Abstract

This paper examines the crucial role of critical materials in sustainable transportation, specifically focusing on electric machines, power electronics, and lightweight materials, while deliberately omitting batteries from the analysis. It addresses the challenges arising from supply chain shortages and presents solutions through legislative, economic, and technological measures. Ensuring a stable supply of these materials is crucial for supporting the transition to greener and more efficient future transportation.

1. Introduction

The shift towards sustainable transportation is an essential element in the worldwide initiative to decrease carbon emissions and address climate change [1]. All developed countries and significant industrial actors strive to meet the striving climate ambitions (such as the goals of the Paris Agreement, the “Net-Zero Emissions by 2050” directive, and the United Nations Sustainable Development Goals [2]). Despite the long history of electric vehicles (EVs) [3], their widespread adoption, along with other green transportation technologies, has accelerated radically mainly in recent years, driven by these key directives [4]. While much attention has been put on the development and deployment of advanced battery technologies, other EV components also play equally vital roles in this transition, relying on a diverse range of critical materials (CMs) and components [5]. These include semiconducting materials, rare earth (RE) metals, copper, aluminum, and carbon fiber, which are essential for manufacturing electric machines (EMs), power electronics, and lightweight EV structures.

However, the supply chains for these CMs face significant challenges, similar to those encountered with lithium, cobalt, nickel, manganese, and graphite, all of which are vital for manufacturing EV batteries. In recent years, global shortages of semiconducting materials, such as silicon, germanium, silicon carbide (SiC), and gallium nitride (GaN) have disrupted production across various industries, including EV manufacturing [6]. The concentration of RE materials mining in a few specific regions has exacerbated geopolitical tensions and increased supply risks [7]. Additionally, the growing demand for copper, aluminum, and carbon fiber has further strained existing supply chains, underscoring the urgent need for diversification and innovation [8].

It is important to note that beyond the manufacturing of EVs themselves, the infrastructure required to support sustainable transportation (such as charging stations and grid capacity) also faces material supply bottlenecks that must be addressed to ensure a smooth transition [9].

This paper aims to identify the primary causes of supply chain shortages in these CMs and to analyze various efforts and strategies to address these challenges. By examining potential solutions, it seeks to provide valuable insights for policymakers, industry stakeholders, and researchers working toward a resilient and sustainable transition to green transportation.

2. Importance of Critical Materials in Sustainable Transportation

Most of the raw materials needed for sustainable transportation are considered critical. These materials are vital for various industries and technologies, but face supply risks due to limited availability and few substitutes. Their unique properties make them indispensable. Economic superpowers like the United States, the European Union, and China regularly update lists of CMs to manage supply chain vulnerabilities and ensure access to these essential resources [10,11].

The manufacturing of EVs is the most decisive factor in advancing sustainable transportation, which relies on diverse materials, many of which are considered critical.

In this field, much attention is given to the shortages of CMs needed for batteries, such as lithium, cobalt, and nickel. These materials are indeed crucial, as they form the backbone of the energy storage systems that power EVs. However, the focus on battery materials often overshadows the importance of other CMs that are equally vital for the overall production and functionality of EVs.

EMs, used mainly for traction purposes, heavily rely on RE permanent magnets (PMs) needing neodymium and dysprosium for achieving high efficiency and performance [12]. These powerful PMs are crucial for their role in enhancing EM performance. Copper, with its excellent conductivity, is another essential material, used primarily in EM windings. EMs are controlled by converters that utilize advanced semiconductors like SiC and GaN, known for their high efficiency and good thermal management. Tantalum and niobium, used in capacitors, improve reliability under high-temperature and -voltage conditions, ensuring optimal operation in EVs.

Lightweight metals, such as aluminum and magnesium, are crucial for reducing the overall mass of EVs, directly impacting their range. Aluminum is also extensively used in vehicle frames, body panels, and other structural components due to its high strength-to-mass ratio and corrosion resistance. Magnesium, being even lighter, is employed in vehicle applications where mass and volume reduction is very critical. Diverse carbon fiber composites are used in high-performance EVs to achieve substantial mass savings, enhancing both efficiency and performance.

The development of the specific infrastructure needed by EVs, such as charging stations and renewable energy grid integration, also requires several CMs. Copper is fundamental for the electrical wiring and components of charging stations. Steel and aluminum are used in constructing charging station enclosures and support structures.

Electrotechnical materials, such as silicon steel and aluminum, are essential for manufacturing transformers and conductors needed for grid integration. These are crucial for managing the increased electrical load from EV charging and ensuring a stable and reliable power supply. Additionally, electric generators convert wind energy to electricity and require some of the already mentioned CMs.

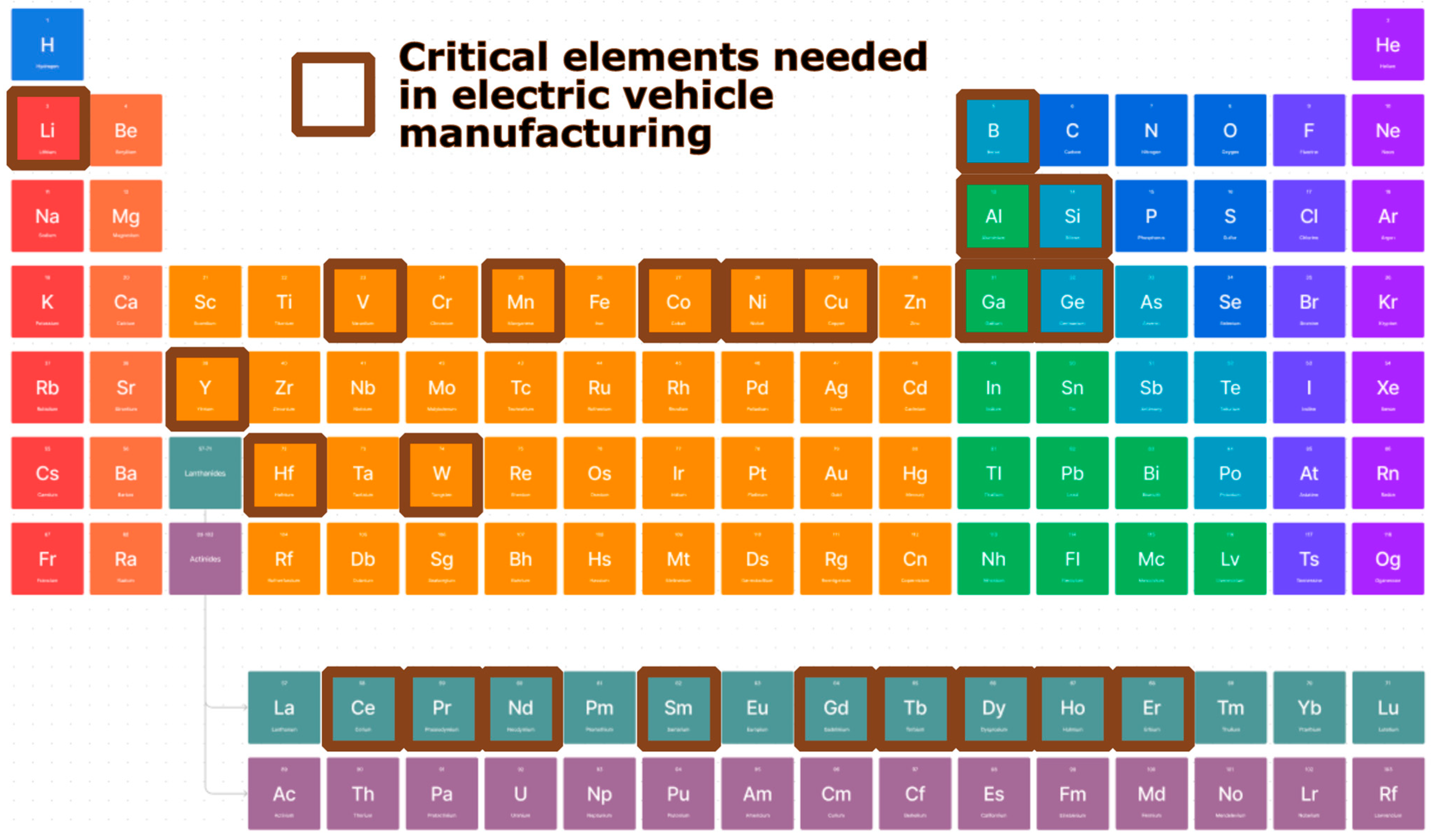

The substantial number and variety of CMs required in the manufacturing of EVs are highlighted in the periodic table of elements provided in Figure 1.

Figure 1.

Critical elements of the periodic table needed for the manufacturing of EVs.

3. Supply Chain Shortages

The availability of CMs needed for the transition to sustainable transportation can be compromised by a wide range of factors. Each material faces specific challenges in ensuring an adequate supply, but there are also common issues. These include the concentration of production, along with economic, political, and social limitations on the expansion of production capacities, as well as widespread export restrictions, which play a significant role. Furthermore, the risks are exacerbated by insufficient transparency within mineral supply chains and governance issues faced by countries involved in production and processing [13,14].

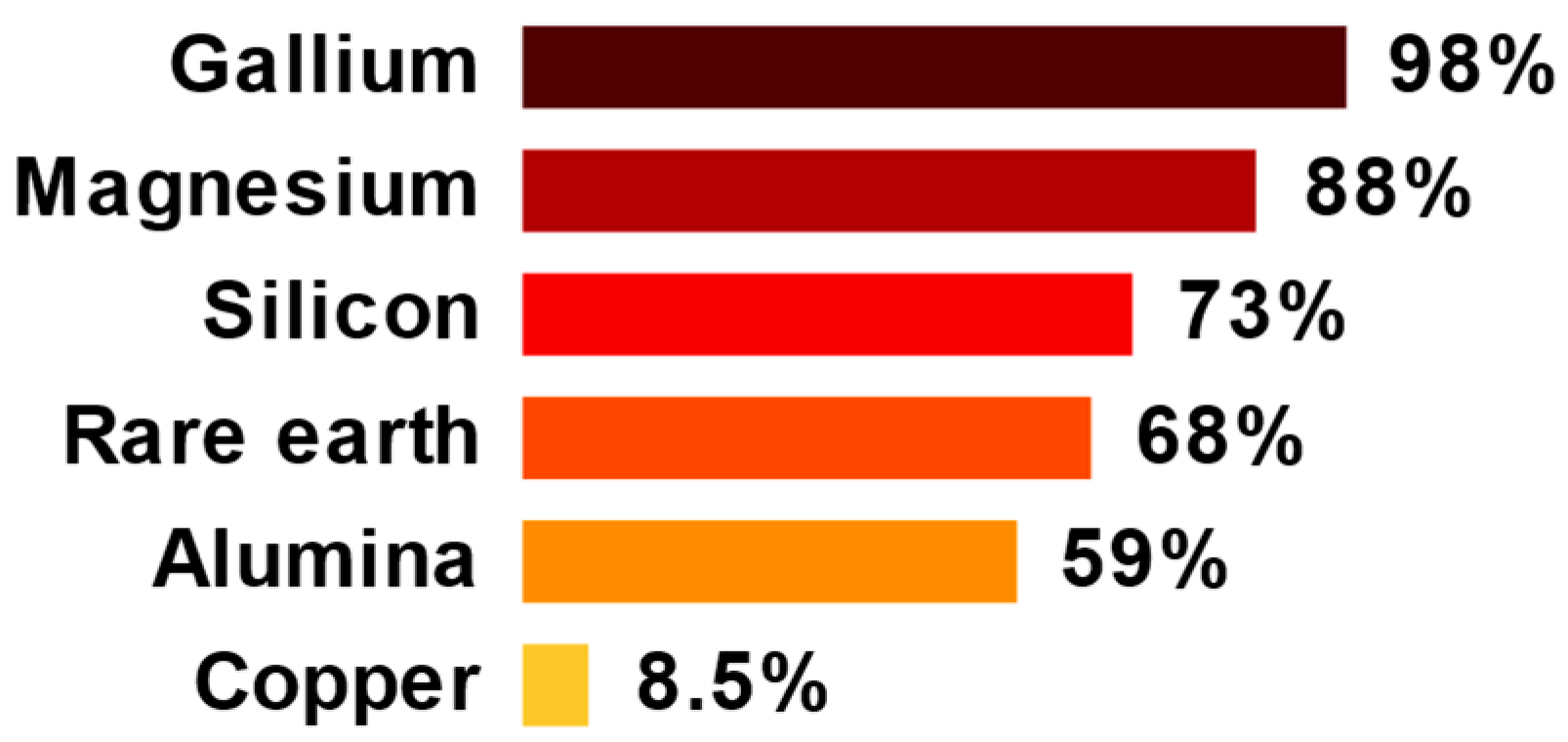

One of the most significant supply risks for CMs stems from the geographic concentration of resources in just a few countries. China, which holds the largest share of mineral mining and material processing globally, dominates the supply of nearly all CMs under discussion (see Figure 2) [7,15].

Figure 2.

China’s share in the extraction/production of CMs.

This concentration of production not only makes the supply chain highly vulnerable to external disruptions, but also exposes it to risks such as export restrictions and price volatility. These factors further heighten geopolitical tensions, as developed countries around the world compete for stable access to CMs essential for key industries [16].

The COVID-19 pandemic, along with persistent conflicts such as the Russia–Ukraine war and escalating tensions in the Red Sea region, has led to considerable disturbances in global supply chains. The instabilities triggered by such events affect the production, transportation, and access to key resources, further complicating efforts to maintain a steady supply of these CMs [17].

Supply chain shortages could be mitigated by increasing, within certain limits, the mining and production of these CMs, as most of them have abundant deposits. However, mining any material is a destructive activity that leads to soil erosion, water and air pollution, and loss of biodiversity. Additionally, mining and material processing are very energy-intensive activities. Consequently, all developed countries are imposing very strict regulations on these activities to limit them and make them more environmentally friendly [18,19].

4. Solutions and Mitigation Strategies

A variety of strategies can be employed to alleviate the previously mentioned supply risks, which may encompass the adoption of legislative, economic, and technological interventions.

4.1. Legislative Actions

To minimize the risks associated with the supply of CMs, developed countries have implemented numerous economic strategies. These include significant centralized policies and strategic investments, which are essential for achieving the targeted societal and environmental goals.

In 2018, the European Commission unveiled the “Raw Materials Initiative”, a collection of strategies designed to manage, plan, and restructure national industrial production and the CM supply chain. This aims to ensure reasonable access to all of the CMs for all European Union countries [20]. To implement this initiative, the “Critical Raw Materials Act” was introduced in 2023 to reduce dependence on external CM sources [21].

The United States also has implemented several legislative and executive measures to address CM supply chain shortages. One of the most notable legislative actions is the “Inflation Reduction Act” of 2022, which aims to tackle a range of economic and environmental challenges. This legislation includes provisions to strengthen the supply chain for CMs, ensuring that the country can meet the rising demand for green technologies while maintaining its competitive edge in the global market [22]. Moreover, several executive orders have been issued by US presidents to support these objectives.

Basically, CM shortages can be mitigated by reducing dependency on imports. This can be achieved through two primary strategies: increasing the domestic mining and production of these materials and enhancing the recovery of materials through recycling.

Developed countries, excluding China, have limited resources of CMs needed for EVs. Moreover, existing stringent environmental and social regulations significantly hinder and increase the cost of mining operations. Despite these challenges, governments are actively supporting and investing the reopening of mines, with a focus on employing more advanced and cleaner technologies in the short term. Additionally, there is a growing emphasis on increasing the share of small-scale mining, particularly in areas with smaller but high-grade deposits [23]. In the long term, governments plan to conduct geological surveys and exploration activities to identify and evaluate potential CM deposits. Furthermore, efforts are being made to extract CMs from unconventional sources, such as deep-sea mining.

The required amount of mining and processing of CMs can be significantly reduced through sustainable material management practices. These processes promote more efficient and environmentally friendly utilization and recycling of vital materials. One of the most promising approaches is the expansion of the circular economy, which has the capacity to diminish the demand for newly extracted and processed resources.

A fundamental step in adopting this approach is the recycling of CMs from end-of-life equipment and waste [24]. Supplementary to reducing dependency on CMs, recycling can enhance the economic competitiveness of developed countries. Except for copper and aluminum, functional recycling rates for most CMs remain very low, despite the availability of existing technologies, which, unfortunately, are often environmentally harmful. Effective recycling is further hindered by inefficient waste management systems, inadequate collection infrastructures, and a lack of economic incentives.

4.2. Technological Solutions

Engineers across various disciplines involved in EV-related research can play a crucial role in alleviating CM supply shortages through their innovative work.

Materials scientists can enhance processing technologies for CMs to extract more raw materials from the same quantities of mined ores.

Another straightforward approach is to replace the CMs with ones that are more easily accessible. Graphene, often referred to as the “wonder material” of our century, holds significant potential for addressing CM shortages. As a carbon allotrope, its raw material is abundantly available across the globe [25]. However, its production is still in the developmental stages, and its cost remains high, although it is steadily decreasing. With excellent electrical and thermal conductivity, graphene has the potential to replace or enhance traditional conductor materials and is an ideal choice for manufacturing heatsinks for EVs [26]. Additionally, its exceptional mechanical properties (such as strength and elasticity) make it suitable for use in polymer composites, allowing it to replace heavier metallic components in EVs, thereby contributing to overall mass reduction and improved efficiency. In EMs, RE PMs can be replaced by ferrites, although this comes at the cost of increased motor volume. Alternatively, PM-free EMs can also be used in EVs.

Artificial intelligence (AI) is also expected to revolutionize materials science by enabling the more efficient design of new materials and identifying optimal correlations between their structural, elemental, and physical properties [27].

A potential way to reduce the need for CMs is by optimizing the mass of various components without compromising their performance. Today, researchers have access to a wide range of optimization methods that can be applied for this purpose [28]. Moreover, AI can play a significant role in enhancing these optimization processes.

The required quantity of CMs can also be significantly reduced during manufacturing by utilizing additive manufacturing techniques, which allow for the production of various parts with minimal material waste [29]. AI algorithms can optimize manufacturing processes by identifying bottlenecks and suggesting improvements, leading to better raw material utilization and reduced waste.

As already mentioned, recycling is a key strategy in mitigating supply chain shortages of CMs. This process can be improved in two ways: by continuously advancing recovery technologies, and by designing equipment to be easily disassembled and prepared for recycling. In this regard, modular design is a particularly promising approach [30].

5. Conclusions

The transition to sustainable transportation, driven by the rise in EVs, has significantly strained the supply chain for CMs. While battery materials receive much attention, other essential components also play a crucial role. This paper explores some challenges and solutions related to the supply chain shortages of these CMs. It can be concluded that, although various effective mitigation approaches exist, each presents significant challenges and requires robust collaboration among countries and researchers across a wide range of scientific and technological disciplines.

Author Contributions

Writing—review and editing, D.A., N.K., D.-C.P., L.B. and L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

No original research data were created during this study; the presented data are available through the cited sources.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Vandycke, N.; Viegas, J.M. Sustainable Mobility in a Fast-changing World: From Concept to Action; Palgrave Macmillan: London, UK, 2022. [Google Scholar]

- Pedersen, C.S. The UN sustainable development goals (SDGs) are a great gift to business! Procedia CIRP 2018, 69, 21–24. [Google Scholar] [CrossRef]

- Vescan, I.; Szabó, L. A Brief History of Electric Vehicles. J. Comput. Sci. Control Syst. 2022, 15, 19–26. [Google Scholar]

- Midttun, A.; Witoszek, N. Energy and Transport in Green Transition: Perspectives on Ecomodernity; Routledge: Abingdon, UK, 2016. [Google Scholar]

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU. A Foresight Study; European Union: Brussels, Belgium, 2020. [Google Scholar]

- Shaw, J. Supply Chain Considerations for GaN & SiC. Available online: https://epsnews.com/2024/07/02/supply-chain-considerations-for-gan-sic/ (accessed on 22 September 2024).

- Yan, W.; Wang, Z.; Cao, H.; Zhang, Y.; Sun, Z. Criticality assessment of metal resources in China. iScience 2021, 24, 102524. [Google Scholar] [CrossRef] [PubMed]

- LePan, N. How Much Copper Is in an Electric Vehicle? Available online: https://www.visualcapitalist.com/how-much-copper-is-in-an-electric-vehicle/ (accessed on 8 September 2024).

- Evans, G. 2024 EV Forecast: The Supply Chain, Charging Network, and Battery Materials Market. Available online: https://www.spglobal.com/mobility/en/research-analysis/2024-ev-forecast-the-supply-chain-charging-network-and-battery.html (accessed on 11 September 2024).

- 2022 Final List of Critical Minerals; U.S. Geological Survey: Washington, DC, USA, 2022.

- Proposal for a Regulation of the European Parliament and of the Council Establishing a Framework for Ensuring a Secure and Sustainable Supply of Critical Raw Materials; European Comission: Brussels, Belgium, 2023.

- Jula, P.A.; Mákszem, B.; Gaidamac, T.; Popa, D.C.; Szabó, L. Tackling risks in the supply chain of rare earth-based permanent magnets used in electrical generators. In Proceedings of the 2023 International Conference on Clean Electrical Power (ICCEP), Terrasini, Italy, 27–29 June 2023; pp. 852–857. [Google Scholar] [CrossRef]

- Nakano, J. The Geopolitics of Critical Minerals Supply Chains; Center for Strategic and International Studies: Washington, DC, USA, 2021. [Google Scholar]

- Popa, D.C.; Szabó, L. Overcoming catch-22 for rare earth metals in green transition: Solutions in electrical machine manufacturing. Renew. Sustain. Energy Rev. 2025, 207, 114917. [Google Scholar] [CrossRef]

- Statista. Available online: https://www.statista.com (accessed on 11 August 2024).

- Geopolitics of the Energy Transition—Critical Materials; International Renewable Energy Agency (IRENA): Masdar City, United Arab Emirates, 2023.

- The Supply of Critical Raw Materials Endangered by Russia’s War on Ukraine. Available online: https://www.oecd.org/en/publications/the-supply-of-critical-raw-materials-endangered-by-russia-s-war-on-ukraine_e01ac7be-en.html (accessed on 29 August 2024).

- Kalantzakos, S. Critical Minerals, the Climate Crisis and the Tech Imperium; Springer Nature: Cham, Switzerland, 2023. [Google Scholar]

- Artudean, D.; Aitonean, N.; Pârcălab, M.; Popa, D.C.; Szabó, L. Strategic Resource Challenges in the Development of Smart Cities. In Proceedings of the 2024 IEEE International Conference on Automation, Quality and Testing, Robotics (AQTR), Cluj-Napoca, Romania, 16–18 May 2024. [Google Scholar] [CrossRef]

- Küblböck, K. The EU Raw Materials Initiative: Scope and Critical Assessment; Austrian Foundation for Development Research (ÖFSE): Vienna, Austria, 2013. [Google Scholar]

- Carminati, R. Critical raw materials act, ambitious goals. Electr. Mot. Eng. 2023, 3, 20–22. [Google Scholar]

- Inflation Reduction Act; US Senate: Washington, DC, USA, 2022.

- Sidorenko, O.; Sairinen, R.; Moore, K. Rethinking the concept of small-scale mining for technologically advanced raw materials production. Resour. Policy 2020, 68, 101712. [Google Scholar] [CrossRef]

- Brandão, M.; Lazarevic, D.; Finnveden, G. Handbook of the Circular Economy; Edward Elgar Publishing: Cheltenham, UK, 2020. [Google Scholar]

- Szabó, L.; Szabó, G.S.; Szabó, R. Usage of Graphene in Power Systems. A Survey. In Proceedings of the 2020 XI International Conference on Electrical Power Drive Systems (ICEPDS), St. Petersburg, Russia, 4–7 October 2020. [Google Scholar] [CrossRef]

- Szabó, L. Additive Manufacturing of Cooling Systems Used in Power Electronics. A Brief Survey. In Proceedings of the 2022 29th International Workshop on Electric Drives: Advances in Power Electronics for Electric Drives (IWED), Moscow, Russia, 26–29 January 2022. [Google Scholar]

- Cheng, Y.; Wang, T.; Zhang, G. Artificial Intelligence for Materials Science; Springer: Cham, Switzerland, 2021. [Google Scholar] [CrossRef]

- Marti, K. Stochastic Optimization Methods; Springer: Berlin/Heidelberg, Germany, 2005; Volume 2. [Google Scholar]

- Szabó, L.; Fodor, D. The key role of 3D printing technologies in the further development of electrical machines. Machines 2022, 10, 330. [Google Scholar] [CrossRef]

- Szabó, L. Advancements in Electrical Machines Design Brought by the Modular Construction. In Proceedings of the 2018 X International Conference on Electrical Power Drive Systems (ICEPDS), Novocherkassk, Russia, 3–6 October 2018. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).