator requires cooling or when the heat load is reduced, the PCM releases the stored heat by reverting to its solid state (or gas to liquid). This can help maintain a more stable temperature in the refrigerator or reduce the need for external cooling.

Javeri-Shahreza et.al. [1] created a dynamic model for a dual-cabinet open-display supermarket refrigerator that has PCMs in the cabinets and evaporators. The most critical design parameters for PCM cases for refrigerators are the PCM’s location, type, and quantity. The effect of the decision factors on design goals has been studied using the established model and a data repository of suitable PCMs. The refrigerator’s design goals include its energy usage, the standard deviation of its cabinet air temperature, the number of compressors that are turned on or off, and the number of refrigerant valves that are opened or closed for the evaporators. The mathematical model’s dynamic behavior was optimized using data from the literature, and the model was numerically simulated by an ordinary differential equation that is compatible with the refrigeration cycle.

Azzouz et al. [2] conducted numerical analysis and confirmed through experimentation the benefits of incorporating PCM on the external surface of a refrigerator evaporator. Different phase change temperatures, different PCM thicknesses, and different thermal loads are used in a parametric study of the refrigerator cycle. The results were categorized into three groups: partial melting (high thermal load), complete melting, and partial freezing (low thermal load). It was noted that the cycle’s performance relies on the amount of thermal load added to the system, with greater thermal loads requiring more energy to be extracted from the PCM. Their analysis projected a 5–14% increase in COP and decreased occurrences of starting and stopping the compressor. They also suggested that food preservation can be achieved without power supply for 4 to 8 h, depending on thermal load.

Azzouz et al. [3] examined placing PCM panels on the exterior of the evaporator to enhance efficiency and heat storage during power outages. Two PCMs were utilized, having varying melting points: water and a eutectic mixture (freezing at −3 °C), under various operational conditions. The researchers found that the cooling ability of the system is slightly lower when using a eutectic aqueous solution compared to water as a PCM. However, the advantage of the eutectic solution is its ability to keep the air in the refrigerated compartment at optimal temperature levels suggested for refrigeration.

Fuqiao Wang et al. [4] investigated the use of phase change materials (PCMs) in different positions of the refrigeration cycle to achieve energy savings and performance improvements. PCMB placed between the condenser and expansion valve that Increased sub-cooling, leading to up to 8% COP improvement. Lowering PCM phase change temperature gives greater sub-cooling but slower PCM recharging. PCMC placed between evaporator and compressor which minimized superheat, leading to 4% and 7% COP improvements for TEV and orifice systems respectively. Also helps stabilize the system by attenuating temperature fluctuations. PCMA placed between compressor and condenser helped in reducing condenser pressure, leading to up to 20% COP improvement. The optimal size, position, and structure of the PCM heat exchangers need to be carefully selected to balance the benefits and the ability to recharge the PCM.

Condensers play a role in expelling heat from hot refrigerant coming out of the compressor. Sonnenrein et al. [5] conducted an experimental investigation on the integration of latent heat storage materials into the condenser (wire and tube condenser) of a ready-made cooling device with A++ energy efficiency rating. They also created a new heat storage material by combining a block polymer with an organic paraffin derivative, in addition to using traditional materials like water, paraffin, PE-HD foil, and aluminum compound film. The addition of graphite compound enhanced the thermal conductivity of this novel material. Their findings showed that utilizing PCMs on the condenser side would lower the condenser temperature at both the inlet and outlet. Heat storage condenser with HCE-SS PCM leading to higher refrigerators COP due to decrease in refrigerant pressure.

Sonnenrein et al. [5] discovered that a material they developed has higher thermal conductivity and can help to equalize the temperature in the condenser, despite the usual low thermal conductivity of PCMs. Additionally, they stated that PCMs can lower refrigerator power consumption by as much as 10%. Reducing the surface area of the condenser by only 25% significantly increases the effect, resulting in a 4% reduction in power consumption.

Tulapurkar [6] used phase change material (PCM) to facilitate thermal storage in a refrigeration system with two evaporators. Leveraging the PCM’s latent heat of energy improved the system’s performance and raised the COP. Additionally, the longer compressor off time improved the quality of the food.

Karthikeyan et al. [7] conducted the sole experiment where PCM was incorporated in both the condenser and evaporator of a refrigerator. PCM was integrated at three separate locations within the refrigerator. The condenser, the freezer and refrigerator sections, all three sites, and a refrigerator without PCM were the four configurations that were examined. Temperature fluctuations were only seen in the freezer and fridge sections, but refrigerators with PCM showed lower fluctuations in all three areas.

Arora et al. [8] The heat transfer coefficient in the vapour phase is low, but the temperature difference between the refrigerant and coolant is high. In contrast, during condensation, the heat transfer coefficient is high, but the temperature difference is low. Therefore, the product of hot is similar in both areas, allowing for the design of the condenser assuming condensation happens throughout.

Udroiu et al. [9] explores a study using an ejector in two-stage cascade refrigeration at very low temperatures. The research tests R-290 and R-170, which are natural refrigerants with low global warming potential. Results show that the ejector improves the cycle in both temperature stages, but evaporation temperature significantly affects energy performance. The study recommends a cascade cycle with ejectors in both stages, leading to a 21% improvement in performance compared to standard cycles, and a 13. 6% improvement over older refrigerants. Using a new refrigerant, R-472A, also results in reduced CO2 emissions in ultra-low temperature cycles.

Yogesh N. et al. [10] analysed the performance (COP) of a vapour compression refrigeration system by introducing phase change material (PCM) and thermoelectric generator (TEG) into the system. The subcooled refrigerant was achieved by extracting heat through PCM in a separate PCM chamber positioned between the condenser and expansion valve. The heat stored in the PCM was provided to the TEG’s hot side, while the cold side was served by an aluminium vessel carrying the condensed water yield accumulated from the evaporator coils. Overall, the employment of PCM and TEG in a vapour compression refrigeration system boosted the cooling effect and COP while reduced the net amount of work required.

Tyagi, V.V et al. [11] examined how the latent heat of fusion and melting temperature of calcium chloride hexahydrate (CaCl2 6H2O) changes when used as a latent heat storage material. A thousand accelerated thermal cycle tests were conducted to assess these changes. Using differential scanning calorimetry (DSC), researchers evaluated the impact of thermal cycling on melting temperature. Results showed that CaCl2 6H2O melts within a stable temperature range and has minimal changes in latent heat of fusion during thermal cycling. This suggests it could be a good phase change material for heating and cooling in various buildings and storage systems.

The literature suggests incorporating PCM into traditional VC refrigeration systems to make use of waste heat in power generation. In the current study, we have successfully incorporated a novel hybrid VC+PCZ approach, marking an innovative development. The heat accumulated in the PCM while subcooling the refrigerant is released to the ambient air at the hot side of the condenser. In this research, a significant amount of heat energy can be effectively stored in the PCM for various practical purposes.

Phase Change Material

PCMs are utilized to absorb latent heat energy while transitioning between physical states. These materials have the capacity to store or release significant amounts of heat when undergoing a phase change [1].

Using PCM for storing heat from a refrigerator’s condenser is an innovative approach for improving energy efficiency, regulating temperature, reducing energy consumption and could reduce the load on the compressor, leading to potential energy savings in refrigeration systems. By optimizing energy use and reducing the need for external cooling or excessive compressor activity, the overall energy consumption can be reduced, leading to less environmental impact.

By removing heat from the refrigerant as it leaves the condenser, this work stores thermal energy in PCM. Calcium chloride hexahydrate (CaCl2⋅6H2O) is selected as the PCM in this investigation. Table 1 lists the characteristics of CCH. As the process proceeds, PCM absorbs heat, reaches the melting point, and changes from a solid to a liquid. The PCM’s temperature doesn’t change throughout this transitional phase, but the surrounding refrigerant medium’s temperature does. The state of the refrigerant is subcooled at the PCM chamber’s exit. Thus, the expansion valve allows more liquid refrigerant to enter the evaporator, boosting the refrigeration effect and, thus, the system’s COP. CCH is widely used in refrigeration and building heat storage materials due to its low phase transition temperature [12]. Inorganic PCMs, such as salt hydrates, are better options for thermal energy storage because they are less expensive and have a larger volumetric thermal storage capacity than biological materials [13].

Table 1.

Properties of CaCl2⋅6H2O [11].

2. Experimental Setup

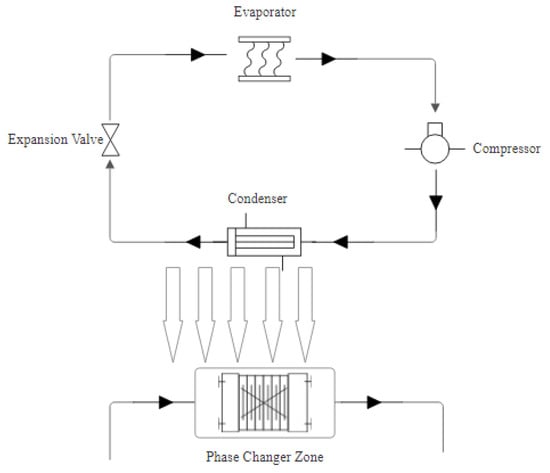

In this investigation, a domestic refrigerator with a capacity of 190 L that runs on the VC cycle Figure 1 was employed.

Figure 1.

Schematic layout of Refrigeration system with Phase Change Zone (PCZ).

The refrigerator’s technical features are listed in Table 2. To maximize waste heat energy absorption, a PCZ chamber was positioned parallel to the condenser unit. The dimensions of the PCZ chamber were 25 cm × 15 cm × 10 cm. PCZ were designed to observe the maximum amount heat energy liberated from the condenser unit to the open atmosphere. These dimensions were calculated from the condenser air to meet the PCZ as effectively to cover all the surfaces of PCMs. It mainly depends on the condenser size and probability of collecting the hot air from the condenser. Stirrer were connected through fan from the condenser unit, it enhance no additional electrical energy of the unit. The heat stored in the PCM was transferred to the PCZ chamber’s hot side via helical refrigerant tubes. Here thickening agents were used as it increase the viscosity of the liquid, which helps to suspend particles and prevent them from settling [14,15], methyl cellulose (MC) was used as a thickening agent.

Table 2.

Specifications of a refrigerator setup.

3. Performance Analysis of a Refrigeration System

The cooling load to network necessary ratio is a VC system’s COP [12]. The performance of the regular VC system, also known as the baseline system, is contrasted with that of the given VC+PCZ system, also known as the innovative system.

A known amount of water was put in a steel container in the freezer, and the water’s initial temperature was noted in order to assess how well both systems performed. First, the performance of the baseline system was evaluated. Readings from the energy metre, temperature, pressure, and refrigerant mass flow rate were recorded every five minutes in Table 3. For the new system, this method was repeated. During the performance testing, the air’s relative humidity was 44% and its room temperature was 36 °C. The COP for the baseline and innovative systems is determined using Equations (1) and (2), respectively [12]. Over the course of the trial, the two innovative system configurations—one with 1 kg of PCM and the other with 2 kg of PCM in a PCM chamber—were evaluated for performance and contrasted with the baseline system that did not contain PCM.

Table 3.

Experimental results of Refrigeration system by using Expansion valve.

3.1. Mathematical Expressions

3.1.1. Performance of a Refrigeration System

The following formula is used to determine the compressor’s swept volume:

Volumetric efficiency is calculated from equation

The refrigerant’s mass flow rate is established by

Equations are used to evaluate the theoretical and actual compressor power, respectively.

Similarly, equations are used to express theoretical and actual refrigeration capacity, respectively.

3.1.2. Phase Changer Zone

In this PCZ, two novel systems were performed with PCMs of two novel systems. Temperature was noted for the 1 kg and 2 kg of PCMs to obtain the performance characteristics of heat released in the refrigeration systems as follows in the Table 4 by using equation 9.

Table 4.

Experimental results of PCZ.

An equation is used to determine how much heat is stored in PCM.

4. Results and Discussion

Experimental setup was initially run with the sample of baseline water and assed the exit temperature of the evaporator. During the test equal time interval was fixed as a benchmark to obtain the results of the system. Here refrigeration effect and COP of the system and waste heat energy mixed with the open atmosphere were calculated. And for the mass proportions of the PCM were identified the effective heat removal rate from the proposed system.

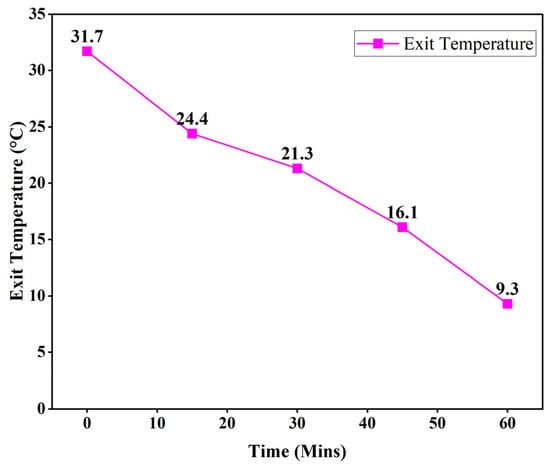

Figure 2 displays a 60-min average temperature difference of 3.1 °C and 3.7 °C. It was achieved by the continuous removal of heat from the evaporator unit to the condenser unit. Average temperature difference were calculated from the evaporator inlet and outlet. This temperature differences helps to identify the refrigeration effects of the systems with the specific time interval. It proved the cooling effect developed in the system with temperature differences.

Figure 2.

Experimental results of variation time with exit temperatures of the evaporator unit.

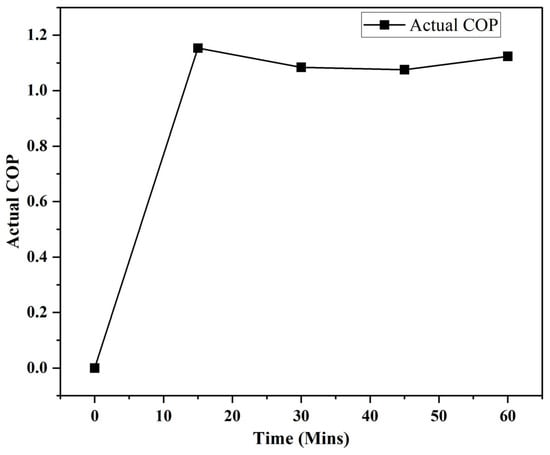

In Figure 3 shows that variation of time with COP of the system. Following parameters were played a major in calculating the COP values like mass flow rate of the refrigerant, temperature difference, efficiency of the condenser and compressor. At initial stage of switched on position there’s no sudden reflection in the performance, so it starts with zero because of latent heat of evaporations and surrounding temperature also need to meet out of maximum temperature of the refrigerant. Time interval based results were calculated by the empirical correlations to find out the actual COP values of the system. From this work, COP values were found in the ranges of 1.0759 to 1.1537 and same meet out with standard values of the domestic refrigeration system.

Figure 3.

Variation of time Vs Actual COP.

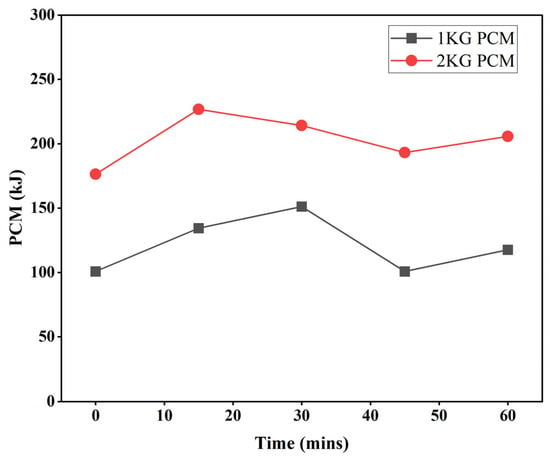

Low grade heat energy were converted from condenser to the PCZ with the help of PCM. The mixture of water and various mass proportions PCM were utilized to find the exit temperatures of PCZ in Figure 4. PCM helps to make the maximum temperature differences compared with the baseline water. This temperature difference and latent heat of the PCM were utilized to produce the larger quantity of heat energy into the lateral applications. In 1 kg of PCM mixtures was obtained latent heat energy in the ranges of 100.8 kJ to 151.2 kJ. And 2 kg of PCM mixtures was obtained latent heat energy in the ranges of 176.4 kJ to 226.8 kJ. It was proved that the PCM mass proportions significantly increase the energy conversion ratio.

Figure 4.

Variation of time with Latent heat collected from the PCZ.

5. Conclusions

The PCZ is an innovative technology designed to enhance the efficiency of refrigeration systems. By extracting additional heat energy from the condenser unit and releasing it into the atmosphere, the PCZ increases the overall output of the refrigeration system.

Two novel system configurations were evaluated to optimize PCM quantity and maximize system performance. One kilogram of PCM in the PCZ chamber and two kilograms of PCM with baseline water are the two new system configurations. From the experimental results proven that refrigeration effect was developed in the evaporation exit temperature in the ranges of 31.7 °C to 9.3 °C. And the actual COP meet out with domestic refrigerator in the ranges of 1.0759 to 1.1537. And finally mass proportions of PCM helps to effective heat removal from condenser in the range of 100.8 kJ to 151.2 kJ in 1 kg PCM mixture and 176.4 kJ to 226.8 kJ in 2 kg of PCM.

During the refrigeration cycle, heat energy from the condenser unit is transferred to the PCZ chamber, where it is absorbed by the PCM. The stored heat energy is then available for supplementary applications, such as generating electricity or providing hot water, utensil cleaning, space heating, or other domestic uses. The supplemental heating capability can also be applied to buildings or industrial processes. And the integration of PCZ technology offers several benefits, including an improved COP, waste heat recovery, and increased system output.

The potential for recovering waste heat from refrigeration systems using PCZ technology is enormous. By optimizing PCM-based methods, this technology can reduce energy consumption in refrigeration systems, increase overall system efficiency, and provide supplementary energy sources. As a result, the PCZ is poised to play a significant role in improving the sustainability and energy efficiency of refrigeration systems.

Author Contributions

Introduction, Literature review and PCM selection N.G.; Conceptualization and experimental work, V.R.D.; Data validation, resources and supervision S.R.; writing—review and editing, K.A. All authors have read and agreed to the published version of the manuscript.

Funding

The authors would like to thank the financial support (SUR/2022/004087) from the Department of Science & Technology, Science and Engineering Research Board—State University Research Excellence (DST SERB-SURE) and Alagappa Chettiar Government College of Engineering and Technology, Karaikudi, Tamil Nadu for the development of this paper.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Javeri-Shahreza, I.; Fakhroleslam, M.; Sadrameli, S.M. Application of phase change materials for performance enhancement of open-display supermarket refrigerators: Numerical simulation and parametric study. J. Energy Storage 2023, 66, 107506. [Google Scholar] [CrossRef]

- Azzouz, K.; Leducq, D.; Gobin, D. Performance enhancement of a household refrigerator by addition of latent heat storage. Int. J. Refrig. 2008, 31, 892–901. [Google Scholar] [CrossRef]

- Azzouz, K.; Leducq, D.; Gobin, D. Enhancing the performance of household refrigerators with latent heat storage: An experimental investigation. Int. J. Refrig. 2009, 32, 1634–1644. [Google Scholar] [CrossRef]

- Wang, F.; Maidment, G.; Missenden, J.; Tozer, R. The novel use of phase change materials in refrigeration plant. Part 3: PCM for control and energy savings. Appl. Therm. Eng. 2007, 27, 2911–2918. [Google Scholar] [CrossRef]

- Sonnenrein, G.; Elsner, A.; Baumhogger, E.; Morbach, A.; Fieback, K.; Vrabec, J. Reducing the power consumption of household refrigerators through the integration of latent heat storage elements in wire-andtube condensers. Int. J. Refrig. 2015, 51, 154–160. [Google Scholar] [CrossRef]

- Tulapurkar, C.; Subramaniam, P.R.; Thagamani, G.; Thiyagaranjin, R. Phase change materials for domestic refrigerators to improve food quality and prolong compressor off time. In Proceedings of the International Refrigeration and Air Conditioning Conference, West Lafayette, IN, USA, 12–15 July 2010. [Google Scholar]

- Karthikeyan, A.; Sivan, V.A.; Maher Khaliq, A.; Anderson, A. Performance improvement of vapour compression refrigeration system using different phase changing materials. Mater. Today Proc. 2020, 44, 3540–3543. [Google Scholar] [CrossRef]

- Arora, C.P. Refrigeration and Air Conditioning, 3rd ed.; Tata McGraw-Hill Publishing Company Ltd.: New Delhi, India, 2009. [Google Scholar]

- Udroiu, C.-M.; Mota-Babiloni, A.; Gim’enez-Prades, P.; Navarro-Esbrí, A.B.-C.J. Twostage cascade configurations based on ejectors for ultra-low temperature refrigeration with natural refrigerants. Int. J. Thermofluids 2023, 17, 100287. [Google Scholar] [CrossRef]

- Nandanwar, Y.N.; Pramod; Walke, V.; Vednath; Kalbande, P.; Mohan, M. Performance improvement of vapour compression refrigeration system using phase change material and thermoelectric generator. Int. J. Thermofluids 2023, 18, 100352. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. Thermal cycle testing of calcium chloride hexahydrate as a possible PCM for latent heat storage, Sol. Energy Mater. Sol. Cells 2008, 92, 891–899. [Google Scholar] [CrossRef]

- Sun, M.; Sha, H.; Liu, T.; Wang, X.; Jiang, D.; Liu, T.; Li, M.; Chen, G. Calcium chloride hexahydrate based supercooling phase change material for a long-term recovery of low-grade thermal energy. Appl. Therm. Eng. 2024, 243, 122663. [Google Scholar] [CrossRef]

- Rahimia, M.; Ranjbara, A.A.; Hosseinib, M.J. Experimental investigation on PCM/fin slab incorporation in a evaporator side of a household refrigerator. Energy Rep. 2023, 10, 407–418. [Google Scholar] [CrossRef]

- Yang, H.; Zou, Y.; Cui, H. Advancements and challenges in enhancing salt hydrate phase change materials for building energy storage: Optimization methodologies and mechanisms. Natl. Sci. Open 2024, 3, 20230056. [Google Scholar] [CrossRef]

- Xie, N.; Huang, Z.; Luo, Z.; Gao, X.; Fang, Y.; Zhang, Z. Inorganic Salt Hydrate for Thermal Energy Storage. Appl. Sci. 2017, 7, 1317. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).