Abstract

Self-compacting concrete is known for its performance in construction, as it minimizes the energy required to compact concrete, providing high strength. Improving the strength and durability parameters of self-compacting concrete is the main priority of modern research. The purpose of this research was to determine the optimal percentage addition of carbon fiber in self-compacting concrete with respect to the maximum positive variation that occurs in concrete strength and durability. Experimental results show that less carbon fiber in the slump affects the workability of the concrete as the slump diameter diminishes. Adding 0.8 percent carbon fiber reduces droop diameter. Addition of carbon fiber to self-compacting concrete decreases slump. The maximum carbon fiber content reduces the blockage ratio, meaning the concrete hardens as lumps emerge. Carbon fiber in concrete increases strength over time. The tensile strength of self-compacting concrete without carbon fiber is poor. The split test is comparable to the compression test. If just 0.6 percent of self-compacting concrete is reinforced with carbon fiber, the effect is positive. Concrete requires water absorption to develop. However, adding carbon fibers to self-compacting concrete limits water absorption. Adding carbon fiber minimizes absorption and hence increases concrete durability. The reported results also illustrate how carbon fiber might improve the resilience and resistance of self-compacting concrete in response to acid attacks, which can limit its service life.

1. Introduction

Because it does not require external or internal vibration for compaction, self-compacting concrete offers various benefits over ordinary concrete in terms of manufacturing and placement. These benefits include higher flow ability and workability, as well as a vital link with crowded reinforcement. Additionally, the laying of self-compacting concrete saves both time and work [1]. With respect to appearance, mechanical performance, and long-term durability, it has the potential to be superior to traditional concrete with self-compacting properties. On the other hand, self-compacting concrete requires specific manufacturing, installation, quality control, and finishing methods. A lack of adherence to manufacturing and deployment standards, norms, and processes may cause problems for specifiers and contractors regarding constructability and cost. Self-compacting concrete has a more challenging time adapting to abrupt changes in water and aggregate moisture content than traditional concrete [2]. If builders use a different self-compacting concrete mixer, for example, or engineers use another method of laying and finishing concrete, these variables may impact its properties. Self-compacting concrete fabrication and placement necessitate strict quality control measures [3] The enhanced flow ability of self-compacting concrete compared to ordinary concrete makes pumping the ideal deployment method.

On the other hand, the increased flow rate of self-compacting concrete increases the possibility of air entrainment, which may lead to bungholes and segregation. Typically, self-compacting concrete has fewer surface faults compared to standard concrete. Still, it can be prone to bungholes, honeycombing, and cracking if the criteria of production and placement are not adhered to [4]. The addition of modifiers to self-compacting concrete is an everyday practice, with the ultimate objectives of improving the strength and durability of self-compacting concrete. In this paper, we aim to determine the effect of the addition of carbon fibers on the strength and durability of self-compacting concrete.

2. Literature Review

For construction enterprises, employing self-compacting concrete is a practical approach to avoid the issues that arise with the use of fling concrete. A building’s sequence, form, and number of additives have no effect on self-compacting concrete. Long distances can be pumped with this material, owing to its considerable fluidity and low segregation rate. Self-compacting concrete is cast to reduce further internal or external vibration [5]. Other than as a complement to cement, mineral amalgamation is also used as a replacement for cement [6]. The durability of concrete refers to its ability to survive adverse environmental conditions, chemical attacks, and abrasion while preserving its optimal technical properties. In contrast to traditional concrete, self-compacting concrete has a high degree of flexibility, owing to which it may be spread through concrete forms without the use of vibration equipment [7].

As a result, the aggregate and hardened paste work well together. Self-compacting concrete must be poured more quickly than regular concrete [8]. It is a very flow able, non-segregating, unique concrete type that can settle into formworks, embracing significantly strengthened, narrow, and deep areas by means of its own weight. Self-compacting concrete, as opposed to conventional concrete, does not require the use of mechanical equipment, such as immersion vibrators, for compaction. The mechanical and long-term durability qualities of standard concrete are not affected by self-compaction [7]. New concrete has been applied throughout the previous three decades to speed up the development of concrete buildings, reduce labor costs, and simplify the process of casting concrete in complicated forms with thick reinforcement.

In high-rise buildings with heavy reinforcement, placement, compaction, and the use of vibrators are all difficult due to the unique fresh properties of concrete, such as flow ability under its own weight, resistance to segregation, and filling and passing ability. It is widely used in these types of difficult areas as beam–column joints and shear walls [9]. Self-compacting concrete is ideal for use in these environments, as it reduces both construction work and resulting noise pollution. Self-compacting concrete allows for fabrication of concrete with uniform homogeneity and uniform strength [10]. By modifying the rheology of concrete using admixtures and additions, more complicated geometries may be created, allowing for the production of more concrete mixes. In recent years, it has become customary to design new concrete components fortified with composite materials on top of them.

As the number of carbon fibers expands, the compressive strength of concrete declines. With respect to breaking strength, carbon fiber content has no effect. As the number of carbon fibers increases, so does the modulus of rupture and the toughness of the mixtures. According to results reported in the literature, scientists were able to construct concrete mixtures that are both crack-resistant and long-lasting. Compressive strength was shown to be improved by adding carbon fibers totaling up to 1% of the cement weight. Adding more carbon fibers decreased compressive strength because the formation of fiber agglomerates occurs as a consequence of the inclusion of fibers, which causes voids to develop in the concrete [5].

As a consequence, the compression strength of concrete is reduces when such voids are present. An increase in carbon fiber dosage also improves tensile strength. Carbon fibers serve as a bridge between cracks during cylinder split, enhancing the split tensile strength. Carbon Fibers are shown in Figure 1 in their raw form. Therefore, as fiber volume expands, an increase in split tensile strength occurs. Flexural strength improved for all specimens when carbon fiber dosage was increased. Over the course of 28 days, the fiber dosage self-compacting concrete showed a 47 percent increase in flexural strength relative to that of self-compacting concrete without carbon fibers. Improved compressive strength was attributable to the effective filling of pores in concrete by carbon fibers, as well as the increase in the area of surface reactivity [11].

Figure 1.

Carbon fibers.

The water absorption capacity of self-compacting concrete decreased with increasing fiber doses, resulting in increased durability, owing to the fibers in self-compacting concrete being present in the pores and the fact that carbon fibers have larger reactive surface area. Concrete reinforced with carbon fibers in a self-compacting form gained strength up to a certain point, beyond which the compressive strength started to decline [8]. The capacity of the fibers to absorb water improved with increasing fiber volume. Increasing the carbon fiber dosage reduced the water absorption capacity of concrete cubes, suggesting increased durability. Because there is less porosity in carbon fiber-filled concrete, less water can seep through the concrete surface.

3. Methodology

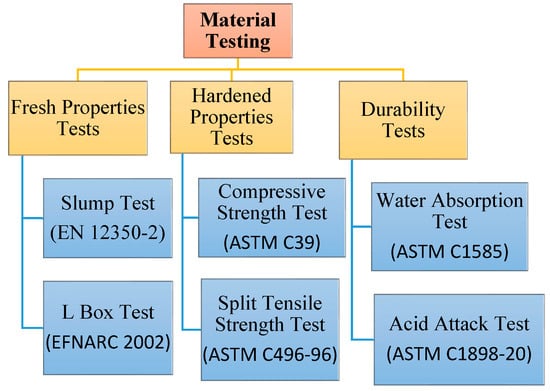

As the aim of this research is to determine the impact of the addition of carbon fiber on the strength and durability characteristics of self-compacting concrete, it was important to select a methodology that involved the testing of both the strength and probability characteristics with varying percentages of carbon fiber. The research design is based on an experimental and quantitative methodology. Tests conducted in this research are shown in Figure 2. Changes in the strength and durability parameters of self-compacting concrete were evaluated with an increasing percentage of carbon fiber [3].

Figure 2.

Material testing.

The mix used in this study was designed according to a standard methodology of concrete mix design, whereby material was volumetrically calculated. Throughout the testing procedure, the core materials of self-compacting concrete were unchanged. Interventions were proposed concerning the observed behavior of the carbon fiber in self-compacting concrete. Previous literature reviews were also considered as qualitative evidence regarding the comparative differences obtained in this study concerning the addition of carbon fiber in self-compacting concrete.

The addition of cement in self-conducting concrete was limited to 503.5 kg/m3, that of micro silica to 26.5 kg/m3, coarse aggregate to 890 kg/m3, fine aggregate to 740 kg/m3, water to 195 kg/m3, and super-plasticizer to 1%. Overall, five experimental trials were conducted, in carbon fiber content was varied. Samples containing 0.2%, 0.4%, 0.6%, and 0.8% carbon fiber were prepared for each experiment conducted according to the test methodologies shown in Table 1. After 7 and 28 days, the compressive and tensile strengths were determined. Water absorption and acid attack tests were conducted after 7, 28, and 56 days. The obtained results were evaluated by comparing them with the standard values so that the impact of carbon fiber on the strength and durability properties of self-compacting concrete could be easily elaborated.

Table 1.

Mix design.

4. Results and Discussion

4.1. Fresh Concrete Results

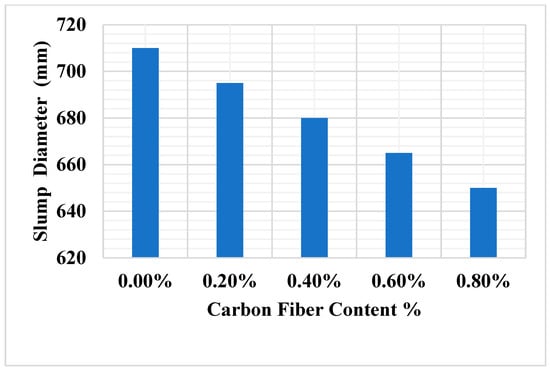

According to the slump test results, an increase in carbon fiber content harms the workability because the slump diameter gradually decreases. From the theoretical perspective, it is essential to consider that a gradual decrease in the availability occurs due to the interaction of the carbon fibers with the other constituents of the concrete, ultimately reducing the flow of concrete by binding the materials together, as shown in Figure 3. The lowest slump diameter was obtained with a maximum carbon fiber addition of 0.8 percent, as shown in Figure 4. Based on these findings, an increase in the content of carbon fiber negatively impacts the slump of self-compacting concrete.

Figure 3.

Slump test (left) and L-box test (right).

Figure 4.

Variation in slump with addition of carbon fiber.

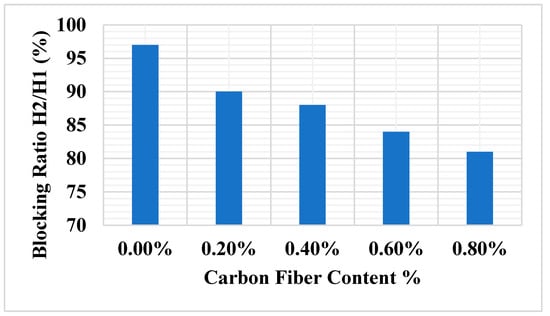

An L-box test was conducted to measure workability; the developing ratio constantly decreased with increased carbon fiber content. With the maximum addition of carbon fiber, the maximum reduction occurred in the blocking ratio, indicating that the concrete became hard as lumps formed, making it impossible for the concrete to flow freely. The sustainable percentage at which workability can be maintained to the required limits is 0.6% addition of carbon fiber as evident from Figure 5.

Figure 5.

Variation in blocking ratio with addition of carbon fiber.

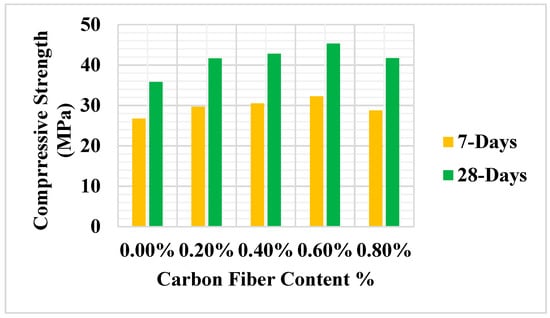

4.2. Hardened Concrete Results

When carbon fiber was added to the concrete, the concrete’s strength gradually increased. The increase in the compressive strength occurred because the carbon fiber provides resistance to the matrix of self-compacting concrete, taking on more load in the form than regular concrete, in which carbon fiber is not present. Similar behavior was observed after 7 and 28 days, indicating that regardless of the testing period, the strength of the concrete will ultimately improve, owing to the presence of carbon fiber. However, it is also evident that with 0.6% addition of carbon fiber, the compressive strength gradually decreases, as shown in Figure 6, owing to the significant alteration of other properties of the concrete with increased carbon fiber content. Therefore, 0.6% carbon fiber content is the optimal limit that can positively impact concrete strength.

Figure 6.

Variation in compressive strength test with the addition of carbon fiber.

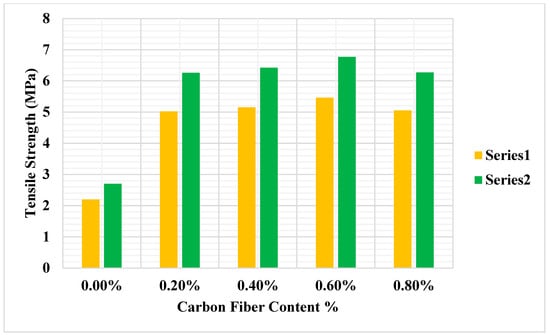

According to our findings, when carbon fiber is not added to self-compacting concrete, the split tensile strength is low. However, a significant increase occurs with the addition of 0.2% carbon fiber, gradually increasing to a maximum value of 0.6% carbon fiber. Similar behavior was observed in the split test compared to the compressive strength test. The theoretical perspective behind the increase in tensile strength of the concrete is that of the ability of the carbon fibers to act as reinforcement and ultimately increase the compressive strength of the concrete. Similar behavior was observed after 7 days as after 28 days, indicating that the positive effect on the tertiary length of self-compacting concrete produced by the addition of carbon fiber is limited to 0.6%, as shown in Figure 7 and Figure 8.

Figure 7.

Compressive strength testing (left) and split tensile strength testing (right).

Figure 8.

Variation in split tensile strength with the addition of carbon fiber.

4.3. Durability Test Results

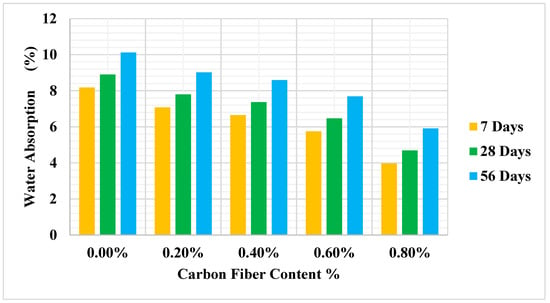

Water absorption capacity is crucial for the development of concrete. However, with increased carbon fiber content, self-compacting concrete shows a significant reduction in water absorption capacity. The test was run for three different periods. The results were all the same due to the negative impact of carbon fiber addition on the water absorption capacity of the self-compacting concrete. Furthermore, the maximum addition of carbon fiber is reached at 0.8%, at which point, the minimum water absorption capacity is obtained, which is less than 6% after 56 days, as evident from Figure 9. Based on these results, it can be concluded that absorption is negatively affected by the addition of carbon fiber, improving the durability of the concrete, as shown in Figure 9.

Figure 9.

Variation in water absorption with the addition of carbon fibers.

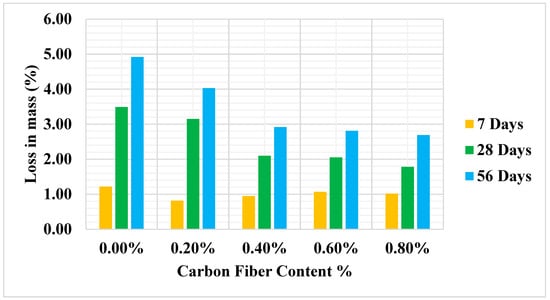

According to our findings, the addition of carbon fiber results in a significant reduction in mass, as shown in Figure 10. Based on these results, the maximum deduction occurs with 0.8% carbon fiber content, also indicating that carbon fiber protects against acid attack on the concrete throughout its life. Self-compacting concrete was observed at all testing periods, as shown in Figure 10, demonstrating that carbon fiber functions as an essential constituent to control the durability of self-compacting concrete and maximize its ability to resist acid attacks, which can reduce the service life of self-compacted concrete.

Figure 10.

Variation in loss of mass with the addition of carbon fiber.

5. Results and Discussion

The slump test findings show that increasing the carbon fiber percentage reduces workability as the slump diameter shrinks. The lowest slump diameter was achieved with 0.8% carbon fiber content. Based on these results, adding carbon fiber to self-compacting concrete reduces slump. The highest accumulation of carbon fiber results in the most significant decrease in blockage ratio, indicating that the concrete hardens as lumps appear. When carbon fiber is added to concrete, its strength progressively improves. However, increasing the carbon fiber concentration in self-compacting concrete reduces its water absorption capability. Based on these findings, adding carbon fiber to self-compacting concrete reduces absorption, increasing its durability.

Author Contributions

Conceptualization, methodology, testing and data collection N.A., data analysis and writing M.H. M.S. is our Supervisor. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We acknowledge the support from my supervisor and my university in completing the testing process and completion of data collection. We also tankful to our parents and peers who supported and guided us in navigating through the challenges we faced throughout this study.

Conflicts of Interest

The authors declare no conflict of interest. All authors agree with the methodology adopted and results obtained.

References

- Wang, Z.; Ma, G.; Ma, Z.; Zhang, Y. Flexural behavior of carbon fiber-reinforced concrete beams under impact loading. Cem. Concr. Compos. 2021, 118, 103910. [Google Scholar] [CrossRef]

- Ostrowski, K.A.; Furtak, K. The influence of concrete surface preparation on the effectiveness of reinforcement using carbon fibre-reinforced polymer in high-performance, self-compacting, fibre-reinforced concrete. Compos. Struct. 2021, 276, 114522. [Google Scholar] [CrossRef]

- Tabatabaei, Z.S.; Volz, J.S.; Baird, J.; Gliha, B.P.; Keener, D.I. Experimental and numerical analyses of long carbon fiber reinforced concrete panels exposed to blast loading. Int. J. Impact Eng. 2013, 57, 70–80. [Google Scholar] [CrossRef]

- Jeevetha, T.; VijayaShanthy, S.; Sivakumar, A.; Singh, N.B. Evaluation on strength parameters of self-compacting concrete incorporated with carbon and glass fibres. Mater. Today Proc. 2021, 45, 708–712. [Google Scholar] [CrossRef]

- Gull, I.; Tantray, M.A. Characteristic influence of carbon fibers on fresh state, mechanical properties and microstructure of carbon fiber based self compacting concrete. Mater. Today Proc. 2021, 38, 3181–3189. [Google Scholar] [CrossRef]

- Li, Y.F.; Li, J.Y.; Ramanathan, G.K.; Chang, S.M.; Shen, M.Y.; Tsai, Y.K.; Huang, C.H. An Experimental Study on Mechanical Behaviors of Carbon Fiber and Microwave-Assisted Pyrolysis Recycled Carbon Fiber-Reinforced Concrete. Sustainability 2021, 13, 6829. [Google Scholar] [CrossRef]

- Guo, Z.; Zhuang, C.; Li, Z.; Chen, Y. Mechanical properties of carbon fiber reinforced concrete (CFRC) after exposure to high temperatures. Compos. Struct. 2021, 256, 113072. [Google Scholar] [CrossRef]

- Wu, L.; Lu, Z.; Zhuang, C.; Chen, Y.; Hu, R. Mechanical Properties of Nano SiO2 and Carbon Fiber Reinforced Concrete after Exposure to High Temperatures. Materials 2019, 12, 3773. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.; Bai, E.; Xu, J.; Chen, J. Research on electromagnetic properties and microwave deicing performance of carbon fiber modified concrete. Constr. Build. Mater. 2021, 286, 122868. [Google Scholar] [CrossRef]

- Galao, O.; Bañón, L.; Baeza, F.J.; Carmona, J.; Garcés, P. Highly Conductive Carbon Fiber Reinforced Concrete for Icing Prevention and Curing. Materials 2016, 9, 281. [Google Scholar] [CrossRef]

- Han, J.; Wang, D.; Zhang, P. Effect of nano and micro conductive materials on conductive properties of carbon fiber reinforced concrete. Nanotechnol. Rev. 2020, 9, 445–454. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).