Electrical Contacting of Aluminum Bus Bars Using Clinching and Functional Elements †

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Measurement of the Electrical Joint Resistance

2.2.2. Test Conditions of the Performed Examinations

3. Results

3.1. Clinching

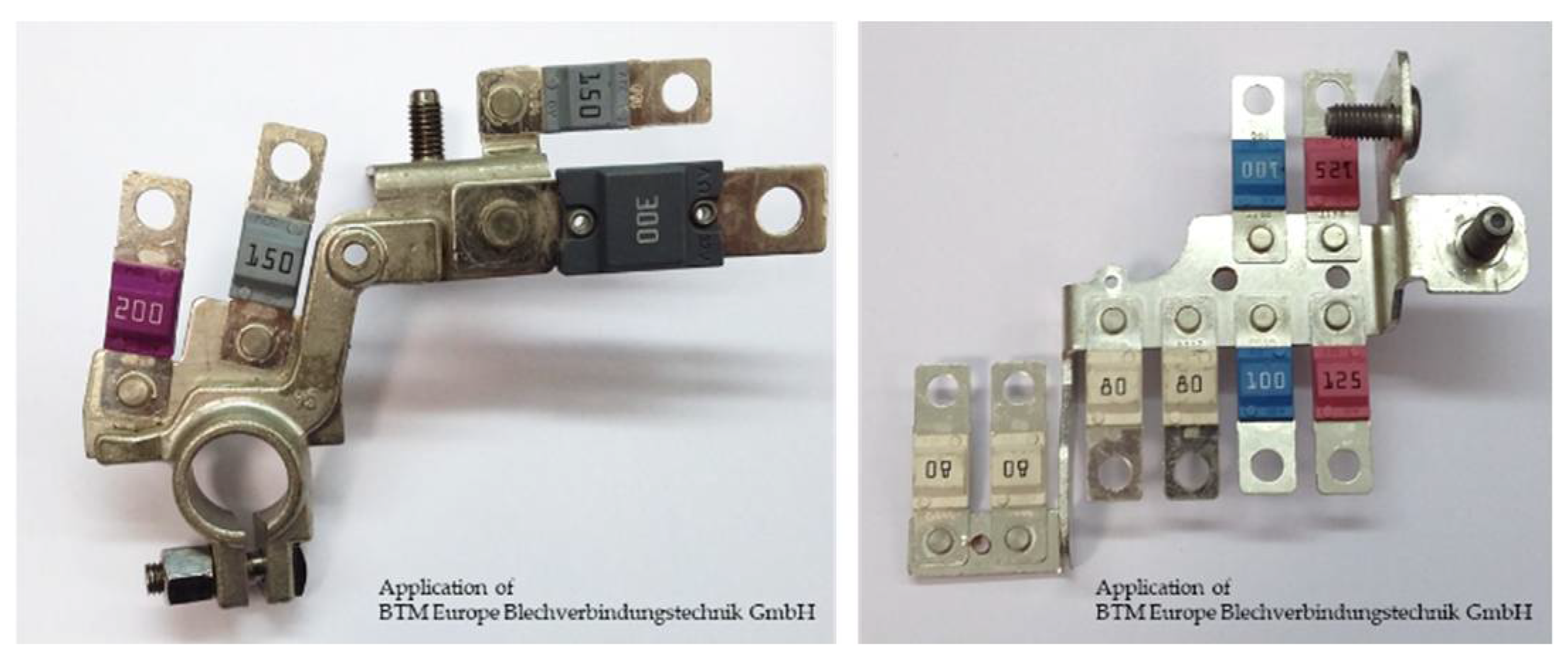

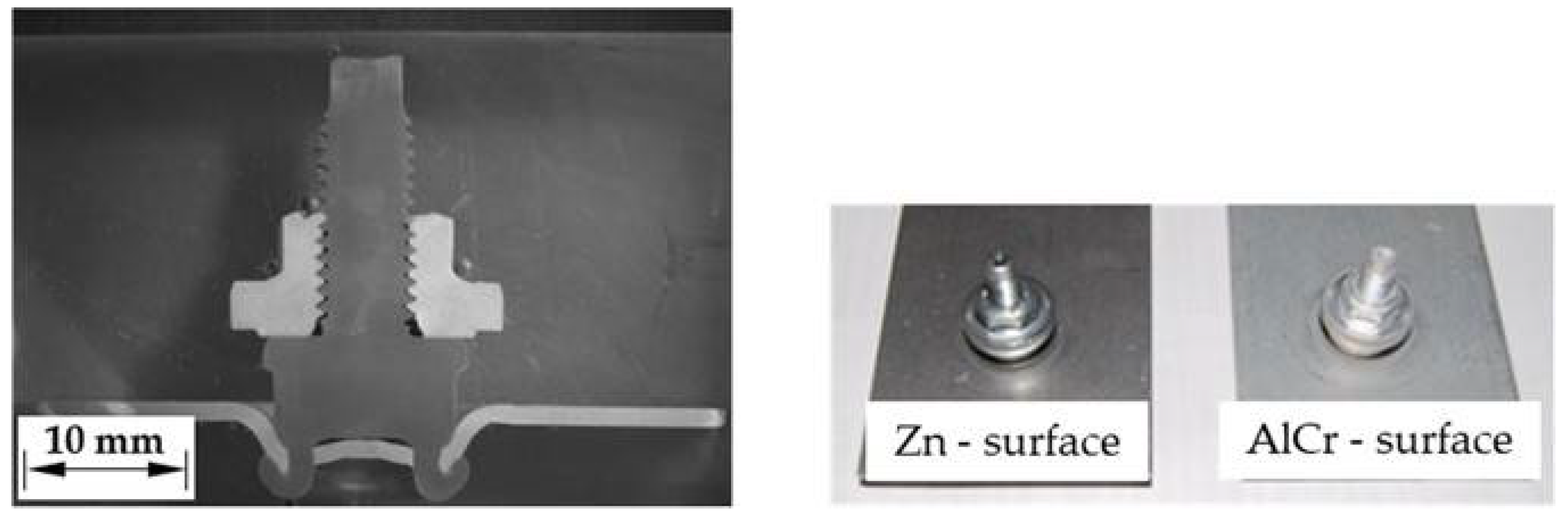

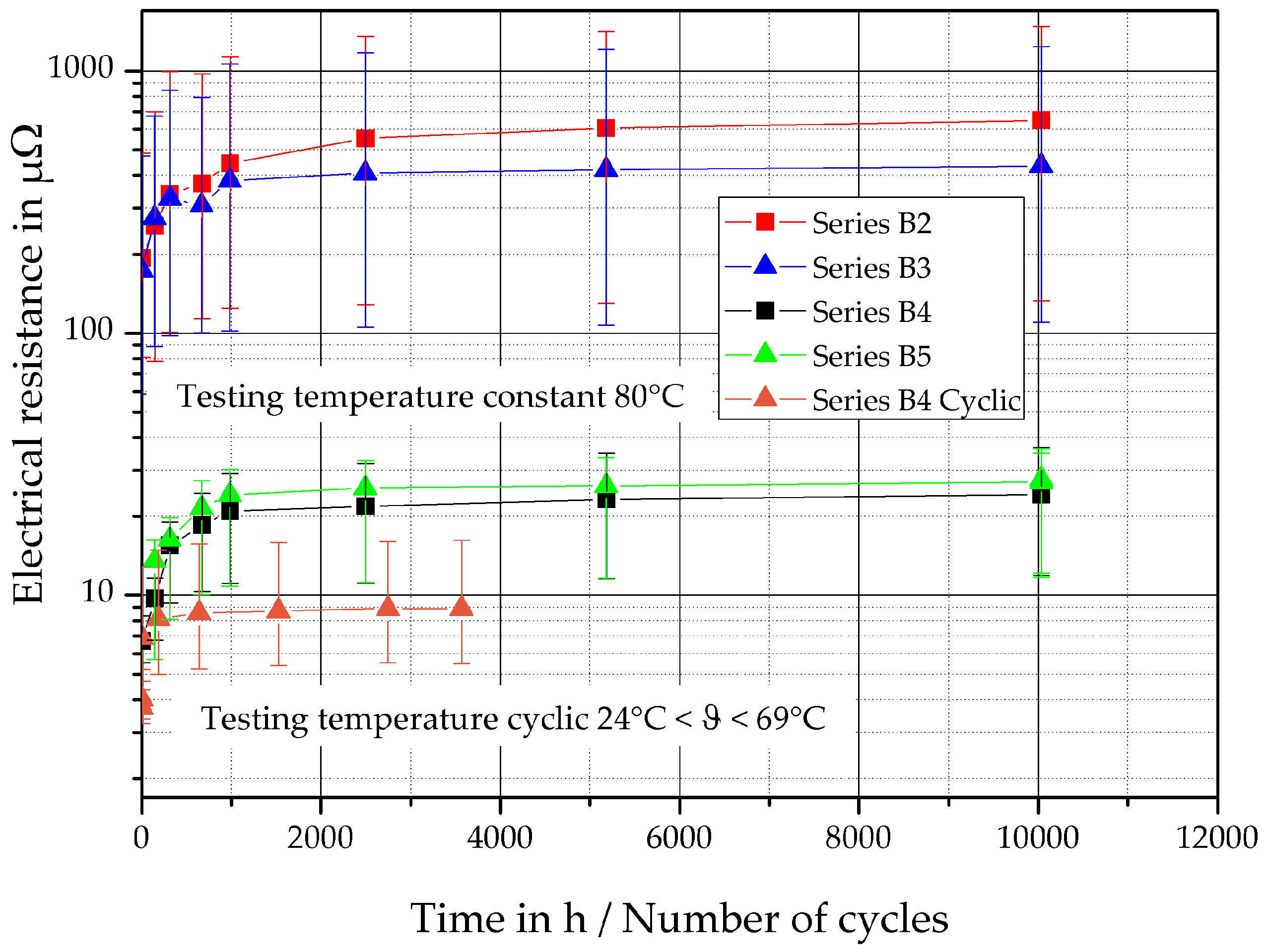

3.2. Functional Elements

4. Discussion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zwicker, M.; Moghadam, M.; Zhang, W.; Nielsen, C.V. Automotive battery pack manufacturing—A review of battery to tab joining. J. Adv. Join. Process. 2020, 1, 100017. [Google Scholar] [CrossRef]

- Meschut, G.; Merklein, M.; Brosius, A.; Drummer, D.; Fratini, L.; Füssel, U.; Gude, M.; Homberg, W.; Martins, P.; Bobbert, M.; et al. Review on mechanical joining by plastic deformation. J. Adv. Join. Process. 2022, 5, 100113. [Google Scholar] [CrossRef]

- Füssel, U.; Großmann, S.; Kalich, J.; Schlegel, S.; Ramonat, A. Optimierung umformtechnischer Fügeverfahren zur Kontaktierung Elektrischer Leiter; European Research Association for Sheet Metal Working: Hannover, Germany, 2019; ISBN 978-3-86776-559-6. [Google Scholar]

- Lee, C.-J.; Kim, J.-Y.; Lee, S.-K.; Ko, D.-C.; Kim, B.-M. Parametric study on mechanical clinching process for joining aluminum alloy and high-strength steel sheets. J. Mech. Sci. Technol. 2010, 24, 123–126. [Google Scholar] [CrossRef]

- Mucha, J.; Kaščák, L.; Spišák, E. Joining the car-body sheets using clinching process with various thickness and mechanical property arrangements. Arch. Civ. Mech. Eng. 2011, 11, 135–148. [Google Scholar] [CrossRef]

- Eshtayeh, M.M.; Hrairi, M.; Mohiuddin, A.K.M. Clinching process for joining dissimilar materials: State of the art. Int. J. Adv. Manuf. Technol. 2016, 82, 179–195. [Google Scholar] [CrossRef]

- Kupfer, R.; Köhler, D.; Römisch, D.; Wituschek, S.; Ewenz, L.; Kalich, J.; Weiß, D.; Sadeghian, B.; Busch, M.; Krüger, J.; et al. Clinching of Aluminum Materials—Methods for the Continuous Characterization of Process, Microstructure and Properties. J. Adv. Join. Process. 2022, 5, 100108. [Google Scholar] [CrossRef]

- Füssel, U.; Liebrecht, F. Untersuchung der Verbindungscharakteristik von Funktionselementen im verschraubten Zustand; European Research Association for Sheet Metal Working: Hannover, Germany, 2011; ISBN 978-3-86776-362-2. [Google Scholar]

- Hahn, O.; Jendrny, J.; Voelkner, W.; Timm, M. Kennwertermittlung an Selbststanzenden Funktionselementen Sowie Niet-, Einpreßmuttern Und -bolzen: Ergebnisse Eines Vorhabens der Industriellen Gemeinschaftsforschung (IGF); EFB: Hannover, Germany, 1999; ISBN 9783867761406. [Google Scholar]

- Wanner, M.-C.; Denkert, C.; Füssel, U.; Süße, D. Beanspruchungsgrenzen für Funktionselement-Verschraubungen: Ergebnisse eines Forschungsvorhabens der industriellen Gemeinschaftsforschung (IGF); EFB-Forschungsbericht EFB-427: Hannover, Germany, 2015. [Google Scholar]

- Denkert, C. Bemessung und Montage umformtechnisch ins Blech eingebrachter Gewindeträger. Ph.D. Dissertation, Universität Rostock, Rostock, Germany, 2020. [Google Scholar]

- European Aluminium Association. The Aluminium Automotive Manual—Joining; European Aluminium Association: Woluwe-Saint-Pierre, Belgium, 2015. [Google Scholar]

- Groche, P.; Wohletz, S.; Brenneis, M.; Pabst, C.; Resch, F. Joining by forming—A review on joint mechanisms, applications and future trends. J. Mater. Process. Technol. 2014, 214, 1972–1994. [Google Scholar] [CrossRef]

- Riedel, F. Eigenschaftsverbesserung von Durchsetzfügeverbindungen Durch Die Kombination mit Stoffschluss; Shaker Verlag GmbH: Düren, Germany, 1997. [Google Scholar]

- Holm, R. Electric Contacts: Theory and Applications; Reprint of the Fourth Completely Rewritten ed. 1967, 3rd Printing 2000; Springer: Berlin/Heidelberg, Germany, 2000; ISBN 9783540038757. [Google Scholar]

- Braunovic, M.; Konchits, V.V.; Myshkin, N.K. Electrical Contacts; CRC Press: Boca Raton, FL, USA, 2017; ISBN 9781315222196. [Google Scholar]

- Pfeifer, S.; Großmann, S.; Freudenberger, R.; Willing, H.; Kappl, H. Characterization of Intermetallic Compounds in Al-Cu- Bimetallic Interfaces. In 2012 IEEE 58th Holm Conference on Electrical Contacts (Holm 2012), Portland, Oregon, USA, 23–26 September 2012; IEEE: Piscataway, NJ, USA, 2012; pp. 1–6. ISBN 978-1-4673-0781-9. [Google Scholar]

- Kindersberger, J.; Löbl, H.; Schoft, S. Plastic Deformation and Loss of Joint Force by Creep in High Current Joints. In Proceedings of the 20th International Conference on Electrical Contacts, Stockholm, Sweden, 19–23 June 2000. [Google Scholar]

- Braunovic, M. Effect of Different Types of Mechanical-Contact Devices on the Performance of Bolted Aluminium-to-Aluminium Joints under Current Cycling and Stress Relaxation Conditions. In Proceedings of the 32th IEEE Holm-Conference on Electrical Contacts, Boston, MA, USA, 27–29 October 1986. [Google Scholar]

- Füssel, U.; Großmann, S.; Kalich, J.; Schlegel, S.; Schmid, J. Elektrisches Eigenschaftsprofil umformtechnischer Fügeverbindungen; European Research Association for Sheet Metal Working: Hannover, Germany, 2014; ISBN 978-3-86776-432-2. [Google Scholar]

- Kalich, J.; Füssel, U. Influence of the Production Process on the Binding Mechanism of Clinched Aluminum Steel Mixed Compounds. JMMP 2021, 5, 105. [Google Scholar] [CrossRef]

- Böhme, H. Mittelspannungstechnik: Schaltanlagen Berechnen und Entwerfen, 2., Stark Bearb. Aufl.; Huss-Medien Verl. Technik: Berlin, Germany, 2005; ISBN 3341014950. [Google Scholar]

- Kirchhoff, V.; Fietzke, F. Entwicklung und Bewertung von PVD-Schichtsystemen auf Verbindungselementen zur Verbesserung der Alterungsbeständigkeit von Nietverbindungen; European Research Association for Sheet Metal Working: Hannover, Germany, 2012; ISBN 978-3-86776-385-1. [Google Scholar]

- Schütz, A.; Gehrke, J. Qualifikation von Belastungs- und Prüfverfahren für die Verwendung in kombinierten Ermüdungsalgorithmen; European Research Association for Sheet Metal Working: Hannover, Germany, 2012; ISBN 978-3-86776-387-5. [Google Scholar]

| Series B1 | Series B2 | Series B3 | Series B4 | Series B5 | |

|---|---|---|---|---|---|

| Element | Self-piercing stud steel | ||||

| Surface | Zinc | Zinc | Zinc | AlCr | AlCr |

| Bus bar | DC04+ZE 75/75; | AlMg0.8Si0.9 passivated | AlMg0.8Si0.9 EDT | AlMg0.8Si0.9 passivated | AlMg0.8Si0.9 EDT |

| Test loads |

|

| |||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Füssel, U.; Schlegel, S.; Reschke, G.; Kalich, J. Electrical Contacting of Aluminum Bus Bars Using Clinching and Functional Elements. Eng. Proc. 2022, 26, 5. https://doi.org/10.3390/engproc2022026005

Füssel U, Schlegel S, Reschke G, Kalich J. Electrical Contacting of Aluminum Bus Bars Using Clinching and Functional Elements. Engineering Proceedings. 2022; 26(1):5. https://doi.org/10.3390/engproc2022026005

Chicago/Turabian StyleFüssel, Uwe, Stephan Schlegel, Gregor Reschke, and Jan Kalich. 2022. "Electrical Contacting of Aluminum Bus Bars Using Clinching and Functional Elements" Engineering Proceedings 26, no. 1: 5. https://doi.org/10.3390/engproc2022026005

APA StyleFüssel, U., Schlegel, S., Reschke, G., & Kalich, J. (2022). Electrical Contacting of Aluminum Bus Bars Using Clinching and Functional Elements. Engineering Proceedings, 26(1), 5. https://doi.org/10.3390/engproc2022026005